Preparation method for GaN nanostructure with adjustable Ga vacancy

A nanostructure and vacancy technology, applied in chemical instruments and methods, gaseous chemical plating, crystal growth, etc., can solve the problems of complex preparation process and high cost, and achieve the effect of simple preparation process, less environmental pollution and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Using high-purity Ga 2 o 3 Powder and NH 3 Gas is used as Ga source and N source respectively, according to 0.8 g Ga 2 o 3 The powder is placed in a ceramic boat, and the ceramic boat is placed in the central heating zone, the horizontal tube furnace is sealed, and the vacuum degree is evacuated to 1×10 -2 Below Pa, Ar gas with a flow rate of 100 sccm was introduced to heat the tube furnace. When the temperature reached 980 °C, ammonia gas with a flow rate of 100 sccm was introduced and kept for 3 h. Then, the heating was stopped, the temperature was naturally lowered to 600°C, the heating device was turned on again, and the temperature was raised to 980°C for 2 hours. Finally, turn off the ammonia gas and keep the argon flow constant. Naturally cool to room temperature, turn off the argon, take out the ceramic boat, and obtain sample GaN-1.

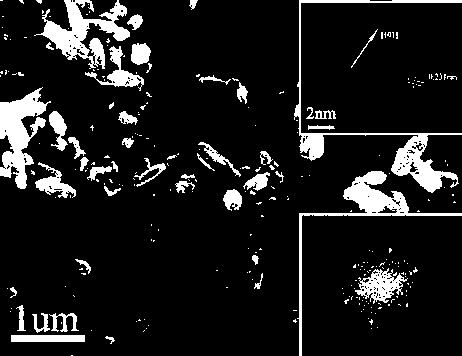

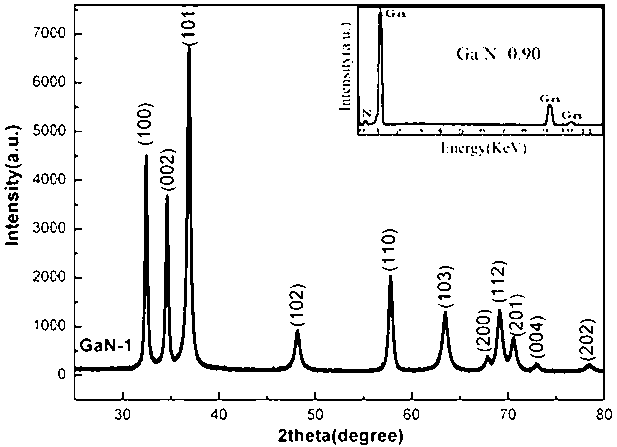

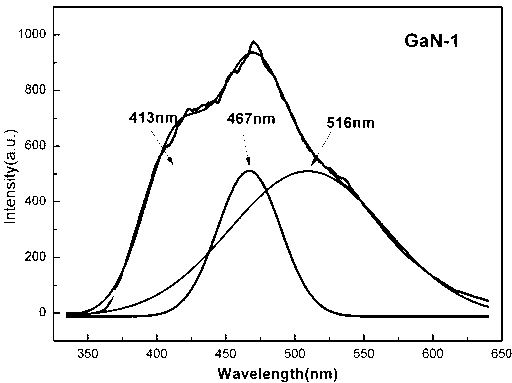

[0019] The XRD spectrum of GaN-1 shows a hexagonal wurtzite structure (ICDD-PDF No. 50-0792), and the inset is an EDS ima...

Embodiment 2

[0021] Using high-purity Ga 2 o 3 Powder and NH 3 Gas is used as Ga source and N source respectively, according to 0.7 g Ga 2 o 3 The powder is placed in a ceramic boat, and the ceramic boat is placed in the central heating zone, the horizontal tube furnace is sealed, and the vacuum degree is evacuated to 1×10 -2 Below Pa, Ar gas with a flow rate of 100 sccm was introduced to heat the tube furnace. When the temperature reached 980 °C, ammonia gas with a flow rate of 150 sccm was introduced and kept for 3 h. Then, the heating was stopped, the temperature was naturally lowered to 600°C, the heating device was turned on again, and the temperature was raised to 980°C for 2 hours. Finally, turn off the ammonia gas and keep the argon flow constant. Naturally cool to room temperature, turn off the argon, take out the ceramic boat, and obtain the sample GaN-2.

Embodiment 3

[0023] Using high-purity Ga 2 o 3 Powder and NH 3 Gas is used as Ga source and N source respectively, according to 0.7 g Ga 2 o 3 The powder is placed in a ceramic boat, and the ceramic boat is placed in the central heating zone, the horizontal tube furnace is sealed, and the vacuum degree is evacuated to 1×10 -2 Below Pa, Ar gas with a flow rate of 100 sccm was introduced to heat the tube furnace. When the temperature reached 980 °C, ammonia gas with a flow rate of 200 sccm was introduced and kept for 3 h. Then, the heating was stopped, the temperature was naturally lowered to 600°C, the heating device was turned on again, and the temperature was raised to 980°C for 2 hours. Finally, turn off the ammonia gas and keep the argon flow constant. Naturally cool to room temperature, turn off the argon, take out the ceramic boat, and obtain the sample GaN-3.

[0024] It can be seen from the above examples that the preparation of GaN nanostructures with adjustable Ga vacancies...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com