Patents

Literature

99results about How to "Improve the effect of adding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grapheme type fiber cigarette filter and preparation method thereof

InactiveCN103005712ALarge surface atomic ratioUnique adsorptionTobacco smoke filtersFiberHazardous substance

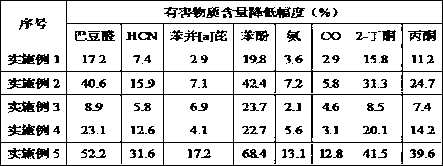

The invention discloses a grapheme type fiber cigarette filter and a preparation method thereof. The filter comprises a fiber carrier, wherein the fiber carrier is provided with a grapheme type material for absorbing harmful components in smoke. The filter loads the grapheme type material on a carbon fiber or acetate fiber carrier; and the carrier is added in the filter by adopting the binary filter production mode in the existing industries to produce a compound filter for absorbing harmful substances in the smoke which is generated when cigarettes are smoked. The filter applies unique phi absorption characteristics and higher surface active atom ratio of novel two-dimensional nanometer materials to efficiently absorb benzo [a] pyrene, volatile aldehyde ketone type cancer promoting molecules, phenol and HCN (Hydrogen Cyanide) under the condition of smaller adding quantity, so that the filter is environment-friendly and has no additional poison; as the amount is small and the effect is high, the harm of the cigarettes to human bodies is reduced under the condition of not influencing the inherent sensory quality of the cigarettes. And at the same time, the method has the advantages of simple technique, large-scale production and low cost, and has wide application foreground in the cigarette field of harm reduction and tar reduction.

Method for preparing plastic biologic packing material of even adulterated powder

InactiveCN101092486AIncreased maximum amount addedImprove the effect of addingSustainable biological treatmentBiological water/sewage treatmentAdhesiveInjection moulding

This invention discloses a method for preparing uniformly powder-doped plastic biofiller. The method comprises: placing plastic granular matrix in a stirring kettle, heating or spraying liquid adhesive so that the surface of plastic granular matrix has viscosity, adding powder, stirring, adhering powder to the surface of plastic granular matrix, adding coupling agent and wetting agent, placing in an injection molding machine, and injection-molding to obtain uniformly powder-doped plastic biofiller. The obtained uniformly powder-doped plastic biofiller has such advantages as high uniformity, good appearance, and high powder doping amount, high processability, no dust, no environmental pollution and no harm to operator's health.

Owner:SOUTH CHINA UNIV OF TECH

Health-caring composition and health-caring product with iron supplementation function, and preparation method thereof

InactiveCN102726738AImprove relative bioavailabilityAdding effect is goodFood preparationSoft gel capsuleBiotechnology

The invention provides a health-caring composition with an iron supplementation function. The health-caring composition comprises an iron raw material, vitamins, substrate oil, a suspending agent, casein phosphoeptide, and the like. A capsule-type health-caring product is prepared by using the health-caring composition. According to the invention, the vitamins and casein phosphoeptide are reasonably added to the formula, such that the relative bioavailability of iron is substantially improved; when folic acid is used in combination with iron, a substantial anemia controlling effect is provided. With the application of soft capsules, the problem of iron odor is solved, and the stability of the product is good. Therefore, the product provided by the invention is advantaged in high safety, reasonable formula, substantial iron supplementation effect, no iron odor, and good stability. The preparation method is simple, and is advantaged in low cost.

Owner:SIRIO PHARMA CO LTD

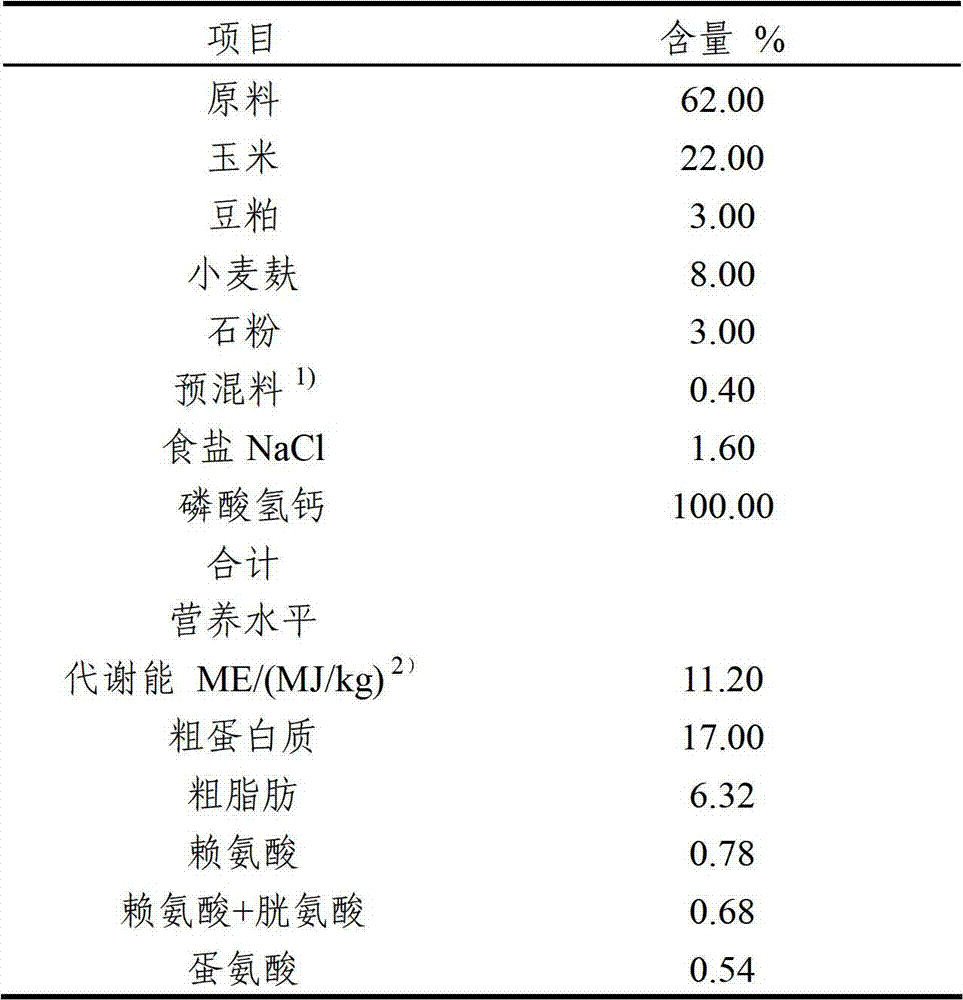

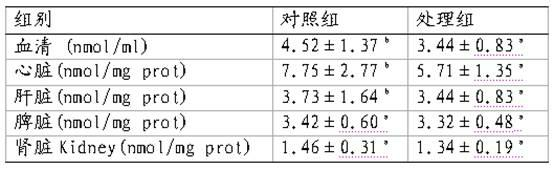

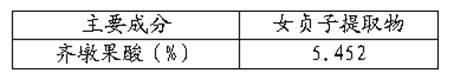

Chinese herbal medicine compound feed for improving meat quality of table poultry and preparation method thereof

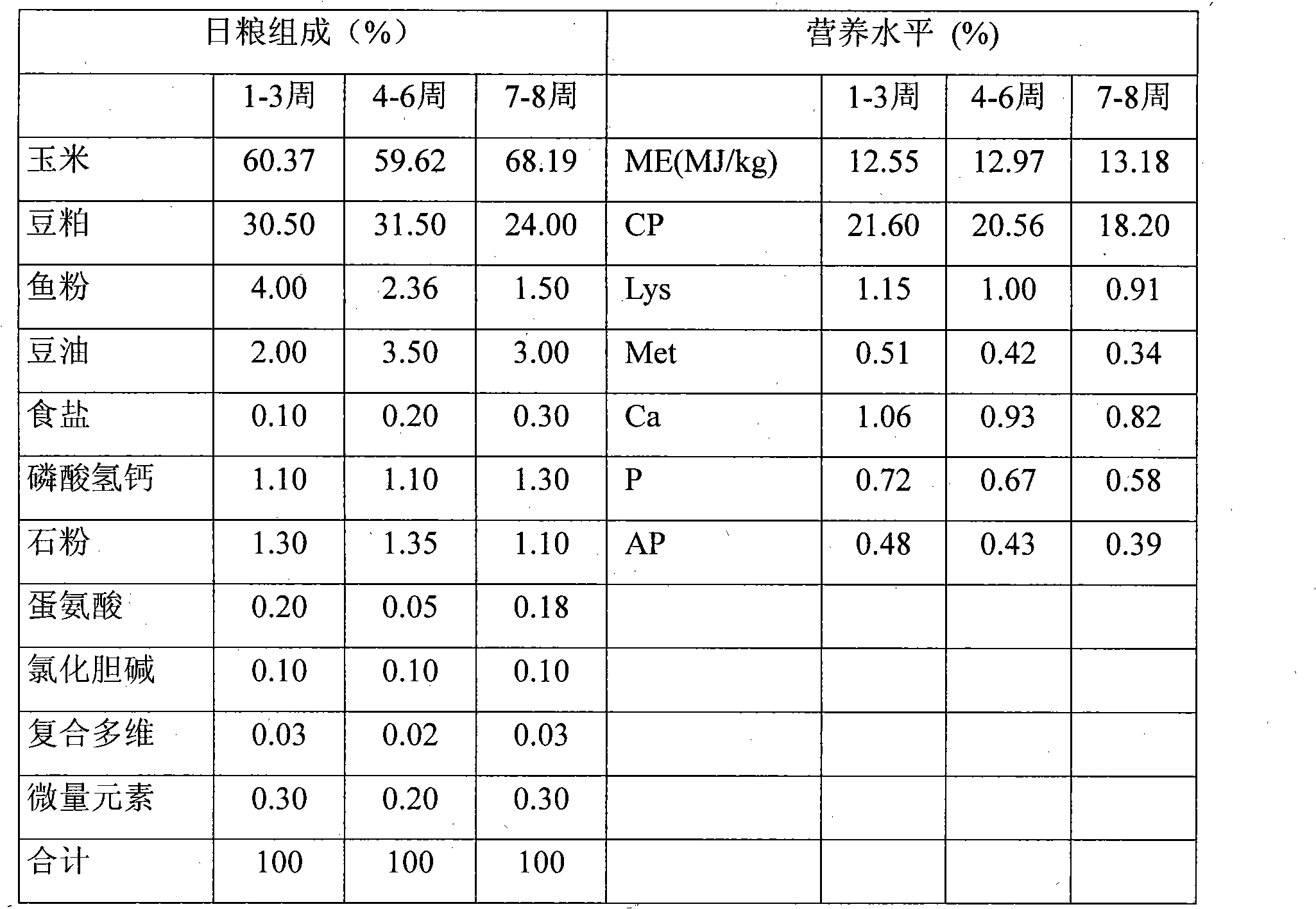

InactiveCN102150758AImprove meat qualityImprove lipid metabolismFood processingAnimal feeding stuffTrace elementStone dust

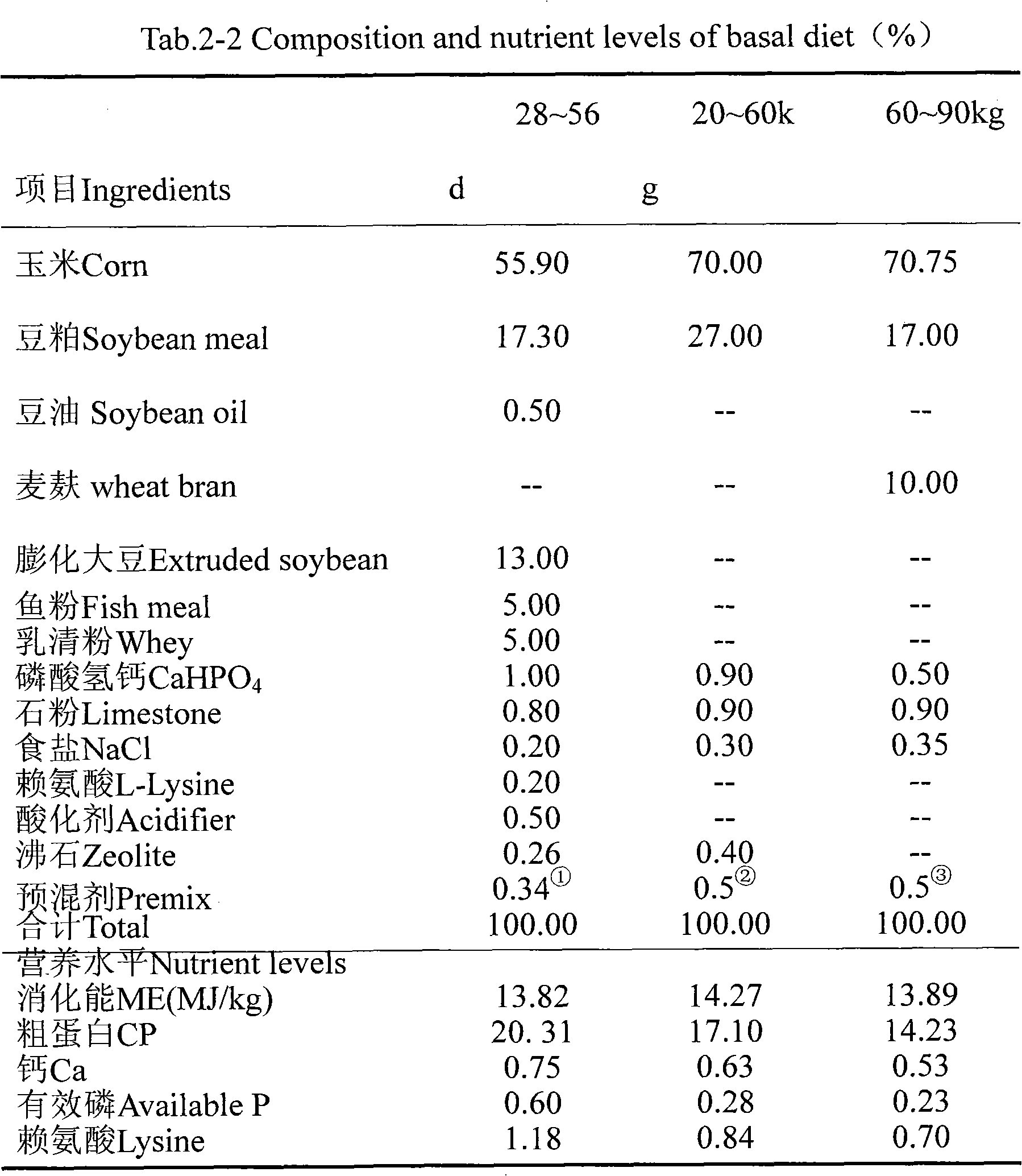

The invention relates to Chinese herbal medicine compound feed for improving meat quality of table poultry and a preparation method thereof, steamed glossy privet fruits with wine are dried at the temperature of 65 DEG C till being constant in weight, shelled, crushed, sieved by an 80-mesh sieve and uniformly added into basic ration for the table poultry according to 1% by weight, and each part of the basic ration for the table poultry comprises 59.62-68.19kg of corn, 24.00-31.50kg of soybean meal, 1.50-4.00kg of fish meal, 2.00-3.50kg of soybean oil, 0.10-0.30kg of common salt, 1.10-1.30kg of calcium hydrophosphate, 1.10-1.35kg of stone dust, 0.05-0.2kg of methionine, 0.10kg of choline chloride, 0.02-0.03kg of compound vitamins, and 0.2-0.3kg of compound trace elements. Sources of raw materials used in the method are wide, the adding effect is obvious, and the Chinese herbal medicine compound feed can simultaneously improve the growth performance of the table poultry, improve the anti-oxidation mechanism of muscles and obviously improve the meat quality of the table poultry.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Heat-resistant stress feedstuff additive for milk cattle

InactiveCN101406251AIncrease profitPromote absorptionAnimal feeding stuffAccessory food factorsSodium bicarbonateMilk cow's

The invention relates to a feed additive, in particular to a heat-resistant stress feed additive for a cow. The additive comprises the following components in weight portion: 4 to 7 portions of milk veteh, 3 to 6 portions of angelica, 4 to 7 portions of seed cowherb, 2 to 5 portions of licorice, 5 to 8 portions of potassium chloride, 2 to 5 portions of sodium chloride, 1 to 2 portions of magnesium chloride, 2 to 5 portions of sodium bicarbonate, 2 to 5 portions of citric acid and 5 to 10 portions of carrier. The milk veteh, the angelica, the seed cowherb, the licorice, the potassium chloride, the sodium chloride, the magnesium chloride, the sodium bicarbonate and the citric acid are subjected to superfine grinding, filtered by a shaking screen of 100 to 200 meshes, and then mixed with the carrier according to a proportion, stirred evenly, sterilized, cooled, and packaged to prepare the feed additive. The feed additive can improve the heat-resistant stress reaction capability of the cow, enhance immune function of the cow organism, and promote quick rehabilitation of sick livestock, and has the effect of controlling breathing, tonifying the blood, and relaxing vein and promoting milk.

Owner:TIANJIN SHENGJI GRP CO LTD

Pretreatment agent for electroless plating, and pretreatment and production of printed wiring board using same

ActiveUS20150072070A1Improve penetrabilityIncrease resistanceInsulating substrate metal adhesion improvementAnti-corrosive paintsEtherPre treatment

A pretreatment agent for electroless plating is provided, which includes: a fluorine compound; a surfactant; and at least one solvent selected from ethylene-based glycol butyl ethers of formula: C4H9—(OC2H4)m—OH where m is an integer of 1 to 4, and propylene-based glycol butyl ethers of formula: C4H9—(OC3H6)n—OH where n is an integer of 1 to 4. Also provided are a method for pretreating a substrate to be used for a printed wiring board, and a process for producing a printed wiring board, both of which include using a pretreatment agent for electroless plating as described above.

Owner:C UYEMURA & CO LTD

Method for preparing Chinese medicinal herb feed additive for improving stress resistance of pigs

InactiveCN101849623AFast growthImprove antioxidant functionAnimal feeding stuffAnimal scienceSulfate

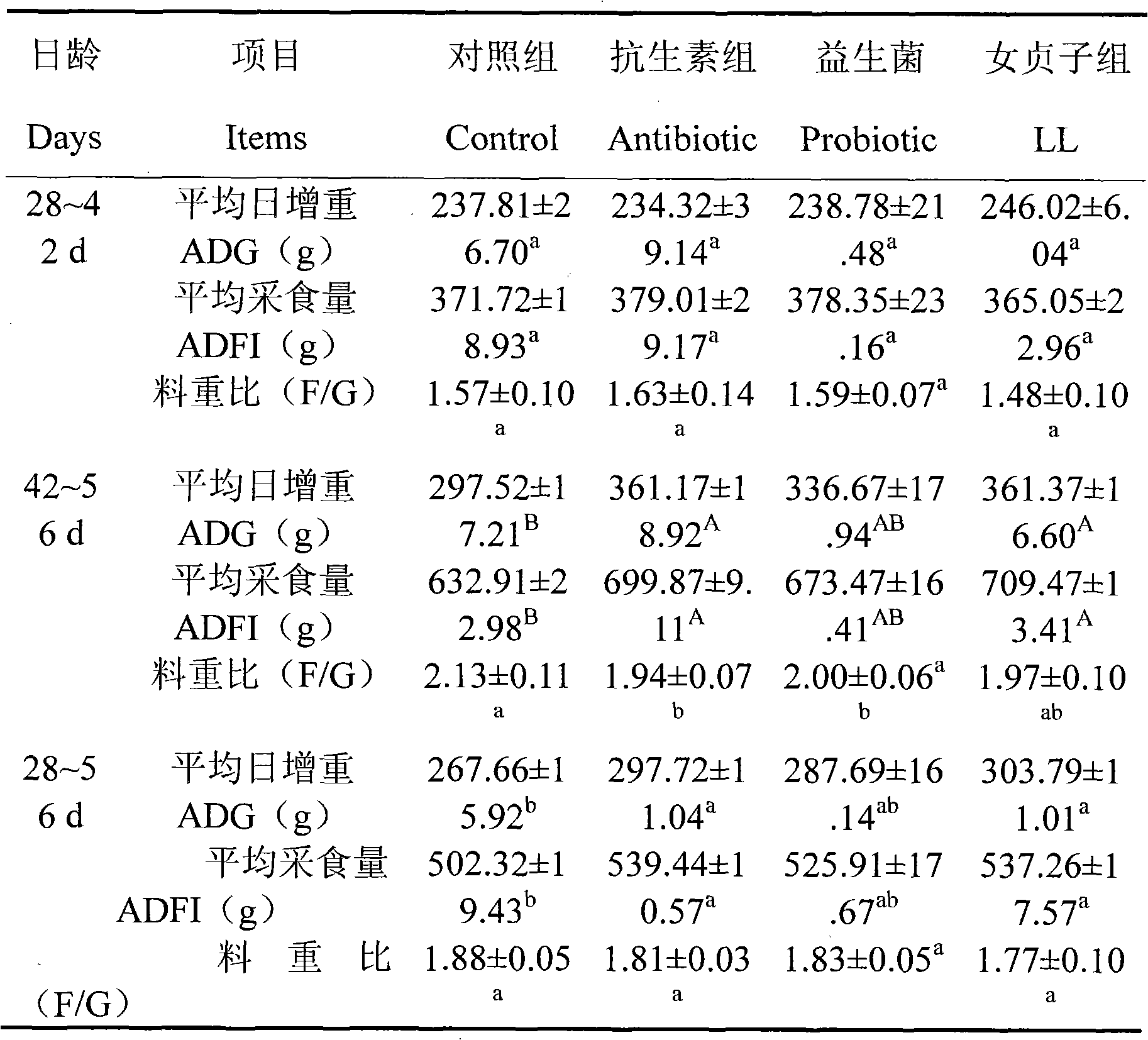

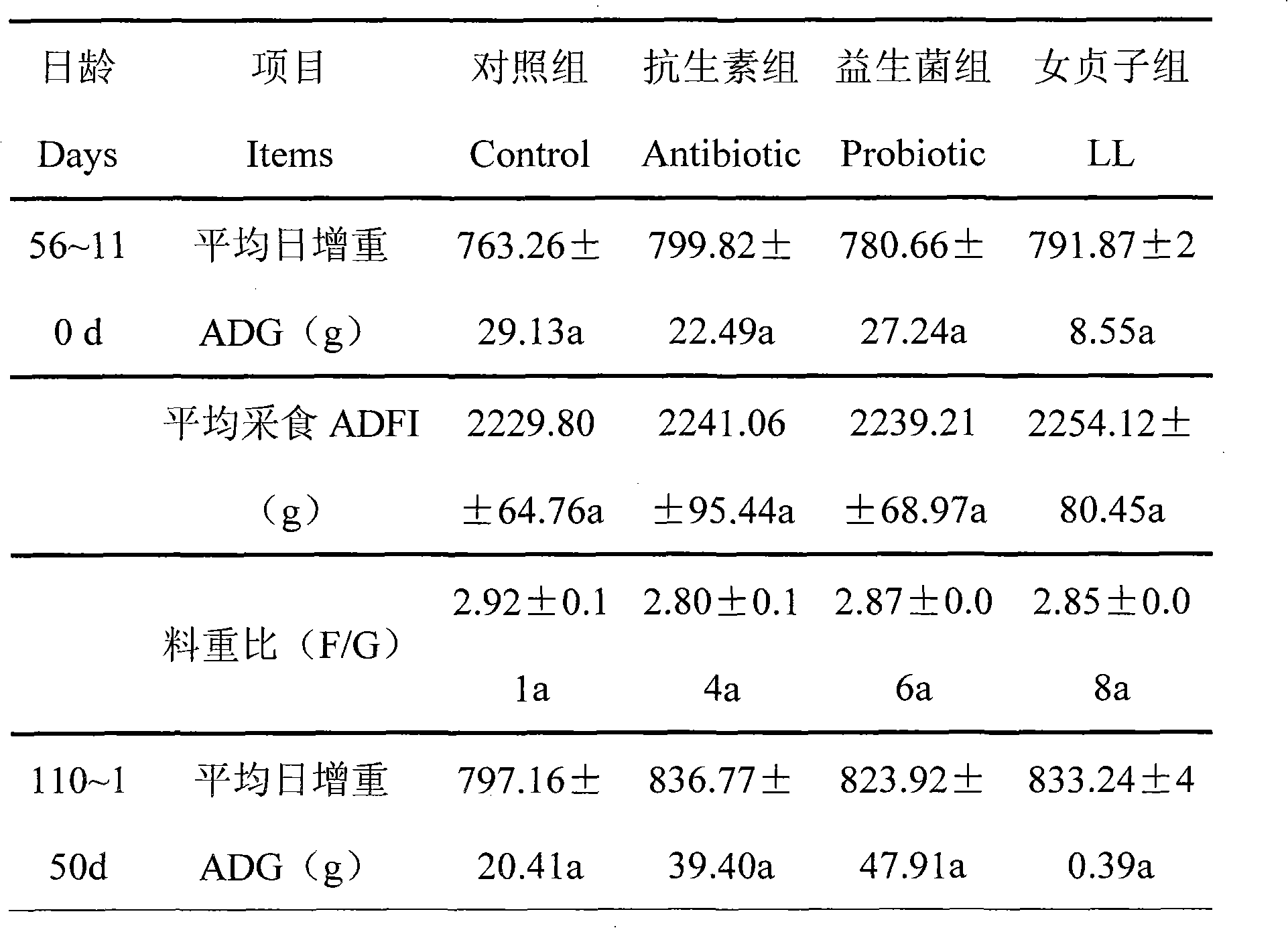

The invention provides a method for preparing Chinese medicinal herb feed additive having the characteristics of low price, simple production and use, small adding amount, obvious adding effect, no adverse reaction and the like and capable of improving stress resistance of pigs. The method for preparing the Chinese medicinal herb feed additive for improving the stress resistance of the pigs comprises the following steps of: crushing glossy privet fruits with a sieve of 60 meshes, then drying the glossy privet fruits at the temperature of between 50 DEG C, and uniformly adding 1 percent of glossy privet fruits into feed of weaning piglets, growing pigs and fattening pigs. The method can improve the growing speed of the pigs to a certain degree, improve the in vivo lipid metabolism, improve the oxidation resistant function in the pig bodies and improve the quality of pork, and can be applied to pig raising production practices by partially substituting antibiotics (colistine sulfate), so the method has certain practice significance for modernized research and further development of substituting for the antibiotic feed additive.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Composite type diesel fuel cetane number improver and production process thereof

InactiveCN103911194AImprove securityImprove the effect of addingLiquid carbonaceous fuelsFuel additivesChemistrySafety coefficient

The invention discloses a composite type diesel fuel cetane number improver and a production process thereof. The production process successively includes the following steps: (1) mixing isooctanol and cyclohexanol (or n-butanol) in proportion to prepare a mixed alcohol; (2) respectively sending fuming nitric acid, concentrated sulfuric acid and the mixed alcohol simultaneously into a micro channel reactor by metering pumps in proportion, and carrying out a reaction; (3) allowing the product to flow into an ester acid separation tank through an outlet of the micro channel reactor, and after removing an acid layer, allowing to go into a crude product tank; and (4) refining the crude product to obtain the target product. The composite type diesel fuel cetane number improver and the production process thereof have the advantages that: (1) the safety coefficient of the product is high, and the explosion sensitivity of the product is lower than any one of single-improvers; (2) the adding effect of the product is good; (3) the micro channel reactor has the advantages of compact structure, easy operation, low energy consumption, safety, reliability and high production efficiency; (4) the whole process device is small in size and low in investment cost; and (5) the target product has no need of compounding, and thus the procedures are reduced.

Owner:PUCHENG RUIYING NEW MATERIAL TECH

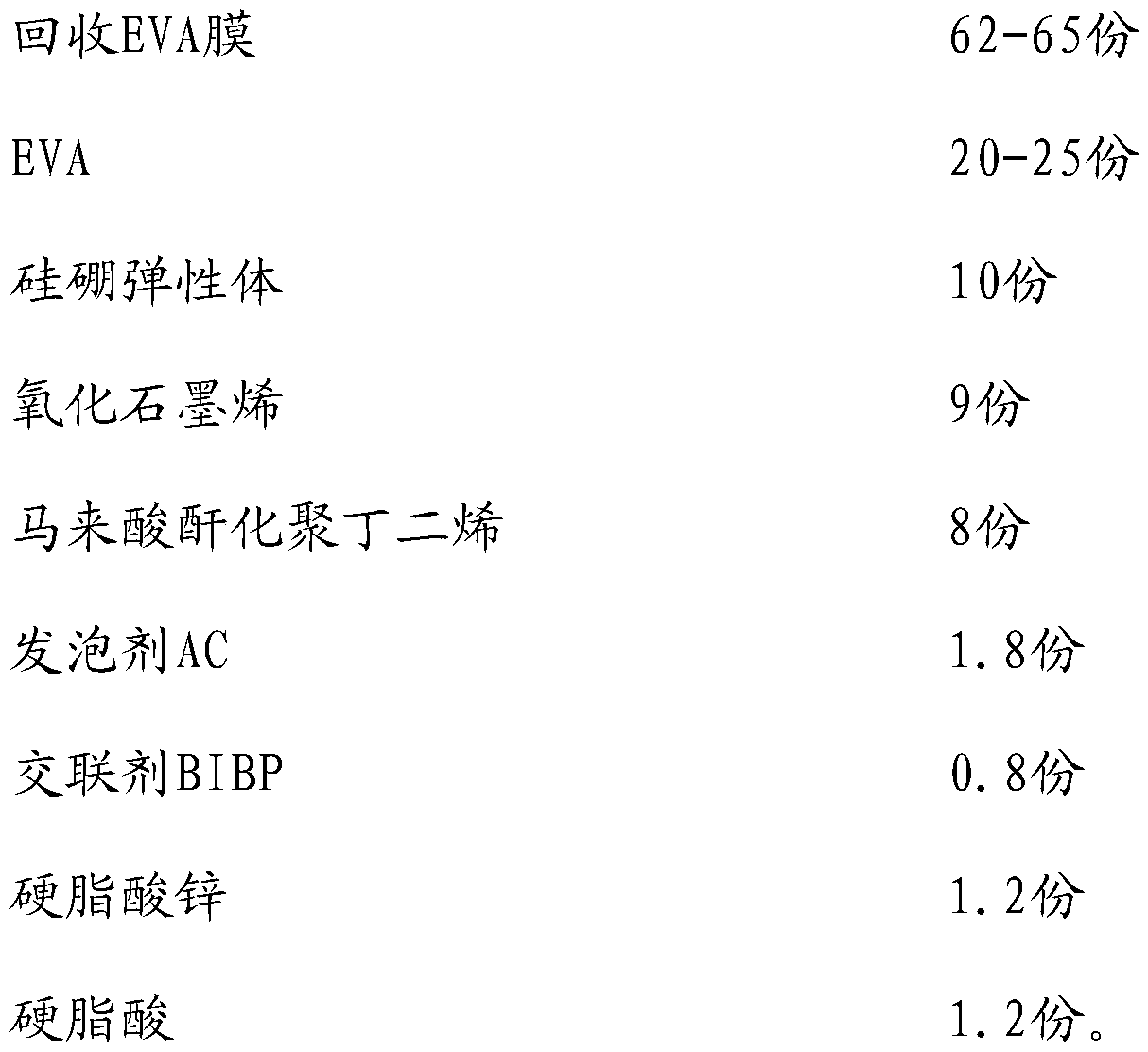

Light jogging shoe sole preparation method

InactiveCN110818990ASolve pollutionSolve the problem of poor performance of the prepared soleSolesPolymer scienceCross linker

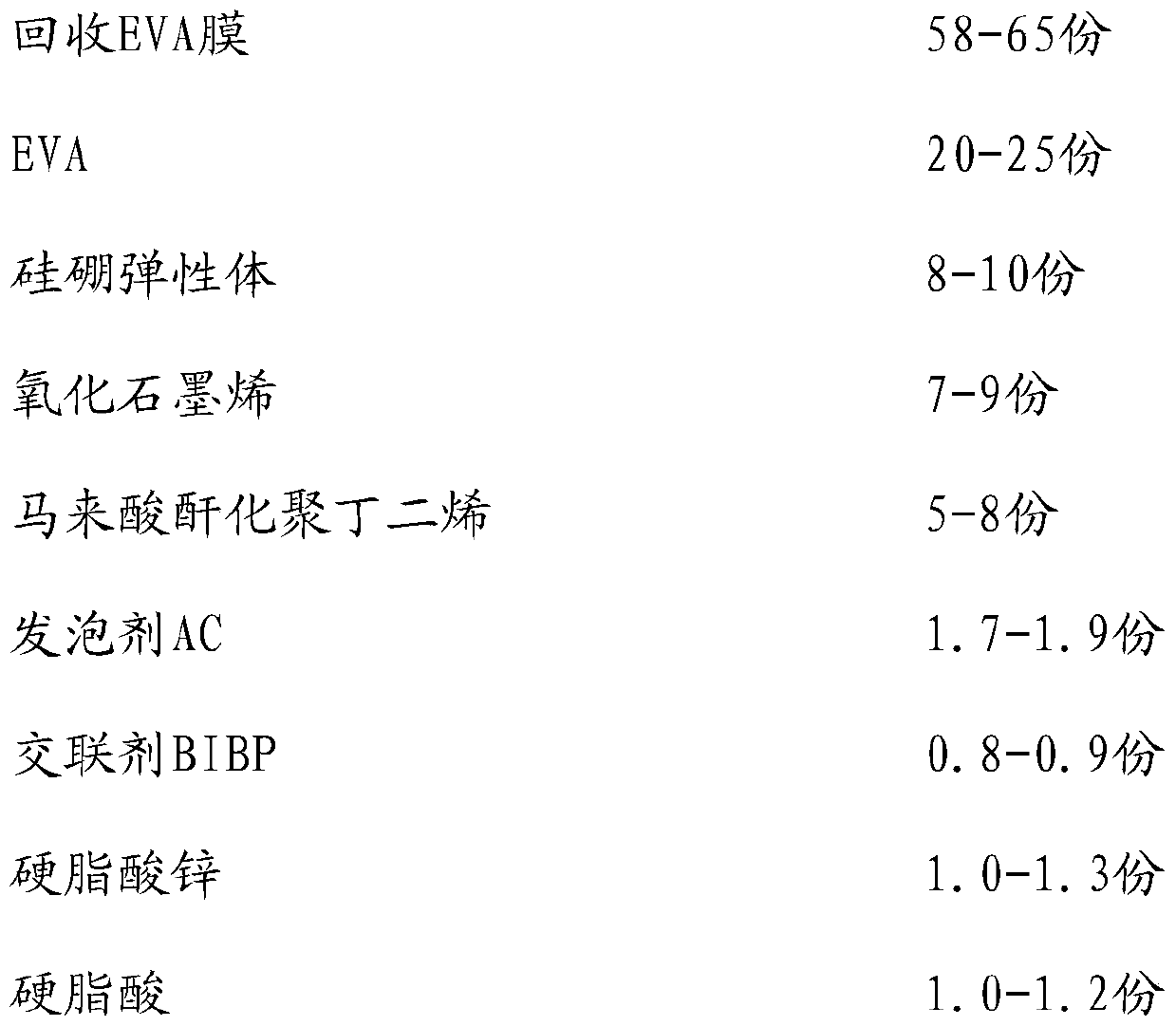

The invention discloses a light jogging shoe sole preparation method, wherein the light jogging shoe sole is prepared from the following raw materials by weight: 58-65 parts of a recovery EVA film, 20-25 parts of EVA, 7-9 parts of graphene oxide, 5-8 parts of maleic anhydride polybutadiene, 1.7-1.9 parts of a foaming agent AC, 0.8-0.9 part of a cross-linking agent BIBP, 1.0-1.3 parts of zinc stearate and 1.0-1.2 parts of stearic acid. The preparation method comprises: internal mixing, open mixing, granulation, and one-time injection molding. According to the invention, the prepared light jogging shoe sole has advantages of light weight, comfort, low cost and the like, and the high-value resource recycling of EVA shoe sole remnant, inferior-quality products, waste products and leftover materials is achieved.

Owner:MAOTAI FUJIAN SOLES CO LTD

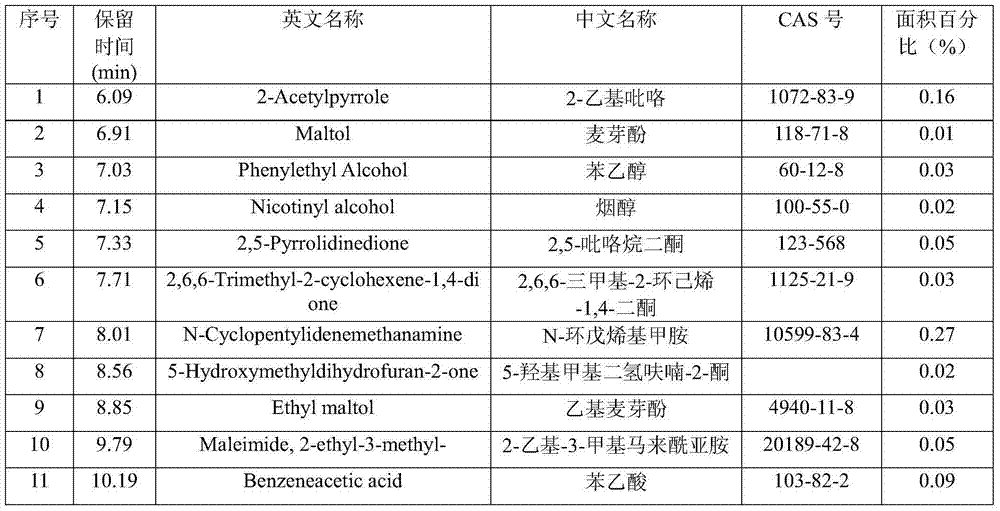

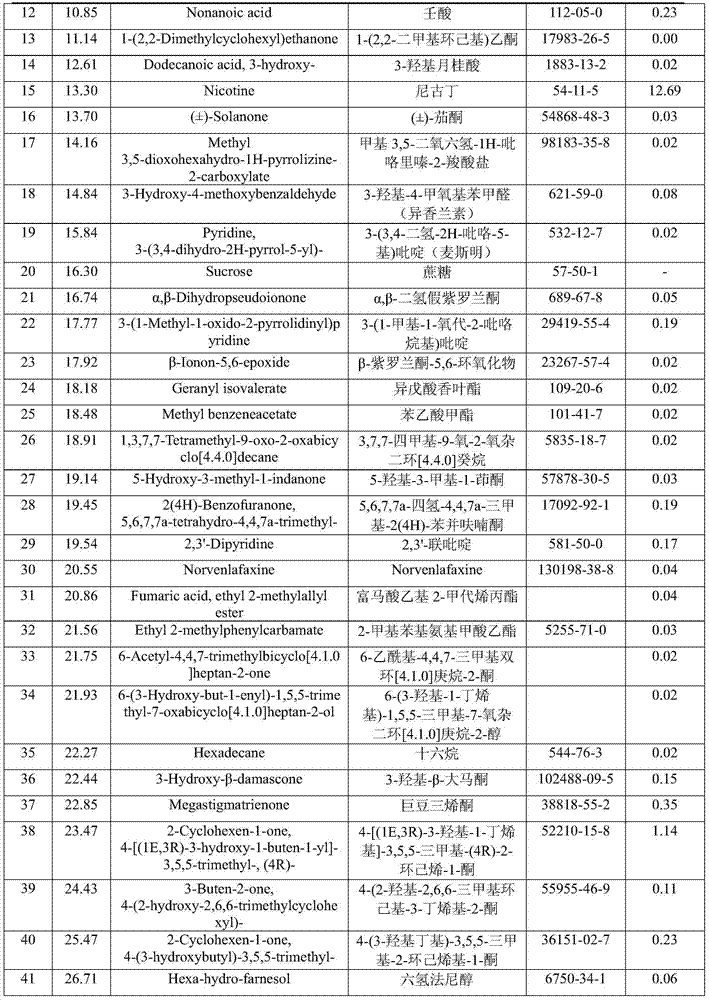

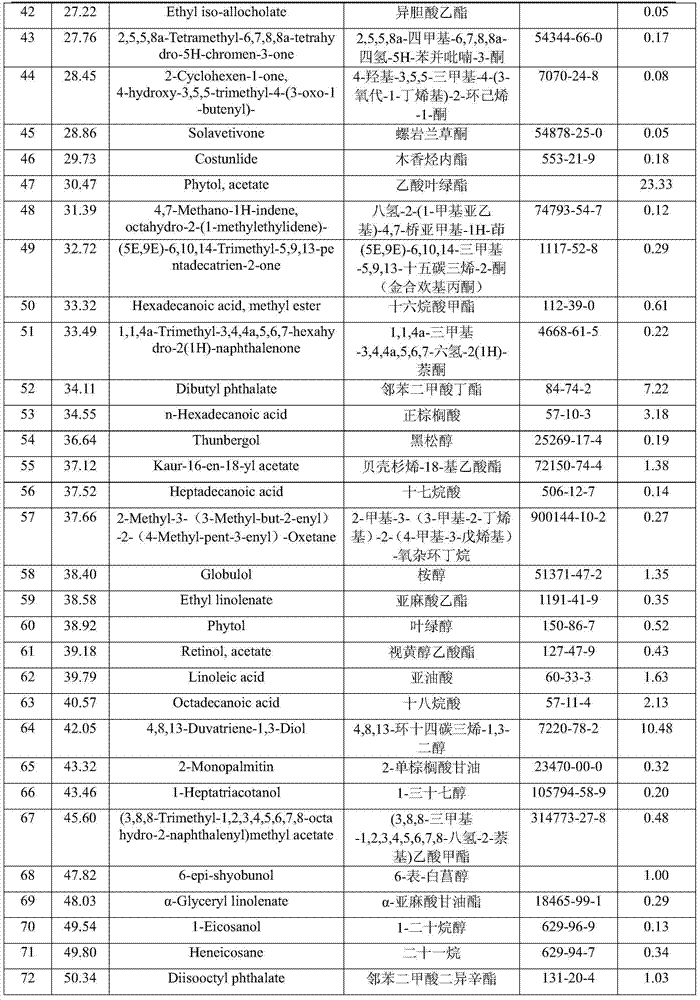

Method for extracting tobacco flavor from tobacco forks by use of supercritical fluid extraction technique

InactiveCN104726200AAvoid wastingAvoid pollutionTobacco preparationEssential-oils/perfumesFlavorPollution

The invention discloses a method for extracting a tobacco flavor from tobacco forks by use of a supercritical fluid extraction technique. The method comprises the following steps: preprocessing tobaccos of different types and crushing the preprocessed tobacco forks to the range of 10-80 meshes; adding the crushed samples to a supercritical fluid extraction kettle and adding an entrainer having the concentration of 60%-100%; performing carbon dioxide supercritical fluid extraction at an extraction temperature of 40-65 DEG C and under an extraction pressure of 200-350bar; adding the tobacco fork extracts to cut stems in the ratio of 0.005-0.05% of the weight of the tobaccos by the tobacco types, or adding to a slice coating liquid in the ratio of 30%-70% to prepare tobacco slices, or directly adding in the ratio of 0.1%-1% to prepare the tobacco slices; and adding the cut stems or the slices to a cigarette formula in the proportion of 2%-15%, thereby preparing into cigarette products. The method is capable of remitting the insufficiency of raw materials, and also reducing the pollution to the environment and avoiding the waste of resources.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

Graphene modified flame retardant polystyrene particle and extrusion and pelletizing method thereof

The invention relates to a graphene modified flame retardant polystyrene particle and an extrusion and pelletizing method thereof, and belongs to the technical field of industrial production method ofgraphene modified flame retardant polystyrene particles. The technical problem to be solved by the present invention is to improve the production efficiency and achieve the industrial production of graphene modified flame retardant polystyrene particles. The technical scheme is that the graphene modified flame retardant polystyrene particle is prepared by mixing the following raw materials: polystyrene, graphene, a plasticizer, an antioxidant, a polystyrene resin, a flame retardant, a foaming agent and dispersing agent. The extrusion and pelletizing method comprises: 1, preparing materials, wherein various raw materials are prepared according to a certain weight part ratio; 2, preparing graphene masterbatch; and 3, preparing the graphene modified flame retardant polystyrene particles by using a twin-screw extruder and an underwater pelletizing system. According to the present invention, the method is used for preparing graphene modified flame retardant polystyrene particles, and further has characteristics of high production efficiency, environmental protection and resource saving.

Owner:南京法宁格节能科技股份有限公司

Attapulgus stone as cut tobacco additive and/or filter tip in to bacco industry

InactiveCN1528214ARich in mineral resourcesAbundant resourcesTobacco treatmentTobacco smoke filtersCellulose acetateTar

The present invention relates to application of attapulgite in tobacco industry. It can be used as additive for tobacco shred, and its added quantity is 0.01-0.5 wt% of weight of tabacco shred in the tobacco shred, it also can be used as additive for filter tip, when it is used as additive for filter tip, firstly, the attapulgite powder glyceride tracetate suspension liquor whose weight ratio is 0.1-10% can be prepared, then the suspension lqiuor can be sprayed on the cellulose acetate fibre bundle by means of filter tip machine so as to obtain qualified filter rod for cigarette. Its invention can reduce tar content and nicotine content in the cigarette.

Owner:盱眙欧佰特粘土材料有限公司

Multilayer ceramic capacitor and manufacturing method thereof

ActiveCN1728303AHigh dielectric constantTemperature characteristic flatteningFixed capacitor electrodesFixed capacitor dielectricCapacitanceAlkaline earth metal

The present invention provides a multilayer ceramic capacitor and its manufacturing method. The multilayer ceramic capacitor comprises a dielectric layer and an internal electrode layer that are alternately laminated. Barium titanate particles containing an alkaline earth metal component except for Ba in a proportion of not more than 0.2 atomic % (BMTL), and barium titanate particles containing an alkaline earth metal component except for Ba in a proportion of not less than 0.4 atomic % (BMTH) coexist in the dielectric layer in an area ratio of BMTL to BMTH of 0.1 to 9. This provides excellent reliability of capacity temperature characteristic and high-temperature load lifetime, if the dielectric layer is thinned.

Owner:KYOCERA CORP

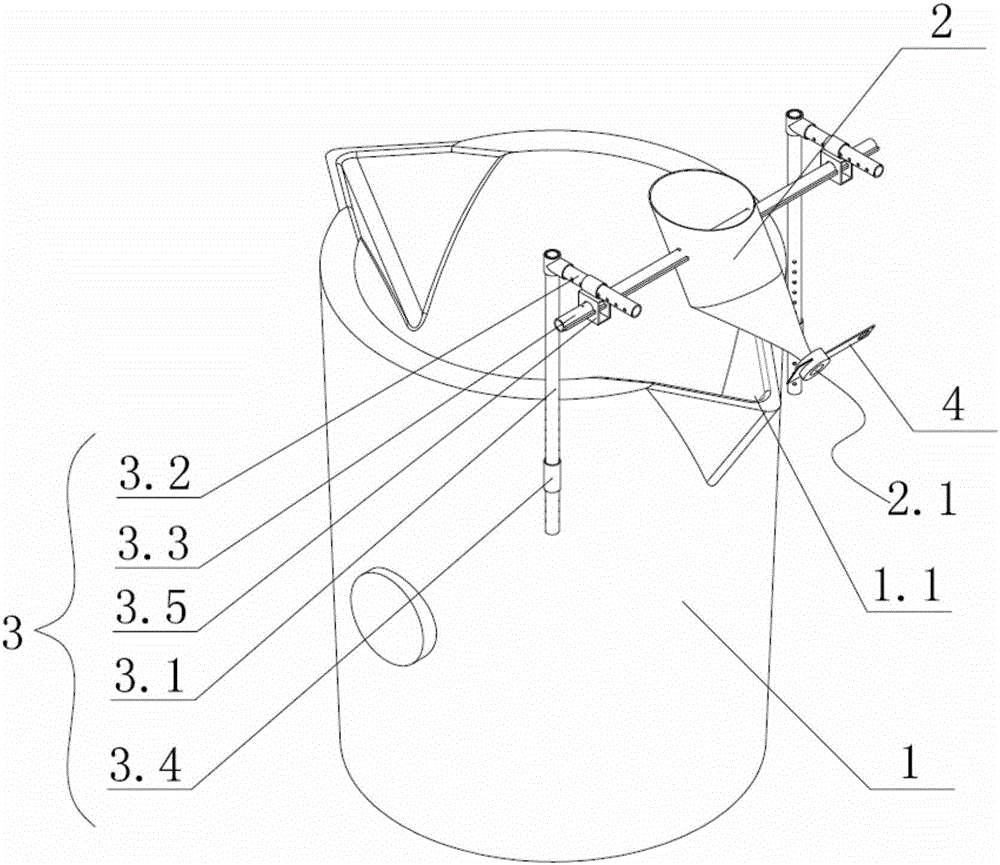

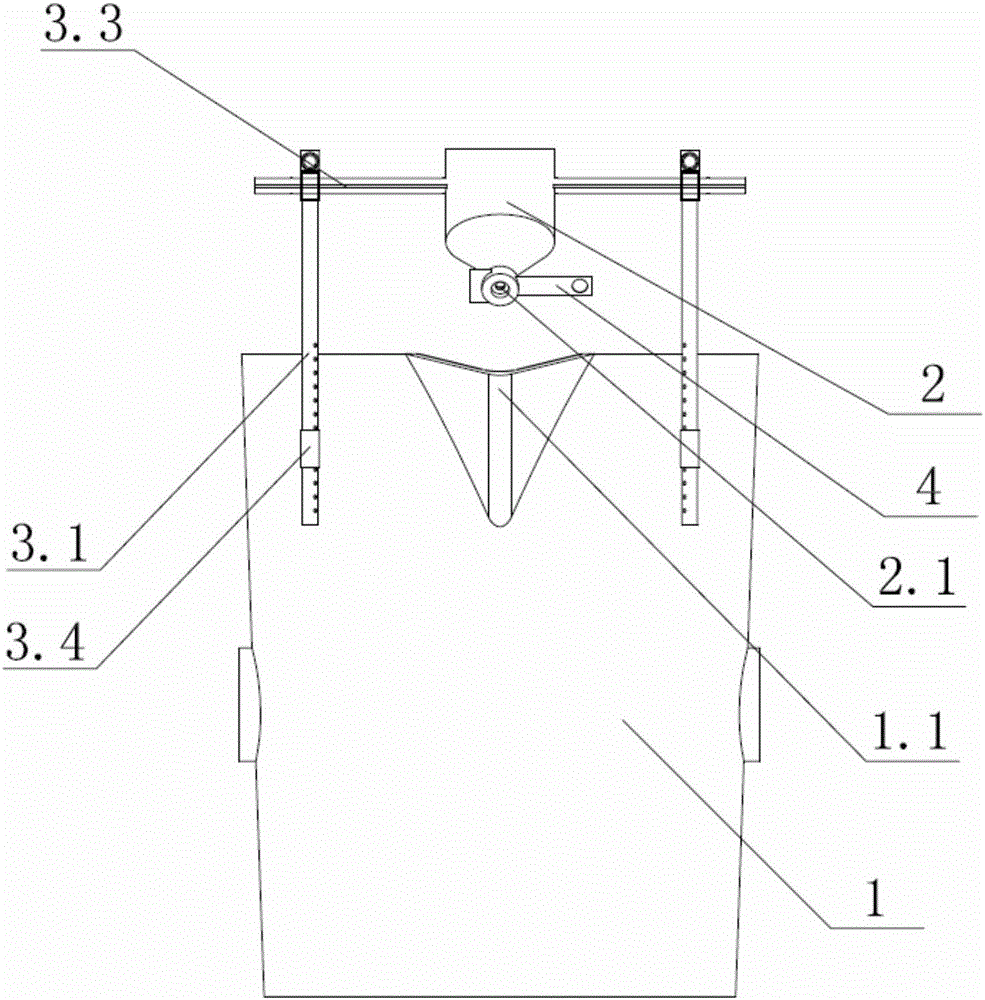

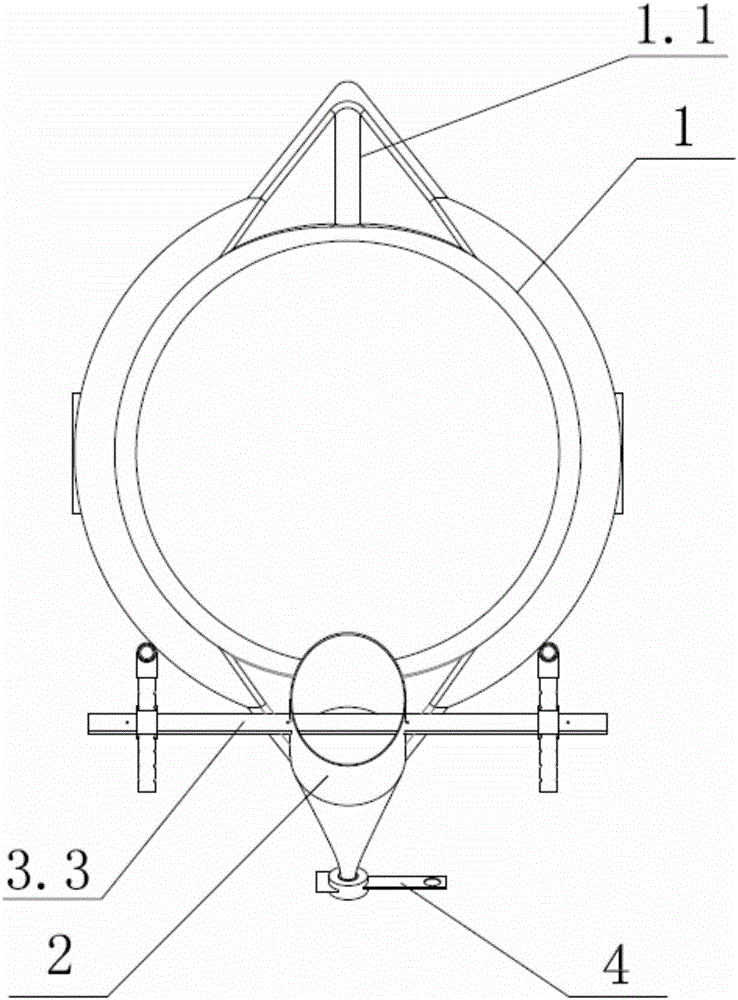

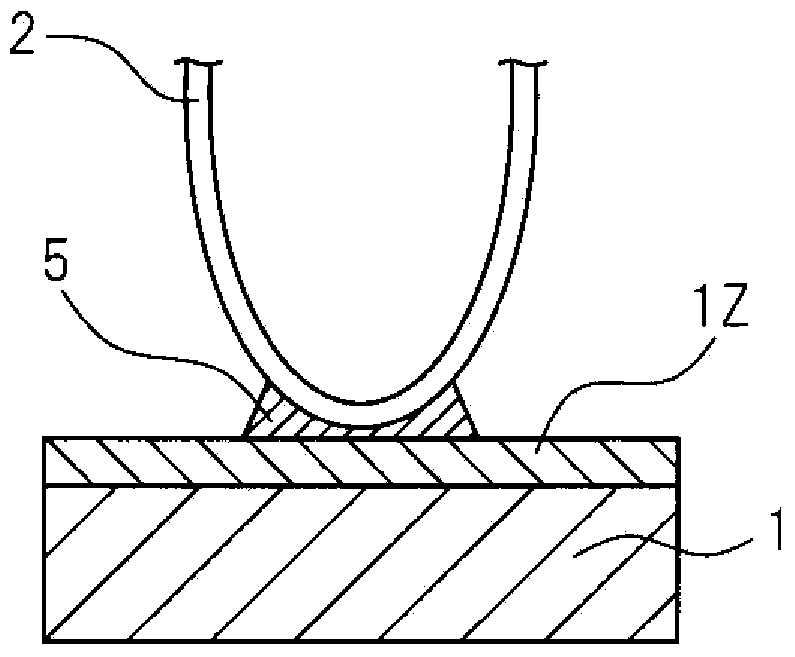

Fixed casting ladle for casting

ActiveCN105965000AImprove temperature uniformityAvoid strandedMelt-holding vesselsMetallurgyInoculation

The invention discloses a fixed casting ladle for casting. The fixed casting ladle for casting comprises a casting ladle body (1) provided with a sprue (1.1) and is characterized in that an inoculation hopper (2) is arranged above the casting ladle body (1) and fixed to the casting ladle body (1) through a support (3); a discharge port (2.1) of the inoculation hopper (2) points to the outside of the casting ladle body (1) and is located on an area where the sprue (1.1) faces. The fixed casting ladle for casting is simple in structure, low in equipment cost and capable of making the inoculation hopper and the sprue of the casting ladle in linkage.

Owner:宁波日星铸业有限公司

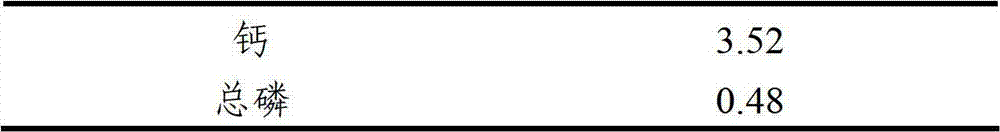

Feed additive for producing eggs rich in omega-3 fatty acid

InactiveCN107455604ALower cholesterol levelsRaise ALAFood processingAnimal feeding stuffMoistureCellulase

The invention provides a feed additive for producing eggs rich in omega-3 fatty acid. The feed additive is prepared from the following components in parts by weight: 28-59 parts of perilla seeds, 30-50 parts of schizochytrium powder, 10-20 parts of lotus seed husks, 0.5-1 part of protease and 0.5-1 part of cellulase, wherein the grain size of the perilla seeds is 60 meshes, the moisture content is less than or equal to 10%, the crude fat content is greater than or equal to 40%, the linolenic acid content is greater than or equal to 15%, and the perilla seeds are obtained by baking or airing fresh perilla seeds at the temperature lower than 80 DEG C, grinding the fresh perilla seeds and then sieving the powder with a 60-mesh sieve; and the grain size of the schizochytrium powder is 60 meshes, the moisture content is less than or equal to 10%, the crude fat content is greater than or equal to 40%, and the DHA content is greater than or equal to 15%. The feed additive can increase the contents of omega-3 polyunsaturated fatty acid and DHA in eggs and also can obviously improve the egg quality.

Owner:永州市掌望生态农业有限公司

Plastic optical fiber modified by nanometer materials and method for preparing plastic optical fiber

ActiveCN106046223AImprove heat resistanceLow water absorptionCladded optical fibreOptical waveguide light guideMethacrylatePolymer science

The invention discloses a plastic optical fiber modified by nanometer materials and a method for preparing the plastic optical fiber. The method includes steps of weighing, by weight, 1-10 parts of yttrium trifluoroacetic acid, dissolving the yttrium trifluoroacetic acid in mixed solution of ethyl alcohol and water, adding 90-99 parts of tetraethyl orthosilicate into the mixed solution and adjusting the PH (potential of hydrogen) of the mixed solution until the PH of the mixed solution reaches 1.5-2.0; adding the mixed solution into a high-pressure kettle until 1 / 2-2 / 3 of the volume of the high-pressure kettle is filled with the mixed solution, sealing the high-pressure kettle and carrying out reaction under the condition of temperature of 60-80 DEG C for 0.5-10 hours; drying products obtained in the high-pressure kettle, cleaning the products by the aid of ethyl alcohol and drying and smashing the products to obtain nanometer auxiliaries; weighting 0.1-10 parts of the nanometer auxiliaries, mixing the nanometer auxiliaries and 90-99.9 parts of methacrylic ester monomers with one another and carrying out heating polymerization to obtain plastic optical fiber pre-polymerization bars; heating the plastic optical fiber pre-polymerization bars, drawing the optical fiber pre-polymerization bars to obtain a plastic optical fiber with a required diameter so as to obtain the plastic optical fiber modified by the nanometer materials. The plastic optical fiber and the method have the advantages that the plastic optical fiber is good in heat resistance and low in water absorption, and the application range can be expanded.

Owner:江西井圣塑料光纤科技协同创新有限公司

Plant feed additive for broiler chicken, premix compound and compound

InactiveCN102823774AImprove palatabilityReduce churnAnimal feeding stuffBiotechnologyAdditive ingredient

The invention discloses a plant feed additive for broiler chicken. The plant feed additive comprises the following ingredients in parts by weight: 20 to 40 parts of pine needle, 20 to 40 parts of Echinacea, 5 to 15 parts of hawthorn, 5 to 15 parts of yam and 3 to 10 parts of multiflower knotweed vine. The plant feed additive provided by the invention is added into daily ration of broiler chicken at the dosage being 500 to 1000mg / Kg, the production performance of the broiler chicken can be improved to a certain degree, and the immune function of the broiler chicken is enhanced. The plant feed additive also has the characteristics that the price is low, the production and the use are simple, the addition is little, the addition effect is obvious, no adverse reaction is caused, and the like.

Owner:BEIJING DABEINONG TECH GRP CO LTD +2

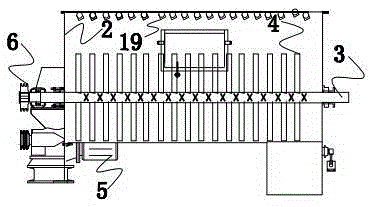

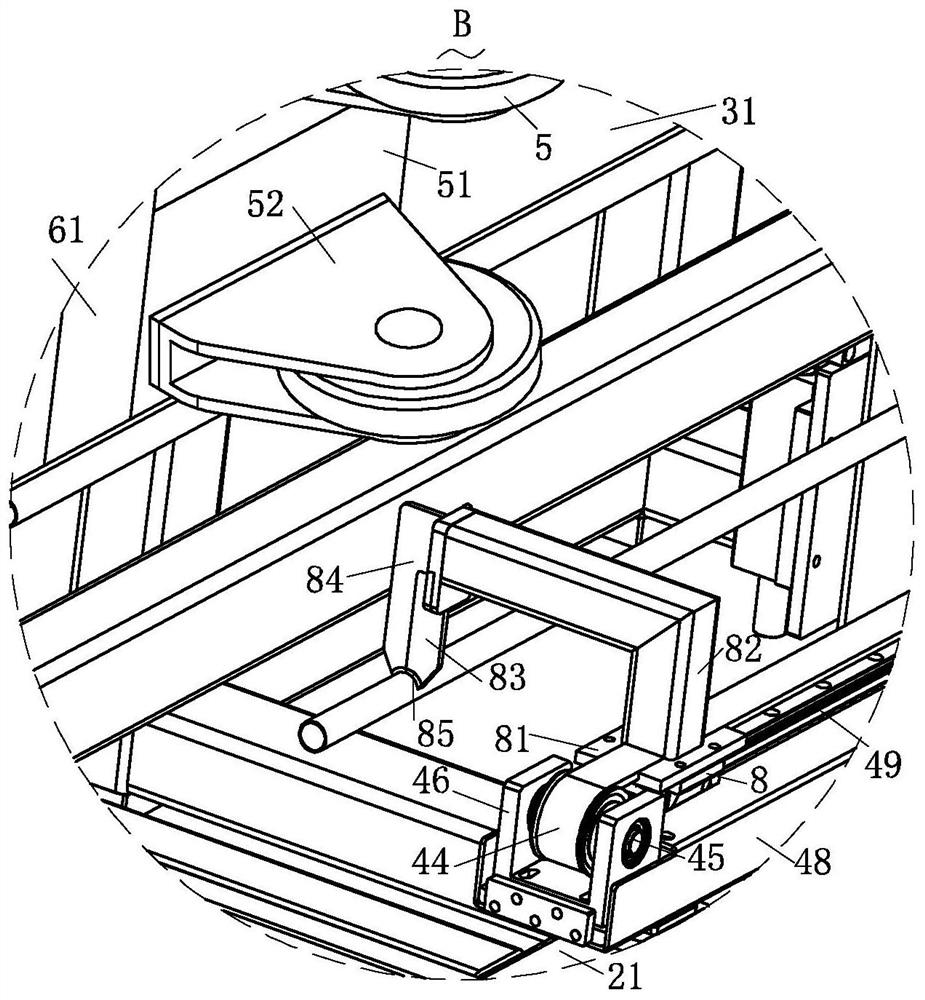

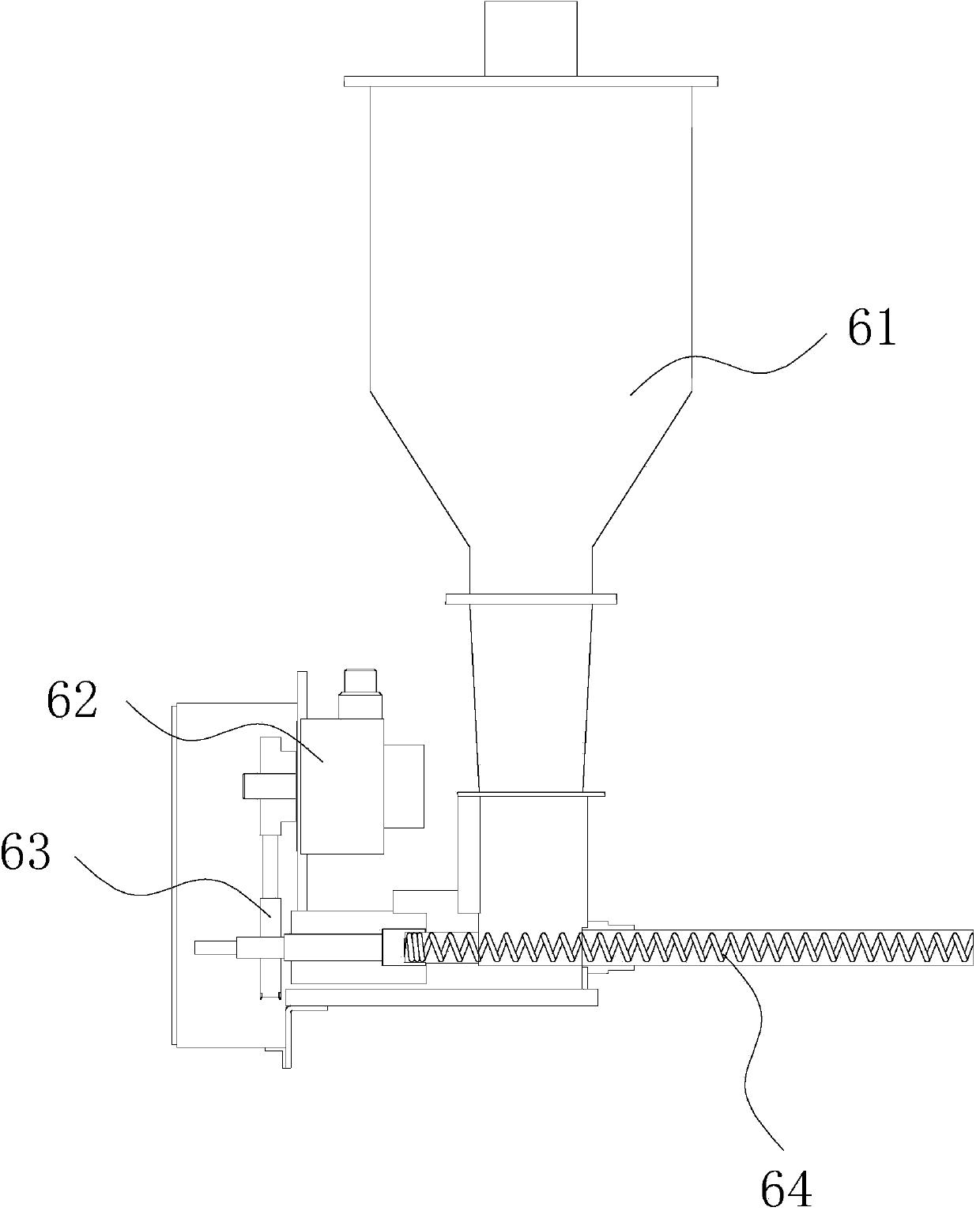

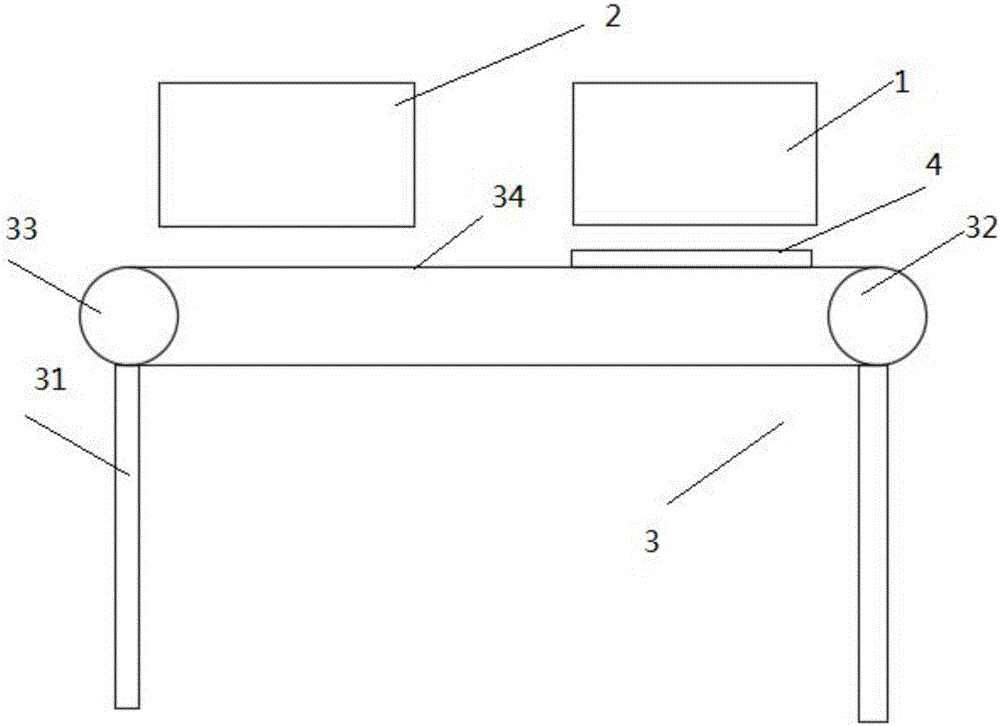

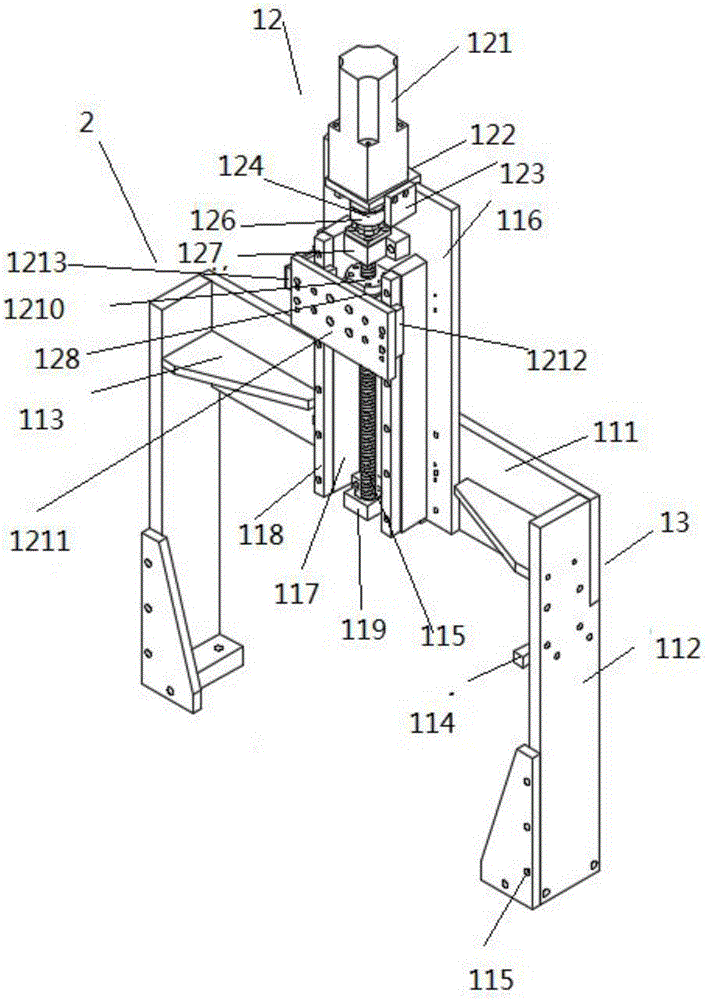

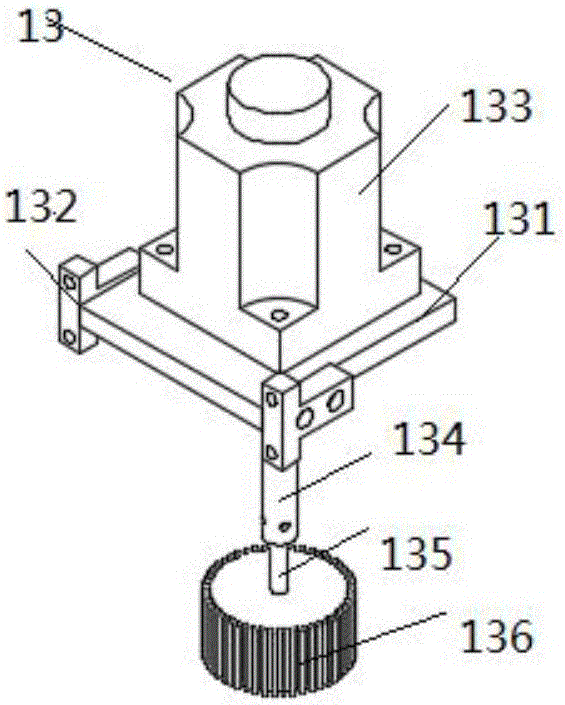

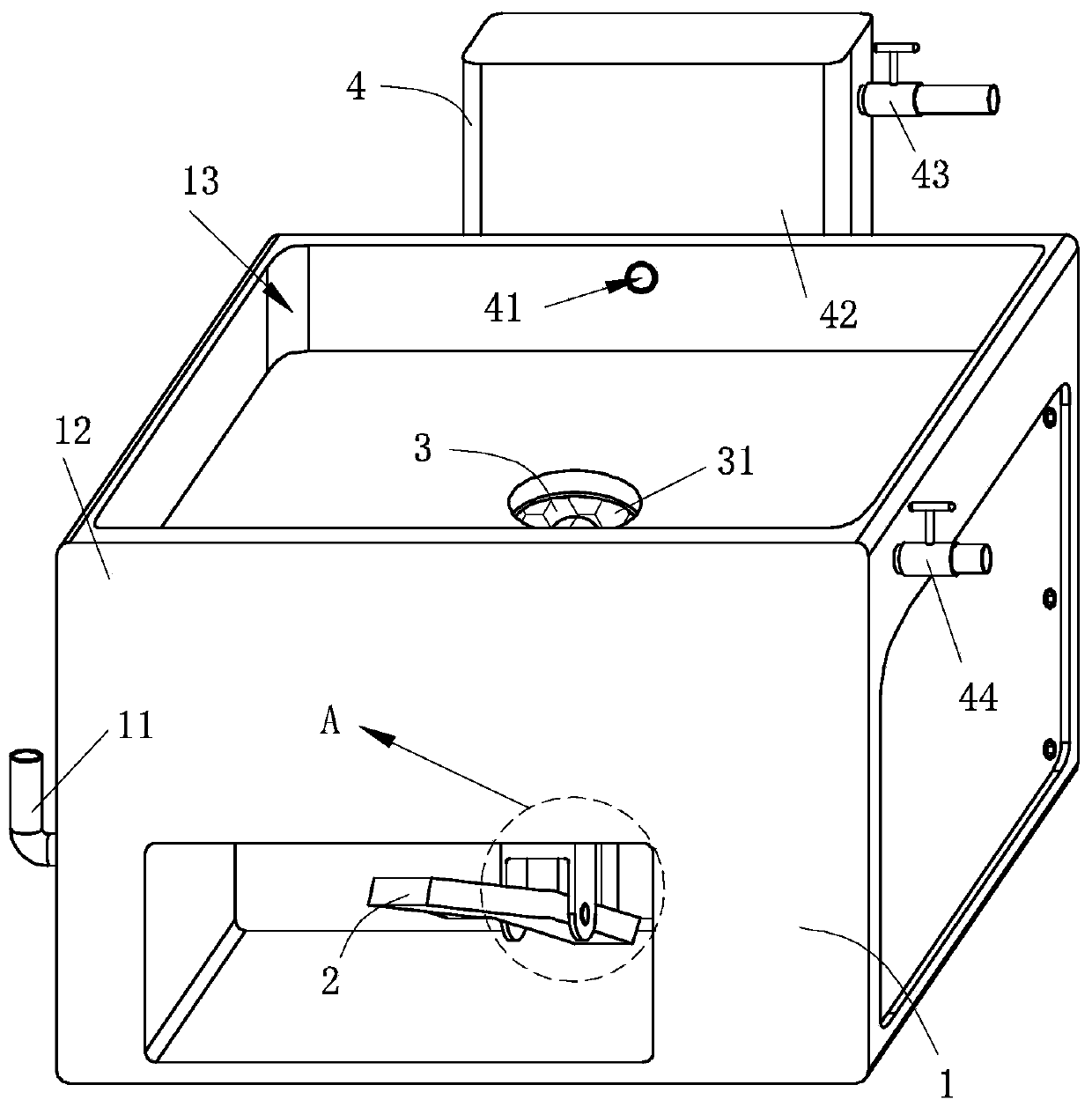

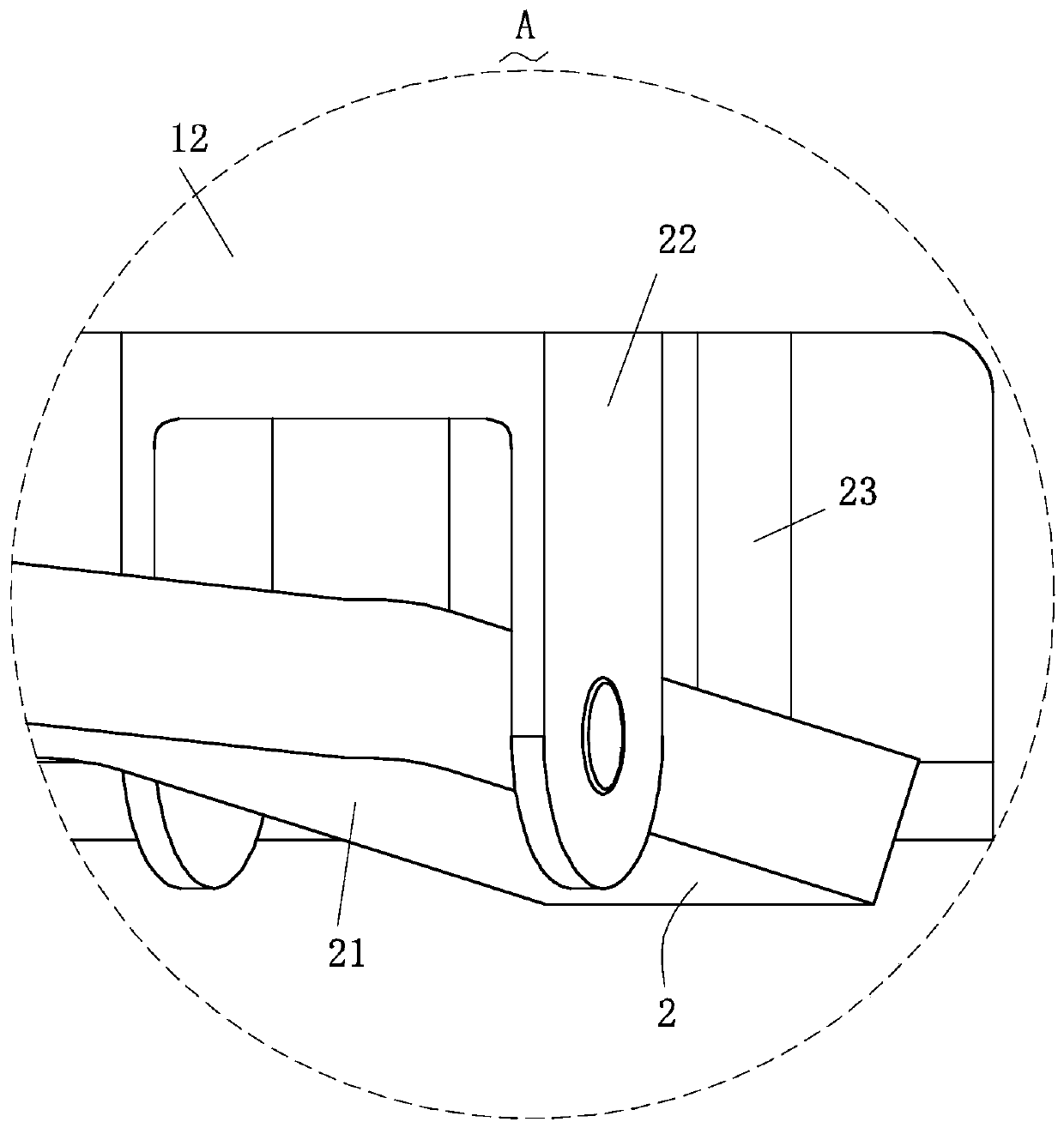

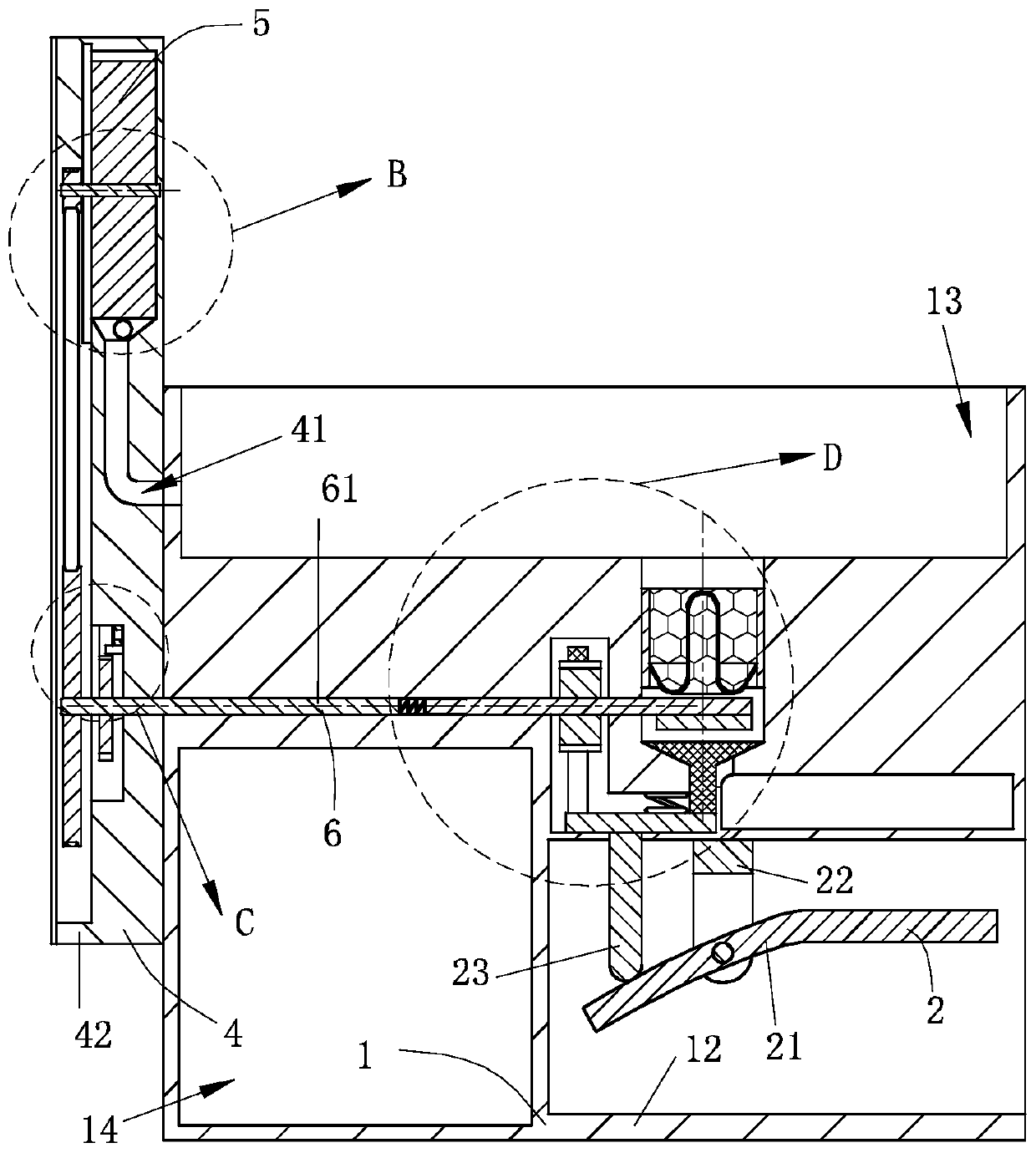

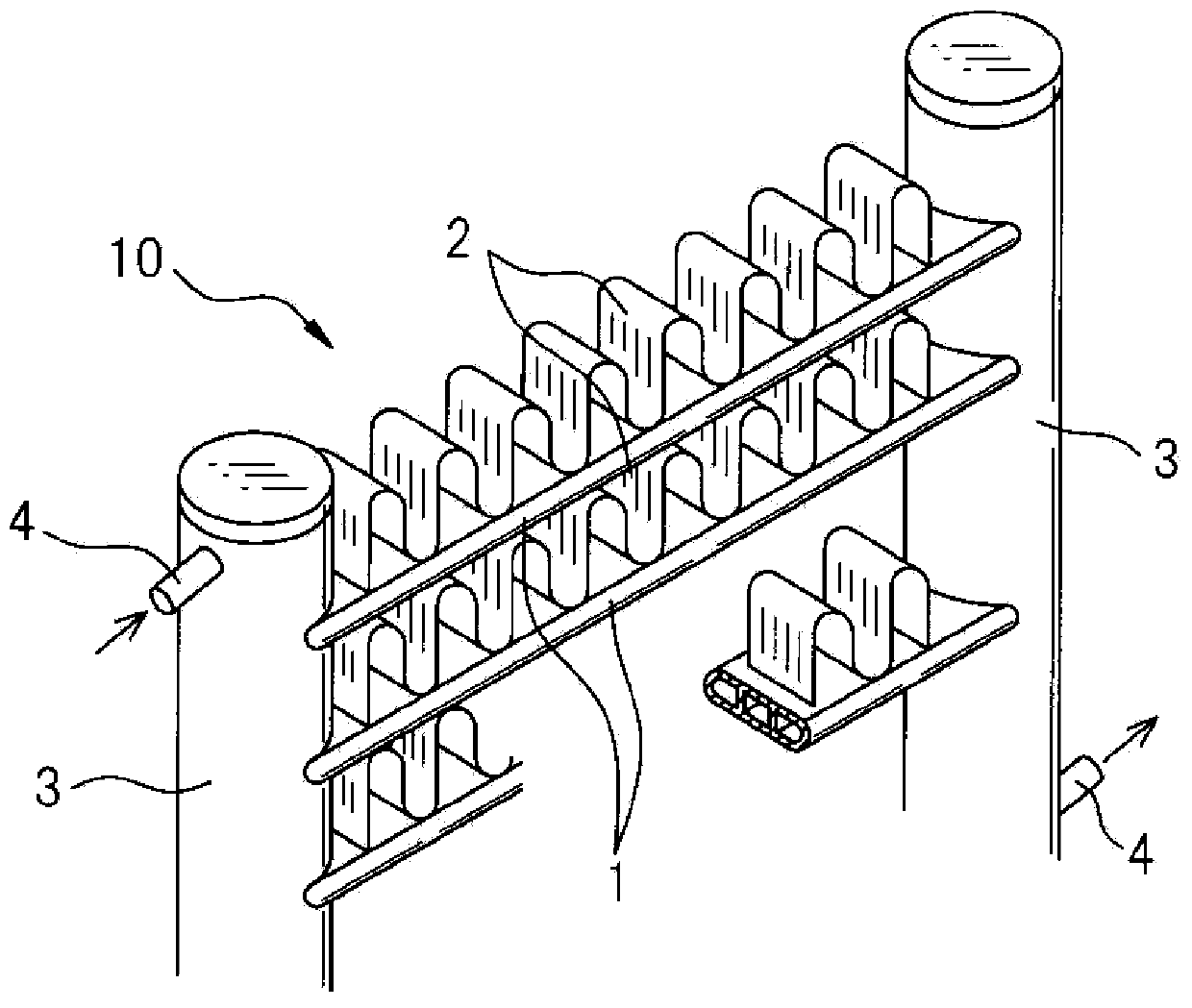

Plastic foam particle laminating dryer

A plastic foam particle laminating dryer comprises a rack. A laminating box is arranged on the rack. A stirring device is arranged in the laminating box. The stirring device is driven by a servo motor arranged on the rack. A storage box and a spraying device used for spraying fire retardant and a curing agent to particles in the laminating box are arranged above the laminating box. The rack is further provided with a drying box connected with the laminating box and used for drying the laminated particles, heat exchangers connected with the drying box and used for supplying heat to the drying box, and an induced draught fan used for performing impurity removing and screening on the dried particles. The heat exchangers are driven by an air blower. The plastic foam particle laminating dryer further comprises a metering weighing device connected with the storage box. Particles in the metering weighing device are conveyed to the storage box through a draught fan. The servo motor, the spraying device, the induced draught fan, the air blower, the draught fan and the metering weighing device are controlled by a control system through signals. The plastic foam particle laminating dryer is high in automation degree, even in adding and capable of effectively screening caked clusters, and disengaging is avoided after adding.

Owner:QINGDAO HEINOSKY TECH CO LTD

Chinese herb extract for weanling pigs and preparation method thereof

InactiveCN102326694ALow priceSimple productivityAnimal feeding stuffAccessory food factorsBiotechnologySchisandra chinensis

The invention discloses Chinese herb extract for weanling pigs and a preparation method thereof. The extract consists of shizandra berry and fruit of glossy privet . The preparation method comprises the following steps that: a. the shizandra berry and the fruit of glossy privet are weighed according to a weight ratio to be pulverized; b. the pulverized shizandra berry and fruit of glossy privet are dried through an oven; and c. the dried shizandra berry and fruit of glossy privet are put into a super-critical extraction kettle to be extracted, so yellow sticky liquid extract can be obtained. The Chinese herb extract for weanling pigs has the beneficial effects that: by improving the content of productivity indexes and oxidation-resistant indexes and partial seroenzyme activity of weanling pigs, the productivity and the oxidation resistant function of the weanling pigs can be finally improved. The extract has the characteristics of low price, simplicity in production and use, less addition, obvious addition effect, no adverse reaction and the like.

Owner:SHANDONG NEW HOPE LIUHE GROUP

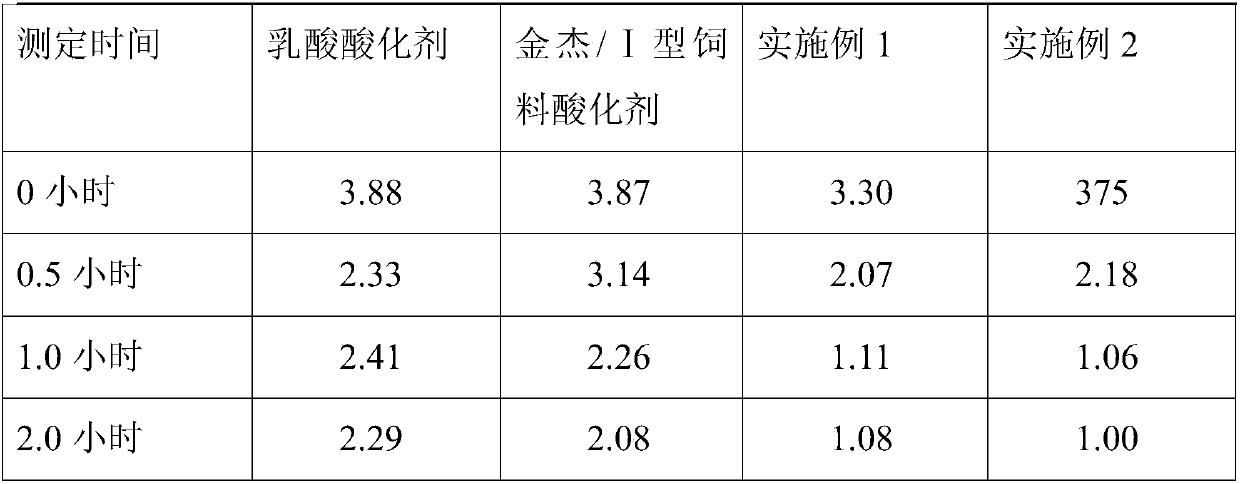

Feed acidifying agent and preparation method thereof

InactiveCN108013230AStable pHPromote reproductive growthAccessory food factorsOrganic acidSodium Bentonite

The invention provides a feed acidifying agent and a preparation method thereof. The feed acidifying agent comprises 1-10 wt% of hydrochloric acid, 20-80 wt% of an organic acid, 1-30 wt% of bentonite,5-30 wt% of a filler and 5-30 wt% of a coating material. The preparation method comprises the following steps: 1) adding the hydrochloric acid and bentonite into a mixer, and uniformly mixing the hydrochloric acid with bentonite; 2) adding the organic acid and the filler into the mixer, and uniformly mixing above materials to obtain a soft material; 3) placing the soft material prepared in step 2) in a swing machine, and swinging the soft material by a screen to prepare granules; 4) drying the granules obtained in step 3) in a boiling bed, and allowing the dried granules to go through a screen; and 5) processing the coating material to form a coating solution, placing the granules in a coating pan, coating the granules by using the coating solution, drying the coated granules after spraying of the coating solution is completed, and allowing the dried coated granules to go through the screen in order to obtain the feed acidifying agent. The hydrochloric acid and the organic acid are successfully cooperatively used to make the acidifying agent have a good pH value adjusting effect, and has a stronger inhibition effect on existing acidifying agents.

Owner:珠海天凯生物科技有限公司

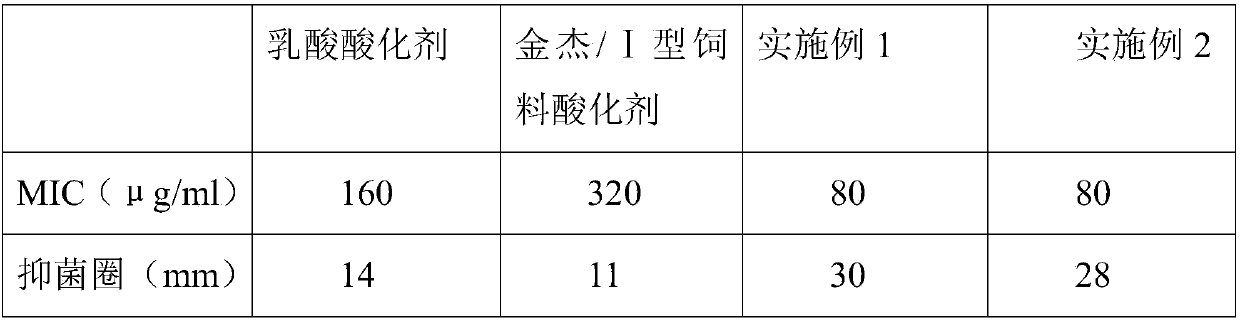

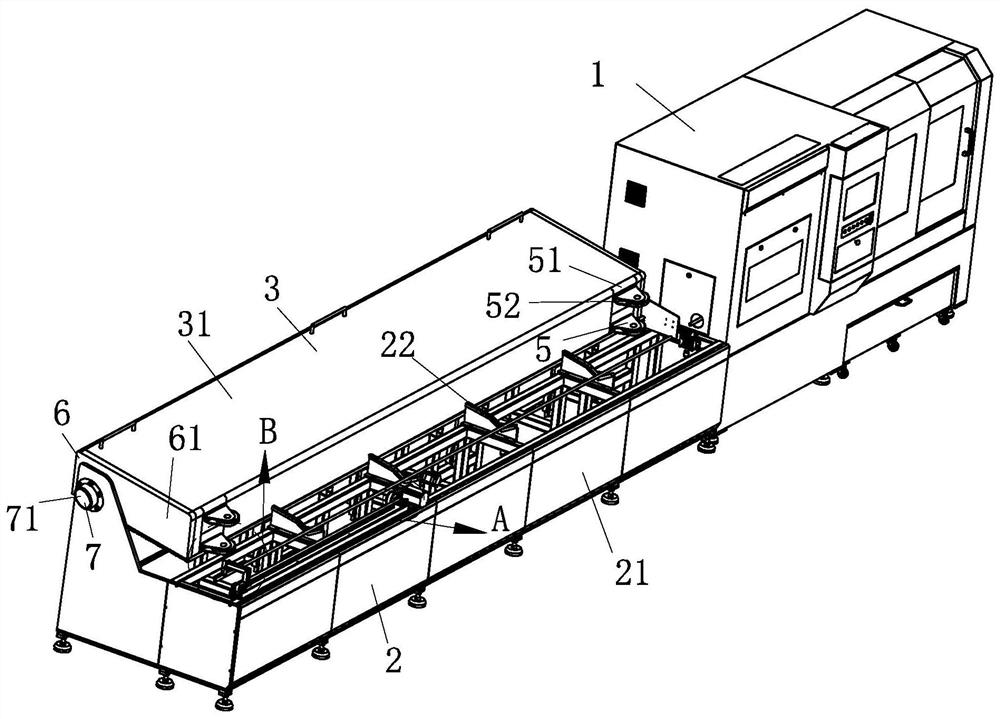

Round tube laser cutting machine convenient for adding materials

ActiveCN113732524AImprove the effect of addingImprove stabilityLaser beam welding apparatusEngineeringLaser cutting

The invention relates to the technical field of laser cutting, in particular to a round tube laser cutting machine convenient for adding materials. The machine comprises a laser cutting machine body, and one side of the laser cutting machine body is connected with a supporting structure for storing round tube materials; an angle adjusting structure is arranged on the supporting structure, the angle adjusting structure is connected to an arrangement structure, the arrangement structure is connected to a storage structure used for storing round tube materials, and the arrangement structure is in linkage with a moving structure used for moving on the storage structure; and the round tube materials are conveniently stored through the storage structure and then moved through the moving structure, then the arrangement structure abuts against the angle adjusting structure, the angle adjusting structure drives the arrangement structure, the storage structure on the arrangement structure is turned over to the top end of the supporting structure, then the round tube materials are more conveniently and rapidly added, secondary carrying of the round pipe materials is effectively avoided, meanwhile, temporary replacement of different materials is facilitated, and then the laser cutting efficiency and quality are greatly improved.

Owner:浙江沪云光电设备股份有限公司

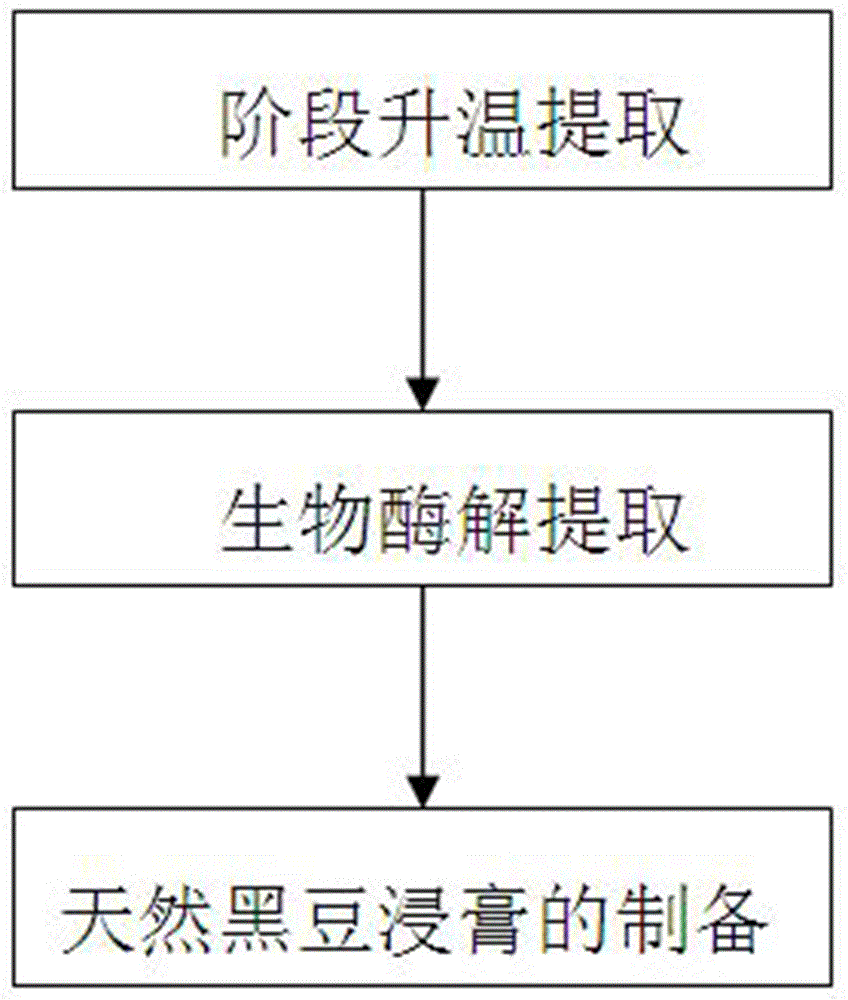

Natural black bean extract and preparation method thereof

The invention discloses a natural black bean extract and a preparation method thereof. The black bean extract is prepared from the following raw materials in parts by weight: black beans 100 parts, revertose 2 parts and purified water 1,300 parts, and the revertose is prepared from D-glucose and D-xylose according to the weight ratio of 2:1. The preparation method comprises staged heating extracting, biological enzymolysis extraction and preparation of the natural black bean extract. Food added with the natural black bean extract tastes natural and is pure in aroma, unmated feeling caused by smell of chemical additives does not exist, the natural black bean extract contains more beneficial substances and meets various demands of human bodies, the addition effect is higher than that of the traditional chemically synthesized beans essence additives, the nutrition of the food is improved, and the natural black bean extract is safe and does not have side effects to human bodies, meets demands of people to pure natural food, and is pure natural substitute goods of existing chemically synthesized beans essences.

Owner:HANGZHOU NAIQUE BIOLOGICAL TECH CO LTD

Processing method of mango whole juice

The invention relates to a processing method of mango whole juice. The processing method is characterized in that mangoes with peel are produced into fruit juice, so that the utilization rate of the mangoes is increased, the waste of peel resources is reduced, and the production cost of the fruit juice is reduced; a composite brown stain inhibitor consisting of D-sodium erythorbate, L-cysteine andphytic acid in best compounding ratio is added before fermentation, so that the condition of brown stain of the fruit juice of the mangoes with peel, produced by an enzyme method is controlled; and pectinase and cellulases are added for enzymolysis, so that the yield of the mango juice is increased.

Owner:ANHUI FUNAN CHANGHUI FOOD

Method for using attapulgite tobacco additive and filter tip additive

InactiveCN1228003CRich in mineral resourcesAbundant resourcesTobacco treatmentTobacco smoke filtersCellulose acetateTar

The present invention relates to application of attapulgite in tobacco industry. It can be used as additive for tobacco shred, and its added quantity is 0.01-0.5 wt% of weight of tabacco shred in the tobacco shred, it also can be used as additive for filter tip, when it is used as additive for filter tip, firstly, the attapulgite powder glyceride tracetate suspension liquor whose weight ratio is 0.1-10% can be prepared, then the suspension lqiuor can be sprayed on the cellulose acetate fibre bundle by means of filter tip machine so as to obtain qualified filter rod for cigarette. Its invention can reduce tar content and nicotine content in the cigarette.

Owner:盱眙欧佰特粘土材料有限公司

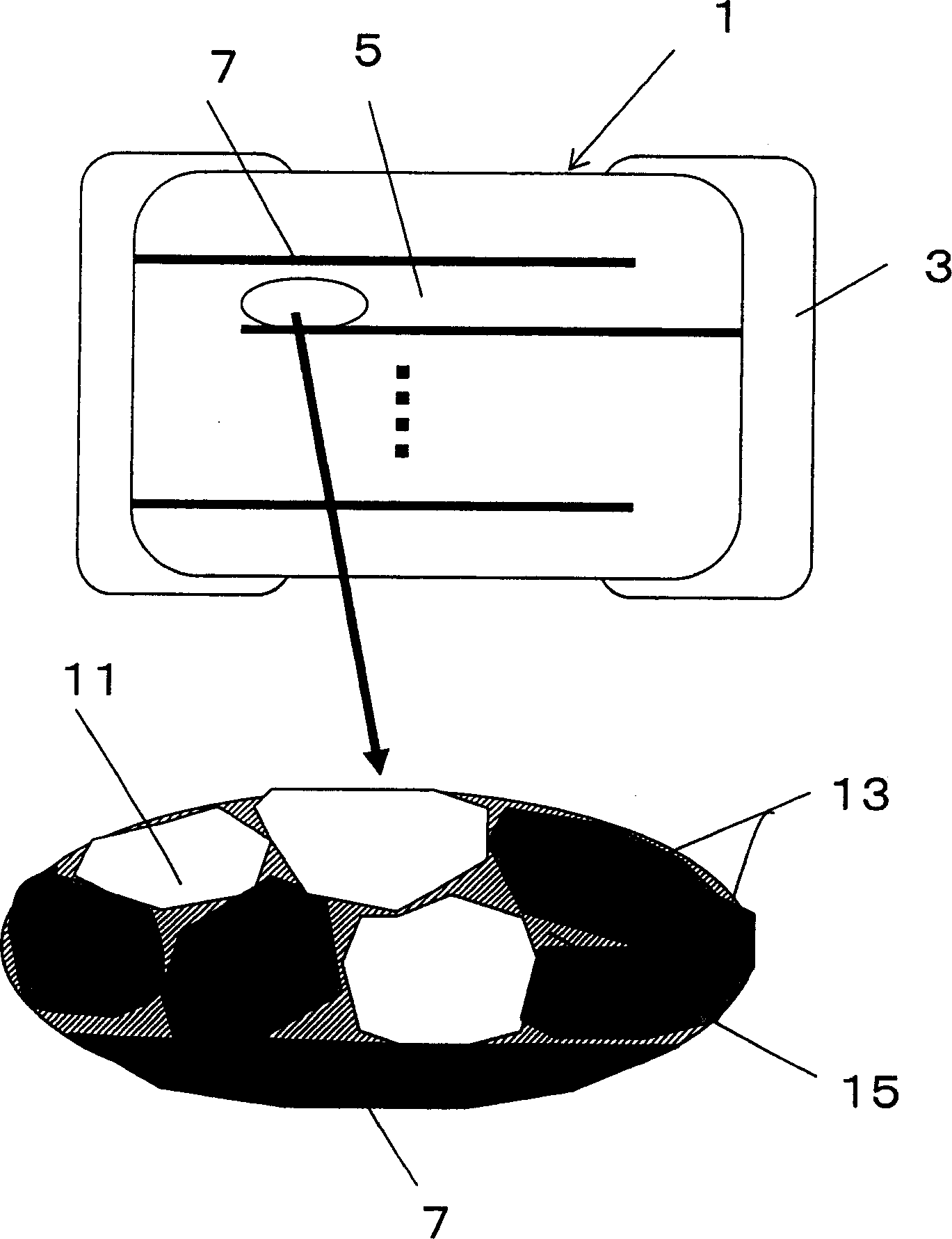

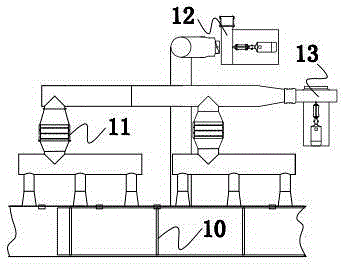

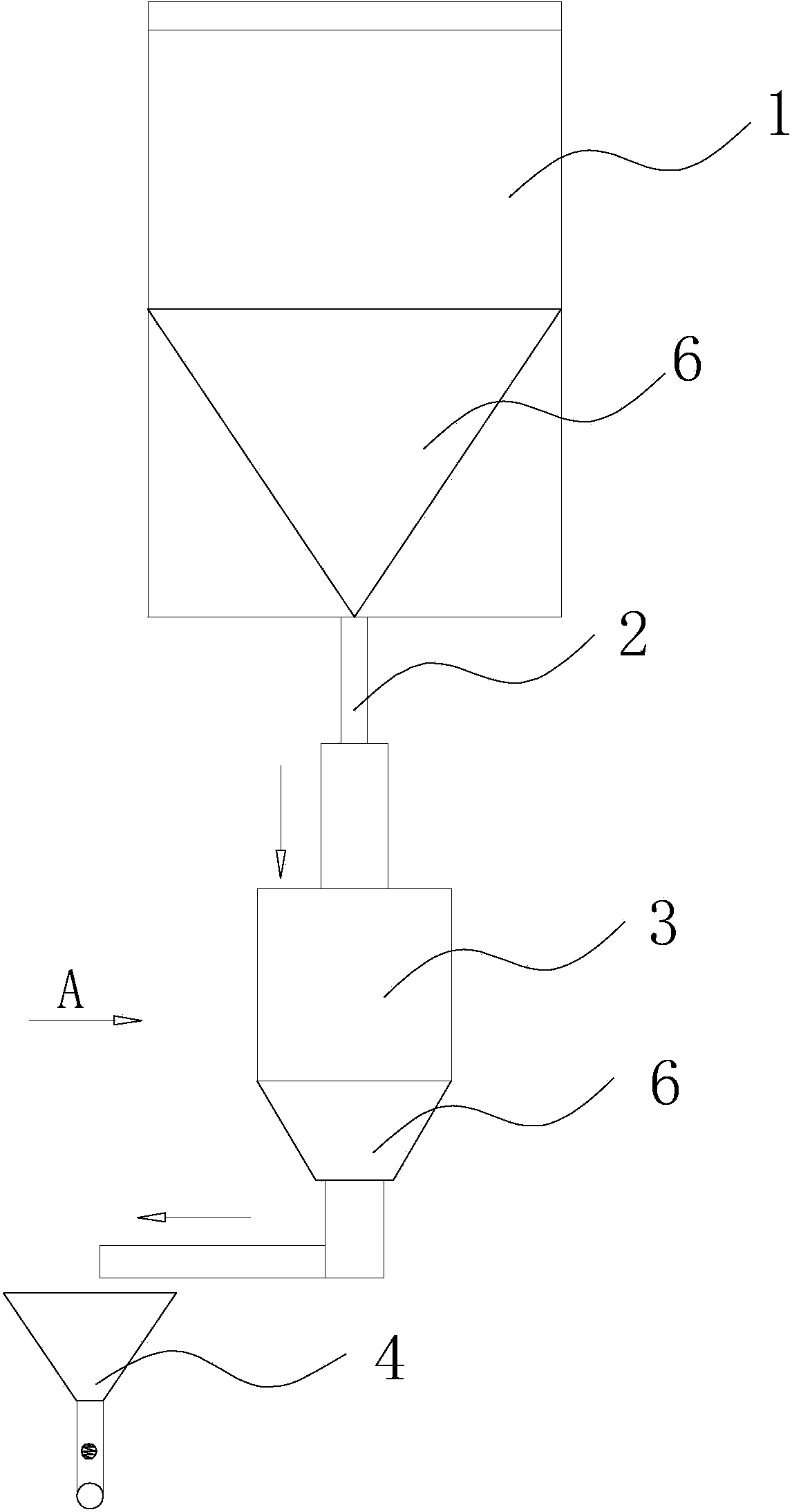

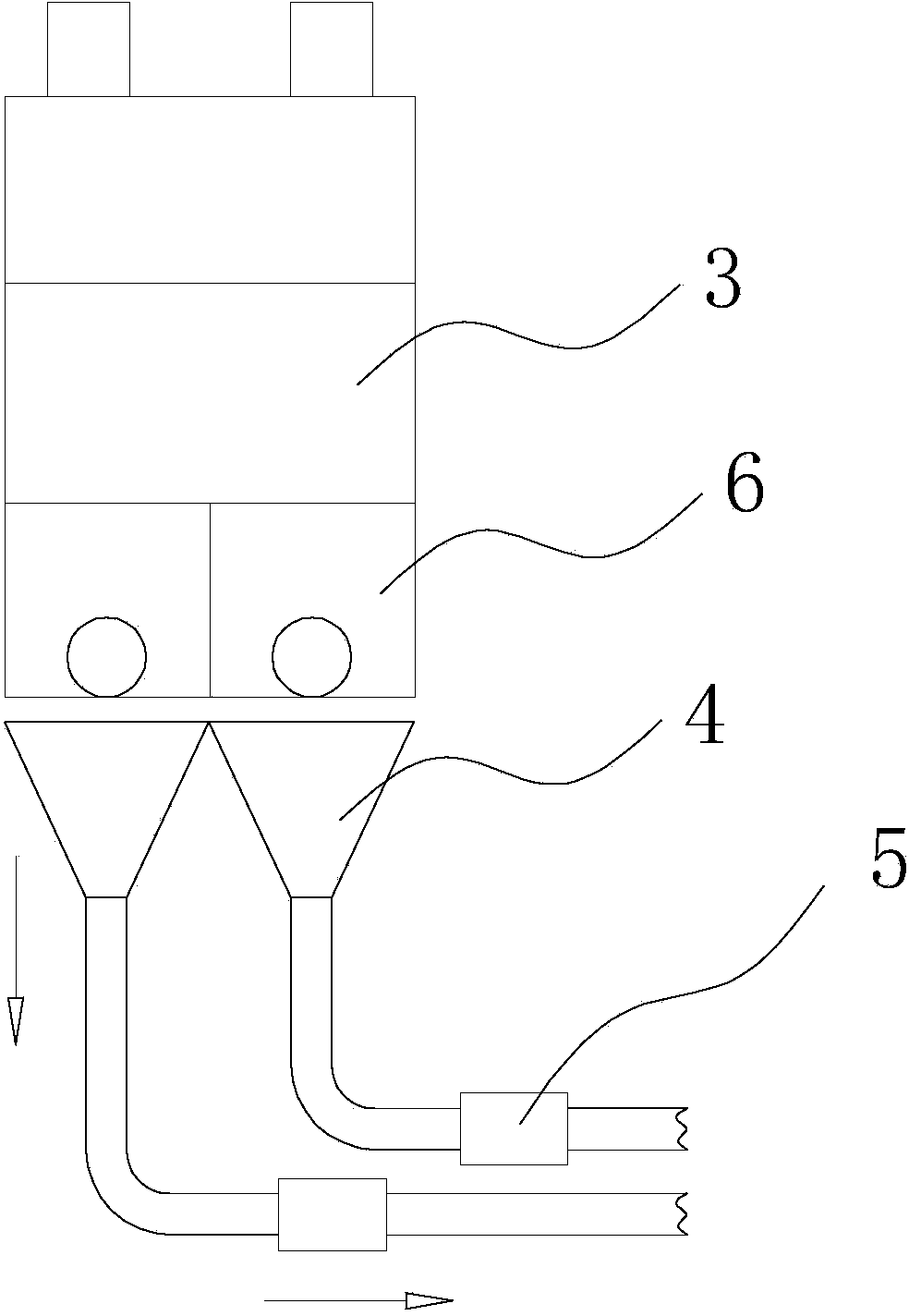

Macromolecule uniform distribution and adding technology

The invention relates to a macromolecule uniform distribution and adding technology which is high in rate, more uniform in adding, and capable of effectively screening macromolecules. The technology comprises the following steps that firstly, macromolecules are stored in a macromolecule storage mechanism, meanwhile, an automatic heating device is provided, the temperature is kept between 45 DEG C and 55 DEG C, the dryness of the macromolecules is ensured, and therefore macromolecule materials can be provided for production of a machine at any time; secondly, a high-speed air spraying gun is utilized for spraying the macromolecules in the macromolecule storage mechanism to a macromolecule feeding mechanism, and then the macromolecules are conveyed to a macromolecule quantification mechanism; thirdly, the macromolecules are conveyed out of the macromolecule quantification mechanism through a high-precision spring, the high-speed air spraying gun is utilized for uniformly blowing the macromolecules popped up through the high-precision spring to a uniform distribution and adding mechanism, then, the macromolecules enter an absorber forming channel through the uniform distribution and adding mechanism, and therefore the macromolecules can be uniformly mixed with absorber cotton cores.

Owner:QUANZHOU HANWEI MACHINERY MFG

Condenser pipe burr removing-refrigerant fluid adding device

ActiveCN106625090AGood culling effectSimple structureEdge grinding machinesGrinding carriagesEngineering

The invention provides a condenser pipe burr removing-refrigerant fluid adding device, comprising a condenser pipe burr removing device and a refrigerant fluid adding device. A condenser pipe is fixed at a clamping component, a motor controls a lead screw to rotate to drive a nut block to move, and the nut block drives a moving plate such that the burr removing device moves up and down; and the burr removing device drives a burr removing brush to rotate by rotation of a removing motor, such that the condenser pipe is subjected to the work of burr removing. The condenser pipe burr removing-refrigerant fluid adding device is simple in structure and reasonable in design, manpower source is greatly saved by adopting an automated technology, and the burr removing effect for the condenser pipe is ideal. Based on prior art, the condenser pipe burr removing-refrigerant fluid adding device is simple in structure and smart in design, and has a good refrigerant fluid adding effect particularly for a refrigerating device tank body with smaller size; and the device avoids the defects in an adding process to a large extent, and meanwhile, the device is very good in stability.

Owner:嘉兴顾翔制冷设备有限公司

Domestic sewage treatment system based on environmental protection

ActiveCN111408175ARelieve pressurePrevent splashStationary filtering element filtersWater flowSewage

The invention relates to the technical field of domestic sewage recycling systems, in particular to a domestic sewage treatment system based on environmental protection which comprises a storage structure, an opening and closing structure, a filtering structure, a flow guide structure, a pressure relief structure, a transmission structure, a first limiting structure and a second limiting structure. The pressure relief structure is connected to a transmission structure in the storage structure, the first limiting structure and the second limiting structure which are used for limiting are arranged on the transmission structure, the opening and closing structure used for controlling opening and closing of water flow is arranged in the storage structure, and the second limiting structure is connected to the opening and closing structure; the transmission structure is conveniently driven through the pressure relief structure; due to the arrangement of the transmission structure, the pressure relief effect of the pressure relief structure on water flow is better; when the opening and closing structure seals the storage structure, the opening and closing structure drives the second limiting structure to limit the transmission structure, so that when the opening and closing structure does not seal the storage structure, the transmission structure drives the filtering structure to shake, the filtering structure is prevented from being blocked, and the scrap filtering effect is better.

Owner:刘金波

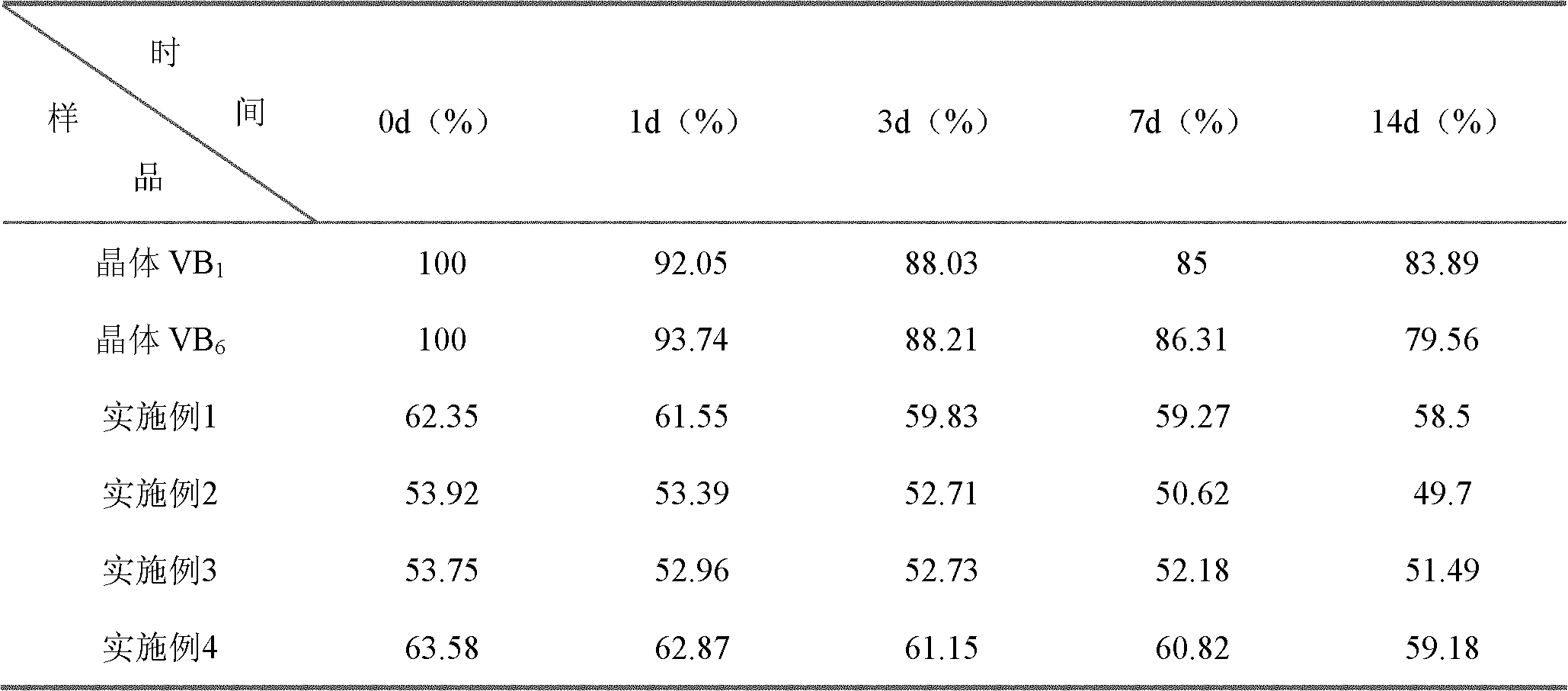

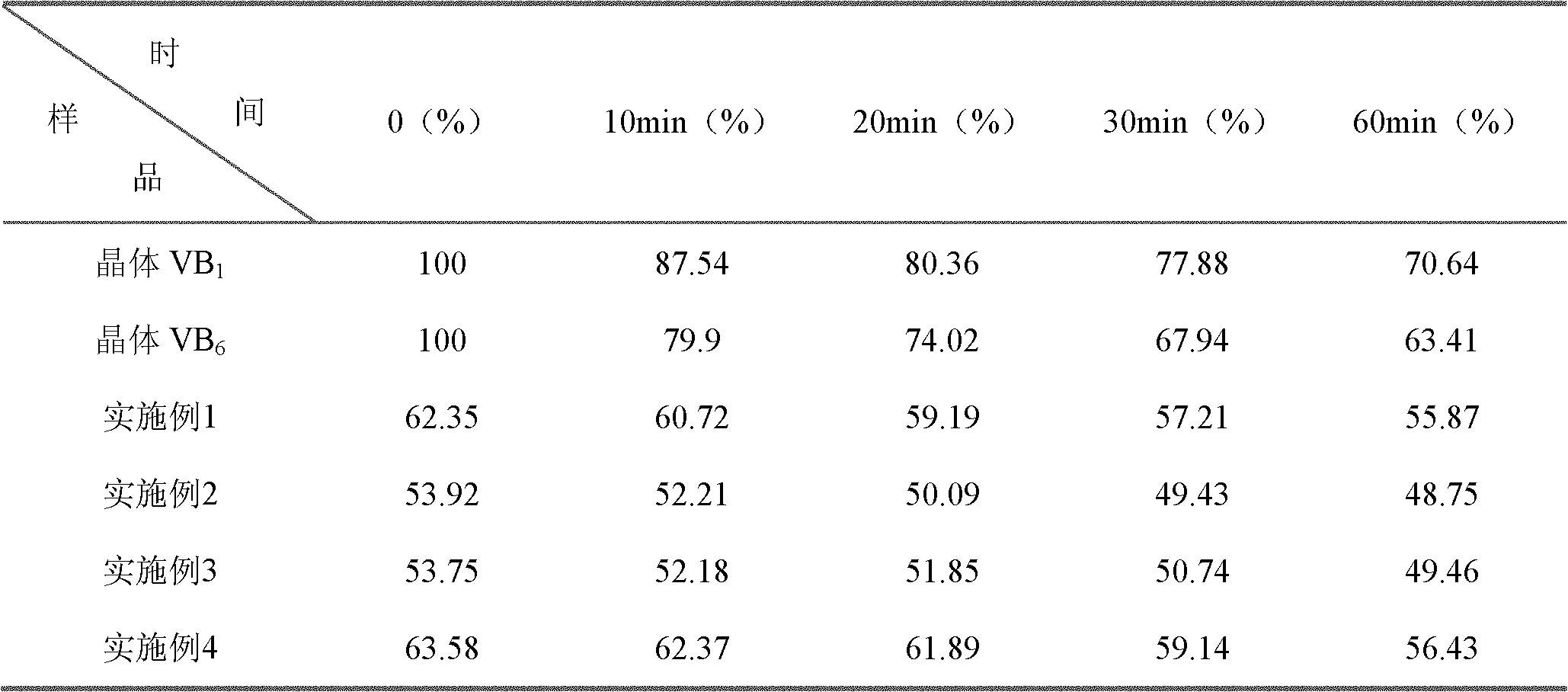

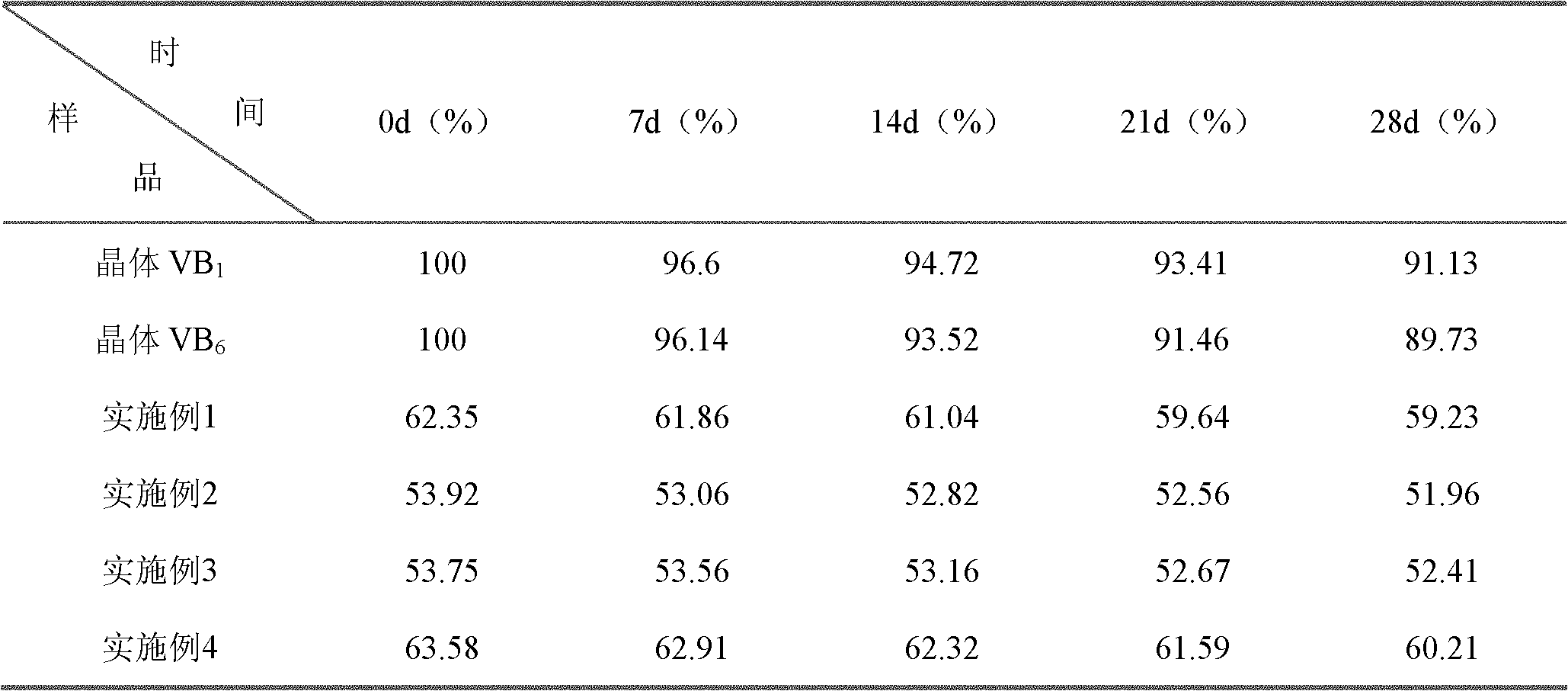

B-family crystal vitamin microcapsules and method for preparing microcapsules by utilizing solvent evaporation method

ActiveCN102150748AGood slow releaseSlow release rateClimate change adaptationAnimal feeding stuffShrimpSolvent evaporation

The invention discloses B-family crystal vitamin microcapsules and a method for preparing the microcapsules by utilizing the solvent evaporation method. In the preparation method, raw materials comprise the following components in parts by weight: 1-1.3 parts of ethyl cellulose, 1-4 parts of Span80, 3-9.4 parts of B-family crystal vitamin, 26-47.4 parts of cyclohexane and 32-55.6 parts of dichloromethane; and the preparation method comprises the following steps: dissolving the ethyl cellulose in the dichloromethane according to the formula to get solution A; further dissolving the Span80 in the cyclohexane to get solution B, sequentially adding the solution A and the B-family crystal vitamin into the solution B under the situation of keeping the temperature of the solution B at 30 DEG C-40 DEG C, uniformly stirring till becoming thick, air-drying the thick solution, then smashing and finally getting the B-family crystal vitamin microcapsules. The vitamin microcapsules have slow-release effect and good stability, and can greatly improve the adding effect of the B-family crystal vitamin and reduce the feed cost, the method is simple, low in cost and applicable to large-scale production, and products are used for feed for fishes and shrimps and can greatly improve the cultivation benefits.

Owner:广东省农业科学院畜牧研究所 +1

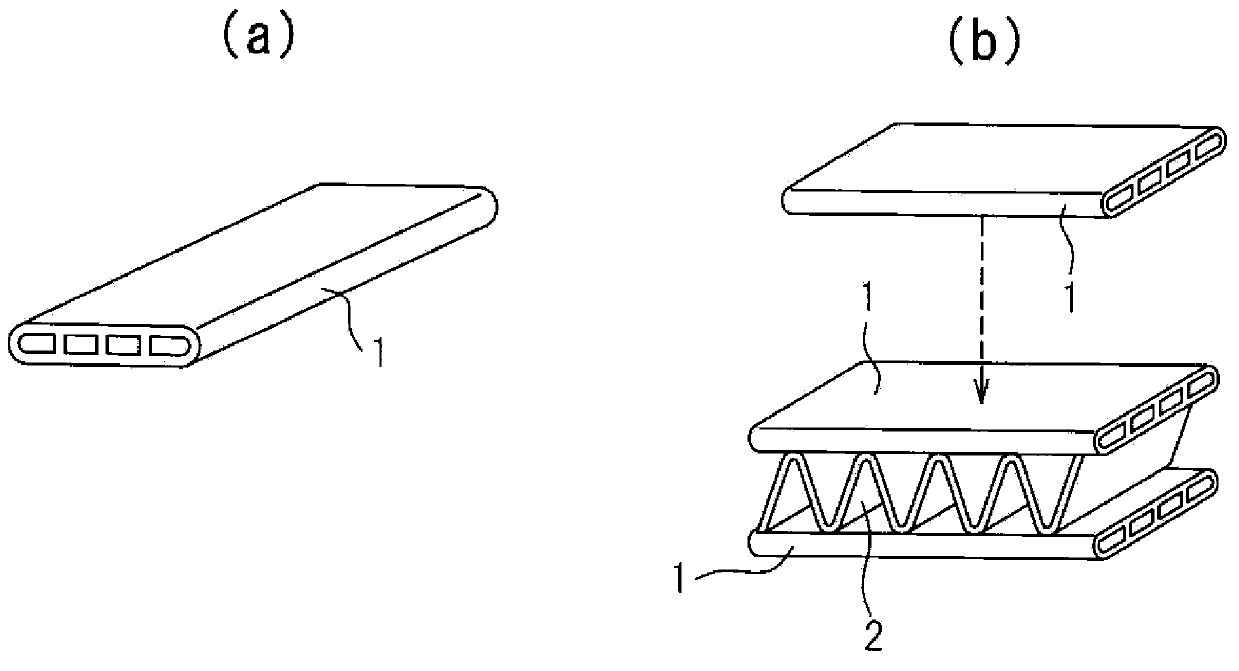

Aluminum alloy for microporous hollow material which has excellent extrudability and grain boundary corrosion resistance, and method for producing same

ActiveCN104220615AEasy extrusionWith strengthStationary conduit assembliesMetal layered productsChemical compositionGrain boundary

As an aluminum alloy for a microporous hollow material, an aluminum alloy is provided which contains Cu, which is an element having poor grain boundary corrosion resistance, in a reduced amount, can have a nobly kept spontaneous potential, contains a transition metal that does not adversely affect extrudability of the material, and has excellent corrosion resistance and extrudability. An aluminum alloy having a chemical composition comprising, in mass%, 0.05 to 0.20% of Fe, 0.10% or less of Si, 0.15 to 0.32% of Cu, 0.08 to 0.15% of Mn, 0.05% or less of Zr, 0.06 to 0.15% of Ti, 0.03% or less of Cr, and a remainder made up by Al and unavoidable impurities, wherein the amount of a gas in an alloy billet is 0.25 cc / 100 g or less; and a method for producing an aluminum alloy, comprising producing a DC cast billet having the above-mentioned chemical composition by a melt treatment employing proper casting conditions so that the content of a gas in the DC cast billet can be reduced to 0.25 cc / 100 g or less, and then subjecting the DC cast billet to a soaking treatment, wherein the soaking treatment comprises heating the DC cast billet to 550 to 590 DEG C at a rate of 80 DEG C / hour or less, then holding the heated DC cast billet at that temperature for 0.5 to 6 hours, and then holding the resultant product at a temperature falling within the range from 450 to 350 DEG C for 0.5 to 1 hour or cooling the resultant product to 200 DEG C or lower at a cooling rate of 50 DEG C / hour.

Owner:NIPPON LIGHT METAL CO LTD +1

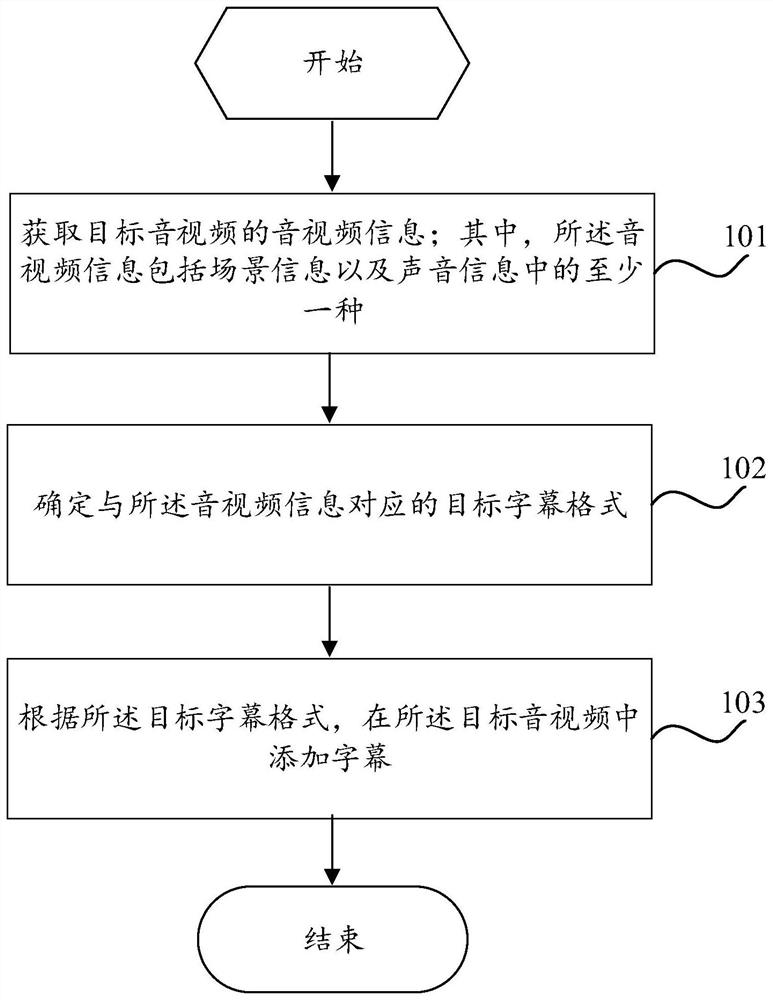

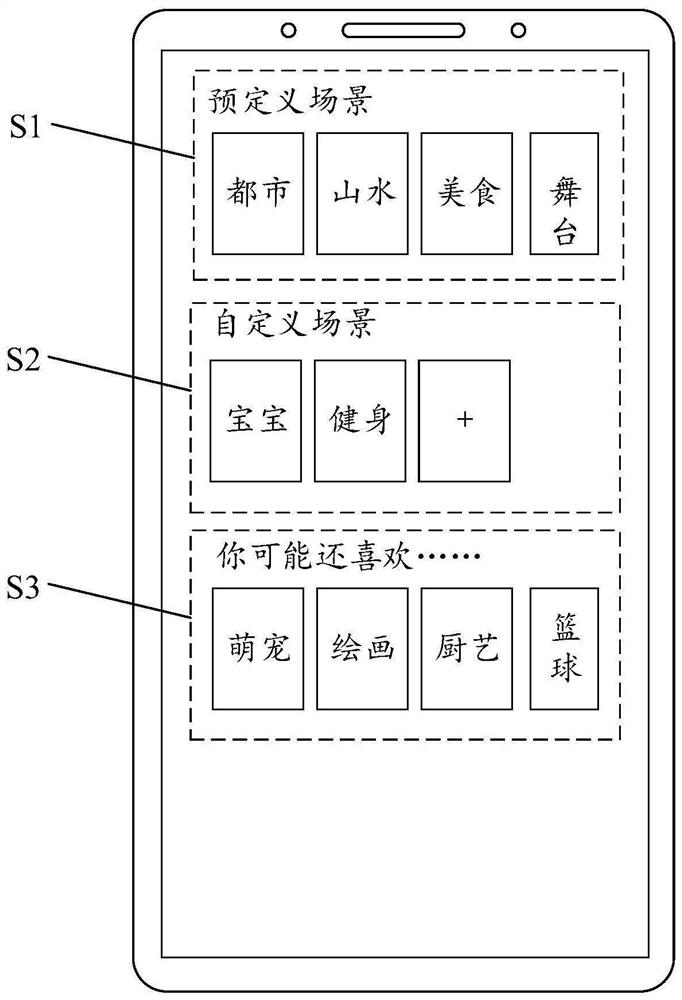

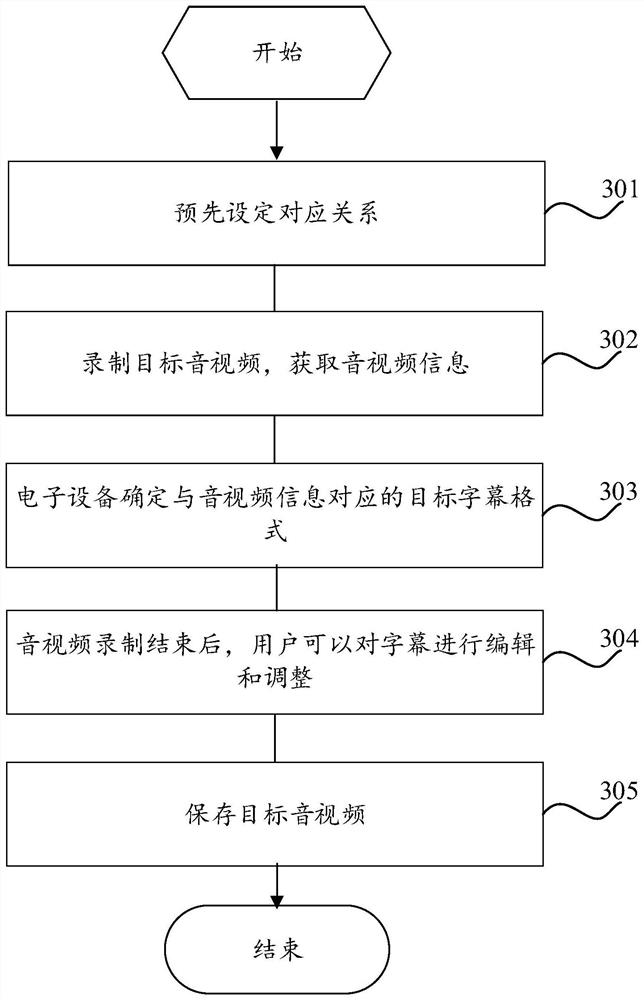

Subtitle adding method and device

ActiveCN112653919AQuick addImprove the effect of addingSelective content distributionPersonalizationSubtitle

The invention discloses a subtitle adding method and device, and belongs to the field of mobile communication. The method comprises the following steps: acquiring audio and video information of a target audio and video, wherein the audio and video information comprises at least one of scene information and sound information; determining a target caption format corresponding to the audio and video information; according to the target caption format, manual operation of a user being not needed; and the subtitles added according to the target subtitle format being matched with the audio and video information, so that the subtitle adding effect is improved, and the personalized requirements of users are met. According to the embodiment of the invention, the problem of tedious operation of adding subtitles to audios and videos through electronic equipment in the prior art is solved.

Owner:VIVO MOBILE COMM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com