Method for making tea-based beverage through capsule beverage machine

A beverage machine and capsule technology, which is applied in the field of tea making by capsule beverage machines, can solve the problems of not realizing multiple brewing of a cup of tea, unsatisfactory brewing effect, and limited quality of tea raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

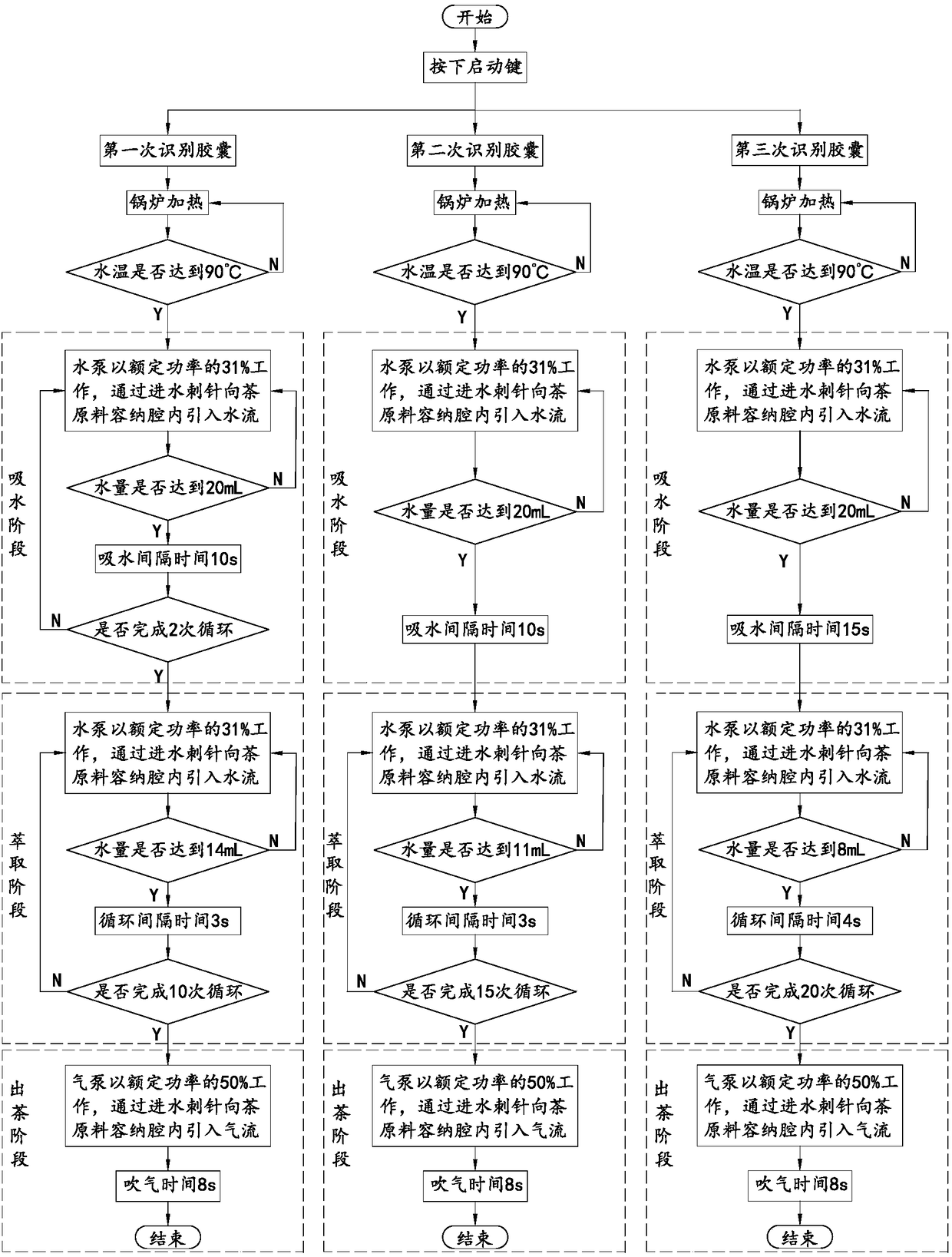

Embodiment 1

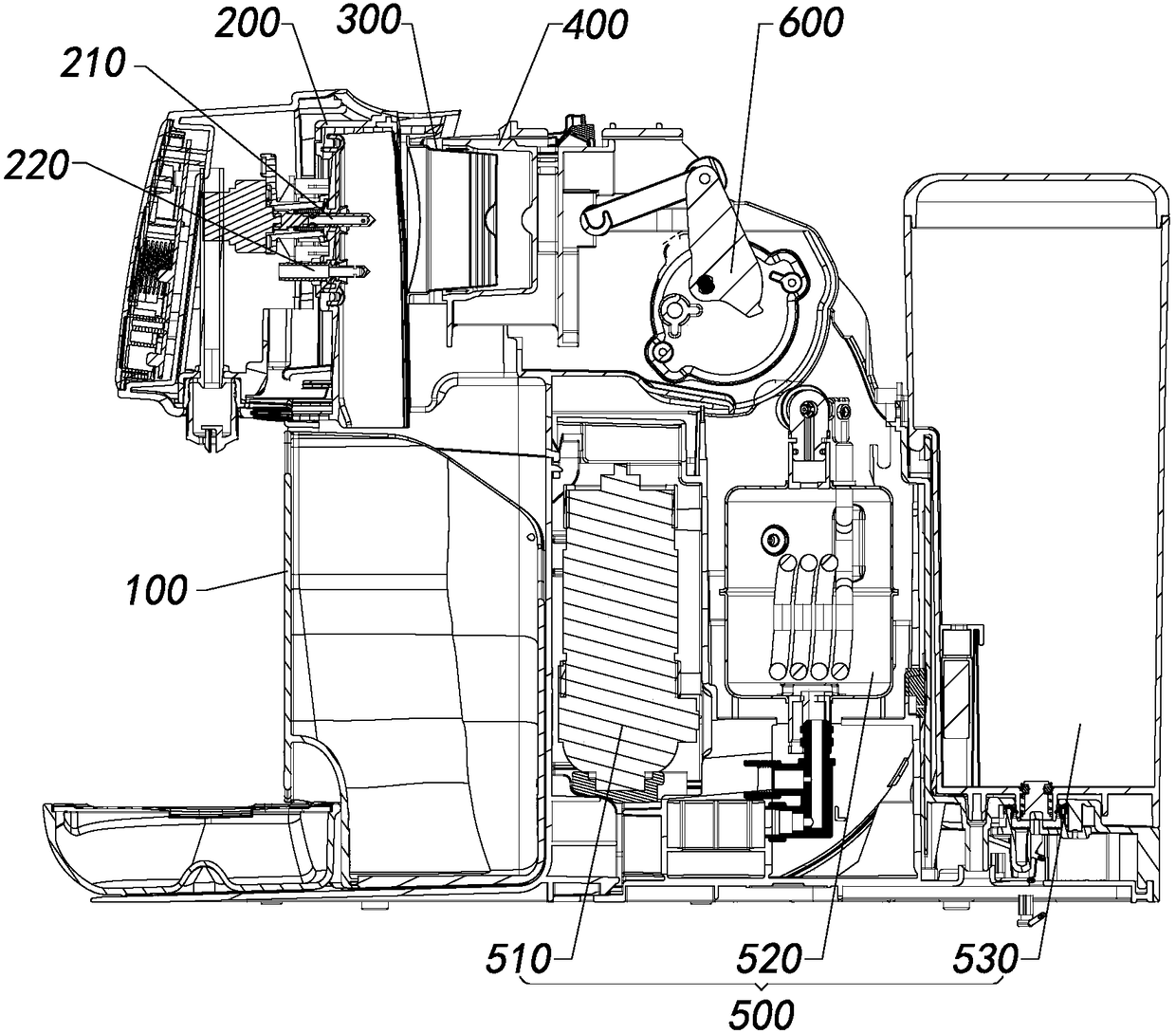

[0049] refer to figure 1 , the capsule beverage machine used in the embodiment of the present invention is a horizontal model, including a machine base 100, a brewing head 200, a brewing cup 400 for accommodating the capsule 300, a liquid supply mechanism 500, an air supply mechanism (usually an air pump ) and the driving mechanism 600 for driving the brewing cup 400. The water inlet needle 210 and the outlet needle 220 are installed on the same side of the brewing head 200. The water inlet needle 210 is higher than the outlet needle 220, and the water inlet needle 210 and the outlet needle 220 are both horizontal Setting (horizontal or approximately horizontal form), the liquid supply mechanism 500 and the air supply mechanism are connected to the water puncture needle 210; the capsule 300 is accommodated in the brewing cup 400, and the central axis of the capsule 300 is also horizontal or approximately horizontal form.

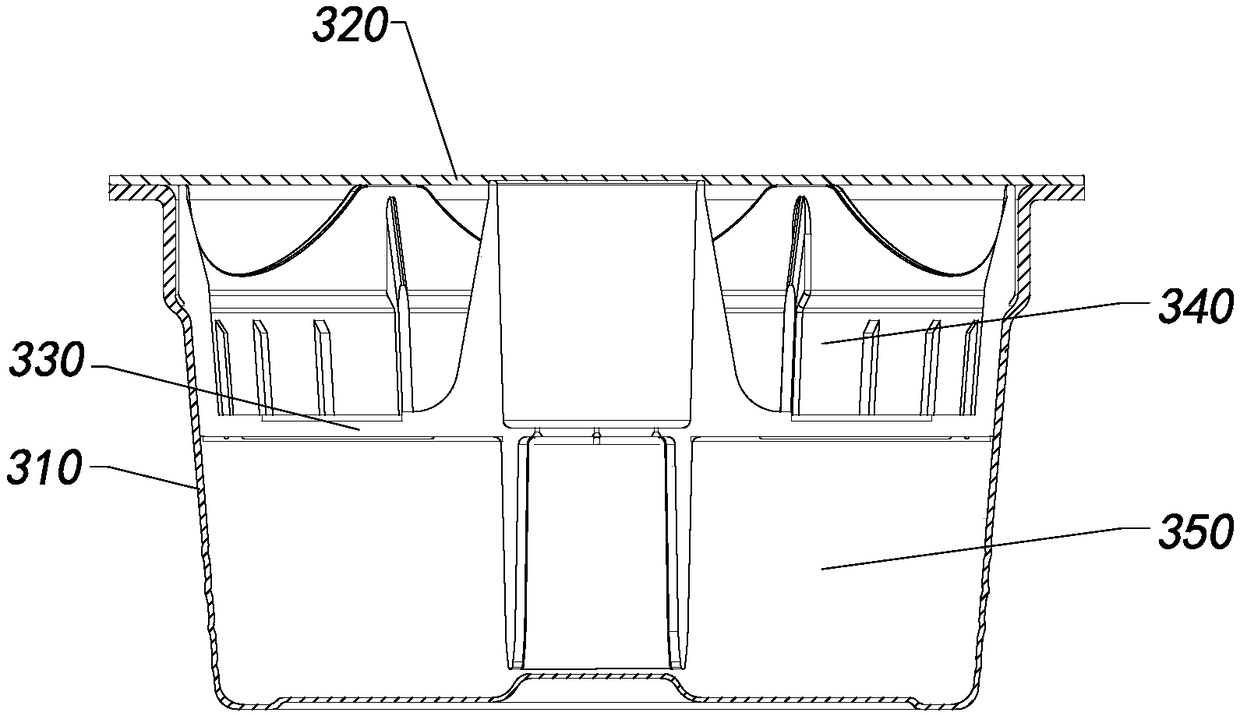

[0050] refer to figure 2 , the inside of the capsul...

Embodiment 2

[0084] The difference between this embodiment and Embodiment 1 is that in this embodiment, during the cycle interval of the tea extraction step, the air supply mechanism introduces gas into the tea raw material storage chamber through the water inlet puncture needle, so as to promote the extraction of soluble substances in the tea raw material . The introduction of gas into the tea raw material holding chamber helps the leaching of soluble substances in the tea raw material, increases the concentration of the tea drink, and also reduces the water content of the tea raw material, so that the tea raw material can fully absorb water in the next tea extraction step to improve the extraction effect. Especially in the case of brewing the same capsule three times, the above-mentioned blowing process can be introduced in the tea extraction stage of the second and / or third brewing to increase the leaching rate of soluble substances in the tea raw materials, thereby achieving Ensure the...

Embodiment 3

[0086] The difference between this embodiment and Embodiment 1 is that in this embodiment, in the water absorption stage, after the tea raw material is steeped, the air supply mechanism introduces gas into the tea raw material storage cavity through the water inlet puncture needle to promote Drain the water from the tea ingredients. Drain the water from the tea raw material by blowing air, so that the tea raw material can absorb water better and promote the extraction during the tea extraction stage, especially in the case of three brewing of the same capsule, it can be used in the second and / or third time The water absorption stage of brewing introduces the above-mentioned blowing process, so that the tea raw materials can obtain a better extraction state. When brewing tea raw materials that are difficult to extract, the above-mentioned blowing process can be introduced in the water absorption stage of each brewing to improve the extraction effect.

[0087] The embodiment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com