Silicon material cleaning device

A cleaning device and technology for silicon materials, applied in cleaning methods and utensils, cleaning methods using tools, cleaning methods using liquids, etc., can solve problems such as large loss of silicon materials, improve quality, reduce costs, and reduce acid consumption. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

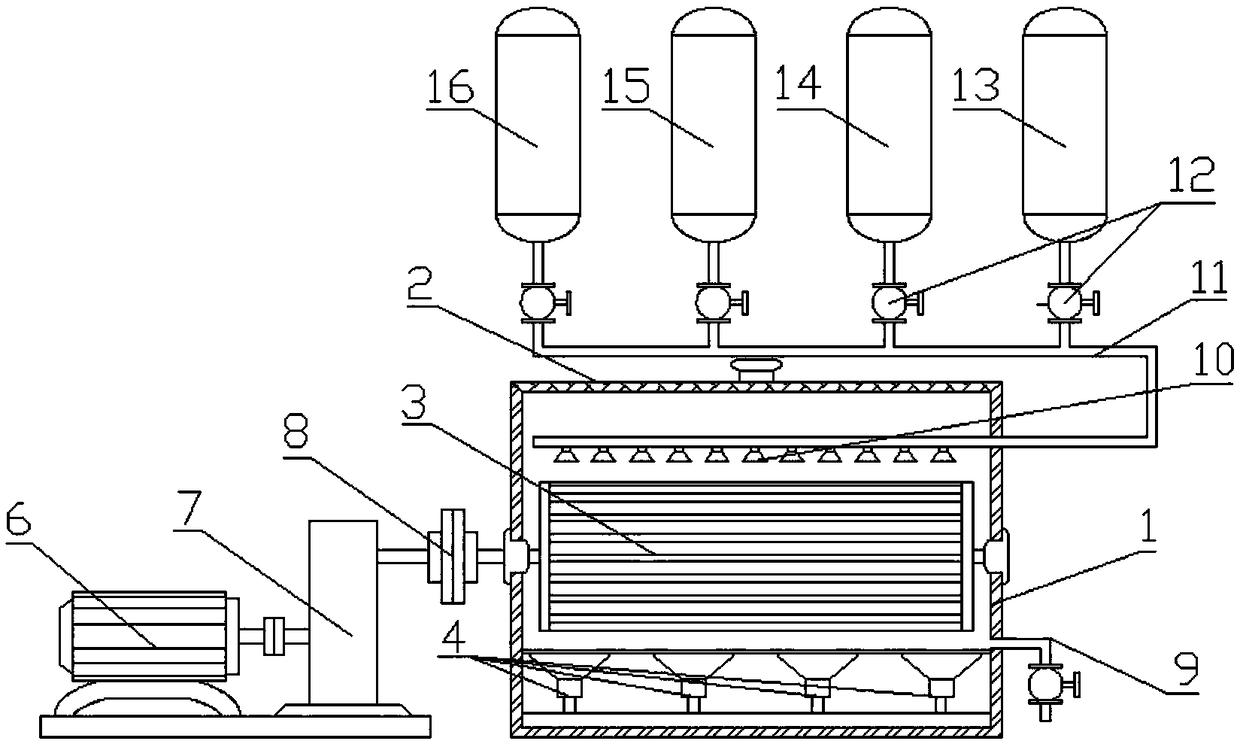

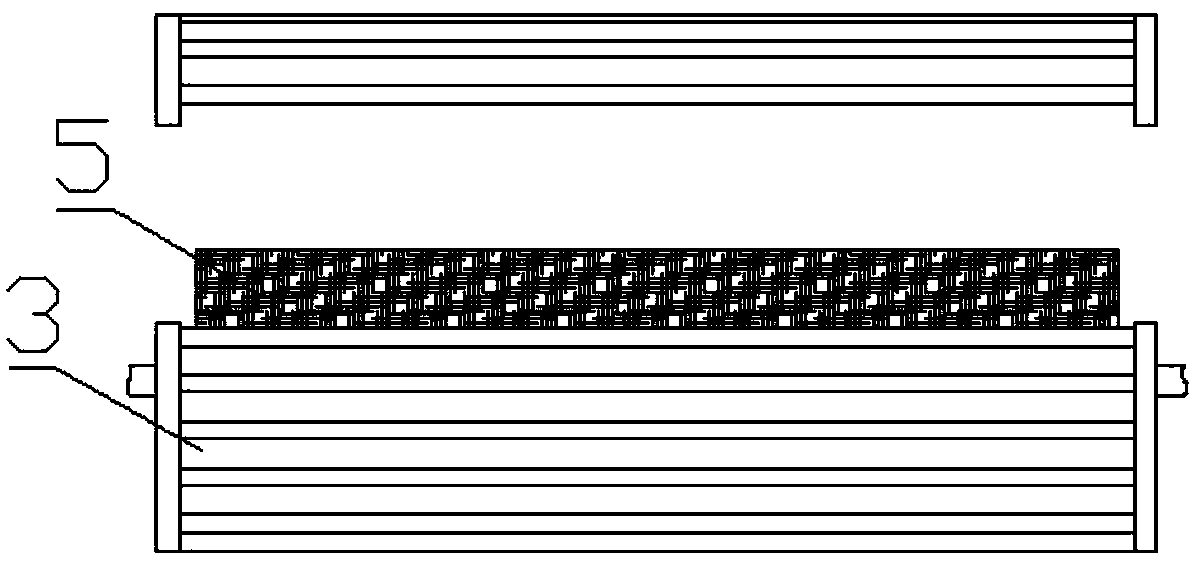

[0029] see Figure 1-2 As shown, the technical solution adopted in the present invention is: a silicon material cleaning device, the main structure of the silicon material cleaning device is designed as a cleaning tank 1, a cleaning tank cover 3 is placed on the top of the cleaning tank 2, and the cleaning tank cover 3 is placed on the top of the cleaning tank 2. A cleaning drum 3 is installed in the groove 1, and a cleaning brush 5 is installed inside the cleaning drum 3. The cleaning drum 3 is powered by a drive motor 6, and a speed regulating device 77 is installed on the right side of the drive motor 6. A connecting bearing 8 is installed between the speed regulating device 7 and the cleaning tank 1, an ultrasonic generator 4 is installed on the bottom of the cleaning tank 1, and a water outlet pipe 9 is arranged on the middle and lower part of the right side of the cleaning tank 1. 1 The top of the right side is provided with a water inlet pipe 11, and a spray device 10 i...

Embodiment 2

[0040] The difference between this embodiment and embodiment 1 is:

[0041] The concentration of the aqueous ethanol solution contained in the aqueous ethanol tank 13 is 8%.

[0042] The lye contained in the lye tank 14 is a dilute mixed solution of sodium hydroxide and sodium carbonate, wherein the concentration of the dilute mixed solution of sodium hydroxide and sodium carbonate is designed to be 6%.

[0043] The acid liquid inside the acid liquid tank 16 is a dilute mixed solution of hydrofluoric acid, nitric acid and hydrochloric acid, wherein the concentration of the dilute mixed solution of hydrofluoric acid, nitric acid and hydrochloric acid is designed to be 5%.

Embodiment 3

[0045] The difference between this embodiment and embodiment 1 is:

[0046] The concentration of the aqueous ethanol solution contained in the aqueous ethanol tank 13 is 10%.

[0047] The lye contained in the lye tank 14 is a dilute mixed solution of sodium hydroxide and sodium carbonate, wherein the concentration of the dilute mixed solution of sodium hydroxide and sodium carbonate is designed to be 10%.

[0048] The acid liquid inside the acid liquid tank 16 is a dilute mixed solution of hydrofluoric acid, nitric acid and hydrochloric acid, wherein the concentration of the dilute mixed solution of hydrofluoric acid, nitric acid and hydrochloric acid is designed to be 6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com