Patents

Literature

179results about How to "Concentration controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

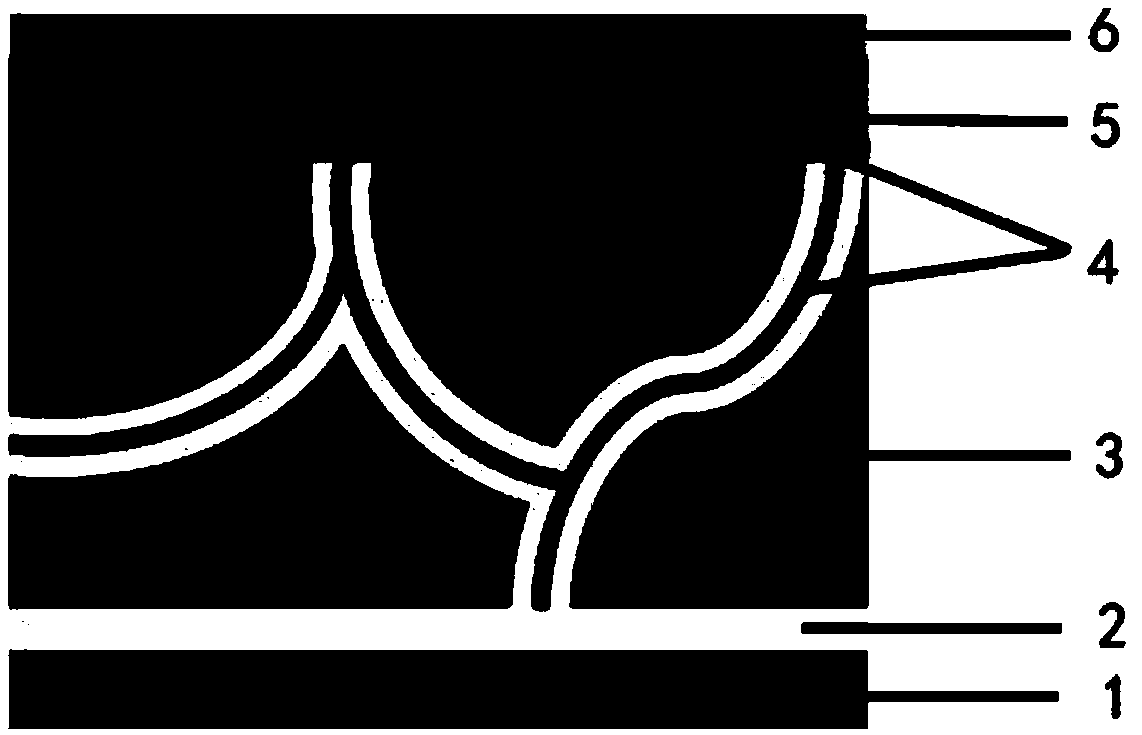

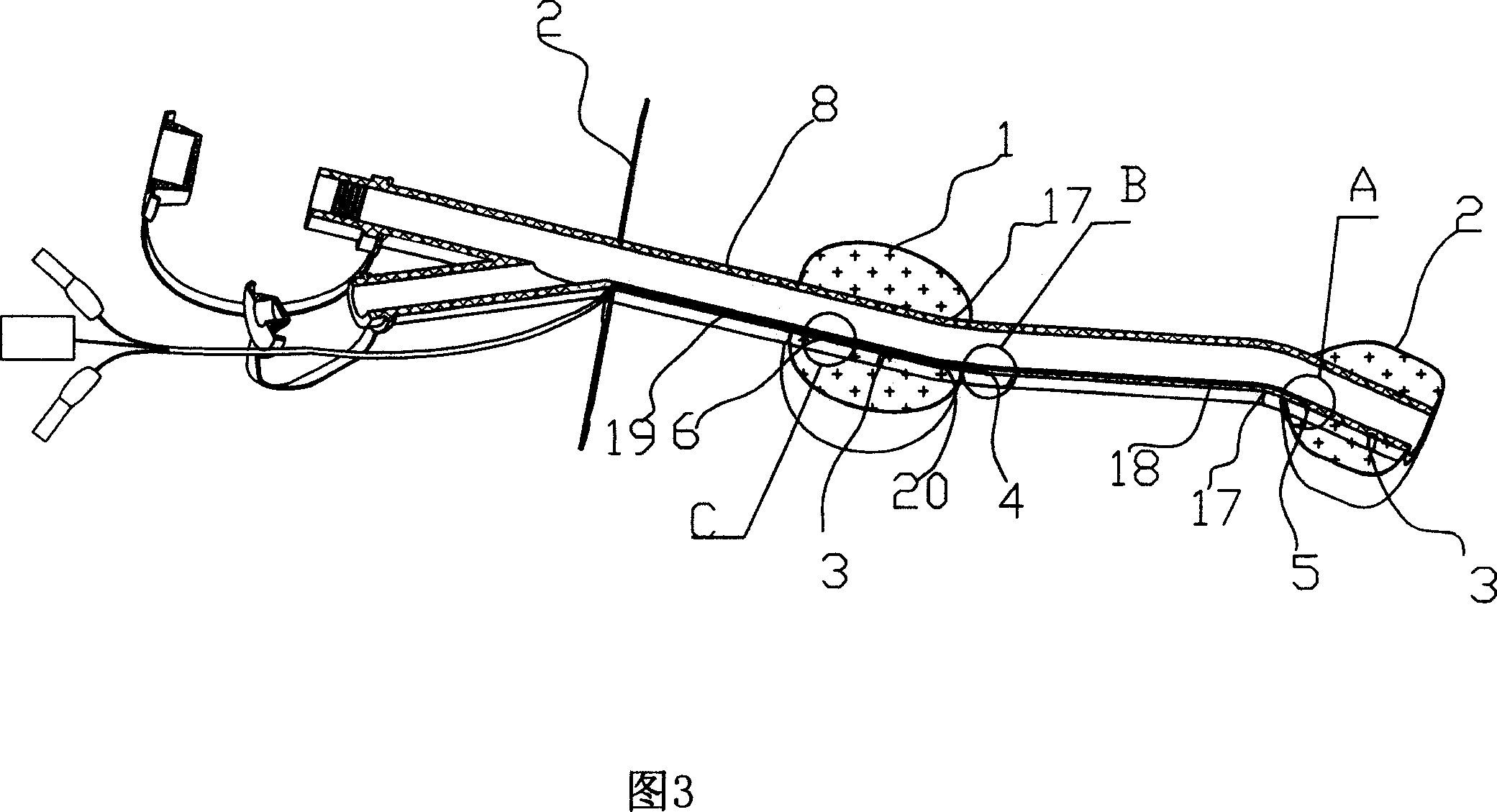

Inverse Y-shaped ventilation method for coal mining working face

InactiveCN102071958ASolve accumulated puzzlesConcentration controllableTunnel/mines ventillationGas removalEconomic benefitsCoal pillar

The invention relates to an inverse Y-shaped ventilation method for a coal mining working face. In the method, a transportation roadway is arranged on one side of the coal mining working face; a railway roadway and a return air roadway are sequentially arranged on the other side of the coal mining working face; coal pillars are positioned between the railway roadway and the return air roadway; contact roadways are formed at certain intervals; sealed partition walls are arranged among the contact roadways; before the working face is actually mined, the contact roadways near the working face are communicated so as to form a return air contact roadway; a beside-roadway wall body is built along the border of a gob, which is close to the back of the working face; a sealing wall is constructed at the position which is 1 to 2m away from the back of the return air contact roadway so as to seal a gob-side entry and the return air roadway; when the working face is actually mined, air flow passes through the railway roadway and the transportation roadway to enter the coal mining work face and returns to the return air roadway through the gob-side entry and the return air contact roadway; and the stroke of the air flow forms an inverse Y shape. The ventilation method is characterized by simple structure and stable air flow, solves the problem of gas accumulation at the upper corner of an actual mining working face and the problem that the god-side entry is difficult to maintain, and has obvious social and economic benefits.

Owner:CHINA UNIV OF MINING & TECH +1

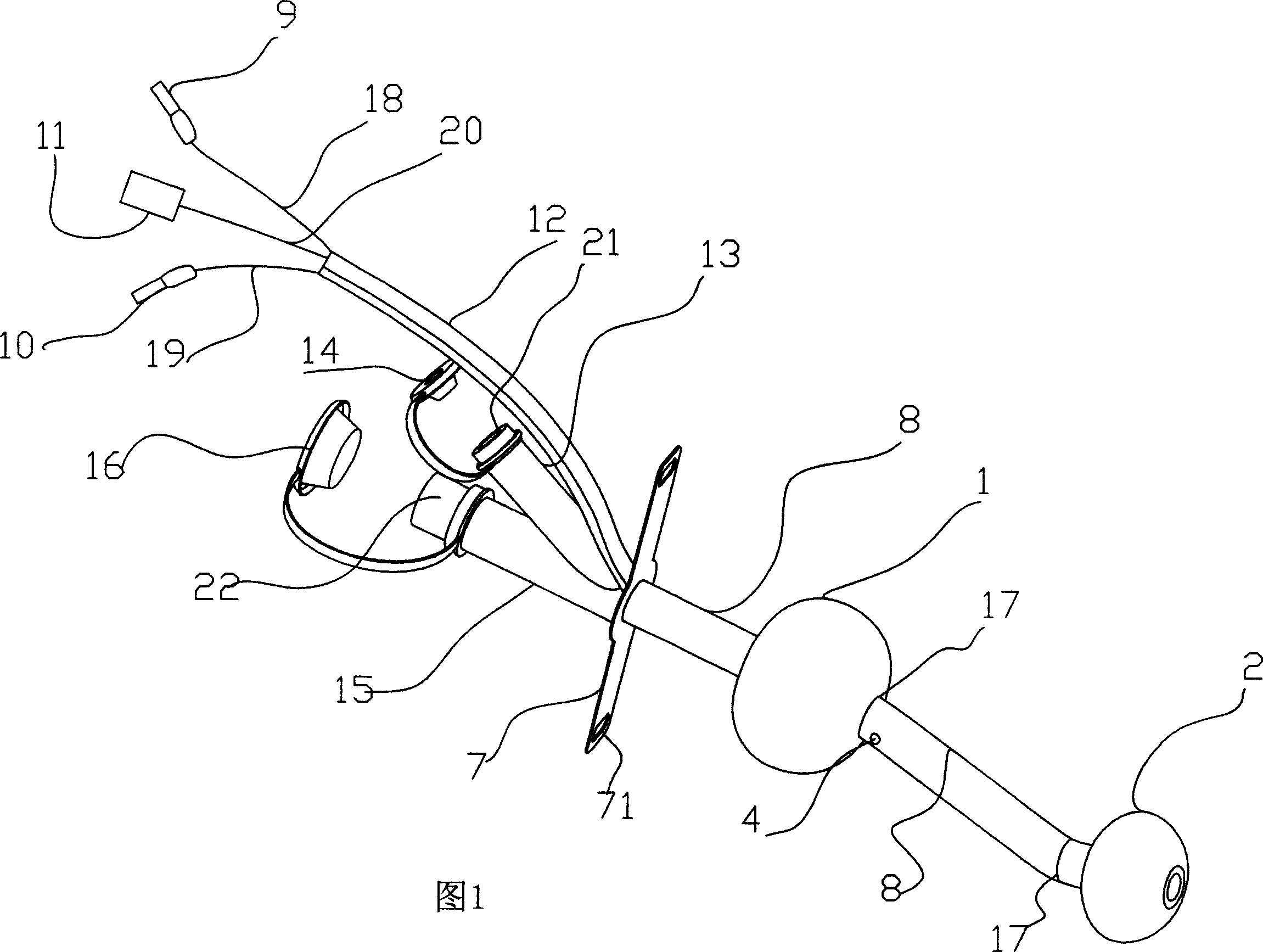

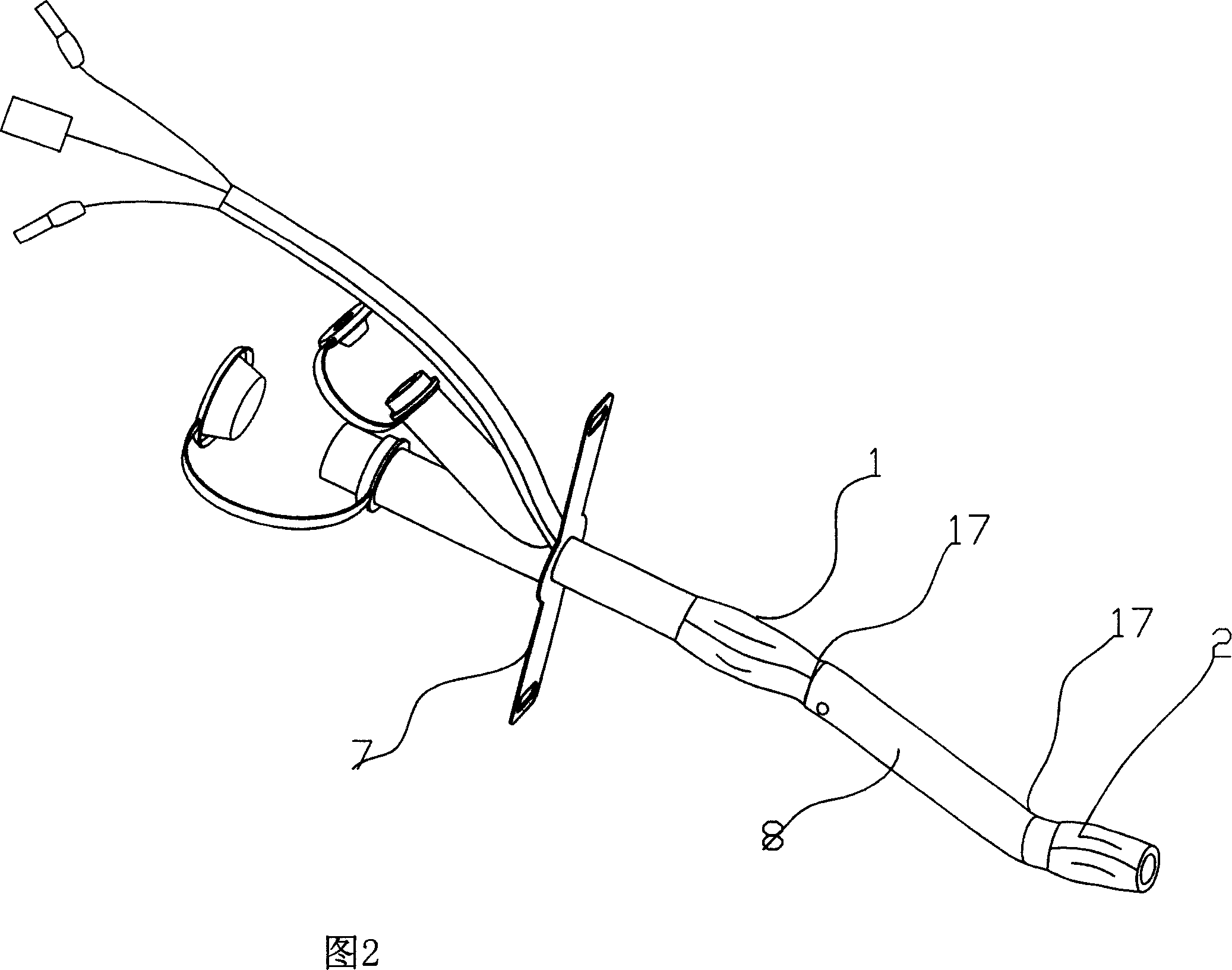

Production process for preparing high-performance diamond wire saw

InactiveCN101591796AUniform electrodepositionConcentration controllableElectrolytic coatingsChemical vapor deposition coatingHydrogenWater vapor

The invention discloses a production process for preparing a high-performance diamond wire saw, which comprises the following steps: firstly, reacting diamond with tungsten oxide, water vapor and hydrogen at a temperature of between 65 and 900 DEG C to form a W-W2C layer on the surface of the diamond so as to realize surface alloyed tungsten of the diamond; secondly, preparing electroplating bath by the diamond of the surface alloyed tungsten and watt type nickel plating solution, and carrying out electroplating by using a nickel plate as an anode and a steel wire as a cathode; making the diamond of the surface alloyed tungsten do electrophoresis motion under the action of an electric field and electrodeposited on the surface of the steel wire, and simultaneously electrodepositing the metal nickel on the surface of the steel wire. The diamond wire saw prepared by the production process has the advantages of even distribution of diamond grain, high mass percentage of a diamond plating layer and high electroplating speed; and the diamond and a nickel matrix are in metallurgical bonding, so the bonding capacity of the matrix for cutting diamond grains is remarkably improved, and the cutting capacity and the service life of the diamond wire saw are greatly improved. The production process is suitable for industrialized production, and can replace the prior production process for the diamond wire saw.

Owner:CHANGSHA DIAT NEW MATERIAL SCI & TECH

Preparation method of non-porous or porous polymer microsphere of surface function

InactiveCN101045755AAvoid defects that destroy the porous structure of the microspheresAvoid duplication of seed polymerization process stepsSolubilityPolymer science

This invention relates to a preparation method of surface functional, imperforation or multihole polymer microsphere, belongs to functional polymer material technosphere. The steps: remove polymerization inhibitor in alkene monomer; add mono-olefin monomer to continuous phase solvent, form reaction system, inlet nitrogen, takes reaction under homothermal condition to obtain seed polymer microsphere; mix seed polymer microsphere solution and activator, form first-order swelling reaction solution; then add mono-olefin monomer, monomer with functional group and cross-linking agent, and make them swell to seed microballoon sphere, form second grade swelling reaction solution; finally add water-solubility polymerization inhibitor, form blending reaction solution, isothermal reaction, ultimately separate to obtain imperforation polymer microsphere with functional surface; or use organic solvent to extract to obtain multihole polymer microsphere with functional surface.

Owner:SHANGHAI JIAO TONG UNIV

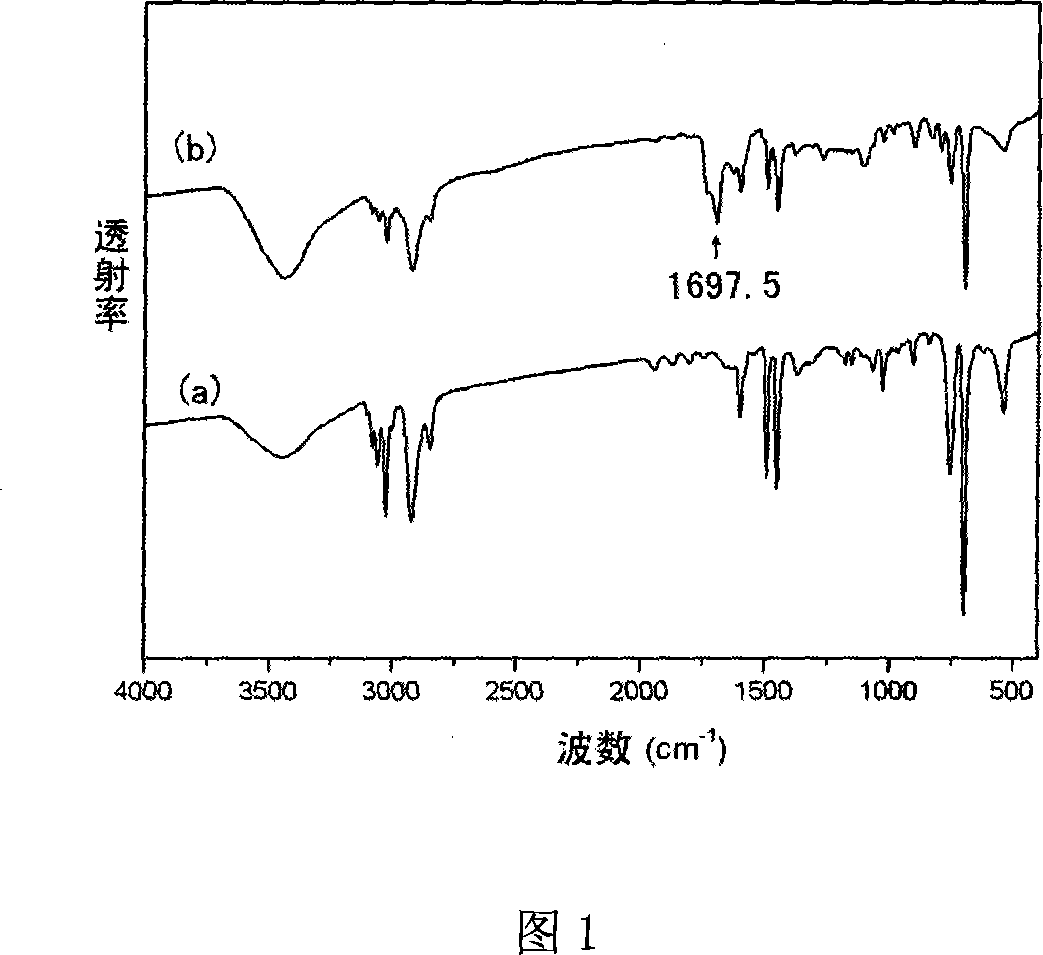

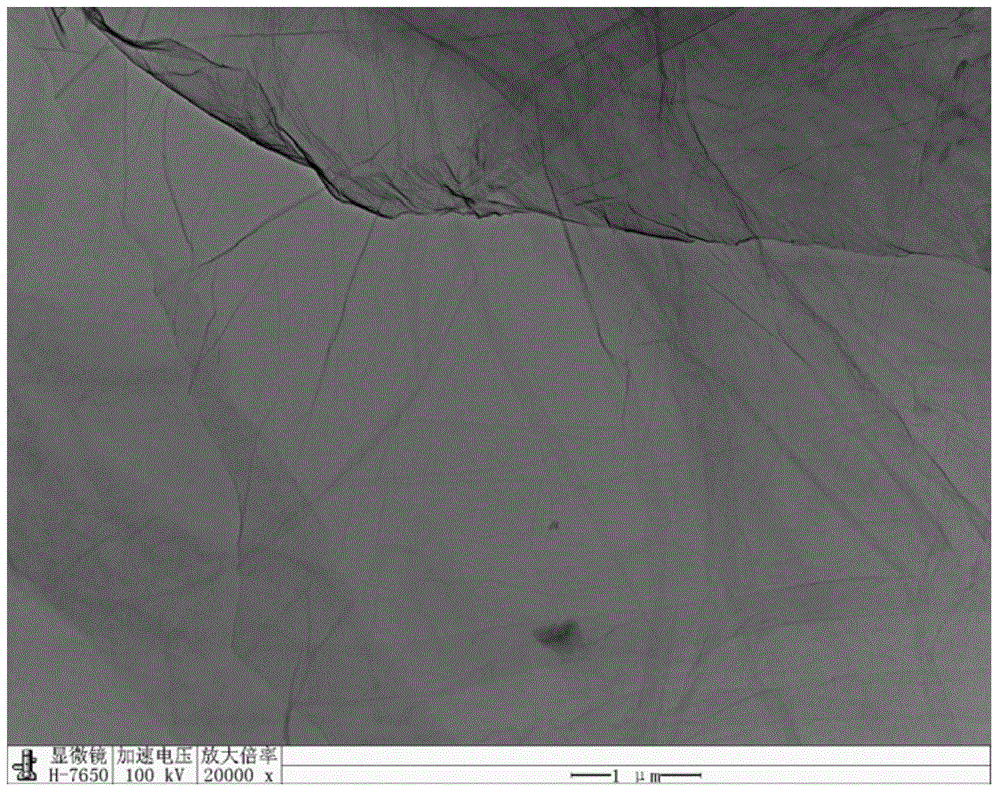

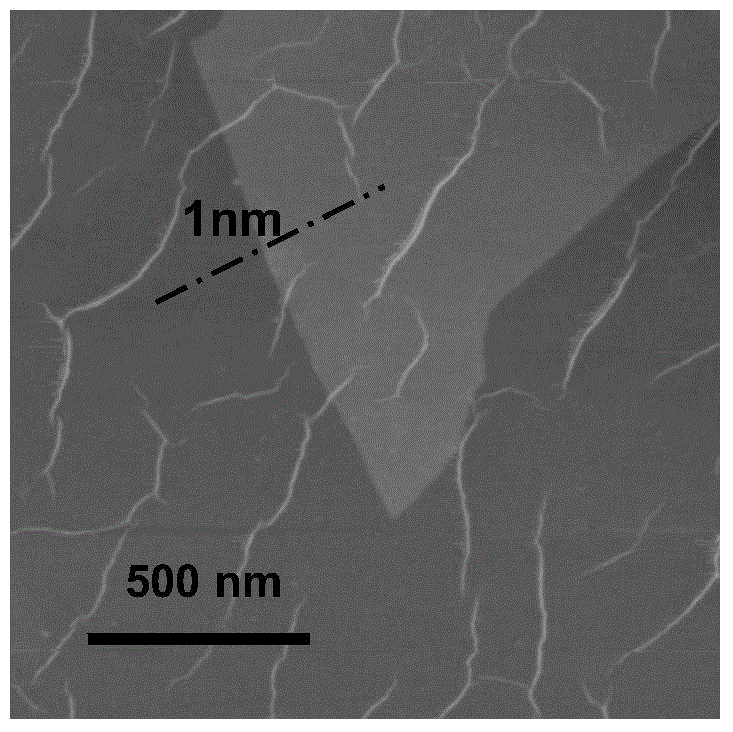

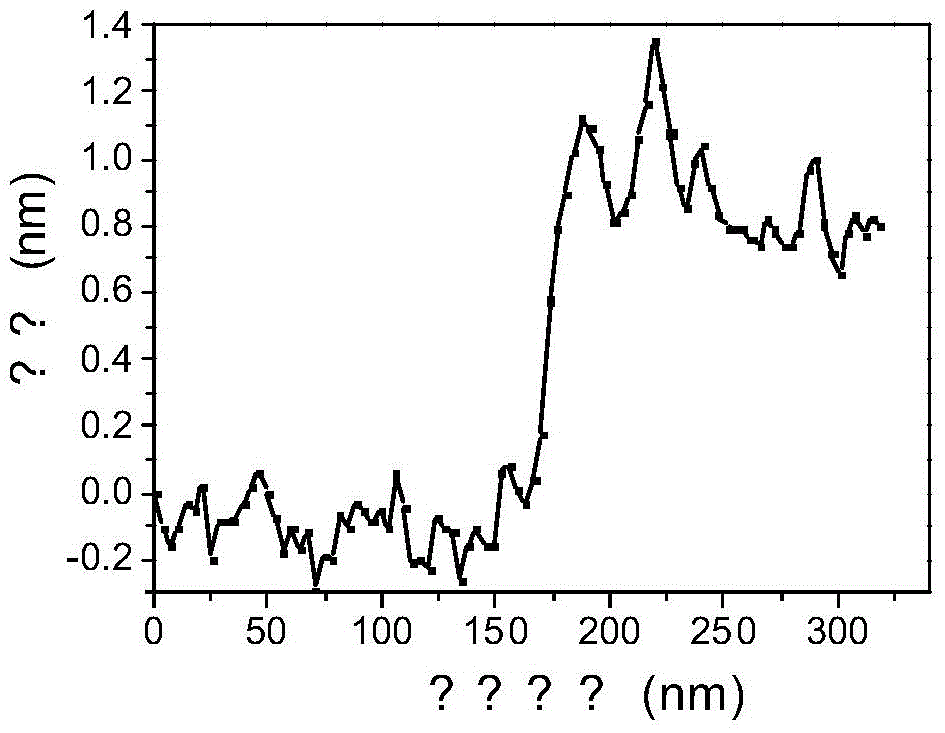

Graphene oxide solution for wet spinning and preparation method thereof, graphene fiber and preparation method of graphene fiber

ActiveCN105088415AEasy qualityQuality improvementInorganic material artificial filamentsWet spinning methodsFiberPre expansion

The invention provides a preparation method of a graphene oxide solution for wet spinning; the preparation method includes the following steps: carrying out centrifugal concentration on a graphene oxide solution, to obtain the graphene oxide solution for wet spinning. The graphene oxide solution is subjected to centrifugal concentration so as to obtain the graphene oxide solution for wet spinning finally. The preparation method of the graphene oxide solution for wet spinning simplifies operation processes, and omits ultrasound, dialysis and pre-expansion processes and the like; the experimental preparation process is simple, the conditions are easy to control, and large-scale production can be realized. In addition, the graphene oxide solution used for wet spinning and prepared by the preparation method provided by the invention has the advantages of stable quality, good water solubility, controllable concentration, and easy adjustment of the size of obtained graphene fiber.

Owner:UNIV OF SCI & TECH OF CHINA

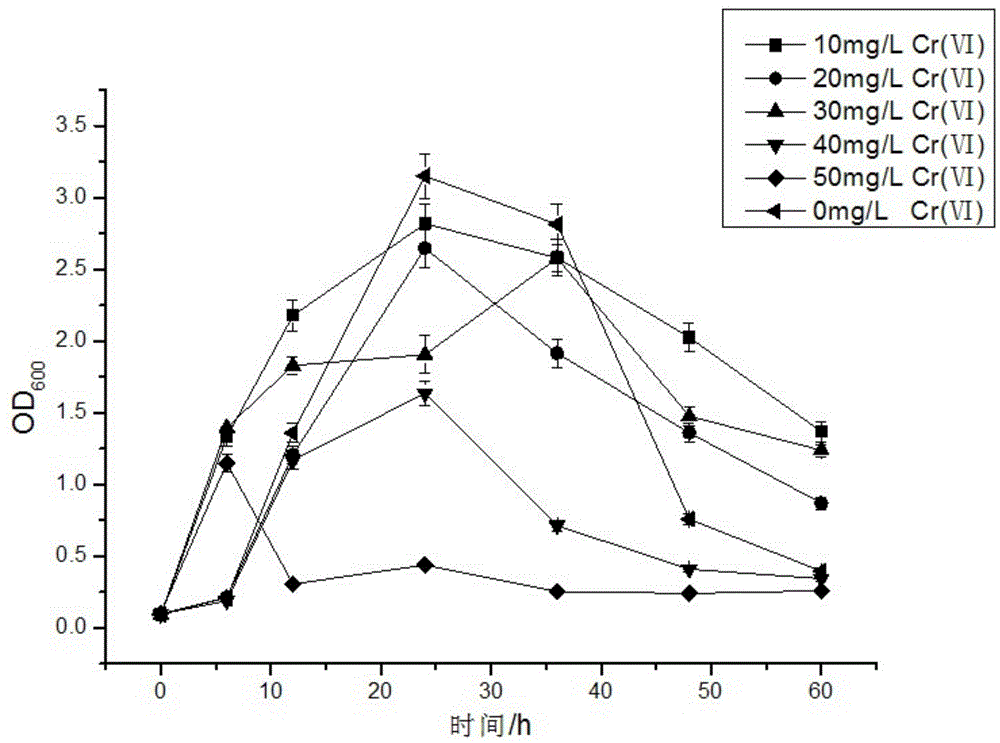

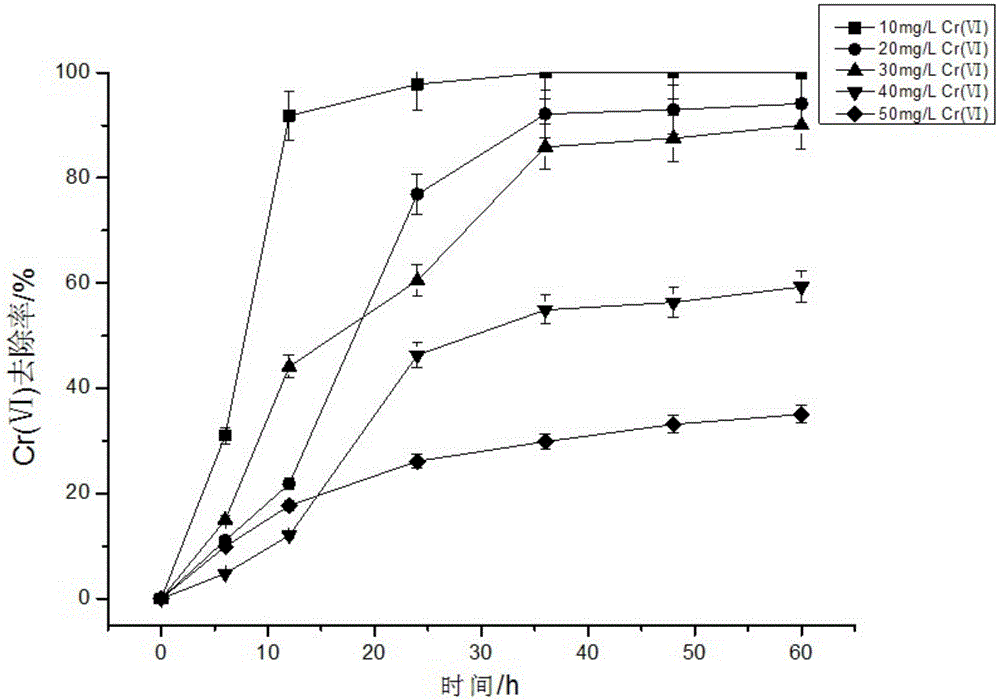

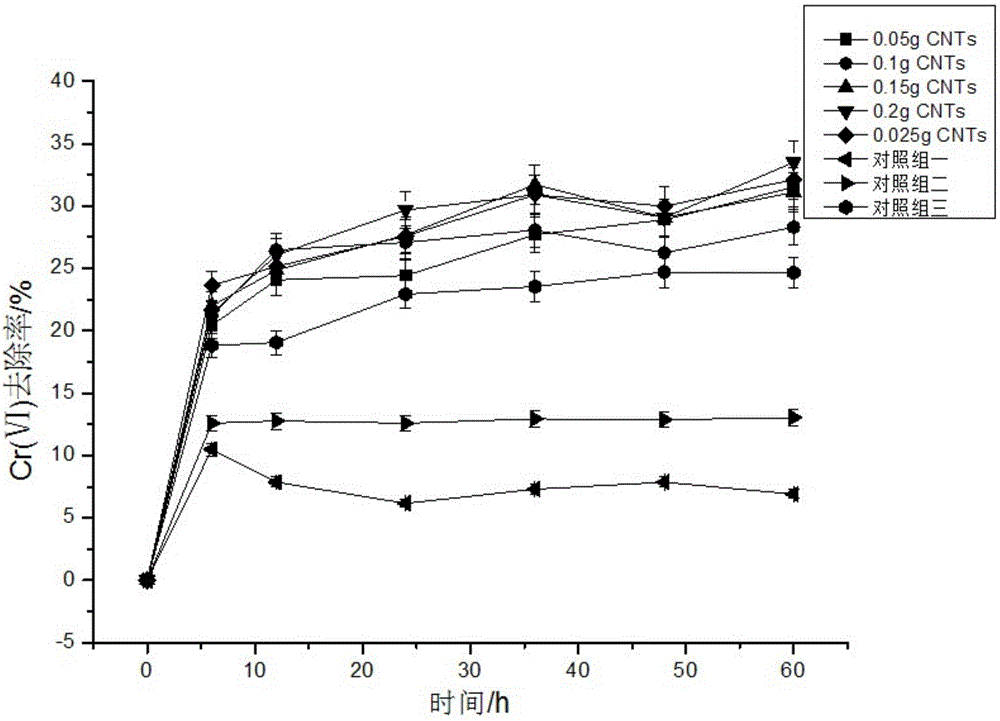

Method of treating hexavalent chromium wastewater by immobilized microorganisms

InactiveCN104386831AConcentration controllableStrong poison resistanceBacteriaWater contaminantsMicrobial agentTherapeutic effect

The invention discloses a method of treating hexavalent chromium wastewater by immobilized microorganisms. The method aims at solving the problem that the human health is affected as the environment is severely polluted by the hexavalent chromium wastewater. The method comprises the following steps: a step I of preparing immobilized microorganism particles and a step II of treating wastewater, wherein in the step I, a microbial agent is dissolved into a sodium alginate solution, an additive is added to form a mixed solution, then the mixed solution is added into a calcium chloride solution to obtain embedded particles, and the embedded particles are stewed and immobilized, and washed by normal saline to obtain the immobilized microorganism particles. According to the method of treating hexavalent chromium wastewater by immobilized microorganisms disclosed by the invention, by selecting and matching the additive and a culture medium, the treatment effects and treatment efficiency of the hexavalent chromium wastewater can be greatly improved to meet the needs of industrially treating the hexavalent chromium wastewater. The method of treating hexavalent chromium wastewater by immobilized microorganisms has the advantages of low cost, small equipment investment, convenience in operation, and the like, has a wide market prospect and a high application value, and is worthy of being popularized and applied on a large scale.

Owner:SOUTHWEAT UNIV OF SCI & TECH

One-shot forming process for preparing split-blip brush wire

InactiveCN101011200APrevent penetrationIncrease productivityFibre treatmentCurling-ironsPolyesterLithium hydroxide

The invention relates to a method for preparing dual-sharp printing wires by one time. The invention comprises that sheathing a film outside the polyester wires to form wire beam to be cut into wire cake; packing the wire cake by the politef coat, and be tied by the beam; immerging the wire cake in the processing liquid of shaping kettle, for 25-35min at 115-128Deg. C, while the processing liquid is formed by mixing caustic soda, caustic potash, or lithium hydrate and water, and the processing liquid is added as 28-42%; taking out the wire cake, removing the coat, washing in water to remove the left liquid and corrosion material, arranging into fixed support to be dewatered by dewatering machine, dried or baked by bake oven to be packed into final product. The invention has high efficiency and low cost, without pollution.

Owner:王小芳

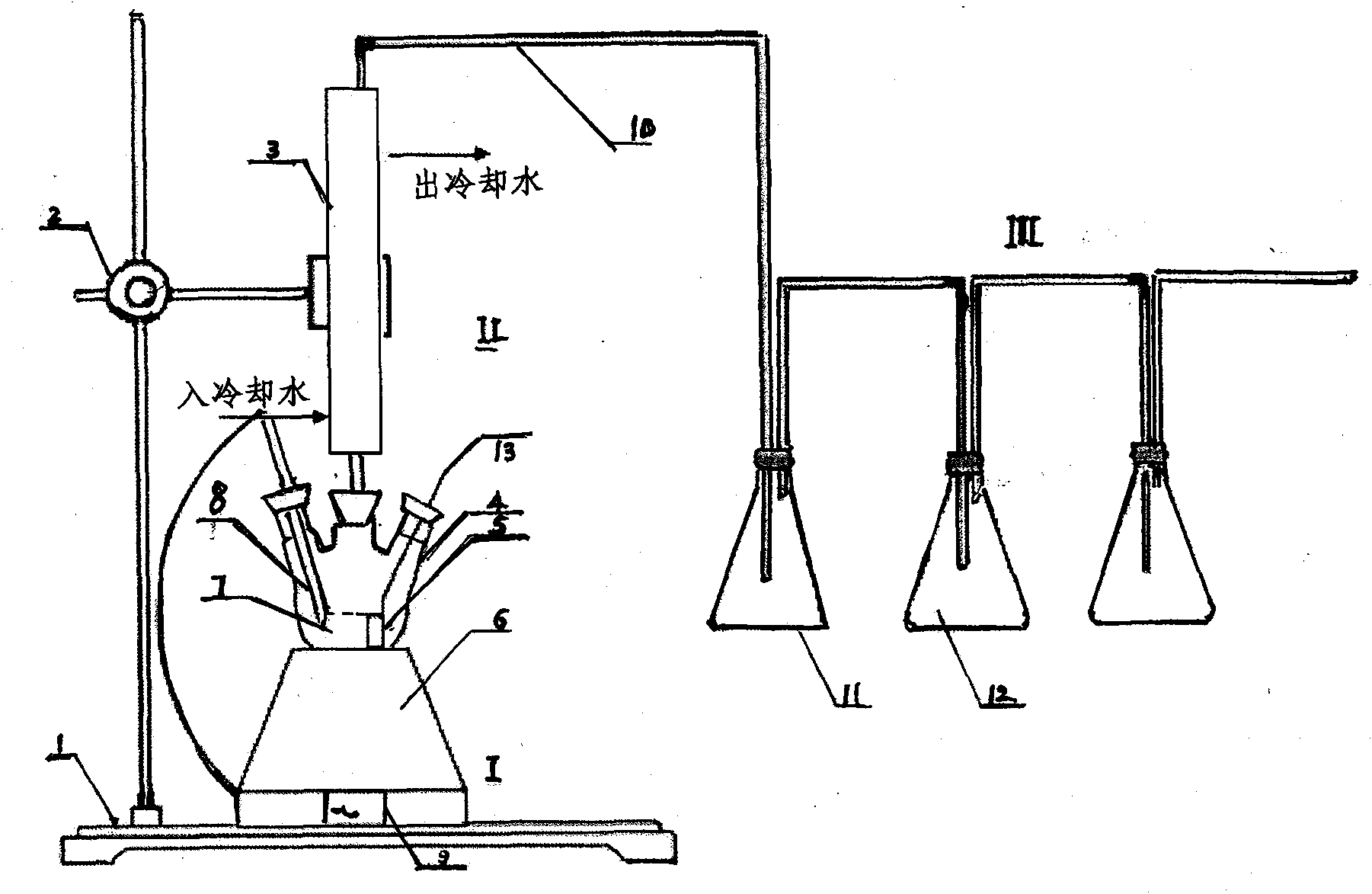

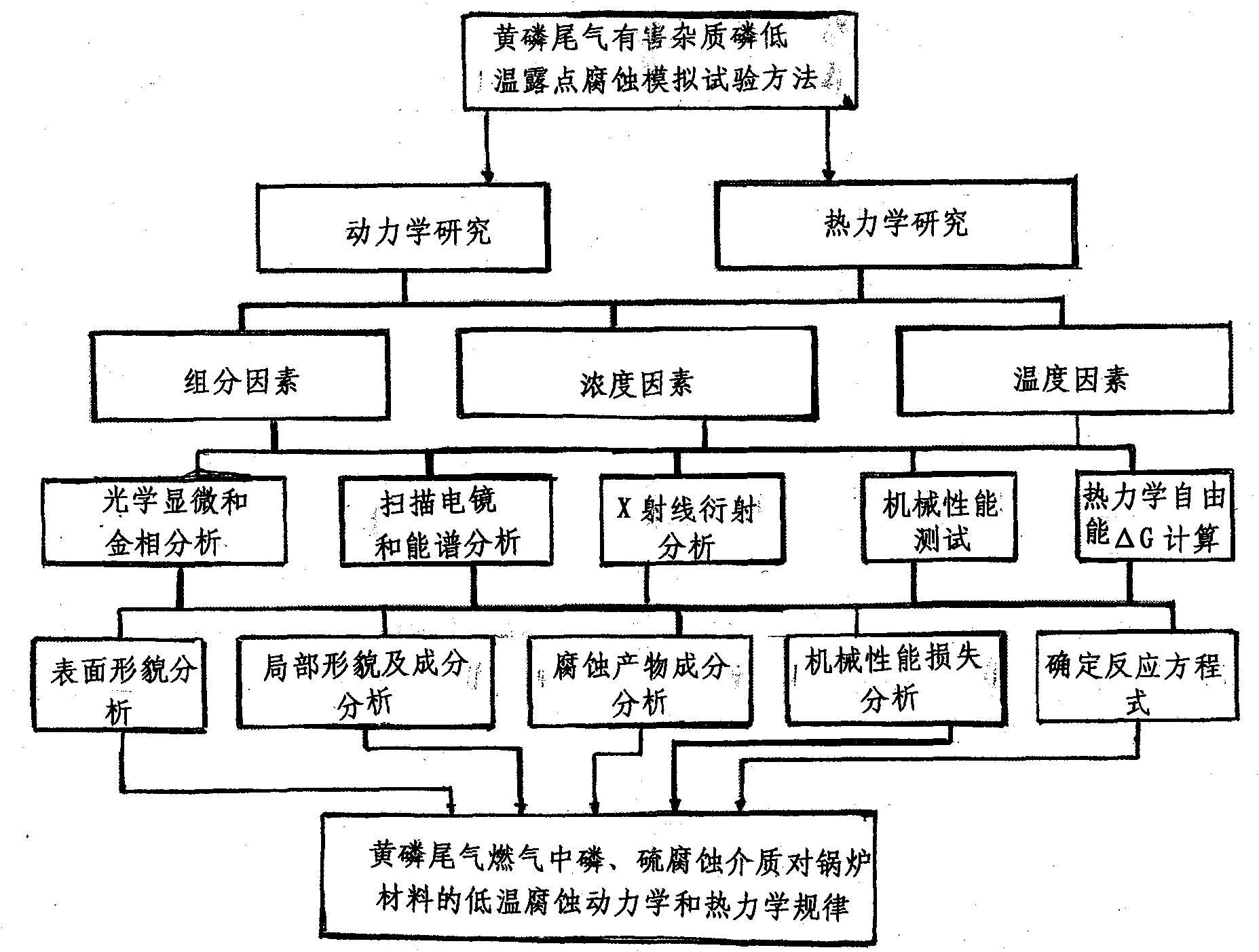

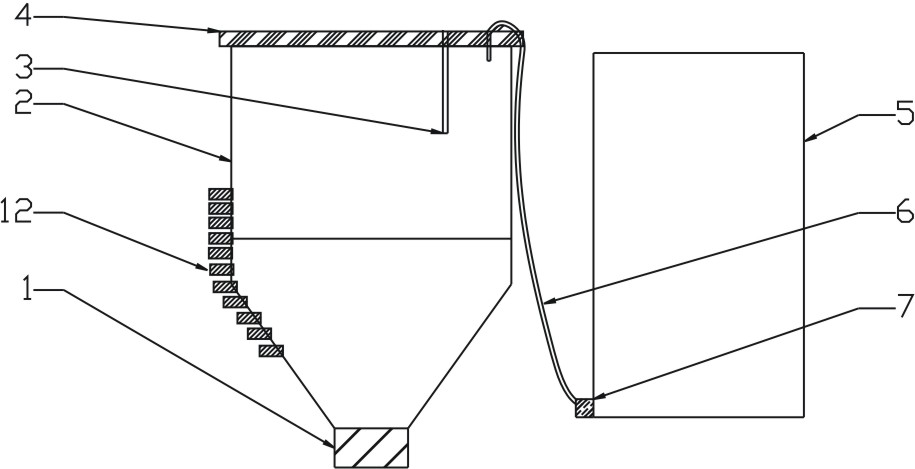

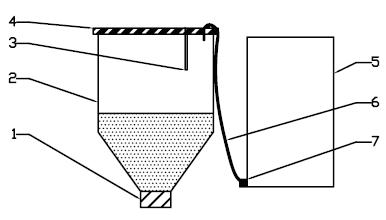

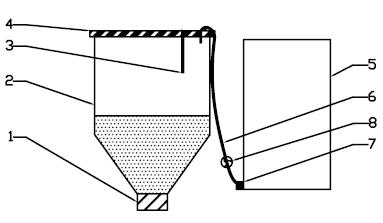

Low-temperature dew point corrosion experiment method for phosphorus in yellow phosphorus tail gas on boiler material and device thereof

InactiveCN101929945ASolve the problem of low temperature corrosion hazardsAvoid factors that are difficult to controlWeather/light/corrosion resistancePreparing sample for investigationHeating temperaturePollution

The invention relates to a low-temperature dew point corrosion experiment method for phosphorus in yellow phosphorus tail gas on a boiler material, and a device thereof, in particular to a yellow phosphorus tail gas phosphorus component low-temperature dew point corrosion experiment method and a device for implementing the method. A yellow phosphorus tail gas phosphorus component low-temperature dew point corrosion experiment system is contained, and consists of a heating temperature control system, a condensation reflux system and a tail gas treatment system. The experiment heating temperature control device adopts an air heating jacket, and has good temperature control capacity and quick, even and stable heating; and a tail gas absorbing device is arranged, so pollution is free in the experiment. The method and the device can perform dew point corrosion study on acids, can better simulate the low-temperature dew point corrosion of impurities such as the phosphorus on the boiler material in the yellow phosphorus tail gas comprehensive utilization, and also can be used for comprehensive utilization study on other industrial waste gases (tail gases).

Owner:KUNMING UNIV OF SCI & TECH

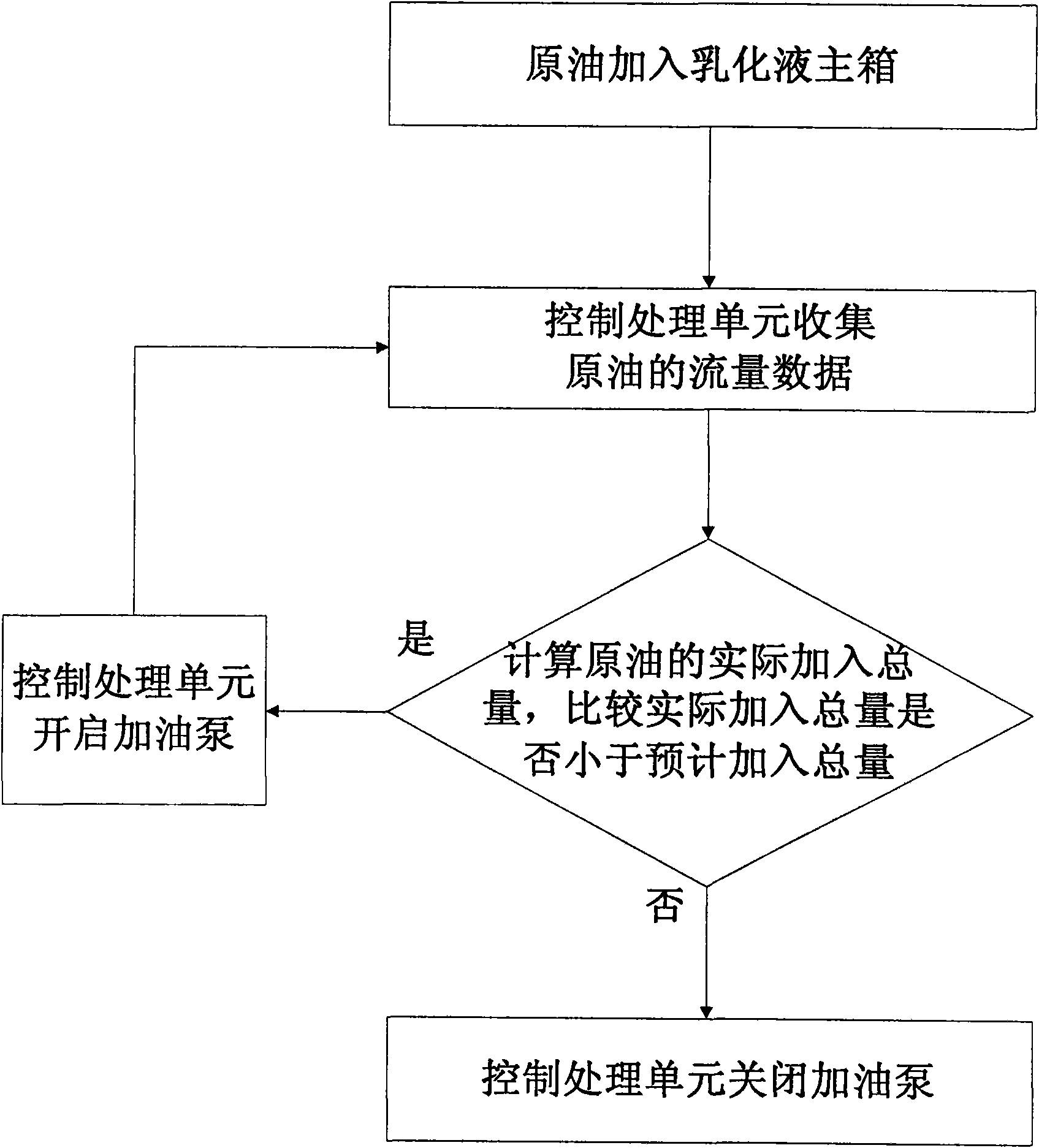

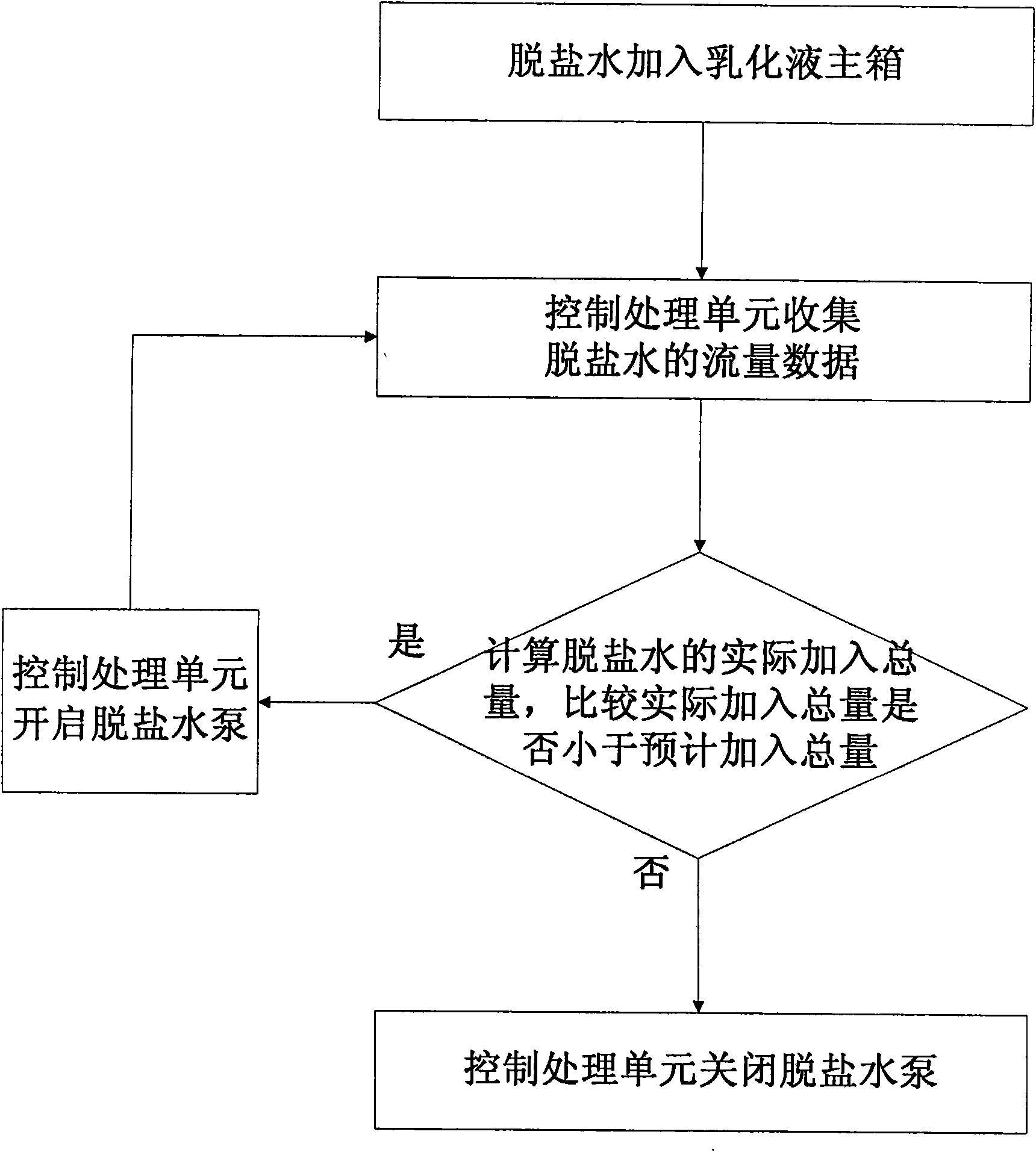

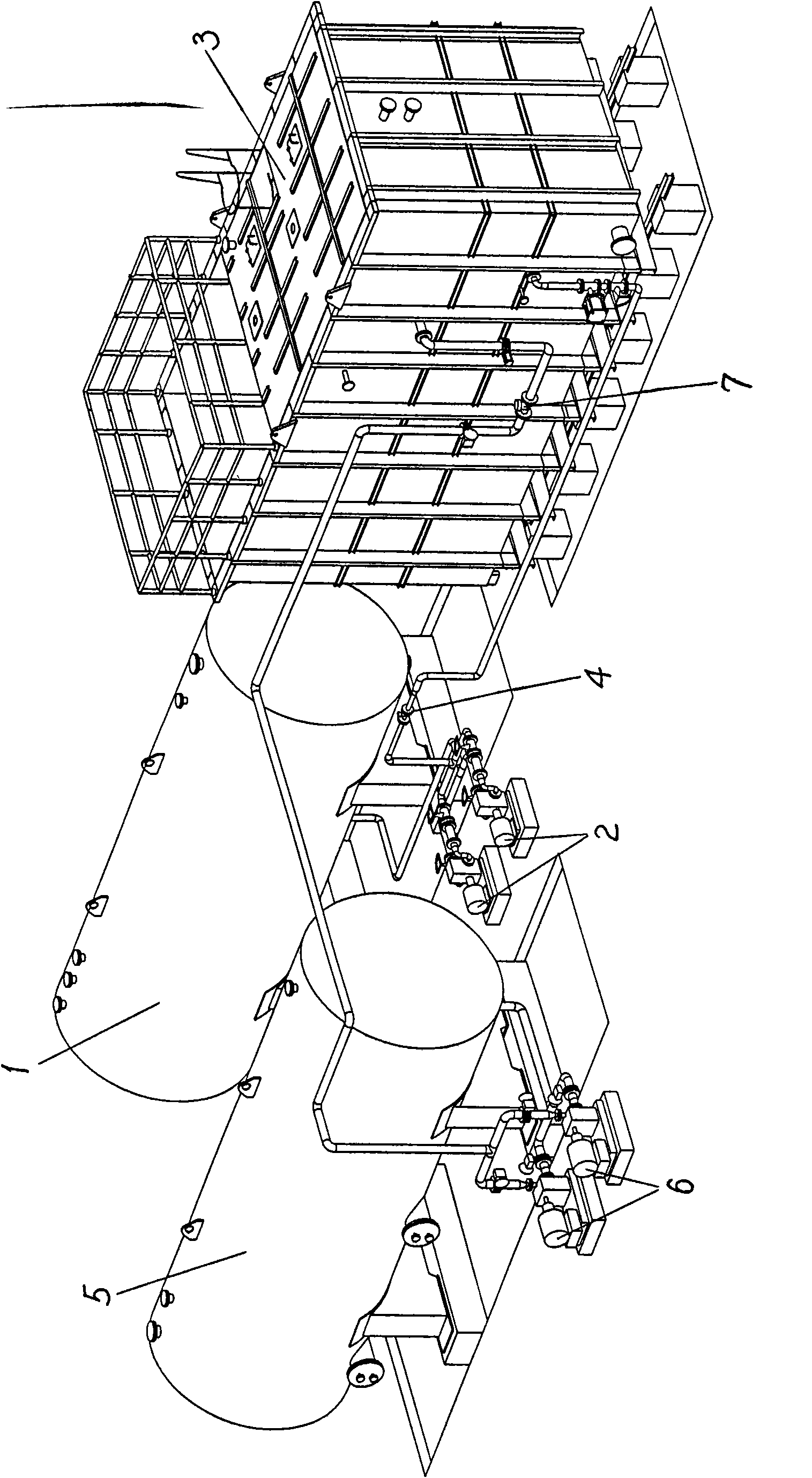

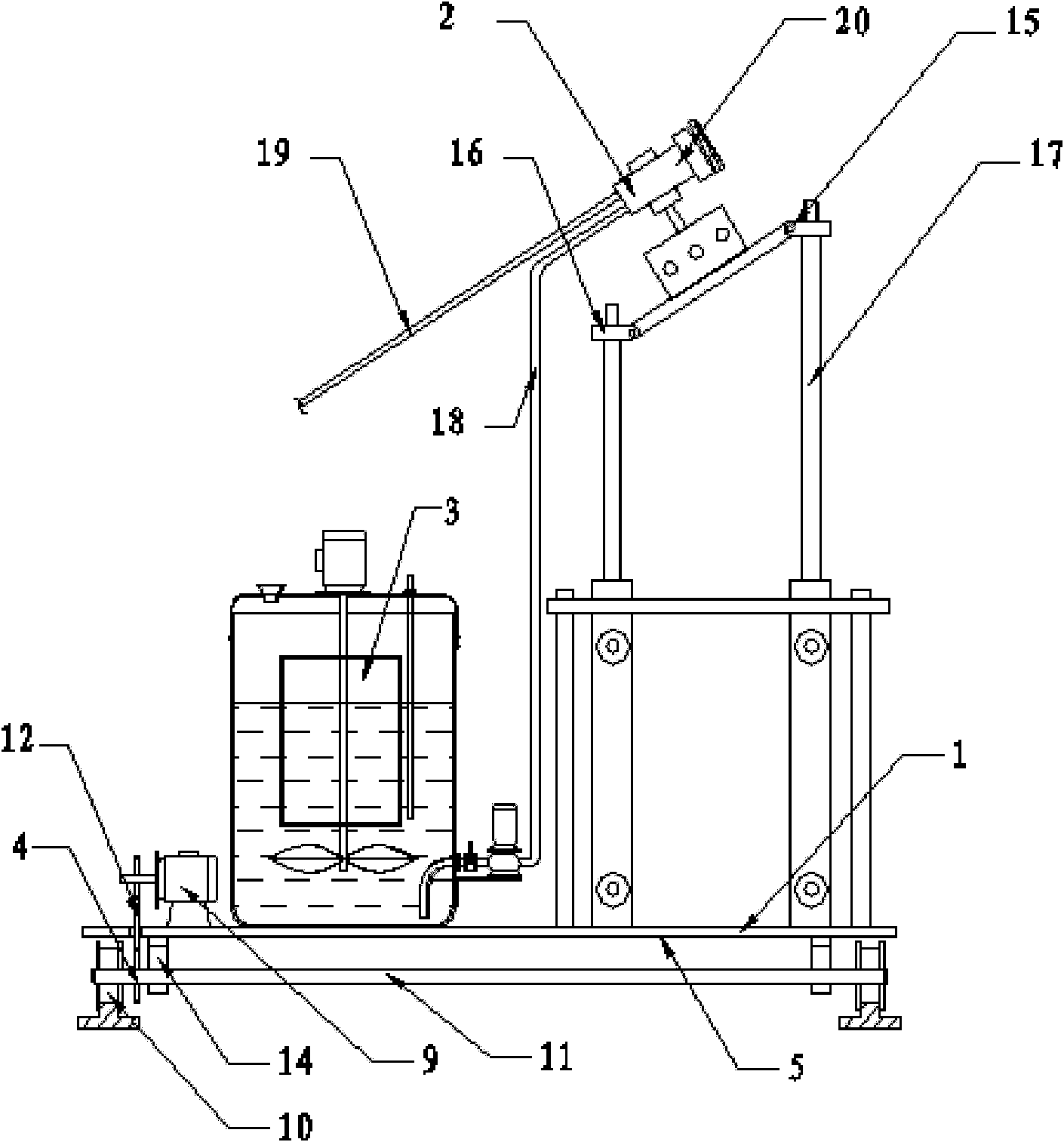

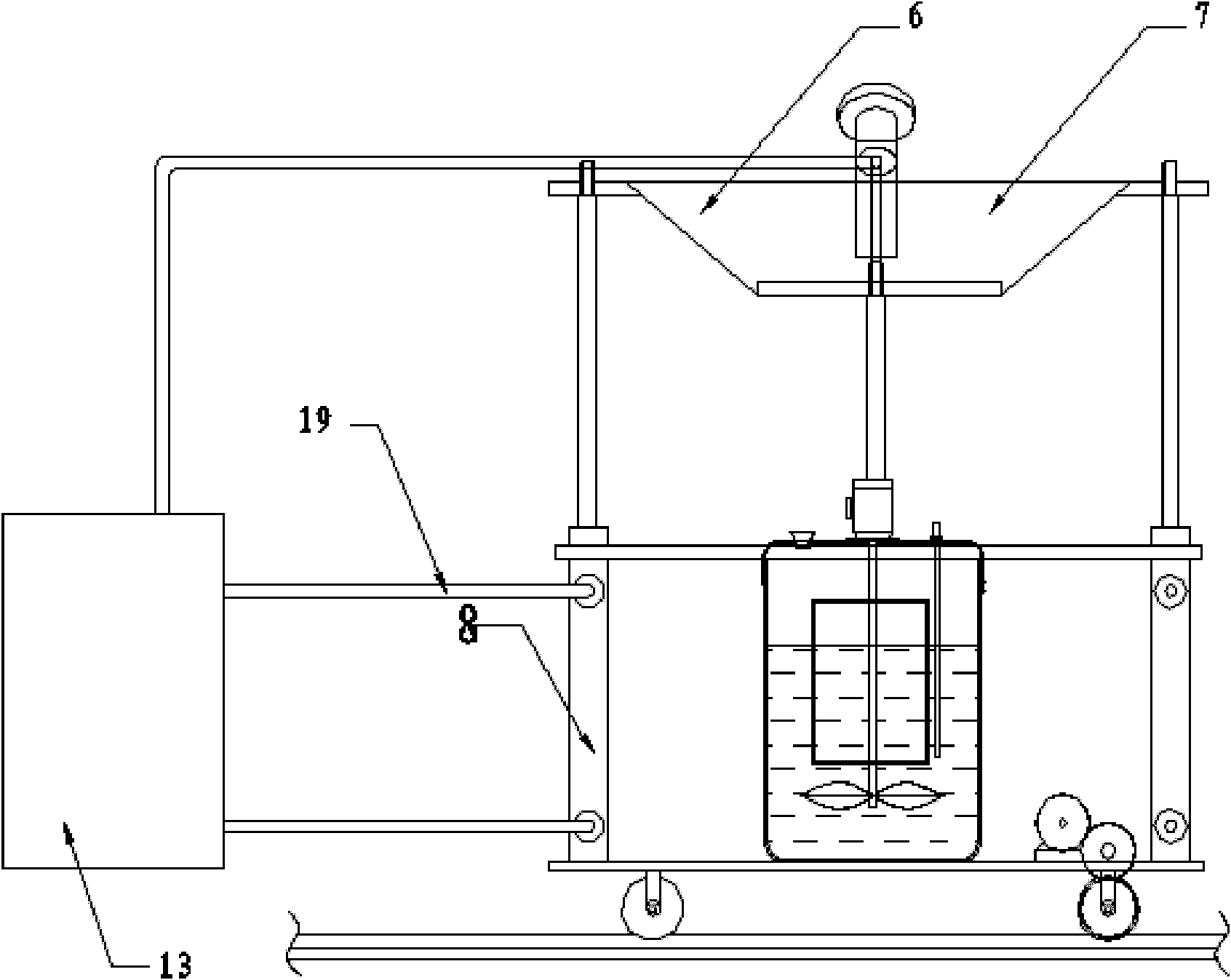

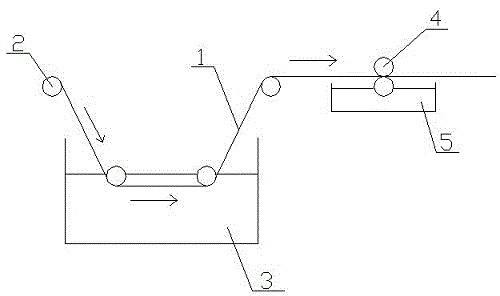

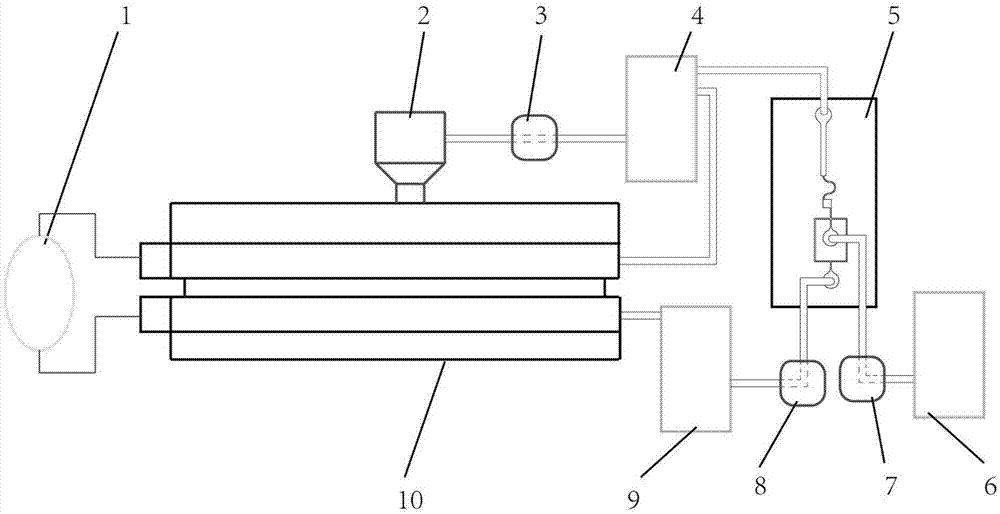

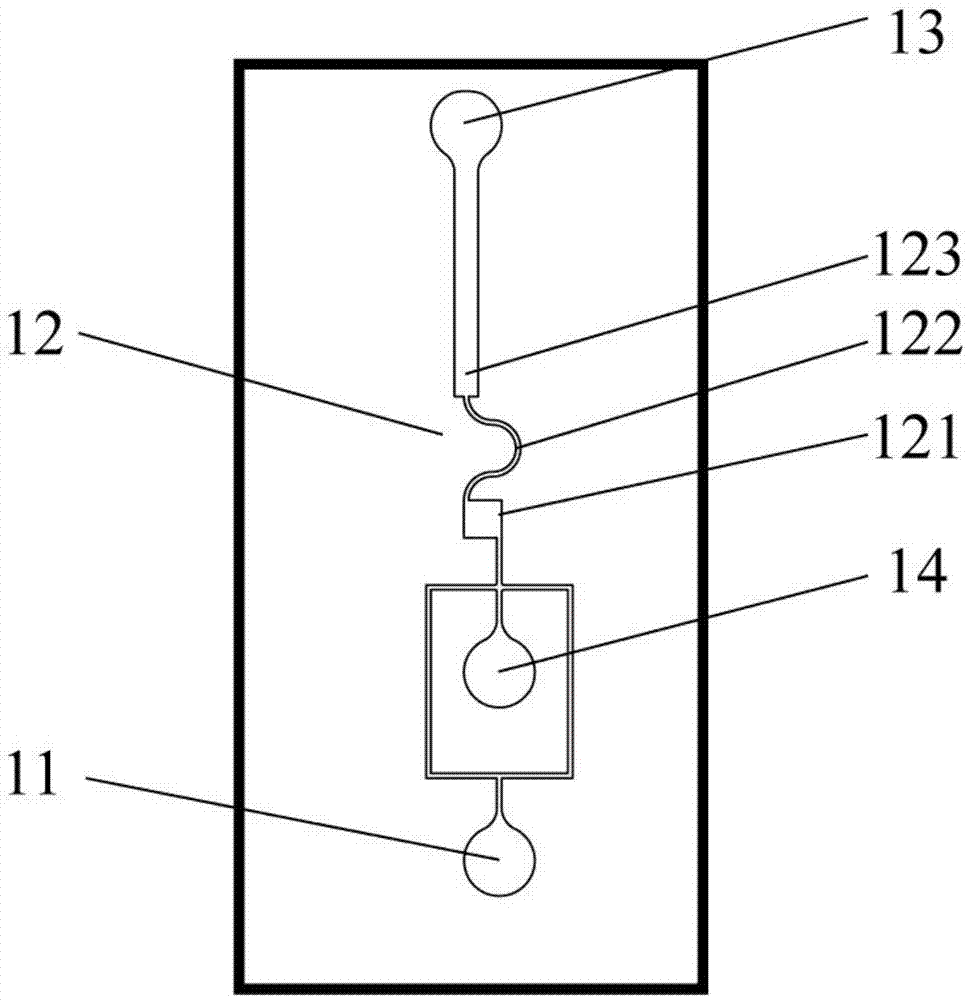

Method for compounding concentration of emulsion used for rolling mill and compounding device

InactiveCN101574633AConcentration is easy to controlHigh precisionMixing methodsMixer accessoriesEmulsionSalt water

The invention relates to a method for compounding concentration of emulsion used for a rolling mill, wherein the process of adopting crude oil to prepare the emulsion is realized by flow-controlled adding process of crude oil and the process of adopting desalted water to prepare the emulsion is realized by flow-controlled adding process of desalted water. The crude oil is transferred to an emulsion main tank from a crude oil tank through a dispensing pump and a flow meter is adopted to monitor flow data of the crude oil and the flow data is sent to a control processing unit; and the desalted water is transferred to the emulsion main tank from a desalted water tank through a desalted-water pump and a flow meter is adopted to monitor the flow data of the desalted water and the flow data is sent to a control processing unit. The compounding device comprises the crude-oil tank, the dispensing pump, the desalted water tank, the desalted water pump, the emulsion main tank, two flow meters and two control processing units. With the invention, the concentration of the emulsion can be easily controlled and the precision is high; the operation is simple, convenient and feasible and the maintenance is convenient; both contamination and waste can be reduced; the manufacturing cost can be reduced; and the lubricating effect of the emulsion is good and the service life of rollers can be prolonged.

Owner:BAOSTEEL ENG & TECH GRP

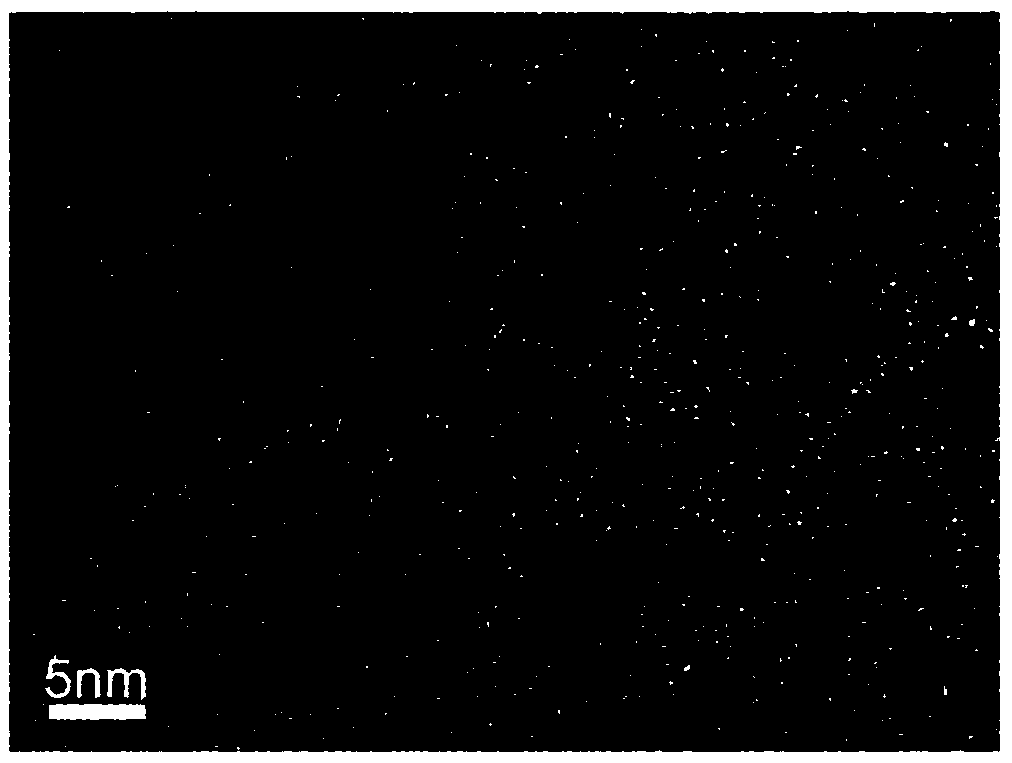

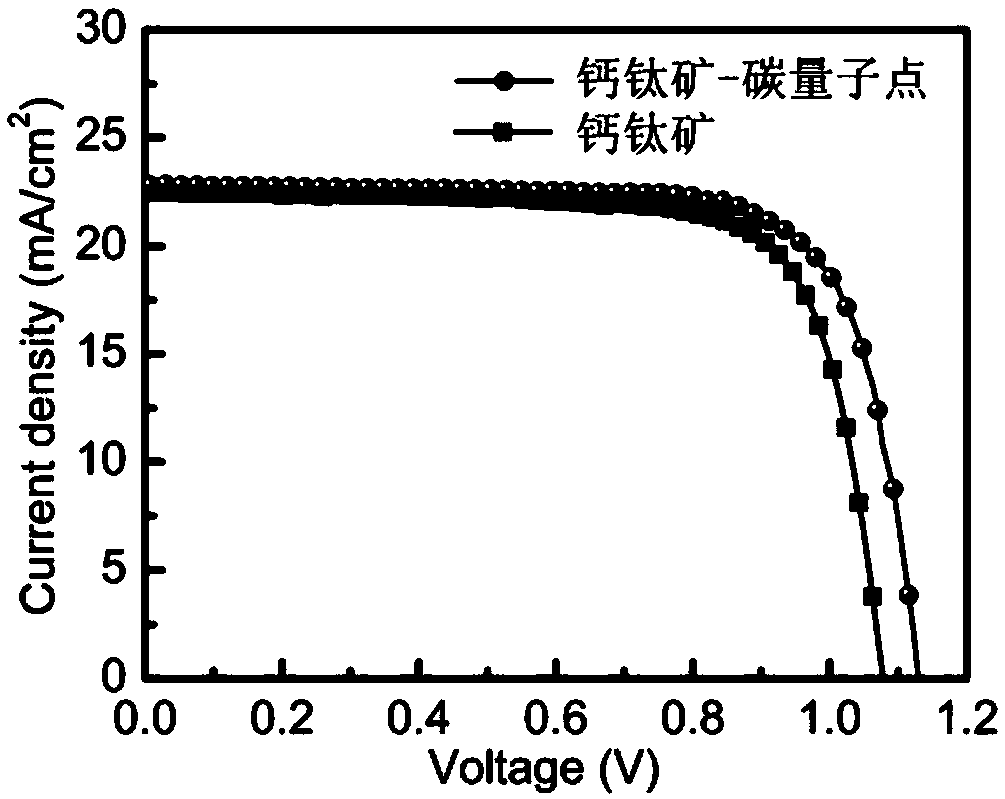

Preparing method of carbon quantum dot modified perovskite solar cell

InactiveCN108878661AGood dispersionImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingElectron transmissionPhotoelectric conversion efficiency

The invention belongs to the technical field of solar cells, and relates to a preparing method of a carbon quantum dot modified perovskite solar cell. The preparing method comprises the steps that a carbon quantum dot solution is prepared in situ through a pulse laser irradiation anti-solvent; then a transparent conductive substrate covered with an electron transmission layer is spin-coated with aperovskite precursor solution, the carbon quantum dot solution is dripped onto a perovskite thin film in the spin-coating process, and the perovskite thin film modified by carbon quantum dots is formed after heat treatment; and finally, a hole transport layer and a metal electrode are prepared, and preparation of the perovskite solar cell is completed. The carbon quantum dots prepared through themethod are controllable in size and excellent in dispersity and stability, and can be directly introduced into the perovskite thin film, and the preparation process of perovskite is simplified advantageously. The carbon quantum dot modified perovskite solar cell prepared through the preparing method is high in photoelectric conversion efficiency and good in stability, the maximum efficiency can reach 21% or above, and the carbon quantum dot modified perovskite solar cell has extremely high practical application value.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

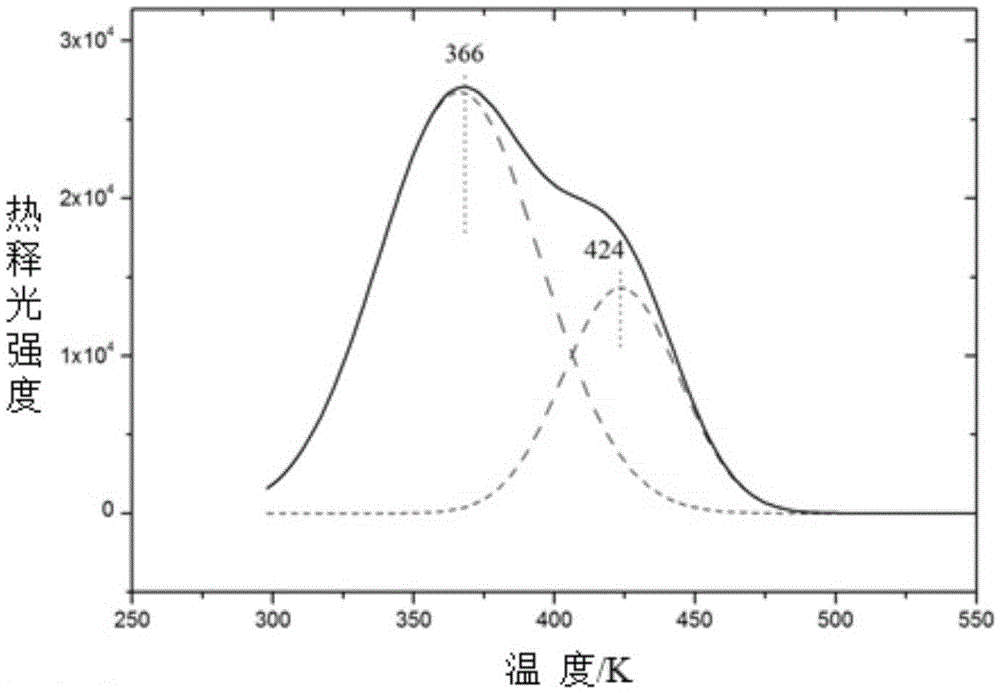

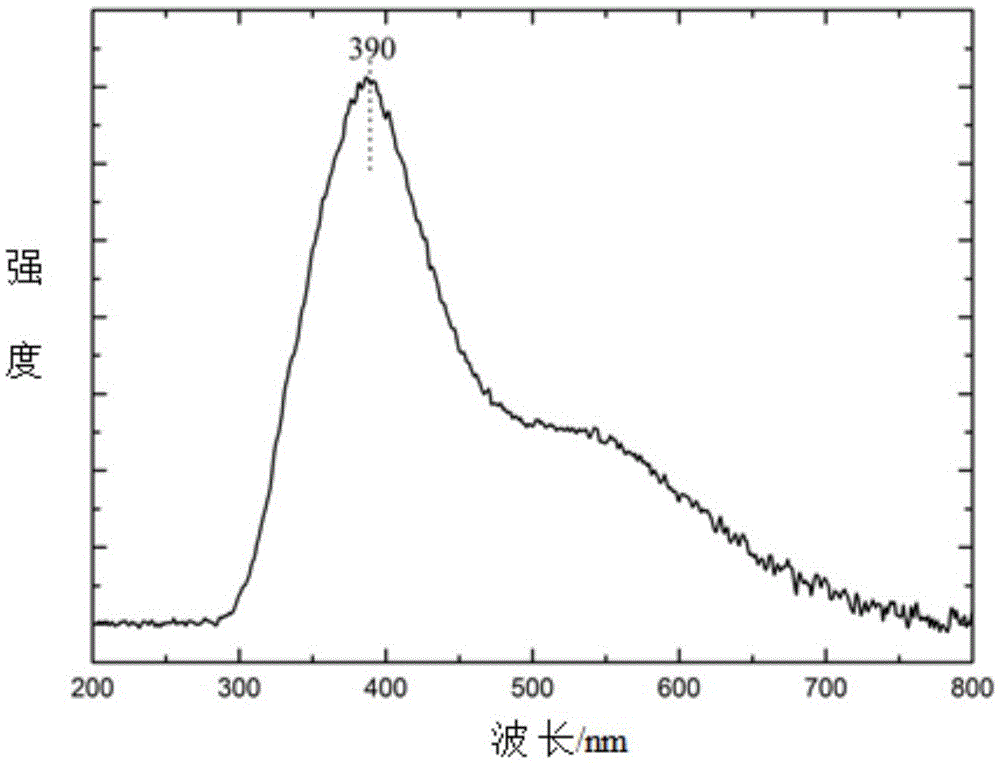

Gallium oxide crystals with thermoluminescence performance and preparation method thereof

ActiveCN105603528AImprove capture efficiencyStable thermoluminescent performancePolycrystalline material growthAfter-treatment detailsThermoluminescenceDecomposition

The invention relates to gallium oxide crystals with thermoluminescence performance and a preparation method thereof. The gallium oxide crystals comprise gallium oxide and Ge4+ doped in gallium oxide, and the doping concentration preferably ranges from 0.1 mol% to 10 mol%. The gallium oxide crystals are prepared through a mode guide method. Compared with the prior art, the germanium-doped gallium oxide crystals have the good thermoluminescence performance, and the Ge4+ doping concentration can be controlled. A mixed atmosphere of Ar and CO2 is adopted, Ar gas and CO2 gas introduced at different stages are combined, decomposition and volatilization of the gallium oxide crystals in the growing process are effectively restrained, and the crystals are short in growth period and low in cost.

Owner:TONGJI UNIV

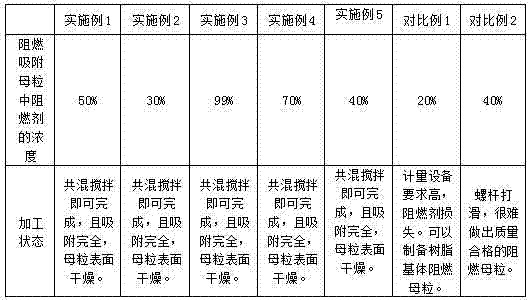

Flame retardant adsorption master batch and preparation method thereof

ActiveCN104744840ASolve the difficulty of addingSolving Dispersion ProblemsPolymer sciencePolyolefin

The invention discloses a flame retardant adsorption master batch and a preparation method thereof. The flame retardant adsorption master batch is prepared by mixing and absorbing 1-7 parts of a porous adsorbing material particle and 99-30 parts of a flame retardant additive, wherein the porous adsorbing material particle is a polyolefin open-cell foamed plastic or natural porous material with a partial open-cell structure or sponge or netty microstructure; the average particle size of the porous adsorbing material particle is 1-10 mm, the porosity is at least 30% and the average diameter of the micropore is 50-200 mu m. The porous adsorbing material particle is taken as a storage stack for absorbing a liquid or suspending flame retardant, wherein the maximum concentration is 99%; in the high polymer material machining process, the adding amount of the master batch is few, the operation is convenient and the physical and mechanical properties influence on the resin material is small; the traditional master batch preparation process can be replaced without an expensive device or heating treatment, so that the master batch preparation period and device utilization rate are greatly shortened.

Owner:安徽星贝达新材料科技有限公司

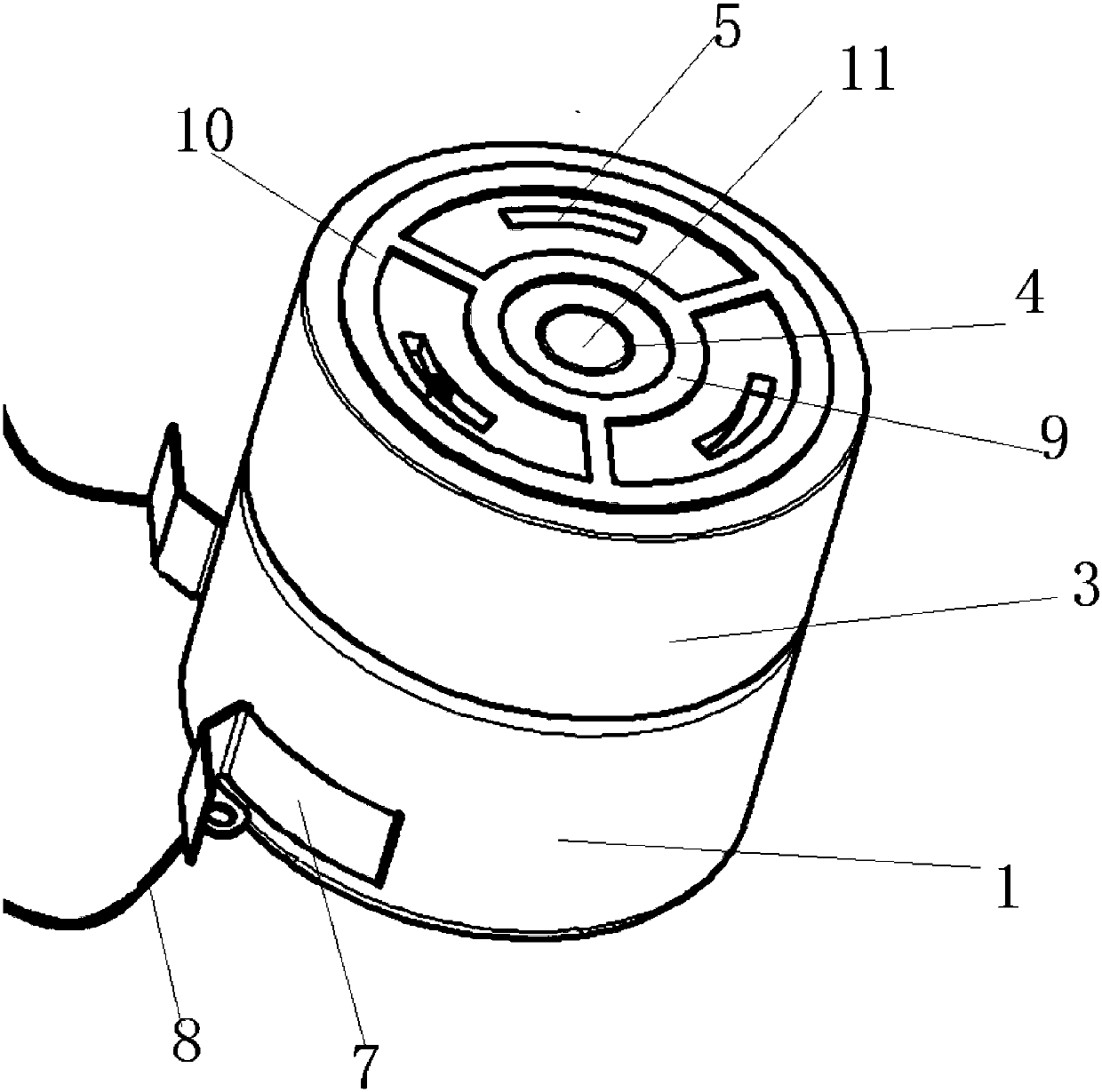

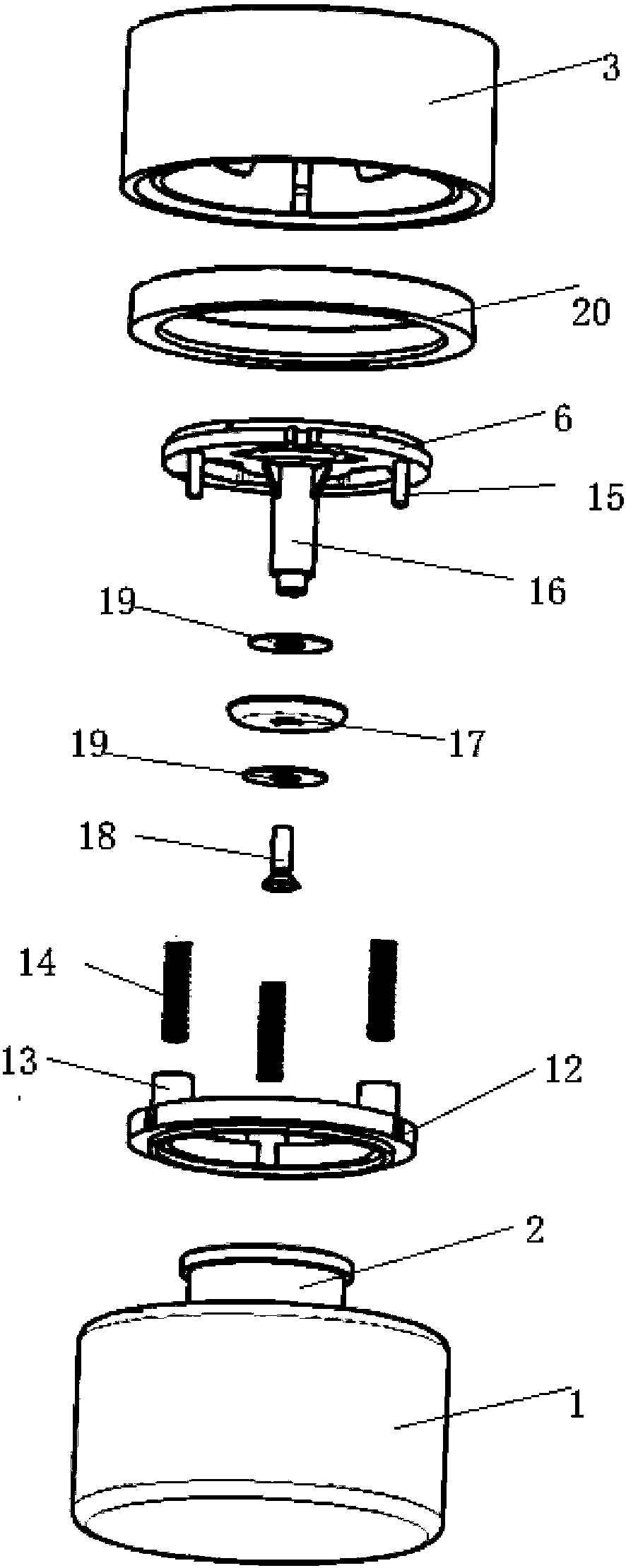

Fully automatic bean milk machine and bean milk making method

ActiveCN101861896AConcentration controllableSatisfy taste needsBeverage vesselsMilk substitutesProcess engineeringControl circuit

The invention discloses a method for preparing beverages, in particular to a bean milk making method of a fully automatic bean milk machine, which comprises the following steps of: adding a material, pouring a certain amount of water, turning on the machine to preheat the mixture to a designed temperature, and automatically controlling the bean milk machine to crush the material and cook the material with a control circuit board to make bean milk. The fully automatic bean milk machine is characterized in that: a material amount detection device is arranged on the bean milk machine and transmits the detection data to the control circuit board; the control circuit board controls and determines required poured water amount according to the detected data of the adding amount of the material and pouring the amount of water into the machine; and the control circuit board controls the crushing and cooking milk making processes according to the practical adding amount of the material and the pouring amount of the water and fully and automatically finish the bean milk making program. The subsequent bean milk making process is determined and the total pouring amount of the water is regulated according to detecting amount of beans. Because the total bean to water ratio can be controlled, the concentration of the bean milk can be controlled; the bean milk making process is also greatly optimized; and bean milk better satisfying the needs of customers can be made.

Owner:JOYOUNG CO LTD

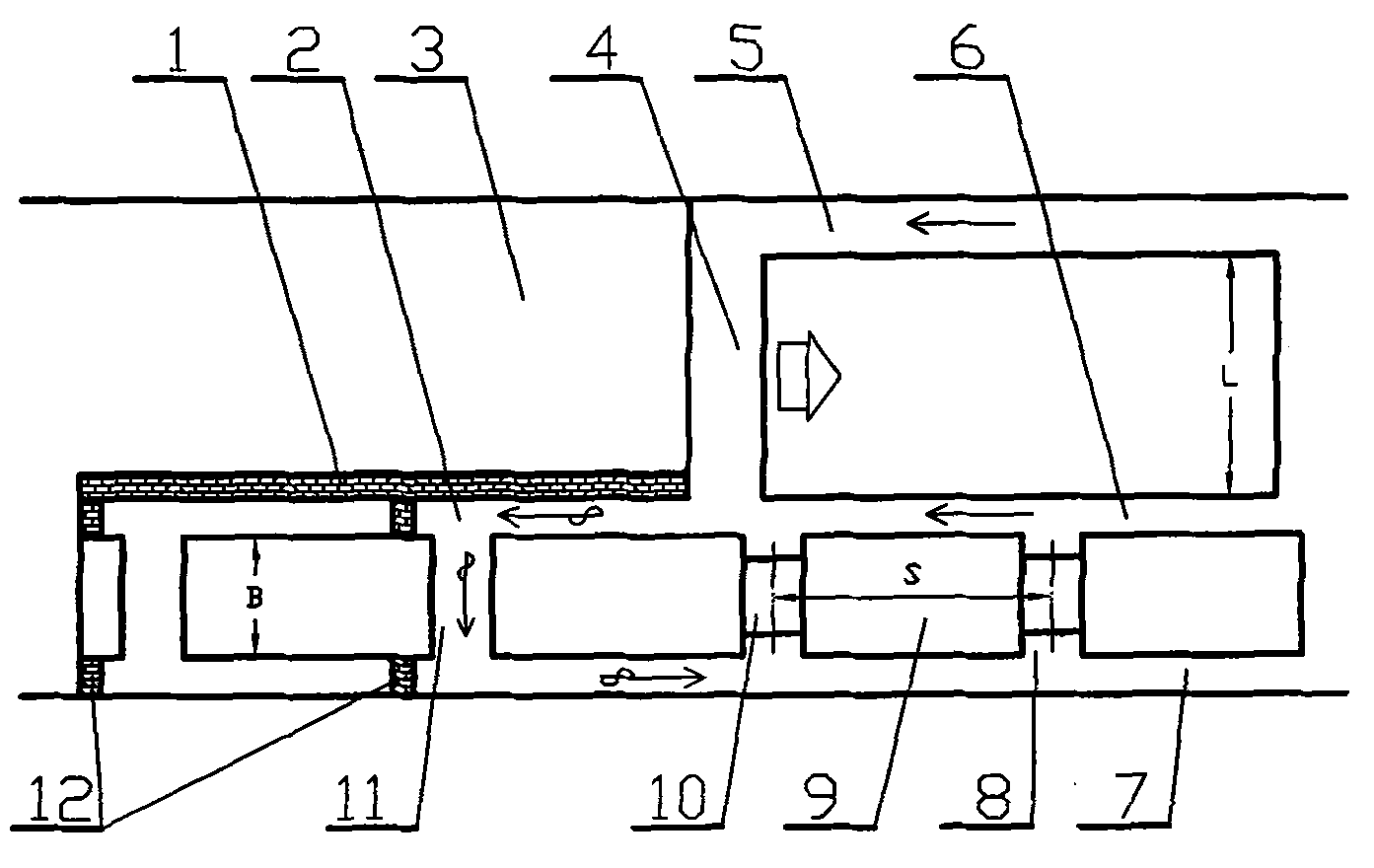

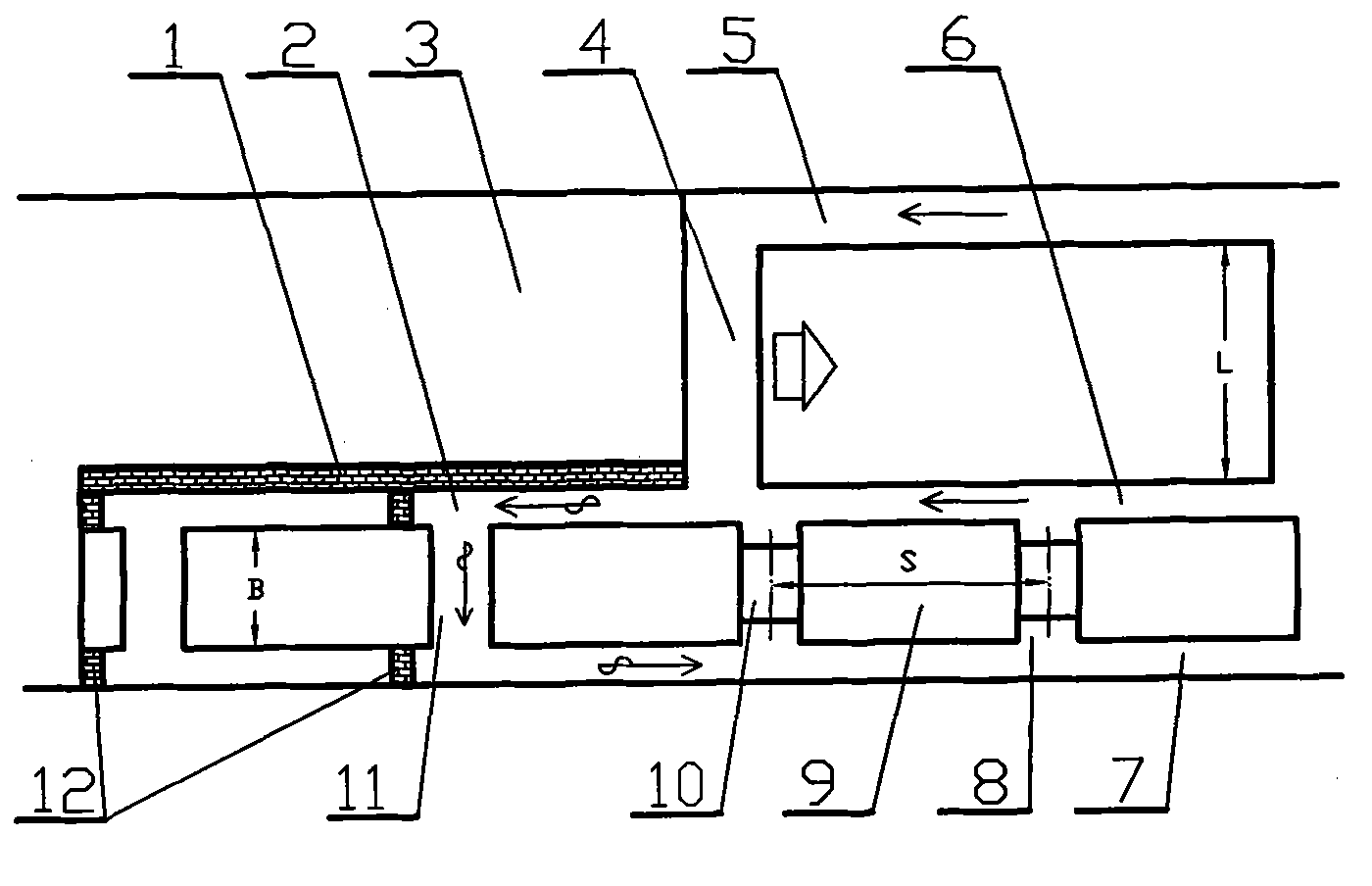

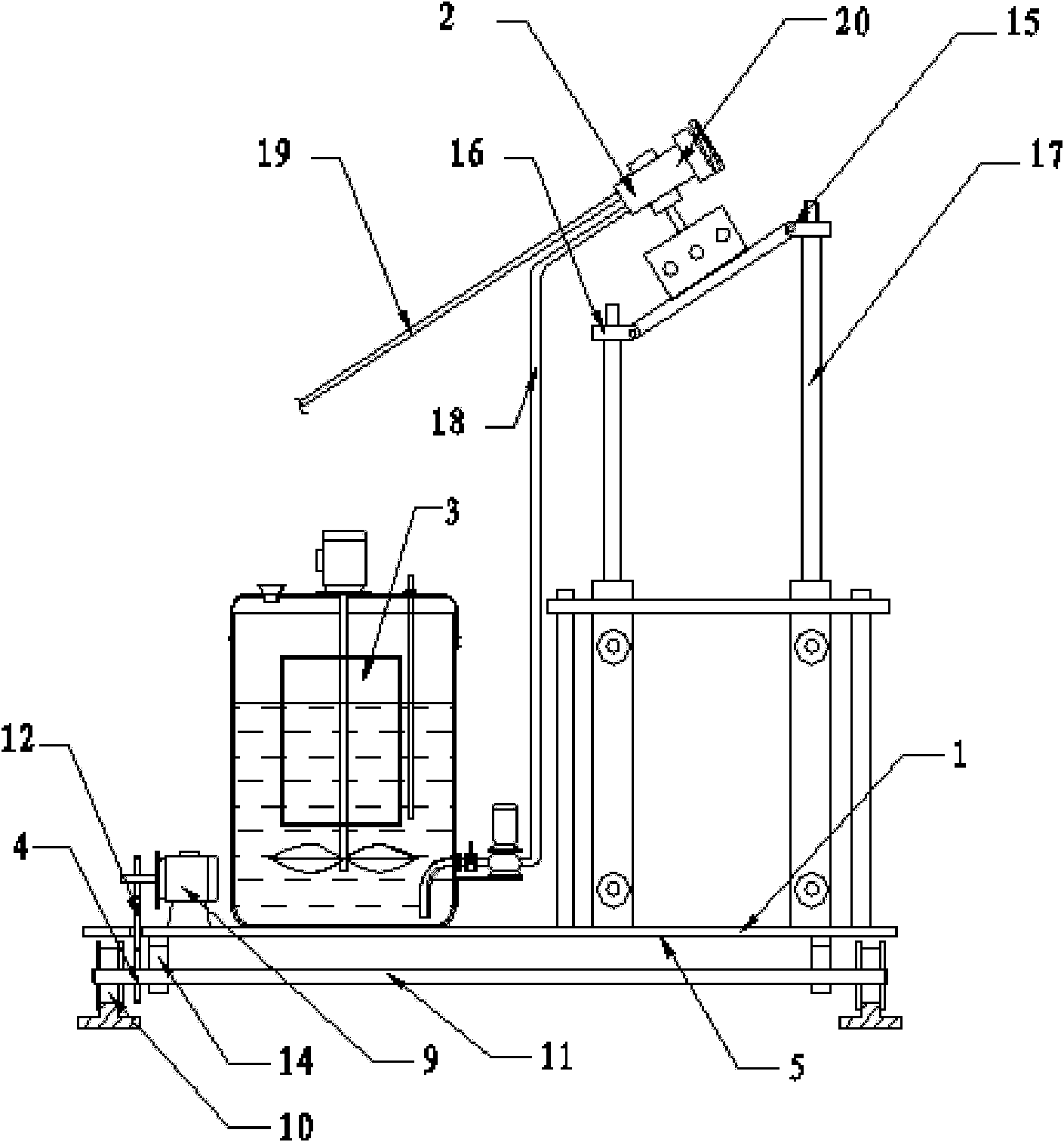

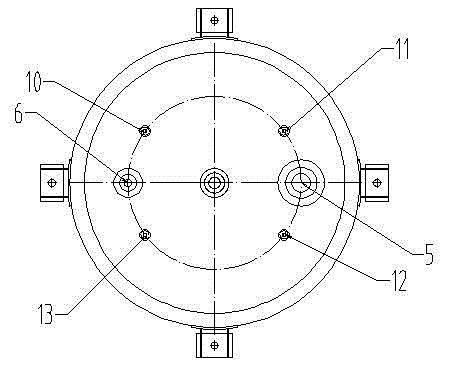

Movable automatic powder spraying system

InactiveCN101927225AEasy to control colorConcentration controllableSpraying apparatusSpray coatingEngineering

The invention discloses a movable automatic powder spraying system. The system comprises a movable bracket, a spray gun, a powder supply system and a moving device, and is characterized in that the bottom of the movable bracket is provided the moving device; the movable bracket is provided with the powder supply system, a vertical cylinder, an angle adjusting plate and the spray gun; the vertical cylinder is fixed on the movable bracket; the angle adjusting plate is connected with the vertical cylinder; and the upper surface of the angle adjusting plate is provided with the spray gun. The movable automatic powder spraying system is an integrated automatic powder spray system provided with the powder supply system, a spray coating system and a moving system; the system can easily control the color and the concentration of a paint, ensure the paint quality, realize automatic powder supply operation and spray coating operation and move on the upper side, lower side, left side and right side of a workpiece for spray coating; and thus the coating quality is greatly improved, the labor intensity of workers is reduced and a new level is provided for the spray coating industry.

Owner:ZHEJIANG YUCHENG HUAER COATING EQUIP MFG

Means for taking-care of anus and intestine

InactiveCN1947668AAvoid harmUniform pressureBodily discharge devicesEnteral tube careIntestinal structure

Owner:高静静

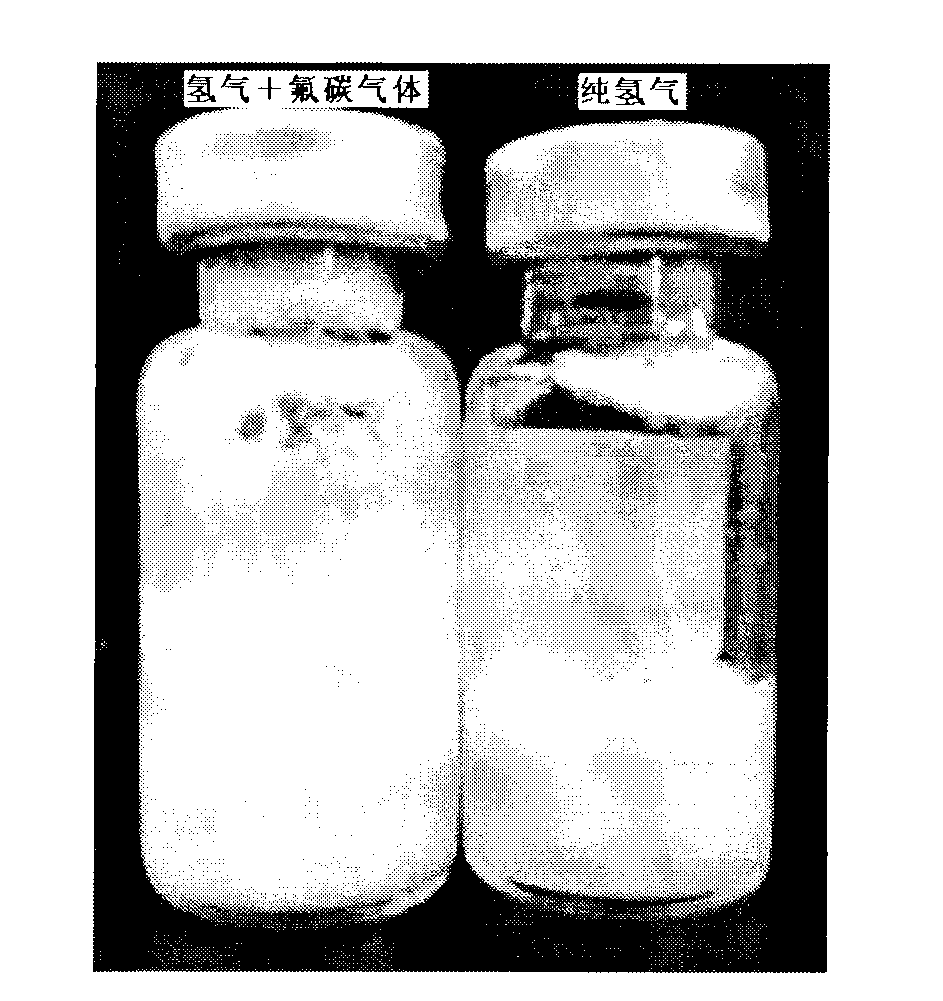

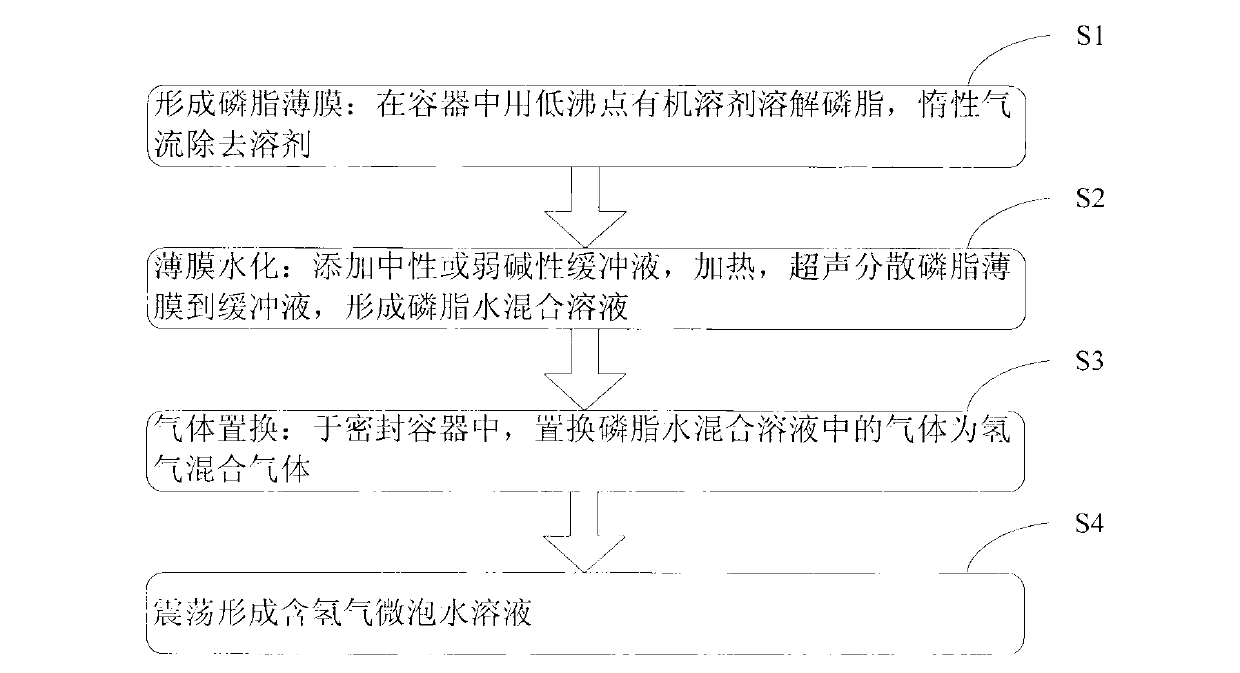

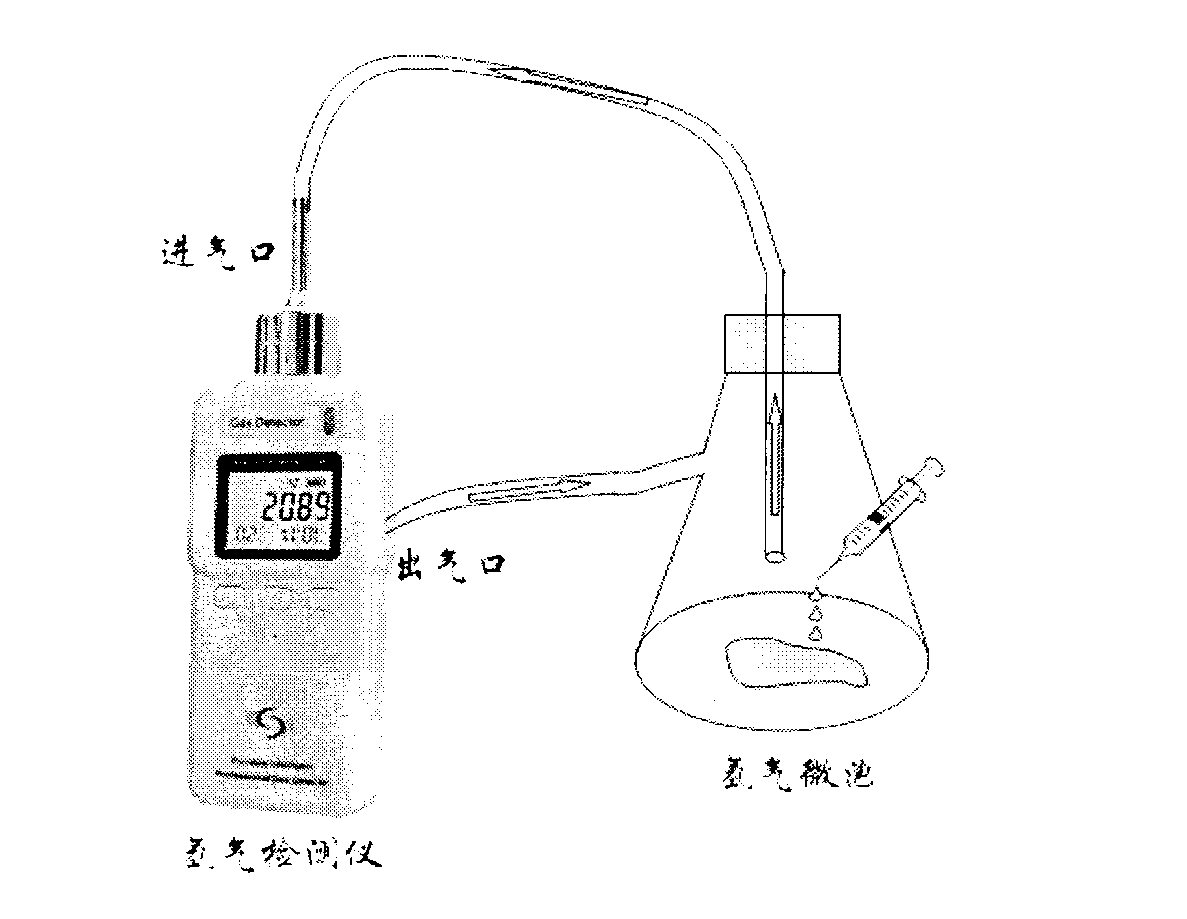

Preparation method of hydrogen-microbubble-containing aqueous solution, and product and application of method

ActiveCN103099780AImprove solubilityConcentration controllableAntipyreticInorganic active ingredientsHydrogen concentrationUltrasound contrast media

The invention relates to a novel hydrogen-containing medicine dosage form. Hydrogen is made into a hydrogen-microbubble-containing aqueous solution in a manner of coating by phospholipid, so that the hydrogen content of the solution can greatly increase, the hydrogen concentration can be controlled, and the hydrogen is more stable. In addition, by virtue of a microbubble technology, the hydrogen-microbubble-containing aqueous solution can also be taken as an ultrasonic contrast agent and has multiple function effects.

Owner:广州康臣药业有限公司

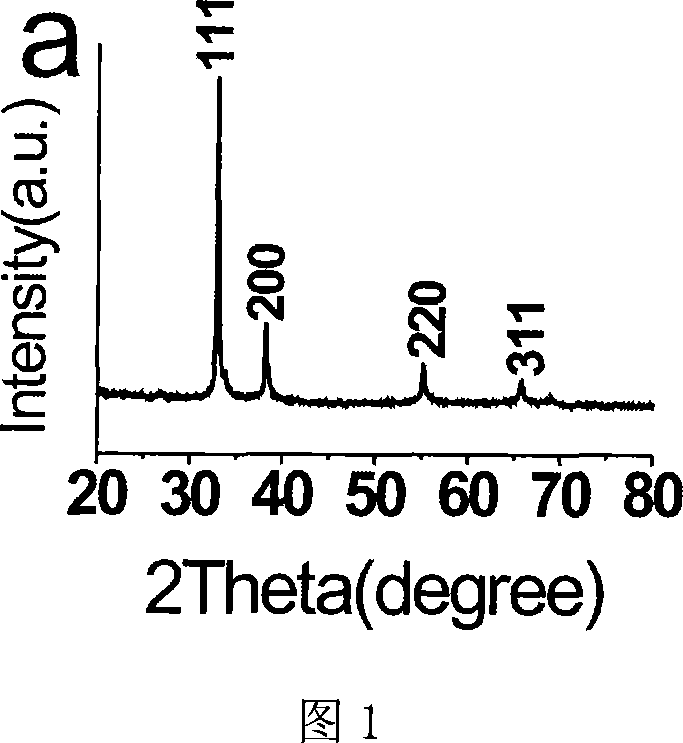

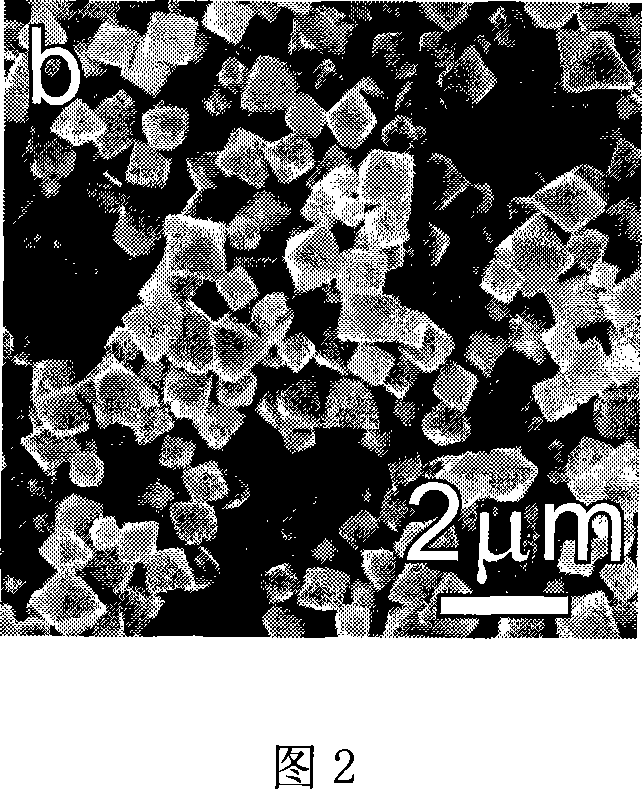

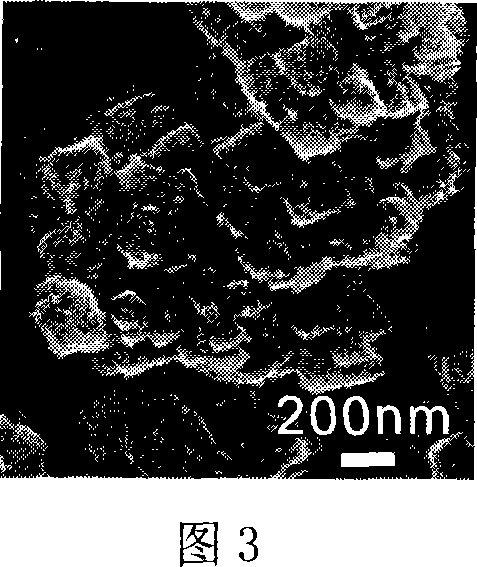

Shape and size controllable preparation method of micro-nano silver oxide

InactiveCN101054199AEasy to operateReduce processNanostructure manufactureSilve compoundsMicro nanoSilver oxide

A method for preparing micro-nano Ag2O with controllable shape and size relates to a micro-nano Ag2O, particularly to a method for realizing the controllable growth of the micro-nano Ag2O in shape and size by changing the concentration of the reactants. The invention provides a method for changing the reactants concentration from the whole and realizing the controllable growth of the micro-nano Ag2O in shape and size, which is a method for preparing micro-nano Ag2O with controllable shape and size. Mix AgNO3 and ammonia at the Moore ratio of 1:(0.2-10) to produce a mixture A of AgNO3 and ammonia. Add NaOH into the mixture A till the mixture A produces deposit. Stir the mixture and put it still to produce the mixture B. Centrifugate the mixture B and wash the deposit with water and alcohol for at least once in sequence to produce the target product.

Owner:XIAMEN UNIV

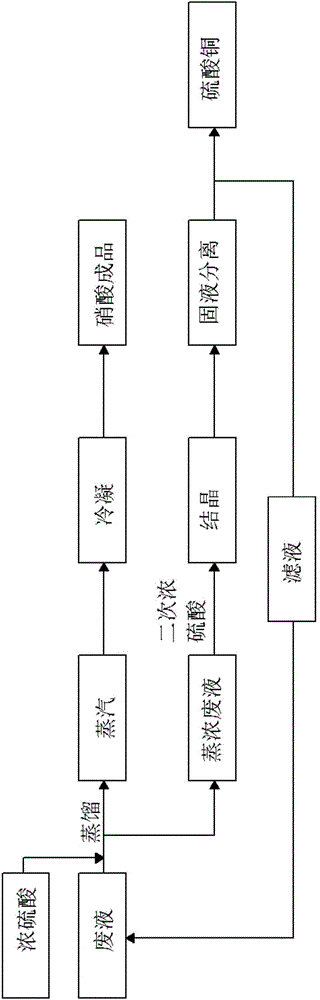

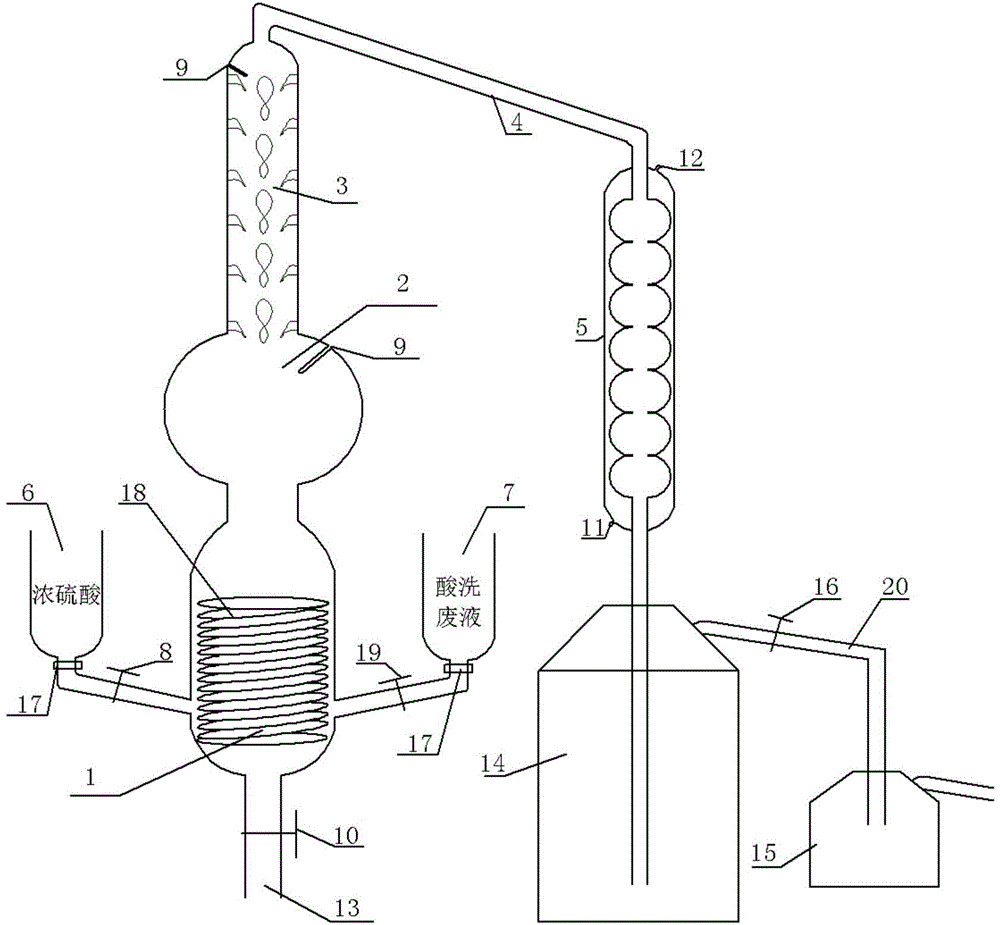

Device for recycling nitric acid from waste liquor containing copper nitrate and use method of device

InactiveCN104085865AConcentration controllableImprove the distillation effectWater/sewage treatment by heatingCopper sulfatesDistillationCopper nitrate

The invention discloses a device for recycling nitric acid from waste liquor containing copper nitrate. Repeated addition of concentrated sulphuric acid or adoption of a reverse extraction technology is not needed, cost and space occupied by equipment are saved, operation steps are simplified, resource optimization is realized, design is simple and reasonable, and control is easy. The device for recycling nitric acid from the waste liquor containing copper nitrate comprises a concentrated sulphuric acid storage tank and an acid pickling waste liquor storage tank and is characterized in that a metering pump is respectively arranged at the outlet of the bottom of each of the concentrated sulphuric acid storage tank and the acid pickling waste liquor storage tank and is respectively communicated to the inner cavity of a heating unit, a heating wire is arranged in the inner cavity of the heating unit, a crystal outlet pipeline is arranged at the bottom of the heating unit, a distillation flask and a rectifying unit are sequentially arranged at the outlet in the upper part of the heating unit, the outlet in the upper part of the distillation flask is communicated with the inlet in the lower part of the rectifying unit, the outlet in the upper part of the rectifying unit is externally connected with an inner cavity inlet in the upper part of a condensation unit, an inner cavity outlet in the lower part of the condensation unit is connected to the lower part of a nitric acid finished product tank by virtue of a guide pipe, and flowing cold water is filled in the outer cavity of the condensation unit.

Owner:KUNSHAN MINGKUAN ENVIRONMENTAL & ENERGY SAVING TECH CO LTD

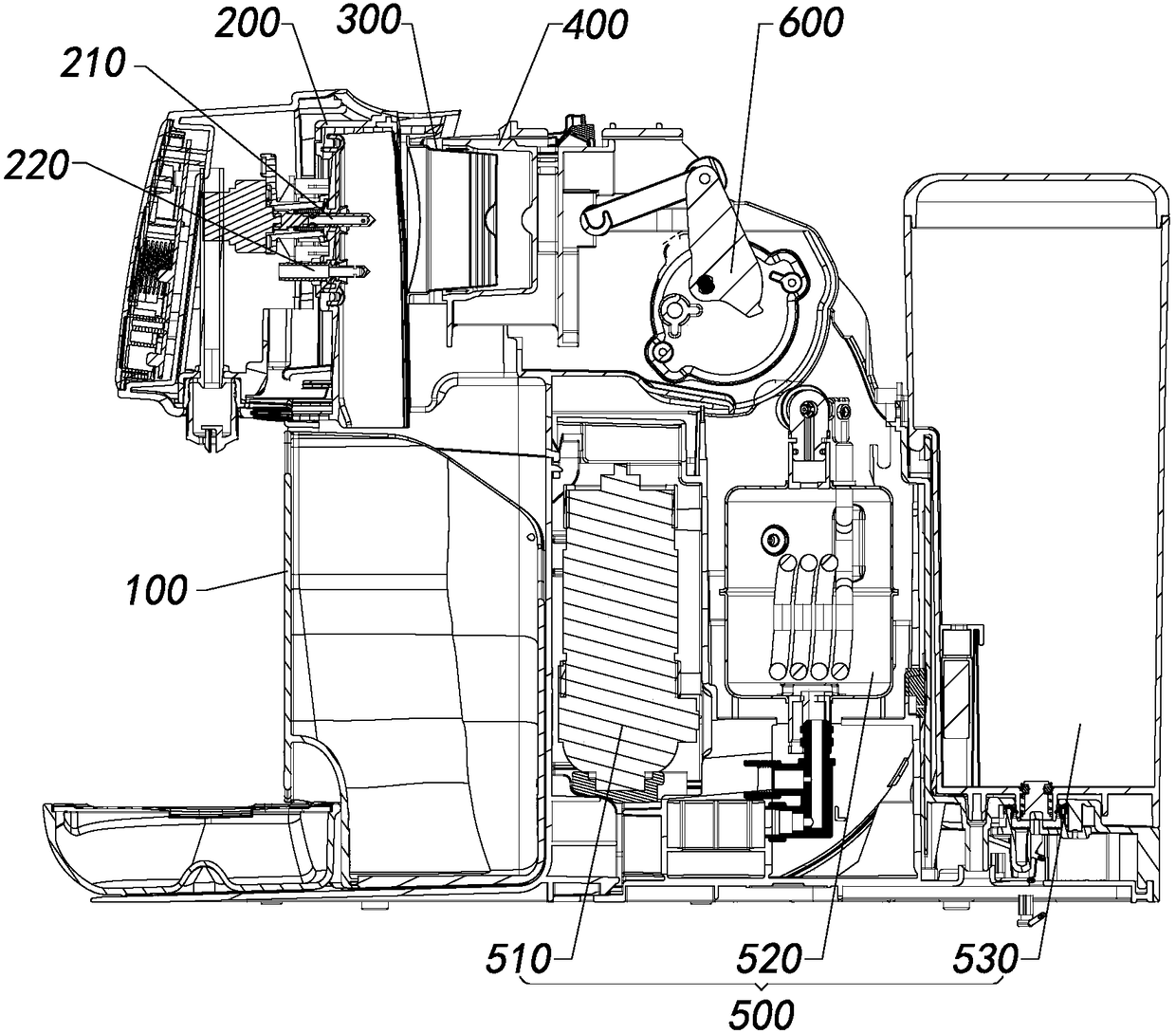

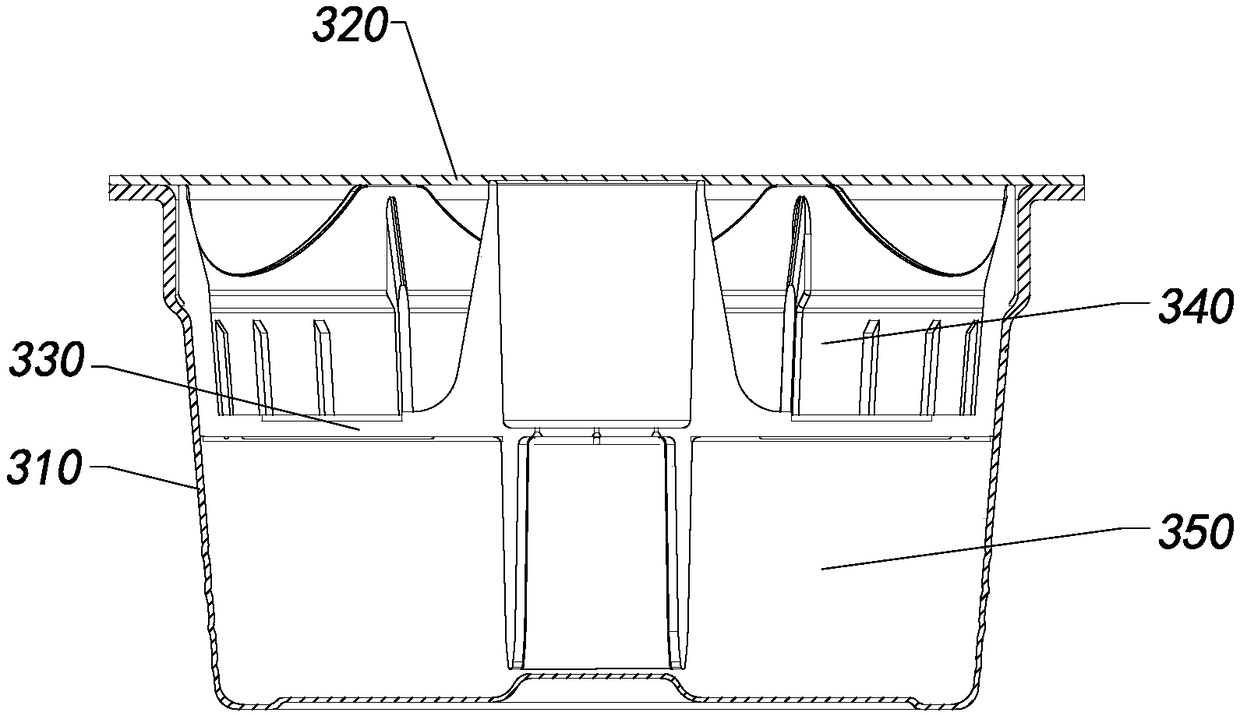

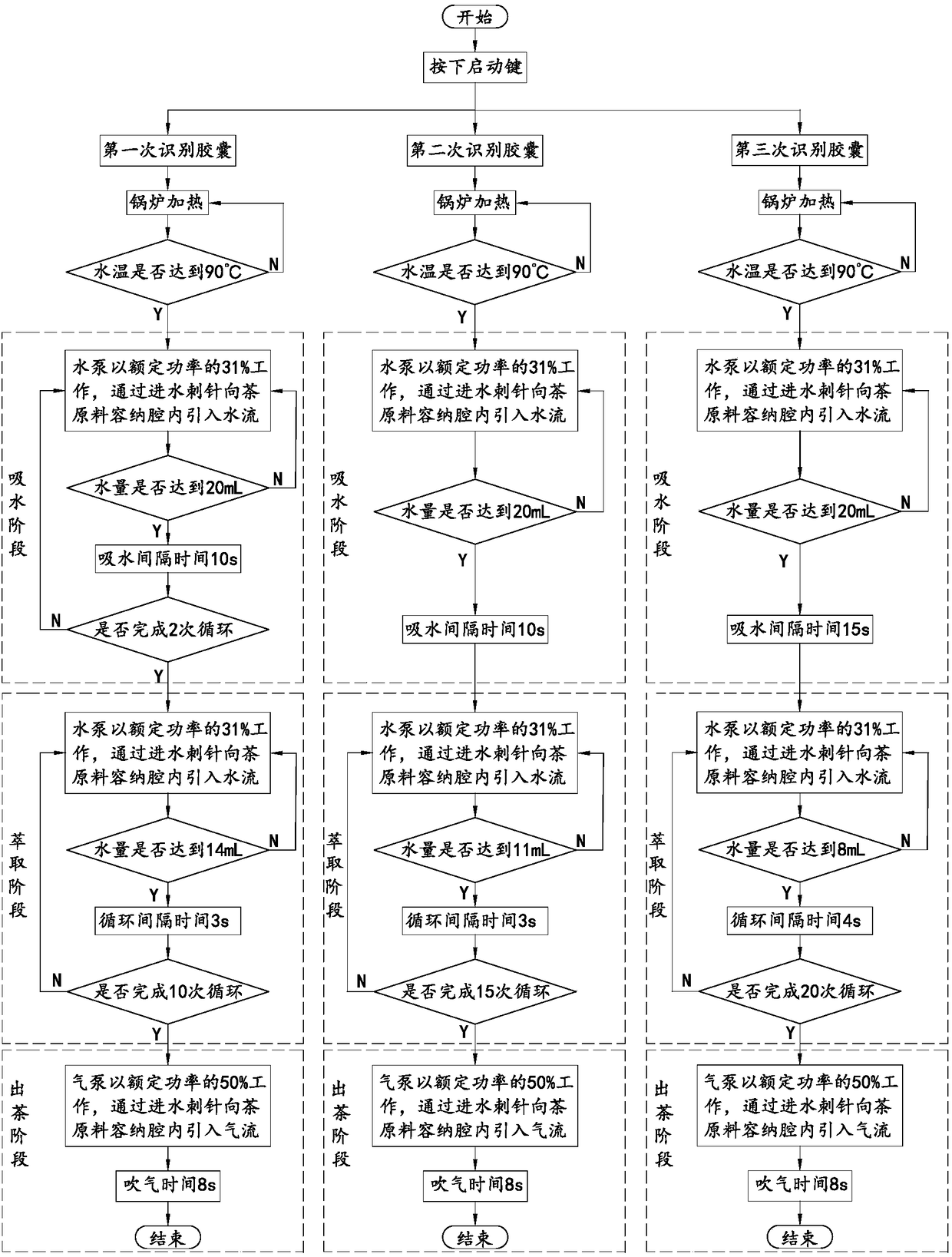

Method for making tea-based beverage through capsule beverage machine

The invention discloses a method for making a tea-based beverage through a capsule beverage machine, and belongs to the technical field of beverage preparation. According to the method for making thetea-based beverage through the capsule beverage machine, the problem that a tea-based beverage made by an existing tea making machine is low in quality is solved. According to the method for making the tea-based beverage through the capsule beverage machine, the capsule beverage machine comprises a brewing head provided with a water inlet pricking needle and a leading-out pricking needle, a brewing cup for accommodating a capsule, and a liquid supplying mechanism; and the liquid supplying mechanism communicates with the water inlet pricking needle, and a tea raw material accommodating cavity is formed in the capsule. The method for making the tea-based beverage comprises the steps that a water-absorbing stage is conducted, specifically, the liquid supplying mechanism leads brewing liquid into the tea raw material accommodating cavity through the water inlet pricking needle, so that tea raw materials are soaked and absorb water; a tea extracting stage is conducted, specifically, the liquid supplying mechanism leads the brewing liquid into the tea raw material accommodating cavity through the water inlet pricking needle, and soluble substances in the tea raw materials are extracted to form tea liquid; and a tea discharging stage is conducted, specifically, the tea liquid in the tea raw material accommodating cavity is discharged through the leading-out pricking needle.

Owner:杭州易杯食品科技有限公司

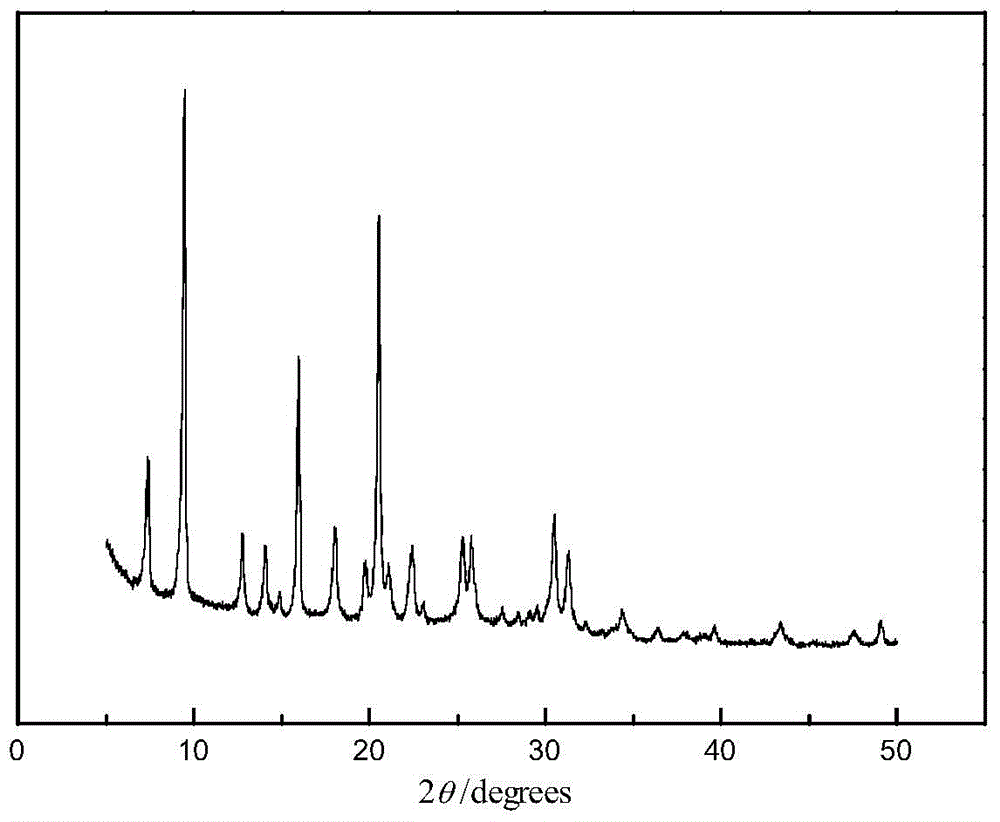

Carbon fiber sizing method

InactiveCN104358050AConcentration controllableReduces sticking and curingLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsYarnCarbon fibers

The invention provides a carbon fiber sizing method. The carbon fiber sizing method has the advantages that the sizing uniformity is effectively improved, the concentration of a sizing agent in a sizing groove is easily controlled, and the curing of the sizing agent on a press roll is obviously reduced; the method also solves the problems of yarn adhering because of easy attaching and curing of resin in the sizing agent, and different sizing amount among batches because of continuous low concentration of the sizing agent in the sizing groove and continuous decrease of sizing amount of carbon fiber.

Owner:JIANGSU HANGKE COMPOSITE MATERIALS TECH

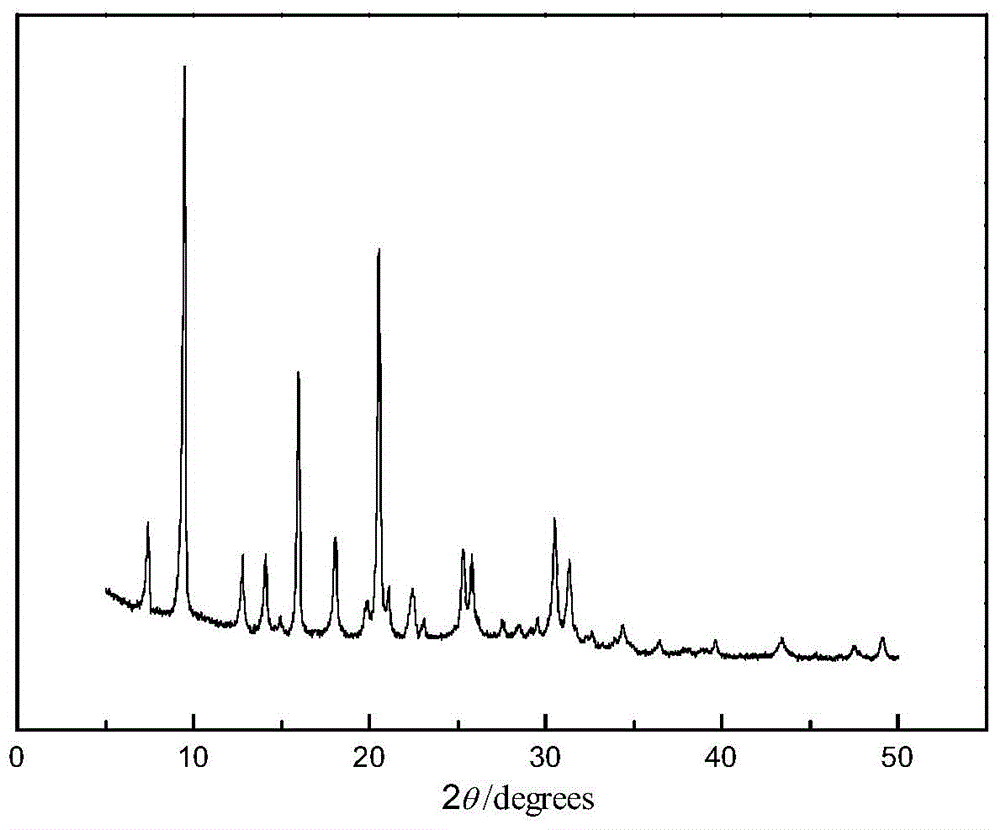

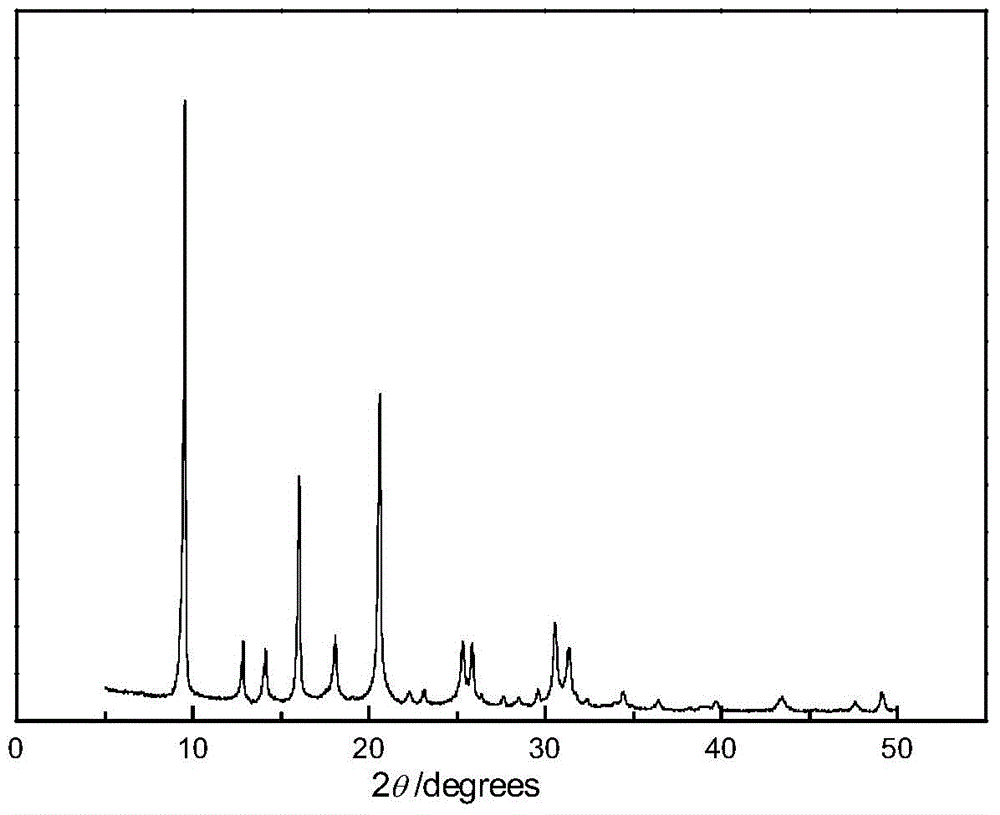

Preparation method of low-silicon SAPO-34 molecular sieve

ActiveCN104556142ALow depolymerization rateConcentration controllableMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveSolid content

The invention discloses a preparation method of a low-silicon SAPO-34 molecular sieve, which is characterized by comprising the following steps: (1) uniformly mixing a silicon source, a phosphorus source and an aluminum source according to the mol ratio of (0.7-2)P2O5:(0.01-0.2)SiO2:Al2O3:(20-100)H2O, and drying to obtain silicon phosphorus aluminum dry glue with the solid content of not lower than 60%; (2) uniformly contacting and mixing the silicon phosphorus aluminum dry glue with a template and a silicon source to obtain a mixture, wherein the addition amount of the template is 1-2.5 mol on the basis of 1 mol of Al2O3 in the silicon phosphorus aluminum dry glue; and (3) putting the mixture in a closed reaction kettle, sectionally crystallizing under autogenous pressure, and recovering the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

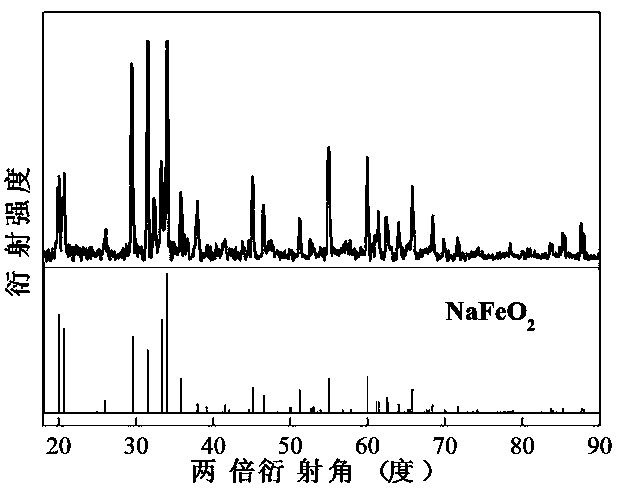

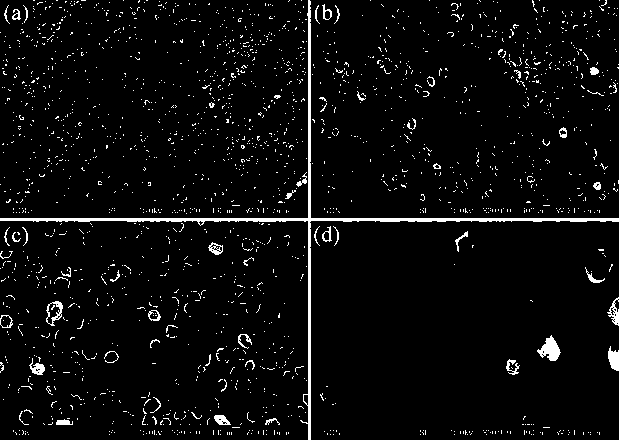

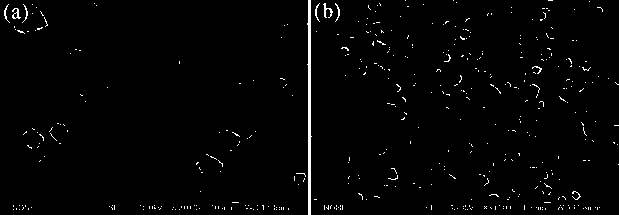

Method for obtaining nano iron plating by direct electroplating

InactiveCN103966634AConcentration controllableReduce the impactMaterial nanotechnologyPlatinumCopper

The invention belongs to the technical field of environmentally-friendly electroplating technologies, and relates to a method for obtaining nano metal iron plating by direct electroplating under the lower temperature through utilizing NaFeO2 as raw material and utilizing a sodium hydroxide water solution as an electrolyte. The method mainly comprises the following steps: using Fe2O3 powder and NaOH (which are chemical analytically pure) as raw materials and mixing at the mass ratio of 2:1, calcinating for 4 h at the temperature of 400 DEG C so as to obtain pure NaFeO2 powder raw material; adopting a NaOH solution with the mass fraction of 30-50 percent as the electrolyte, adopting a platinum wire as the anode and adopting a copper sheet as the cathode; dissolving a defined amount of NaFeO2 powder into the NaOH solution to form a NaFeO2 saturated solution; performing electroplating for 1-3 h under the condition of 25-80 DEG C and 1.8 V constant voltage, taking out the cathode after electroplating, and washing and drying, so that the nano iron plating is obtained.

Owner:SHANGHAI UNIV

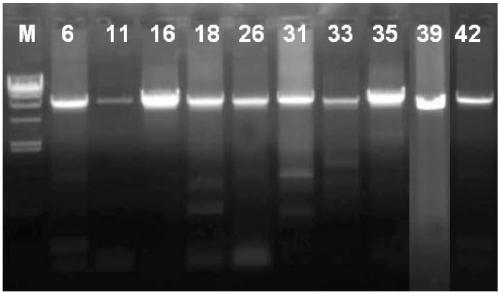

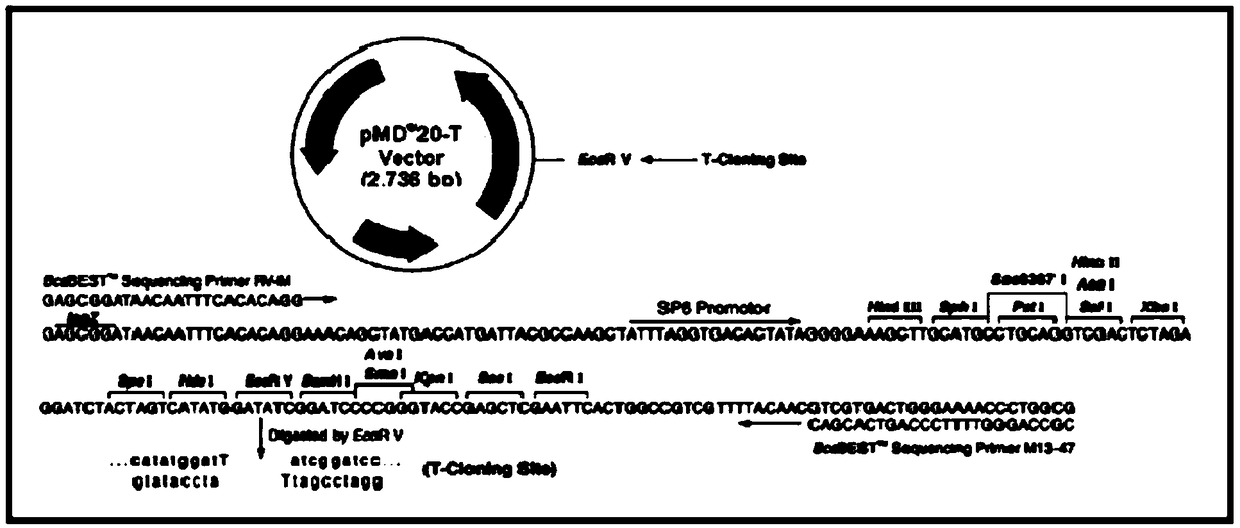

Preparation method, amplification primers and detection reagent for HPV full-length genome quality control product

ActiveCN108929869AAvoid connection inefficienciesSolve the problem of uncertain concentrationMicrobiological testing/measurementVector-based foreign material introductionHuman DNA sequencingCompetent cell

The invention relates to a preparation method, amplification primers and detection reagent for a HPV full-length genome quality control product. The preparation method of the HPV full-length genome quality control product comprises: (1) acquiring a DNA template, (2) carrying out PCR amplification through amplification primers, (3) connecting a target DNA fragment to a vector by a HD Cloning linkage technology, (4) introducing the plasmid into a competent cell and then extracting the plasmid and (5) diluting the plasmid with a human genome. The preparation method of the human papillomavirus full-length genome quality control product can successfully acquire the HPV gene detection quality control product which has no risk of biological infection, can simulate a clinical sample, can be mass-produced, has a controllable concentration and can be stably preserved. The preparation method has good applicability.

Owner:亚能生物技术(深圳)有限公司

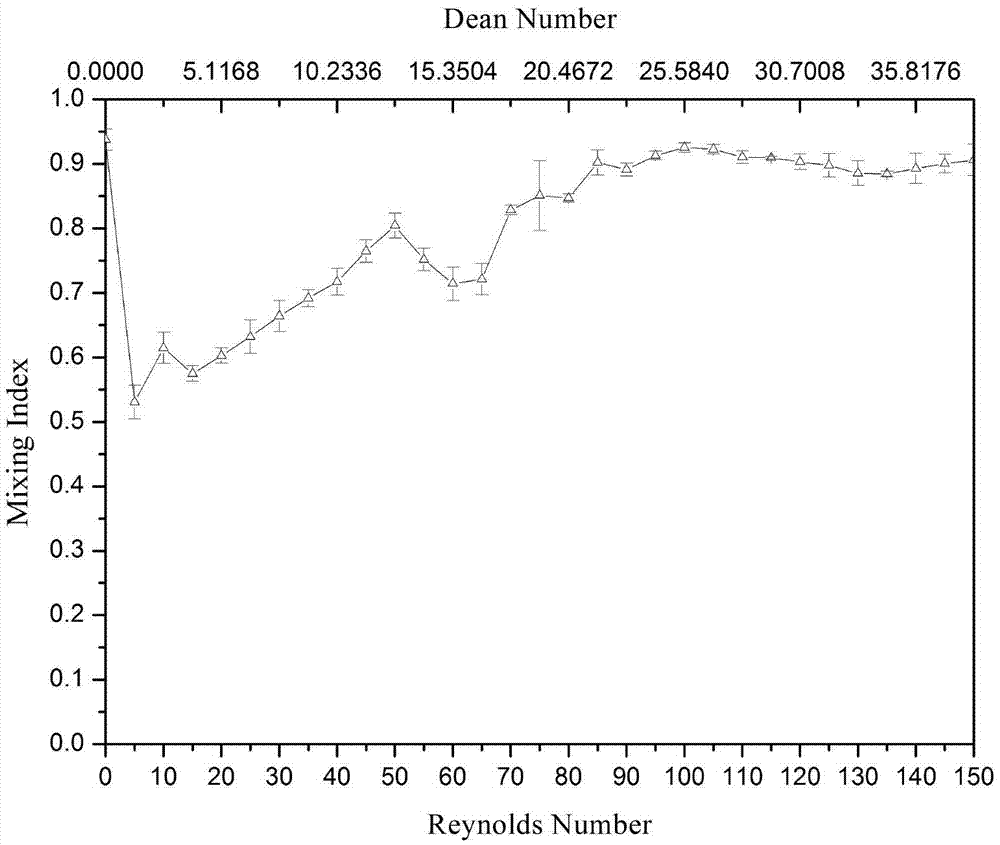

Direct methanol fuel cell supply system and direct methanol fuel cell supply method

InactiveCN105449246AConcentration controllableImprove performanceFuel cellsFuel cellsWater storage tank

The invention discloses a direct methanol fuel cell supply system and a direct methanol fuel cell supply method. The direct methanol fuel cell supply system comprises a direct methanol fuel cell, an ultrasonic atomizer, a micro-fluidic chip, a fuel storage tank, a pure methanol storage tank, a water storage tank, micropumps and supply pipelines; the micro-fluidic chip comprises a flow field channel; the flow field channel is formed in a manner that a square circulating cavity, an arc channel and an expanding cavity are asymmetrically connected in sequence; the pure methanol storage tank and the water storage tank are respectively connected with two inlets of the micro-fluidic chip through the supply pipelines, and the flow of the pure methanol storage tank and the flow of the water storage tank are controlled by the corresponding micropumps; the outlet of the micro-fluidic chip is connected with the fuel storage tank; the outlet of the fuel storage tank is connected with the ultrasonic atomizer through the corresponding micropump; the ultrasonic atomizer is communicated with an anode flow field plate of the methanol fuel cell. The direct methanol fuel cell supply system and the direct methanol fuel cell supply method disclosed by the invention have the advantages that a methanol solution mixed by using the method is controllable in concentration; the methanol solution is mixed evenly, so that a good condition is provided for an atomization supply way, and the performance of the fuel cell is further improved; the discharge stability of the cell is improved by the even methanol solution.

Owner:WUHAN UNIV OF TECH

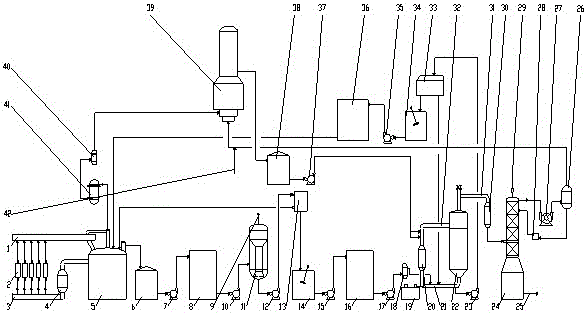

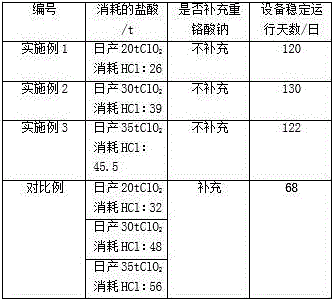

Integrated ClO2 preparation system with relatively independent processes of electrolysis and ClO2 preparation

InactiveCN106044714AReduce the number of decompositionsImprove reaction efficiencyElectrolysis componentsChemical liquid solidificationChemistryElectrolytic cell

The invention discloses an integrated ClO2 preparation system with relatively independent processes of electrolysis and ClO2 preparation. The system is characterized by comprising a NaClO3 electrolysis and crystal preparation unit, a ClO2 generation unit and an HCl synthesis unit, wherein an electrolyte solution containing NaClO3 crystals is fed into a solid-liquid separator for separation, NaCl and Cr2H4Na2O9 entrained by the NaClO3 crystals are washed off, the obtained NaClO3 crystals are dissolved and filtered and then enter a generator, and a solution which is separated out of the solid-liquid separator and contains NaCl and Cr2H4Na2O9 flows back to an electrolysis system and returns to an electrolytic cell for continuous electrolysis, so that NaCl and Cr2H4Na2O9 are only located in a NaClO3 preparation system without entering the ClO2 generation unit and are recycled; NaCl generated in the ClO2 generation unit is dissolved and then is sent to the NaClO3 preparation unit, and accordingly, supplementation of NaCl is not needed basically.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

Effervescent tablet for cleaning automobile glass

InactiveCN103525569AStrong cleaning and decontamination abilityPromote degradationInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsEffervescent tabletEffervescent Tablet Dosage Form

The invention discloses an effervescent tablet for cleaning automobile glass, which comprises nonionic surfactant, polyvinylpyrrolidone and effervescence disintegrant. According to the invention, the effervescent tablet has super high cleaning and dirt-removing capability, favorable biodegradability, mild property, no corrosivity and favorable antistatic property, and can not pollute the environment; a water solution of the effervescent tablet has certain viscosity, has lubricating action, reduces friction between wipers and glass, prevents generation of scratches, causes less irritation to the skin of a user and has excellent low-temperature scourability; and the effervescent tablet is convenient to carry and use and accurate in dosage, and the concentration of the water solution of the effervescent tablet is easy to control.

Owner:SHANGYU LIZI BIOTECH

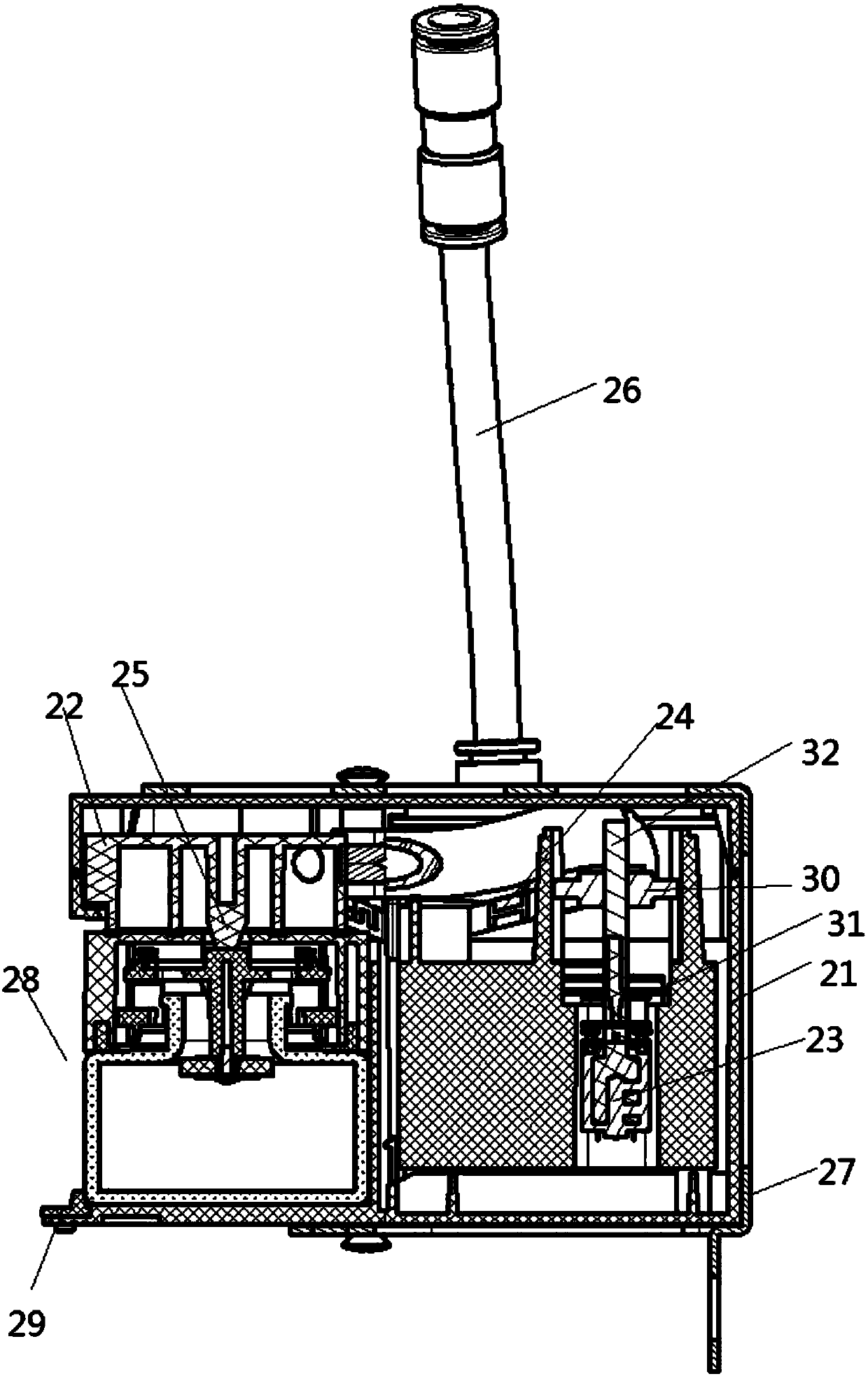

Perfume generating device

ActiveCN107933252ADoes not take up visual spaceGuaranteed aestheticsAir-treating devicesElectric machineryStructural engineering

The invention discloses a perfume generating device which comprises a shell, a perfume bottle assembly, an MCU, a switching assembly, a fan and remaining amount monitoring assembly. The MCU is electrically connected with an LIN transceiver, the perfume bottle assembly comprises a bottle body, a valve assembly and a bottle cover, the bottle cover is provided with an air inlet hole and an air outlethole, and the valve assembly comprises an air door part and an elastic part. The air door part seals the air inlet hole and the air outlet hole, the switching assembly comprises a pressing disc, a motor and a pressing rod hinged into the shell, one end of the pressing rod is connected with the pressing rod, and the other end of the pressing rod is in threaded connection with a transmission shaftof the motor. An air inlet and an air outlet are formed in the pressing disc, the fan is arranged on the air inlet, the shell is provided with a vent opening and an air outlet pipe, the air outlet iscommunicated with the air outlet pipe, the bottle body is connected with two metal sheets, and the two metal sheets, the fan and the motor are electrically connected with the MCU. The perfume generating device can be incorporated with a vehicle control system and is hidden in a console. The perfume bumping spilling probability is reduced, perfume switching is automatically controlled, the fragrance diffusion concentration is controllable, and the remaining amount of perfume is automatically detected.

Owner:TAIZHOU SAILING MOLD & PLASTIC TECH

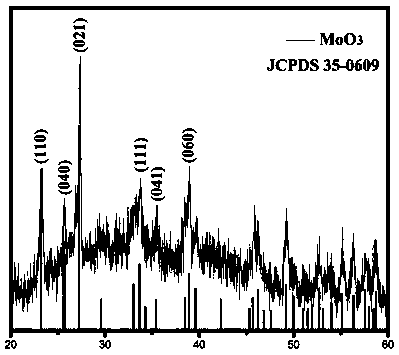

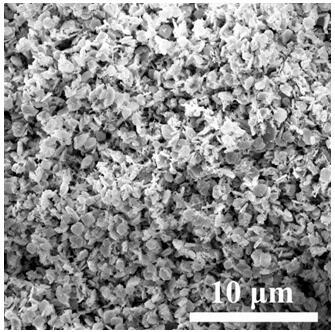

Electrospinning synthesis method of MoO3 sheet structure

ActiveCN109205676AConcentration controllableEasy to control the fiberizing processMolybdenum oxides/hydroxidesFiberSynthesis methods

The invention discloses an electrospinning synthesis method of a MoO3 sheet structure, and the electrospinning synthesis method comprises the steps of: adding a molybdenum salt, hydroxylamine hydrochloride, dopamine hydrochloride and PVP into a mixed solvent of ethanol, DMF and 1,5-pentanediol, stirring to obtain a spinning solution, and forming precursor fiber by an electrospinning method; calcining the obtained precursor fiber to obtain a product. The method designs a novel precursor reaction system, has the advantages such as wide sources of raw materials, low price, simple operation and equipment, controllable parameters, uniform product size, good repeatability and dispersibility, and has broad application prospects in gas sensing, adsorption, and other fields.

Owner:UNIV OF JINAN +1

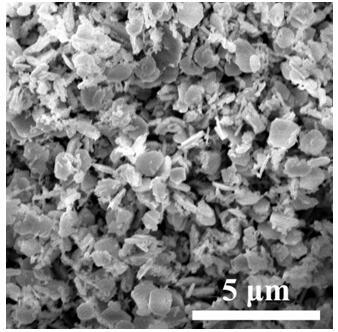

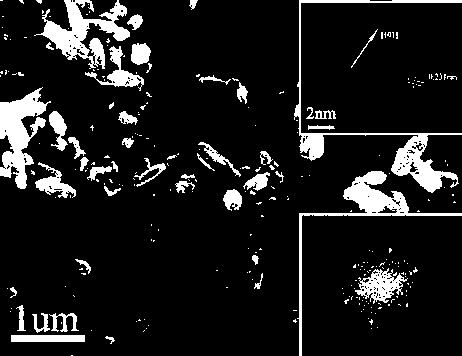

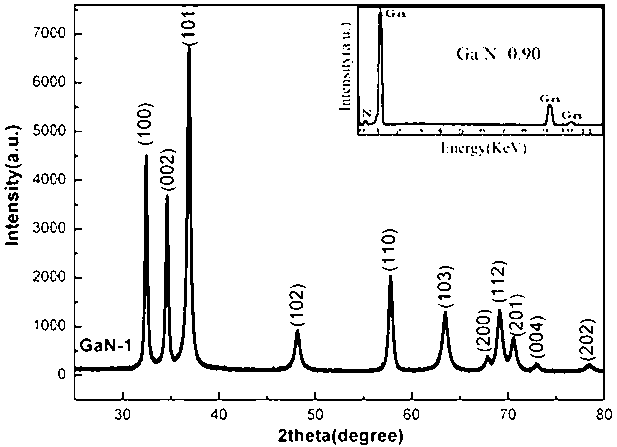

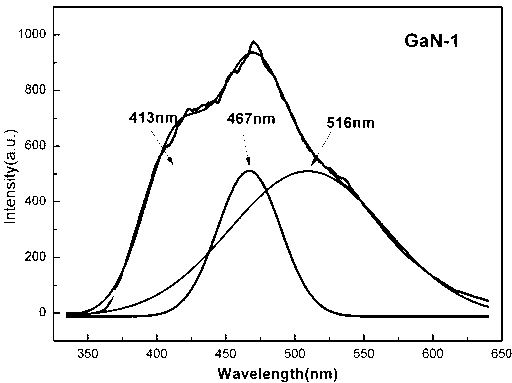

Preparation method for GaN nanostructure with adjustable Ga vacancy

InactiveCN103173738AConcentration is easy to controlSimple preparation processPolycrystalline material growthFrom chemically reactive gasesTube furnaceControllability

The invention discloses a preparation method for GaN nanostructure with adjustable Ga vacancy, belonging to the field of nanometer materials and a preparation technology thereof. The preparation method adopts a chemical vapor deposition method, and comprises the following steps of taking high purity Ga2O3 powder and NH3 gas as Ga source and N source respectively; putting the Ga2O3 powder in a ceramic boat; putting the ceramic boat at a central heating area; sealing a horizontal tube furnace; vacuumizing till the pressure is below 1*10<-2>Pa, aerating argon of flow of 100sccm, and heating the tube furnace; aerating argon of flow of 100-200sccm at 980 DEG C and keeping aerating for 3 hours; stopping heating, naturally cooling to 600 DEG C, opening a heating device again and heating to 980 DEG C and keeping for 2 hours; and naturally cooling to room temperature, turning off argon and taking a sample out. The preparation method has the characteristics of being simple, low in cost, high in productivity, light in environment contamination, and easy to promote, and the product is uniform and is good in controllability.

Owner:XINJIANG UNIVERSITY

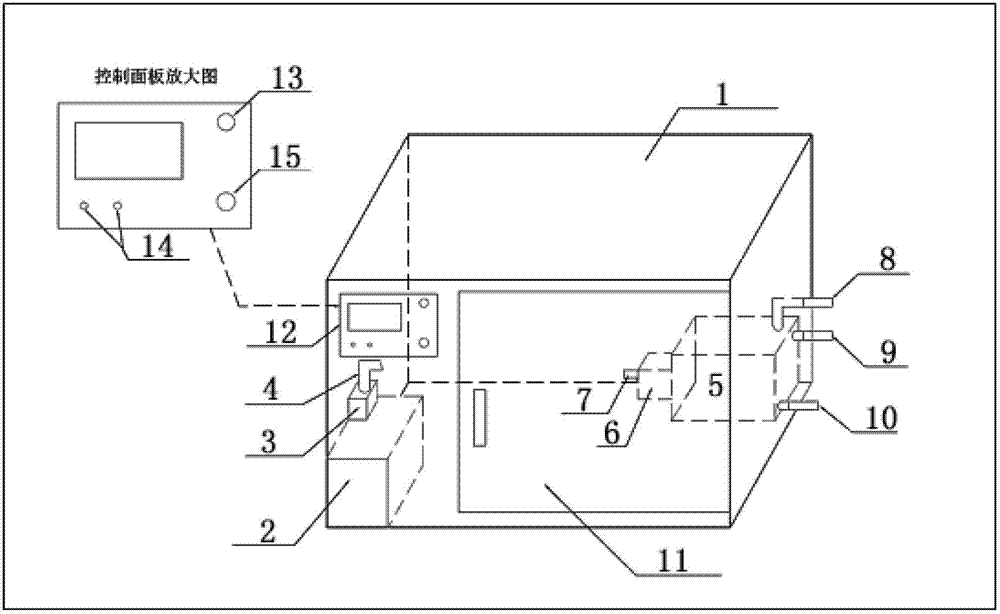

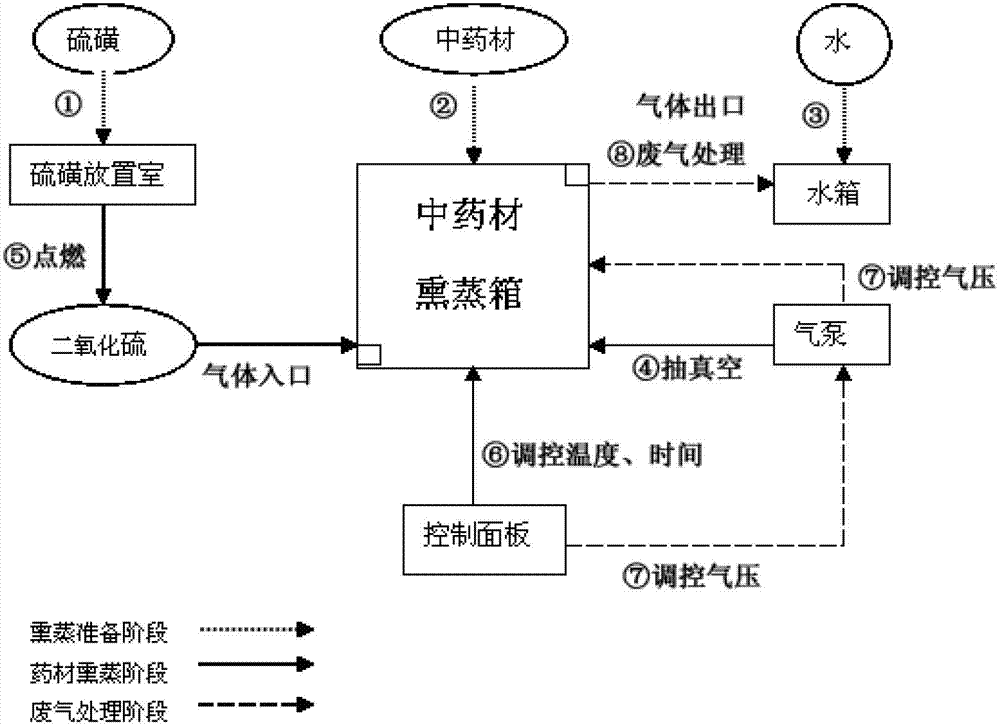

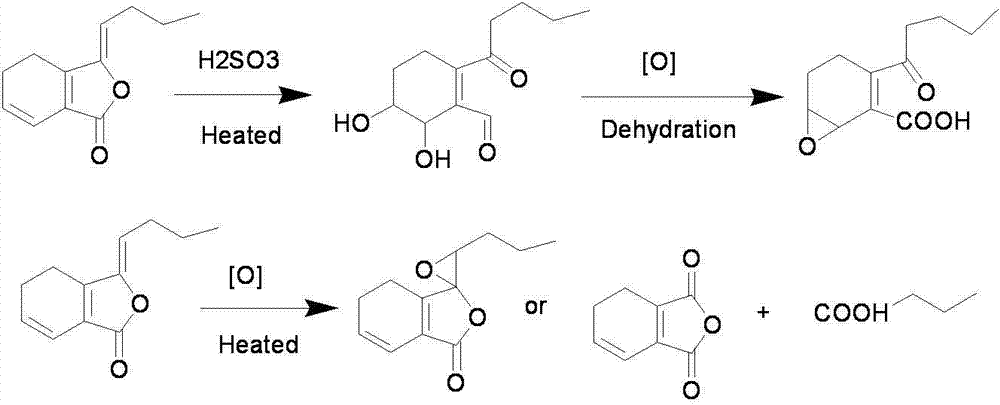

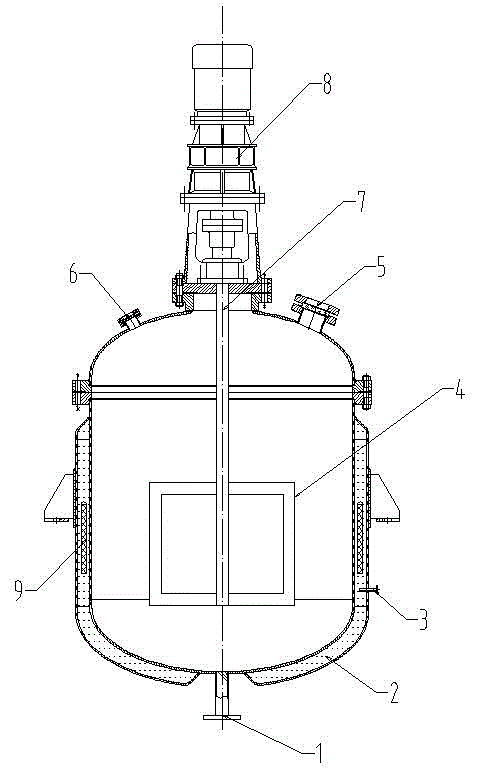

Method and equipment for sulphur fumigation of traditional Chinese medicine materials

ActiveCN102813679AReduce pollutionQuality assuranceFruit and vegetables preservationPlant ingredientsBULK ACTIVE INGREDIENTOxygen

The invention relates to the technical field of processing of traditional Chinese medicine materials, in particular to equipment and a method for sulphur fumigation of traditional Chinese medicine materials and medicinal slices. The method is characterized by comprising the following steps: 1) placing the traditional Chinese medicine materials, i.e. uniformly paving the traditional Chinese medicine materials to be subjected to fumigation in a sulphur fumigation box; 2) adding sulphur proportionally according to the amount of the added traditional Chinese medicine materials; 3) burning the sulphur, setting temperature, time and air pressure in the fumigation box, and subjecting the traditional Chinese medicine materials to fumigation by adopting vacuum and low temperature; 4) monitoring and adjusting temperature and concentration of sulfur dioxide as well as the air pressure in real time; and 5) absorbing and processing sulfur dioxide waste gas. According to the method and equipment for sulphur fumigation of the traditional Chinese medicine materials, controllable operation of the sulphur fumigation process of the traditional Chinese medicine materials is realized. Through controlling key factors such as temperature, concentration of oxygen and sulfur dioxide and the like in the fumigation process, the loss of active ingredients in the traditional Chinese medicine materials is reduced, and the residual quantity of sulfur dioxide and heavy metal in the traditional Chinese medicine materials can be controlled, therefore, the quality of the traditional Chinese medicine materials can be ensured to the maximum degree. The equipment has the characteristics of convenience in operation, controllable fumigation parameters, low cost, convenience in generalization and the like.

Owner:INST OF MEDICINAL PLANT DEV CHINESE ACADEMY OF MEDICAL SCI

Grafted modified chlorinated polyvinyl chloride ultrafiltration membrane, and preparation method thereof

InactiveCN105126645AConcentration controllableEasy to operateUltrafiltrationPolyethylene polyamineUltrafiltration

The invention belongs to the technical field of ultrafiltration membrane manufacturing, and more specifically relates to a grafted modified chlorinated polyvinyl chloride ultrafiltration membrane, and a preparation method thereof. The grafted modified chlorinated polyvinyl chloride ultrafiltration membrane is composed of, by weight, 16.5 to 20.5% of a membrane base material, chemically pure chlorinated polyvinyl chloride (CPVC) resin, 73.0 to 80.5% of a solvent, chemically pure N,N-dimethyl acetamide (DMAC), 2.5 to 5.5% of a pore-foaming agent, chemically pure polyvinylpyrrolidone (PVP) K30, 0.5 to 1.5% of an additive, chemically pure nanometer-grade aluminium oxide (Al2O3); and 0.5 to 1.5% of a grafting agent, chemically pure polyethylene polyamine. According to the preparation method, membrane base material molecules are grafted with charged groups so as to change surface charge of the membrane base material molecules and improve pollution resistance of the grafted modified chlorinated polyvinyl chloride ultrafiltration membrane.

Owner:HUBEI SHASHI WATER TREATMENT EQUIP FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com