Photo-induced hydrogen passivation and defect repair device for LED (Light Emitting Diode) silicon solar cell

A silicon solar cell and defect repair technology, applied in the field of hydrogen passivation, can solve problems affecting solar cell performance, achieve flexible band selection, improve performance, and ensure reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

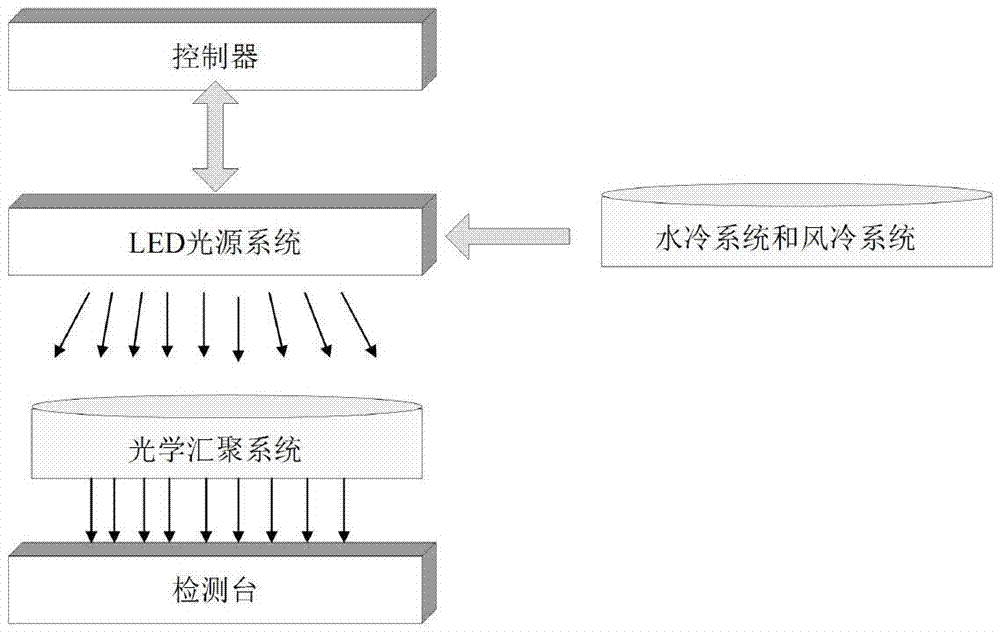

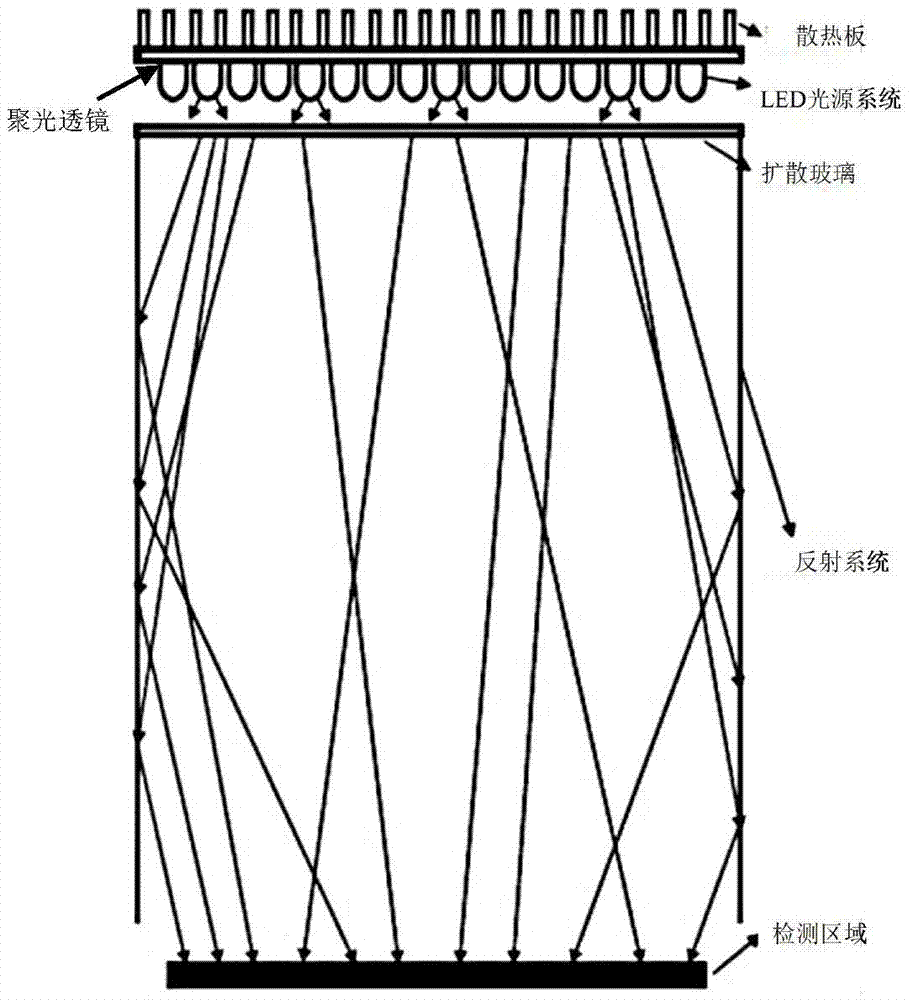

[0032] figure 1 It is a structural representation of the present invention. The invention includes a detection platform for placing silicon solar cells, and the temperature of the detection platform is kept constant. Also includes:

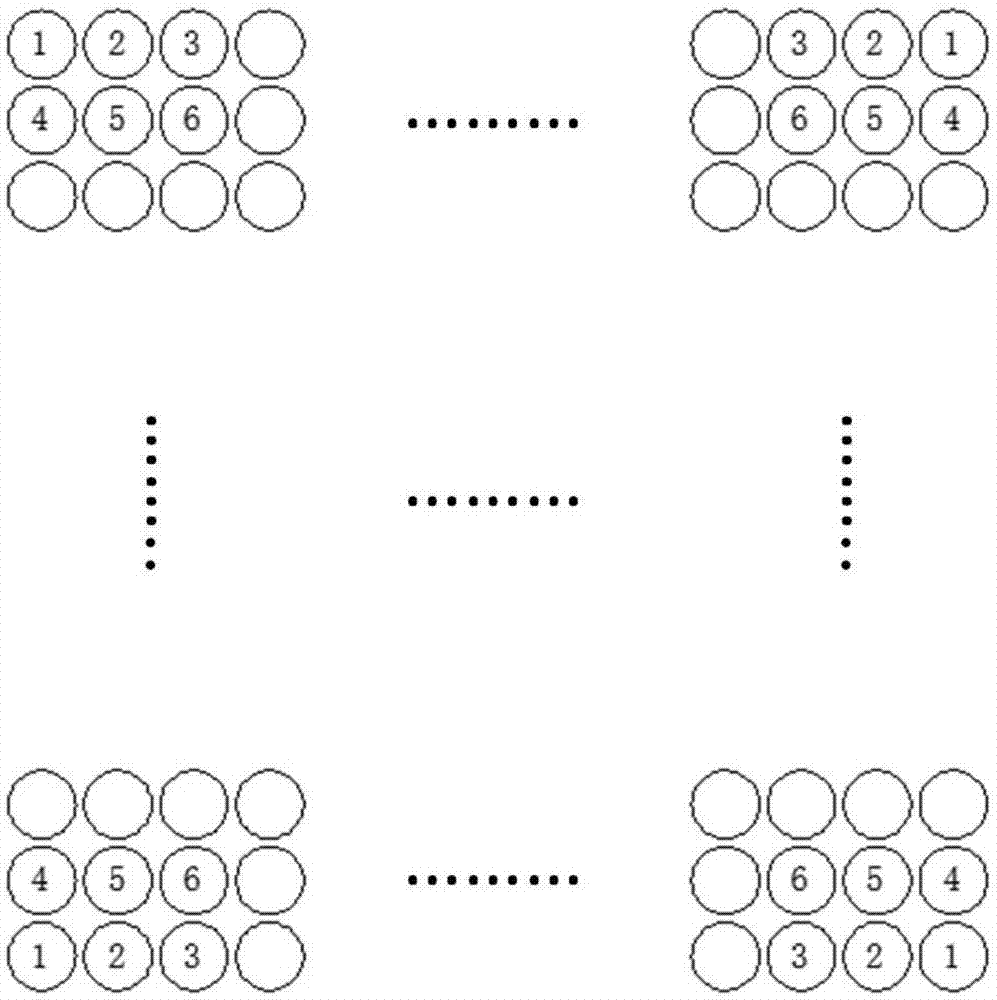

[0033] An LED light source system, including an LED array for emitting light; the wavelength of light emitted by the LED array is 404nm, 940nm or other wavelengths;

[0034] An optical converging system is arranged on the light-emitting optical path of the LED array to converge the light emitted by the LED array to the detection area on the detection table;

[0035] A controller is used to modify the parameter values of the whole device such as temperature and humidity. At the same time, it can control the compensation value of the irradiance intensity of the light emitting line of the LED array, and the parameter data such as the passivation and defects of the detected silicon solar cells Perform analysis operations. The controller is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com