Patents

Literature

220results about How to "Change concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

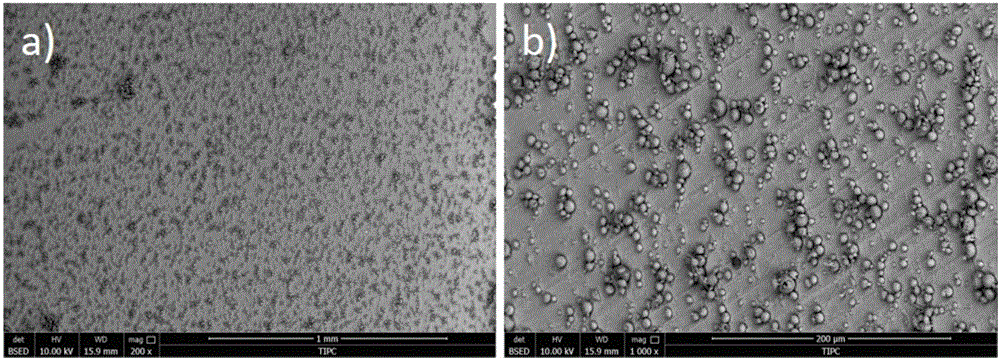

Method for preparing monodisperse polystyrene microsphere with controllable grain diameter

InactiveCN101293936ALow purity requirementGood monodispersityHydrocarbon purification/separationHydrocarbonsPotassium persulfateMicrosphere

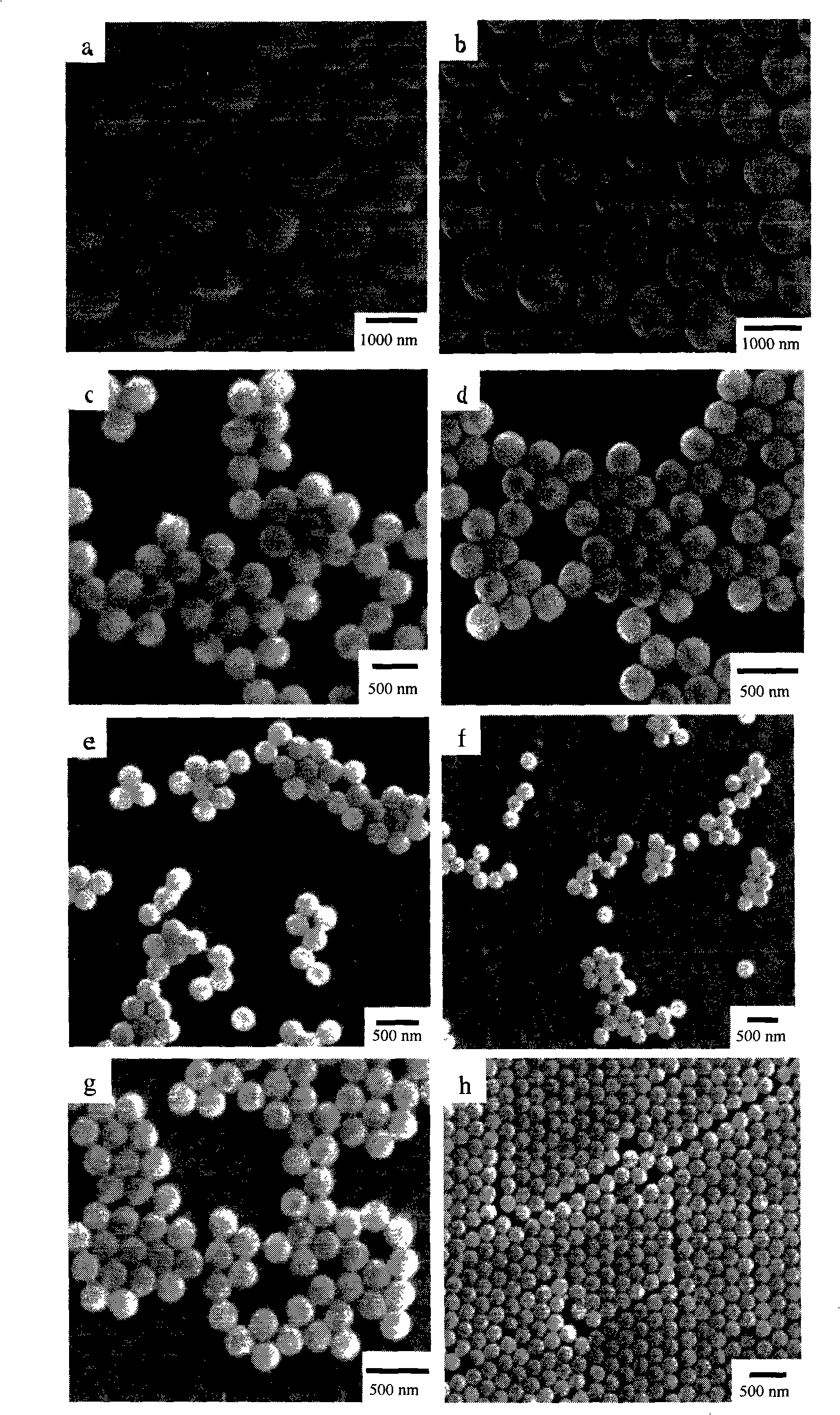

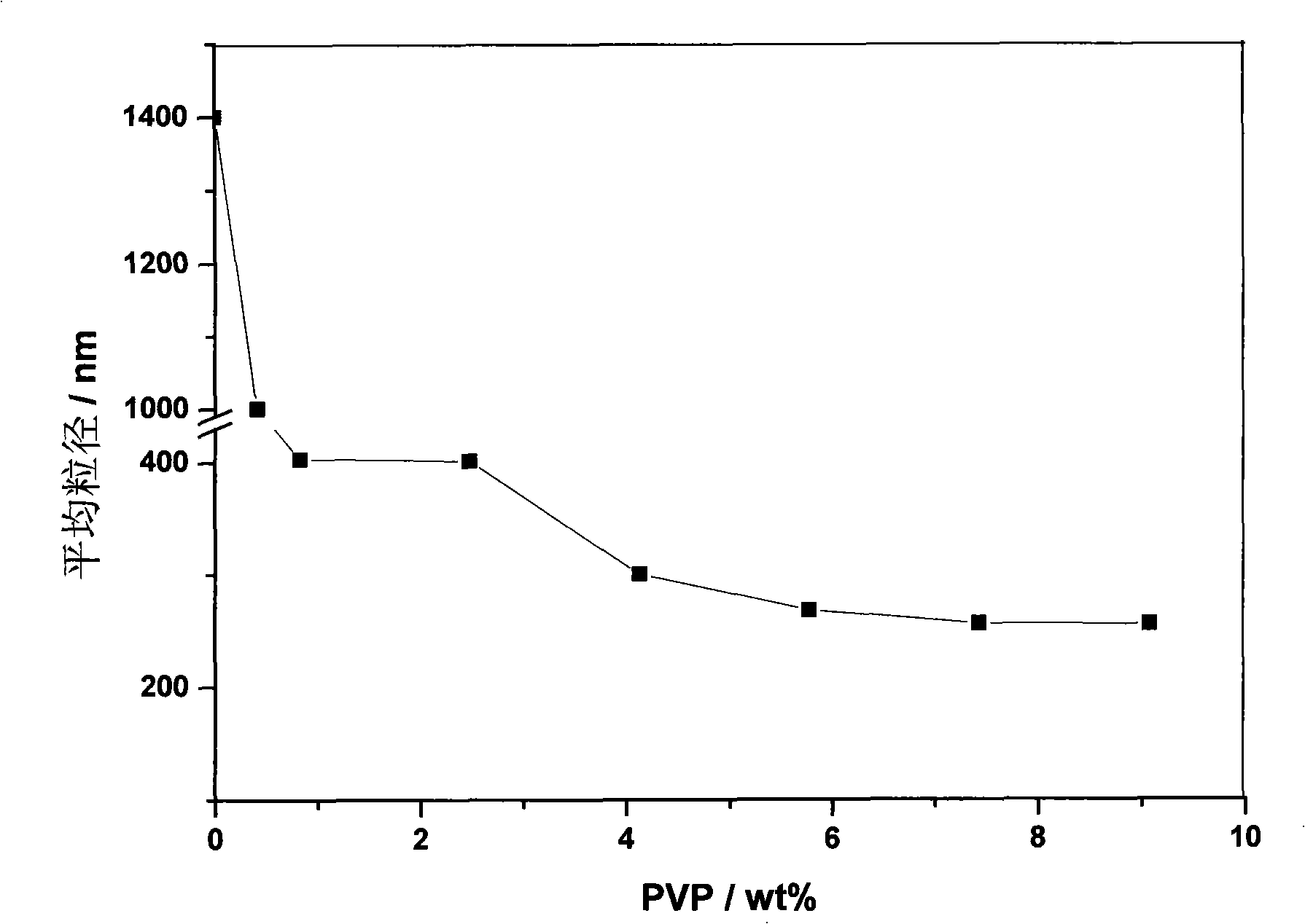

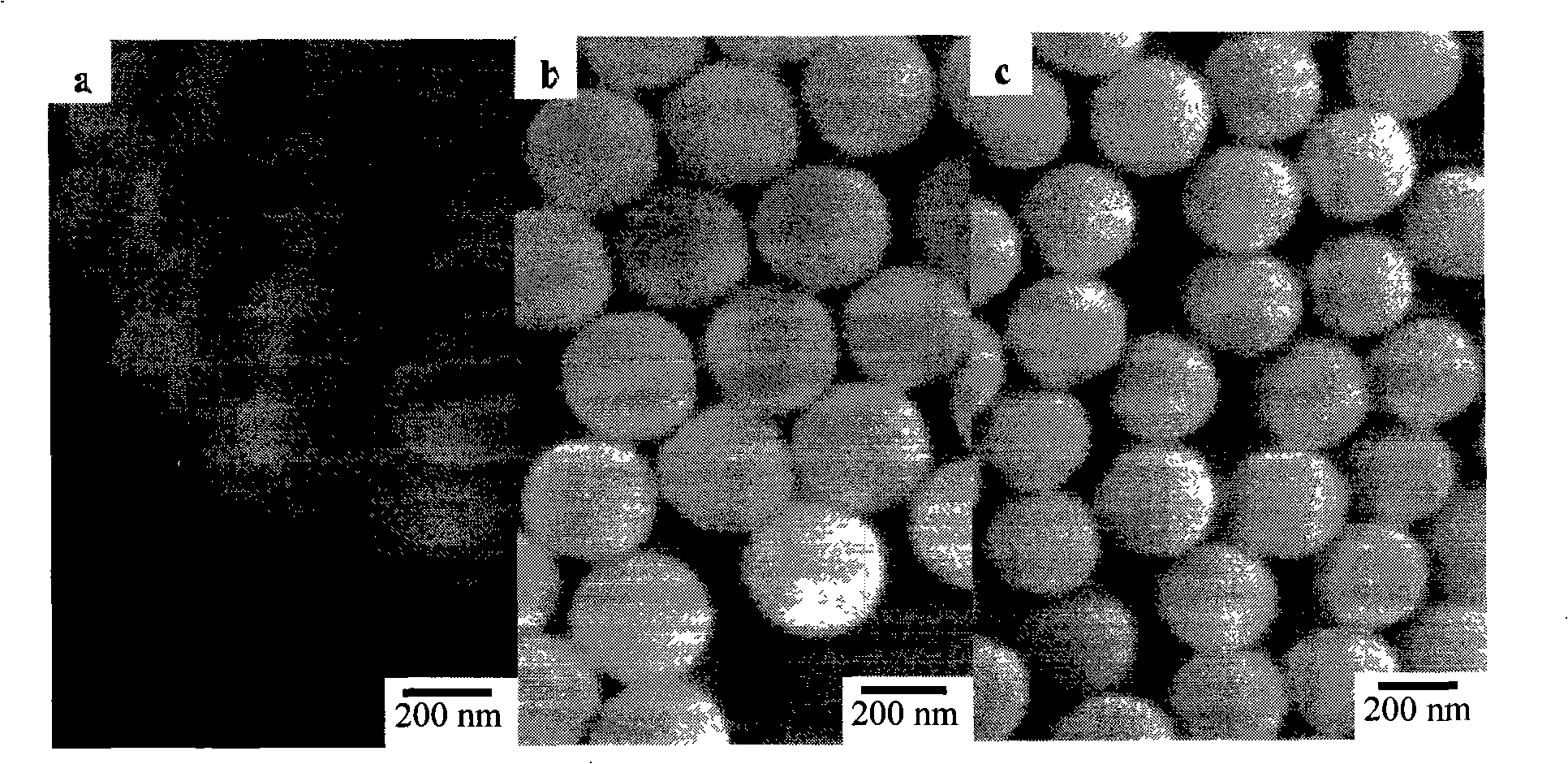

The invention belongs to the technology field of nanometer materials preparation, particularly relates to a preparation method of monodisperse polystyrene microspheres capable of controlling the particle size of the polystyrene microspheres within a certain range by changing the use amount of a stabilizer. The invention prepares polystyrene microspheres with simply purified styrene as a monomer, potassium persulfate as an initiator, water as a reaction medium and polyvinylpyrrolidone as a stabilizer by using soap-free emulsion polymerization. The preparation method uses electromagnetic stirring instead of electric stirring; and has the advantages of relatively low requirements for the uniformity of stirring speed, no need of surfactant, simple process, and low cost. The obtained polystyrene microspheres have good monodispersity, and the particle size thereof can be controlled within the range of 250-1,400nm by changing the use amount of the stabilizer. The monodispersed polystyrene microspheres have important application value as a module or template in construction of photonic crystals, inorganic / organic nanometer composite materials and hollow micrometer / nanometer spheres.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

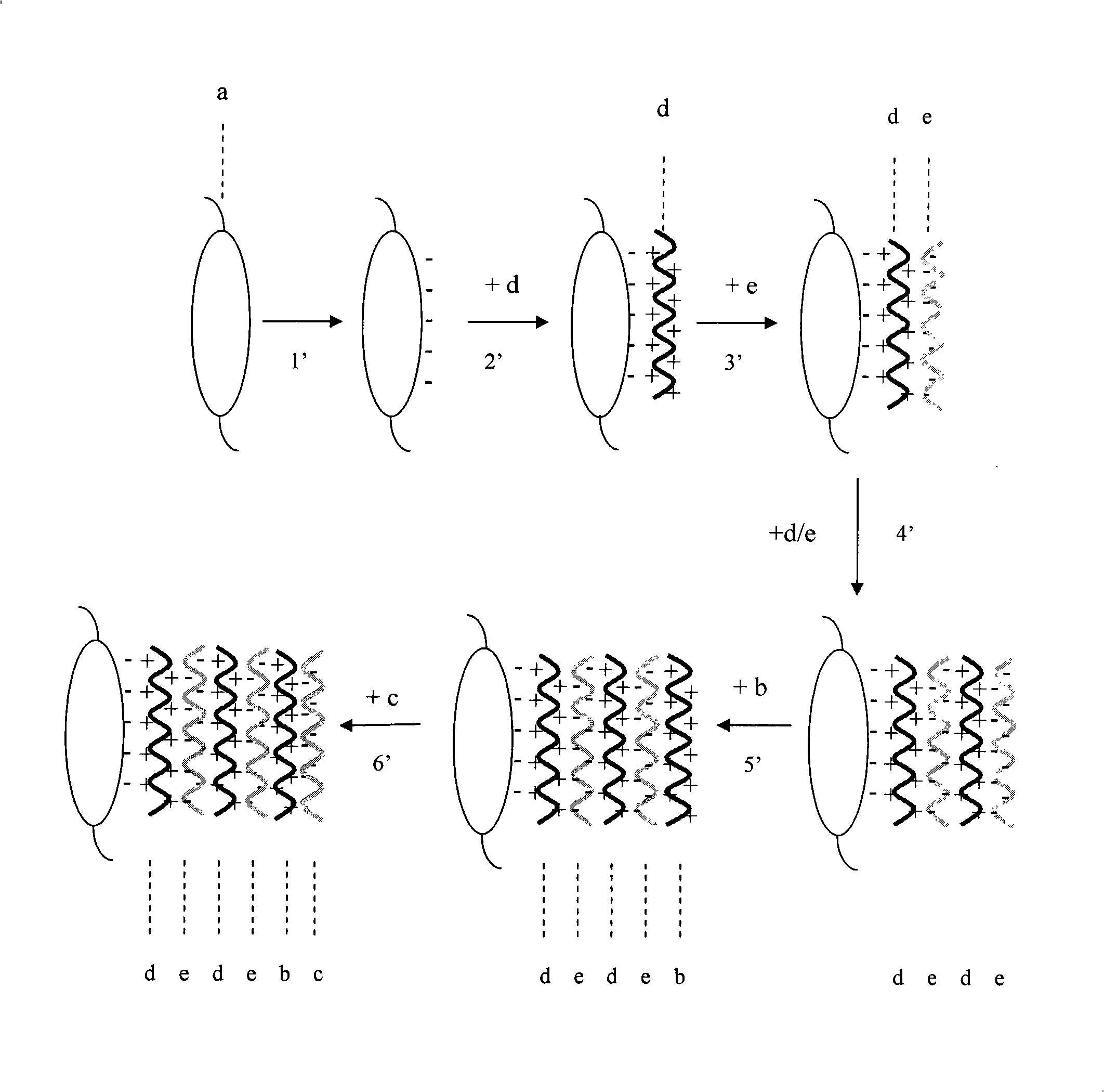

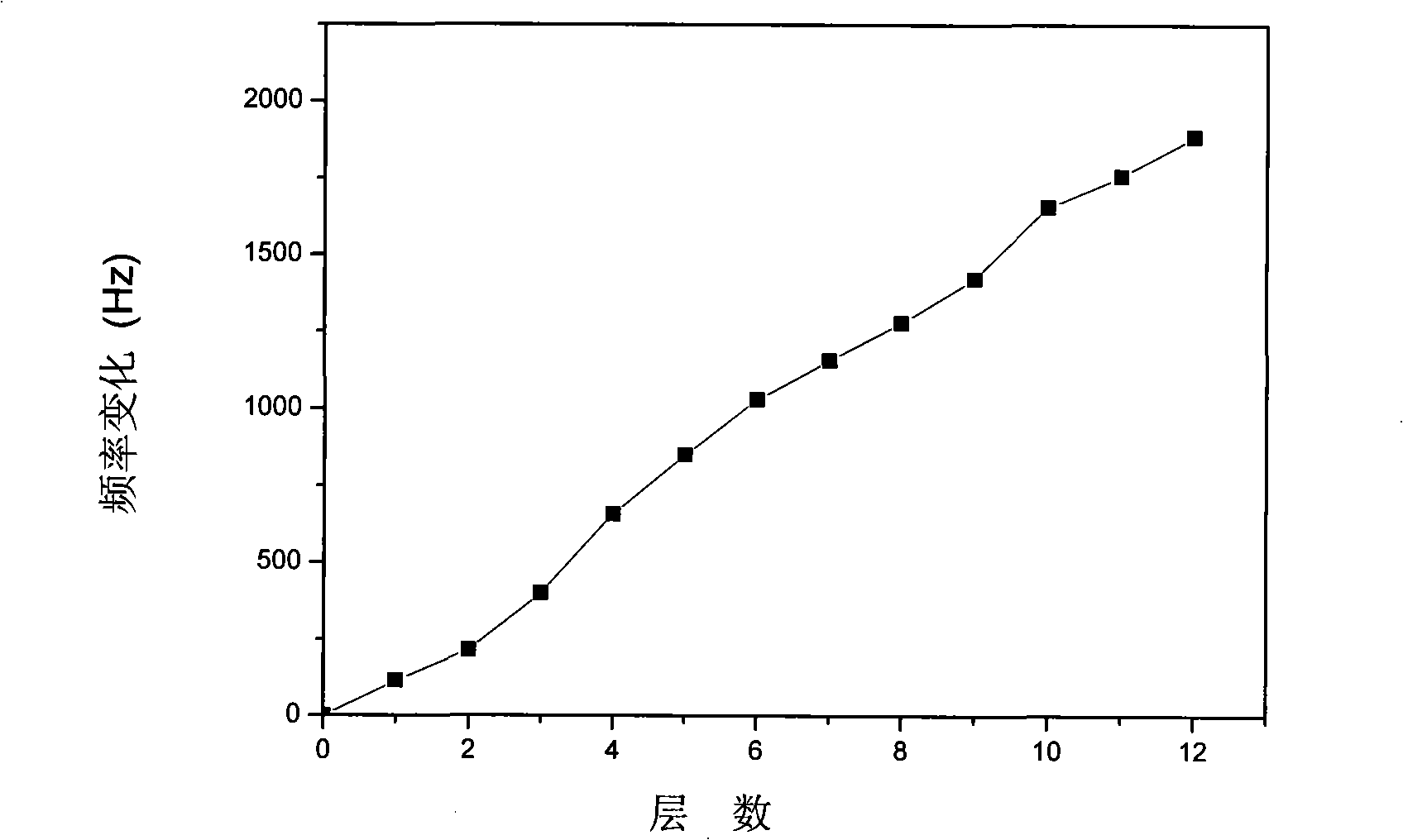

Artificial crystalline len with transforming growth factor resistant beta2 antibody membrane on surface and manufacturing method thereof

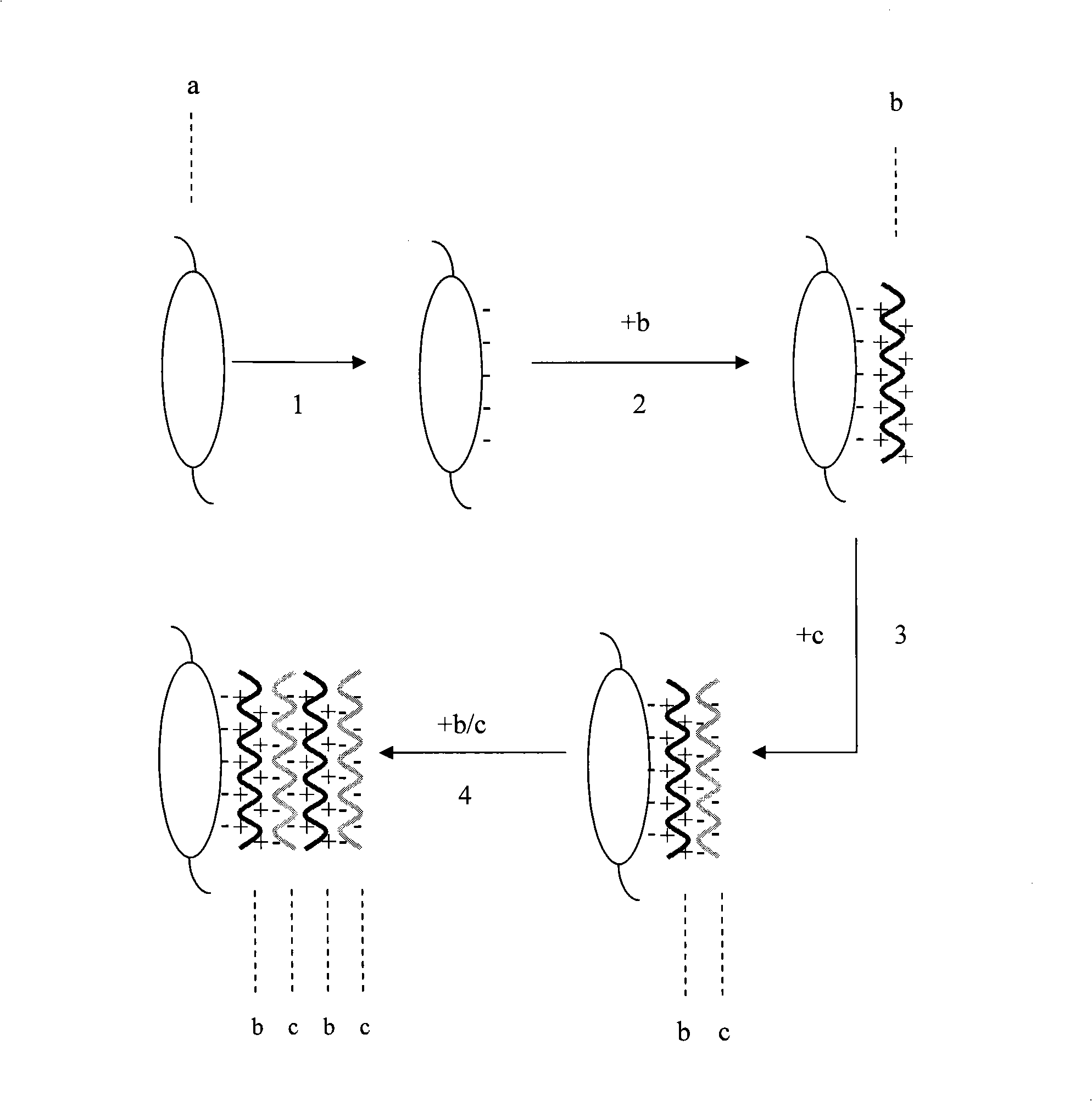

The invention provides an artificial lentis, which contains anti-transforming growth factor beta 2 antibody membrane on the surface and can inhibit intercurrent post-cataract after cataract surgery, and also provides a the production method thereof. The production method includes the steps that: the artificial lentis is charged with positive electricity or negative electricity after the artificial lentis is cleaned, dried, and pretreated on the surface; the artificial lentis is soaked in a polyelectrolyte solution the charge of which is opposite to the surface charge of the artificial lentis for adsorbing, and rinsing the artificial lentis by deionized water, and drying the artificial lentis by nitrogen gas; the artificial lentis is soaked in a phosphate buffering solution of anti-transforming growth factor beta 2 antibody, the pH value of which is 4-10, and the carried charge of which is opposite to that of the polyelectrolyte, for adsorption; finally, the artificial lentis is rinsed by phosphate buffering solution, and the artificial lentis is dried by nitrogen gas; the alternating assembly steps are repeated. The artificial lentis of the invention can inhibit the transformation and differentiation as well as cyst membrane shrinkage of the lentis epithelial cells in a target way, and then interdicts the occurrence of the post-cataract, and has excellent biocompatibility. The production method of the invention is scientific and simple, and can ensure the activity under a dry state and the safety and reliability during medical transplantation of the anti-transforming growth factor beta 2.

Owner:SECOND AFFILIATED HOSPITAL ZHEJIANG UNIV COLLEGE OF MEDICINE

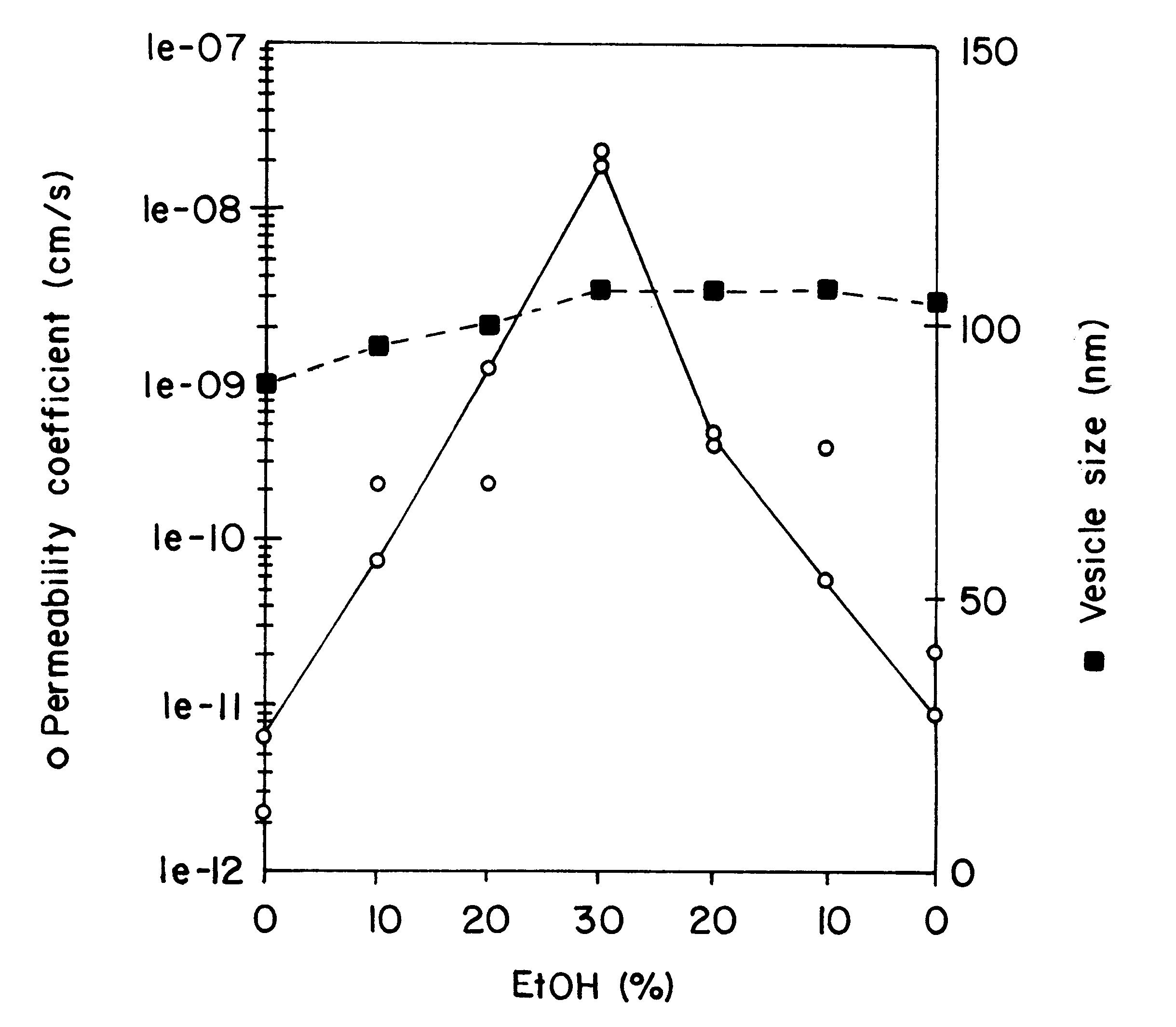

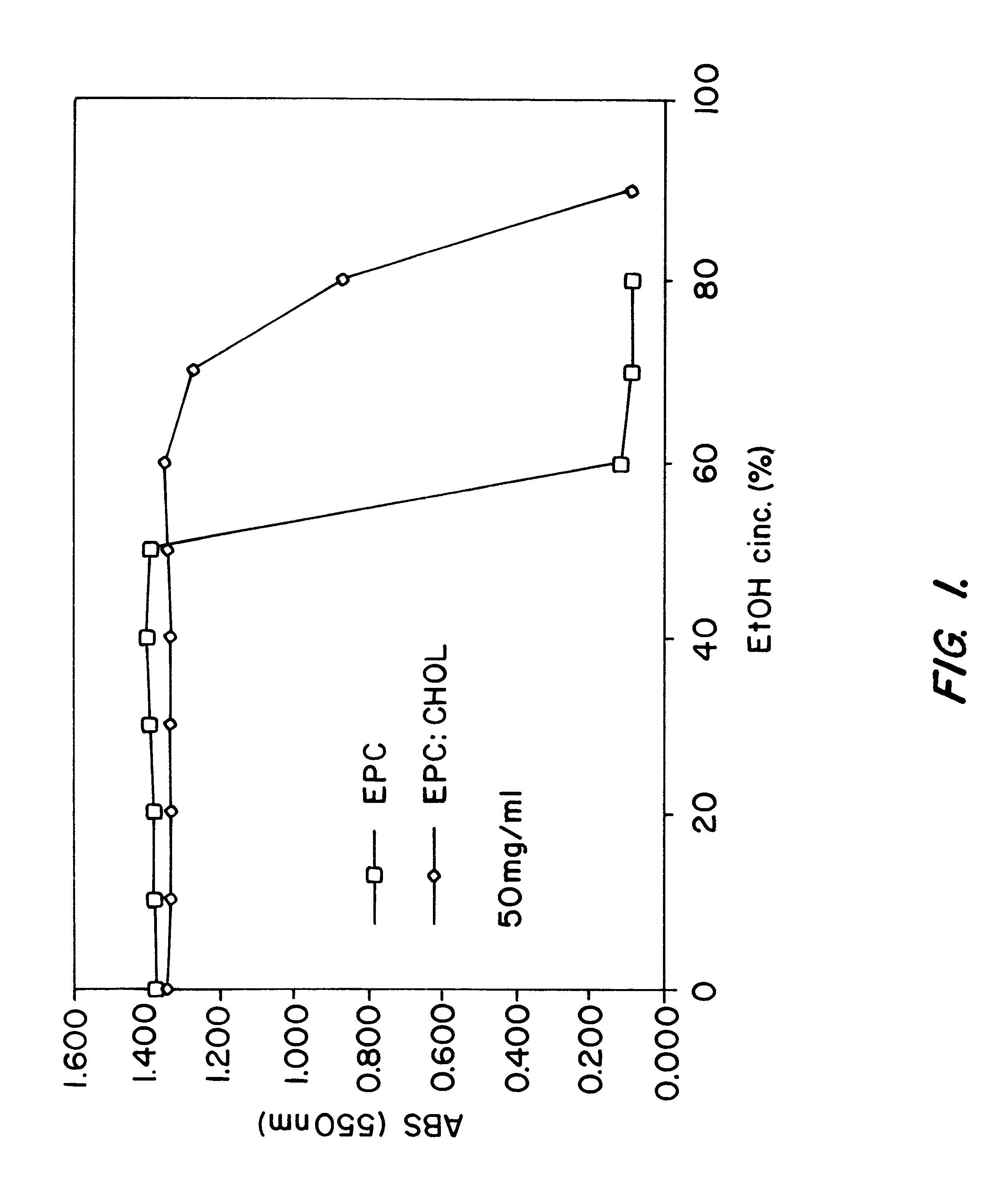

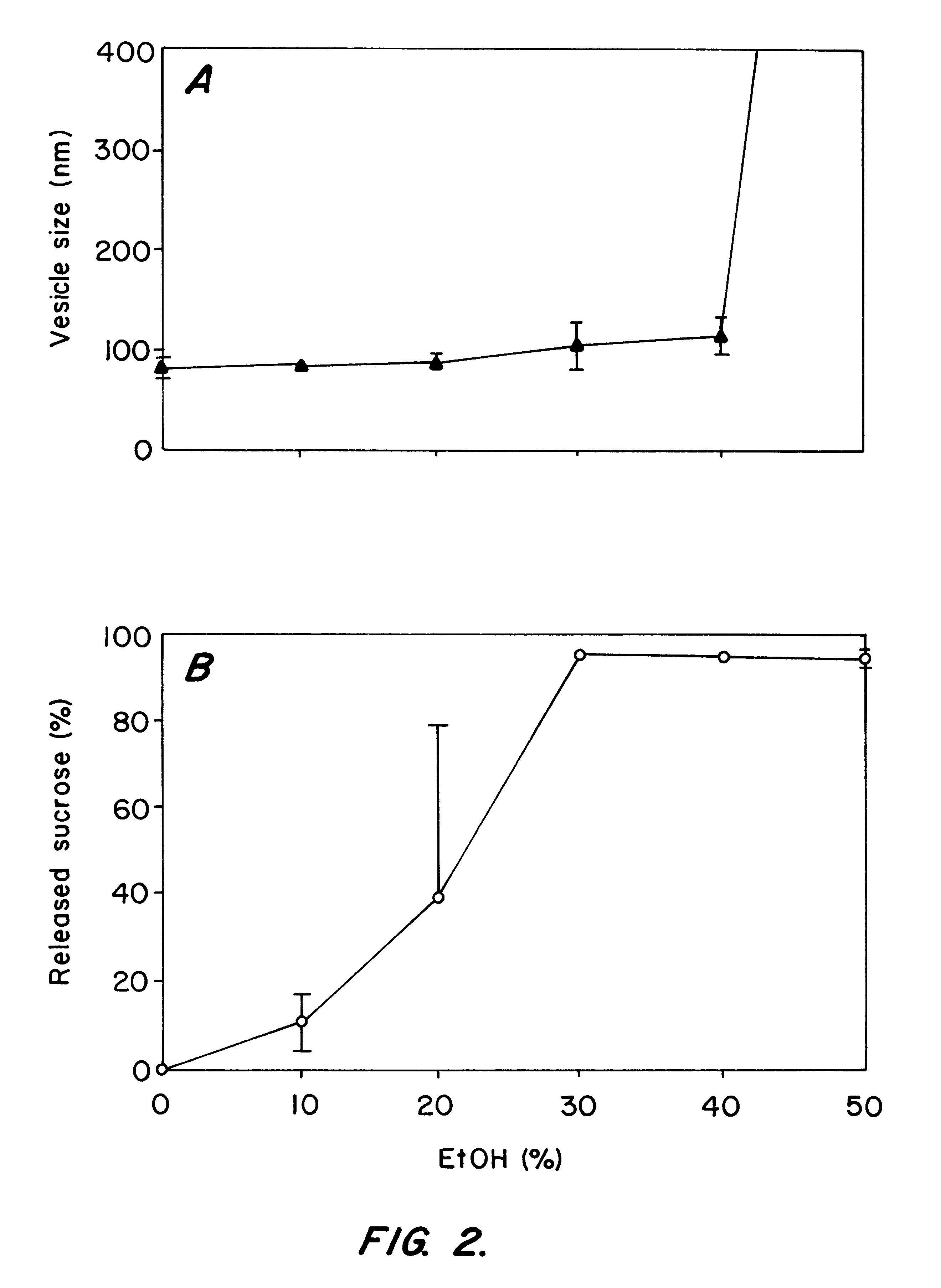

Method of loading preformed liposomes using ethanol

InactiveUS6447800B2Good membrane permeabilityReduce penetrationUltrasonic/sonic/infrasonic diagnosticsBiocideAlcoholLiposome

This invention provides methods of loading preformed liposomes by transmembrane permeation induced by alcohols. Solutes loaded into liposomes by this ethanol mediated process include both small nonpolar molecules and larger species, such as proteins and carbohydrates.

Owner:THE UNIV OF BRITISH COLUMBIA

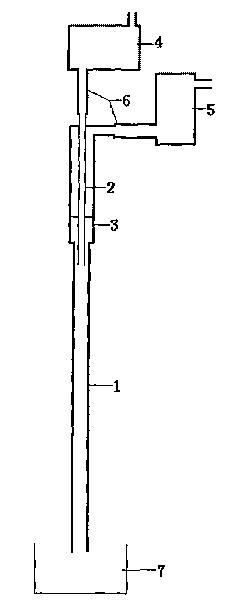

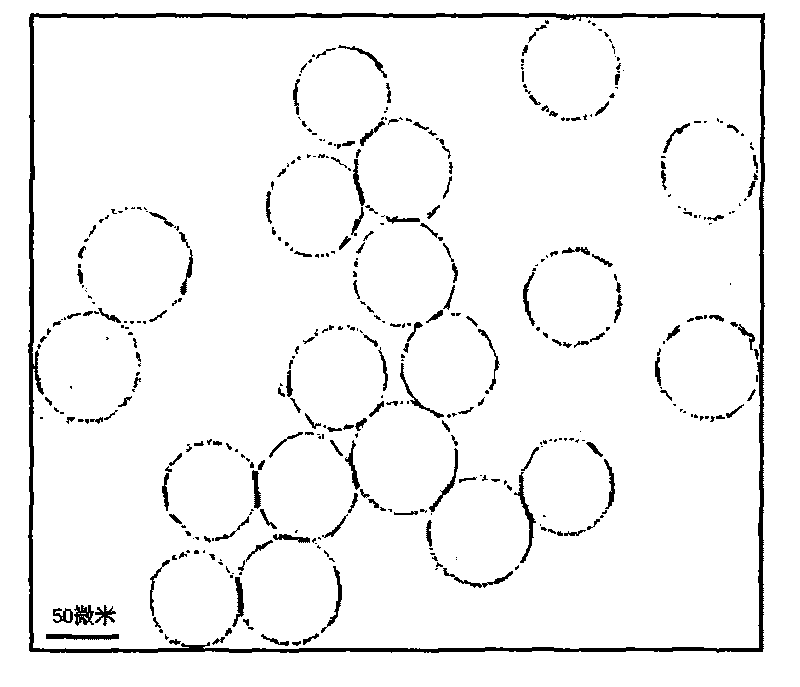

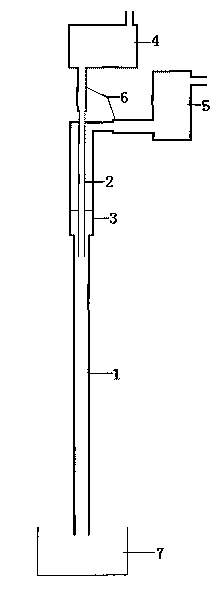

Device and method for preparing gel microspheres with uniform grain sizes

InactiveCN101695646AGood particle size uniformityLittle effect on activityMicroballoon preparationMicrocapsule preparationMicrosphereOil phase

The invention relates to a device and a method for preparing gel microspheres with uniform grain sizes. The outlet ends of a micro-dosage syringe pump and a constant-flow pump of the device are connected with a syringe needle and a stand tube through a hose respectively, a stand in the stand tube inserts and fixes the syringe needle at the position of a center shaft of a capillary glass tube, and the stand tube is communicated with the capillary glass tube. The method comprises the following steps: connecting a container with an oil phase into the inlet end of the constant-flow pump, setting the flow rate of the constant-flow pump, and introducing the oil phase into the stand tube through the hose to ensure that the oil phase flows into the capillary glass tube; filling dispersed phases into a syringe tube of the micro-dosage syringe pump, setting the flow rate of the pump, and introducing the dispersed phases into the syringe needle to ensure that the dispersed phases flow into the capillary glass tube; and collecting the oil phase containing dispersed phase liquid drops by using a glass container at the tail end of the capillary glass tube, solidifying dispersed phase droplets, and washing the mixture to remove the oil phase so as to obtain the gel microspheres with uniform grain sizes. The device and the method have a simple process and can prepare the microspheres with the grain sizes between 10 and 50 microns, and the prepared gel microspheres can be widely used for embedding enzymes, cells or microorganisms and the like.

Owner:OCEAN UNIV OF CHINA

Process control for acetic acid manufacture

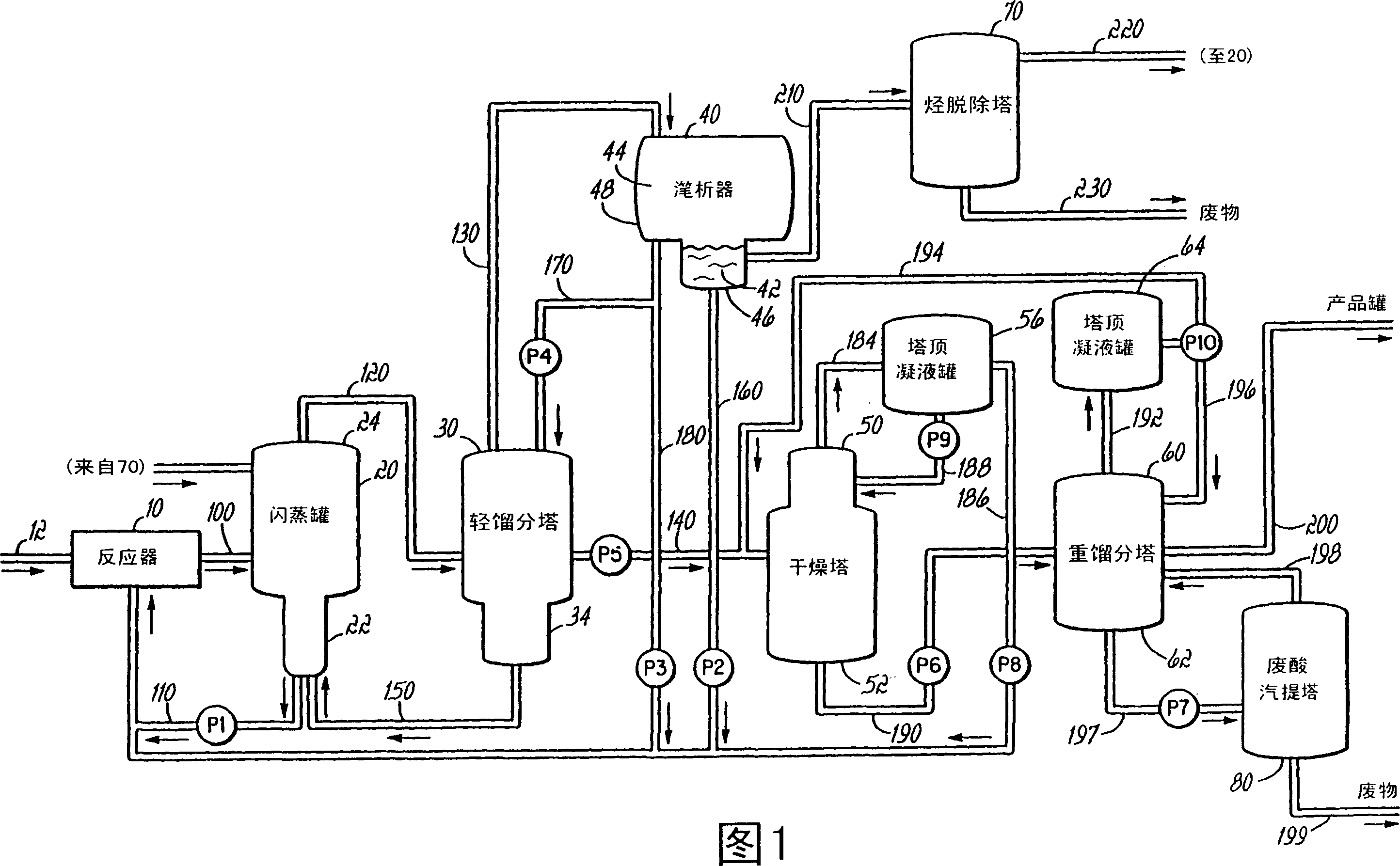

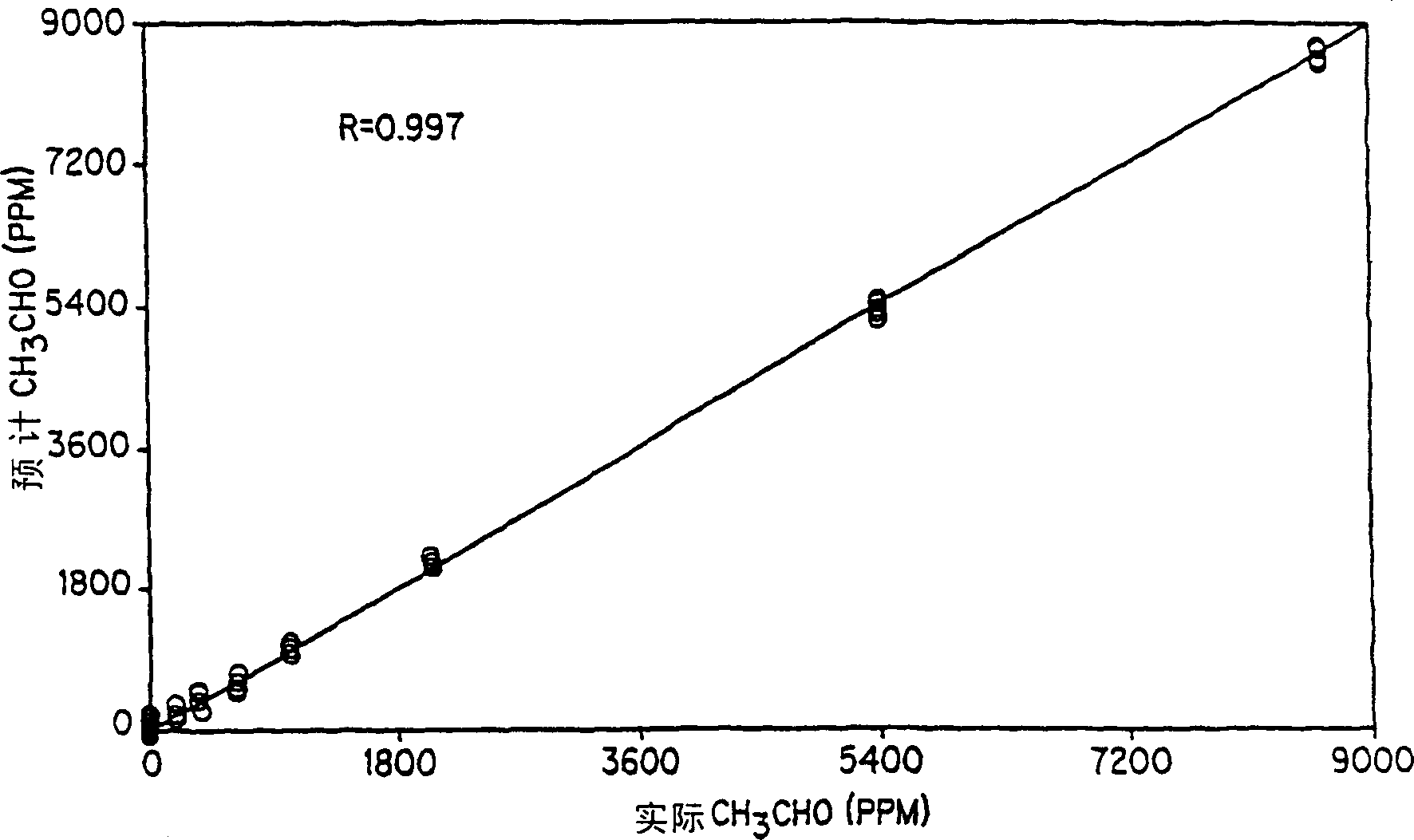

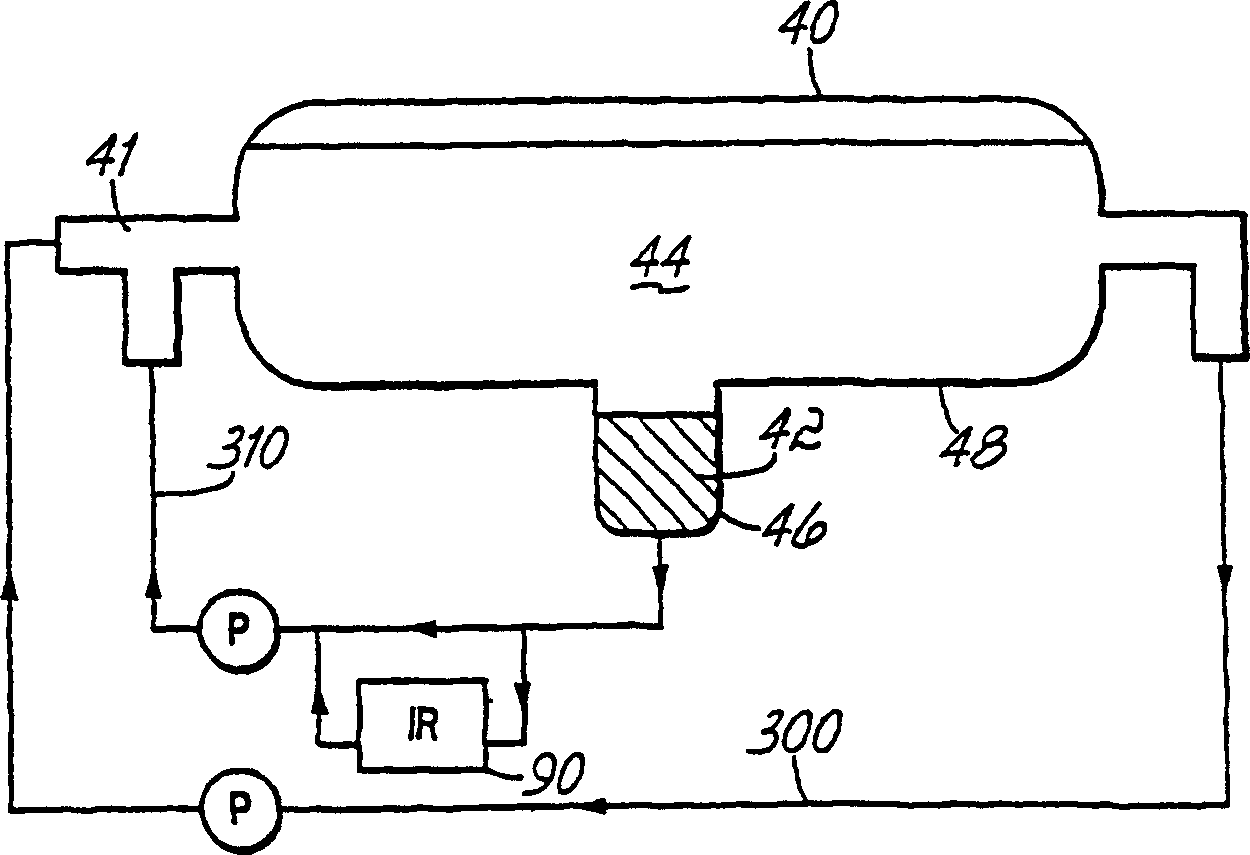

InactiveCN1449369AConcentration increases or decreases to changeChange concentrationProcess control/regulationDistillation regulation/controlInfraredAcetic acid

A method of real time process control in a reaction system for the procuction of acetic acid from the carbonylation of methanol. Raction system samples are collected from columns (30, 40, 50, 60, 70, 80) and / or transfer lines (120, 130, 140, 150, 160, 170, 180, 184, 186, 188, 190, 192, 194, 196, 197, 198, 199, 200, 210, 220) downstream of a reactor vessel (10), and the concentration of one or more components in the sample is measured by an infrared analyzer (90). The concentration measurements are then used to make adjustments in the concentration of components in the reaction system, directly or indirectly, such as by adjusting the temperature profile in a particular column (30, 40, 50, 60, 70, 80), the flow rate of solution in to or out of a column (30, 40, 50, 60, 70, 80), the vent gas rate out of the reactor (10) or a column (30, 40, 50, 60, 70, 80), or the addition or extraction of a component to or from the solution. For optimum process control, the measurements are transmitted to a control unit for real time analysis, and the adjustements are made substantially instantly after the infrared analysis.

Owner:MILLENNIUM PETROCHEM

Method for dispersing liquid metal to micro nano-particles

The invention relates to the field of liquid metal, in particular to a method for dispersing liquid metal to micro nano-particles. The method comprises the specific steps that high molecular polymer is dissolved in N,N-dimethylformamide (DMF), and a polymer solution is obtained; the liquid metal is dripped into the polymer solution, stirring is conducted, and the metal liquid is dispersed to the micro nano-particles. By means of the method for dispersing the liquid metal to the micro nano-particles, the liquid metal can be dispersed to the micro nano-particles without obvious agglomeration and sediment within 50 h; the liquid metal can be efficiently dispersed within a short time, and a method for preparing base materials is provided for printing the liquid metal.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

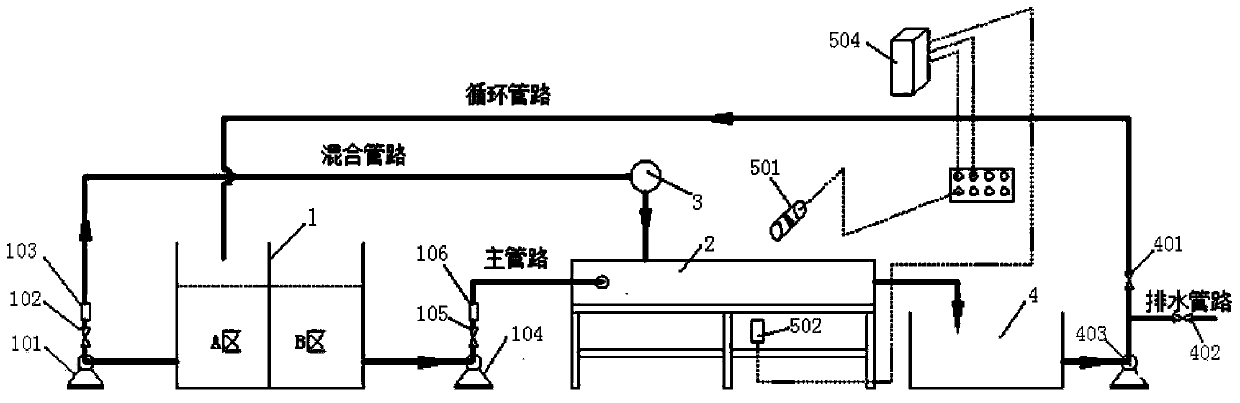

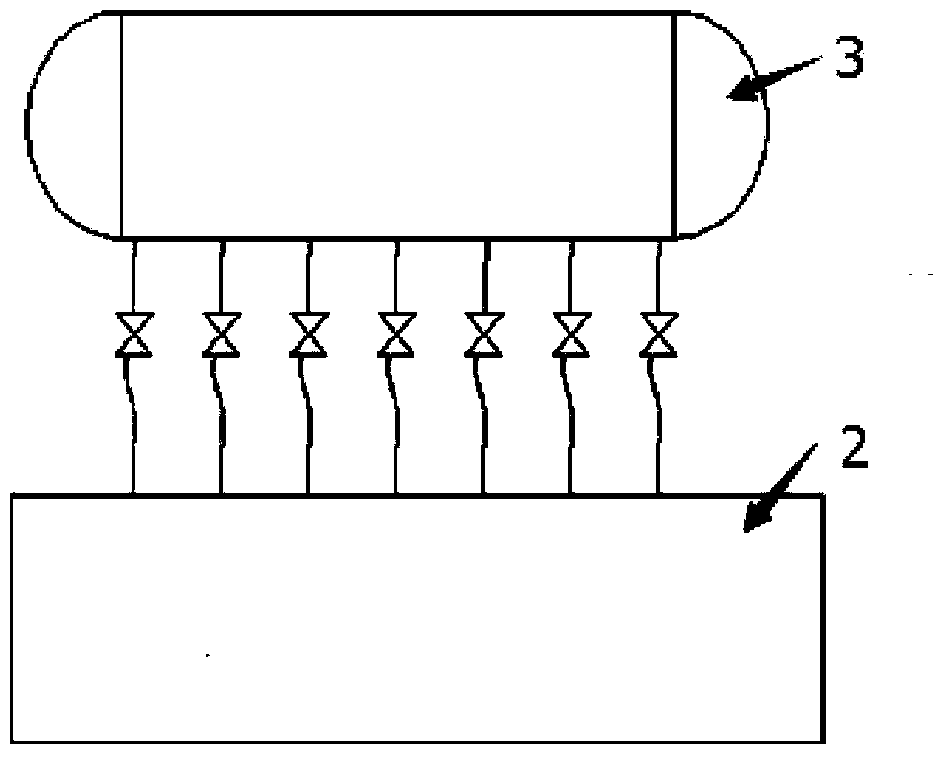

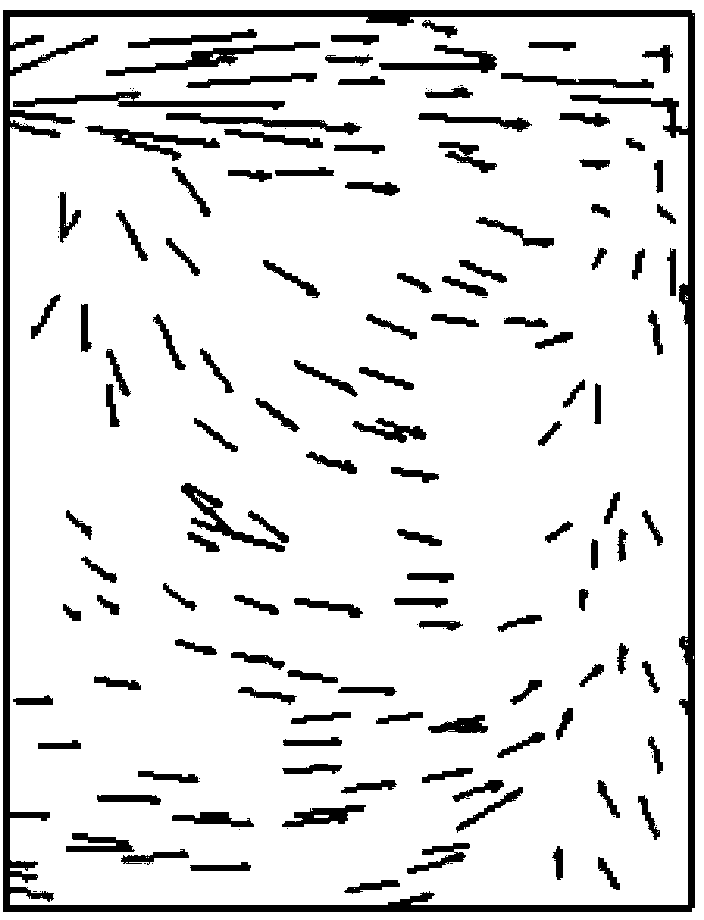

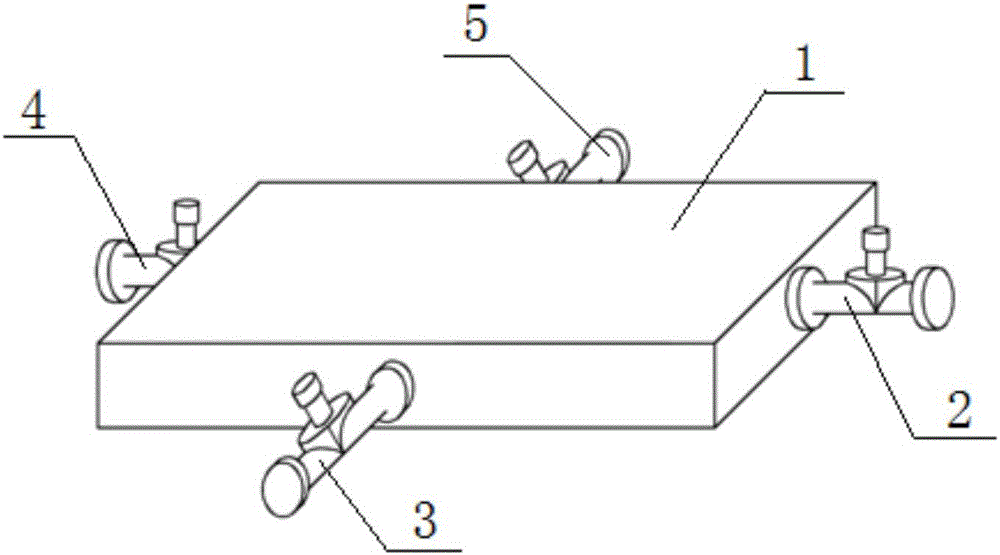

PIV (Particle Image Velocimetry)-based mixed liquid flow field and concentration measuring device and measuring method

InactiveCN104316291AFunctionalFlexibleHydrodynamic testingFluorescence/phosphorescenceWater storageSoil science

The invention belongs to the technical field of fluid measurement, and discloses a PIV (Particle Image Velocimetry)-based mixed liquid flow field and concentration measuring device, and a method of using the device for measuring the flow field or the concentration. The measuring device comprises a main water box, an experimental box body, a buffer tank, a water storage box and a PIV system, wherein the main water box is divided into an A-region box body and a B-region box body for providing liquid of a mixed pipeline and liquid of a main pipeline respectively, the liquid is mixed in the experimental box body, and measurement on the flow filed or the concentration is carried out via the PIV system. Tracer particles are sprayed in water in the main water box and the buffer tank, and the flow field of the mixed liquid is measured via the PIV system; fluorescent particles are added to the two box bodies of the main water box respectively for preparing different concentrations, and the concentration of the mixed liquid can be measured via the PIV system in combination with a LIF (Laser Induce Fluorescence) system; measurement on the mixed flow field and the mixed concentration can be carried out in the same device, water and tracer particles can be saved, and the flow field and the concentration can be detected in real time.

Owner:SOUTH CHINA UNIV OF TECH

Safety monitoring and controlling method for li-ion power battery thermorunaway and device thereof

InactiveCN107437639AChange concentrationRapid coolingCell temperature controlCells structural combinationIonChemical substance

The invention discloses a safety monitoring and controlling method for li-ion power battery thermorunaway and a device thereof. When a li-ion power battery suffers from thermorunaway, a composite medium with cooling and fire-extinguishing effects is used as a safety monitoring and controlling medium to enter a power battery box or battery tank in an injection mode. The safety monitoring and controlling medium is composed of chemical substances which are formed by C, F, H and O elements and have cooling and fire-extinguishing effects. A li-ion battery safety monitoring and controlling device based on the above safety monitoring and controlling method comprises a shell and a safety monitoring and controlling medium filling port, a pressure meter connector, a nozzle and a safety valve pressure relief opening which are arranged on the shell. The safety monitoring and controlling device can effectively prevent or reduce the li-ion battery thermorunaway risk, reduce fire probability of the li-ion battery box (tank), control and extinguish initial fire, and has functions of starting operation for many times and extinguishing re-ignited fire of the power battery box.

Owner:北京理工晋西科技有限公司

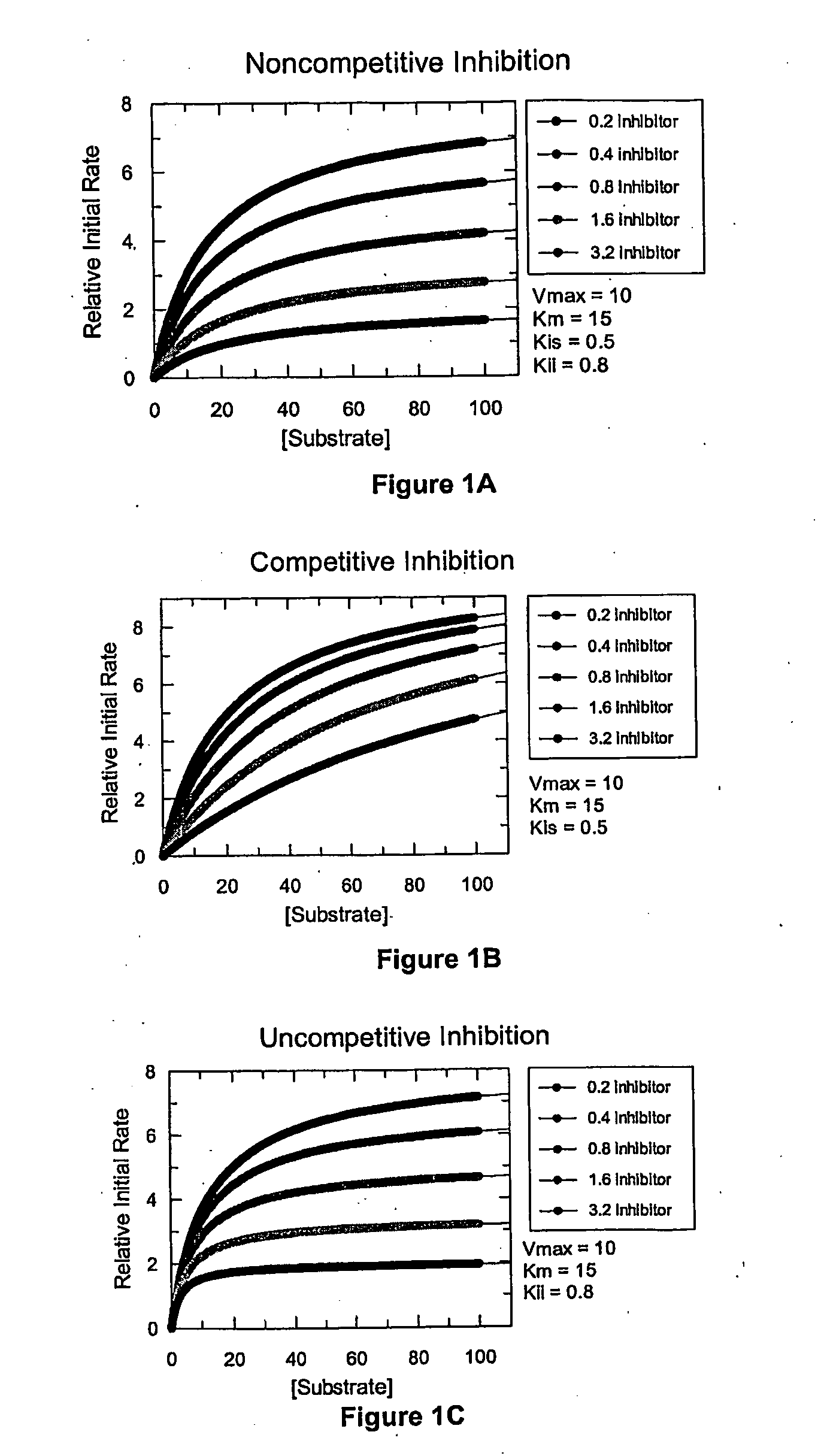

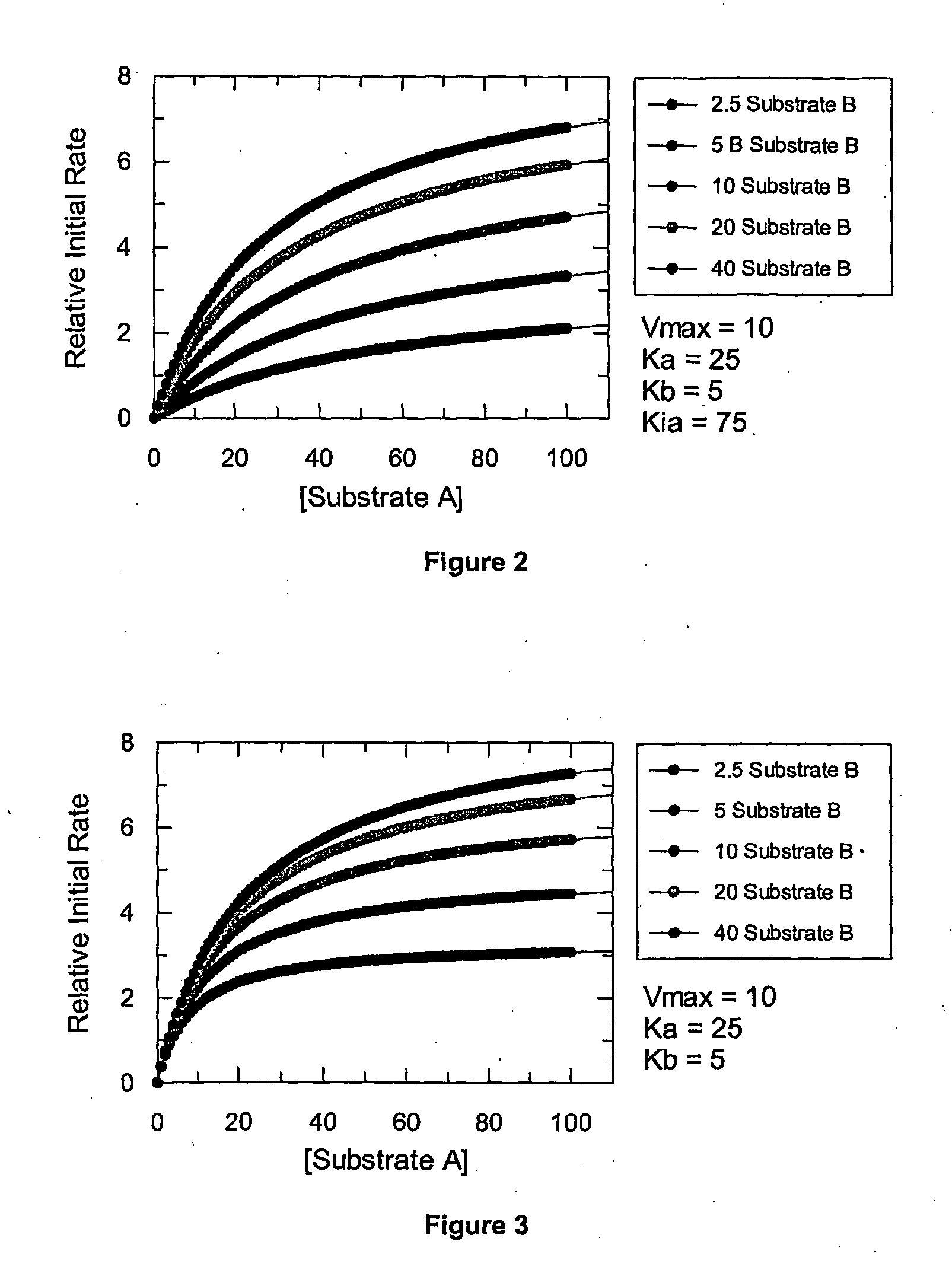

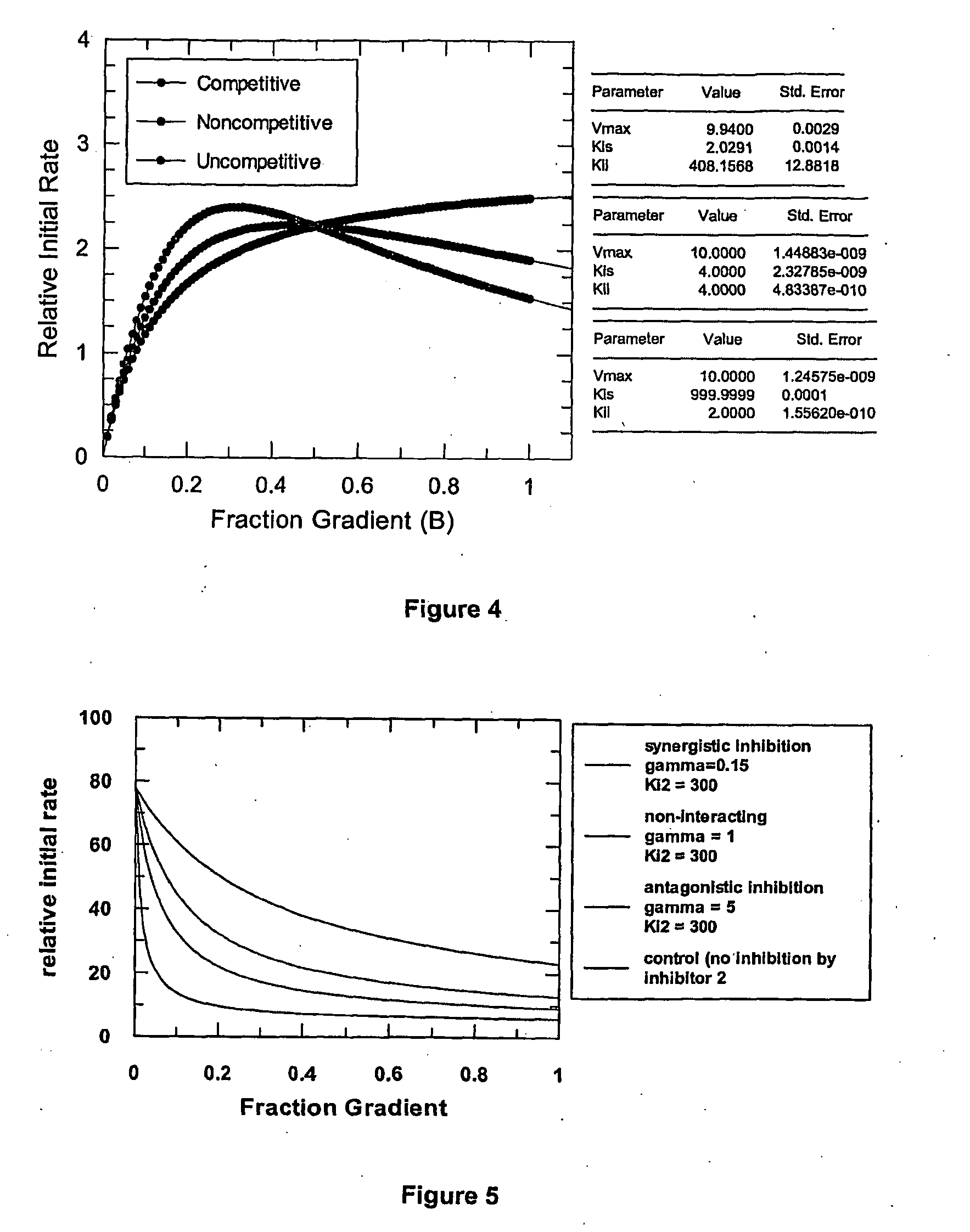

Methods for characterizing biological molecule modulators

ActiveUS20090148858A1Change concentrationConstant ratioCompound screeningApoptosis detectionConcentration gradientBiological activation

Methods for characterizing a biochemical reaction and analysis of reaction products by establishing continuously variable concentration gradients of one or more reagents of the biochemical reaction are provided. Methods for determining mechanism of inhibition or activation, potency of inhibition or activation, or both of an enzyme inhibitor or activator, respectively, are also provided. The continuously variable concentration gradients can be established in a microfluidic chip.

Owner:SCIEX

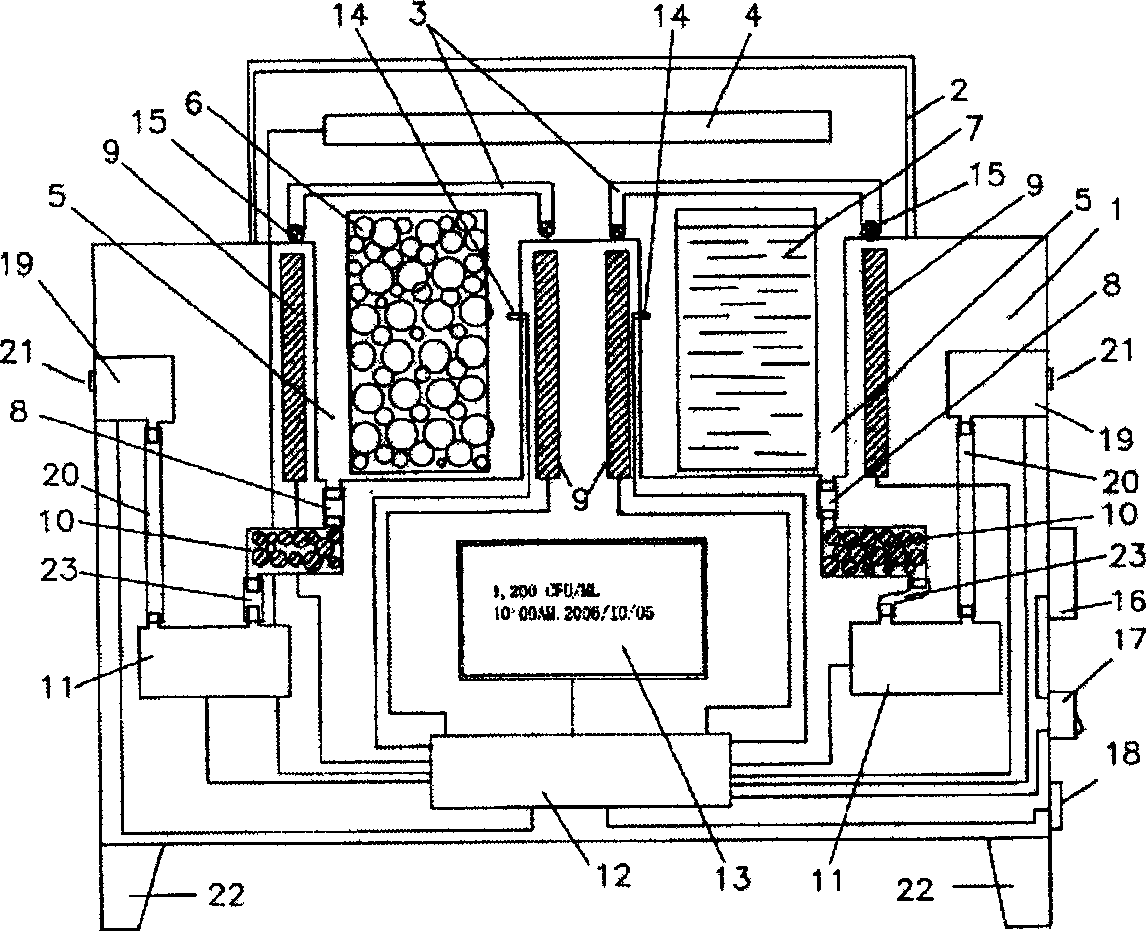

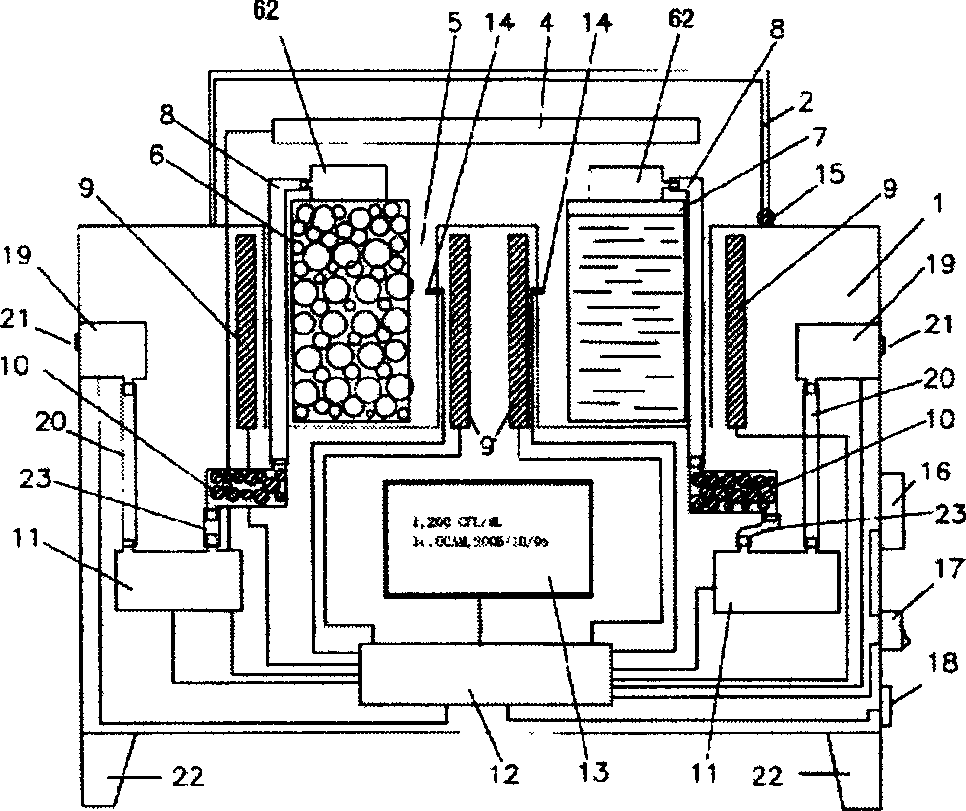

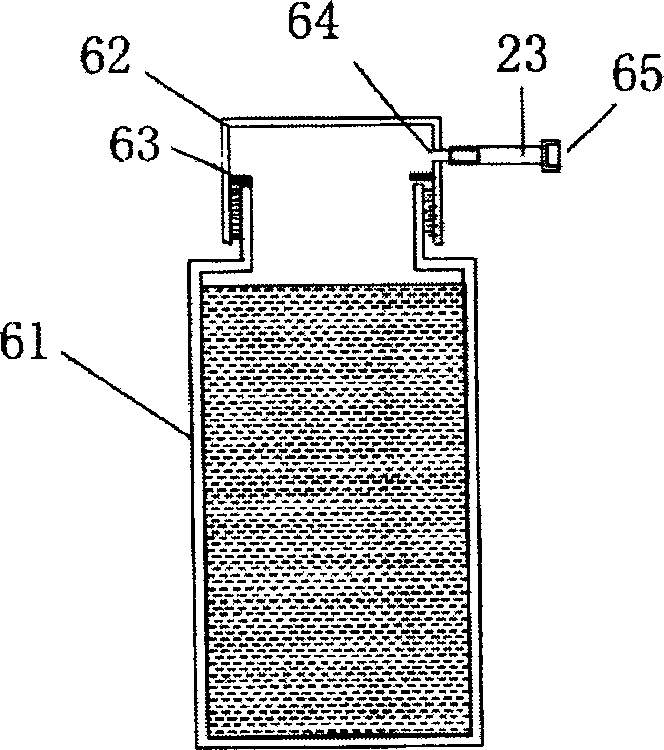

Fast detection method and instrument for microbe content in food

InactiveCN1847405AShort detection timeChange concentrationMicrobiological testing/measurementTesting foodCarbon dioxideFood sample

The fast detection method and instrument for microbe content in food has two parallel sample detecting systems adopted, including one for food sample detection and the other for detecting contrast. These two systems are in the same environment conditions and heated with the same heating element, the CO2 these two systems generate is detected separately in two identical CO2 detecting devices, and the detected data are analyzed and processed to obtain the detection result. The present invention has short detection period, simple structure, low cost and other advantages, and is suitable for fast site detection.

Owner:何宗彦

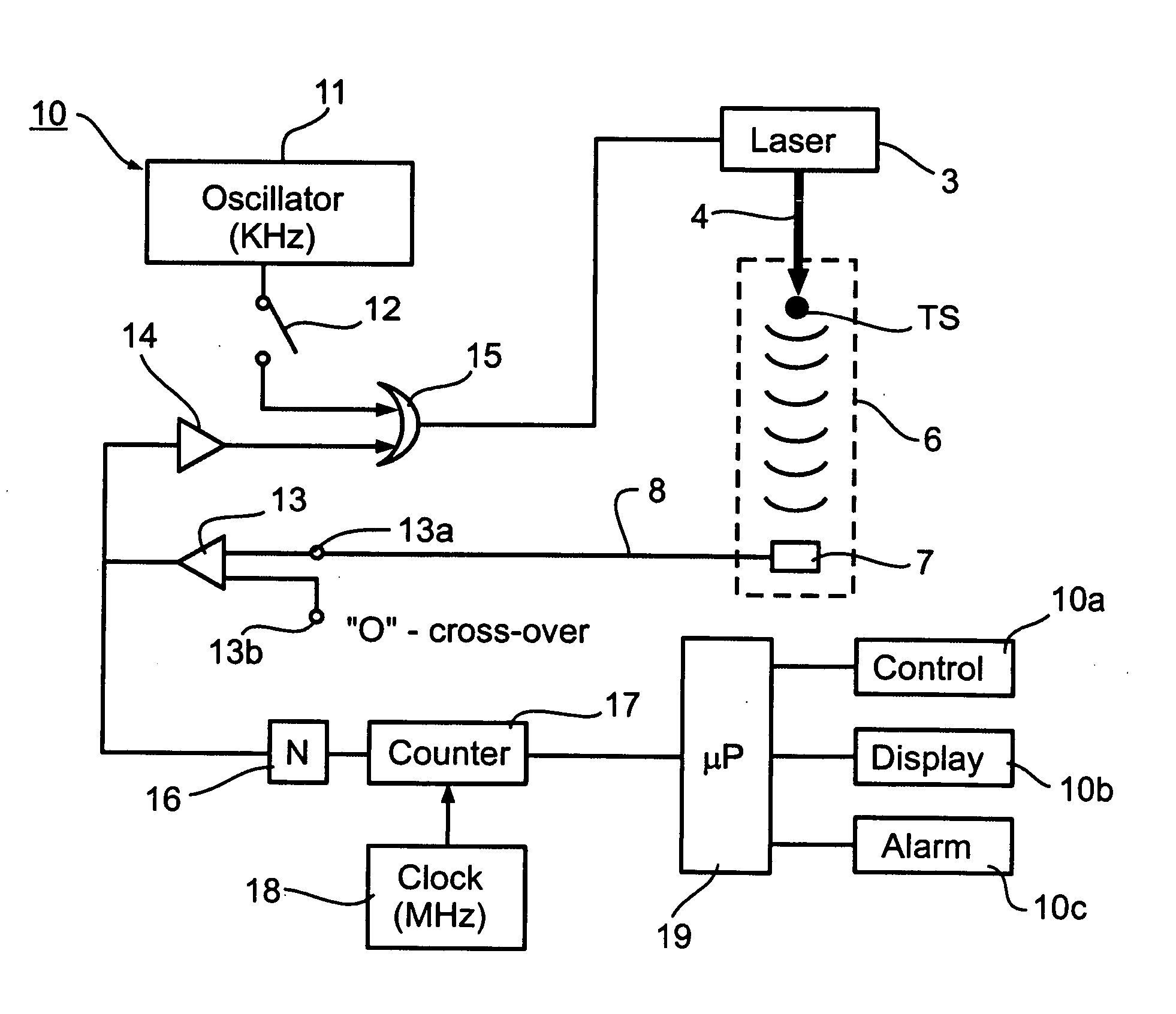

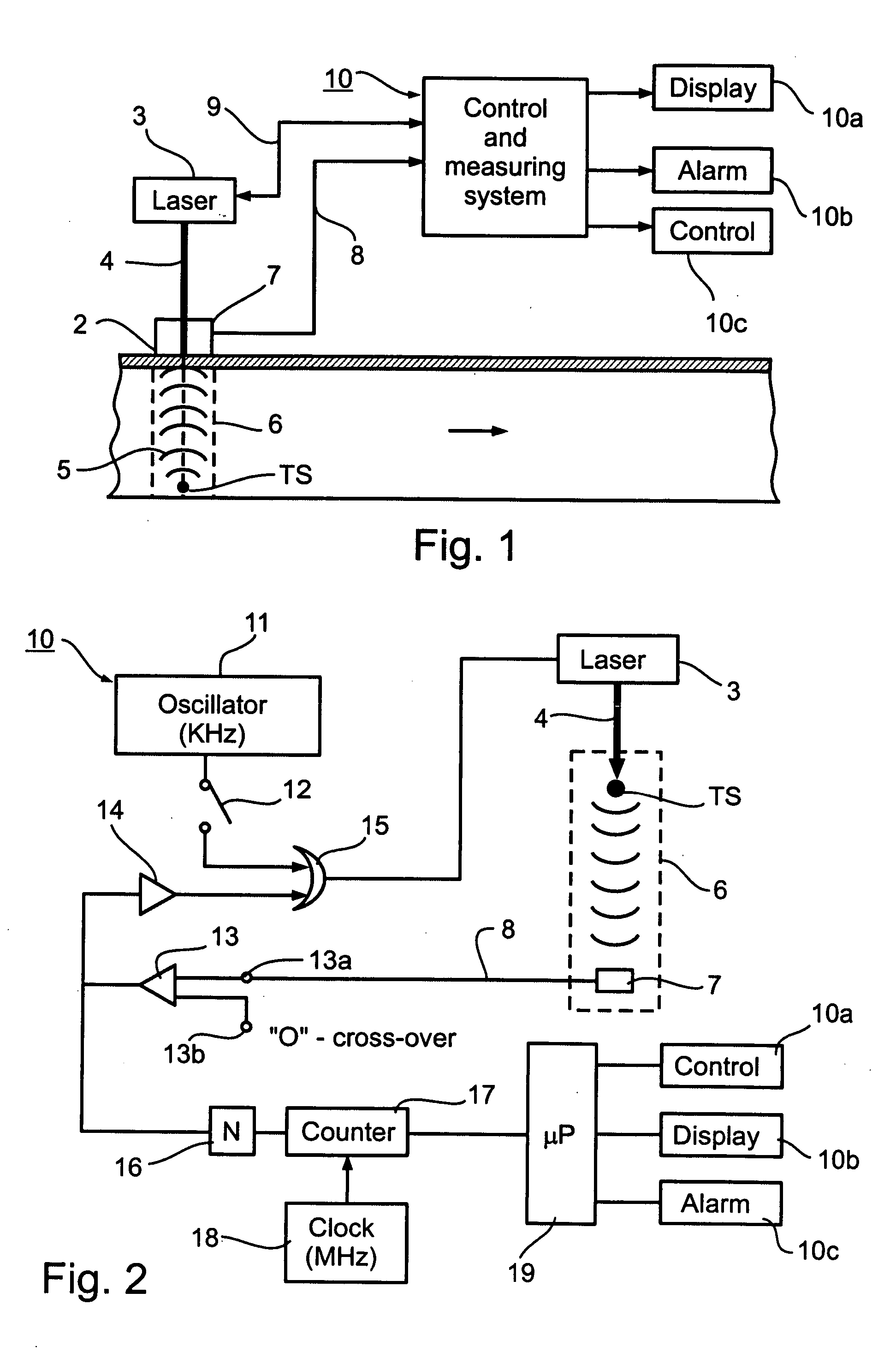

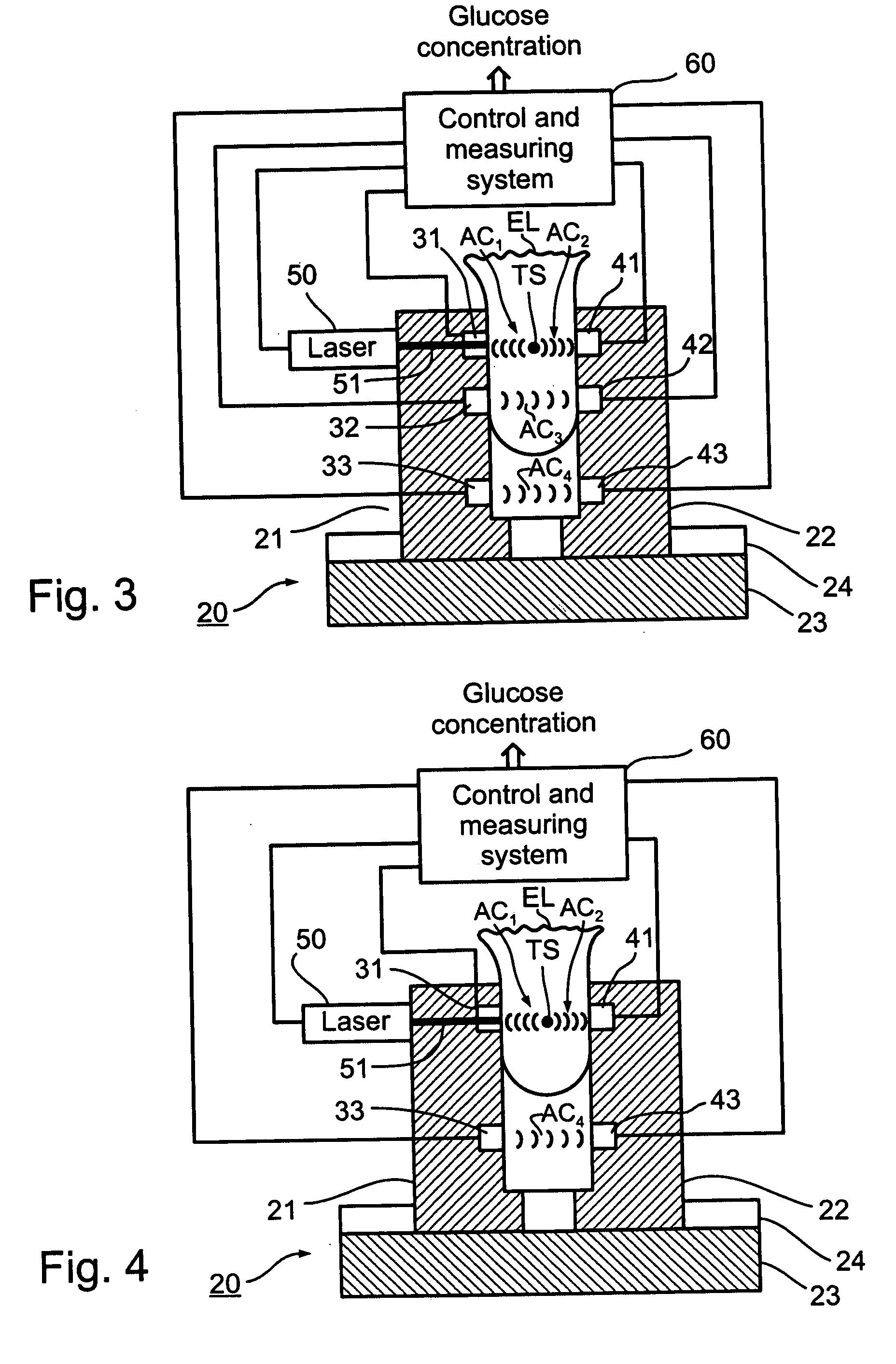

Method and apparatus for non-invasively monitoring concentrations of glucose or other target substances

InactiveUS20050272990A1Improve accuracyImprove reliabilityAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesMedicineAcoustic wave

A method and apparatus for non-invasively measuring concentration of a target substance such as glucose within a body by: activating a pulse source to apply to the body a series of pulses of energy highly absorbable by the target substance to generate, by the photoacoustic effect, a series of acoustic waves propagated through an acoustic channel in the body; detecting the acoustic waves to produce an electrical signal having a frequency corresponding to the frequency of the acoustic waves generated by the photoacoustic effect; controlling the pulse source to change the frequency at which the energy pulses are applied to the body such that the detector detects a whole integer number of wavelengths in the acoustic channel irrespective of variations in the target substance concentration within the body; and utilizing a measurement of the frequency, or change in frequency, of the pulses to produce a measurement of the concentration, or change in concentration, of the target substance.

Owner:NEXENSE

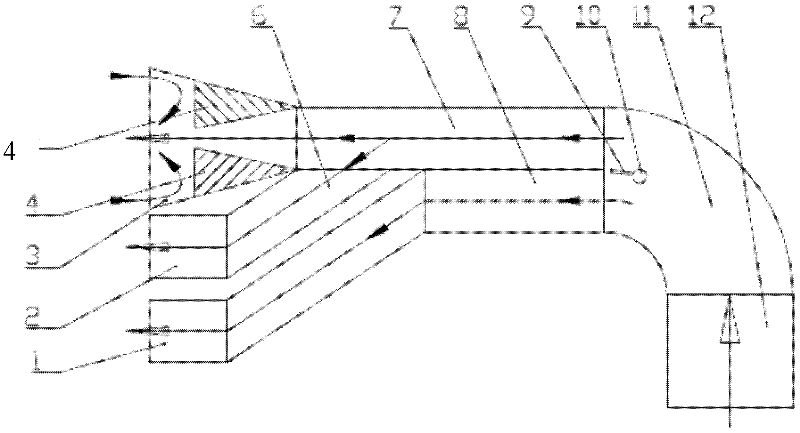

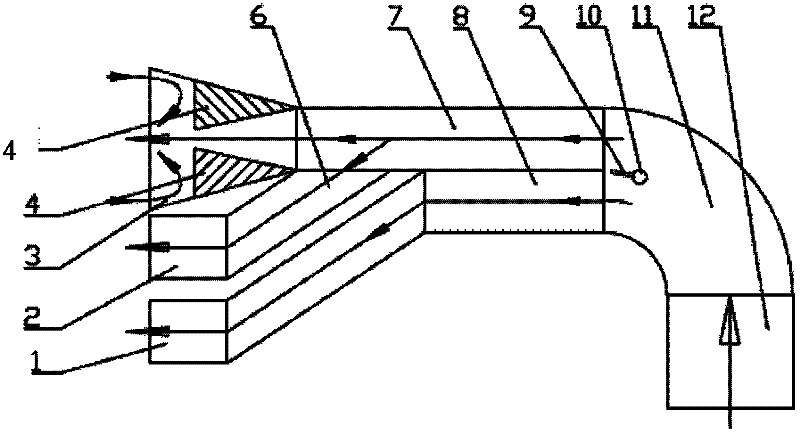

Pulverized coal decoupling combustor and decoupling combustion method thereof

InactiveCN102297425AMeet or exceed concentration efficiencyOver concentration efficiencyPulverulent fuel combustion burnersCombustorGuide tube

The invention relates to a pulverized coal decoupling combustor and a decoupling combustion method thereof. The decoupling combustor comprises a first-stage air duct (12), an inertia separator (11), air current conduits and a spout which are sequentially connected along the air current direction, wherein the air current conduits comprise a dense side air current conduit (7) and a fresh side air current conduit (8); the fresh side air current conduit (8) is communicated with a third-stage spout (1); the dense side air current conduit (7) is connected with a first-stage spout (3); a second-stage spout conduit (6) communicated with the dense side air current conduit (7) is led out of a pipeline between the dense side air current conduit (7) and the first-stage spout (3) on the dense side aircurrent conduit (7); the second-stage spout conduit (6) is communicated with a second-stage spout (2); the first-stage spout (3) is a gradually-increasing spout; a pair of pulverized coal collecting flame stabilizing devices (4) is oppositely arranged at the upper side and the lower side inside the front end of the first-stage spout (3); the cross sections of the pulverized coal collecting flame stabilizing devices (4) along the air current direction is gradually increased; and the area of the cross section of an air current channel is decreased along the air current direction, thus the coupling combustion is realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

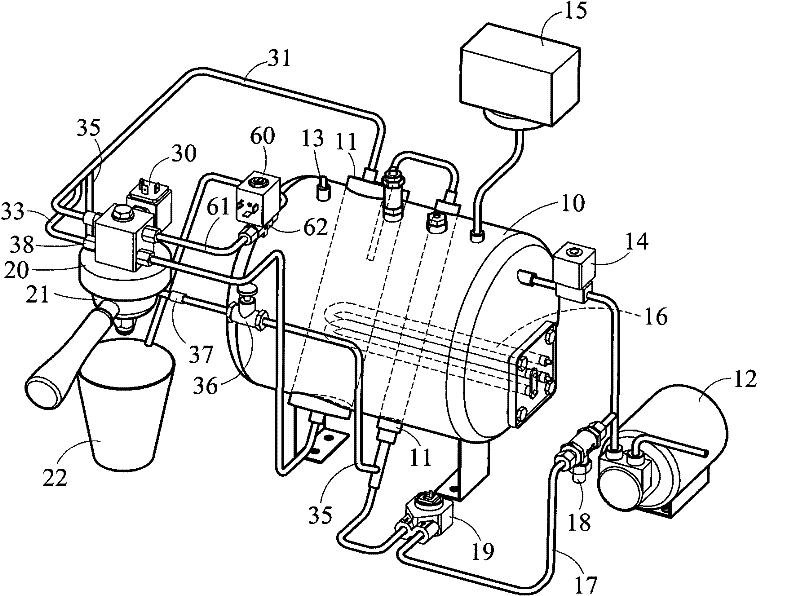

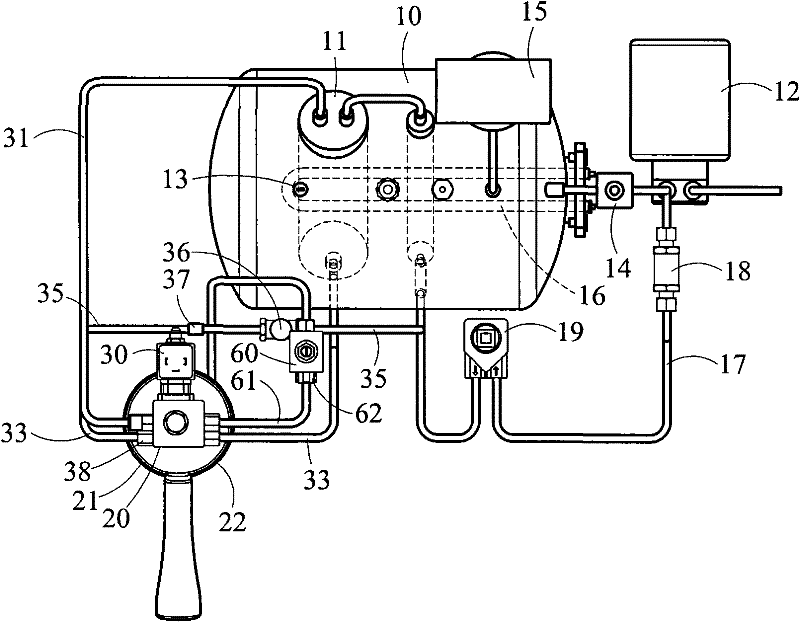

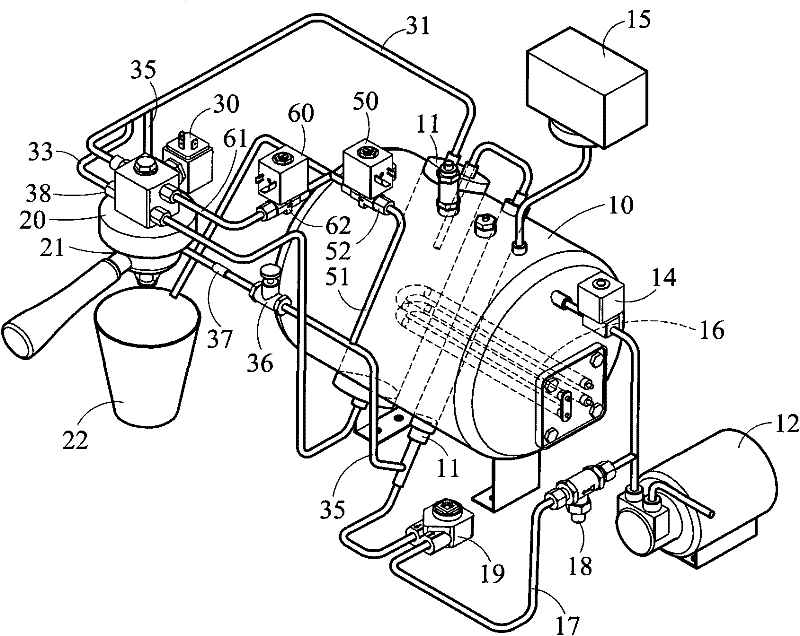

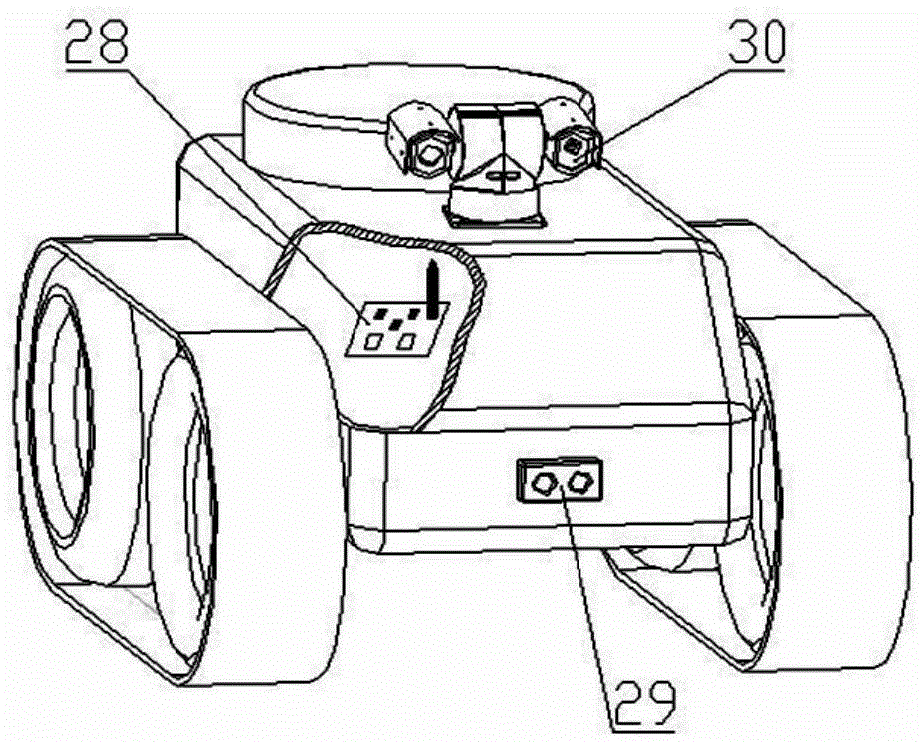

Drink preparation device

The invention discloses a drink preparation device, belonging to the field of machinery. The drink preparation device is mainly used for blending overheated hot water in a hot water pipe with cold water of a set flow rate in a cold water pipe to form a blended water flow with suitable temperature, and transmitting the blended water flow into a liquid dispenser. When a brewing solenoid valve is controlled to be opened, the liquid dispenser dispenses the blended water flow with suitable temperature to a preparation container in which drink components are previously provided so as to prepare drink from the drink components; and when the brewing solenoid valve is controlled to be closed, the liquid dispenser dispenses the blended water flow with suitable temperature to a hot water feeding pipe, and the blended water flow with suitable temperature is directly fed into the drink when a hot water feeding solenoid valve is controlled to be opened. When the brewing solenoid valve and the hot water solenoid valve are both closed, the hot water in a heat exchanger volatiles, passes through a preheating circulation line, and returns to a heat exchanger after being preheated by the liquid dispenser so as to form a preheating circulation.

Owner:刘宗熹

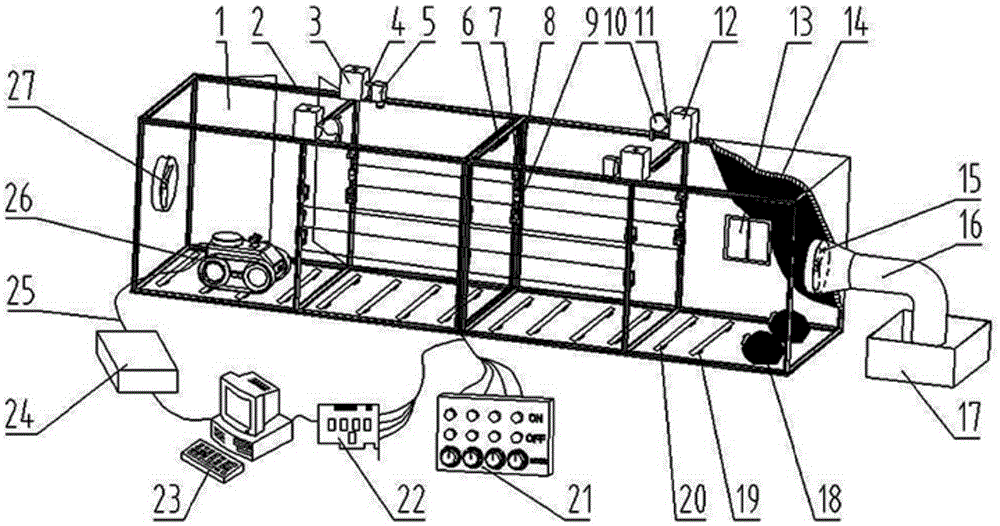

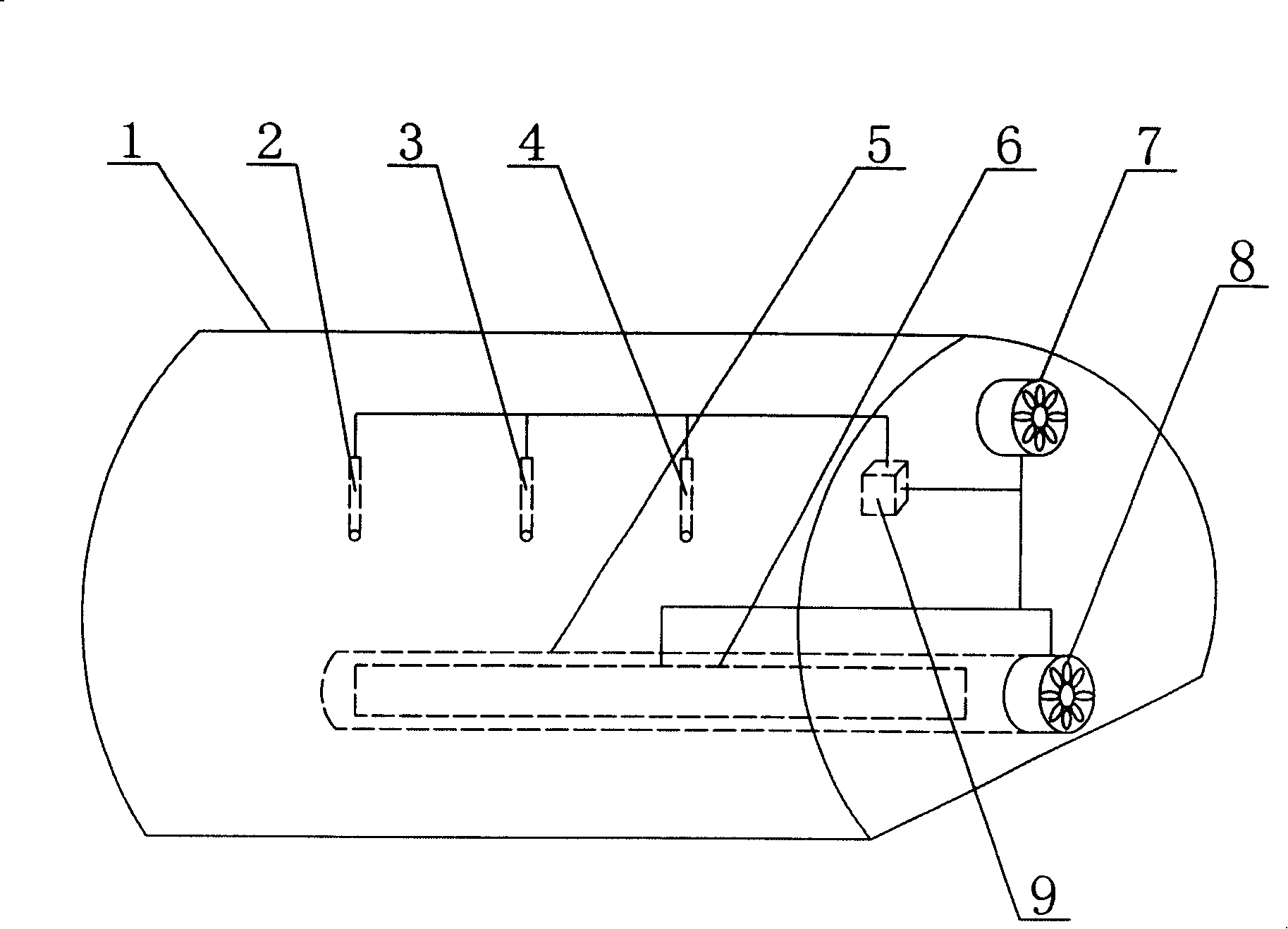

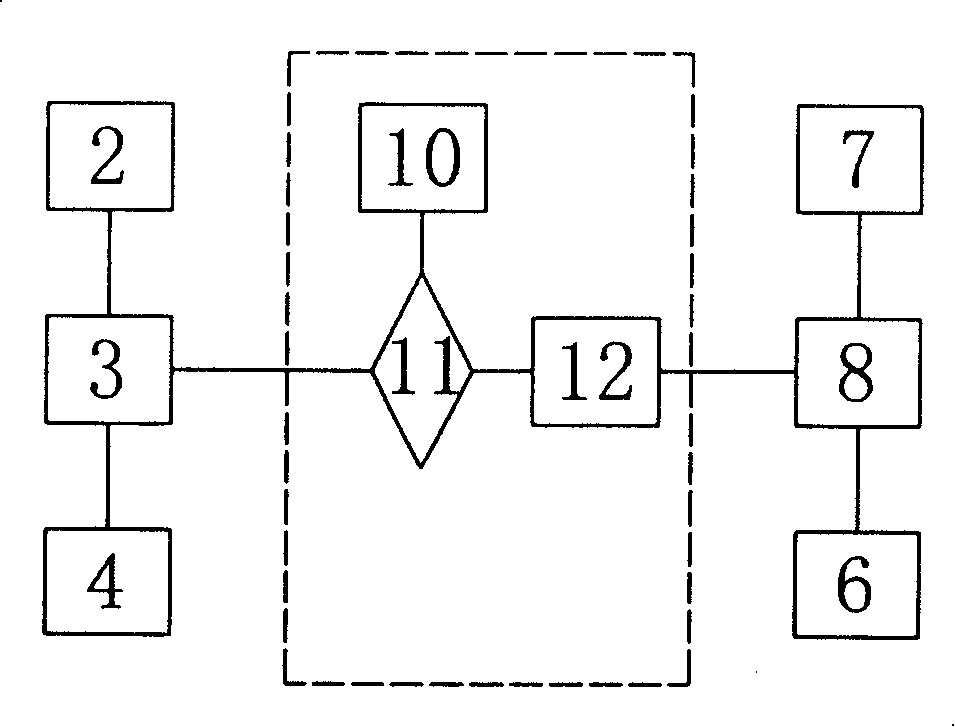

Robot vision experiment environment system based on coal mine tunnel

The invention discloses a robot vision experiment environment system based on a coal mine tunnel. The robot vision experiment environment system comprises a closed box structure made of a steel framework. A channel in the length direction of the closed box structure is used as a working channel of a robot. Pressure plates are arranged on the bottom surface of the working channel at intervals. Pressure detection sensors are arranged below the pressure plates. A barrier is arranged on the bottom surface of the working channel based on experiment requirements. A dust generation system, an illumination system, an air humidification system and a dedusting and dehumidifying system are used for changing the dust concentration, environmental illumination and air humidity in the working channel. A distance between a robot vision device and the barrier is changed by moving the robot. The coal mine tunnel condition can be really reflected, and by changing the dust concentration, air humidity, environmental illumination and the distance between a camera and the barrier, influences of the abovementioned factors on barrier image identification by a coal mine rescue robot can be tested, so that a research experiment platform is provided for achieving underground autonomous navigation of the coal mine rescue robot.

Owner:CHINA UNIV OF MINING & TECH

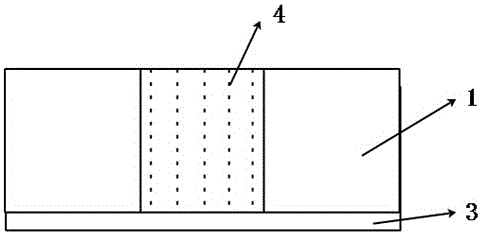

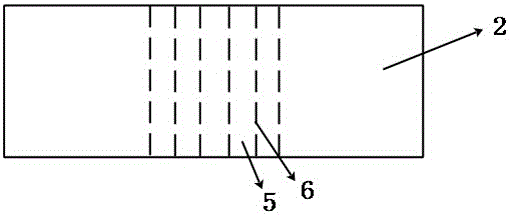

Cigarette filter enabling users to freely select ventilation rate

InactiveCN105768214AImprove recognitionEasy to implementTobacco smoke filtersPaper sheetSmooth surface

The invention relates to a cigarette filter enabling users to freely select ventilation rate. A cigarette filter strand fiber is formed by being wrapped by forming paper, and then is wrapped with tipping paper. The tipping paper has two layers, the tipping paper in contact with the forming paper of the filter is inner layer tipping paper, and the layer outside the inner layer tipping paper is outer layer tipping paper. The inner layer tipping paper is provided with a regular punching area at the middle section, and the surface of the area in contact with the outer layer tipping paper is a smooth surface containing a film. The outer layer tipping paper is provided with adhesive tape strips torn respectively repeatedly at the punching area corresponding to the inner layer tipping paper, and the inner side of the outer layer tipping paper in contact with the punching area of the inner layer tipping paper is coated with adhesive. Adhesive can be torn conveniently, original air holes in the inner layer tipping paper are exposed, and thus the ventilation rate of the filter is changed. The effect of adjusting smoke concentration is achieved finally, and different satisfaction feelings on cigarette smoke are achieved.

Owner:CHINA TOBACCO YUNNAN IND

Ventilating dehumidifier for greenhouse

InactiveCN101189950AAdvanced technologyGood value for moneyClimate change adaptationSaving energy measuresCarbon fibersEngineering

The invention pertains to the field of agricultural machinery, in particular to a mechanical ventilation dehumidifier used for plastic houses and greenhouses, which consists of air supply fans, air supply channels, a control device, a testing device and exhaust fans. Heaters are arranged in the air supply channels; the control device consists of switching groups, single board computers or control machines; the testing device comprises a thermometer, a hygrometer and a carbon dioxide analyzer; the heaters take fiber material as a heating body; the air supply fans and the exhaust fans use switched reluctance motors. By using sunlight shed chambers that are generally used at present, adopting advanced carbon fiber material as the heating body and being driven by switched reluctance motors with high efficiency and energy saving, the invention can realize double-machine synchronization, so as to achieve the purposes of energy saving with high heat efficiency, stability, reliability, and being free of maintenance, thus being capable of adjusting indoor humidity and air conditions. The invention can be broadly applied to sunlight sheds and livestock and poultry greenhouses.

Owner:张兆勘

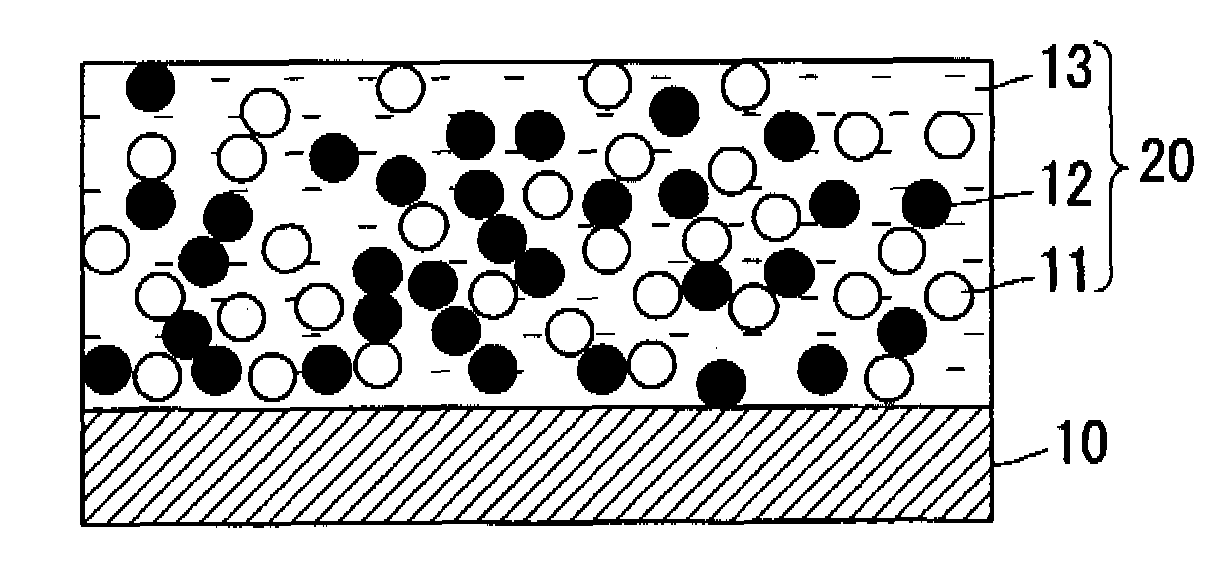

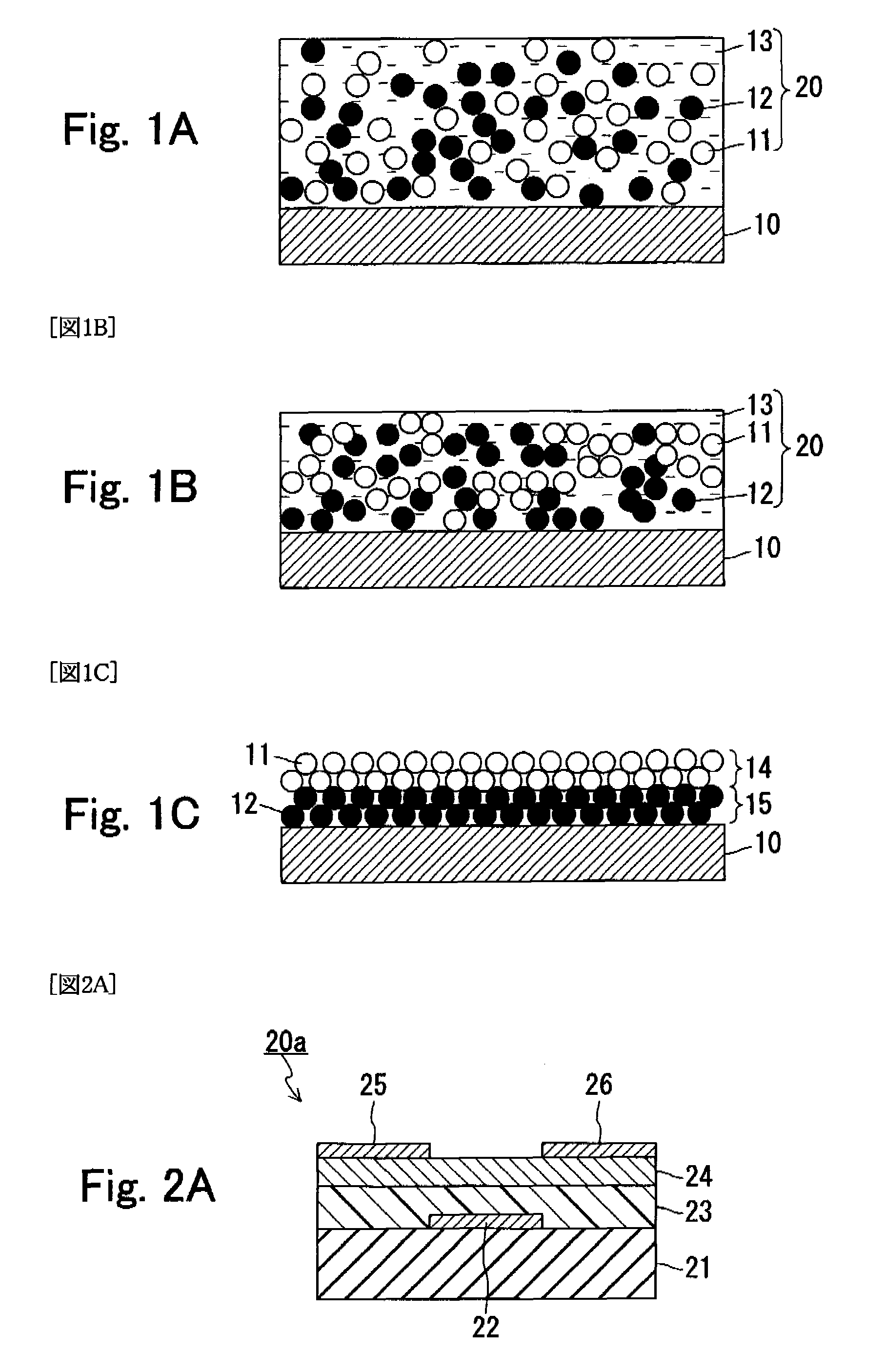

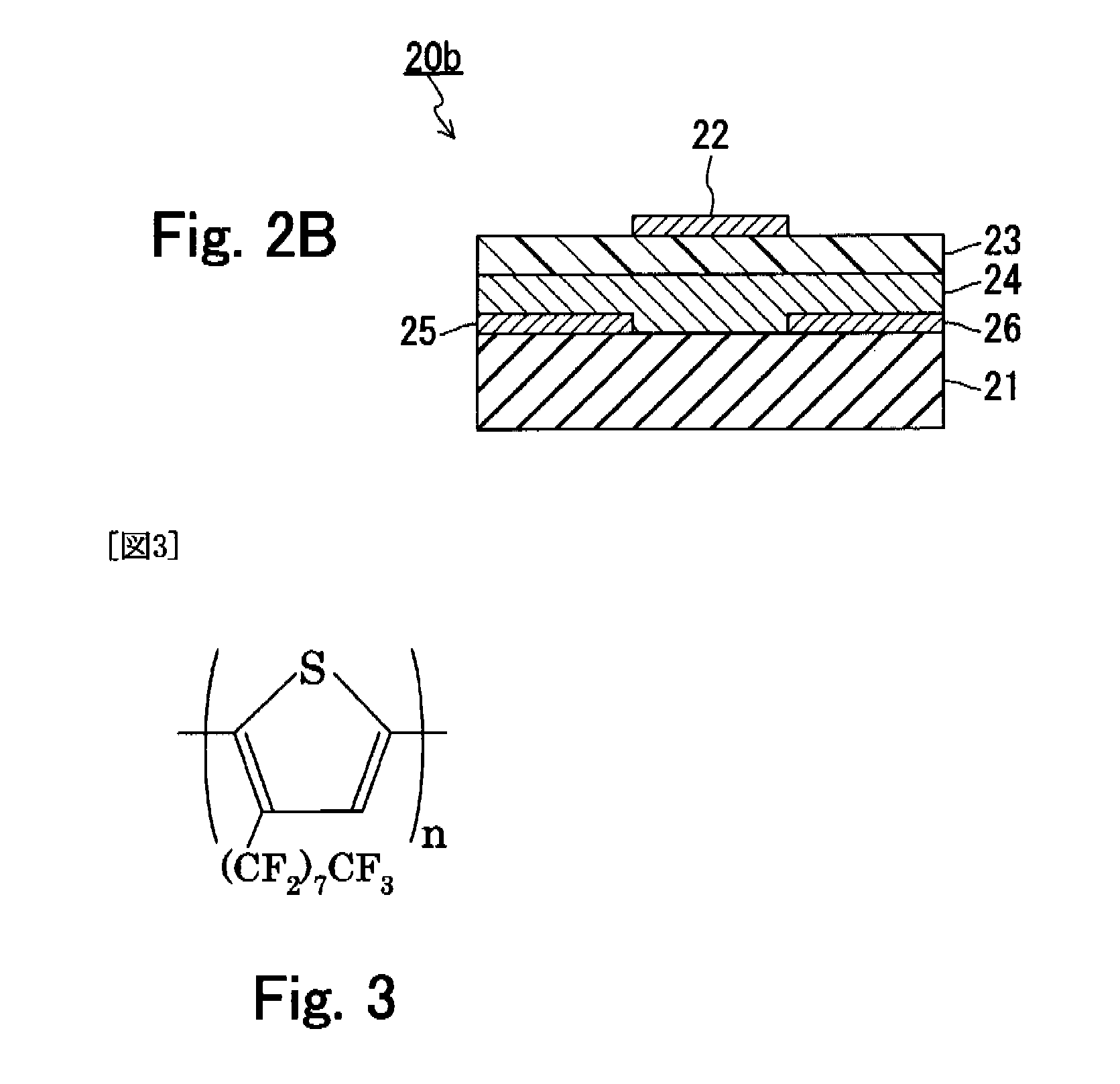

Coating liquid for forming organic layered film, method of manufacturing field effect transistor, and field effect transistor

InactiveUS20070215902A1High carrier mobilityChange concentrationSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsField-effect transistor

A method of manufacturing a field effect transistor of the present invention includes: applying a coating liquid 20 containing a solvent 13 as well as first and second organic molecules 11 and 12 that have been dissolved in the solvent 13; and forming a first layer and a second layer by removing the solvent 13 contained in the coating liquid 20 that has been applied. The first layer contains the first organic molecules 11 as its main component. The second layer adjoins the first layer and contains the second organic molecules 12 as its main component. The first organic molecules 11 are a semiconductor material or a precursor of a semiconductor material. The second organic molecules 12 are an insulator material or a precursor of an insulator material. The first organic molecules 11 and the second organic molecules 12 are not compatible with each other.

Owner:PANASONIC CORP

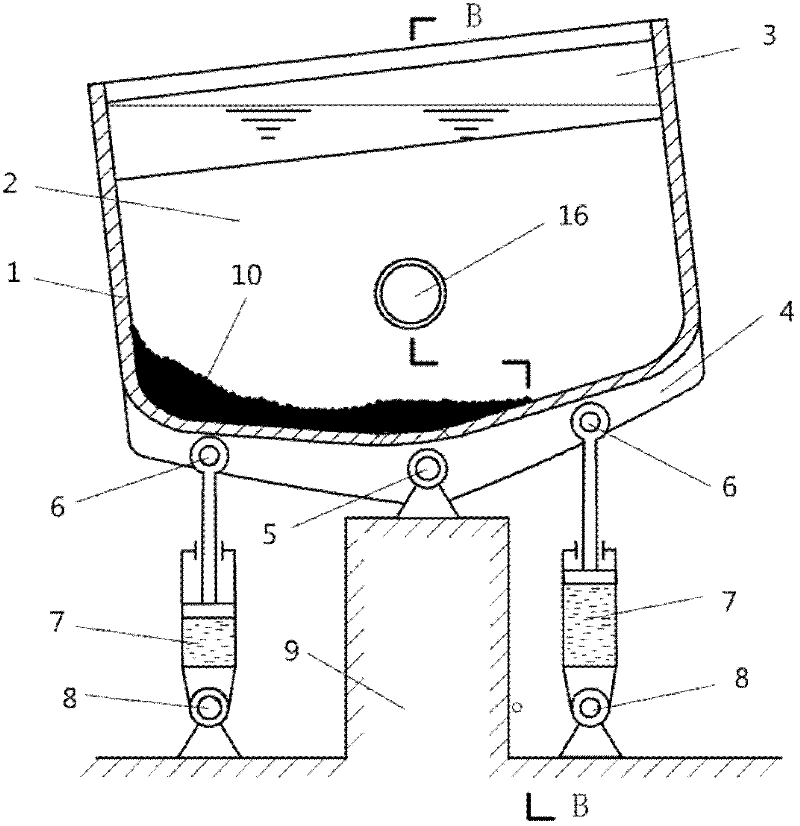

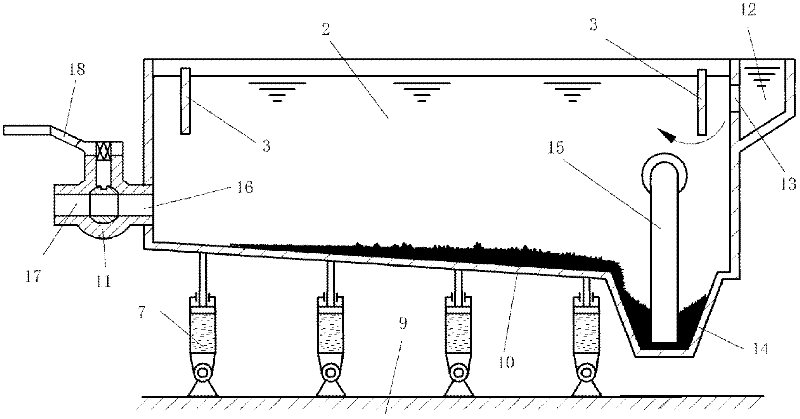

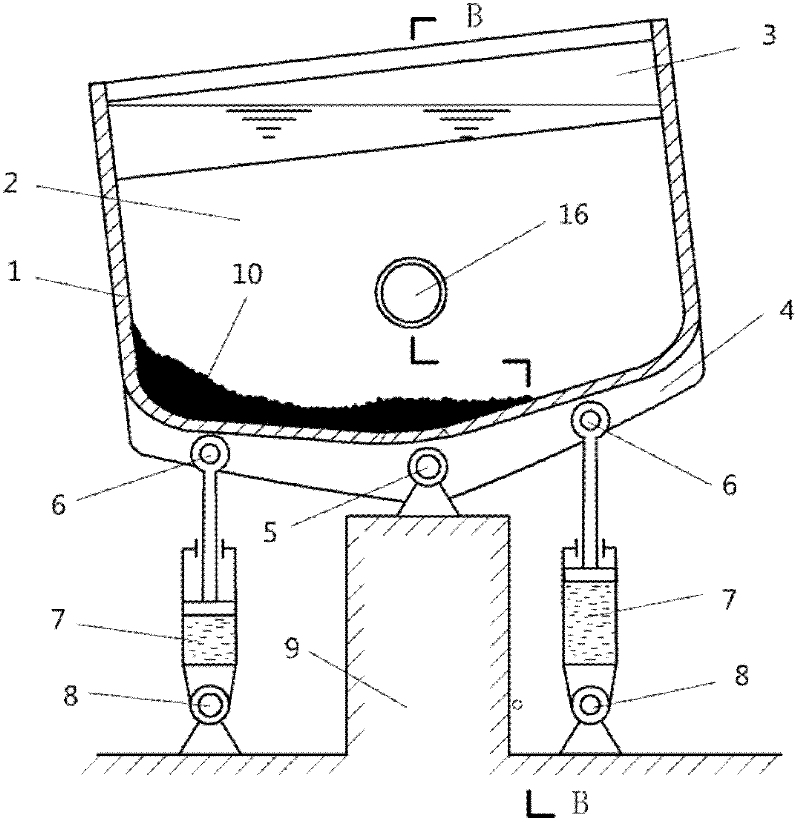

Oscillatory type sewage sedimentation basin and operation method thereof

InactiveCN102350099AChange stateChange concentrationSedimentation settling tanksSettling device inclination controlResonance oscillationFlocculation

Provided is an oscillatory type sewage sedimentation basin, which utilizes a tilting system to tilt a movable basin, so as to generate gradient tangential deformation and resonance on raw water, promote a flocculation reaction and improve sewage treating effect, and an operation method thereof. The movable sedimentation basin is jointed with a pedestal hinge and can tilt around the hinge under a tilting operation of the tilting system. When sewage reaches a destabilization critical state, the tilting mechanism is started to tilt the movable basin to generate gradient tangential deformation on the raw water and promote the flocculation reaction. A basin tilting period is controlled to generate resonance oscillation on the raw water. The resonance promotes fully conduction of the flocculation reaction, so as to purify the raw water repeatedly, separate the settlement thoroughly and reduce suspensions. The settlement progress consumes a short time and energy, has good effect and low costs and is green, environment-friendly and easily operated.

Owner:韦志锋 +1

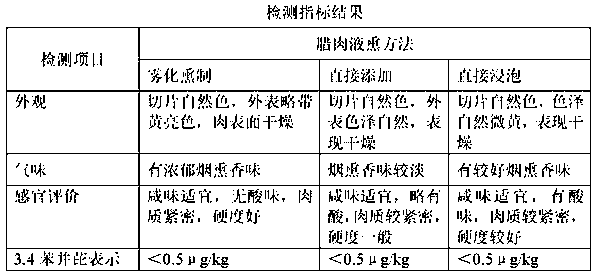

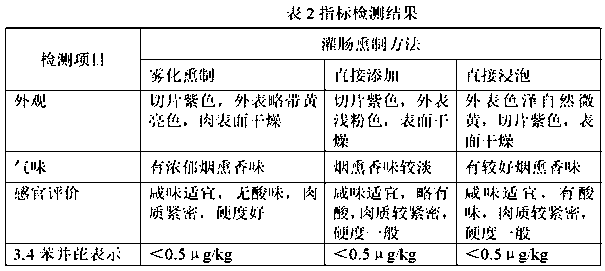

Method for atomization smoke curing of meat products by liquid smoke

InactiveCN107668553AEasy to solveImprove texture qualityFood scienceLiquid smokeUltrasonic atomization

The invention relates to a method for atomization smoke curing of meat products by liquid smoke. According to the method, after pre-roasting of the meat products, a high-and low-frequency ultrasonic alternate atomization process is combined with a hermetic and ventilated smoke curing combined process to realize atomization smoke curing of to-be-smoked meat products, and the smoked products subjected to smoke curing with the liquid smoke have strong smoke curing flavor, and the benzopyrene content is smaller than or equal to 0.5 microgram / kg. By ultrasonic atomization of the liquid smoke, the meat products are smoked by mist droplets of the liquid smoke, and the problem of texture quality decline of the products due to direct adding of the liquid smoke and long-time soaking of the meat products is avoided. In addition, by smoke curing of the meat products with the liquid smoke atomized through an ultrasonic device, high flavor and color stability of the products can be guaranteed.

Owner:HEFEI UNIV OF TECH

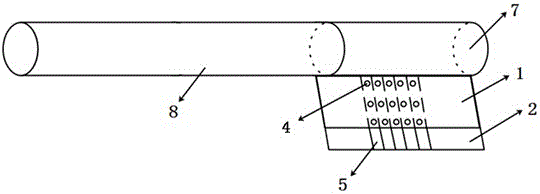

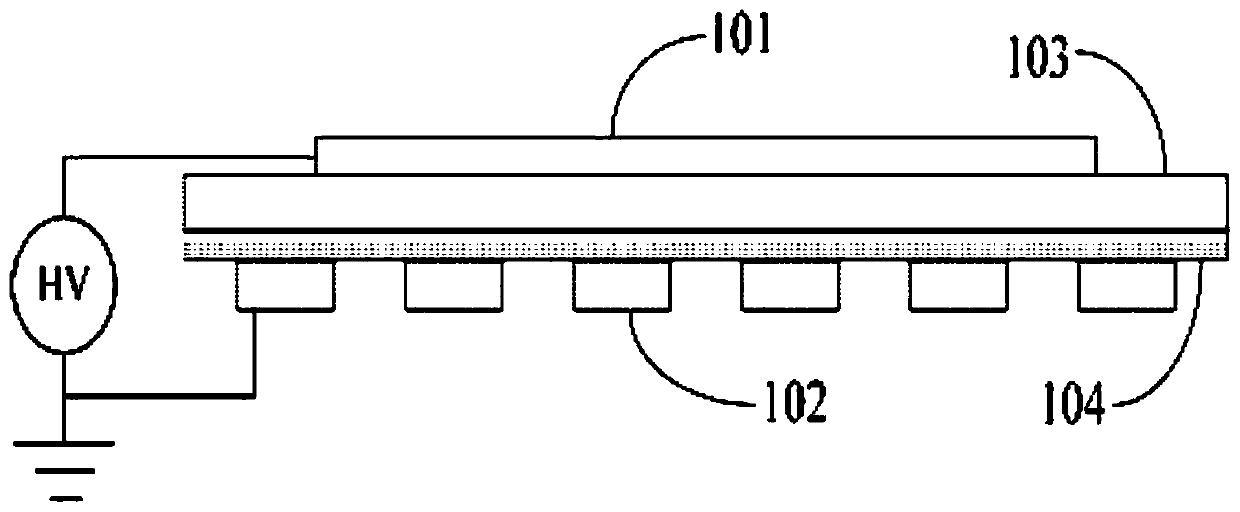

Surface discharge plasma device

The invention discloses a surface discharge plasma device formed by a combined dielectric material. The surface discharge plasma device comprises a high-voltage electrode, a ground electrode and a combined dielectric layer, wherein the high-voltage electrode is of a flat-plate structure; the ground electrode is of a strip-shaped structure; the combined dielectric layer comprises an aluminum oxideceramic layer and a polytetrafluoroethylene layer which are stacked; the high-voltage electrode is tightly attached to the aluminum oxide ceramic layer; the ground electrode is tightly attached to thepolytetrafluoroethylene layer; and when the high-voltage electrode is excited by a high-voltage power supply, the ground electrode generates a discharge plasma distributed along the surface of the ground electrode.

Owner:XI AN JIAOTONG UNIV

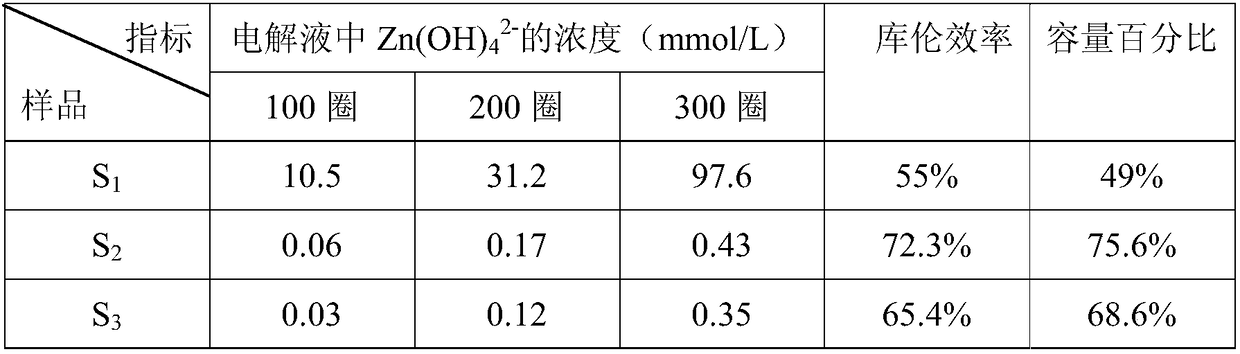

Negative electrode material of zinc-based secondary batteries and preparation method thereof

InactiveCN108288695AChange wrappingCoated evenlyAlkaline accumulatorsCell electrodesResin coatingMetal particle

The invention relates to a negative electrode material of zinc-based secondary batteries and a preparation method thereof. According to the method, a modification reagent is added to make positive charges evenly distributed on the surface of zinc oxide, cationic resin uniformly coats zinc oxide through electrostatic adsorption, and the thickness is 5-50 nm. The zinc oxide coated with the cationicresin is put into a mixed metal salt solution and stirred, metal ions are uniformly adsorbed in a cationic resin coating layer, and a reducing agent is added to make the metal ions reduced to metal elementary substances of 3-7 nm. The cationic resin coating the zinc oxide can effectively inhibit Zn(OH)42- from diffusing into an electrolyte solution and prevent or release the deformation and dendrite growth of zinc negative electrodes in charging and discharging circulation; nanoscale metal particles adsorbed in the cationic resin layer can improve hydrogen evolution overpotential and coulombicefficiency and reduce hydrogen evolution corrosion and dendrite growth. By means of the method, the cycle performance of the zinc negative electrodes can be improved, and the marketization of the zinc-based secondary batteries is facilitated.

Owner:CENT SOUTH UNIV

Combination antihypertensive wafer

InactiveCN101472557AEfficient use ofPrecise coordinationOrganic active ingredientsPharmaceutical delivery mechanismDepressantTherapeutic treatment

The present invention relates to a planar-shaped drug preparation that quickly dissolves or decomposes in an aqueous environment, for the application of active ingredient combinations for the treatment of hypertension, wherein the drug preparations contain at least two active ingredients that are suitable for the treatment of hypertension, and wherein the antihypertensive drug is selected from the group that encompasses beta receptor blockers, alpha receptor blockers, calcium antagonists, ACE inhibitors, AT1 antagonists, centrally acting antihypertensive drugs, direct vasodilators, and diuretics. The present invention also relates to the use of active ingredient combinations according to the invention for the production of an oral drug preparation for the treatment of high blood pressure, to a method for the therapeutic treatment of hypertension, and to a method for the production of a planar-shaped drug preparation.

Owner:LTS LOHMANN THERAPIE-SYST AG

Process for removal of pentavalent arsenic from water

InactiveCN1262665AEffective and economical removalEfficient separationOrganic anion exchangersWater contaminantsPyridiniumAqueous solution

A process for the separation of pentavalent arsenic from an aqueous solution using an N-alkyl pyridinium-containing adsorption medium is disclosed. An oxidizing medium and process for the oxidation of trivalent arsenic to pentavalent arsenic with removal of the pentavalent arsenic so formed is also disclosed.

Owner:AFFINITI

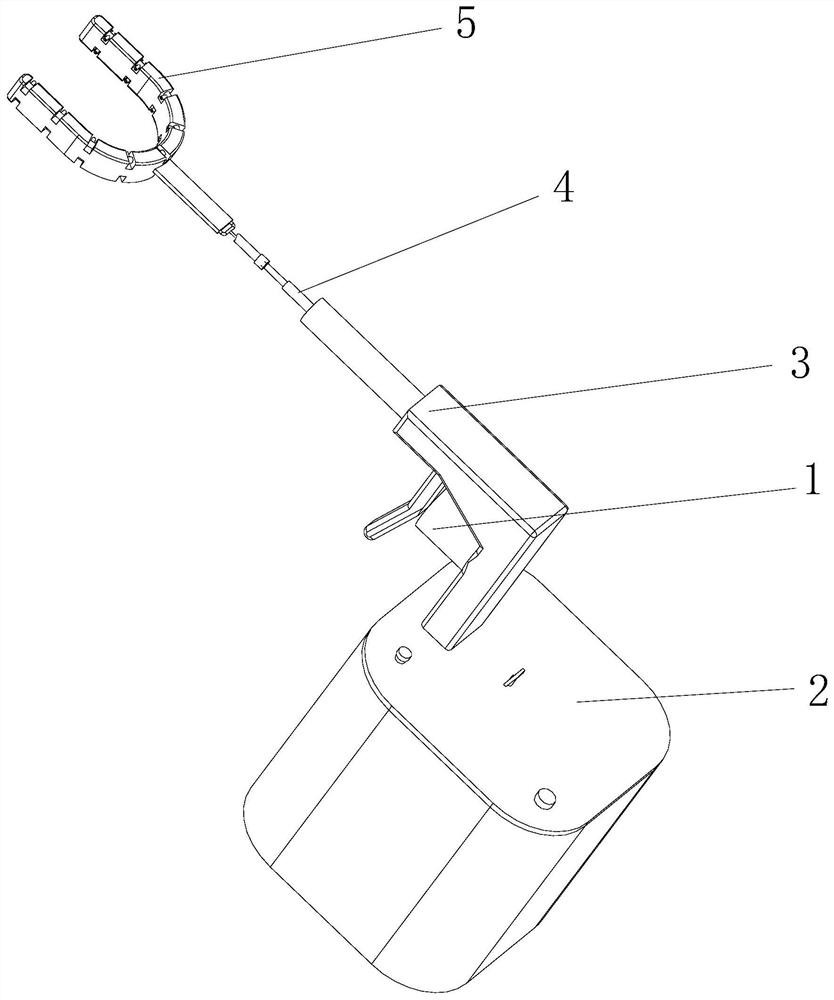

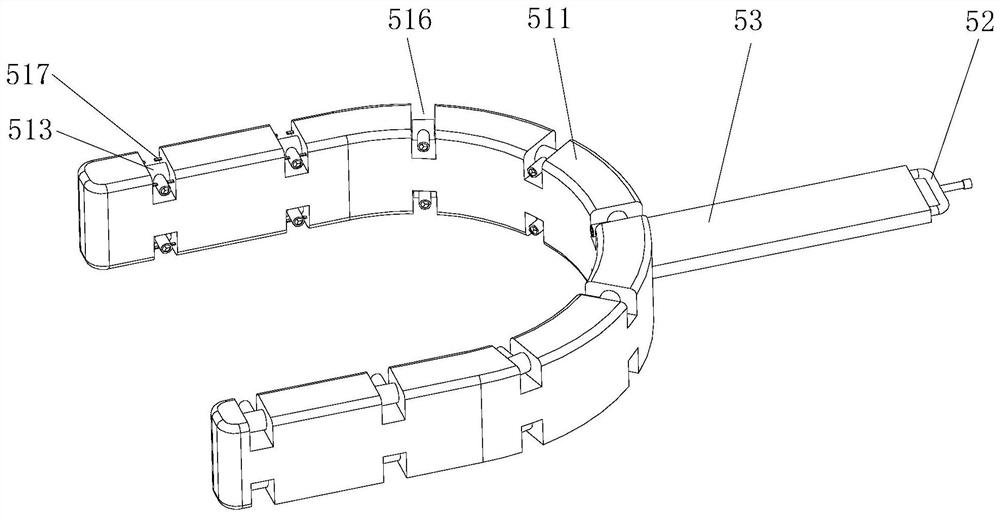

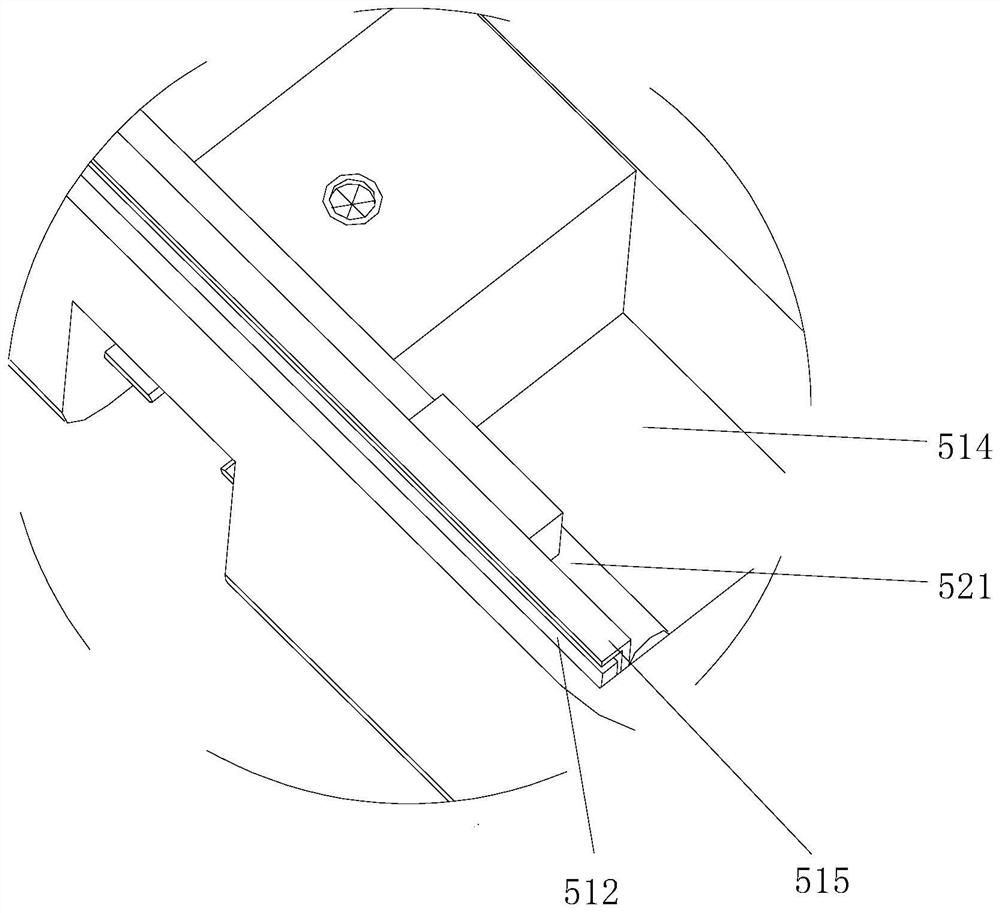

Drug administration device for periodontitis treatment

The present invention discloses a drug administration device for a periodontitis treatment and belongs to the technical field of medical appliances. The drug administration device comprises an air compression assembly, a drug storage tank, a shell body, a flow guide pipe and a drug administration assembly, the shell body is arranged on the drug storage tank, the air compression assembly is arranged on the shell body, one end of the flow guide pipe is arranged in the drug storage tank, and the other end of the flow guide pipe is inserted and matched with the drug administration assembly. A plurality of drug administration spraying nozzles are arranged on a positioning rubber sleeve to spray medicines on an inner side and an outer side of a user, when the inner side of the gingiva needs medicine spraying, teeth of the patient abut against a liquid outlet pipe to enable multiple medicine liquid tanks to rotate by 180 degrees on the positioning rubber sleeve, the liquid outlet pipe faces the inner side of the gingiva of the user when the positioning rubber sleeve is placed in the oral cavity, therefore, contact by hands or turning by medical tools is prevented and risks of saliva dripping and pathogenic microorganism infection caused by exposure of the positioning rubber sleeve entering the oral cavity of the patient to air are effectively avoided.

Owner:CENT SOUTH UNIV

Alpha linolenic acid cryogenic separation and purification method

InactiveCN102030629AChange concentrationComplete production processFatty acids production/refiningCarboxylic compound separation/purificationNemorensic acidAlpha-Linolenic acid

The invention discloses an alpha linolenic acid cryogenic separation and purification method, comprising the steps of: uniformly mixing oil rich in alpha linolenic acid and acetone or a methanol solvent according to a volume ratio of 1:(3-6), placing a container containing the mixed solution in an environment at (-30)-(-60) DEG C for refrigeration, separating and removing crystals at low temperature when the temperature reaches (-30)-(-60) DEG C, and desolventizing the solution to remove the solvent accounting for 20-30% of the total volume; repeating the steps of refrigeration, crystal removal and desolventization for 3-5 times for separating and removing the crystals; and after circularly removing the crystals for 3-5 times, repeating the steps of refrigeration and crystal removal once again when the volume ratio of the alpha linolenic acid to the solvent reaches 1:(2-3), and desolventizing the finally obtained mixed solution to obtain the alpha linolenic acid. The method is a pure physical cryogenic separation technology and can improve product quality and yield stability, and the concentration of the obtained alpha linolenic acid is above 80%.

Owner:SHANGHAI MAIFENG MICROWAVE EQUIP

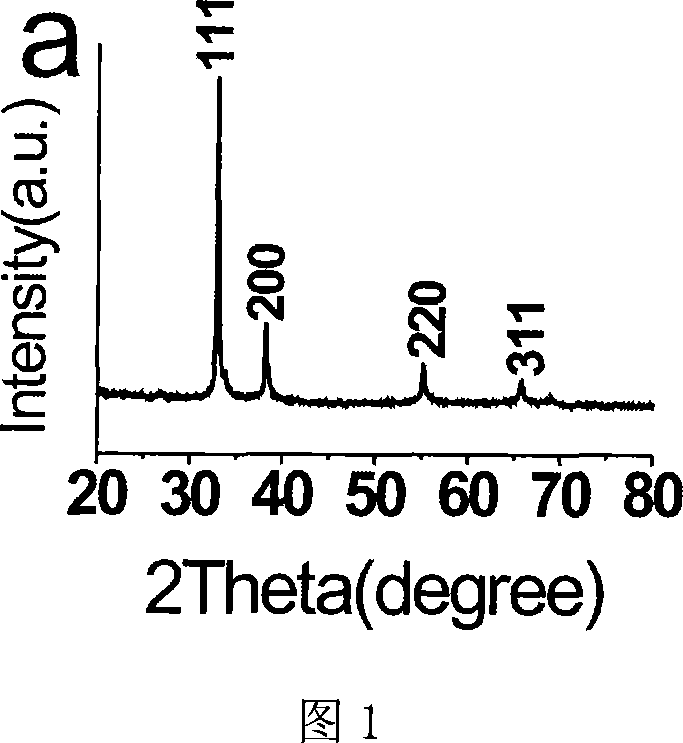

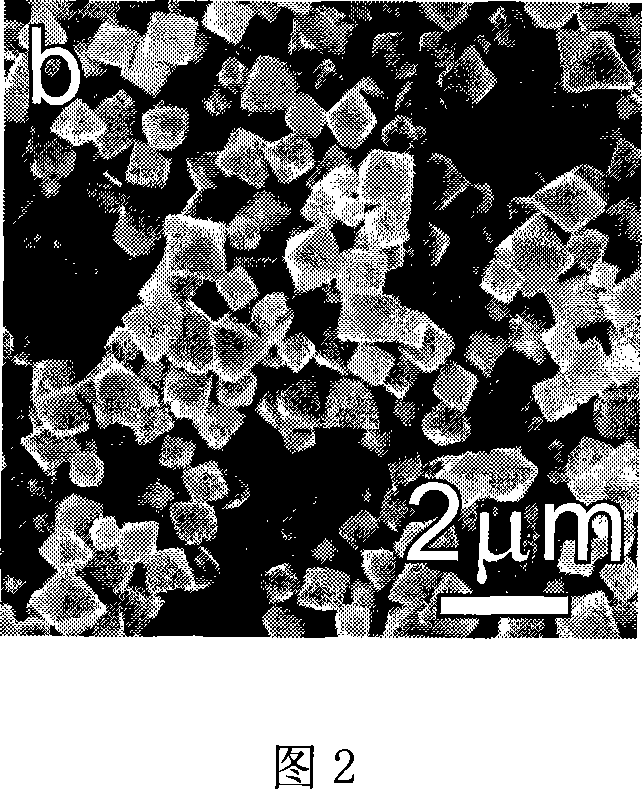

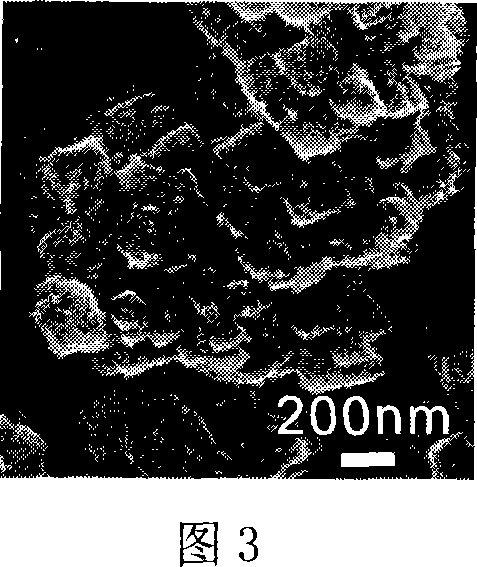

Shape and size controllable preparation method of micro-nano silver oxide

InactiveCN101054199AEasy to operateReduce processNanostructure manufactureSilve compoundsMicro nanoSilver oxide

A method for preparing micro-nano Ag2O with controllable shape and size relates to a micro-nano Ag2O, particularly to a method for realizing the controllable growth of the micro-nano Ag2O in shape and size by changing the concentration of the reactants. The invention provides a method for changing the reactants concentration from the whole and realizing the controllable growth of the micro-nano Ag2O in shape and size, which is a method for preparing micro-nano Ag2O with controllable shape and size. Mix AgNO3 and ammonia at the Moore ratio of 1:(0.2-10) to produce a mixture A of AgNO3 and ammonia. Add NaOH into the mixture A till the mixture A produces deposit. Stir the mixture and put it still to produce the mixture B. Centrifugate the mixture B and wash the deposit with water and alcohol for at least once in sequence to produce the target product.

Owner:XIAMEN UNIV

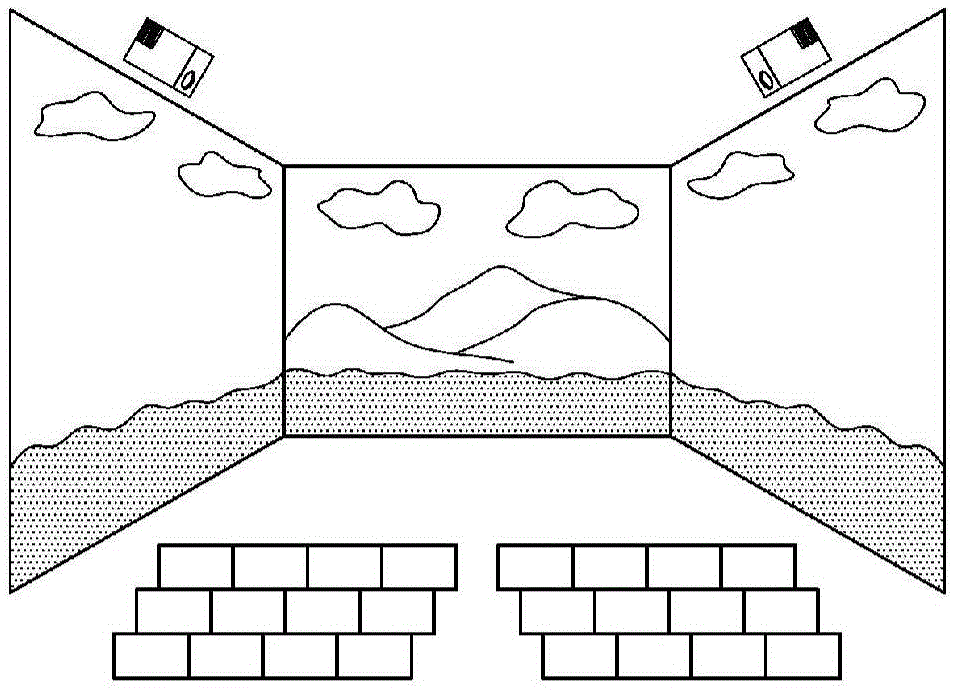

Multi-projection system with projection surface comprising non-solid material

InactiveCN105143975ALow heterogeneityStable formationProjectorsStereoscopic photographyProjection systemComputer science

The present invention provides a multi-projection system including a plurality of projection surfaces arranged in a single theater so as not to be parallel to each other, wherein the plurality of projection surfaces may comprise a projection surface including a non-solid material.

Owner:CJ CGV

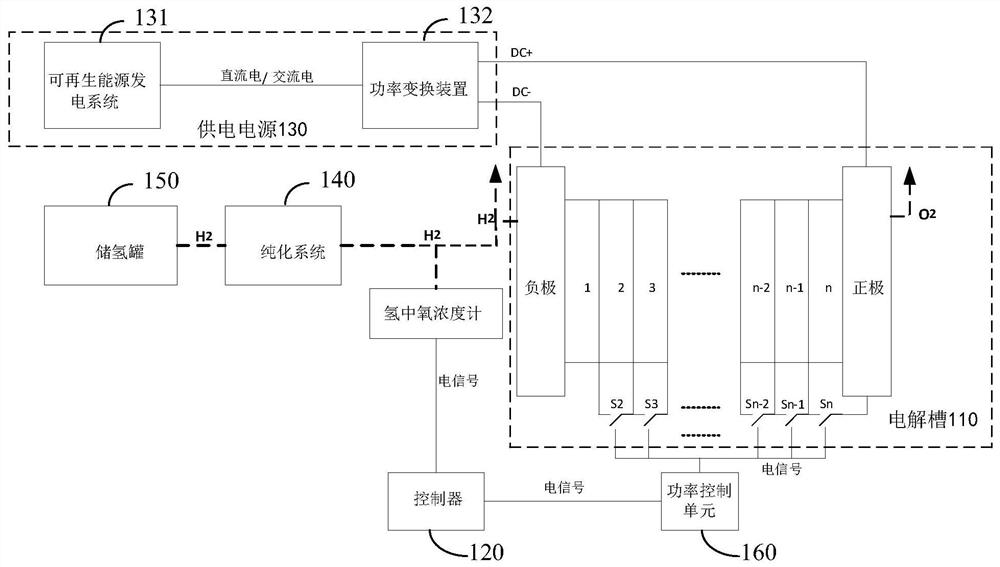

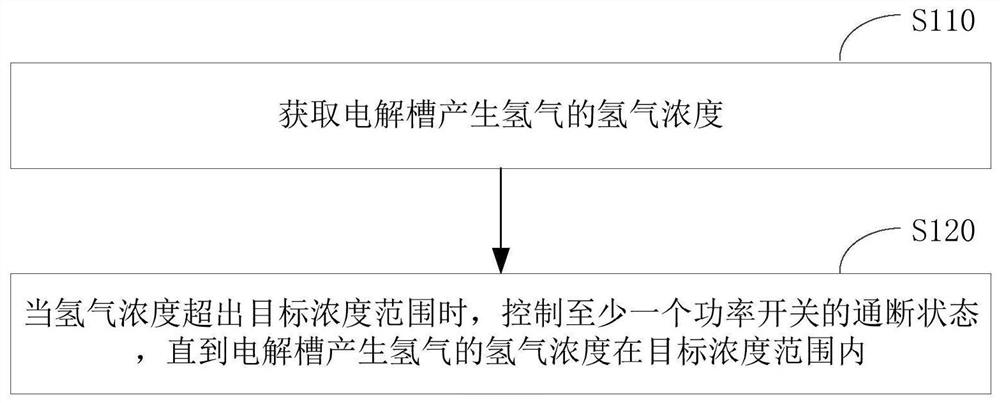

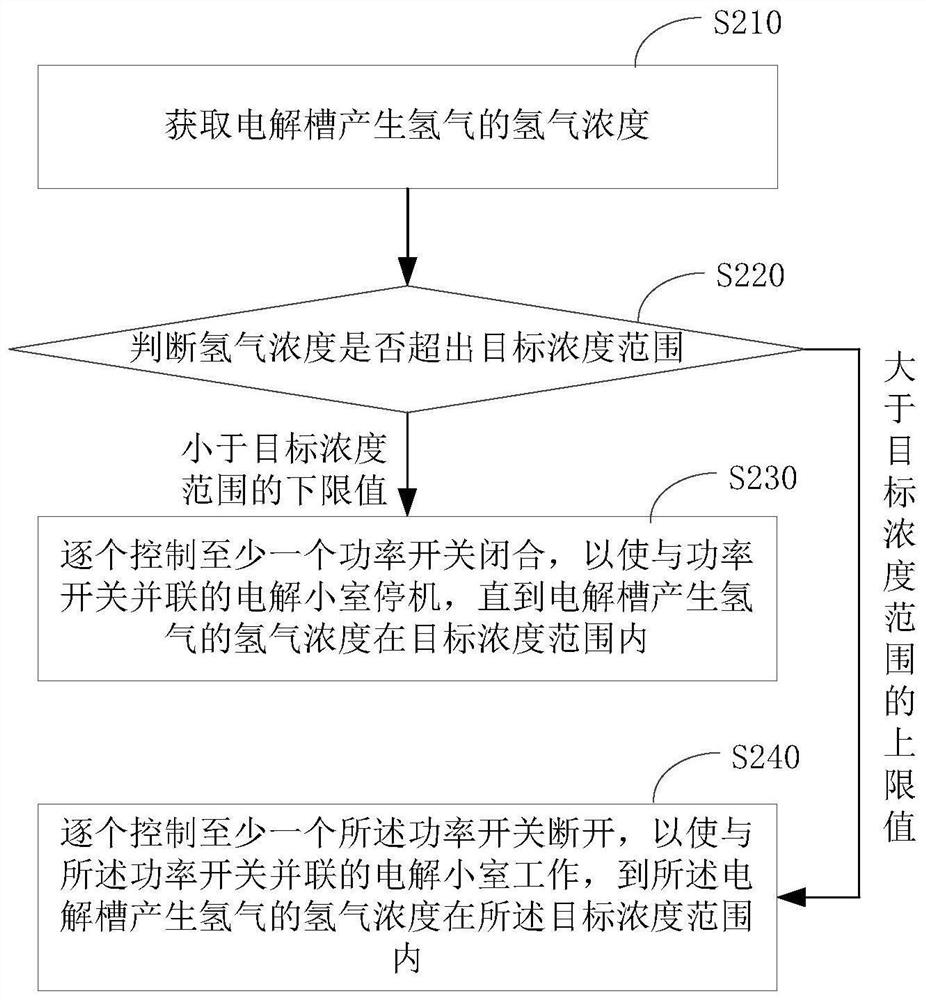

Water electrolysis hydrogen production control method and system and controller

PendingCN112725832AChange concentrationIncrease productionCellsEnergy inputHydrogen yieldRenewable energy

The invention provides a water electrolysis hydrogen production control method and system and a controller. According to the scheme, the method comprises the steps: controlling the working state of an electrolytic cell according to the concentration of hydrogen generated by the electrolytic cell, and controlling the on-off state of at least one power switch when the concentration of hydrogen exceeds a target concentration range so as to adjust the number of electrolysis cells participating in hydrogen production in the electrolytic cell; equivalently, the power required by the electrolytic cell is adjusted so that the hydrogen concentration generated by the electrolytic cell is changed, and finally, the hydrogen production concentration of the electrolytic cell is stabilized within a target concentration range. According to the scheme, the working state of the electrolytic cell is dynamically adjusted according to the hydrogen production concentration of the electrolytic cell, electric energy generated by a renewable energy power generation system in a weak power generation area is fully utilized, and hydrogen yield and hydrogen purity are improved.

Owner:阳光氢能科技有限公司

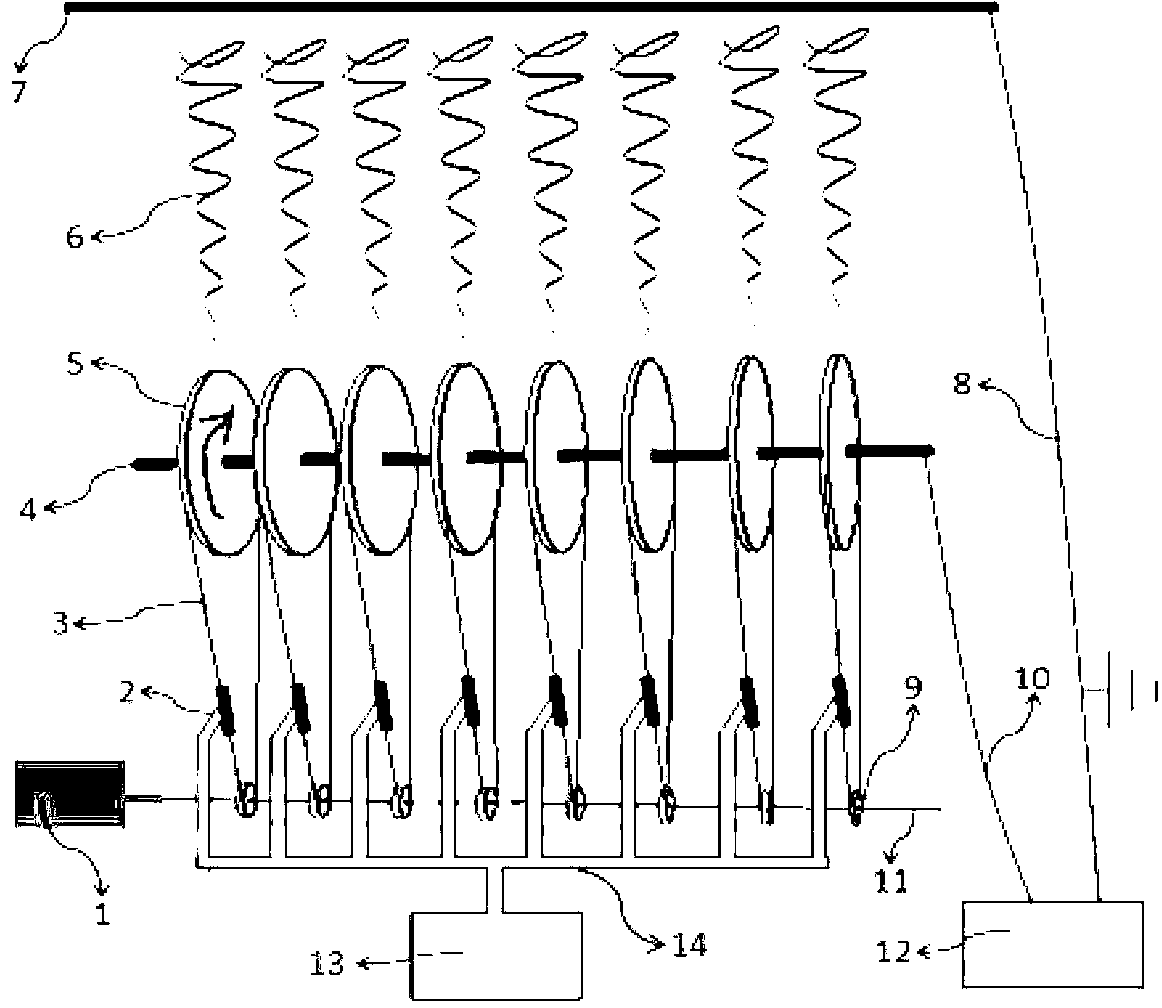

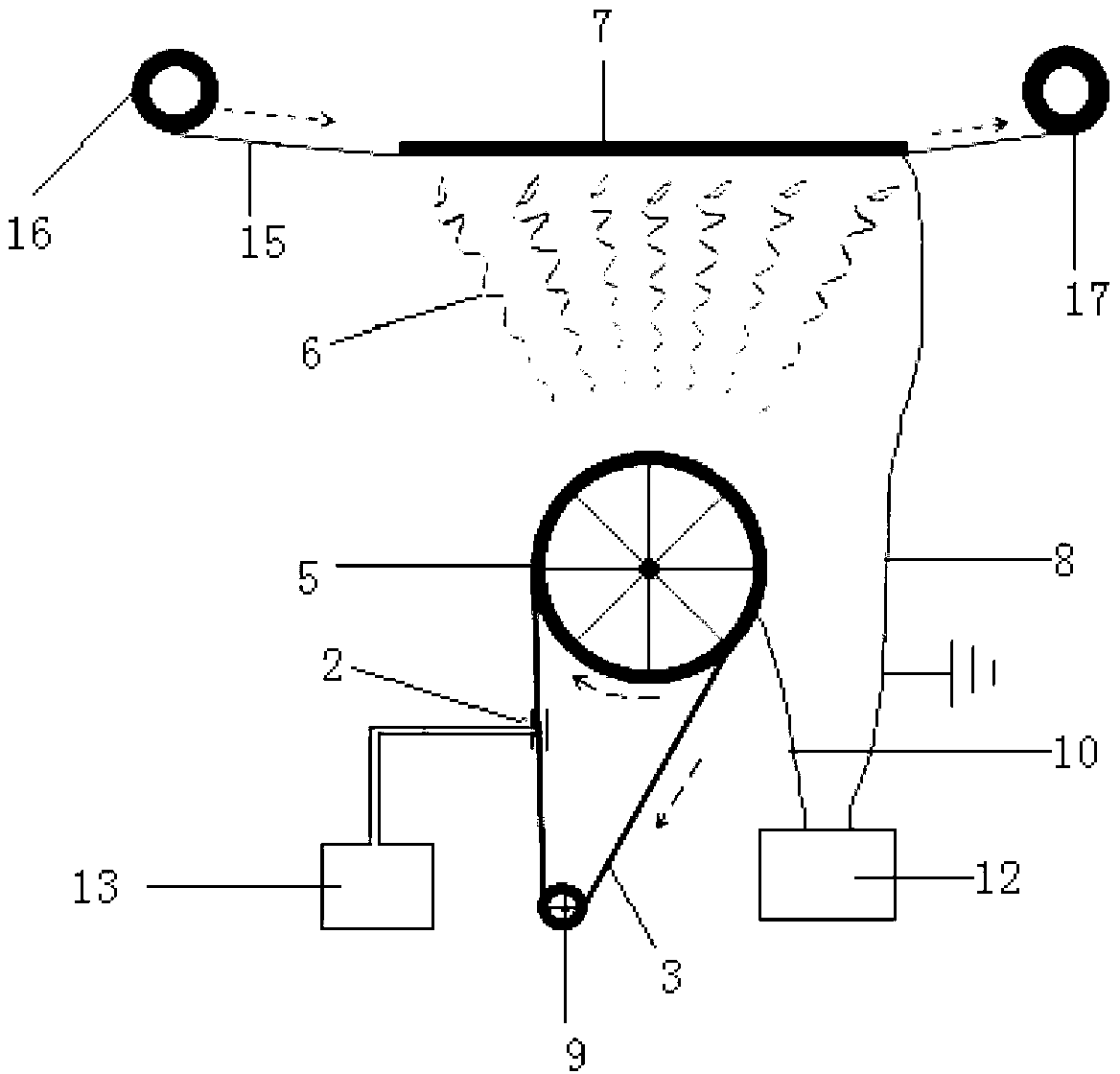

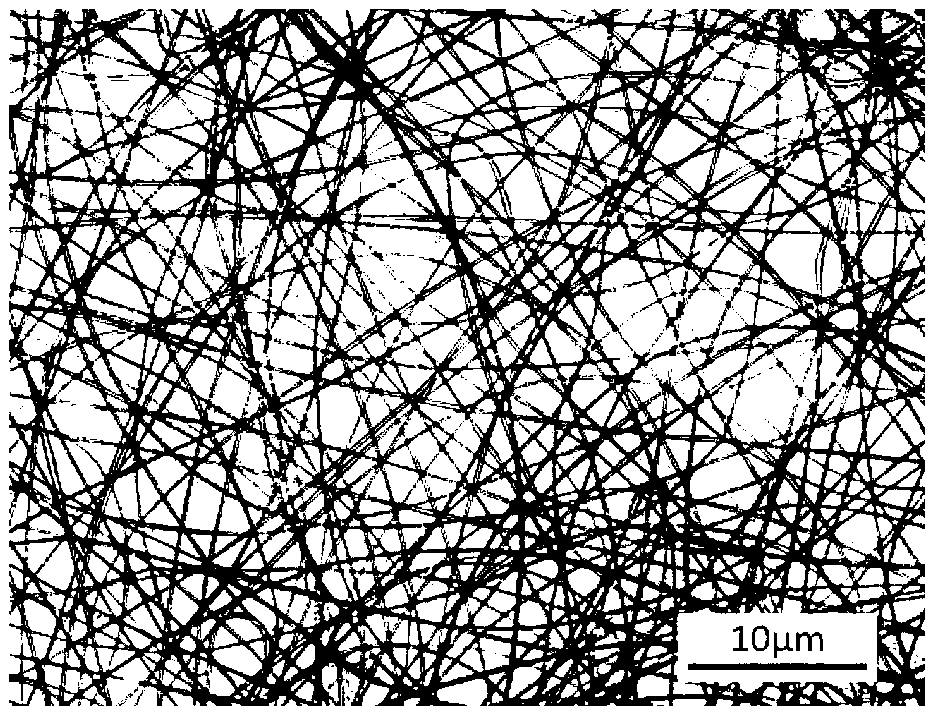

Compound annular electrode electrostatic spinning device

InactiveCN103215665AEffective protectionEfficient use ofFilament/thread formingMicro nanoElectrospinning

The invention belongs to the technical field of electrostatic spinning equipment and relates to a compound annular electrode electrostatic spinning device. The main structure of the compound annular electrode electrostatic spinning device comprises a motor, a liquid brush, an insulating tape, a metal shaft, a metal annular electrode, micro-nano fibers, a metal collector, a high-voltage power supply negative electrode, an insulating pulley, a high-voltage power supply positive electrode, an insulating shaft, a high-voltage power supply, a liquid supply system, a distribution pipe, a connection substrate, a feeding rotary drum and a discharge rotary drum. The metal annular electrode is arranged on the metal shaft, and one end of the metal shaft is connected with the high-voltage power supply through the high-voltage power supply positive electrode; the insulating pulley is arranged on the insulating shaft, and the motor is in linkage with the insulating shaft, drives the insulating pulley to rotate and drives the metal annular electrode to rotate through the insulating tape; the distribution pipe is communicated with the liquid supply system, the liquid brush is arranged on an opening of the distribution pipe, the insulating tape penetrates through the liquid brush, the metal collector is located over the metal annular electrode, and the feeding rotary drum and the discharge rotary drum are arranged at two ends of the metal collector. The compound annular electrode electrostatic spinning device is simple in structure, reliable in principle, low in manufacturing cost, good in effect and environment-friendly, and conditions are easy to control.

Owner:QINGDAO UNIV

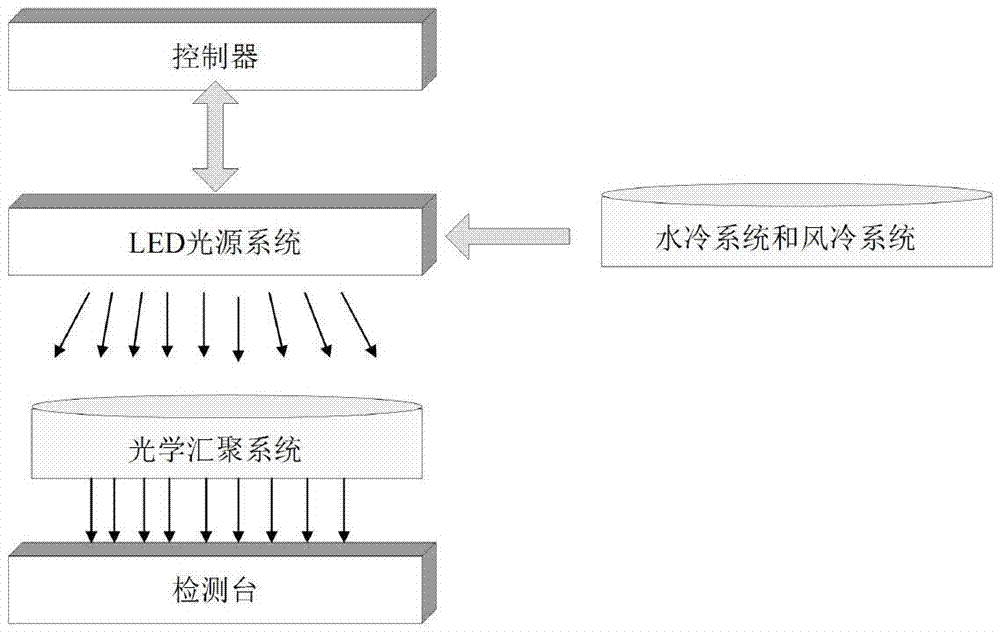

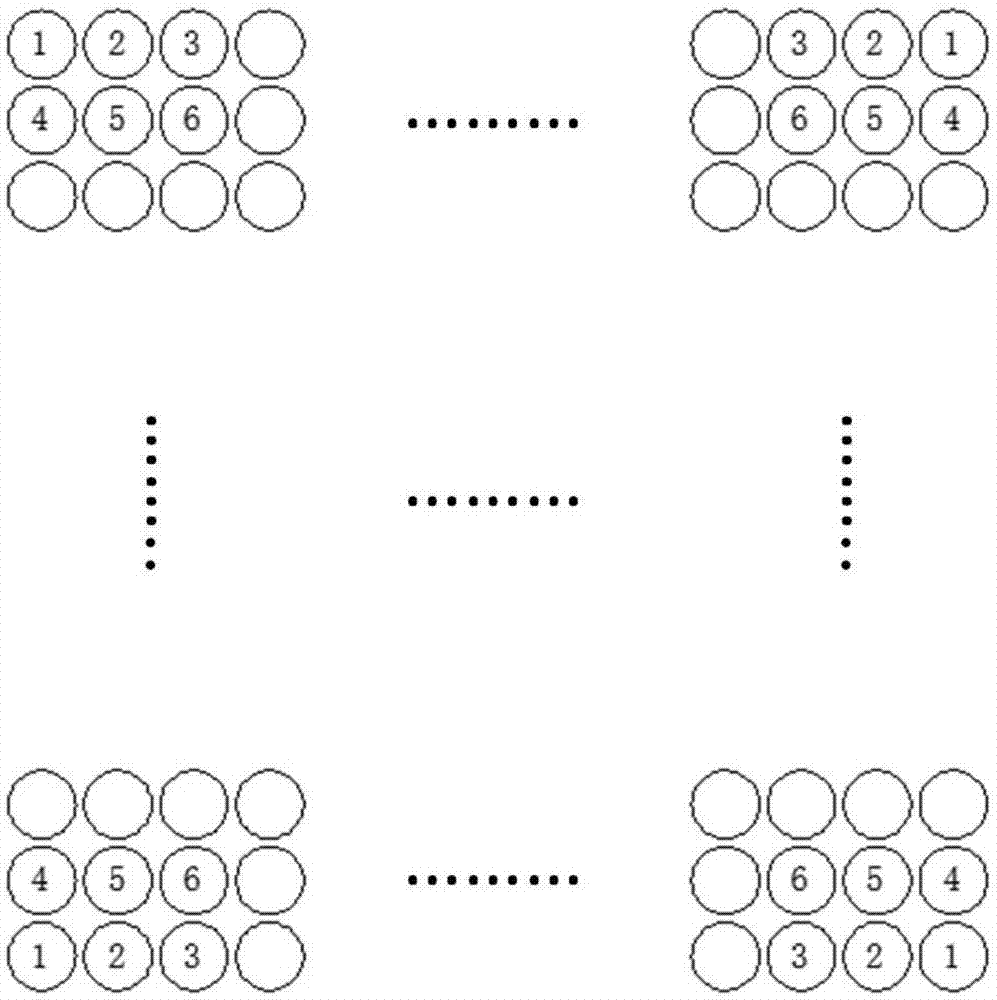

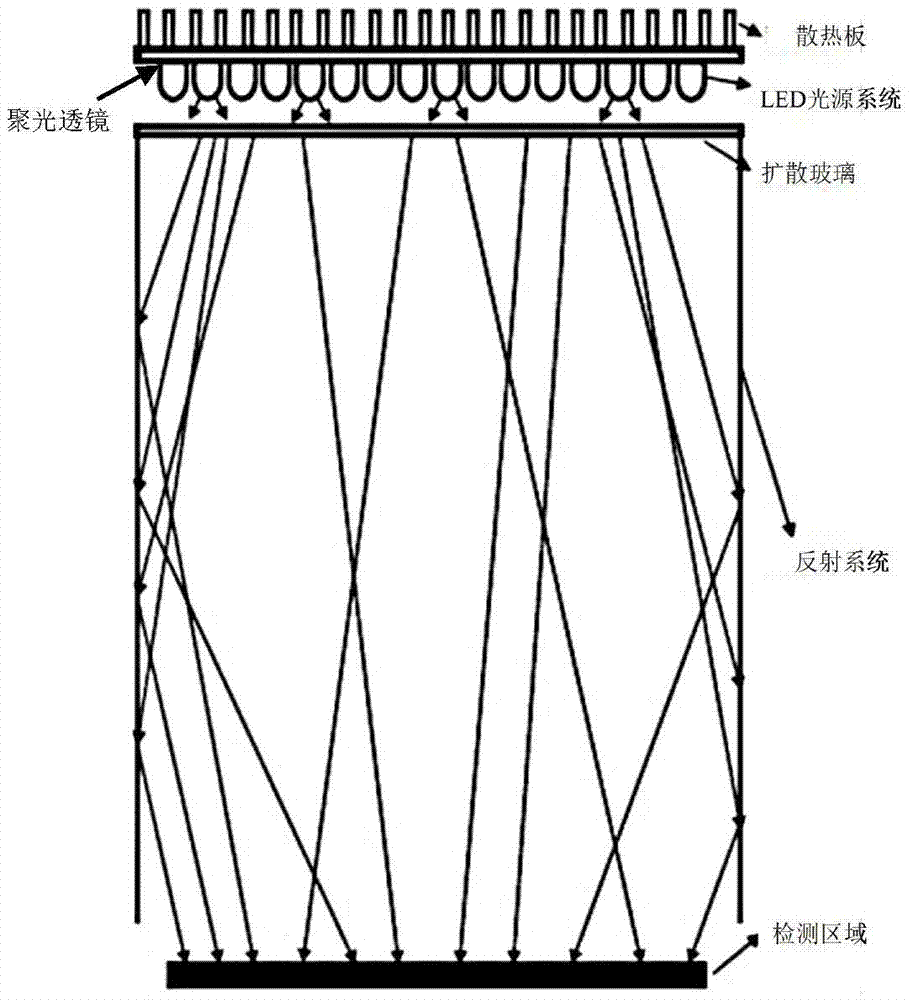

Photo-induced hydrogen passivation and defect repair device for LED (Light Emitting Diode) silicon solar cell

ActiveCN105449044AReduce compoundingImprove performanceFinal product manufacturePhotovoltaic energy generationLattice defectsDefect repair

The invention discloses a photo-induced hydrogen passivation and defect repair device for an LED (Light Emitting Diode) silicon solar cell. The device comprises a test bed for placing the silicon solar cell and keeping the temperature constant, and further comprises an LED light source system, an optical convergence system and a controller, wherein the LED light source system comprises an LED array for emitting light; the optical convergence system is arranged on a light emitting path of the LED array, and is used for converging the light emitted by the LED array to a detection area of the test bed; and the controller is used for modifying the parameters of the light emitted by the LED array as well as analyzing and calculating the passivation and defect parameters of the silicon solar cell. The device improves the conversion efficiency of the solar cell by passivating impurity defects in crystalline silicon, passivating a silicon material and repairing lattice defects such as dislocation in a polycrystalline silicon material.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com