Magnetic tile surface defect detection method based on improved machine vision attention mechanism

A technology of attention mechanism and defect detection, applied in optical testing flaws/defects, instruments, image data processing, etc., can solve problems such as insufficient detection accuracy and speed, and achieve good adaptability, high reliability, and high algorithm accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

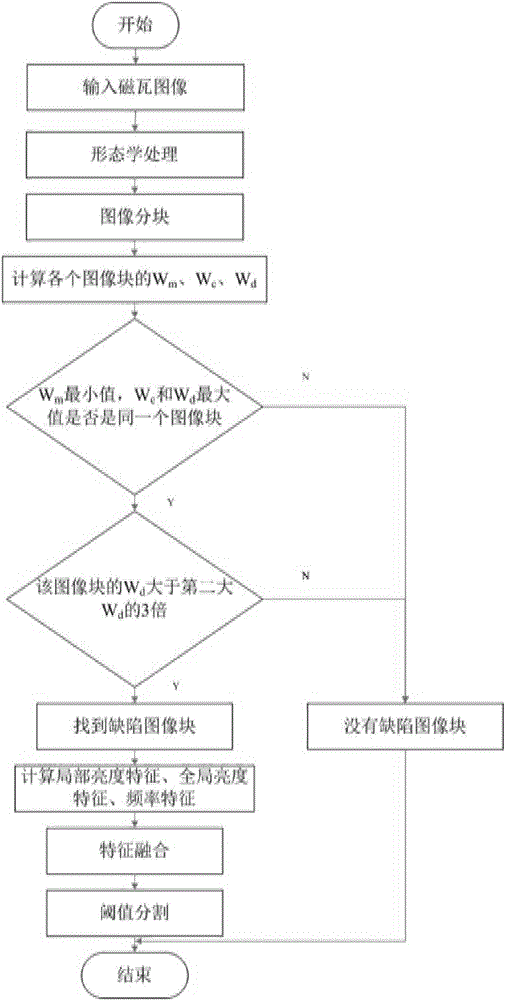

[0066] combine figure 1 , a method for detecting surface defects of magnetic tiles based on an improved machine vision attention mechanism in this embodiment includes the following steps:

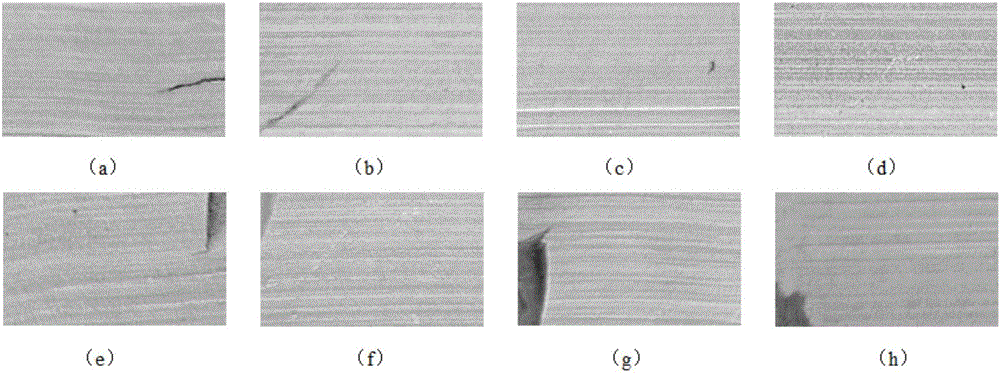

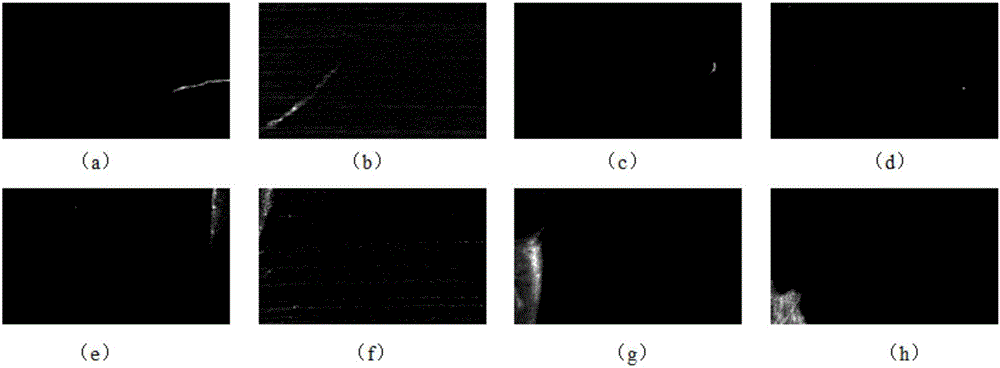

[0067] Step 1: Input the original image of the surface of the magnetic tile. During image processing, some areas with low gray values are easily confused with defect areas, which interferes with the processing results. This embodiment proposes a method of combining the top-hat and bottom-hat transformations of morphology to improve the contrast between the defect area and the background, suppress the gray value of the high-brightness area, enhance the overall gray contrast of the image, and facilitate the identification of the defect area .

[0068] The process of performing top-hat and bottom-hat transformations is:

[0069] Top hat transformation graph T hat (f) is the opening operation γ(f) of the image subtracted from the original image f, and the bottom hat transformation map B h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com