Method for dispersing liquid metal to micro nano-particles

A technology of micro-nano particles and liquid metal, which is applied in the direction of nanotechnology, can solve the problems of easy agglomeration of liquid metal, achieve large-scale dispersion and realize the effect of large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment is a method for dispersing liquid metal into micro-nano particles, which specifically includes the following steps:

[0025] (1) Take 100g of DMF and place it in a 250ml beaker, add a magnet and place it on a magnetic stirrer, take 10g of PVDF powder and pour it into the beaker, turn on the magnetic stirrer and stir for 30min to obtain a polymer solution;

[0026] (2) 4g liquid metal (Ga 75.5 In 24.5 ) into the polymer solution obtained in step (1), and continue to stir for 6h, the liquid metal can be dispersed into micro-nano particles;

[0027] In step (1) and step (2), the stirring speed is 300-500 rpm.

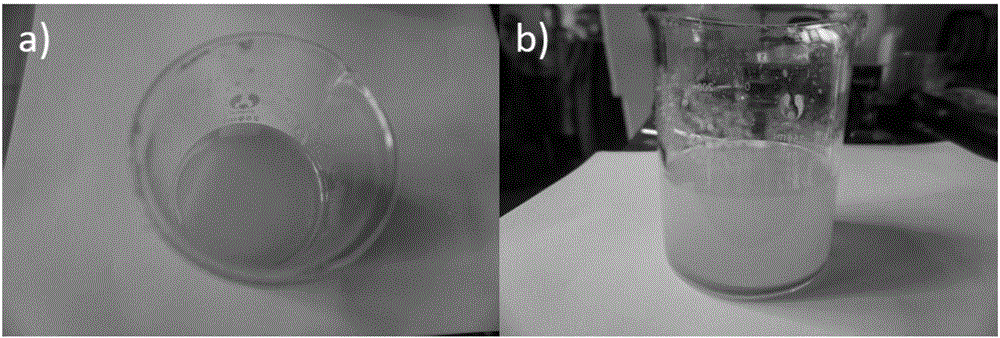

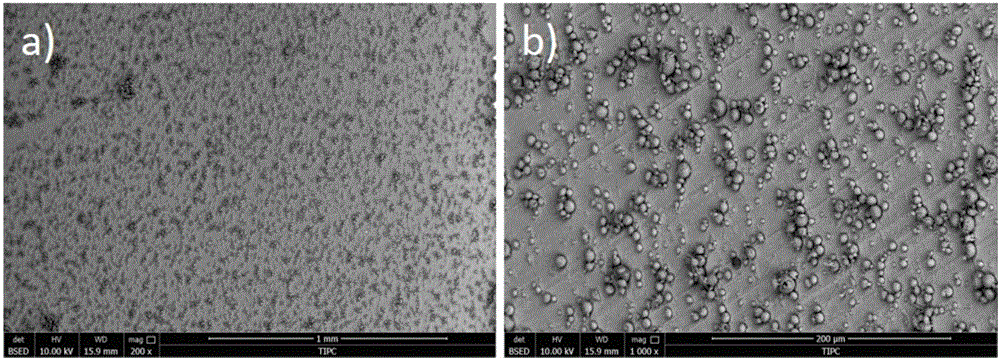

[0028] In the present embodiment, step (2) finally obtains the liquid metal solution ink that can be used for printing on paper, and its macroscopic view is as follows figure 1 Shown; Electron microscope scanning image of liquid metal micro-nanoparticles in liquid metal ink figure 2 As shown, the diameter of its micro-nano particles is 10nm-10μm...

Embodiment 2

[0031] This embodiment is a method for dispersing liquid metal into micro-nano particles, which specifically includes the following steps:

[0032] (1) Take 100g of DMF and place it in a 250ml beaker, add a magnet and place it on a magnetic stirrer, take 5g of PVDF powder and pour it into the beaker, turn on the magnetic stirrer and stir for 30min to obtain a polymer solution;

[0033] (2) 1g liquid metal (Ga 75.5 In 24.5 ) into the polymer solution obtained in step (1), and continue stirring for 1 hour, the liquid metal can be dispersed into micro-nano particles.

[0034] In step (1) and step (2), the stirring speed is 300-500 rpm.

[0035] The liquid metal micro-nano particles in the liquid metal solution obtained in this example have a diameter of 100 nm to 10 μm, and the liquid metal solution has no obvious agglomeration and sedimentation phenomenon after being stored at room temperature for 50 hours, and a small amount of metal deposits after 30 days.

Embodiment 3

[0037] This embodiment is a method for dispersing liquid metal into micro-nano particles, which specifically includes the following steps:

[0038] (1) Take 100g of DMF and place it in a 250ml beaker, add a magnet and place it on a magnetic stirrer, take 20g of PVDF powder and pour it into the beaker, turn on the magnetic stirrer and stir for 30min to obtain a polymer solution;

[0039] (2) 8g liquid metal (Ga 75.5 In 24.5 ) into the polymer solution obtained in step (1), and continue stirring for 12 hours, the liquid metal can be dispersed into micro-nano particles.

[0040] In step (1) and step (2), the stirring speed is 300-500 rpm.

[0041] The liquid metal micro-nano particles in the liquid metal solution obtained in this example have a diameter of 100 nm to 10 μm, and the liquid metal solution has no obvious agglomeration and sedimentation phenomenon after being stored at room temperature for 50 hours, and a small amount of agglomeration occurs after 35 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com