A-A2O continuous flow sewage denitriding and dephosphorizing system and short-range denitriding method

A technology for nitrogen and phosphorus removal and sewage, applied in the direction of sustainable biological treatment, aerobic process treatment, aerobic and anaerobic process treatment, etc., can solve the problems of difficult short-term denitrification, complex operation and control, etc., to reduce costs, Good sludge settling performance and the effect of reducing the amount of sludge generated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

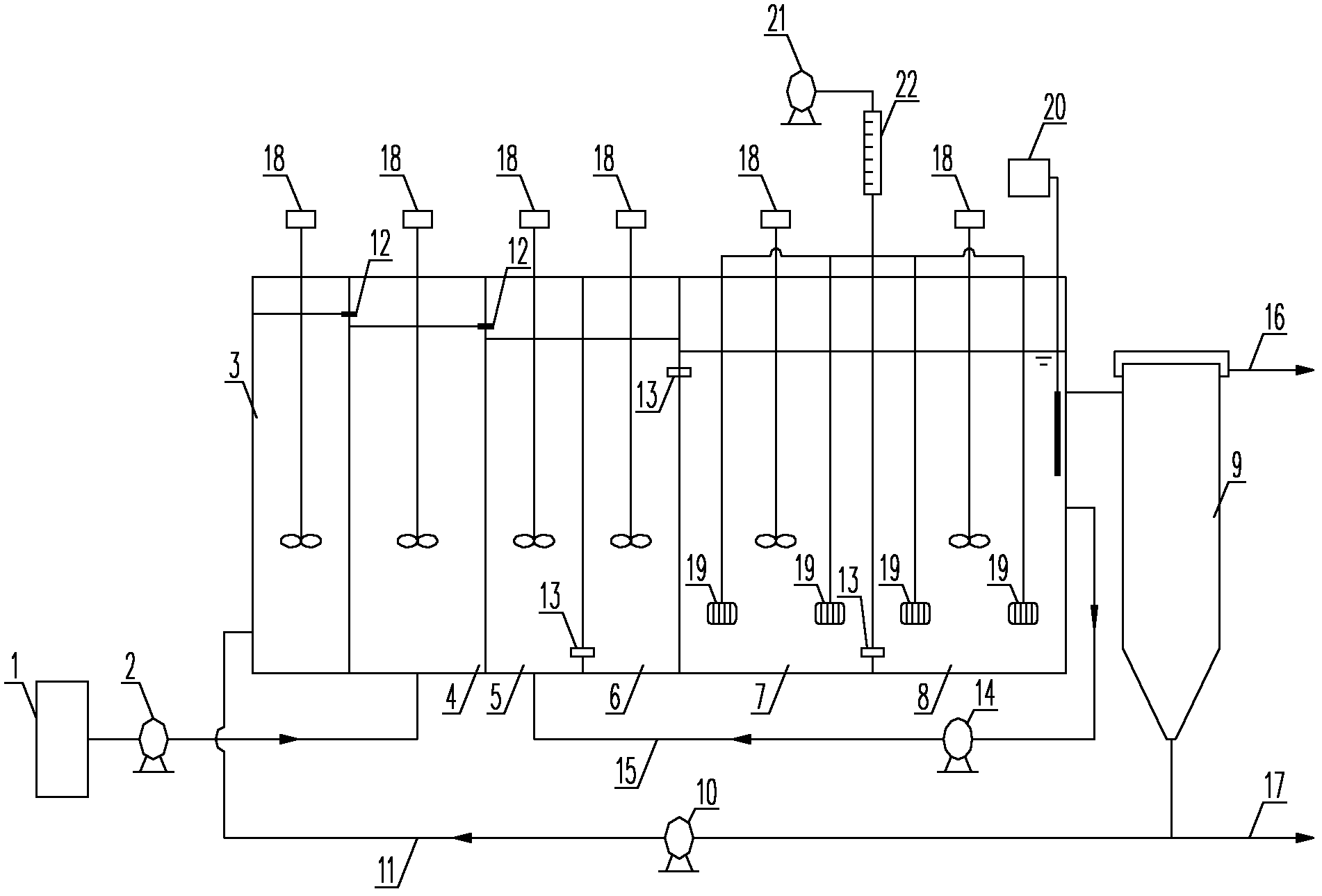

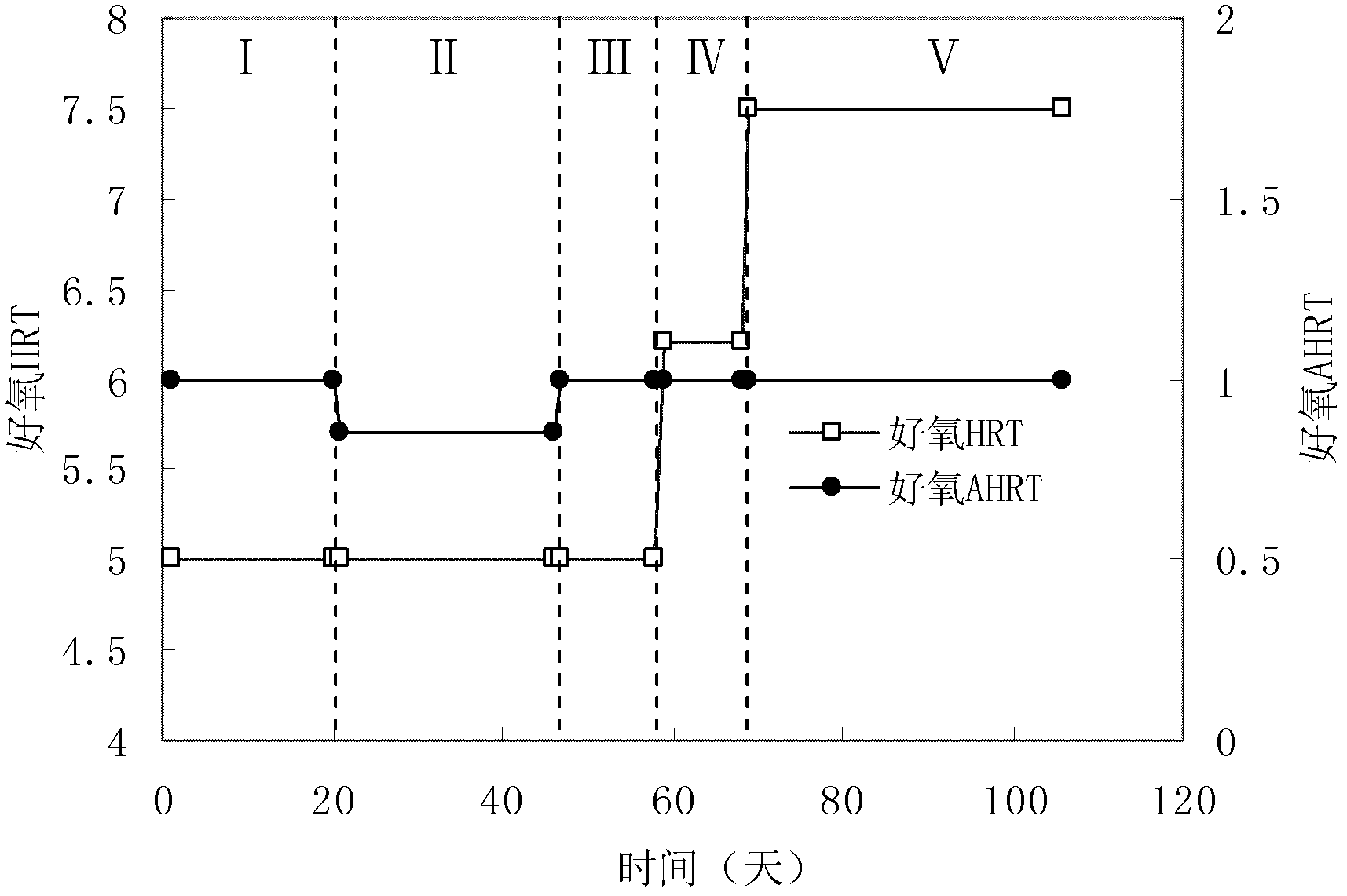

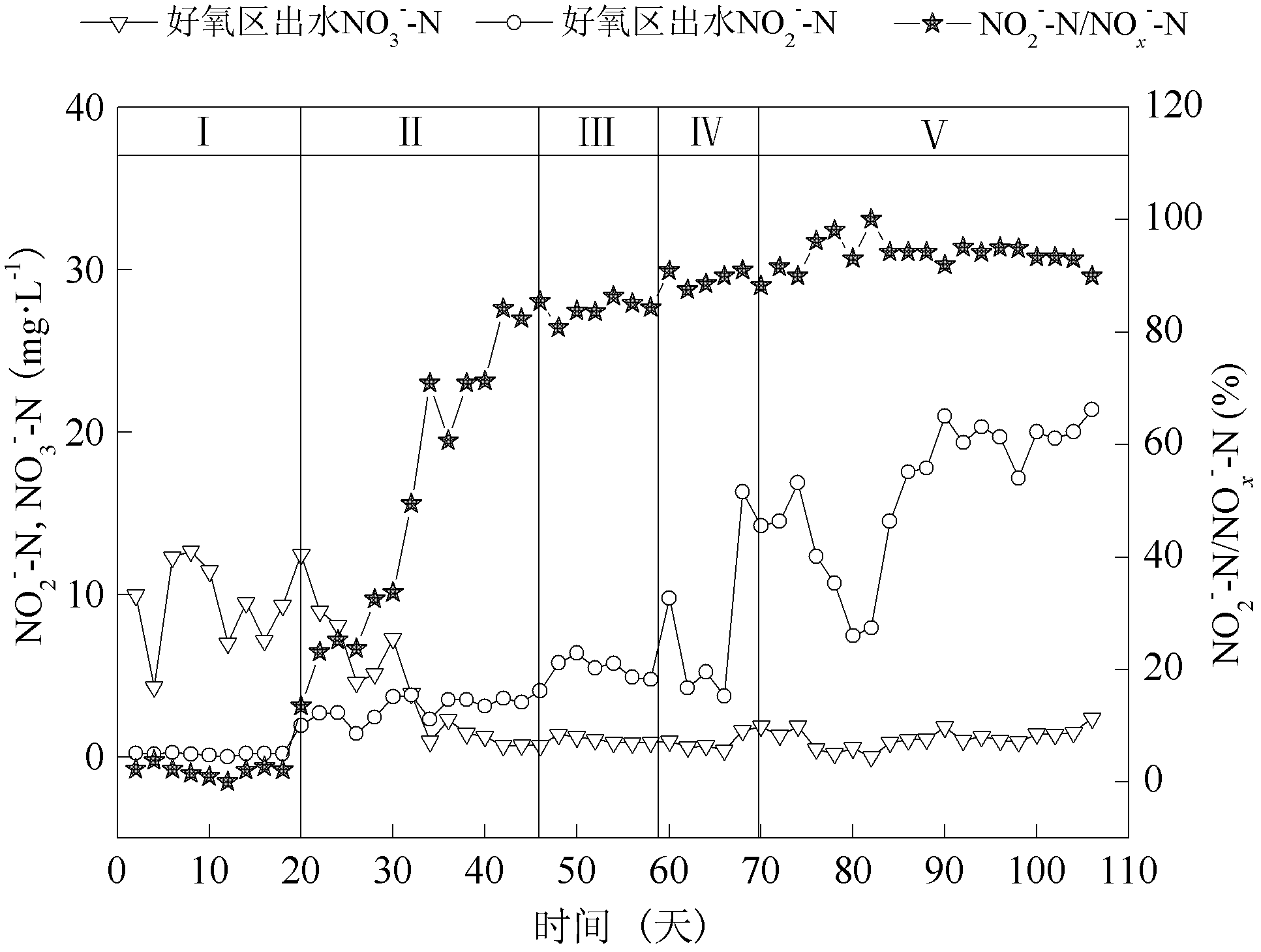

Embodiment 1

[0049] Embodiment 1: adopt as figure 1 A-A shown 2 O The continuous flow system treats the actual domestic sewage from a septic tank in a residential area. Its water quality index is: COD concentration 105-271mg / L, NH 4 + -N concentration is 56-81 mg / L, pH value is 7.1-7.5, and C / N average value is 2.53. The inoculum sludge was taken from the return sludge of the secondary settling tank of an urban sewage treatment plant in Beijing, which belongs to the whole process of denitrification sludge. During operation, the water temperature is around 23°C. The concentration of mixed liquid suspended solids (MLSS) in the reactor is (2500±500) mg / L. Operate according to the control method of the above five stages, and the operating parameters of each stage are shown in Table 1, and a total of 106d operations are performed. image 3 Shows the change of nitrite nitrogen accumulation rate during operation, Figure 4 The removal rate of ammonia nitrogen and total nitrogen during oper...

Embodiment 2

[0053] Embodiment 2: adopt as figure 1 A-A shown 2 O The continuous flow system treats the actual domestic sewage from a septic tank in a residential area. Its water quality index is: COD concentration 110-282mg / L, NH 4 + -N concentration is 52-78mg / L, pH value is 7.0-7.4, C / N average is 2.6. The inoculum sludge was taken from the return sludge of the secondary settling tank of an urban sewage treatment plant in Beijing, which belongs to the whole process of denitrification sludge. During operation, the water temperature is 20-25°C. The concentration of mixed liquid suspended solids (MLSS) in the reactor is (2400±400) mg / L. The reactor has operated for a total of 107 days, and the operation control methods and treatment effects of the five stages are as follows:

[0054] Phase I controlled the DO concentration in the aerobic zone 1 and aerobic zone 2 to be maintained at 0.3-0.5mg / L, the HRT in the aerobic zone was 4.8h, and the AHRT in the aerobic zone was 0.95h. After ...

Embodiment 3

[0059] Embodiment 3: adopt as figure 1 A-A shown 2 O The continuous flow system treats the actual domestic sewage from a septic tank in a residential area. Its water quality indicators are: COD concentration 108-268mg / L, NH 4 + -N concentration is 55~75mg / L, pH value is 7.1~7.4, C / N average is 2.5. The inoculum sludge was taken from the return sludge of the secondary settling tank of an urban sewage treatment plant in Beijing, which belongs to the whole process of denitrification sludge. During operation, the water temperature is 20-23°C. The concentration of mixed liquid suspended solids (MLSS) in the reactor is (2500±400) mg / L. The reactor has been operated for 105 days in total, and the operation control methods and treatment effects of the five stages are as follows:

[0060] In phase I, the DO concentration in the aerobic zone 1 and aerobic zone 2 was maintained at 0.3-0.5 mg / L, the HRT in the aerobic zone was 5.2 hours, and the AHRT in the aerobic zone was 1.05 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com