Preparation method of freeze-drying oil-injection sliced agaricus bisporus

A bisporus mushroom and its manufacturing method technology are applied in the field of freeze-dried and oil-sprayed Agaricus bisporus slices, which can solve the problems of Agaricus bisporus nutrition loss, dry matter content reduction, and yield decline, and achieve convenient sorting and packaging Operation, large contact surface and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

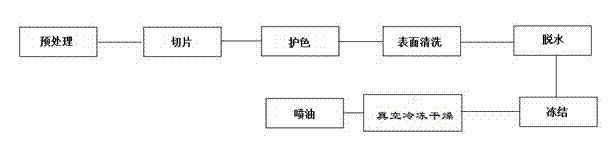

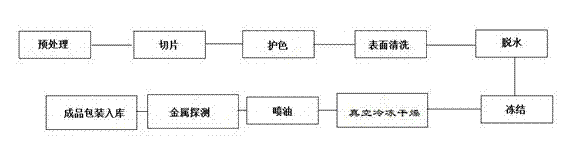

Image

Examples

Embodiment 1

[0026] A method for manufacturing freeze-dried oil-sprayed Agaricus bisporus slices, comprising the following steps: pretreatment, slicing and color protection, and further comprising the following steps:

[0027] Sterilization: Soak the pretreated Agaricus bisporus in chlorine dioxide solution of 240ppm color zone for 7 minutes, rinse the residual chlorine dioxide solution with clean water after soaking, and send it to slice and color protection in turn;

[0028] Surface cleaning: Clean the surface of the Agaricus bisporus slices after the color protection treatment with clean water, and then rinse them in sterile water for 5 minutes to ensure that there is no color protection solution on the surface of the Agaricus bisporus slices after rinsing;

[0029] Dehydration: Put the Agaricus bisporus slices after surface cleaning into the dehydrator for dehydration. The working speed of the dehydrator is 400 rpm, and the dehydration time is 30 seconds;

[0030] Freezing: put the deh...

Embodiment 2

[0036] A method for manufacturing freeze-dried oil-sprayed Agaricus bisporus slices, comprising the following steps: pretreatment, slicing and color protection, and further comprising the following steps:

[0037] Sterilization: Soak the pretreated Agaricus bisporus in a chlorine dioxide solution of 250ppm color zone for 7 minutes, rinse the residual chlorine dioxide solution with clean water after soaking, and send it to slice and color protection in turn;

[0038] Surface cleaning: Clean the surface of the Agaricus bisporus slices after the color protection treatment with clean water, and then rinse them in sterile water for 3 minutes to ensure that there is no color protection solution on the surface of the Agaricus bisporus slices after rinsing;

[0039] Dehydration: Put the Agaricus bisporus slices after surface cleaning into the dehydrator for dehydration. The working speed of the dehydrator is 300 rpm, and the dehydration time is 35 seconds;

[0040] Freezing: put the d...

Embodiment 3

[0046] A method for manufacturing freeze-dried oil-sprayed Agaricus bisporus slices, comprising the following steps: pretreatment, slicing and color protection, and further comprising the following steps:

[0047] Sterilization: Soak the pretreated Agaricus bisporus in chlorine dioxide solution of 260ppm color zone for 6 minutes, rinse the residual chlorine dioxide solution with clean water after soaking, and send it to slice and color protection in turn;

[0048] Surface cleaning: Clean the surface of the Agaricus bisporus slices after the color protection treatment with clean water, and then rinse them in sterile water for 4 minutes to ensure that there is no color protection solution on the surface of the Agaricus bisporus slices after rinsing;

[0049] Dehydration: Put the Agaricus bisporus slices after surface cleaning into the dehydrator for dehydration. The working speed of the dehydrator is 220 rpm, and the dehydration time is 40 seconds;

[0050] Freezing: put the deh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com