Bitangent circular thick and thin separation adjustable direct-current coal powder combustor

A technology of pulverized coal burner and thick-light separation, which is applied in the direction of burners, burners burning powder fuel, and combustion methods, etc., and can solve the problems of not minimizing the amount of generation, unfavorable combustion, and difficult maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

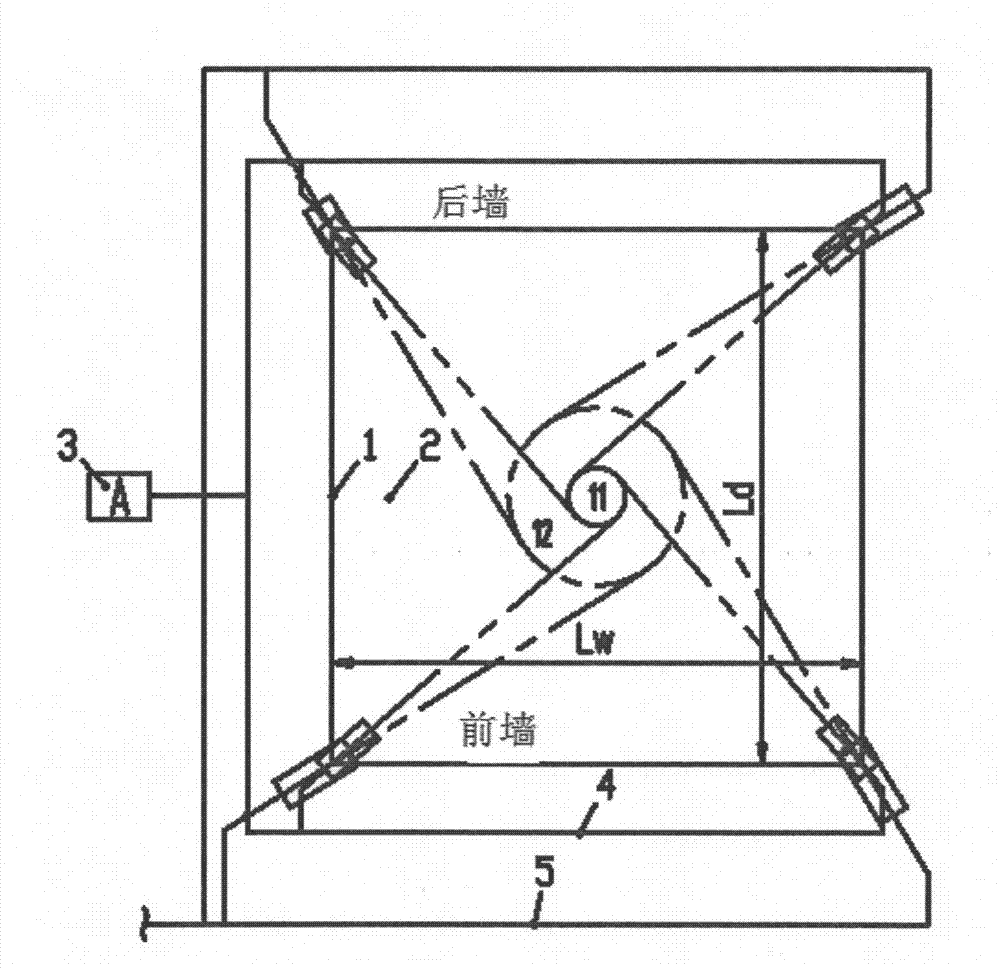

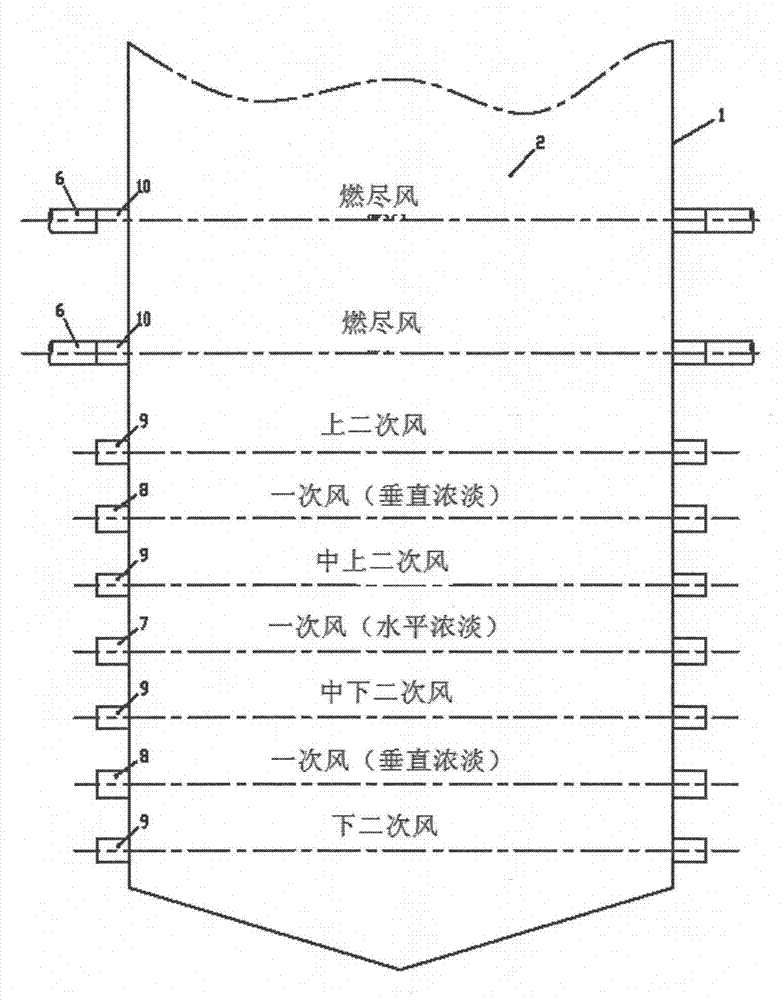

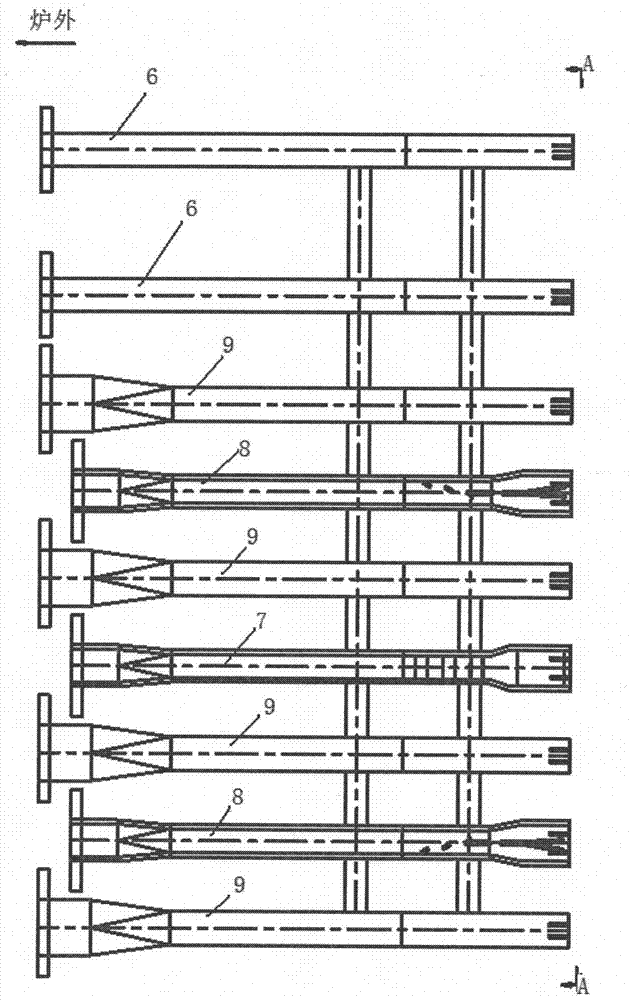

[0021] The main combustion zone of the direct-current pulverized coal burner with double tangential circle thick-thin separation adjustable belongs to the anoxic oxidation zone, which is helpful for raising the furnace temperature and promoting the ignition and combustion of pulverized coal. Due to the existence of the overfired air volume, there will also be an alternating redox storage area in the main burner area, which can form a local reduction area and initially reduce the produced NO X , lack of oxygen and partial combustion of pulverized coal suppresses the higher combustion flue gas temperature, making NO X It is suppressed at the initial combustion, and the burnout zone will be supplemented as burnout air to promote the final burnout of coke. Its specific structure is:

[0022] It includes a hearth 2, a primary air duct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com