A direct-flow pulverized coal burner with adjustable primary wind speed for thick and thin phases

A pulverized coal burner, an adjustable technology, is applied in the burners, burners, combustion methods and other directions of burning powder fuel, can solve the problems of poor adaptability of coal types, complex structure, difficult to replace, etc., and achieves strong ignition stability, Low NOX generation and good coking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

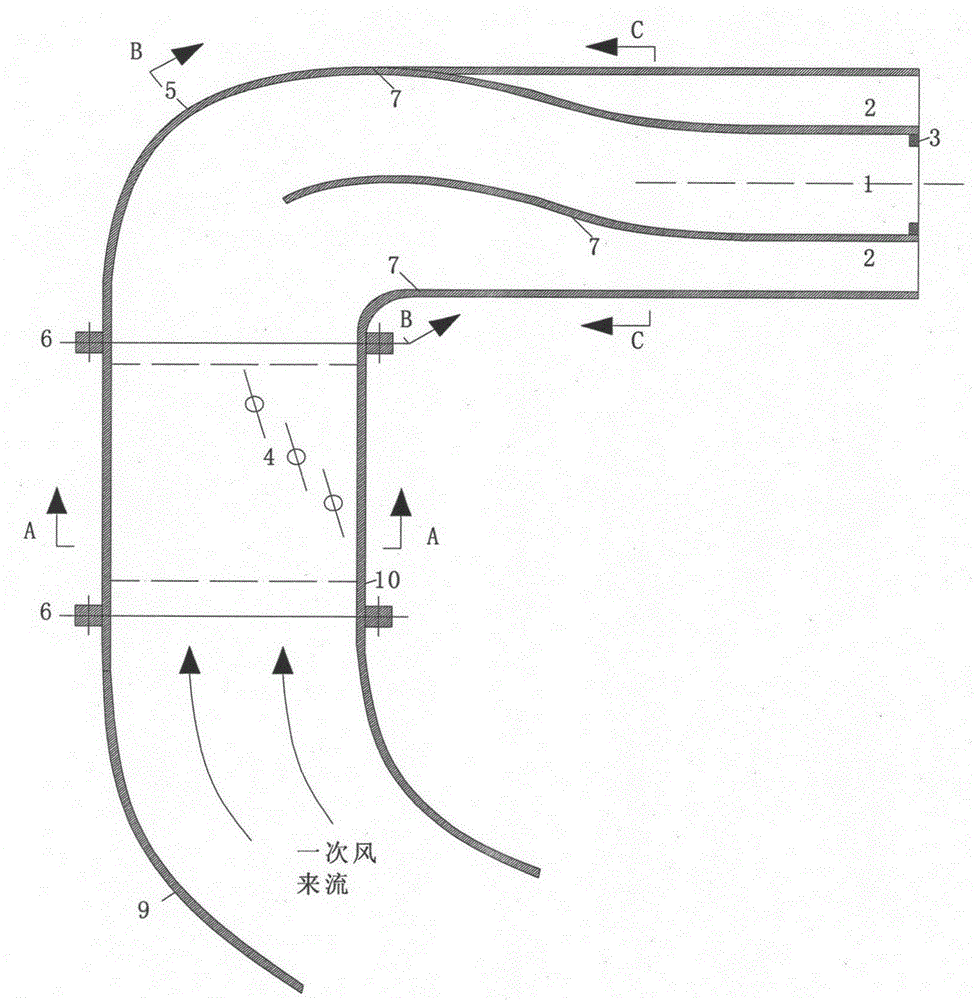

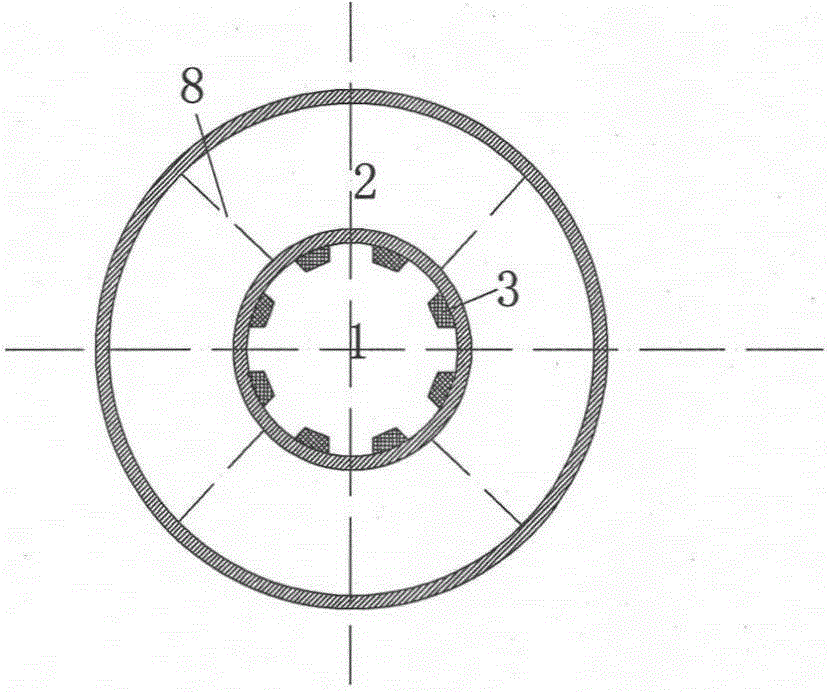

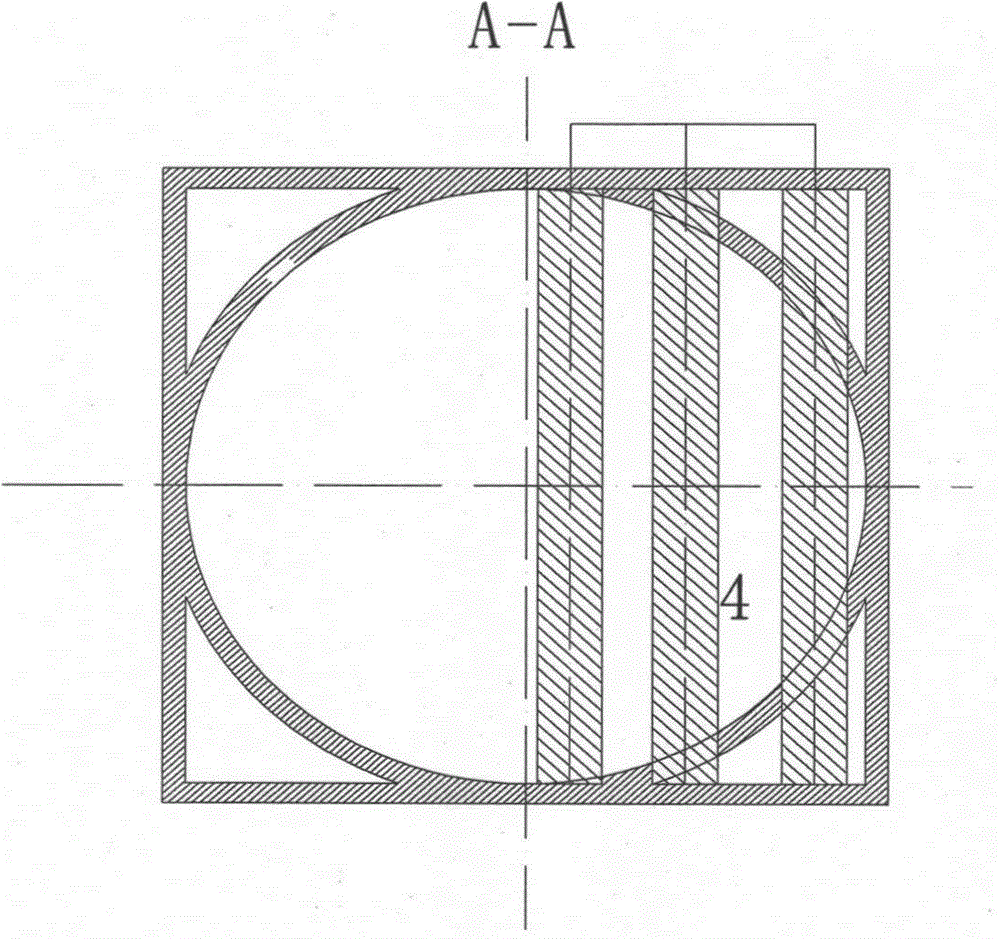

[0025] Such as figure 1 As shown, the direct-current pulverized coal burner with adjustable primary wind speed of the thick and thin phases of the present invention includes a burner elbow 9, and the burner elbow 9 is connected to one end of the square-circle conversion pipe 10 through the flange 6, and the square-circle conversion pipe 10 is The joints at both ends have a circular cross-section, and the middle part has a square cross-section. The other end of the square-to-circle conversion pipe 10 is connected to one end of the elbow 5 through the flange 6. The other end of the elbow 5 constitutes the light-phase nozzle 2. Inside the elbow 5 is a Dense phase spout conduit, the rear end of the dense phase spout conduit is located on the inner side of the curved part of the elbow 5 . The front end of the dense phase nozzle conduit constitutes the dense phase nozzle 1, such as figure 2 As shown, the dense phase nozzle 1 and the light phase nozzle 2 are concentric circles. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com