Method for removing ammonia nitrogen from industrial waste water produced in synthetic ammonia industry

A technology for industrial wastewater and synthetic ammonia, applied in the field of ammonia nitrogen removal from synthetic ammonia industrial wastewater, can solve the problems of large amount of supplemented organic carbon source, increased kinetic energy consumption, high operating cost, shortened reaction residence time, reduced floor space, The effect of preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

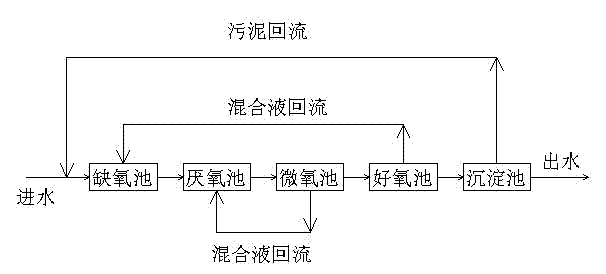

[0011] Treated water volume 417m 3 / h, the COD content in synthetic ammonia industrial wastewater is about 600mg / L, and the ammonia nitrogen content is about 350mg / L. Synthetic ammonia industrial wastewater enters the anoxic tank first, and contains nitrate nitrogen (NO 3 - -N) mixed with reflux water for denitrification reaction, denitrifying denitrification bacteria use organic matter in wastewater as electron donors, and nitrate nitrogen (NO 3 - -N) As an electron acceptor, the denitrification reaction is carried out under the condition of PH=7.5-9.2 and dissolved oxygen (DO) is less than 0.5mg / L, so that NO 3 - -N is reduced to nitrogen (N 2 ) removal, the hydraulic retention time of the anoxic pool is 12 hours; the wastewater after denitrification enters the anaerobic pool, and contains nitrite nitrogen (NO 2 - -N) mixed with reflux water for anaerobic ammonium oxidation reaction to convert ammonia nitrogen (NH 4 + -N) as an electron donor, with nitrite nitrogen ...

Embodiment 2

[0013] Treated water volume 210m 3 / h, the COD content in synthetic ammonia industrial wastewater is about 450mg / L, and the ammonia nitrogen content is about 250mg / L. Synthetic ammonia industrial wastewater enters the anoxic tank first, and contains nitrate nitrogen (NO 3 - -N) mixed with reflux water for denitrification reaction, denitrifying denitrification bacteria use organic matter in wastewater as electron donors, and nitrate nitrogen (NO 3 - -N) As an electron acceptor, the denitrification reaction is carried out under the condition of PH=7.5-9.2 and dissolved oxygen (DO) is less than 0.5mg / L, so that NO 3 - -N is reduced to nitrogen (N 2 ) removal, the hydraulic retention time of the anoxic pool is 7 hours; the wastewater after denitrification enters the anaerobic pool, and contains nitrite nitrogen (NO 2 - -N) mixed with reflux water for anaerobic ammonium oxidation reaction to convert ammonia nitrogen (NH 4 + -N) as an electron donor, with nitrite nitrogen (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com