Patents

Literature

270results about How to "Save oxygen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

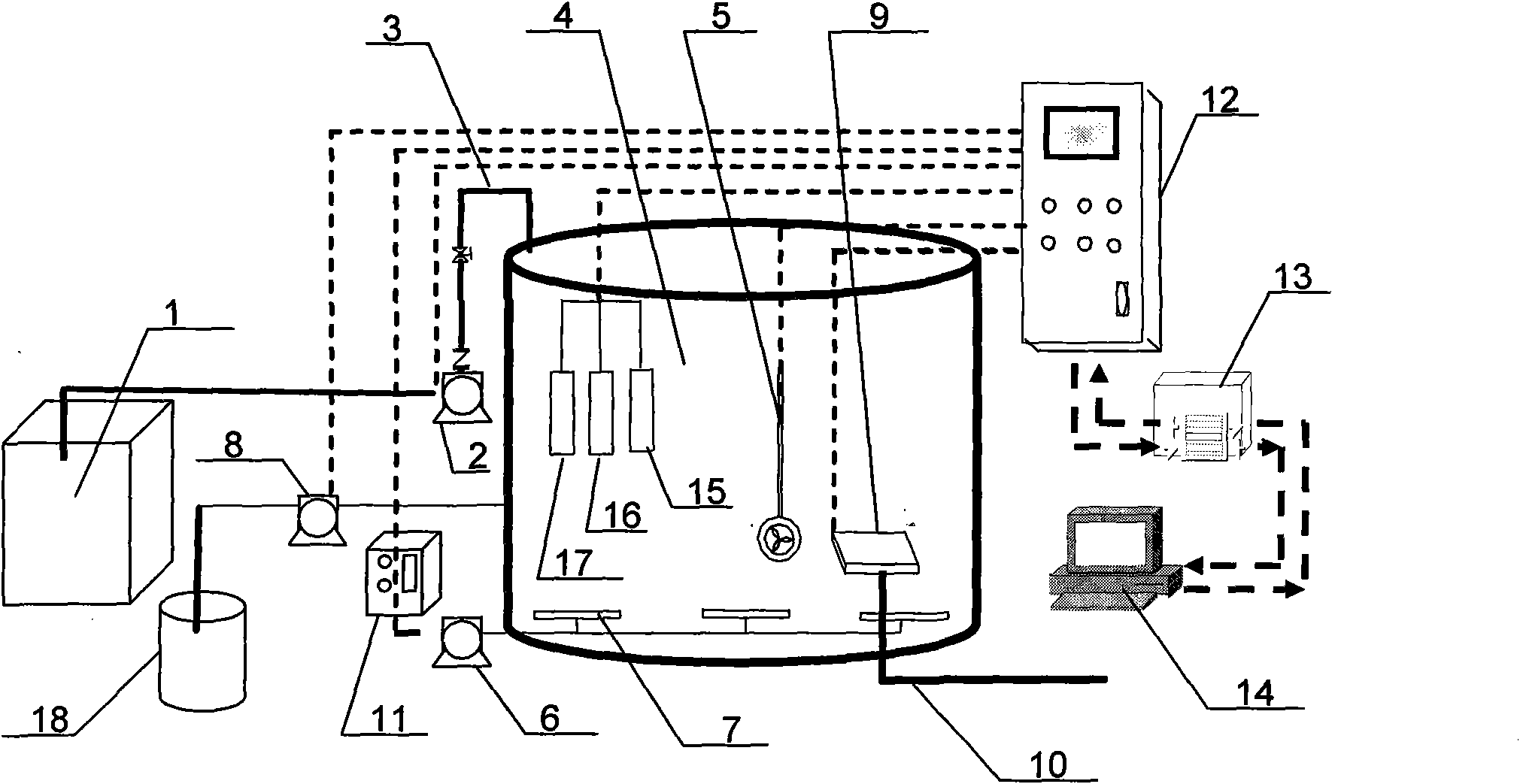

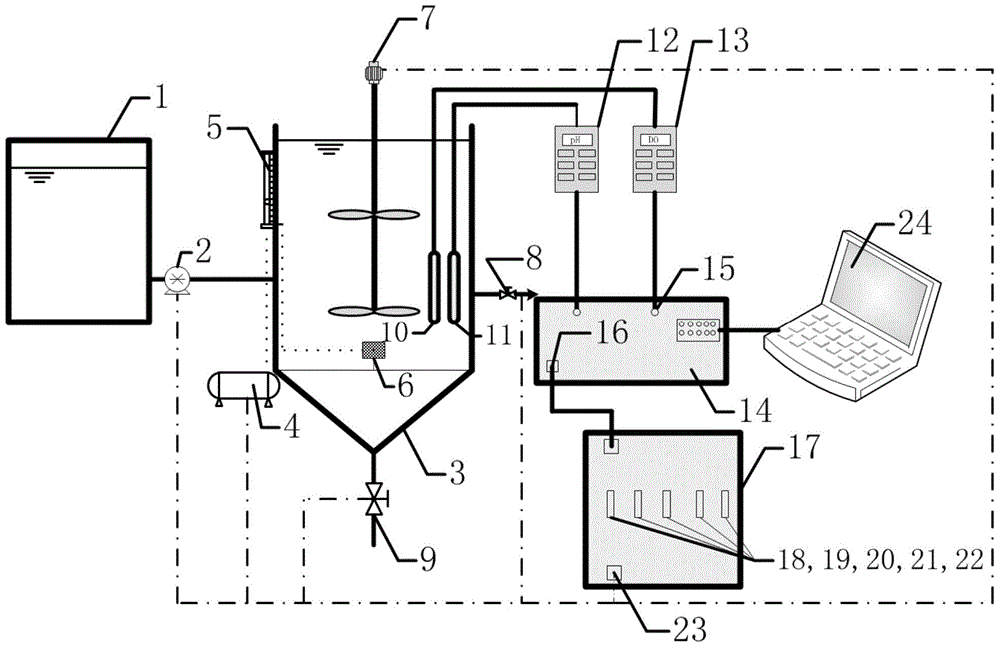

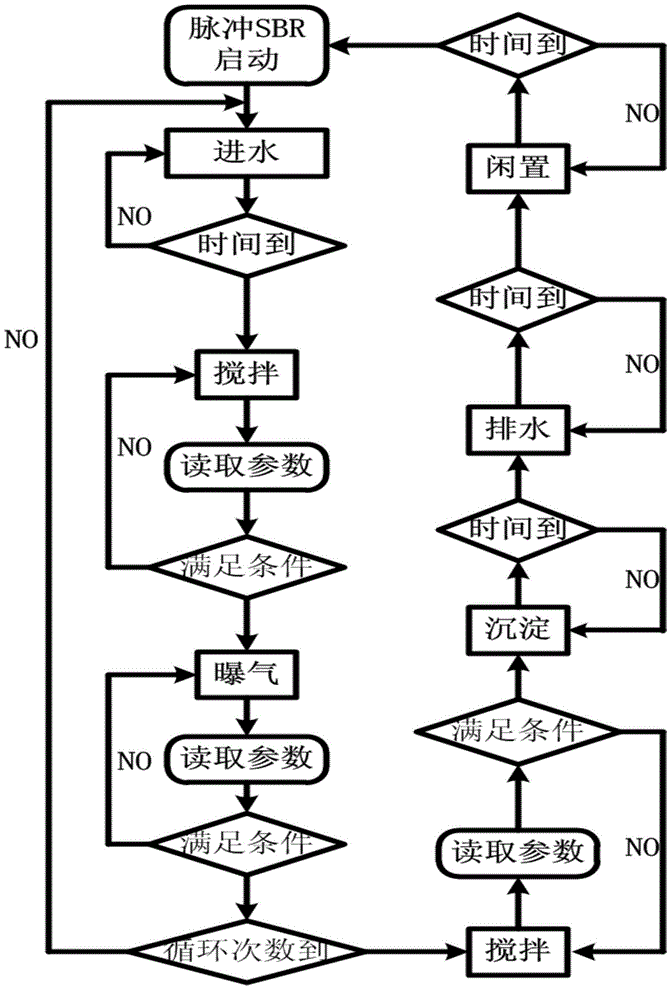

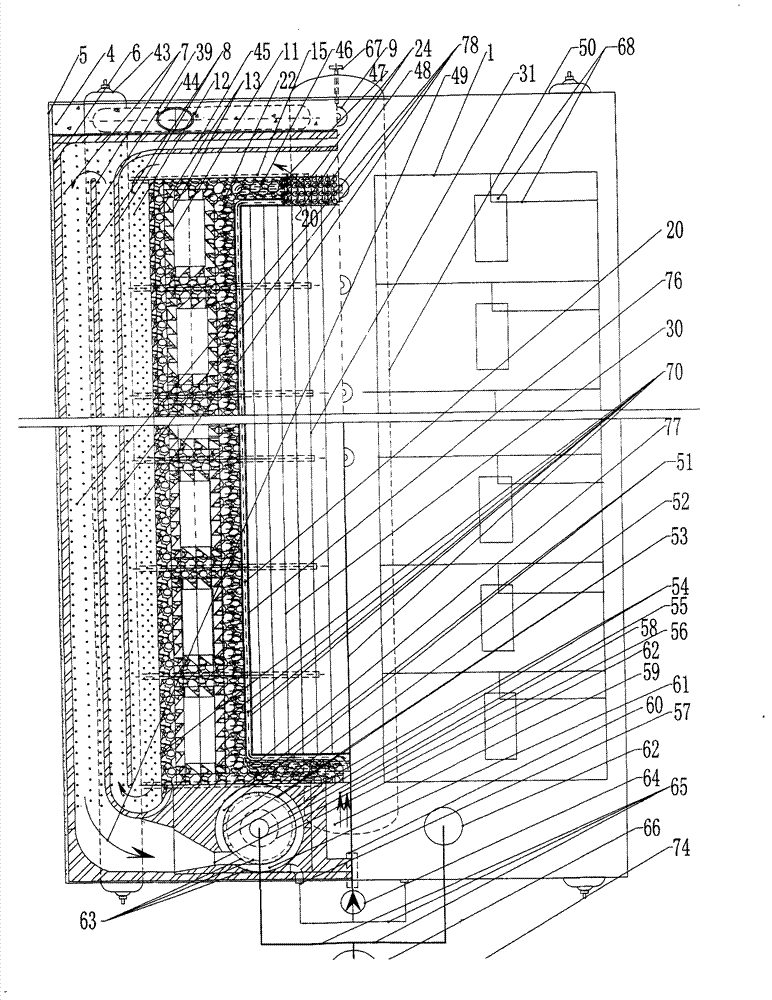

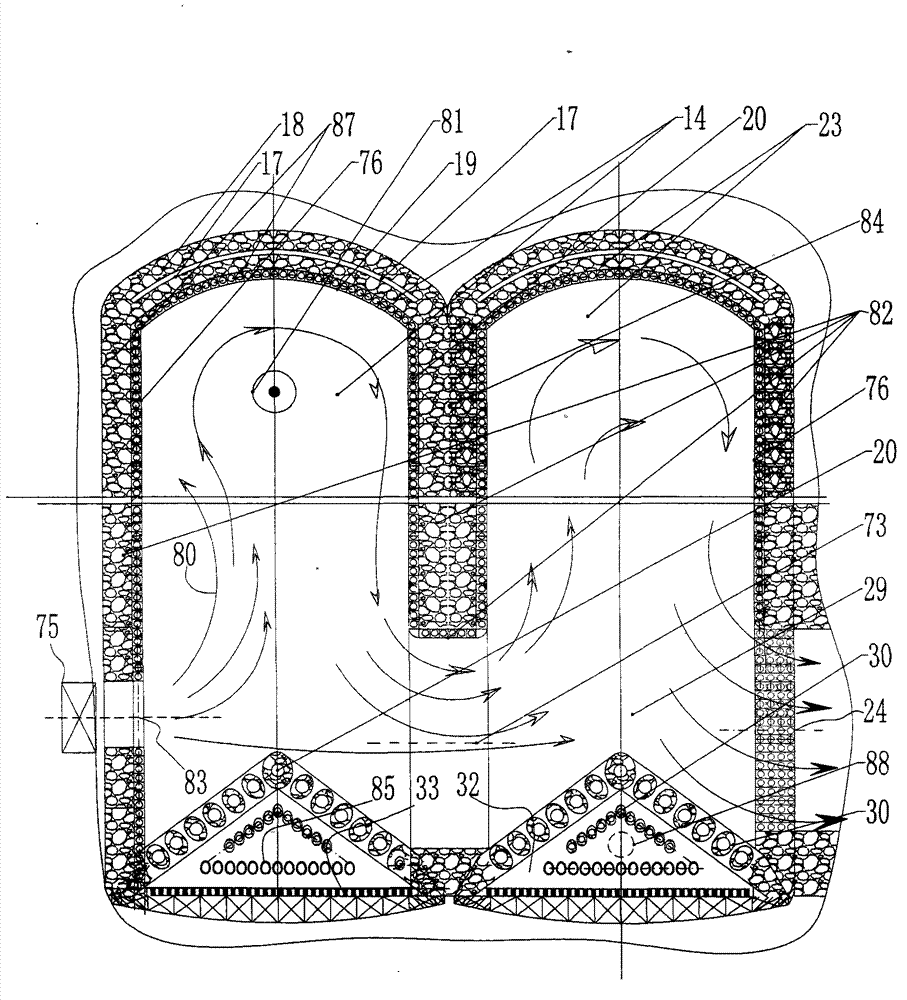

SBR alternant aerobic/anaerobic technology for biological denitrification and real time control device and method thereof

InactiveCN1569690AIncrease speedShort reaction timeTreatment with aerobic and anaerobic processesSludgeTime control

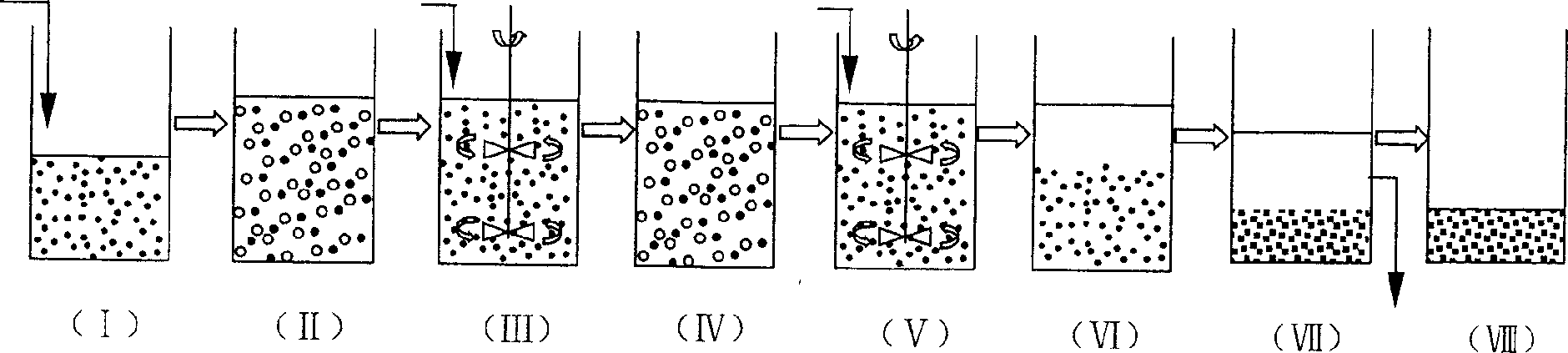

The invention discloses a SBR alternant aerobic / anaerobic technology for biological denitrification and real time control device and method thereof which consists of, dividing the waste water to be treated into three portions, loading each portion into a reactor, alternatively carrying out the operating mode of aerobic aeration and anoxybiotic agitating under real time procedure control, so as to realize the organics degradation and nitrogen-containing compound removal.

Owner:BEIJING TANSI ENVIRONMENTAL PROTECTION TECHCO

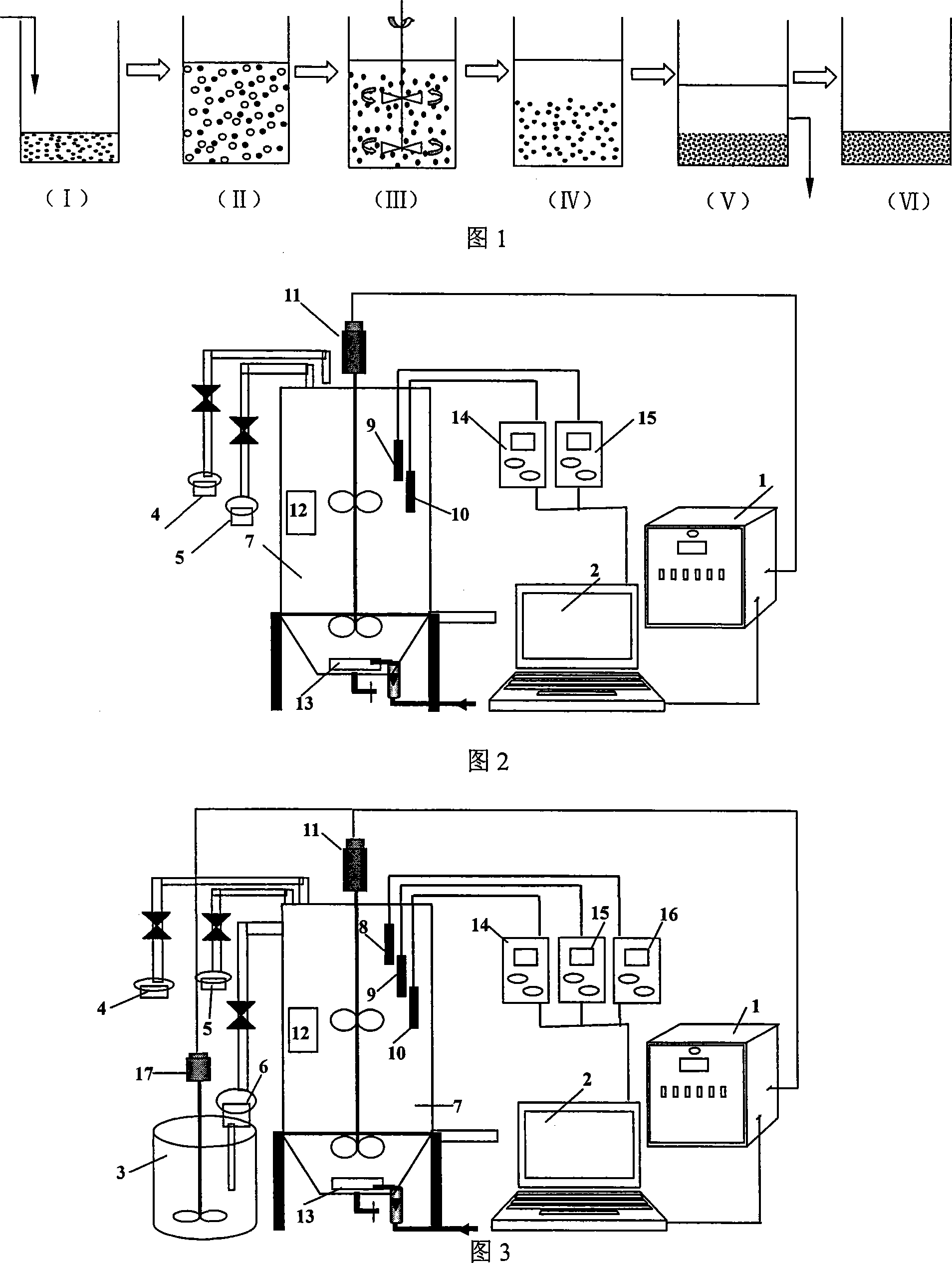

Real-time controlling method for denitrification by reinforced circulating type active sludge process

ActiveCN101182074AAvoid wastingControlled Aerobic AerationTreatment with aerobic and anaerobic processesElectric programme controlReal-time Control SystemSludge bulking

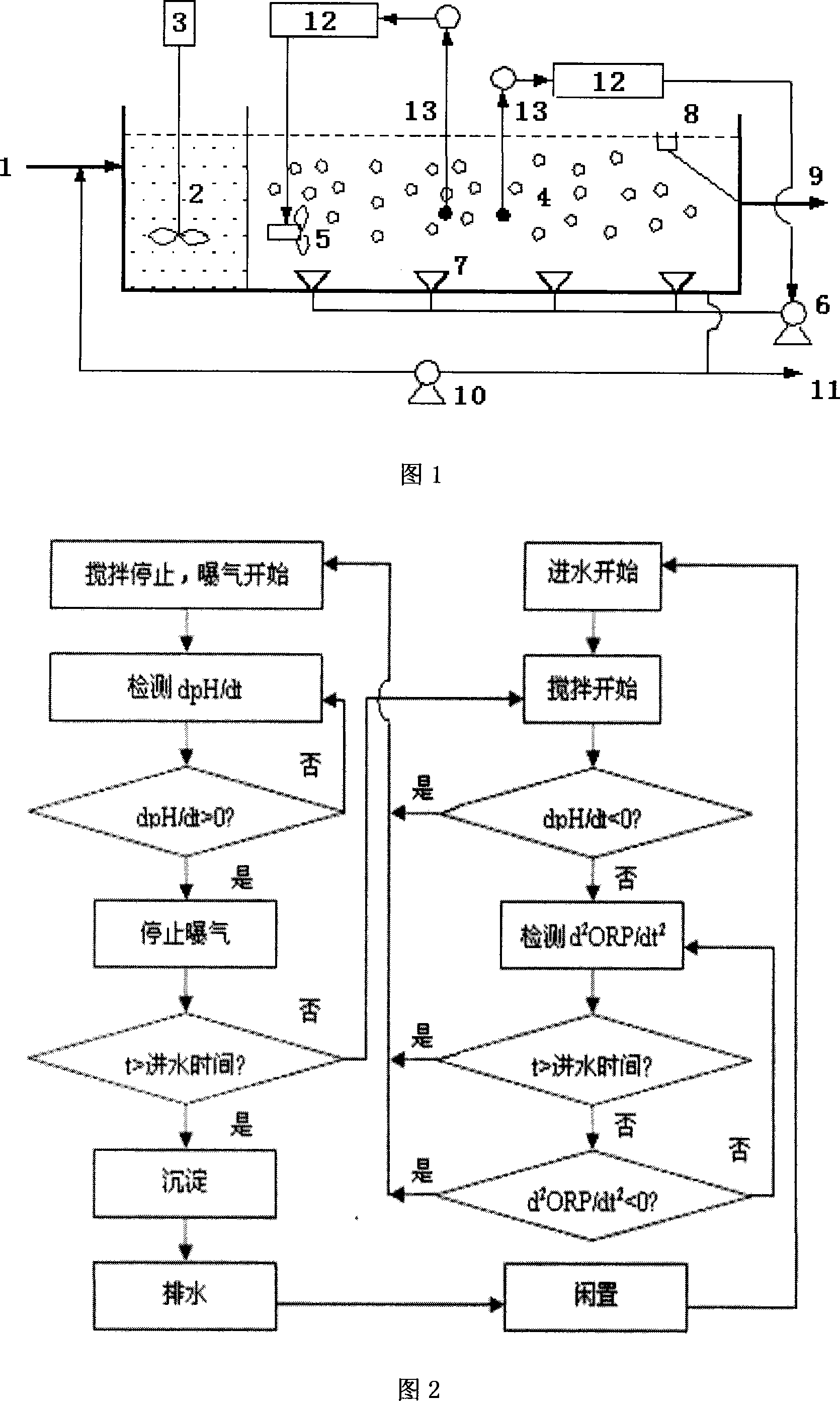

The invention discloses a real-time control method for denitrification by an enhanced circulating activated sludge method, which belongs to the field of biological denitrification of sewage and is suitable for advanced treatment of urban sewage. The effect of circulating activated sludge method on nitrogen and phosphorus removal is not ideal. The steps of the present invention: open the agitator in the main reaction zone at the same time as entering the water, and carry out the denitrification process under the anoxic condition, and stop stirring when a maximum value appears on the pH value curve and an inflection point appears on the ORP curve; Oxygen is supplied to the mixed solution to degrade organic matter and nitrify nitrogenous compounds, and stop aeration when a minimum value appears on the pH curve; repeat the above steps until the end of the water inflow stage, and react with the aerobic aeration stage end of period. The following process is similar to the traditional CAST method. It enters the sedimentation, drainage, and idle stages in turn, repeating all steps in turn and discharging sludge regularly. The whole process is completed by a real-time control system, which is easy to operate, low in cost, strong in impact load resistance, and not prone to sludge bulking.

Owner:CHONGQING KANGDA ENVIRONMENTAL PROTECTION IND GRP

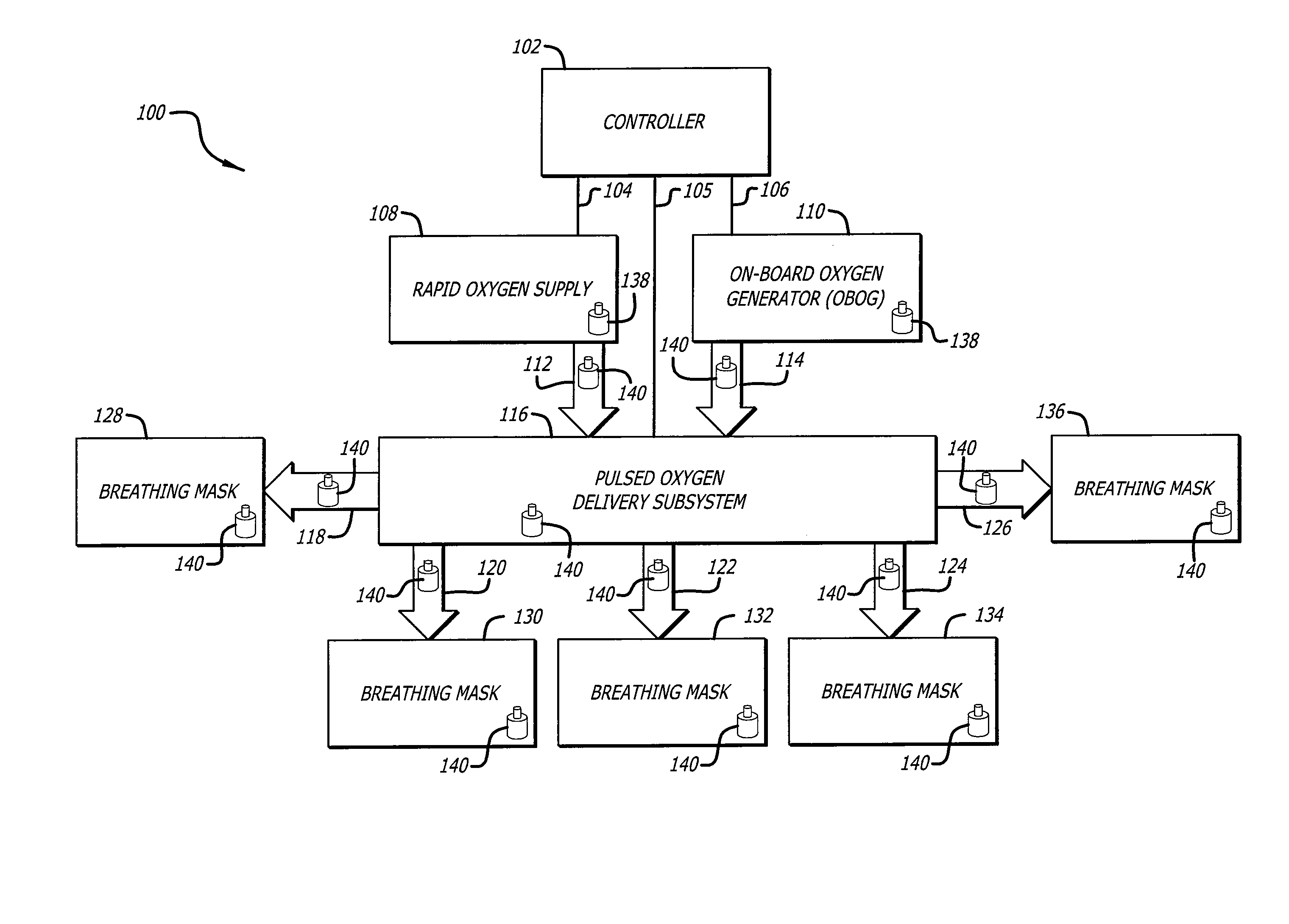

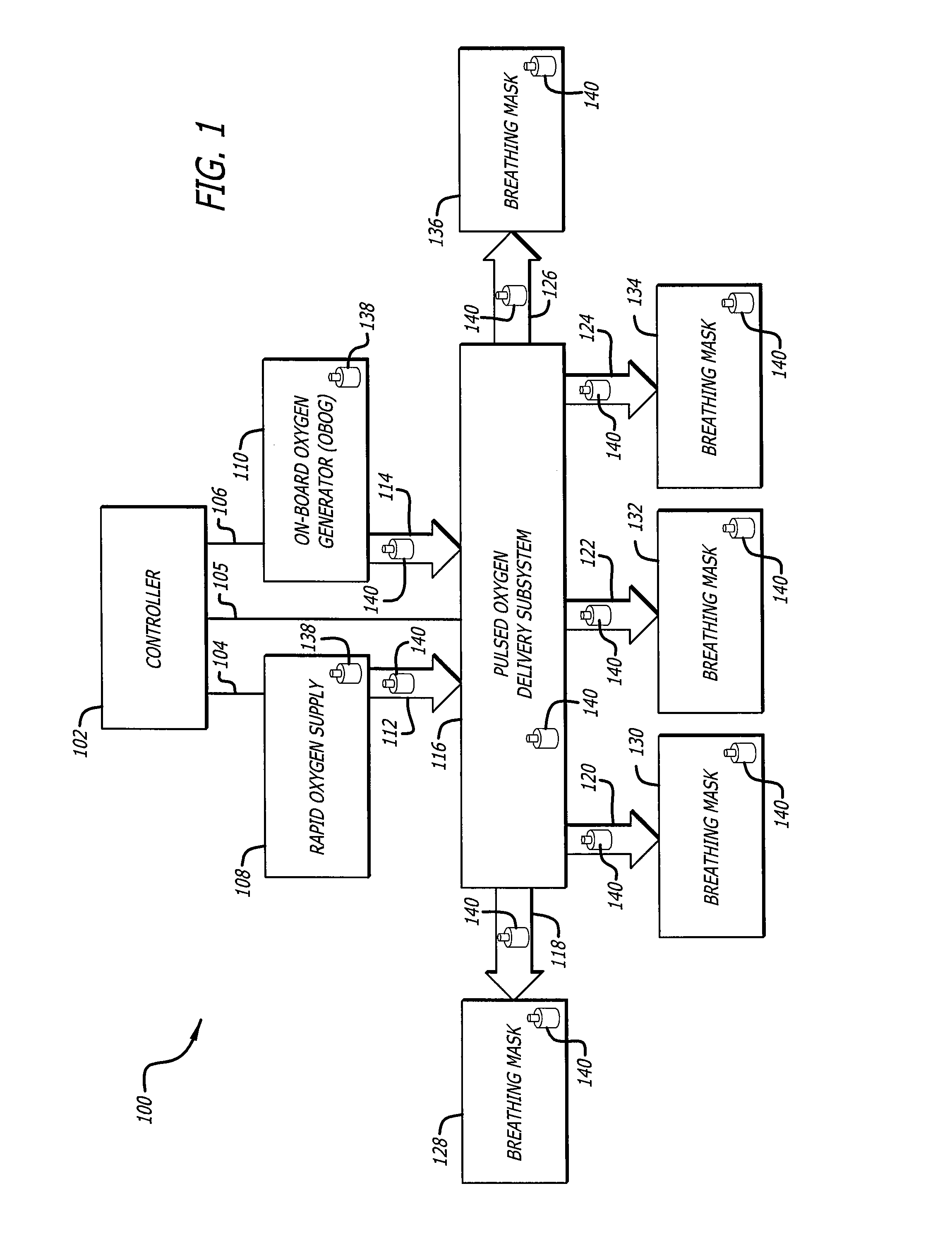

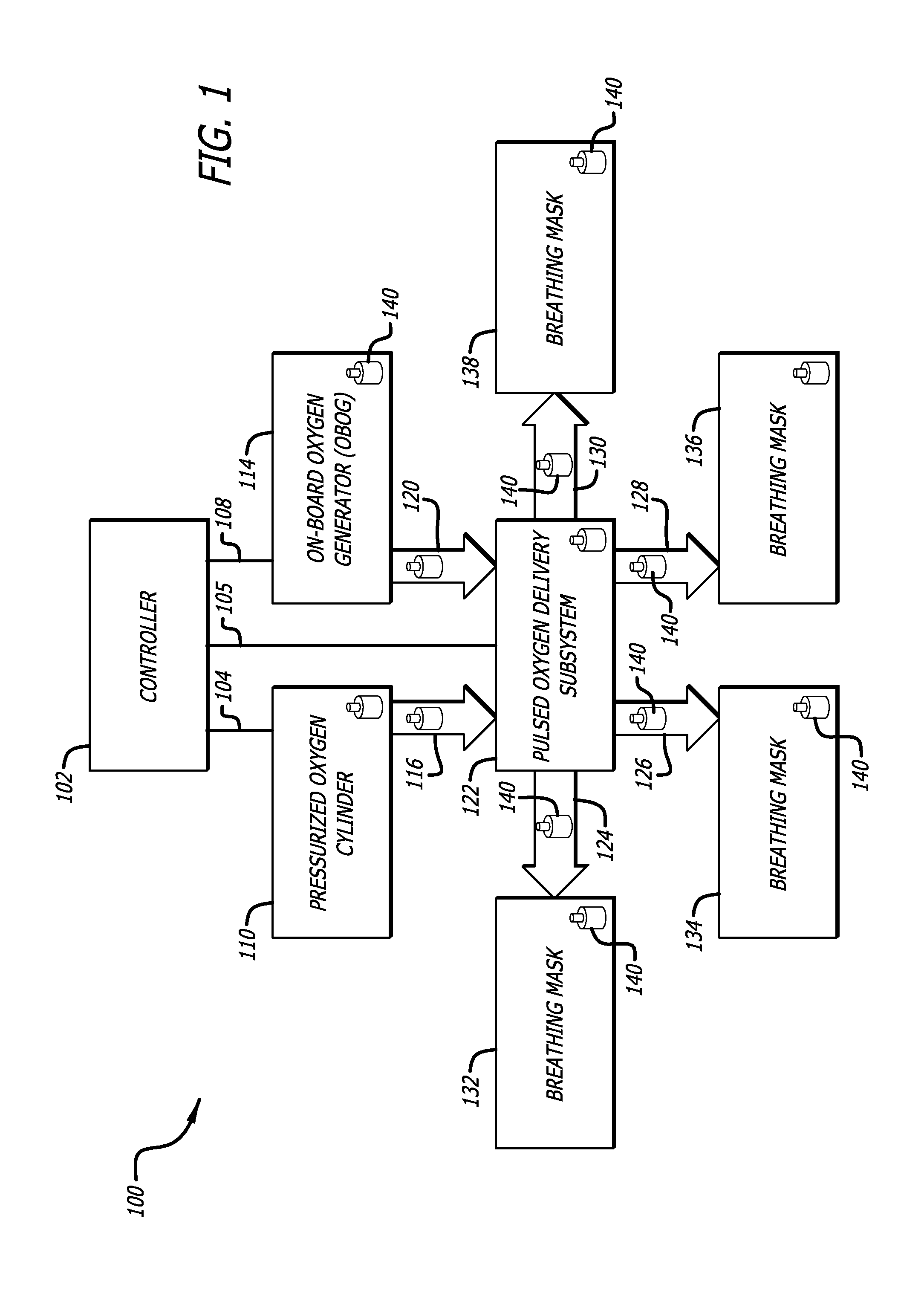

On-board generation of oxygen for aircraft pilots

ActiveUS20130312744A1Reduce maintenance costsReduce needRespiratorsOperating means/releasing devices for valvesAirplaneOn board

The present invention provides a system and method for supplying and managing oxygen suited for use on-board an aircraft for providing breathable oxygen to pilots and cockpit crew. Components of the system work together to optimize oxygen utilization while reducing costs from maintenance and added weight of traditional pressurized gaseous cylinders. Components include a rapid oxygen supply for immediate use in emergency situations, an on-board oxygen generator (OBOG), a controller, a pulsed oxygen delivery subsystem that detects inhale / exhale phases and adapts to physiological requirements, and a breathing mask for each pilot and cockpit crew member.

Owner:BE AEROSPACE INCORPORATED

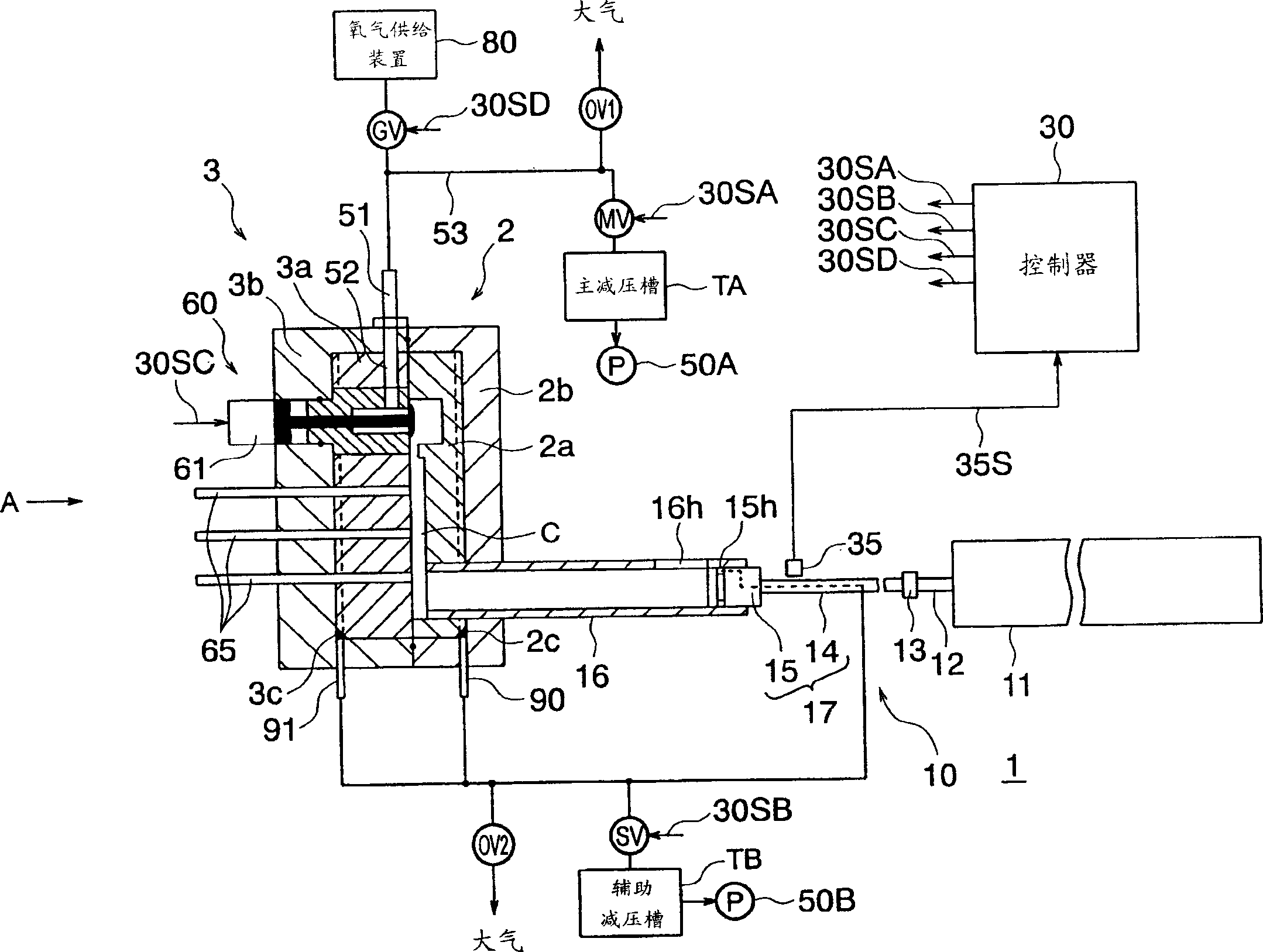

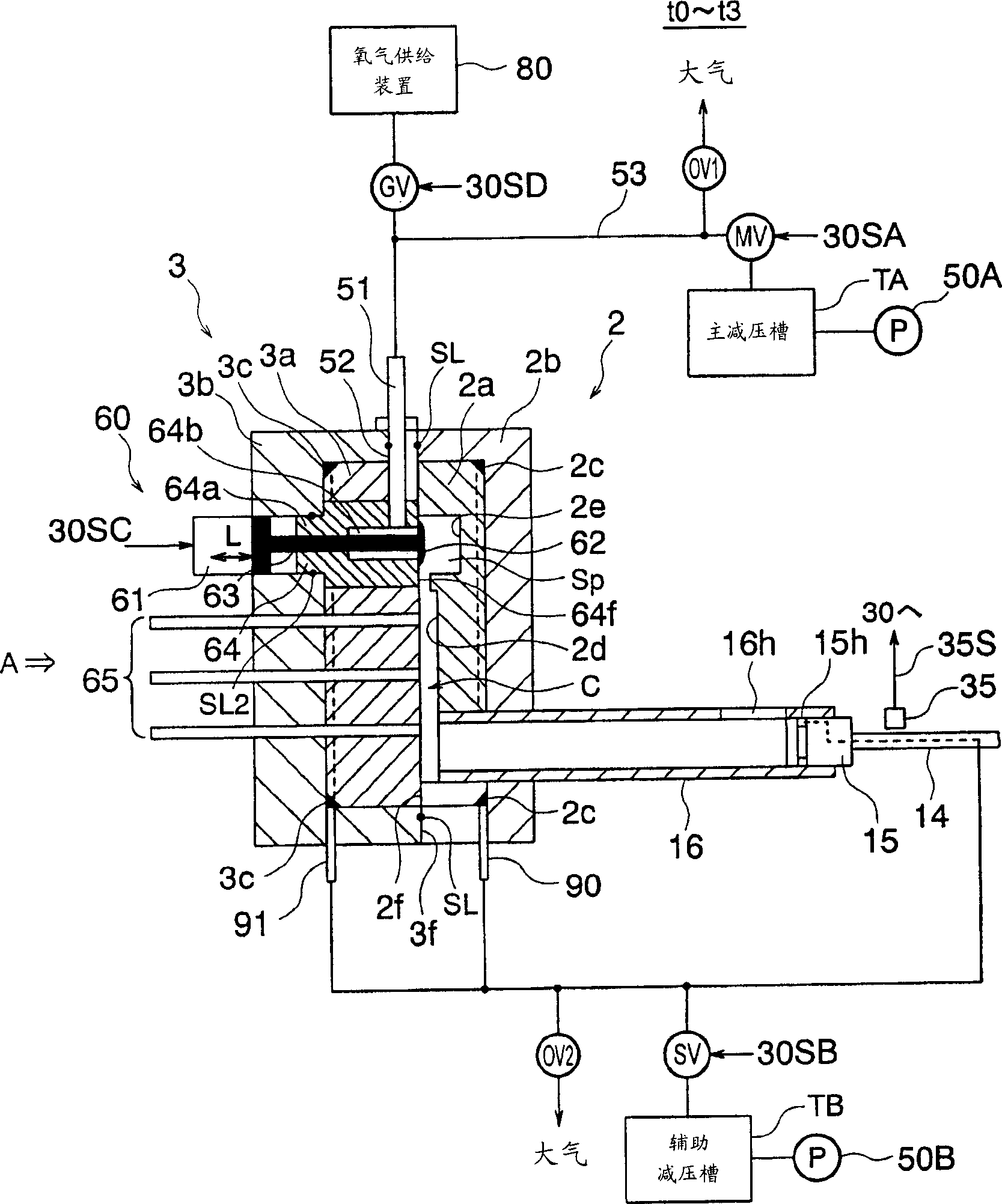

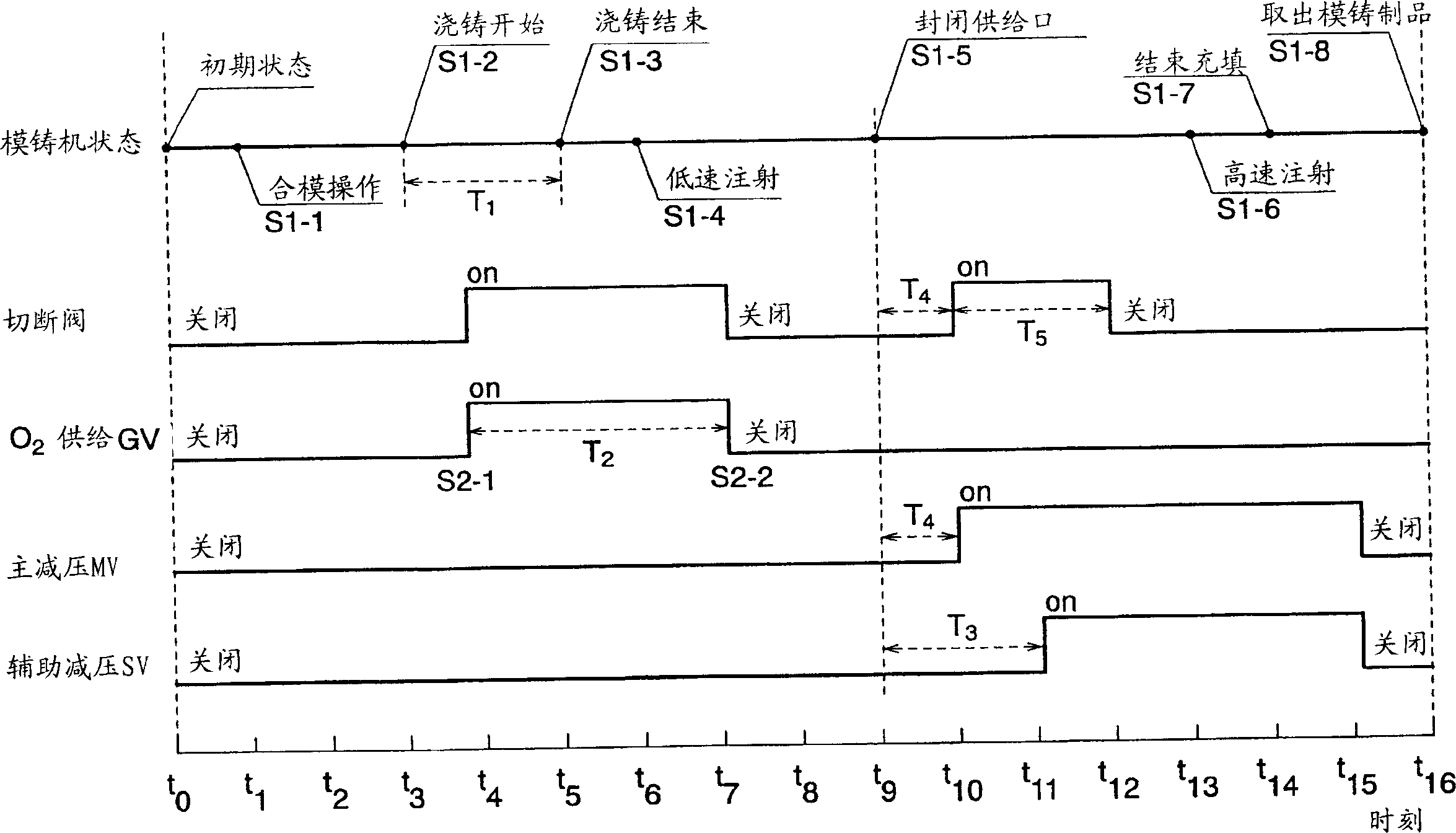

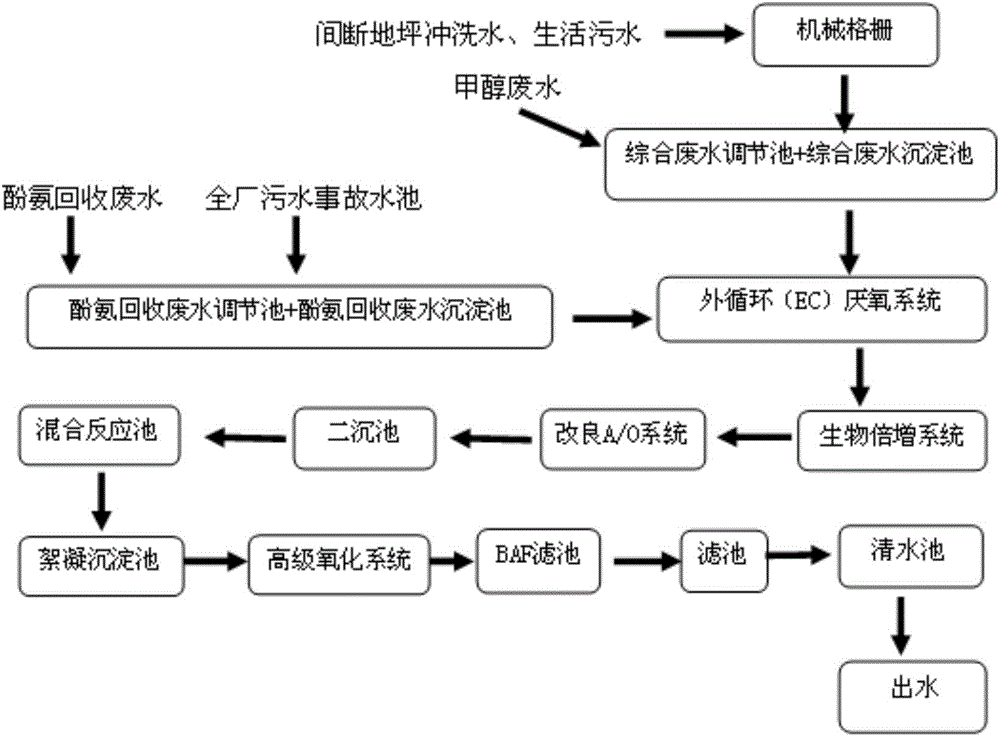

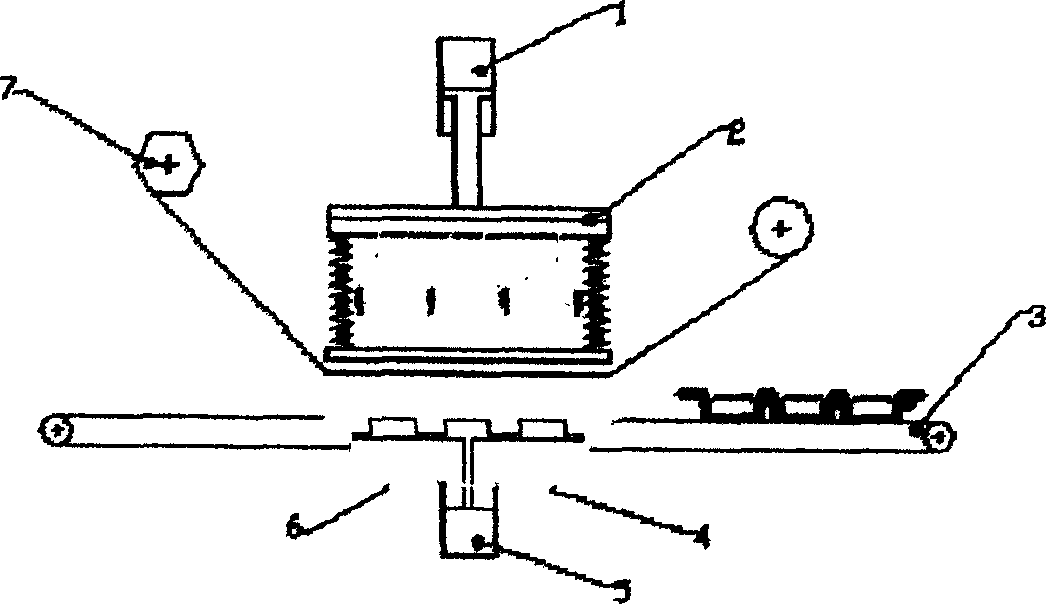

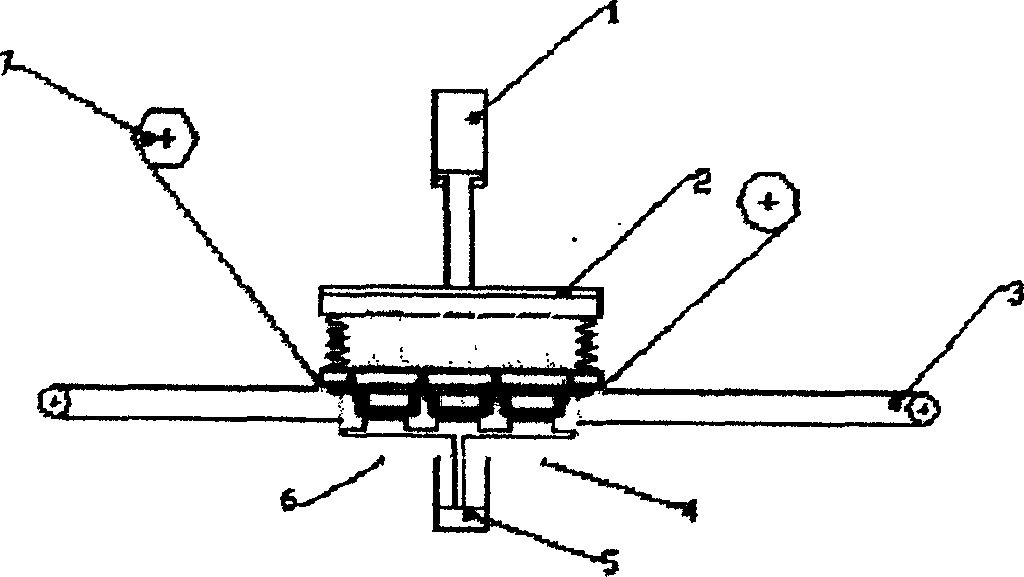

Die-casting device and vacuum process

The purpose of this invention is to improve a die casting apparatus by using an oxygen-replacing die casting method, with which a high quality die cast product can be produced. The oxygen gas is filled up into a cavity C and an injection sleeve 16 by using an oxygen gas supplying device 80, and after purging inner parts in the cavity C and the injection sleeve 16 with the oxygen gas, portions having the possibility of infiltrating the outer air into the cavity C, for example, an auxiliary reducing pressure tank B and a third opening / closing valve SV for performing the reduced pressure exhausting from a fixed die flowing path 2c and a moving die flowing path 3c, and a main reducing pressure tank TA and a first opening / closing valve MV for performing the pressure reduction in the cavity C are simultaneously and parallel driven.

Owner:TOSHIBA MASCH CO LTD

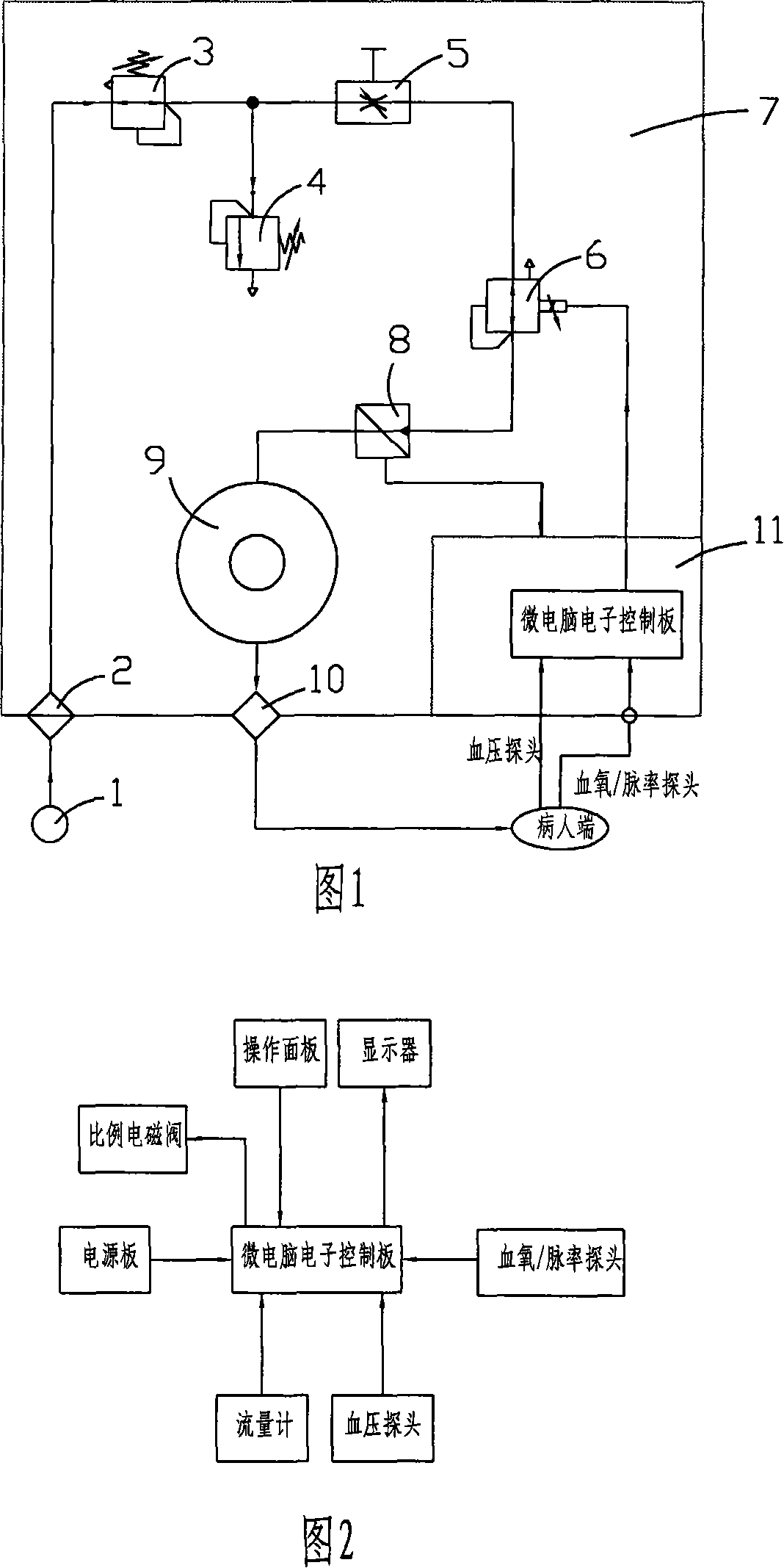

Method and device for monitoring controlling oxygen inhalation instrument

InactiveCN101121051AChange oxygen concentrationUninterrupted careRespiratorsData processing applicationsLower limitMicrocomputer

The present invention discloses a method and an installation of monitoring and controlling an oxygen inhalator. Under the control of a microcomputer, an upper limit and a lower limit of a patient blood oxygen saturation are set, and a preset flow velocity ratio is set for the oxygen inhalator. The oxygen inhalator is opened and supplied with oxygen at the preset flow velocity, after a period of time, the blood oxygen saturation inside the body of the patient who inhales oxygen is inspected, the flow velocity of a proportion electromagnetic valve which is in series in an gas path of the oxygen inhalator is regulated properly until the blood oxygen saturation is within a preset range. The apparatus not only has the characteristics of the oxygen inhalator and a monitor but also closely combines the oxygen inhalator and the monitor to realize an interaction. The apparatus provides monitoring of life sign parameters such as the blood oxygen saturation and can automatically change an oxygen inhalation flow velocity with the preset flow velocity range according to the timely collected changes of the patient life singe such as the blood oxygen saturation and accordingly a patient oxygen inhalation concentration is changed, then the patient life sign is improved.

Owner:北京新华卫拓医疗器械有限公司

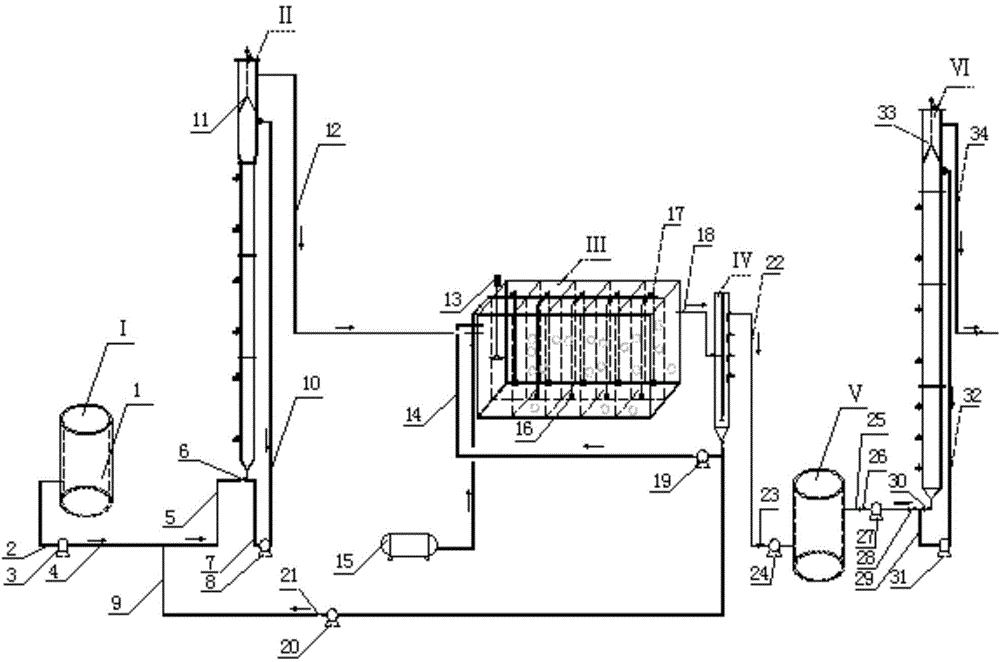

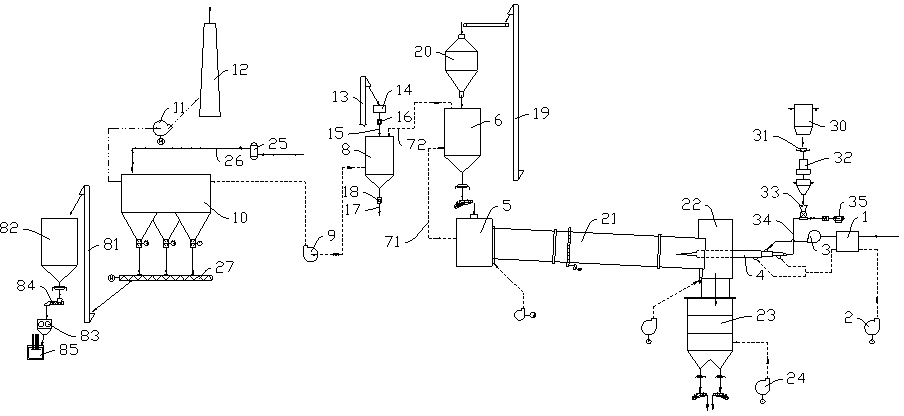

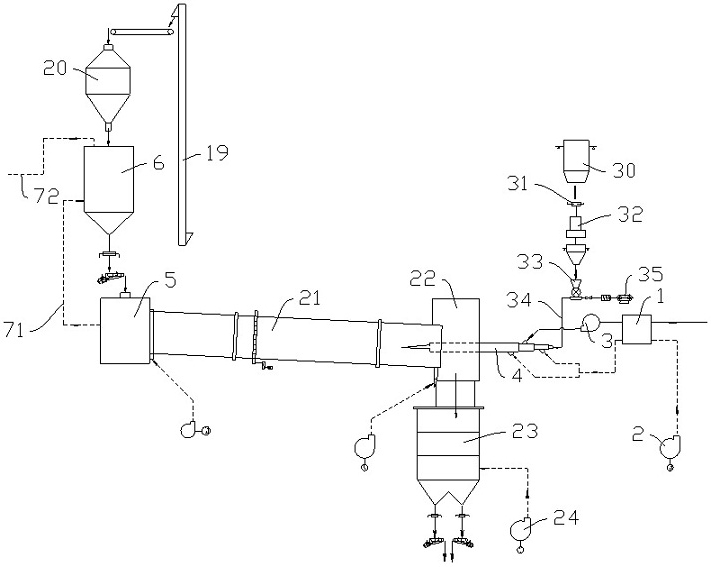

Advanced nitrogen removal method for treating late landfill leachate with upflow anaerobic sludge blanket, anoxic/oxic and anaerobic ammonia oxidation reactor combined process

ActiveCN104860482ASimultaneous carbon and nitrogen removalReduce concentrationMultistage water/sewage treatmentTotal nitrogenOxygen

The invention relates to an advanced nitrogen removal method for treating late landfill leachate with an upflow anaerobic sludge blanket (UASB), anoxic / oxic (A / O) and anaerobic ammonia oxidation reactor (ANAOR) combined process, and belongs to the field of biological nitrogen removal. The following difficult problems exist in late landfill leachate treatment: due to high ammonia nitrogen content, total nitrogen in outlet water is unlikely to meet the standard; a carbon source often needs to be additionally added, so that the landfill leachate treatment cost is greatly increased. The late landfill leachate is treated with the UASB, A / O and ANAOR combined process, and a biological treatment technology is enhanced, so that the landfill leachate treatment cost is reduced to the maximum extent. Through short-cut nitrification-anaerobic ammonia oxidation coupling, without additionally adding the carbon source, the removal effect and efficiency of ammonia nitrogen and total nitrogen are improved and a problem that ammonia nitrogen and total nitrogen in the outlet water of the late leachate do not meet the standard is solved. The method can be widely applied to treatment of high-ammonia-nitrogen-content wastewater and is especially suitable for treating the late landfill leachate filled for more than 5 years in urban garbage landfill sites.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

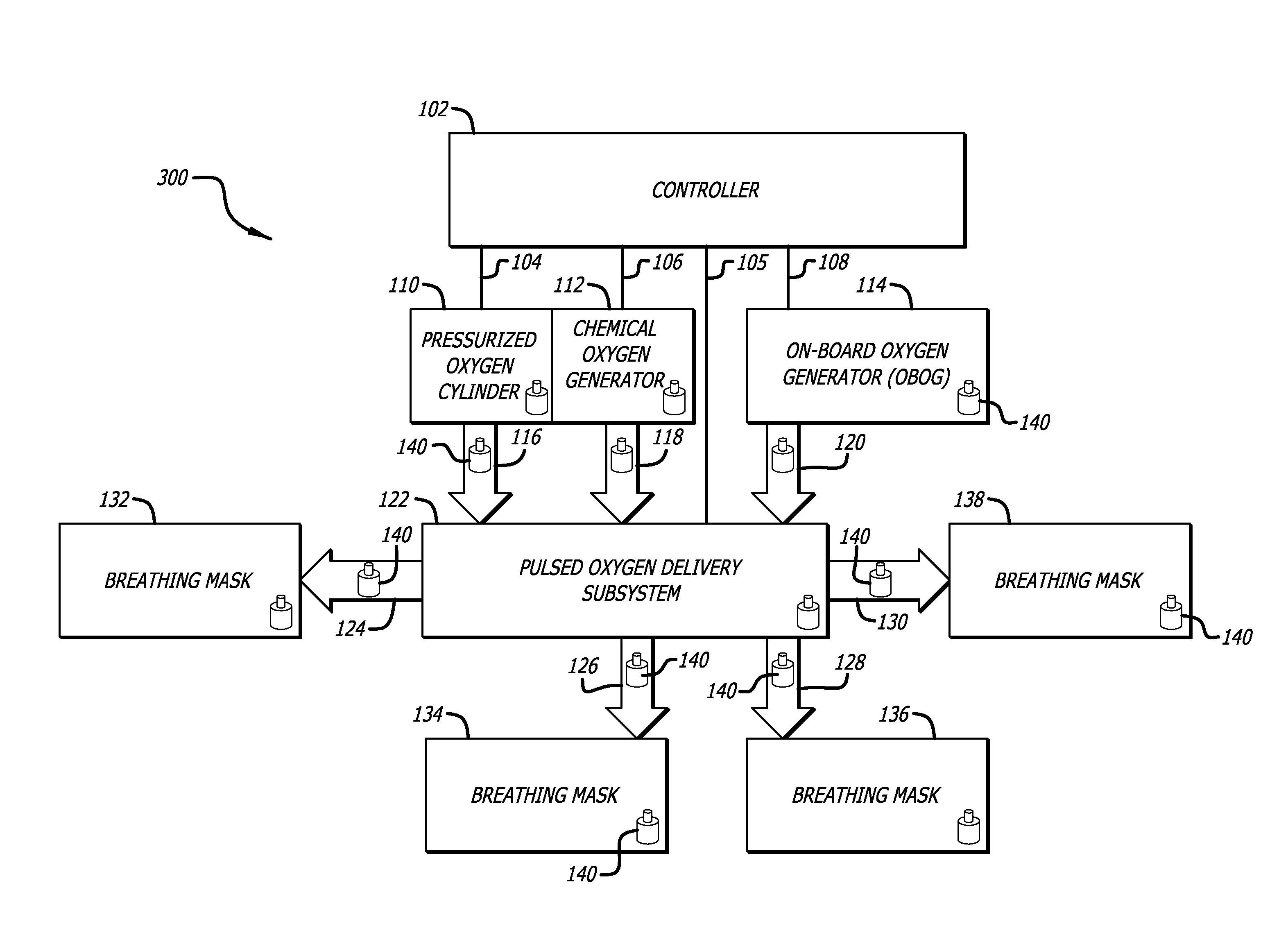

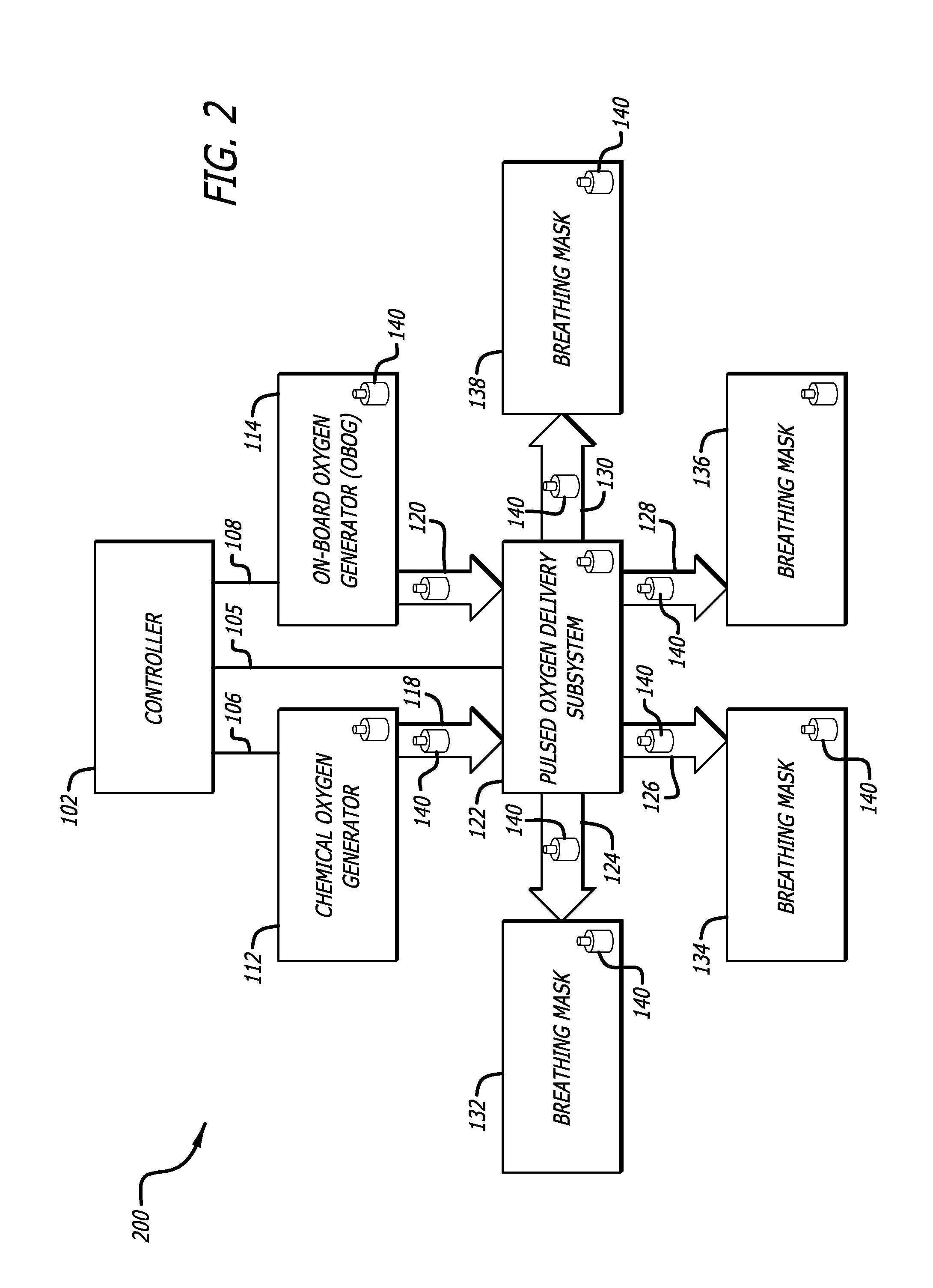

On-board generation of oxygen for aircraft passengers

ActiveUS20130312743A1Save oxygenReduce maintenance costsRespiratorsOperating means/releasing devices for valvesOxygen utilization rateOn board

The present invention provides a system and method for supplying, generating, conserving, and managing oxygen that is ideally suited for use on-board an aircraft for supply of breathable oxygen to passengers and flight crew. The system includes several components that together optimize oxygen utilization while reducing costs from maintenance and added weight of traditional pressurized gaseous cylinders. Components of the system include a pressurized cylinder of oxygen enriched gas or a chemical oxygen generator for rapid use in emergency situations, an on-board oxygen generator (OBOG) of the ceramic oxygen generator (COG) type incorporating solid electrolyte oxygen separation (SEOS) technology, a controller, a pulsed oxygen supplier, a crew / passenger breathing mask, and one or more sensors including sensors that detect inhale / exhale phases and communicate with the controller so that flow of oxygen may be regulated for conservation and to adapt to physiological needs.

Owner:BE AEROSPACE INCORPORATED

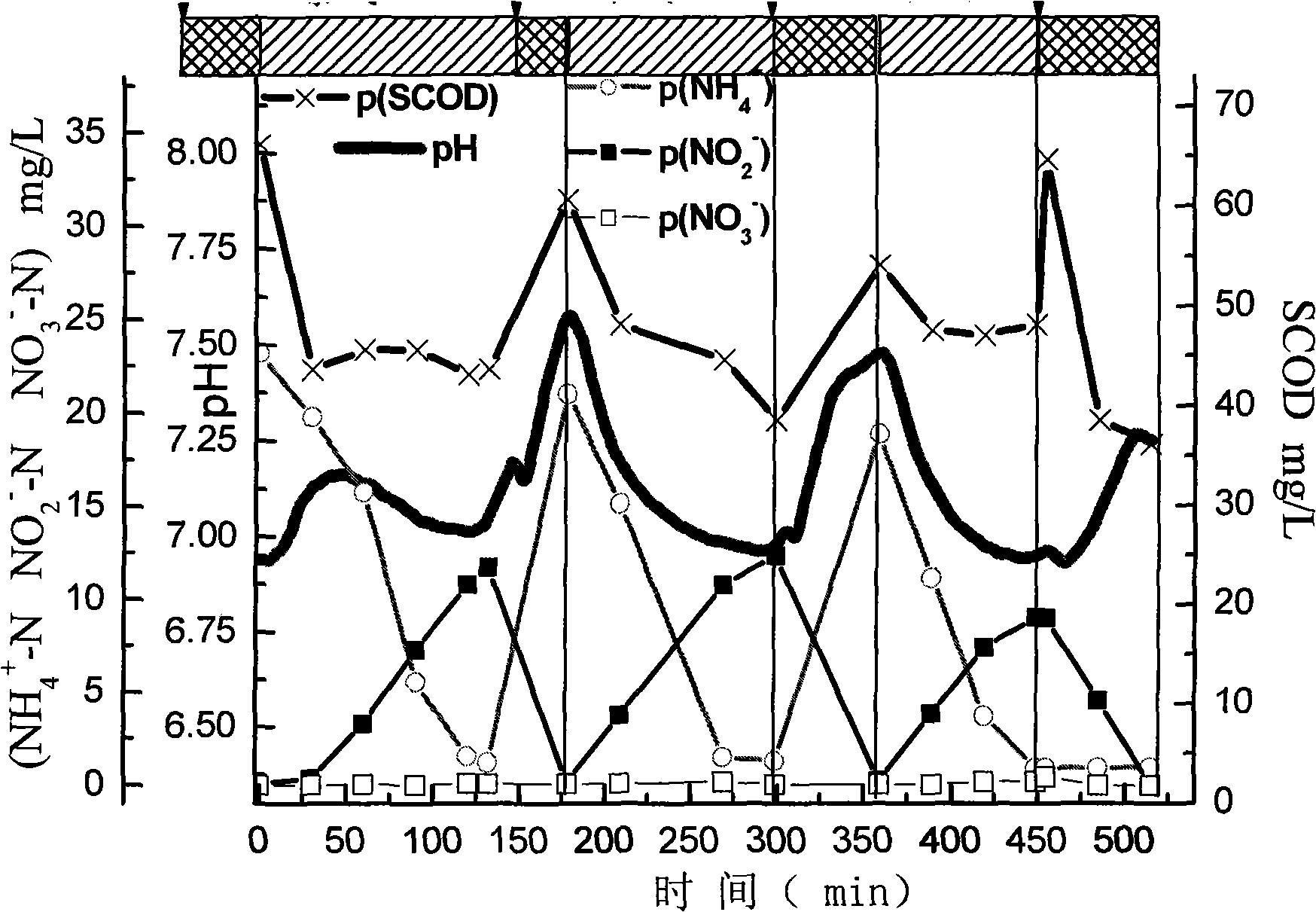

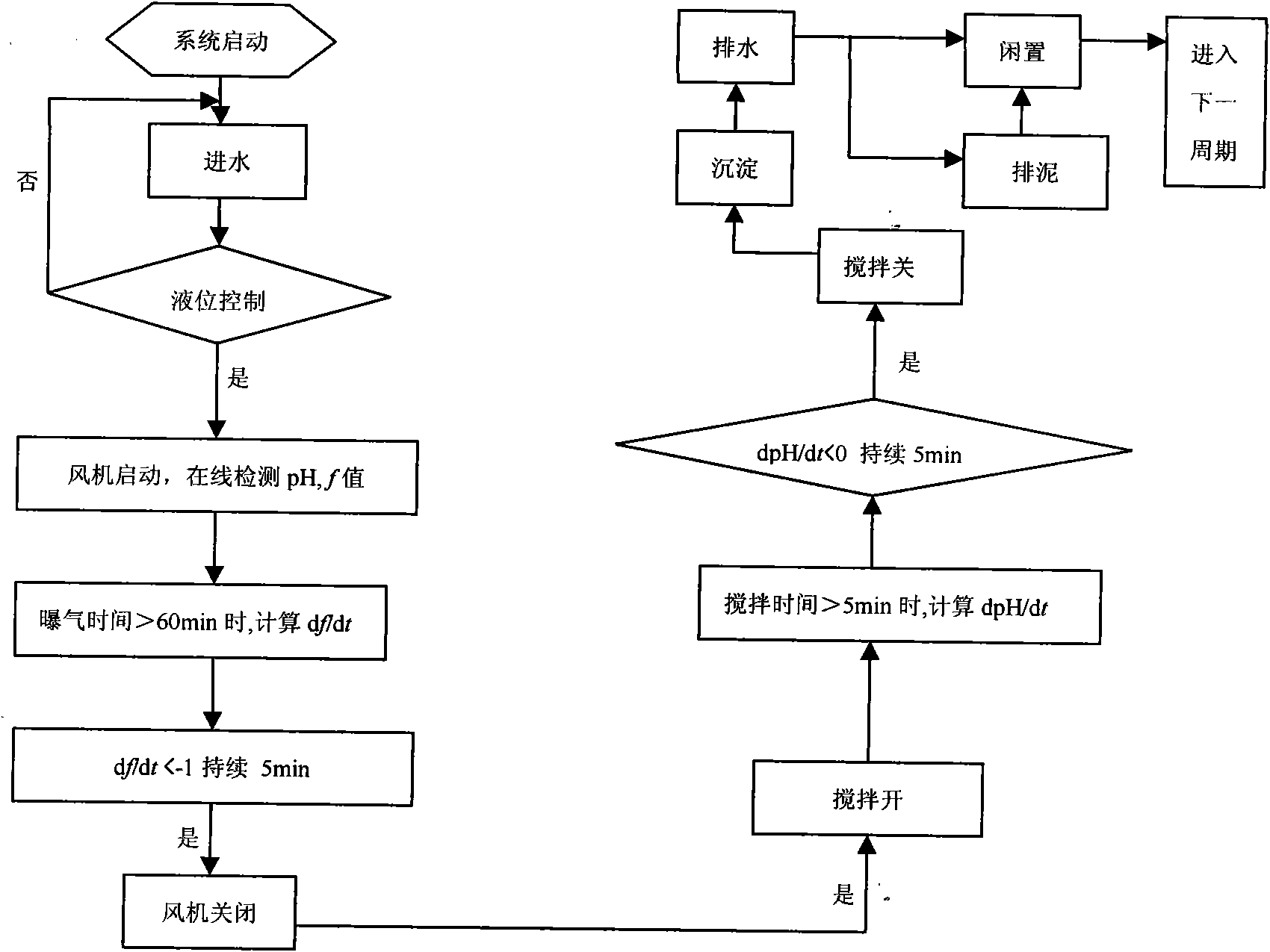

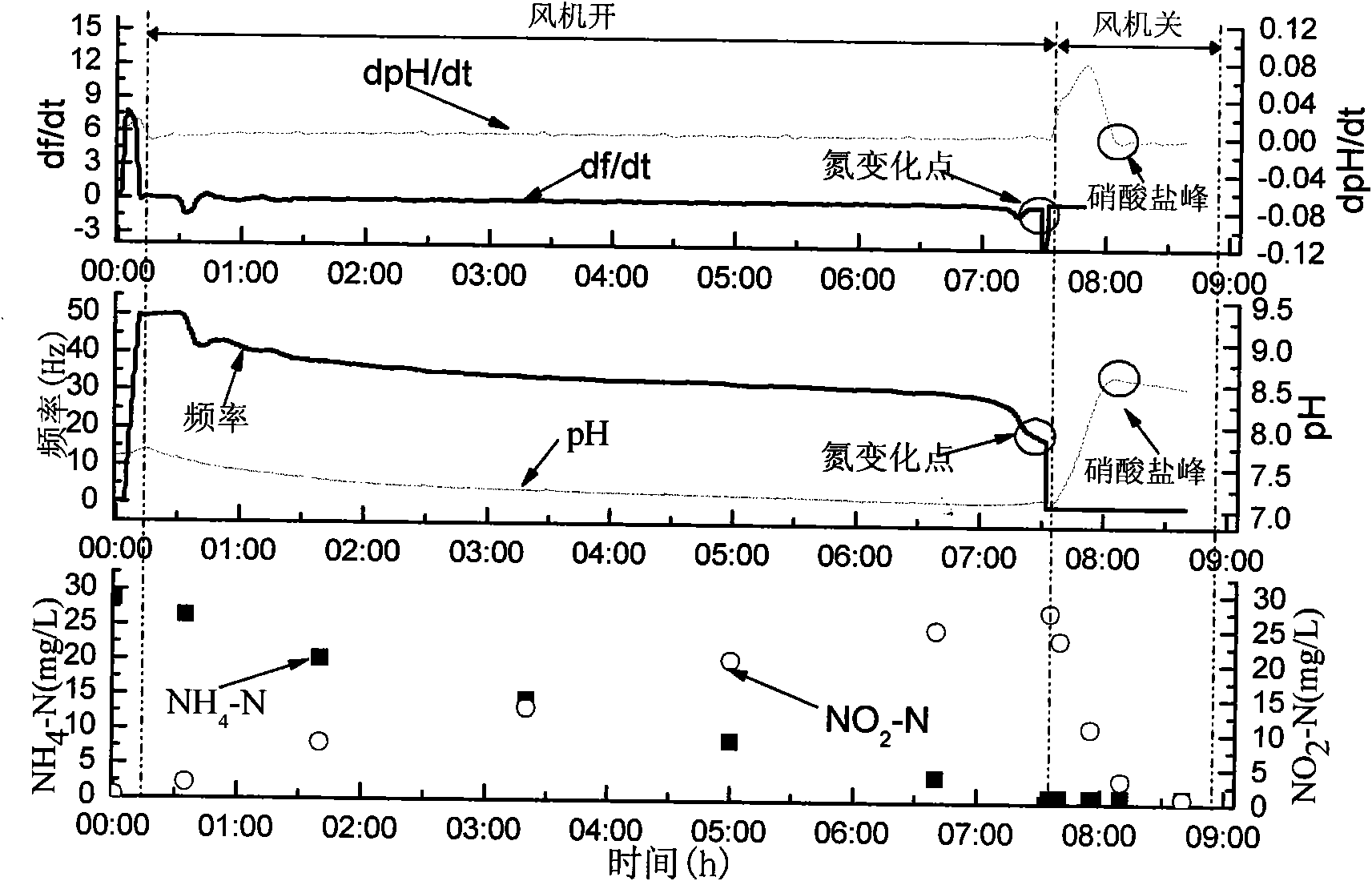

Method for fast realizing short distance deep denitrogenation by SBR process

ActiveCN101264978AImprove denitrification effectReduce total nitrogenTreatment with aerobic and anaerobic processesSustainable biological treatmentSludgeRetention time

The invention relates to a rapid nitrogenous wastewater biological treatment process, particularly to a method for rapidly realizing short distance deep denitrogenation by SBR process. The prior short distance biological denitrogenation technique is not suitable for treating wastewater with low C / N ratio. The inventive method comprises the steps of feeding water, aerating, adding equal amount of raw wastewater, aerating, adding equal amount of raw wastewater, aerating, adding external carbon source, aerating, settling, draining, and idle running. The temperature in the overall process is controlled at 30-33 DEG C, the water dissolved oxygen concentration during nitration stage is controlled in the range of 0.8-1.2 mg / L, the mean sludge retention time in the system is 12-15 days, and the aeration amount and the denitrification time of the short distance deep denitrogenation by SBR process is controlled based on the change feature of online parameter pH value. The inventive method has the advantages of good denitrogenation effect, high degree of automation, low energy consumption, convenient operation, low cost, and suitability for treatment of wastewater with low C / N ratio.

Owner:QINGDAO CHENGTOU SHUANGYUAN WATER CO LTD

Quick start method for short-range deep denitrification by SBR (Sequencing Batch Reactor) process at low temperature

ActiveCN102079609ARemarkable effect of energy saving and consumption reductionLow running costTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentSequencing batch reactorRetention time

The invention relates to a quick start method for a nitrogenous wastewater biological treatment technique, in particular to a quick start method for a short-range deep denitrification technique by an SBR (Sequencing Batch Reactor) process at low temperature. The existing short-range deep denitrification technique can not be easily started at low temperature. The time for the short-range deep denitrification in the starting stage in the invention is short. The method provided by the invention comprises the steps of water injecting, aerating, denitrifying, precipitating, water discharging, sludge discharging, and standing. In the invention, frequency is used as the process control parameter in the aerating stage, and the retention time of the sludge is kept within 30-40 days, thereby realizing the quick start of short-range deep denitrification by the SBR process at low temperature (11-17 DEG C). The invention has the advantages of high denitrification efficiency and operating cost saving, can easily realize automation, can realize quick start at low temperature, and can also stably operate at normal temperature.

Owner:北控水务(中国)投资有限公司

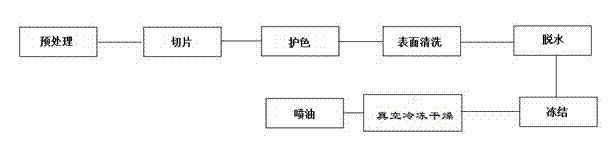

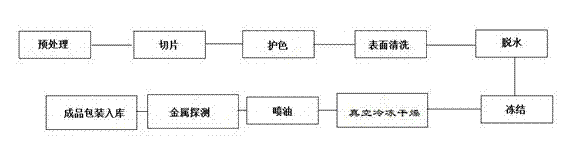

Preparation method of freeze-drying oil-injection sliced agaricus bisporus

InactiveCN102960428AReduce exposureEasy to storeFruits/vegetable preservation by coatingAgaricusAdditive ingredient

The invention discloses a preparation method of free-drying oil-injection sliced agaricus bisporus. The preparation method comprises the following steps: preprocessing, slicing and protecting color and also comprises the steps of sterilizing, cleaning surfaces, dewatering, freezing, conducting vacuum freeze-drying and injecting oil. The freeze-drying oil-injection sliced agaricus bisporus prepared by the method does not damage the original color, aroma and taste and shape of a product; the nutrition ingredients can not be lost, the production efficiency is high, and the yielding rate is high; and the prepared sliced agaricus bisporus has low water content (below 4%) so as to be light in weight, and is easy to store.

Owner:四川江茂食品有限公司

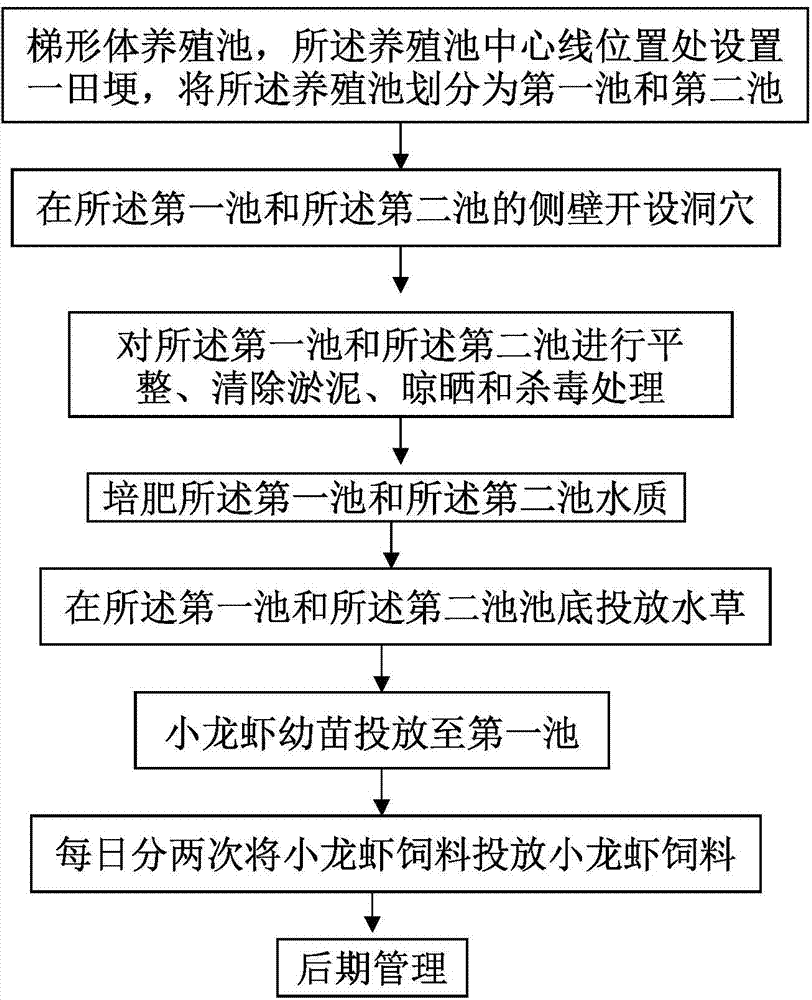

Culture method for increasing survival rate of crays

InactiveCN104839059APrevent climbing outAvoid lossClimate change adaptationPisciculture and aquariaShrimpWater quality

The invention provides a culture method for increasing survival rate of crays. The method includes: (1) building a culture pond which is a trapezoid, arranging a ridge at the position of the center line of the culture pond, and dividing the culture pond into a first pond and a second pond via the ridge; (2) constructing cray caves, to be more specific, forming the caves in the side walls of the first pond and the second pond; (3) pretreating the culture pond, leveling the first pond and the second pond, and performing desludging, airing and disinfection; (4) performing fertility betterment of water; (5) putting in aquatic plants, tying the aquatic plants into stacks with ropes, and putting the stacks into the bottoms of the first pond and the second pond at an interval of 5 meters; (6) putting in cray fries; (7) putting in feed, to be more specific, putting in cray feed twice every day; (8) performing later period management. In the cray culture process, the crays are cultured in the first pond and the second pond alternatively so as to disinfect the first pond or the second pond thoroughly, and survival rate of the crays is increased.

Owner:许玲

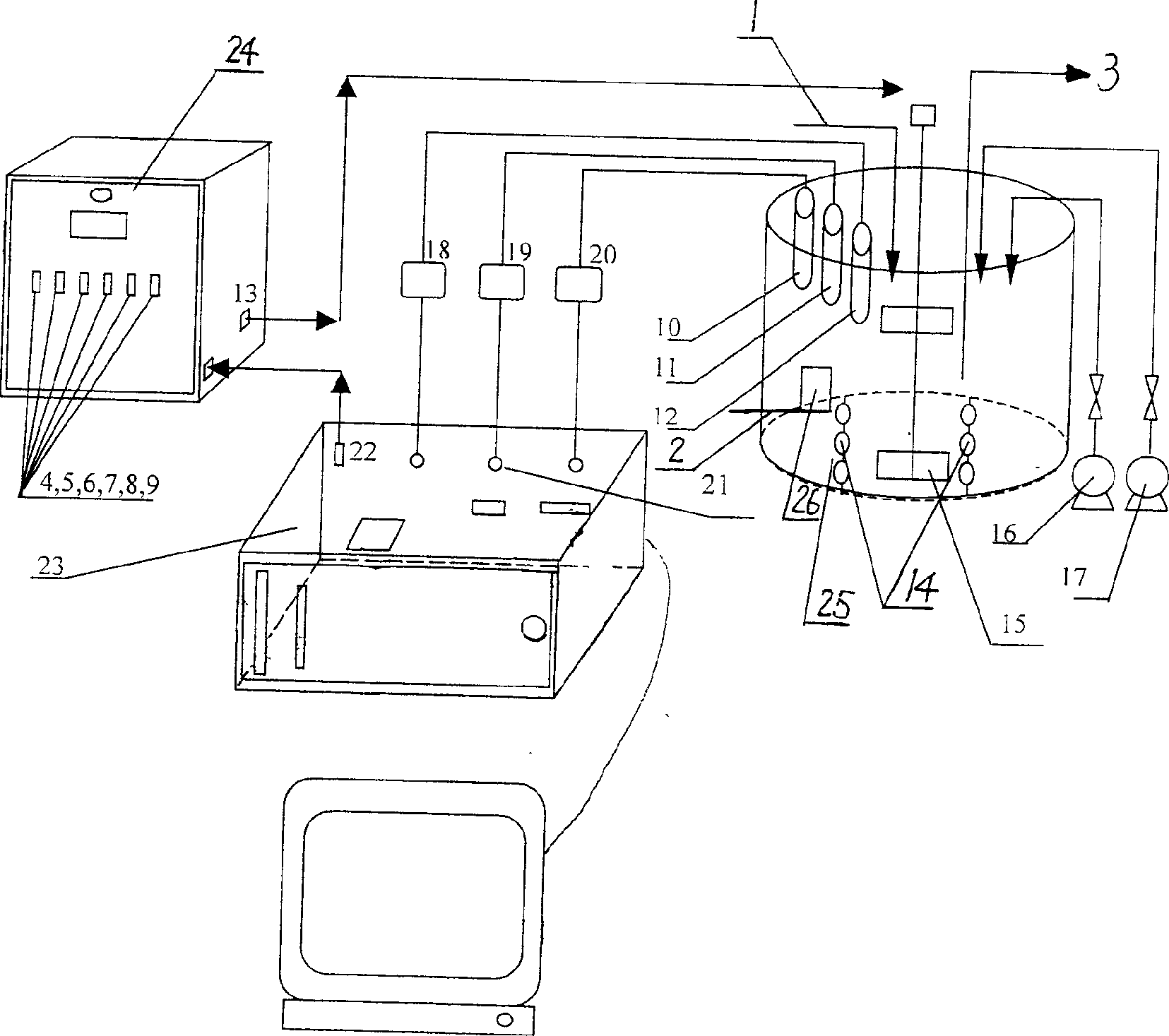

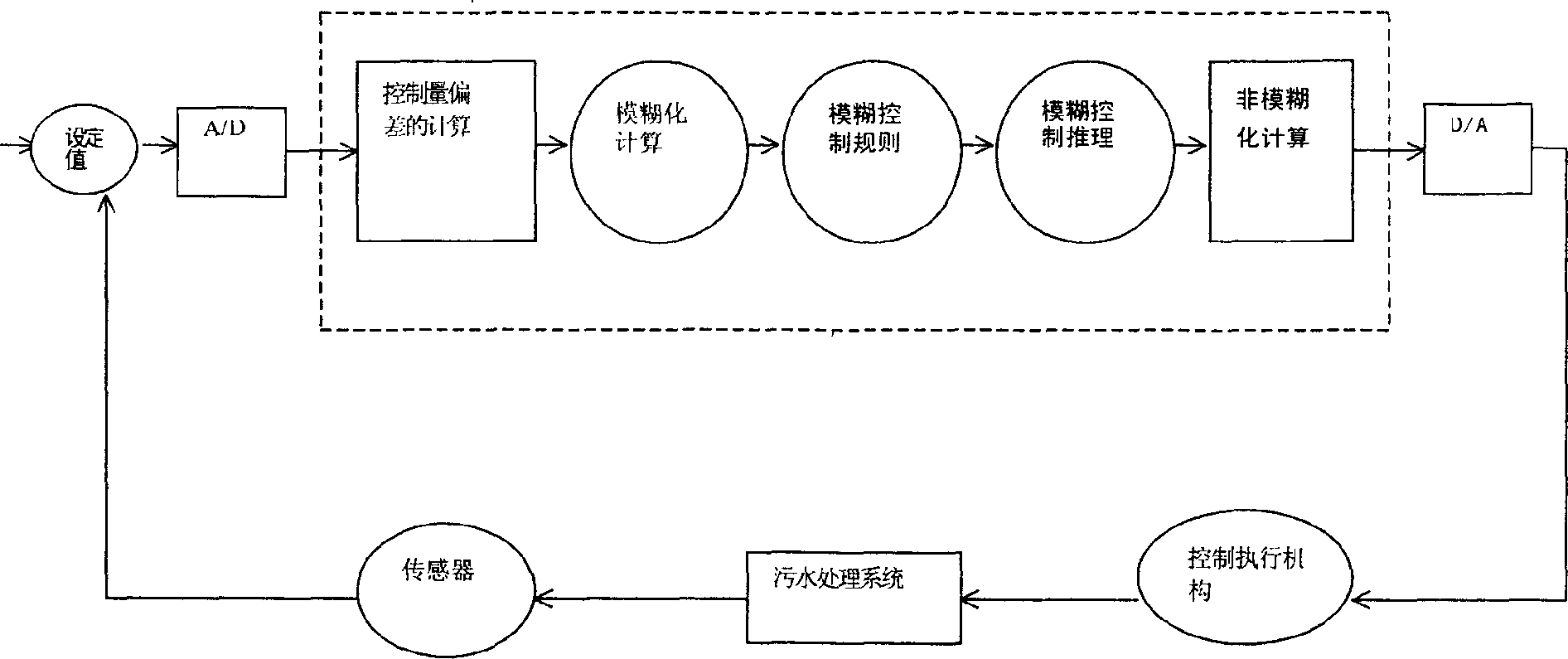

Device and method for quickly realizing short range biological denitrification by salinity suppressing combined with fuzzy control

ActiveCN101113053AEnriched growthInhibition of sludge bulkingTreatment with aerobic and anaerobic processesSustainable biological treatmentSeawaterSewage treatment

A device for fast realization of shortcut biological denitrification through salinity inhibition combined with fuzzy control and methods thereof pertain to the technical field of sewage biological denitrification of SBR method and are suitable for sewage disposal in nitrogen-containing industry and advanced treatment of town sewage. The invention adjusts the mass concentration of crude salt of inlet water in 5-7.5 g / L (Cond value is 8.92-12.95 mc / cm) to quick realize the accumulation of nitrite in normal temperature above 90 percent by adding crude salt of a certain concentration (the crude salt is obtained directly by basking seawater without any processing) and combining with controlling the time of nitrification and denitrification in real time, the method is designed to solve the problems of long starting time of the existing shortcut biological denitrification technology and difficulty to maintain. The method can not only fast realize the accumulation of nitrite in high proportion stably in reaction system to enable the nitrating types to be fast and long-time stabilized on shortcut nitrification, but also has the advantages of low cost, flexibility in operation and management and seldom causing sludge bulge, etc.

Owner:CHONGQING KANGDA ENVIRONMENTAL PROTECTION IND GRP

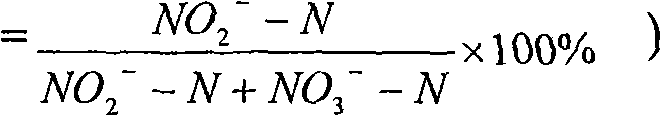

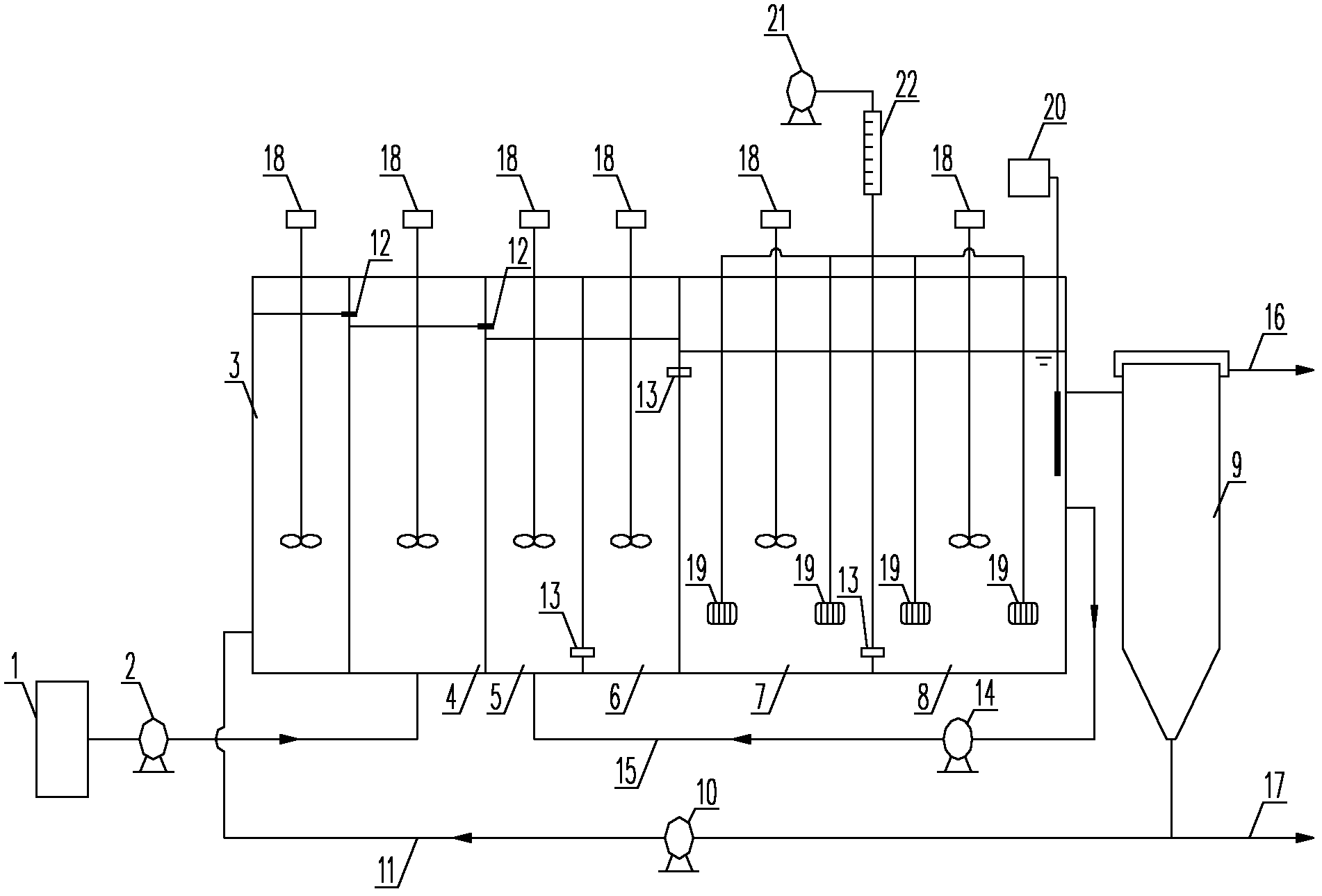

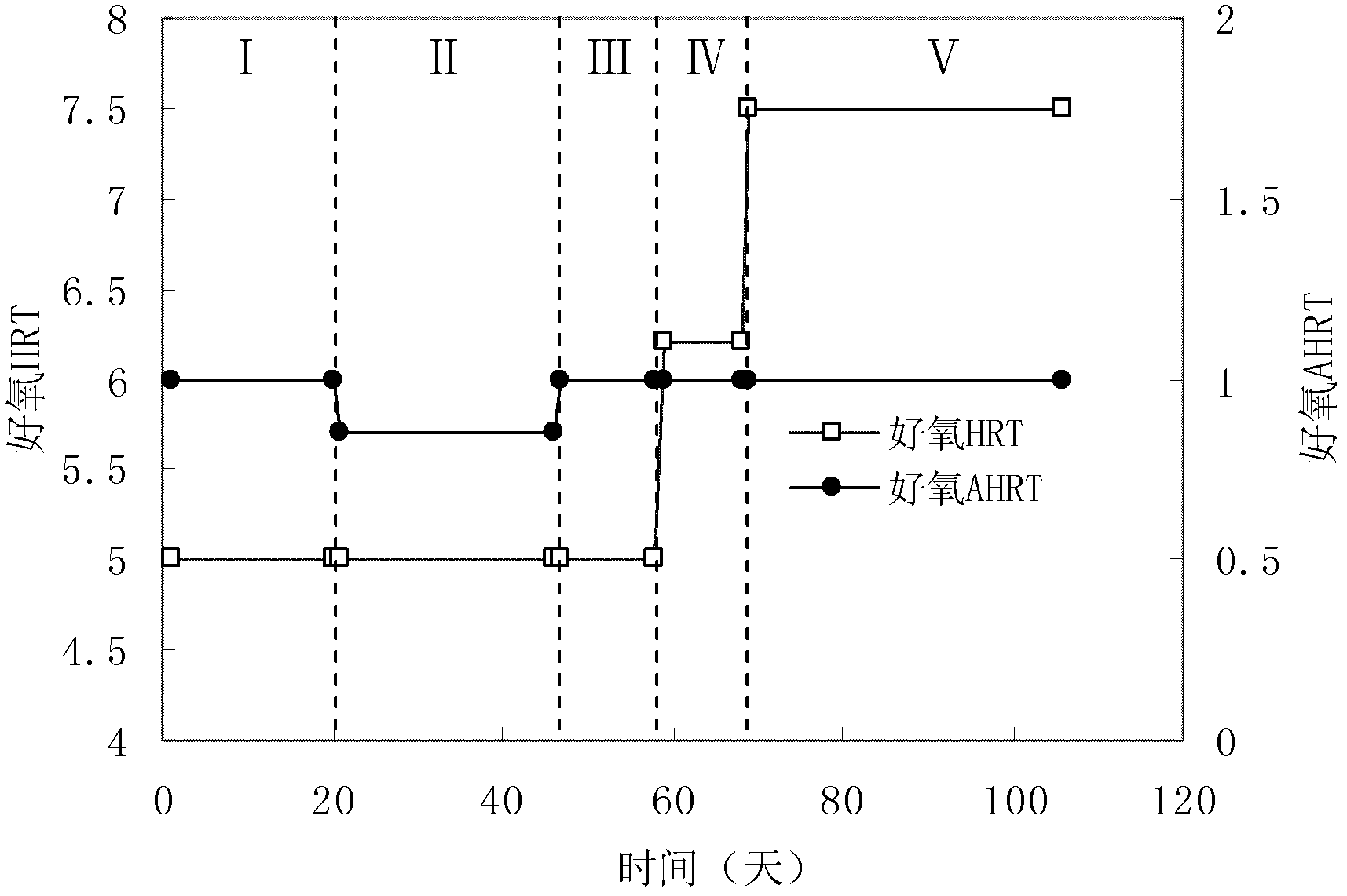

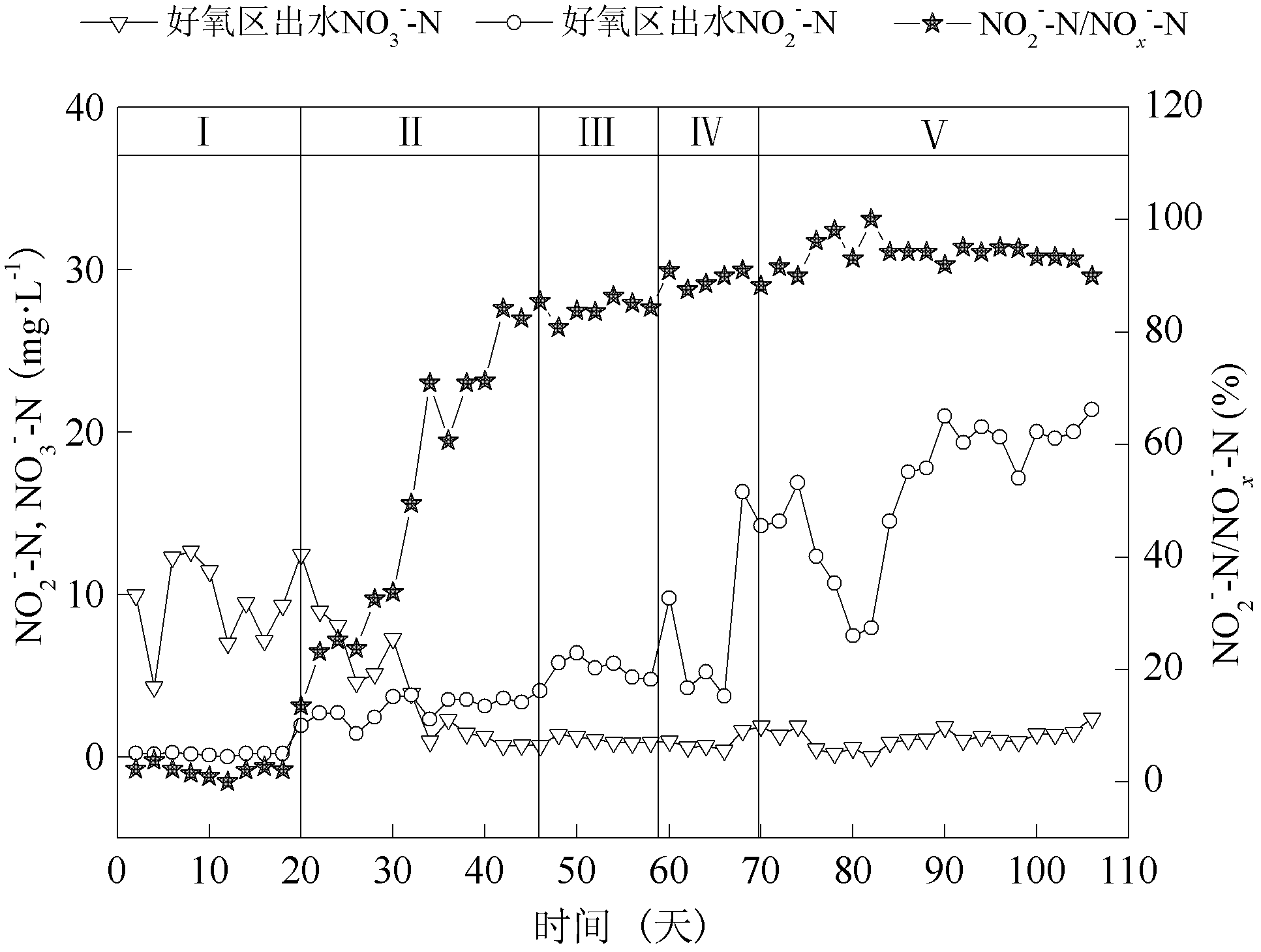

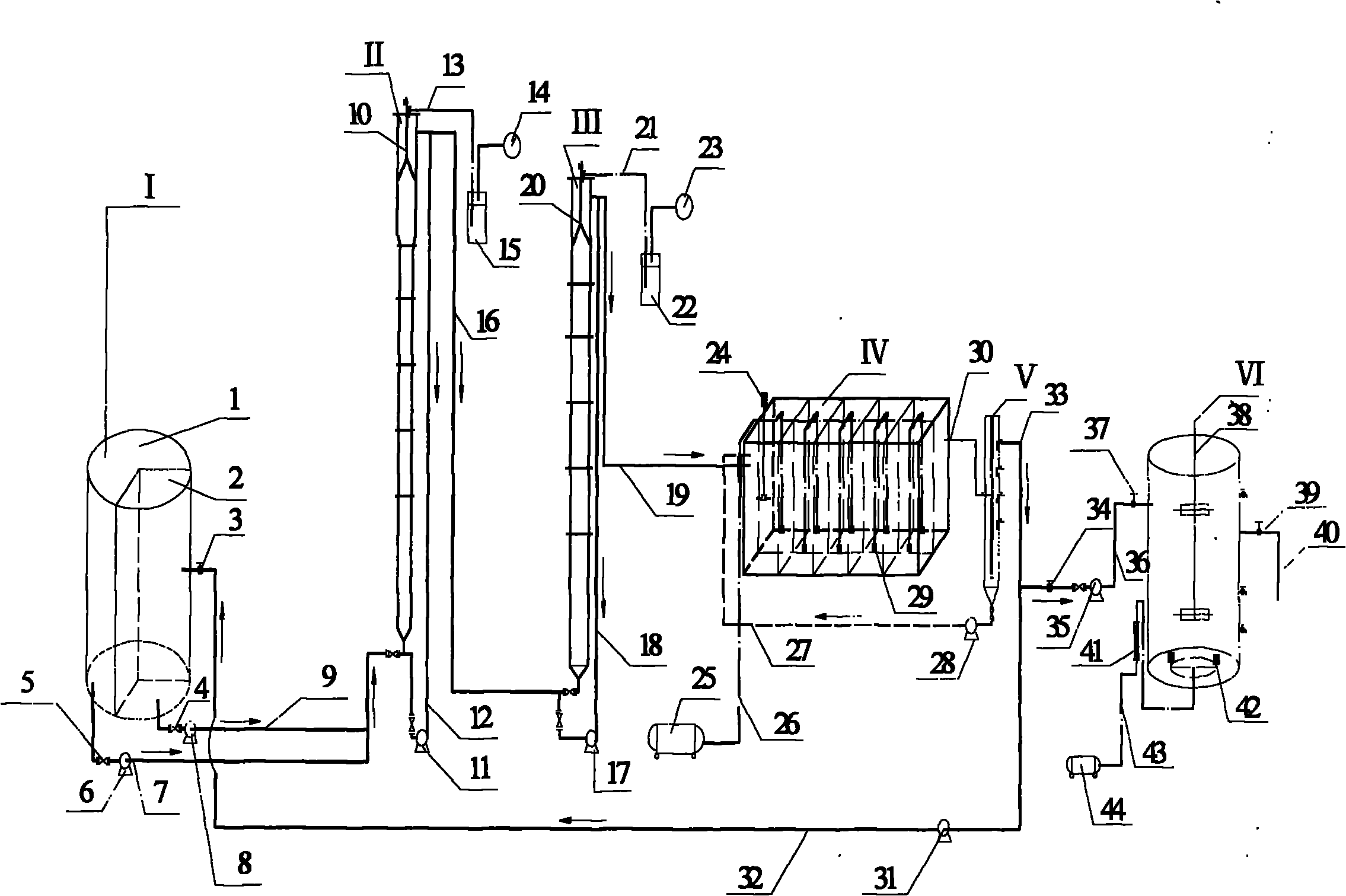

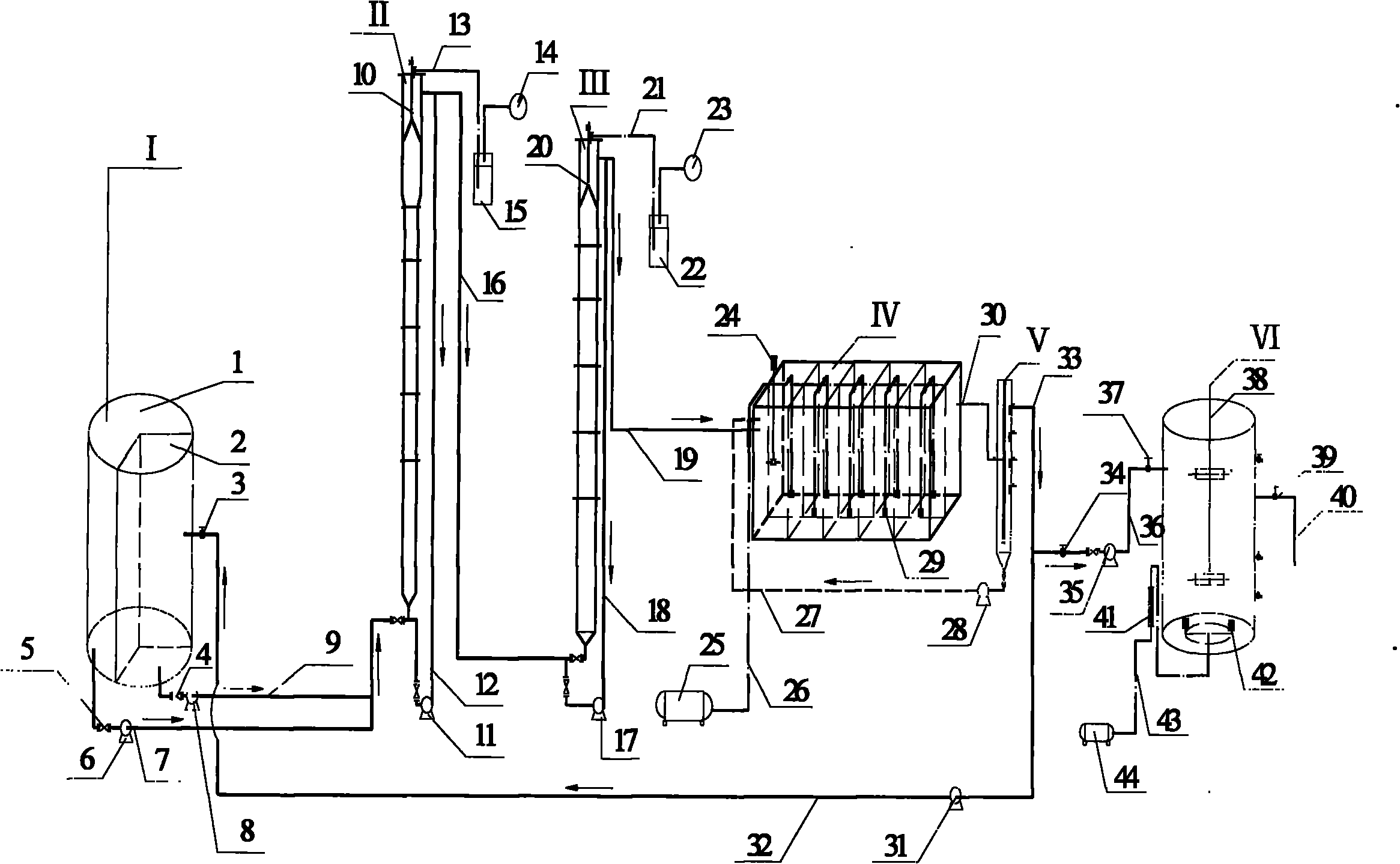

A-A2O continuous flow sewage denitriding and dephosphorizing system and short-range denitriding method

InactiveCN102432106AReduce processing costsReduce eutrophicationTreatment using aerobic processesTreatment with aerobic and anaerobic processesContinuous flowSewage

The invention discloses an A-A2O continuous flow sewage denitriding and dephosphorizing system and a short-range denitriding method, belonging to the field of biological treatment of sewage. Short-range denitrification refers to an economical and efficient biological sewage denitriding method. The conventional short-range denitrification is mostly realized in a batch-type denitriding treatment system while short-range denitrification is difficult to realize due to the running regulating and controlling complexity of a denitriding and dephosphorizing continuous flow treatment system which is applied practically mostly. In the A-A2O continuous flow sewage denitriding and dephosphorizing system for treating domestic sewage in the invention, short-range denitrification is realized by regulating and controlling the DO (Dissolved Oxygen) concentration, the nominal hydraulic dwell time and the practical hydraulic dwell time of the aerobic region. The nitrite accumulation rate is stably maintained at 90 percent, the ammonia nitrogen removing rate is over 95 percent, and the total phosphorus removing rate is over 90 percent. According to the invention, technical problems caused by the conventional application of short-range denitrification to the continuous flow biological sewage denitriding and dephosphorizing system are solved, the application range of short-range denitrification is expanded, and running regulation and control of short-range denitrification can be realized for the continuous flow biological sewage denitriding and dephosphorizing system.

Owner:BEIJING UNIV OF TECH

Method for treating rubbish percolates of different times for deep denitrification by using bipolar USAB+A/O+SBR process

InactiveCN101805096ATake advantage ofHigh denitrification efficiencyTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationTotal nitrogen

The invention discloses a method for treating rubbish percolates of different times for deep denitrification by using a bipolar USAB+A / O+SBR process, which belongs to the technical field of biological denitrification and is suitable for performing advanced treatment on the rubbish percolates. In the method, water output by an A / O reactor passes through a secondary sedimentation tank, then part of the water flows back into a first-stage UASB reactor to perform denitrification, so the method fully uses sufficient carbon sources of raw water, realizes an efficient denitrification efficiency, and fully uses the characteristic that the rubbish percolates contain high-concentration organic substances. Dissolved oxygen (DO), an oxidation-reduction potential (ORP) and a pH value sensor are used for monitoring the degradation and the short-range nitrification / denitrification processes of the organic substances in the reactor, and the short-range nitrification / denitrification processes can be well controlled according to monitored pH values and ORP values. The average ammonia nitrogen concentration of final yielding water is 2 mg / L, the total nitrogen concentration is lower than 40 mg / L, and the ammonia nitrogen removal rate and the total nitrogen removal rate are above 98 percent. The method completely depends on biological treatments, reduces the cost and simplifies the process. The method performs denitrification on the rubbish percolates, not only realizes complete nitrification but also realizes short-range nitrification, and realizes the deep removal of the nitrogen in the rubbish percolates.

Owner:LANZHOU SHUISEN ELECTRONICS TECH

Device and method for treating urban sewage through repeated-water-inlet SBR by fully utilizing carbon source in raw water

ActiveCN105036334AImprove denitrification effectLow costTreatment with aerobic and anaerobic processesSequencing batch reactorTotal nitrogen

The invention discloses a device and a method for treating urban sewage through a repeated-water-inlet SBR by fully utilizing a carbon source in raw water, and belongs to the field of biological sewage treatment through a biochemical method. The device comprises a raw water box, a sequencing batch reactor (SBR) and a computer. The method comprises the following steps: feeding urban sewage into the SBR, and then performing stirring and aeration; repeating the stirring and aeration for 2-3 times; after the final aeration is finished, continuously performing stirring, precipitating and water discharging. In the stirring processes, the pH values of denitrification ending points are monitored in a real-time time, and in the aeration processes, the DO and pH values of shortcut nitrification ending points are monitored in a real-time manner. The carbon source in the raw water is fully utilized for denitrification, one part of organic matters in the raw water is directly utilized, and the other part of organic matters is stored into sludge to be used as an internal carbon source to be utilized by the denitrification reaction in the final stirring process. The anoxic denitrification time and the aerobiotic aeration time can be accurately controlled, the utilization rate of the carbon source in the raw water and the total nitrogen removal rate are improved, and the energy consumption is reduced.

Owner:BEIJING UNIV OF TECH

Utilization method and system for tail gas of calcium carbide furnace

InactiveCN102620573AEliminate potential safety hazardsLess investmentWaste heat treatmentHigh concentrationCombustor

The invention provides a utilization system for the tail gas of a calcium carbide furnace. By the system, without purification treatment, the tail gas of the calcium carbide furnace is directly conveyed into a burner and then burnt, investment to the purification treatment of the tail gas of the calcium carbide furnace is eliminated, and hidden danger in the purification treatment of the tail gas of the calcium carbide furnace, which contains high-concentration carbon oxide (CO), is eliminated. The utilization system for the tail gas of the calcium carbide furnace comprises a heat exchanger, a pressurizing conveying fan and a lime rotary kiln, wherein the heat exchanger cools the tail gas of the calcium carbide furnace; the lime rotary kiln is provided with the burner; and a calcium carbide furnace tail gas discharge pipe, the heat exchanger, the pressurizing conveying fan and the burner are sequentially connected in series. The invention also provides a utilization method for the tail gas of the calcium carbide furnace. The method comprises the following steps of: reducing the temperature of the tail gas of the calcium carbide furnace to 200 to 400 DEG C; pressurizing the tail gas of the calcium carbide furnace to be over 3,000 Pa by using the pressurizing conveying fan; conveying the tail gas of the calcium carbide furnace into the burner of the lime rotary kiln; and burning the tail gas of the calcium carbide furnace.

Owner:NANJING SUYE CALCIUM IND TECH

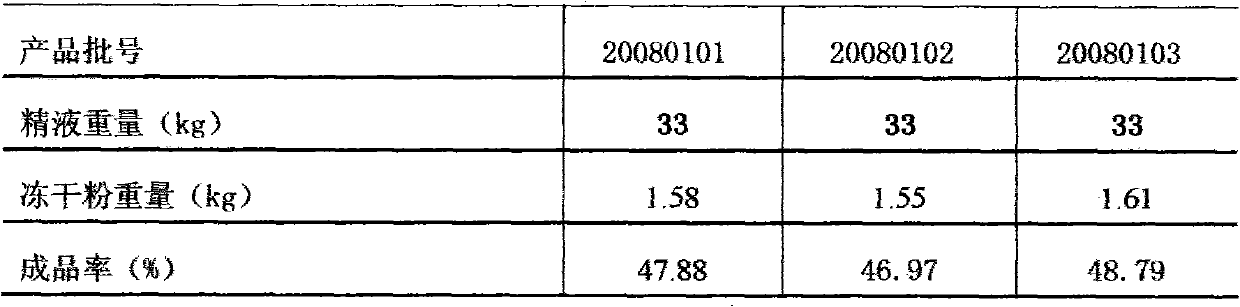

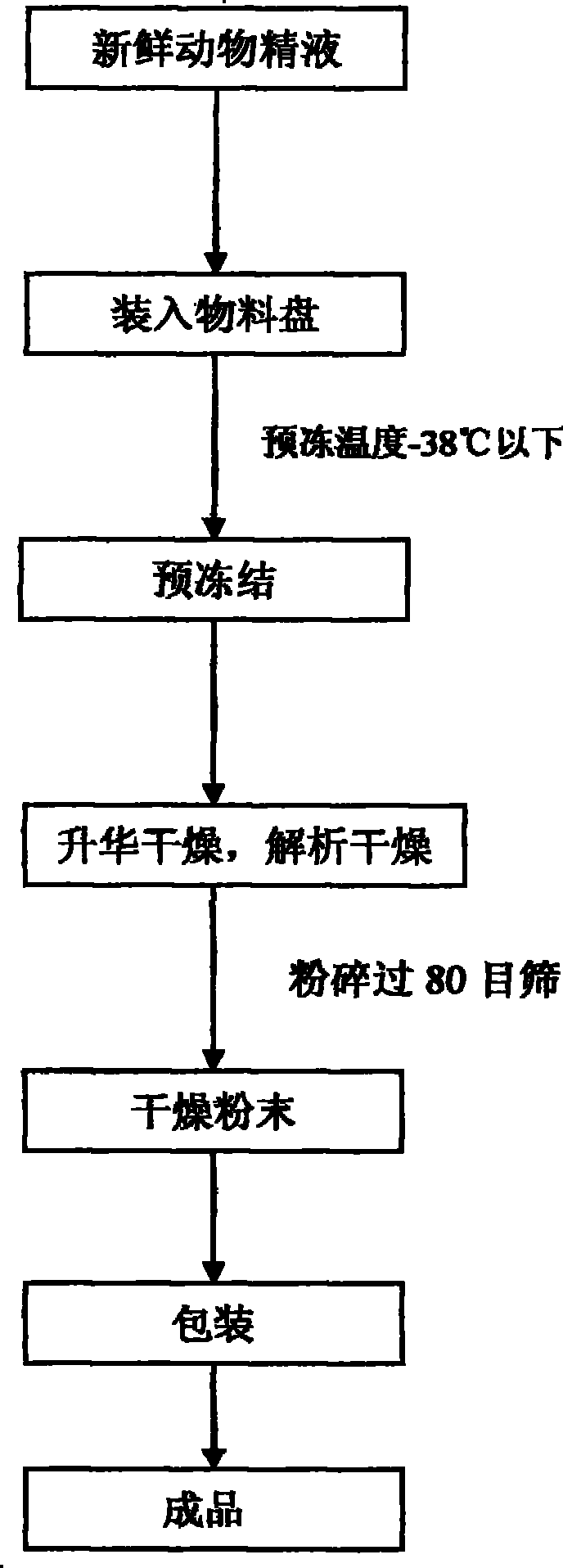

Method for preparing animal semen freeze-dried powder

ActiveCN101904869AHigh medicinal valueReduce lossesPowder deliveryMetabolism disorderMicroorganismFreeze-drying

The invention relates to a method for preparing animal semen freeze-dried powder, which is used for preparing by adopting freeze-dried fresh semen and comprises the steps of prefreezing, sublimation drying and analysis drying. The invention has the following advantages that: (1) protein, microorganisms and the like can not denature or lose biological activity; (2) the loss of certain volatile components in the matter is small; (3) the growth of microorganisms and the action of enzymes are prohibited, so that the original nature of the freeze-dried powder can be maintained; (4) the volume is almost unchanged, the original structure is maintained, and the phenomena of concentration and hardening do not occur; (5) the dried matter is loose, porous and spongy, the dissolution is quick and complete after water addition, and the original nature can be recovered immediately; (6) certain easily oxidized substances in vacuum are protected; and (7) more than 95-99% of water can be removed by drying, and the dried product can stored for a long time without deterioration.

Owner:程辉

Method for processing precast cold laid asphaltic concrete material

The invention discloses a method for processing a precast cold laid asphaltic concrete material, which comprises the following steps of: (1) heating and mixing asphalt, graded broken stone and a mineral powder mixed material in a batching and mixing plant to form an asphaltic concrete mixed material; (2) adopting a mould to mould the asphaltic concrete mixed material in a thermal state into sheets which are convenient to splice and have the thickness of 2-9cm, and reducing to normal temperature; and (3) packaging, loading, and transporting the sheets at normal temperature to construction field, arranging and splicing the sheets in the field, heating, and rolling to achieve good density. The processing method makes more work such as mixing the asphaltic concrete material and primarily rolling and forming performed in a factory, and can achieve specialized and industrial production.

Owner:CHINA COAL NO 3 CONSTR GRP

Frozen and dried maca

The invention relates to frozen and dried maca. The preparation of the maca comprises the following steps of: cleaning maca, airing moisture on the surface of the maca, feeding the maca into a vacuum freezing and drying machine, and cooling and freezing the maca to -35 to -40 DEG C; and drying the frozen maca in vacuum for 15-25 hours at a vacuum degree of 3-10 Pa, thus obtaining the frozen and dried maca, wherein the final drying temperature is controlled to be less than 35-40 DEG C. According to the invention, more than 95%-99% of moisture in the maca can be eliminated, other components in the maca are reserved in an original ecological manner, and particularly, many thermosensitive substances, such as protein, amino acid and volatile substances, are effectively reserved; because the maca is dried with in vacuum with little oxygen, some easily oxidized substances are also protected; and the original shape and properties of the maca is kept, the maca can be preserved for a long time, and thus the effects of maca health-care foods are ensured.

Owner:KUNMING CHUANREN SCI & TECH

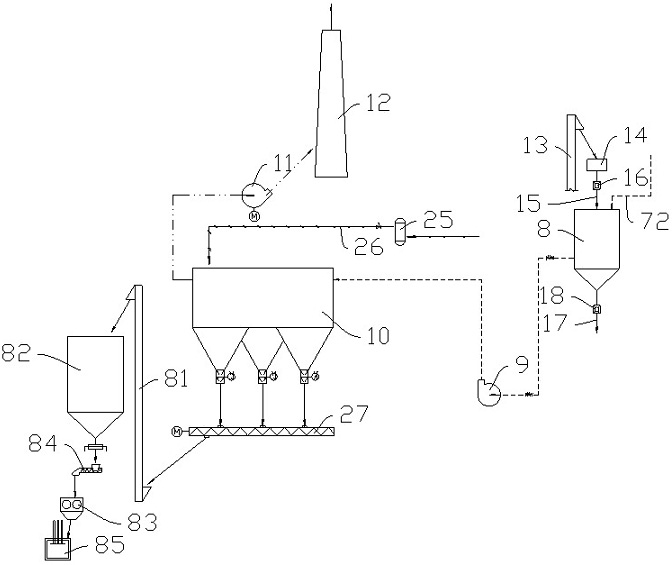

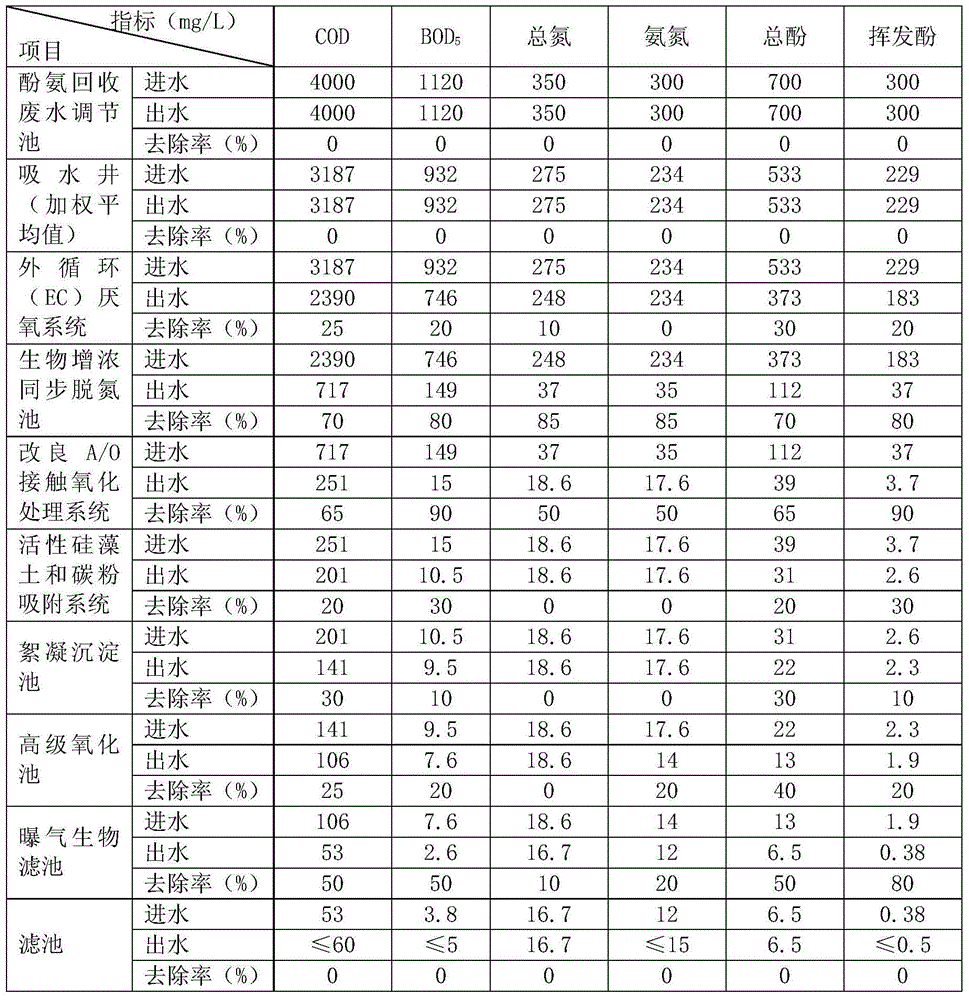

Treatment process for coal-chemical engineering waste water

InactiveCN104961302AEasy to solveReduce alkalinityMultistage water/sewage treatmentSludgeCompound (substance)

The invention discloses a treatment process for coal-chemical engineering waste water. The process comprises a pretreatment stage, a main biochemical treatment stage, an advanced treatment stage and a sludge treatment stage for dehydrating the sludge by using a centrifugal dehydrator in sequence, and specifically comprises the following steps of firstly, pretreatment: firstly, enabling phenol ammonia recovery waste water in the coal-chemical engineering waste water to pass through a phenol ammonia recovery waste water regulating tank, introducing other waste water into a comprehensive waste water regulating tank, and enabling the regulated effluent to respectively enter into corresponding sedimentation basins; secondly, main biochemical treatment: enabling the effluent in the first step to sequentially enter into an external circulation anaerobic system, a biological doubling system, an improved A / O system and a secondary sedimentation tank for corresponding biochemical treatment; thirdly, advanced treatment: enabling the effluent in the second step to sequentially enter into a mixed reaction pond, a flocculating settling pool, an advanced oxidation system, an biological aerated filter and a filtering tank for corresponding treatment, finally discharging the effluent to a clean water basin, and performing dehydration treatment on the sludge generated by the above steps. The treatment process disclosed by the invention has the advantages of more thorough biodegradation and excellent purifying effect of the waste water.

Owner:东华(西藏)低碳科技有限责任公司

Low-temperature cold-squeezing method of green camellia oil without damaging nutrient substances

InactiveCN103555417AMaintain nutrientsMaintain trace elementsFatty-oils/fats productionEdible oils/fatsOrganic solventHazardous substance

The invention discloses a low-temperature cold-squeezing method of green camellia oil without damaging nutrient substances. The low-temperature cold-squeezing method comprises the following steps: after husking, screening and cleaning camellia seeds, storing at low temperature and crushing at low temperature, performing vacuum freezing, drying and dehydrating on crushed camellia seed powder, performing low-temperature cold-squeezing and low-temperature crystal growing by using a low-temperature cold pressing machine, and filtering to obtain finished product camellia oil. According to the low-temperature cold-squeezing method, a low-temperature cold-squeezing technology is adopted in the whole process, low temperature is continuously kept in a process of squeezing the camellia oil, so that the production of harmful substances can be avoided as far as possible in the squeezing process, the quality of the camellia oil after squeezing is high, natural taste and smell of the camellia oil can be kept, so that the physical extract camellia oil technology plays to extreme without using an organic solvent to purify and without the problem of solvent residual, and is suitable for preparing high-grade ecological green camellia oil.

Owner:老知青集团有限公司

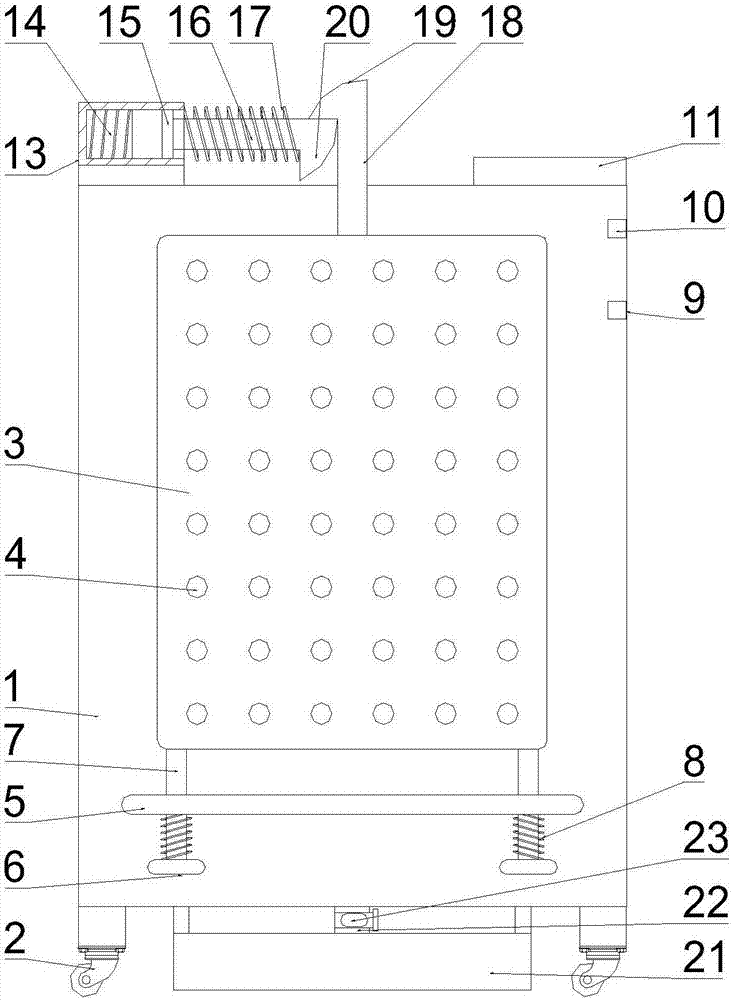

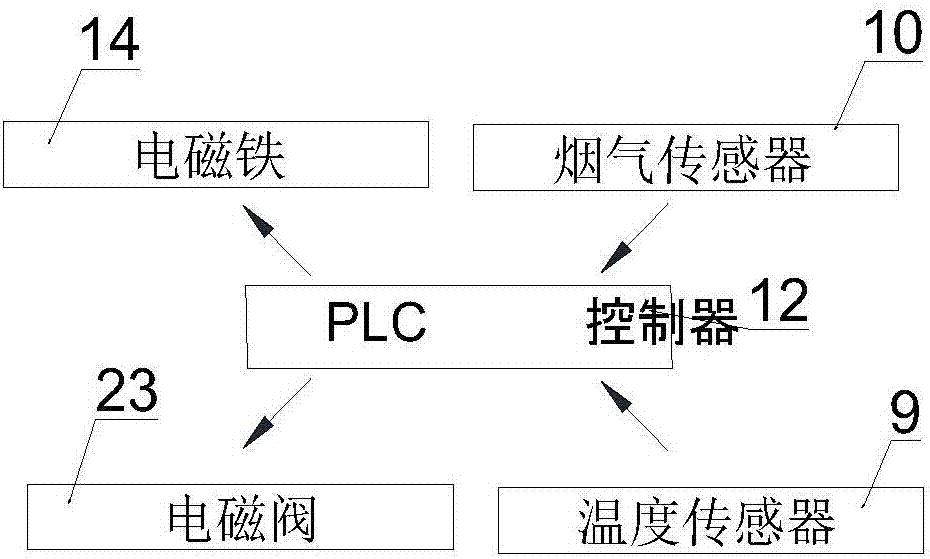

Power cabinet with fire extinguishing function

InactiveCN107275937ASave oxygenImprove ventilationSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsSolenoid valveCoil spring

The invention discloses a power cabinet with a fire extinguishing function, comprising a cabinet body, an electromagnet, a sleeve, a first movable rod, a second movable rod, a first wedging block, a second wedging block, a fixed plate, and a guide column and movable plate; when a fire occurs inside the cabinet, the electromagnet is energized through the action of the temperature sensor and the smoke sensor, and the second wedge-shaped block and the first wedge-shaped block are separated from each other through the attraction of the electromagnet to the iron block. At this time, due to the effect of the first coil spring, the movable plate moves down and resets. At this time, the first cooling hole and the second cooling hole no longer overlap, so that the outside air enters the cabinet, and at the same time the solenoid valve is opened, then The nitrogen in the nitrogen tank enters the cabinet, thereby reducing the oxygen in the cabinet rapidly, which has the effect of quickly extinguishing the fire. When the cabinet returns to normal, pull the movable plate upwards, and the first heat dissipation hole and the second heat dissipation hole overlap at this time , It is convenient for the usual ventilation inside the cabinet, and the operation is simple and fast.

Owner:深圳泽土网络信息有限公司

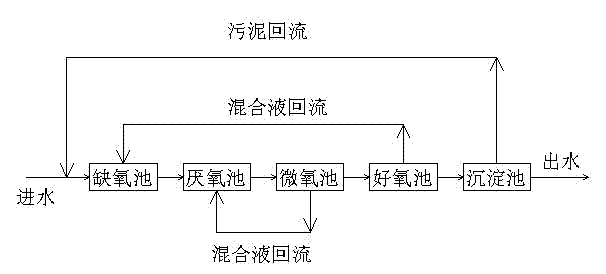

Method for removing ammonia nitrogen from industrial waste water produced in synthetic ammonia industry

InactiveCN102515352AReduce consumptionReduce removal rateTreatment with aerobic and anaerobic processesRetention timePollution

The invention discloses a method for removing ammonia nitrogen from industrial waste water produced in a synthetic ammonia industry. The method provided by the invention comprises the following steps that industrial waste water produced in a synthetic ammonia industry orderly enters into an anoxic pond, an anaerobic pond, a micro-oxygen pond, an aerobic pond and a sedimentation pond; a part of the industrial waste water in the micro-oxygen pond flows back to the anaerobic pond; a part of the industrial waste water in the aerobic pond flows back to the anoxic pond; and a part of the industrial waste water in the sedimentation pond flows back to a water inlet end of the anoxic pond. The method provided by the invention realizes anoxic denitrification, anaerobic ammoxidation and short-cut nitrification and denitrification in the same biological treatment system. The method provided by the invention realizes the short-cut nitrification and denitrification and thus saving an oxygen supply amount by 25% and an organic carbon source utilization amount by 40% and reducing reaction retention time and the capacity. The method provided by the invention realizes the anaerobic ammoxidation and thus reducing energy consumption and preventing secondary pollution. The method provided by the invention has a high ammonia nitrogen removal rate of above 99%. The method provided by the invention has a low alkali consumption amount in the whole flow and has a low operating cost.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Converter less-slag smelting method

ActiveCN112646944ALow oxygenCutting costsManufacturing convertersProcess efficiency improvementSmelting processHeat balance

The invention relates to a converter less-slag smelting method. The converter less-slag smelting method uniformly adopts a less-slag single-slag mode under the conditions of high iron consumption or low iron consumption and complex molten iron silicon change. The converter less-slag smelting method comprises the following process flows of: finishing tapping, remaining slags, adjusting the slags, splashing the slags, adding scrap steel, mixing molten iron, conducting calculation, conducting blowing, controlling an end point and tapping. In the smelting process, the lance position and the oxygen supply intensity are controlled by referring to the CO value; the end oxidizability is effectively controlled through heat balance accurate calculation; the molten steel oxidizability is reduced through process low lance position control; the alloying cost is effectively reduced; and meanwhile, the final slag oxidizability is reduced; the slag splashing furnace protection effect is promoted; and the furnace condition maintenance cost is effectively reduced.

Owner:扬州圣莱特冶金科技有限公司

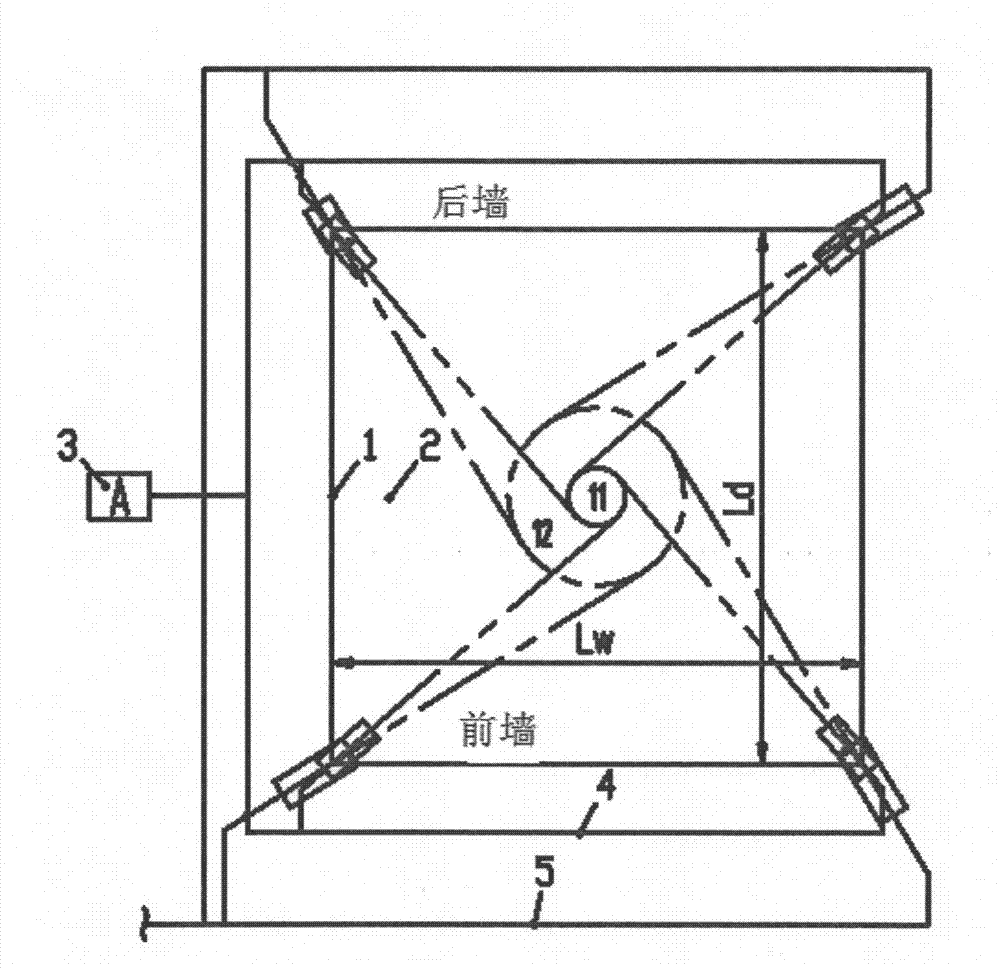

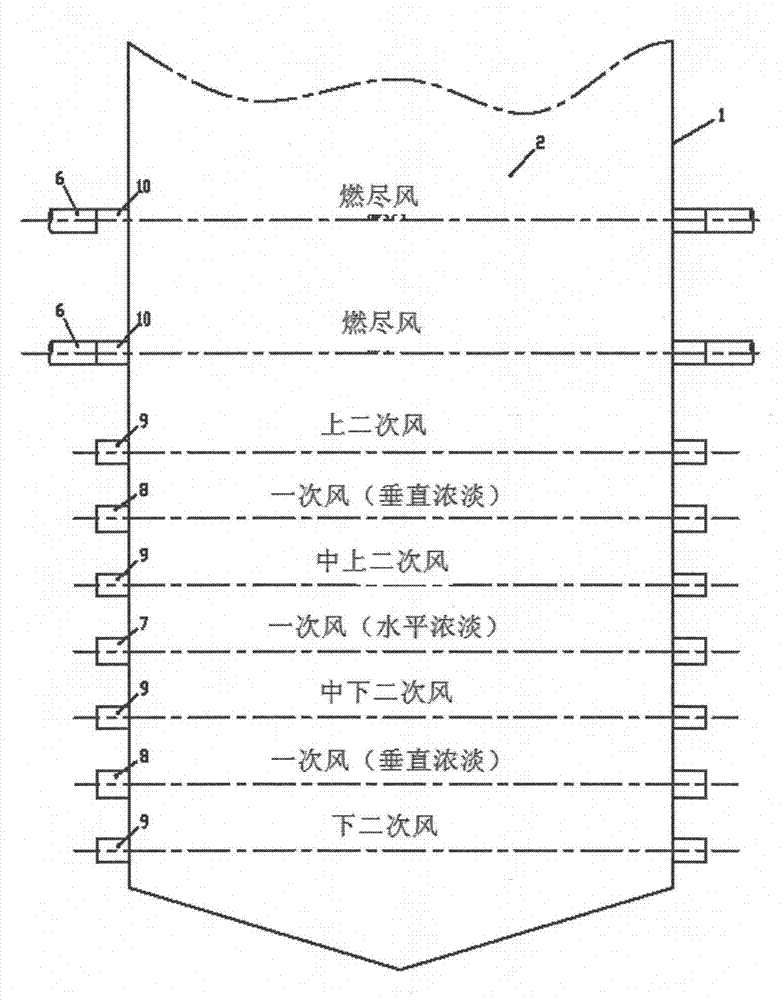

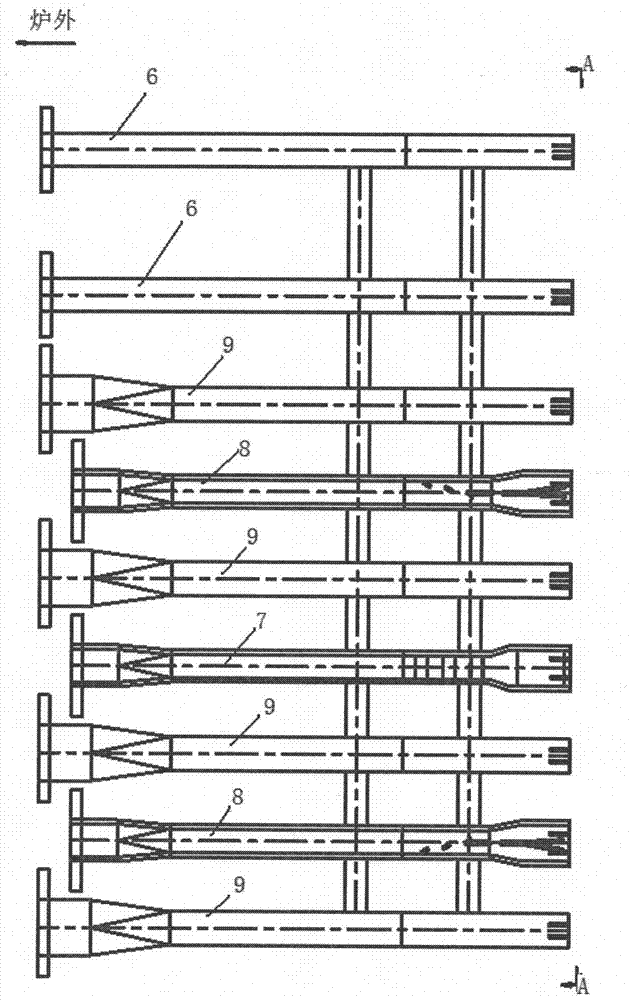

Bitangent circular thick and thin separation adjustable direct-current coal powder combustor

ActiveCN104329669AStrong fire stabilityGood anti-cokingPulverulent fuel combustion burnersCombustorWave shape

The invention relates to a bitangent circular thick and thin separation adjustable direct-current coal powder combustor. Horizontal thick and thin combustion and vertical thick and thin combustion can be realized simultaneously in one set of combustor so that the generation amount of NOX is reduced by 10%-20% when being compared with that of a single combustion manner; the thick and thin separation is realized by using a blind window; after thick and thin coal powder is stabilized by a separation plate, the thick and thin coal powder is separated by a wave-shaped blunt body so that the combustion is stabilized by enhancing the disturbance and the heat expansion at a room temperature is reduced; a bitangent circular combustion manner is adopted to form a powder-in-wind effect in a furnace and the mixing of primary wind and secondary wind is delayed; the oxygen supply amount at the primary period of combustion is reduced and the generation of NOX is inhibited; meanwhile, slag bonding of a furnace wall and high-temperature corrosion are prevented. The arrangement manner of the bitangent circular thick and thin separation adjustable direct-current coal powder combustor has the advantages of strong ignition stability, good anti-caking property, high combustion efficiency, low NOX generation, wide coal types and load adaptability and the like.

Owner:SHANGHAI POWER EQUIP RES INST +1

Water-based combustion-supporting coal gas frying-pan kiln and Mg catalysis low-CO2RO2 emission technology

ActiveCN103047645AKeep aliveSave oxygenCombustion using catalytic materialCombustion apparatusMagnesiumFlue gas

The invention provides a water-based combustion-supporting coal gas frying-pan kiln and Mg catalysis low-CO2RO2 emission technology. Air is not required to be blown in but water vapor completely replaces combustion-supporting coal, oil and gas, magnesium oxide mineral powder and the like are decomposed in a gasification hearth to obtain magnesium vapor, Mg, MgO, H, C, O and other vapor mixed flows detained in the eddy-current cavity at the top in the eddy current vacuum hearth achieve fully catalytic reaction to realize steady operation of a series of reaction dynamic equilibrium in the vacuum hot-carbon ultra-high temperature dry heat furnace environment of magnesium group vapor catalysis matched with mixed vaporization combustion, so that six-in-one ultra-high-efficiency energy conservation and environmental protection are achieved, the generated heat is exchanged in a three-pass hearth by a 'drum-header-tube bank' pressure-bearing assembly outside the dry heat furnace, and all superheat walls of the inner lining of the dry heat furnace are cooled in the way that an auxiliary engine drives recycling of flue gas.

Owner:管理

Production technology of freeze-dried fruit slices

InactiveCN106262108AReduce lossesConstant volumeFood freezingFood dryingAdditive ingredientFreeze-drying

The invention discloses a production technology of freeze-dried fruit slices. The production technology comprises the steps of raw material selecting; slicing; plate arranging on trays; low-temperature freezing at minus 40 DEG C for 6 h; sublimation drying, wherein sublimation drying is achieved through four stages of heating, heating is conducted for 120 min at 5 DEG C in the first stage, heating is conducted for 120 min at 10 DEG C in the second stage, heating is conducted for 240 min at 20 DEG C in the third stage, and heating is conducted for 120 min at 25 DEG C in the fourth stage; packaging to obtain the finished products. The freeze-dried fruit slices obtained through the production technology keep the original color, fragrance, taste and nutrient ingredients and the original appearance of the materials and have the good water reabsorbing property.

Owner:GUANGXI HUITOU INTERNET FINANCE SERVICE CO LTD

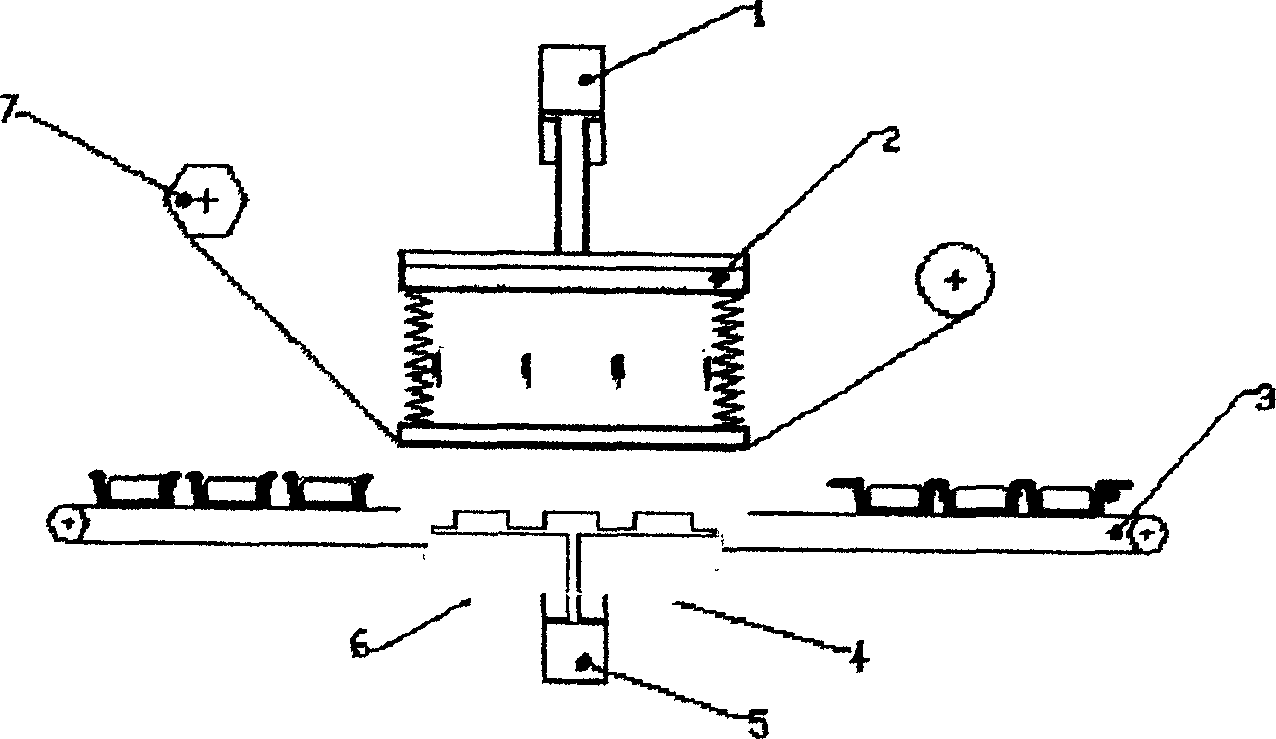

Packaging and fresh-keeping method for foodstuff

InactiveCN1631735ASave on packaging materialsLow costPackaging bakeryEnvironmental resistanceShielding gas

the invention disclose a food preserve and pack method including the following steps: 1) deliver the conjoined package box with the food inside to the packing, sealing and cutting area; 2) the sealing and cutting device (2) presses on the film coating so that the film and the support device will surround the foods and forms a seal cavity; (3) the air pumper evacuates; then pumper aerates into the cavity with protective gases. 4) the sealing and cutting device (2) pressure heat seals the cavity after the aerating; 5)the fluctuating pressure device(1) cuts the package box from the film coating; 6) the deliver mechanism delivers out the sealed package box. Above process including deliver in, locate, film coating press, evacuate, aerate, heat seal, cutand deliver out all finish continuously on a single machine. Each process is controlled by control logic made up of relays or PLC. The invention not only saves the package material, lowers the cost, enhance the efficiency but greatly varies the package patterns, and the preservation is effective and environmental,

Owner:苏明智

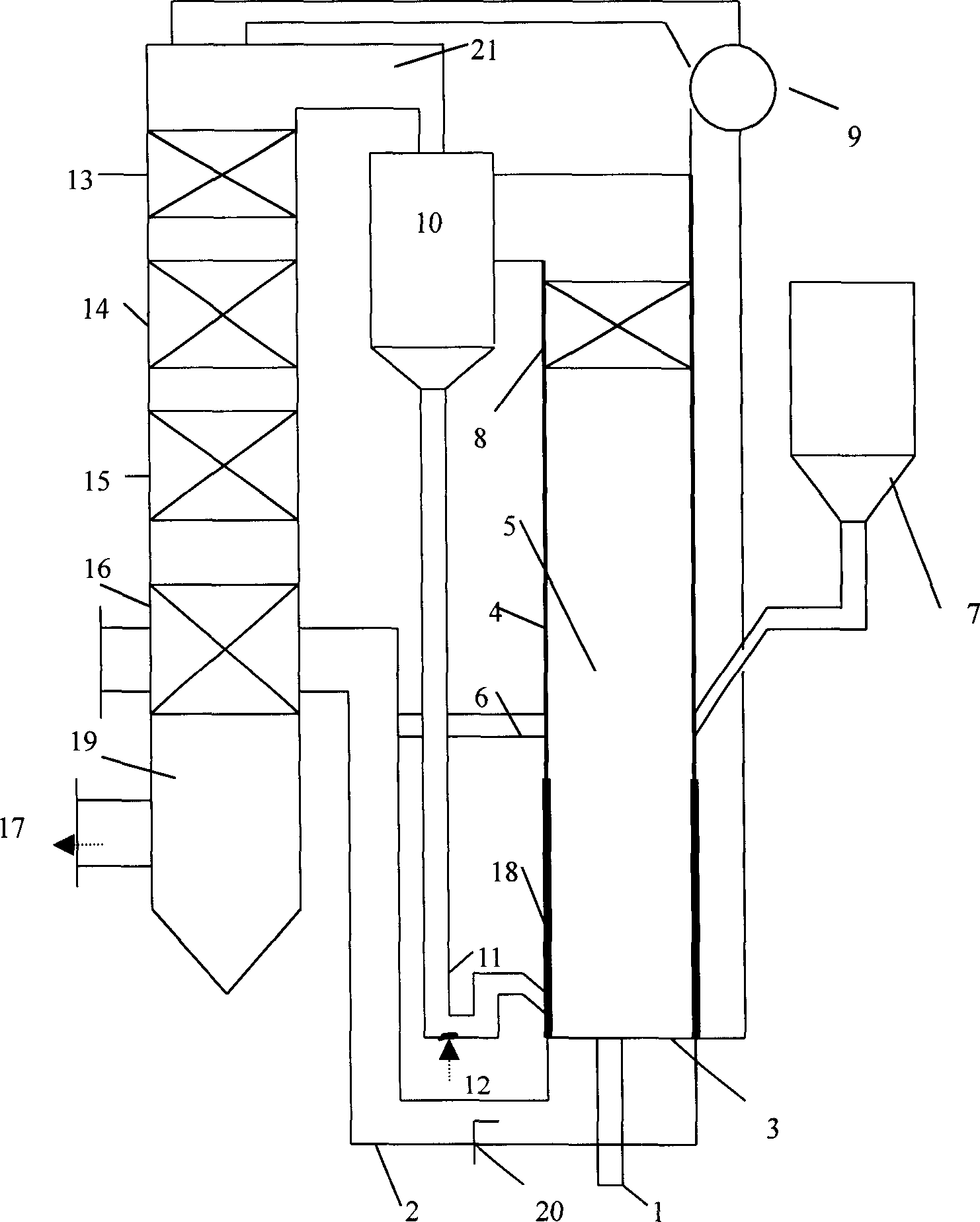

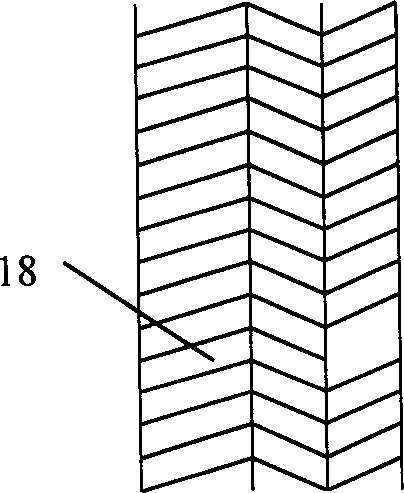

Method and device for burning petroleum coke by use of circulating fluid bed

InactiveCN1415890AControl and reduce emissionsInhibition formationSolid fuel combustionCombustion apparatus

This invention relates to a method and device for using oil coke as fuel in circulation fluidized bed solving the difficulties of burned-out in burning, desulfurization and lumping, slag-bonding appearing in end flue pipe and cyclone separator in the circulation fluidized bed. This invented oil coke combined fuel includes oil coke, coal and desulfurizer which can effectively removed SO2 and eliminate lumping and slag-bonding phenomenon and big mesh sieving is applied for oil coke particles to form thicken or thin phase beds in firing chamber, suitable for subjects balance in bed; warm scuff-resistant coating is designed under the circulation fluidized bed to form high temperature zone good for firing of oil coke and burning-out, stepped burning is good for reducing NOx exhaust.

Owner:TSINGHUA UNIV +1

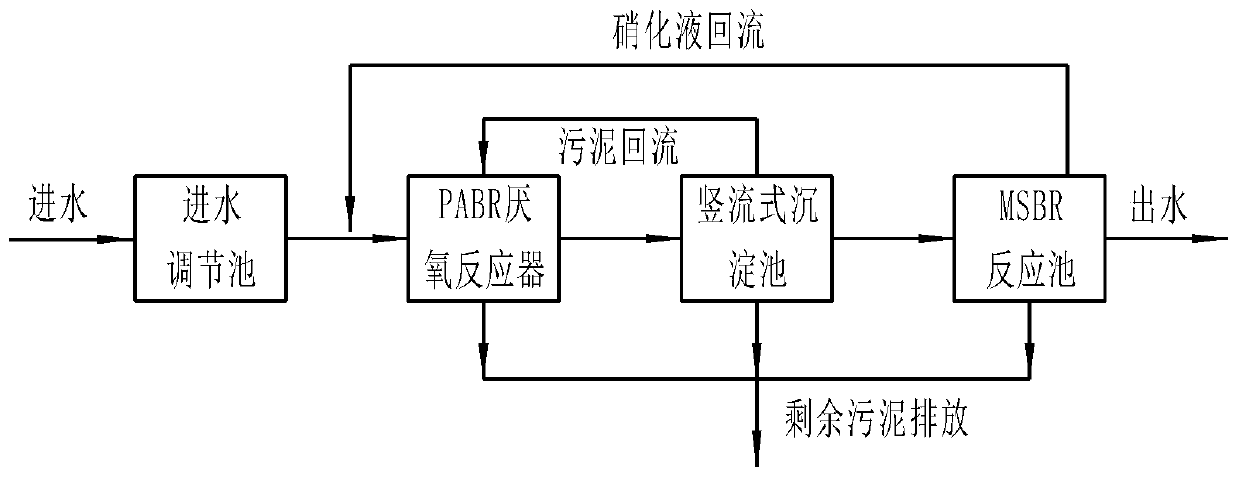

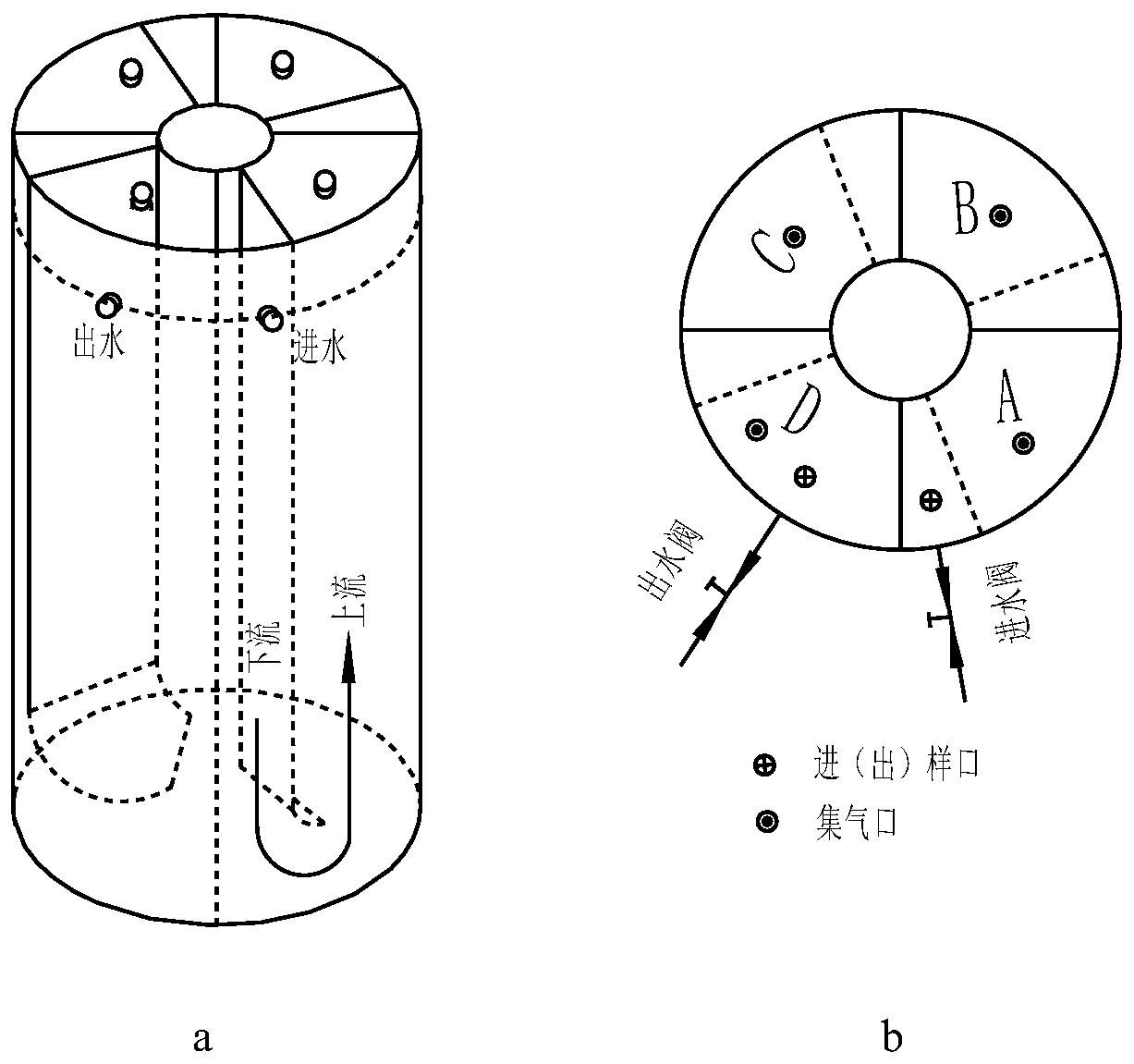

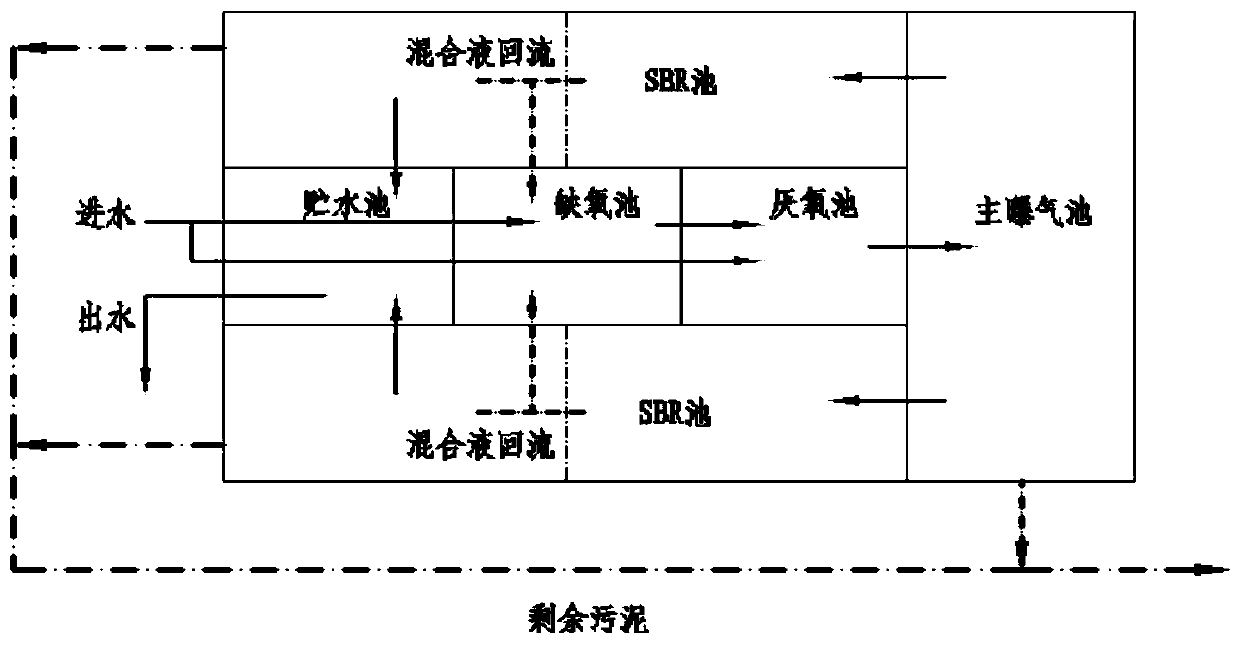

High-concentration livestock and poultry breeding wastewater treatment method

ActiveCN110015812AAlkalinity preventionReasonable distributionWater treatment parameter controlWater contaminantsHigh concentrationMethane production

The invention discloses a high-concentration livestock and poultry breeding wastewater treatment method. The denitrification methane production treatment is carried out by using a PABR reactor to mainly remove organic matters in the livestock and poultry wastewater and the nitrate nitrogen in a backflow liquid, and then the short-range nitrification denitrification treatment is carried out by using a MSBR reaction tank. According to the treatment method, the PABR denitrification methane production coupled with the MSBR short-range nitrification denitrification is utilized to treat the high-concentration livestock and poultry breeding wastewater, so that different microbial populations can better play respective functions in the PABR and MSBR reactors, and the efficient removal of the organic matters, ammonia nitrogen and nitrate nitrogen in the livestock and poultry breeding wastewater can be realized.

Owner:泰州学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com