Flame retardant adsorption master batch and preparation method thereof

A technology of flame retardant master batch and flame retardant, which is applied in the field of new flame retardant adsorption master batch and its preparation, can solve the problems of persistence and uniformity, easy agglomeration of dust in the processing environment, difficult storage and transportation, etc. Uncontrollable factors, improving the preparation process and performance, shortening the preparation cycle and the effect of equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

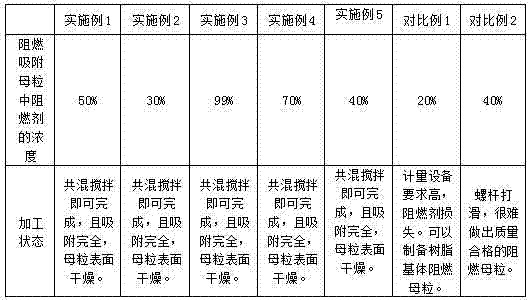

[0044] Example 1 : Weigh 30g polystyrene open-pore particles (EPS, diameter 3mm, porosity 60%) in a 1000 ml beaker, then add 30g liquid flame retardant tris(β-chloroethyl)phosphate (TCEP) Among them, mechanical stirring at a speed of 20 rpm at room temperature for 30 minutes, so that the liquid flame retardant TCEP is completely adsorbed into the polystyrene open-pore particles, and the surface of the particles is dry, and a flame-retardant adsorption masterbatch with a concentration of 50% is obtained.

Embodiment 2

[0045] Example 2 : Weigh 70g of polyurethane open-cell particles (EPU, diameter 3mm, porosity 60%) in a 1000ml beaker, then add 30g of liquid flame retardant tris(β-chloropropyl)phosphate (TCPP), Mechanically stirring at 60 rpm for 20 min at 40°C, the liquid flame retardant TCPP was completely adsorbed into the polyurethane open-pore particles, and the surface of the particles was dry, and a flame-retardant adsorption masterbatch with a concentration of 30% was prepared.

Embodiment 3

[0046] Example 3: Weigh 1g of open-cell polypropylene particles (EPP, particle size 4mm×3mm, porosity 80%) in a 1000ml beaker, and then add 99g of liquid flame retardant tetraphenylresorcinol diphosphate (RDP) Add it in, and stir mechanically at 30 rpm for 10 min at 90°C. The liquid flame retardant RDP is completely absorbed into the adsorption material, and the surface of the particles is slightly dry, and a flame retardant adsorption masterbatch with a concentration of 99% is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com