Die-casting device and vacuum process

A technology of mold casting and decompression tank, which is applied in the field of decompression casting, can solve the problems of quality reduction of molded products, and achieve the effect of prolonging life and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

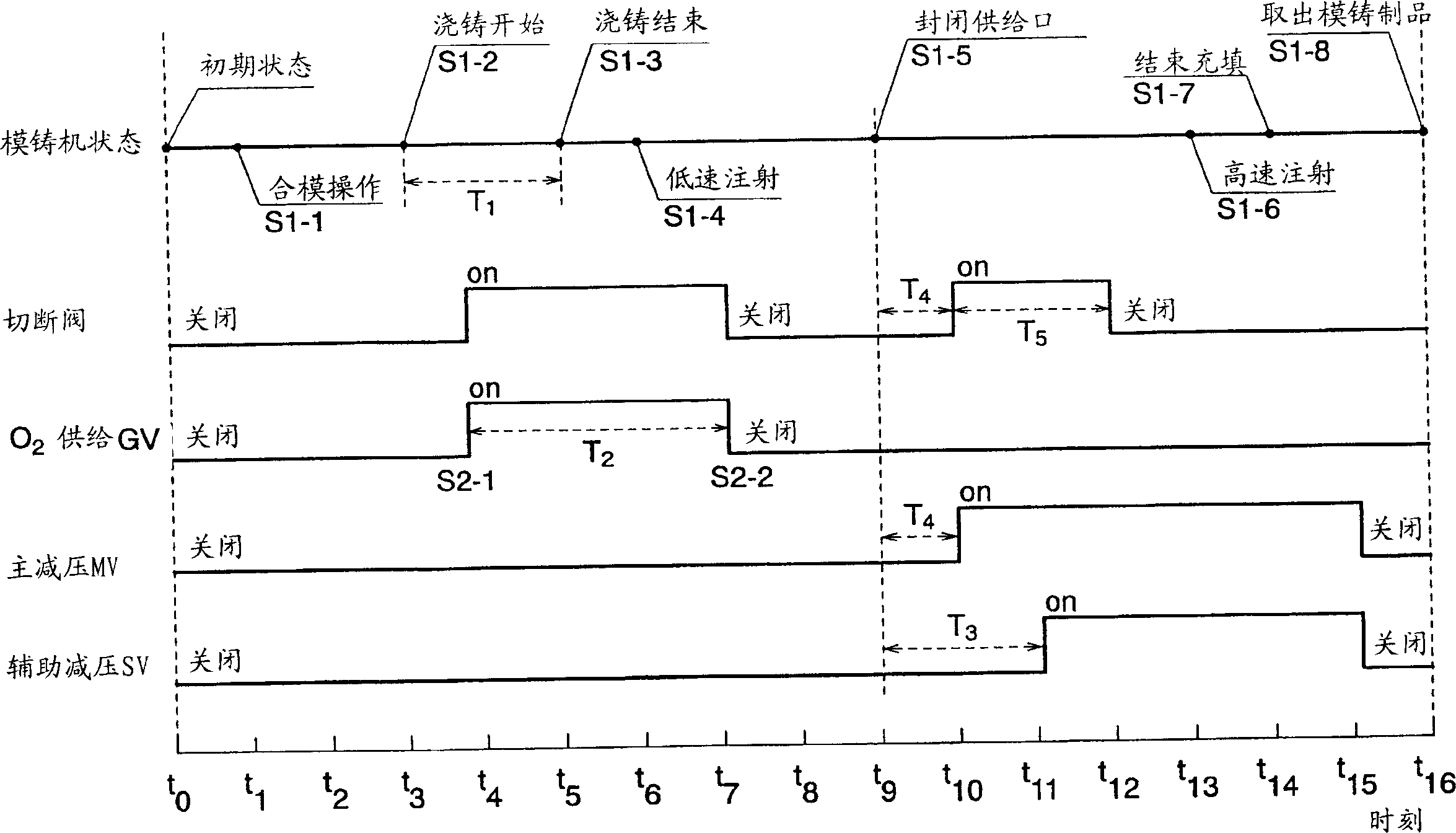

[0044] Structure of the molding device

[0045] The configuration of a die casting apparatus according to one embodiment of the present invention will be described.

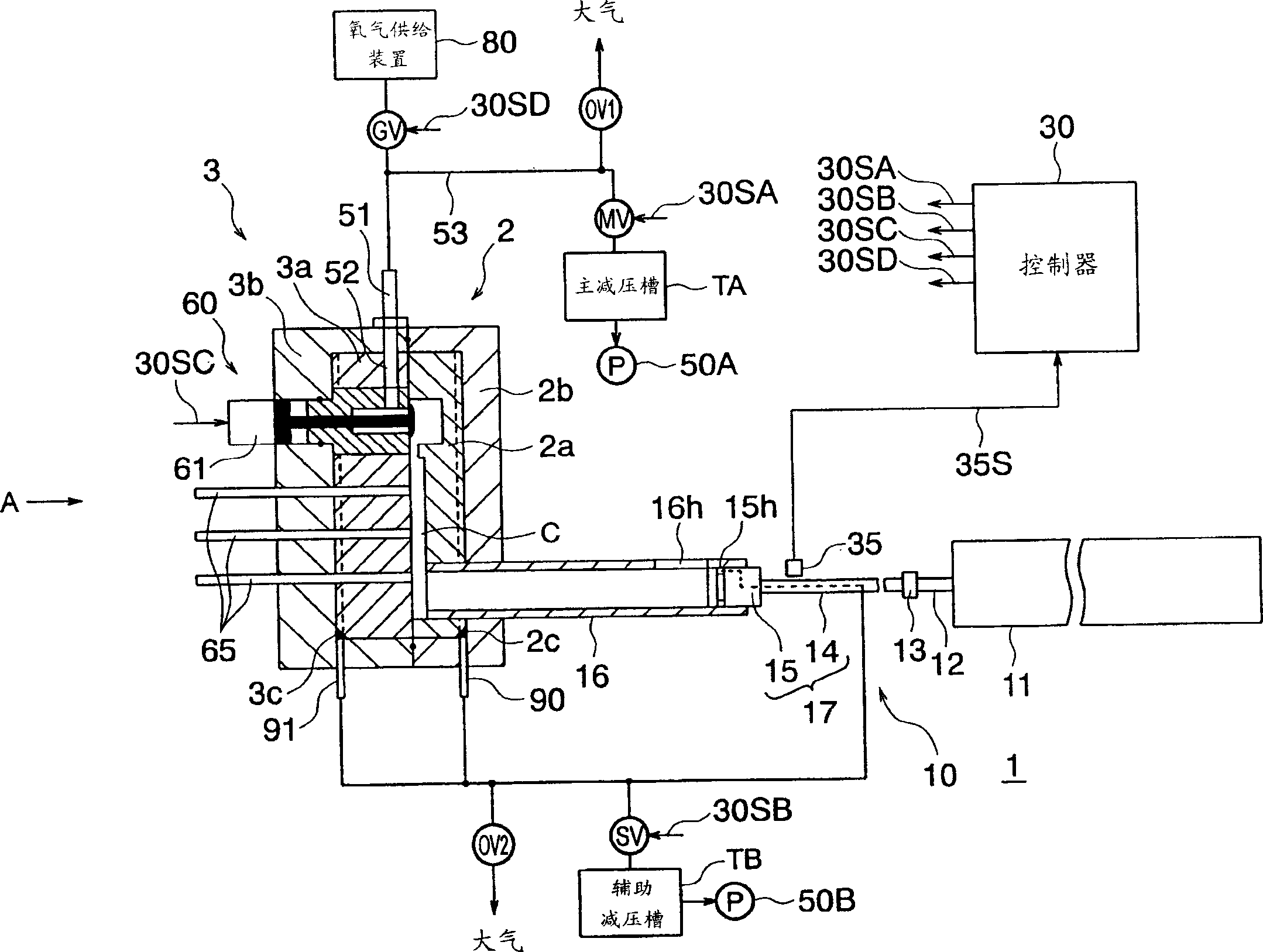

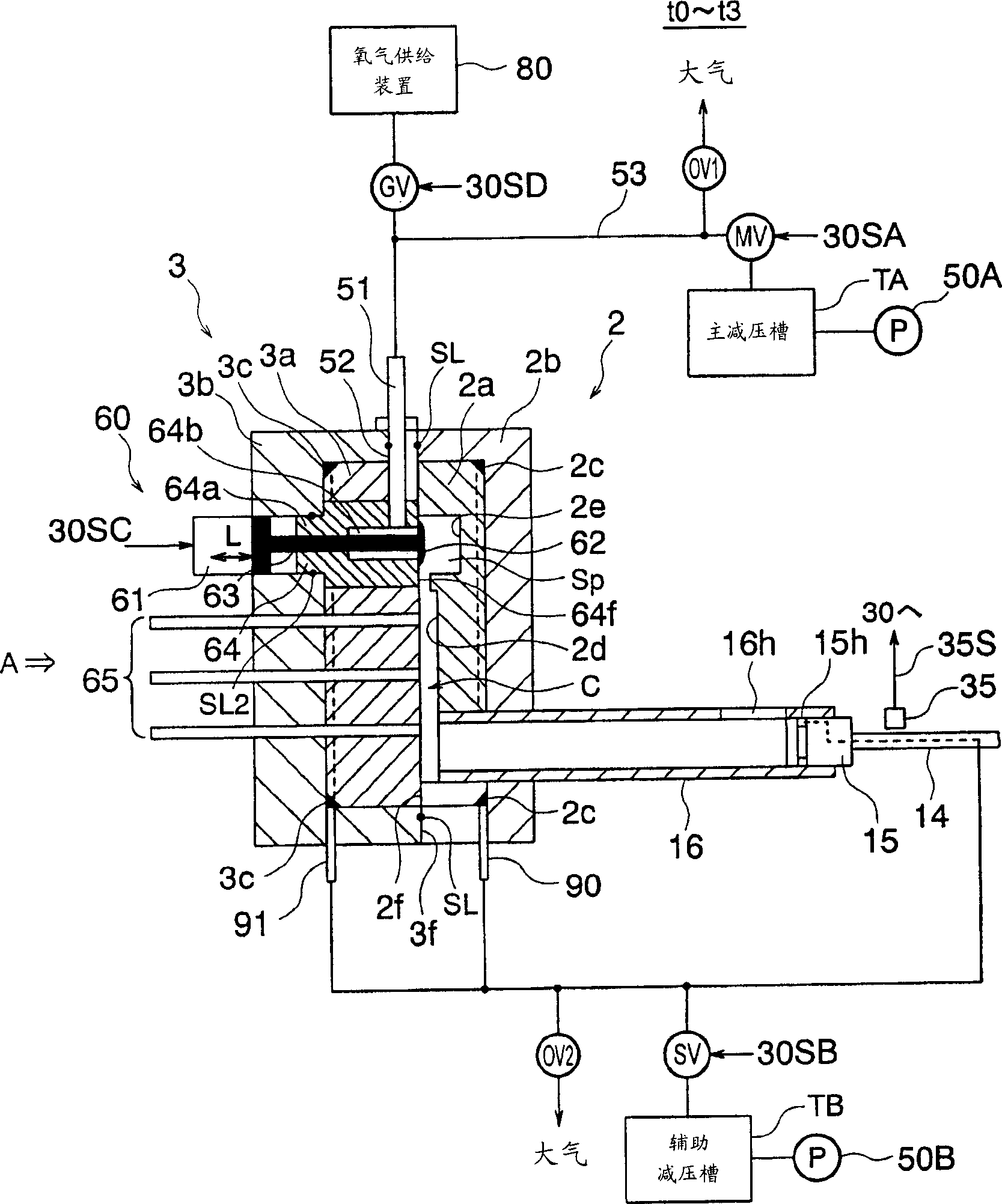

[0046] figure 1 It is a sectional view showing the structure around the die of the die casting apparatus according to one embodiment of the present invention.

[0047] The mold casting device 1 of the present embodiment includes: a fixed mold 2, a movable mold 3 that moves relative to the fixed mold 2, an injection device 10, a controller 30, a main decompression tank TA, an auxiliary decompression tank TB, a shut-off valve (check valve) valve) 60 and oxygen supply device 80.

[0048] The controller 30 is a part that performs various controls of the die casting apparatus 1 described in detail below, and is realized by using an arithmetic processing device such as a computer.

[0049] The injection device 10 includes a hydraulic cylinder 11 , a piston rod 12 , a connector 13 , an injection plunger 17 and an inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com