Preparation method of black rhenium coating

A technology of coating and molten salt, which is applied in the field of molten salt electroplating preparation of high-emissivity black rhenium coating, can solve the problems of high cost, difficulty in ensuring uniform coating thickness of components, and slow deposition speed, etc., and achieves convenient operation, The coating thickness is easy to control and the concentration is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

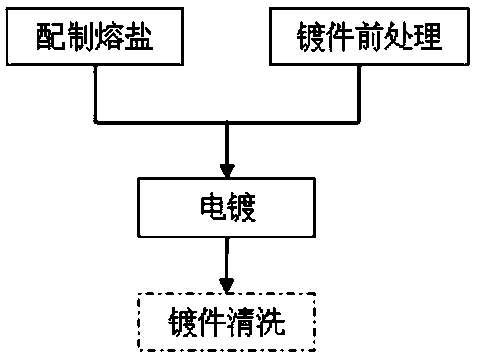

[0037] A kind of preparation method of black rhenium coating, technological process is such as figure 1 shown, including the following steps:

[0038] (1) Molten salt chlorination:

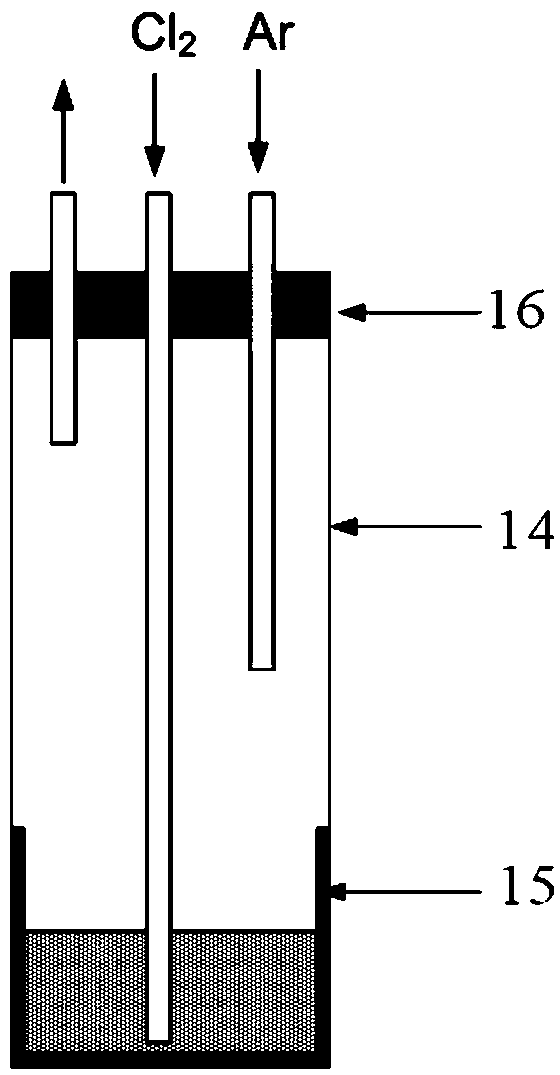

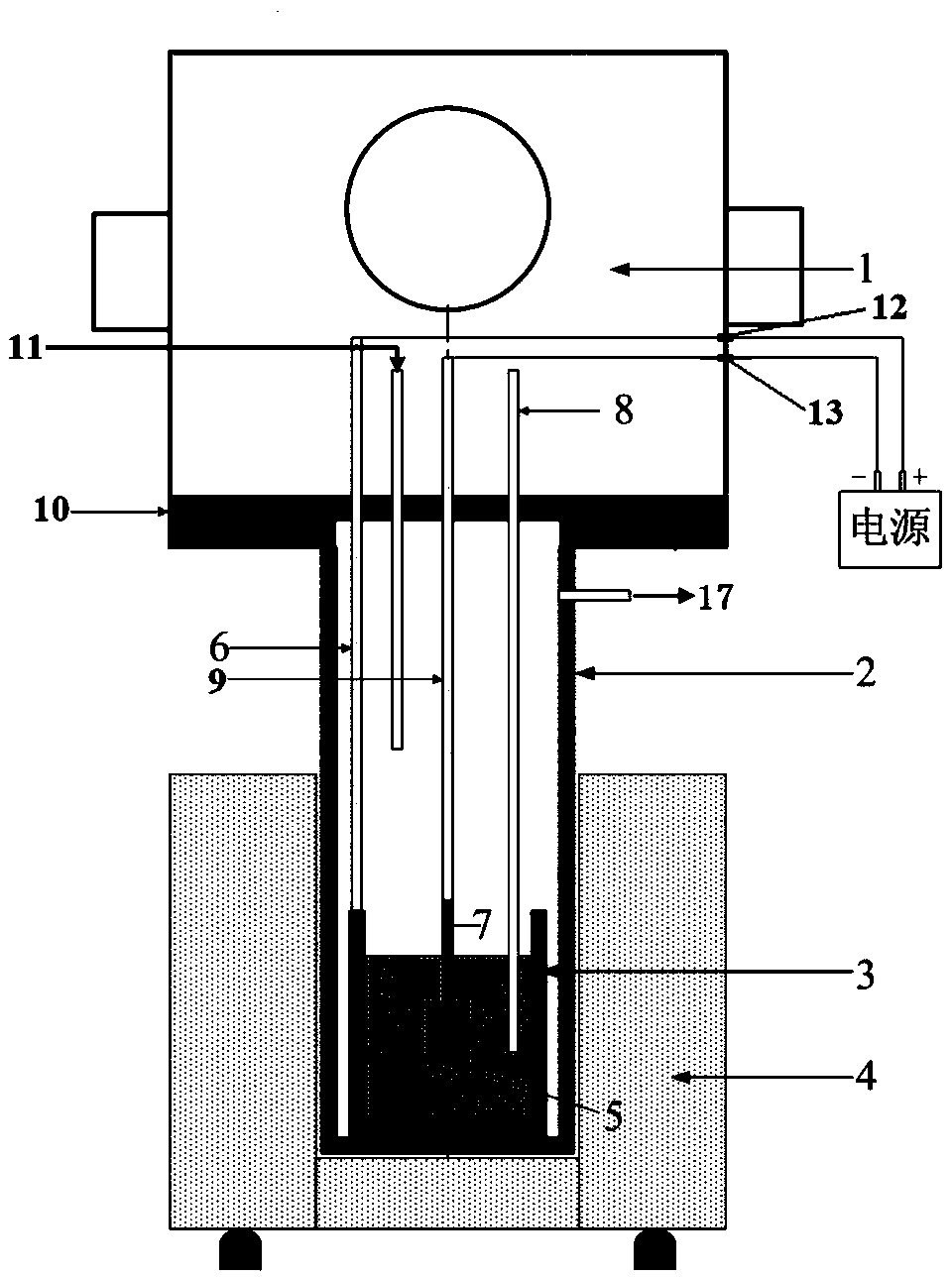

[0039]In the process of preparing molten salt, such as figure 2 The shown molten salt chlorination device, the molten salt chlorination device comprises a quartz barrel 14, a quartz cup 15, two air inlet pipes and an air outlet pipe; the quartz cup 15 is arranged in the quartz barrel 14, and the top of the quartz barrel 14 is provided with There is a rubber plug 16 for sealing, and the air inlet pipe and the air outlet pipe pass through the rubber plug 16. One of the air inlet pipes is used for introducing chlorine gas, and the other air inlet pipe is used for introducing argon gas. When the quartz cup 15 is filled with molten salt, the inlet pipe for chlorine gas is inserted into the molten salt.

[0040] Weigh the CsCl and place it in an oven at 200 °C for 24 h to remove the crystal water. ...

Embodiment 2

[0050] A method for preparing a black rhenium coating is basically the same as the steps in Example 1, except that the plating temperature in step (3) is 850°C.

[0051] Figure 7 and Figure 8 The surface of the black rhenium coating prepared in this example and the microscopic topography of the fracture are respectively, it can be seen from the figure that the surface of the coating is smooth and gray-black. The grain size of the coating is larger than that of Example 1, the surface is densely packed with spire tower-shaped grains with a grain size less than 10 μm, and the coating thickness is about 40 μm. According to the national standard GB 5210-85 "Determination of Coating Adhesion - Pull-off method", the pull-off test was carried out. The average tensile strength measured was 12.2MPa, and the breaking point was the joint between the coating and the substrate. The surface emissivity of the Rhenium coating at room temperature is 0.7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com