Shape and size controllable preparation method of micro-nano silver oxide

A silver oxide, micro-nano technology, applied in nanostructure manufacturing, chemical instruments and methods, nanotechnology, etc., can solve the problems of silver oxide particles difficult to meet the requirements of different industries, uneven particle size, and poor dispersion. To achieve the effect of simple operation, simple equipment and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

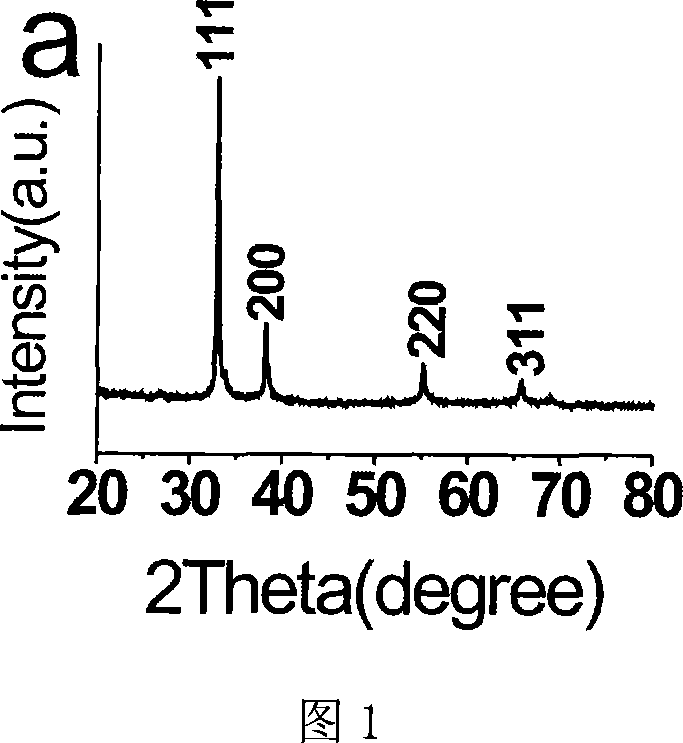

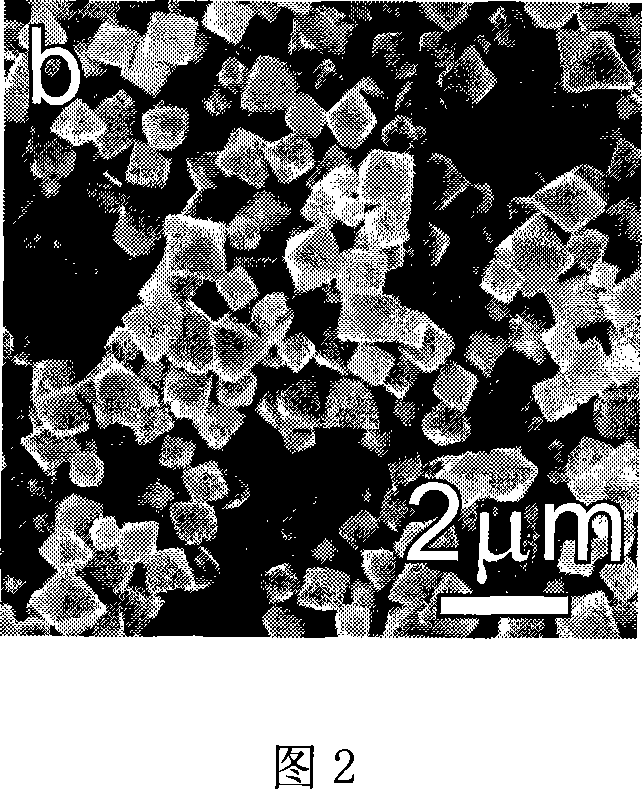

[0016] Example 1: Add 0.042g silver nitrate to 7.5ml 0.053M ammonia water, stir for 5min to obtain a suspension; add 0.25M 0.25ml sodium hydroxide to the suspension, stir for 5min, and let stand for 2 days to obtain a mixture . The mixture was centrifuged and washed to obtain the final product. The product was characterized by XRD and SEM as silver oxide octahedral structure. As shown in Figures 1 and 2.

Embodiment 2

[0017] Example 2: 0.042g of silver nitrate was added to 7.5ml of 0.06M ammonia water, and stirred for 5 minutes to obtain a mixture of trace amounts of silver oxide and silver ammonia solution. Add 0.25ml of 2M sodium hydroxide to the above solution, stir for 1min, and let stand for 5min. The mixture was centrifuged and washed to obtain the target product. The product was characterized by SEM as silver oxide octahedral structure, as shown in Figure 2.

Embodiment 3

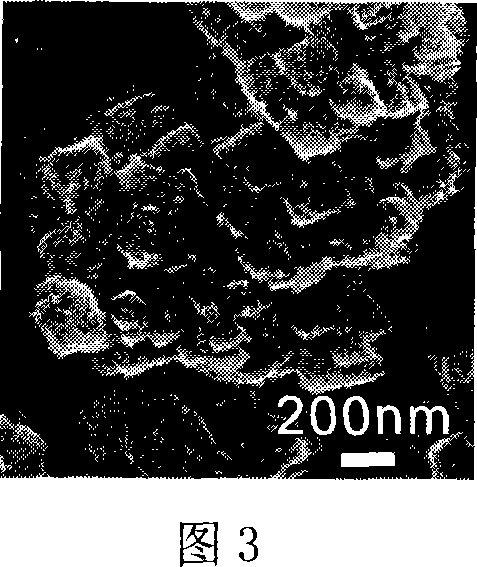

[0018] Example 3: 0.042g of silver nitrate was added to 7.5ml of 0.33M ammonia, and stirred for 6min to obtain silver ammonia solution; 0.25ml of saturated sodium hydroxide was added to the silver ammonia solution, stirred for 5min, left to stand for 12h, and The mixture was washed by centrifugation to obtain the target product, the morphology of which is shown in Figure 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com