Patents

Literature

33results about How to "Rich in mineral resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

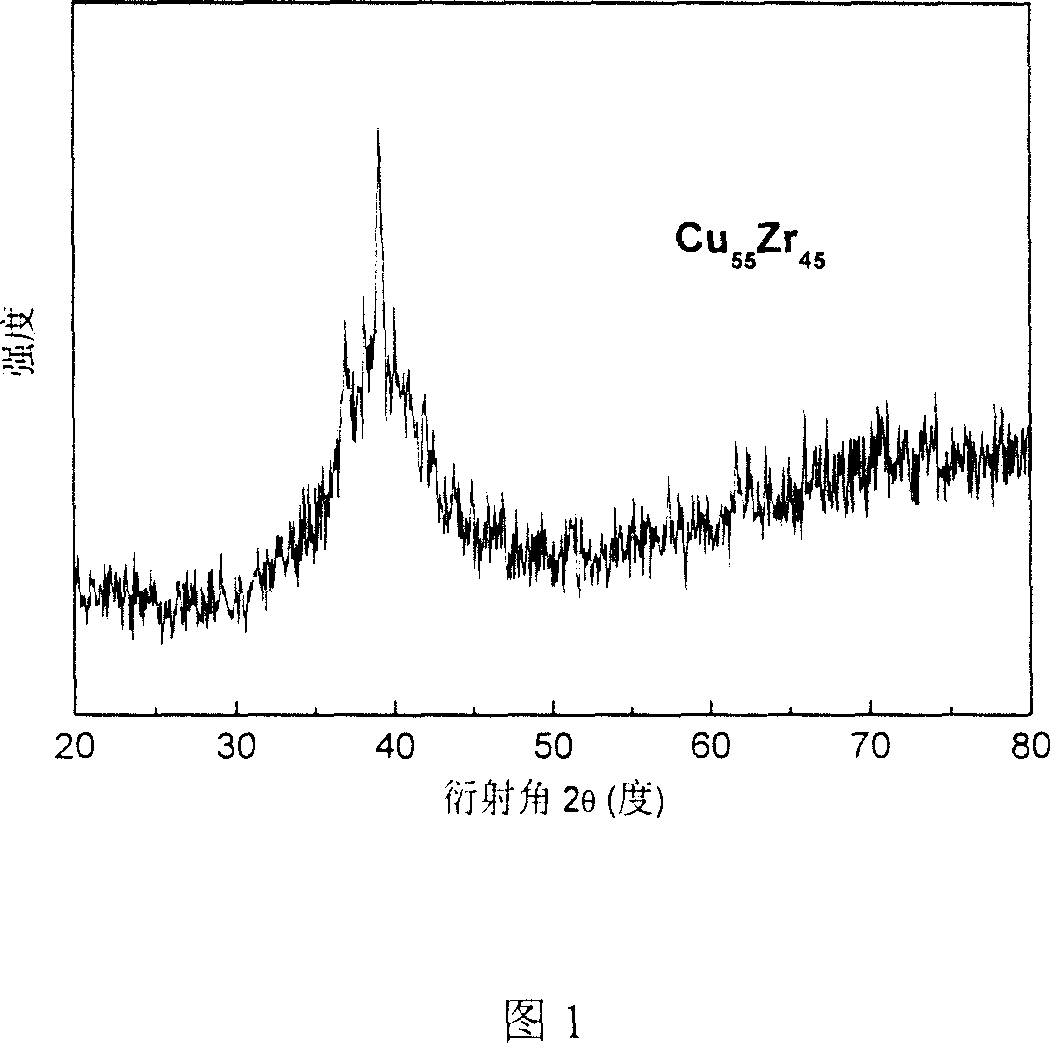

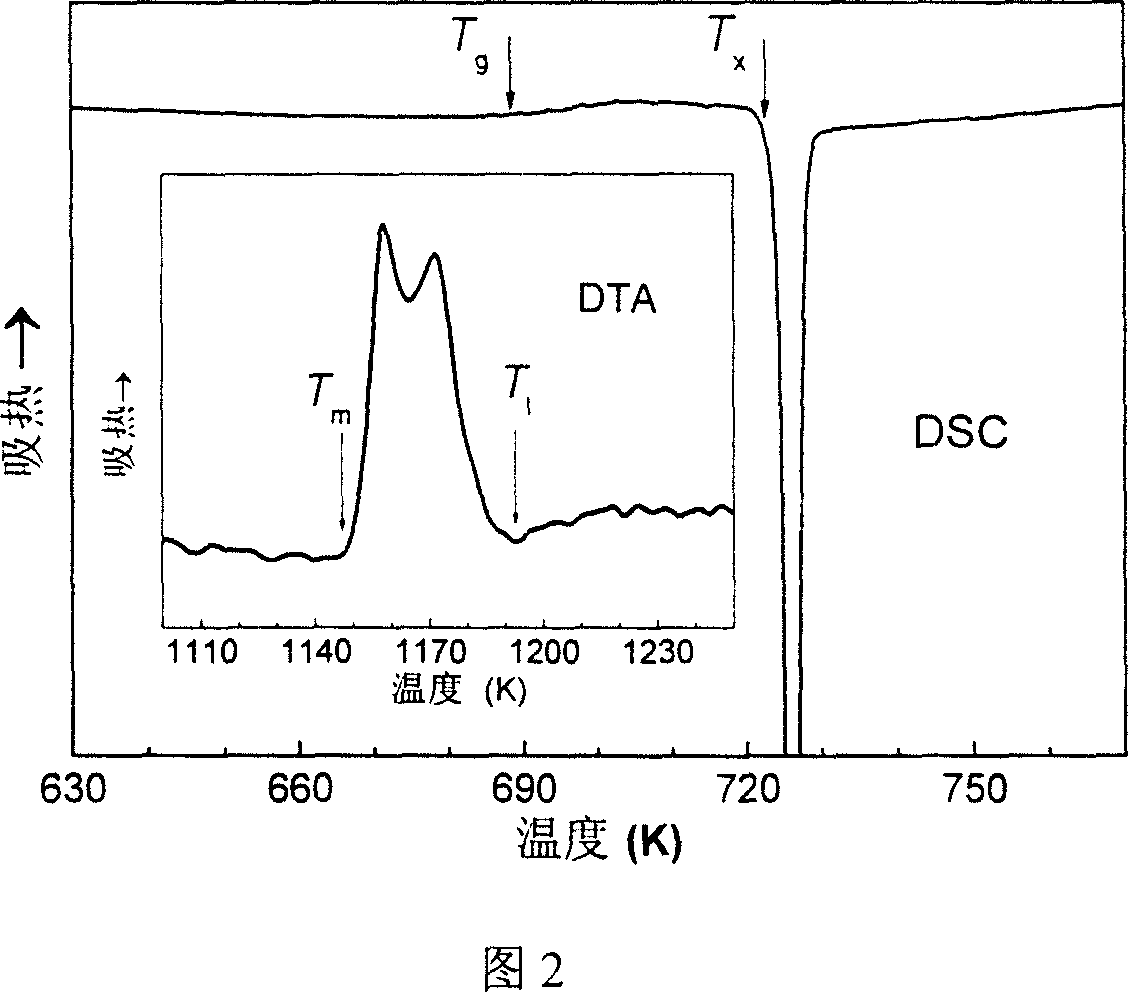

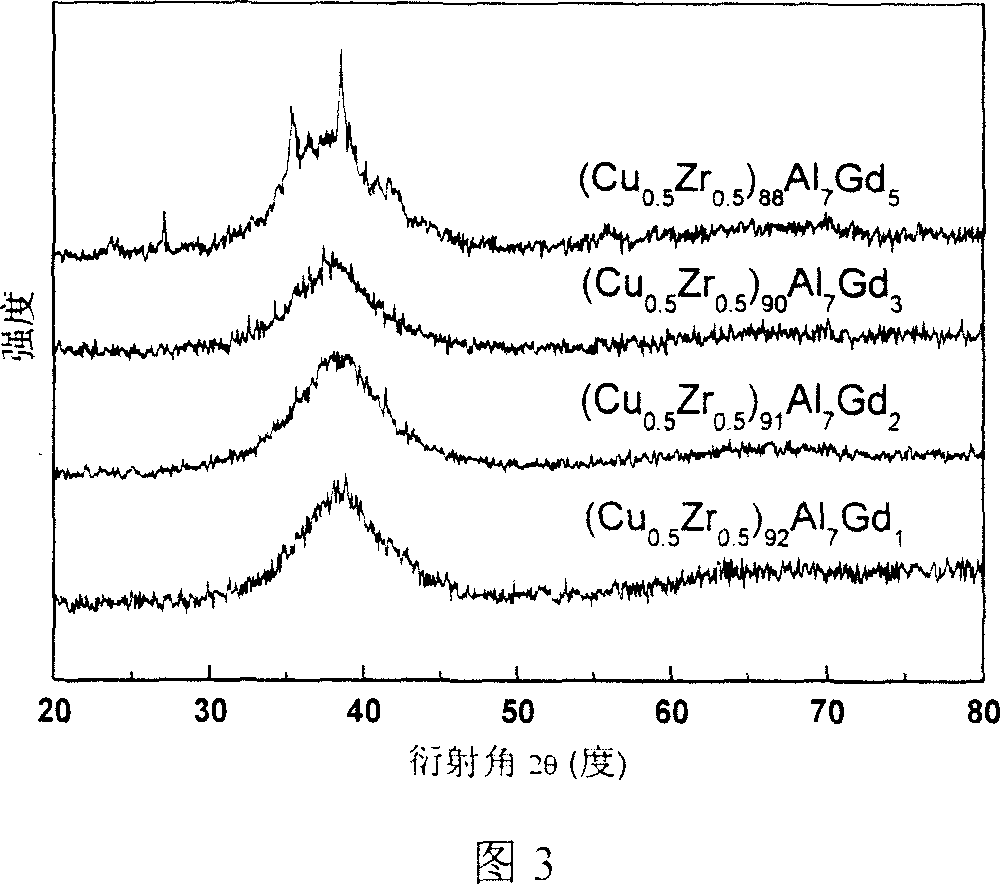

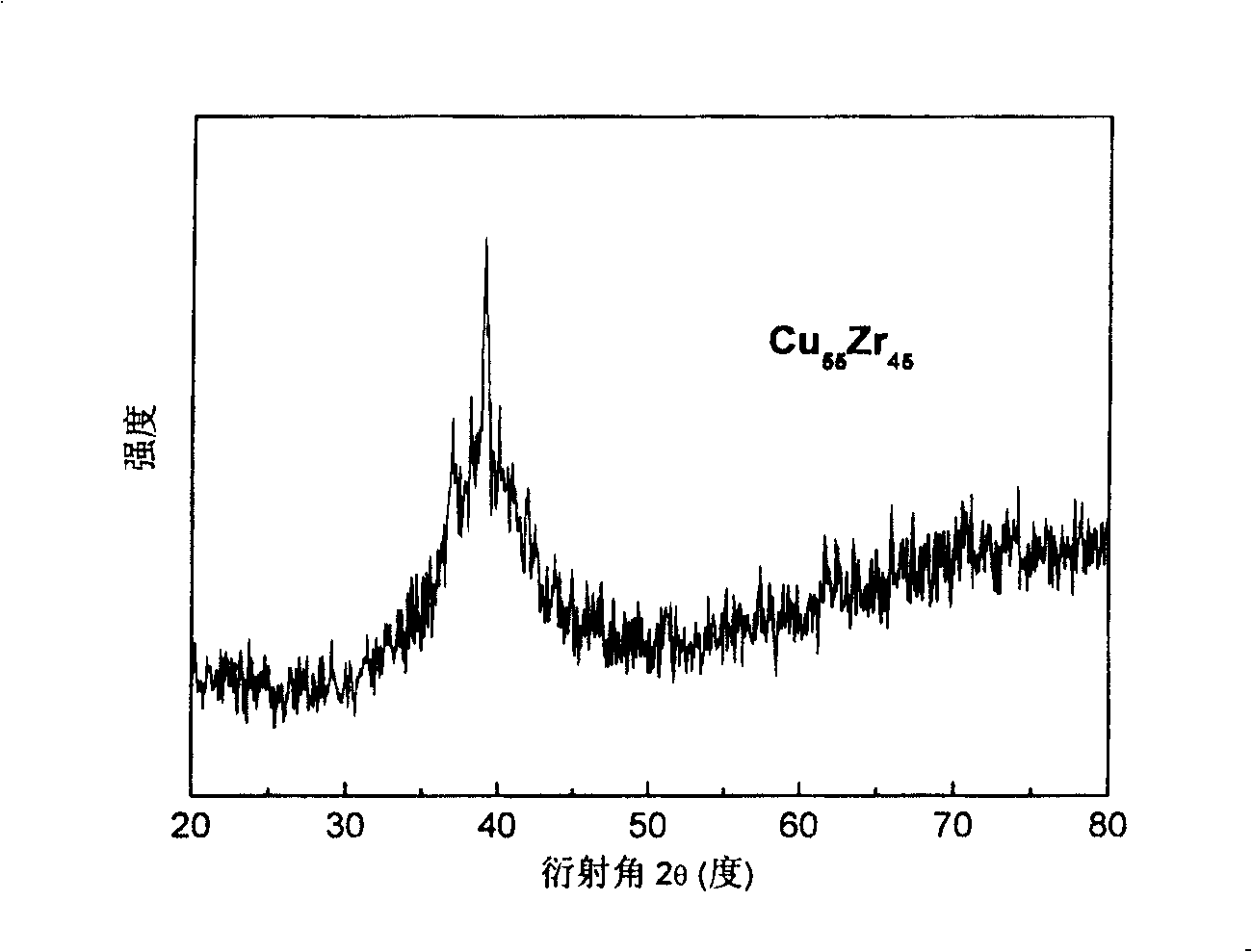

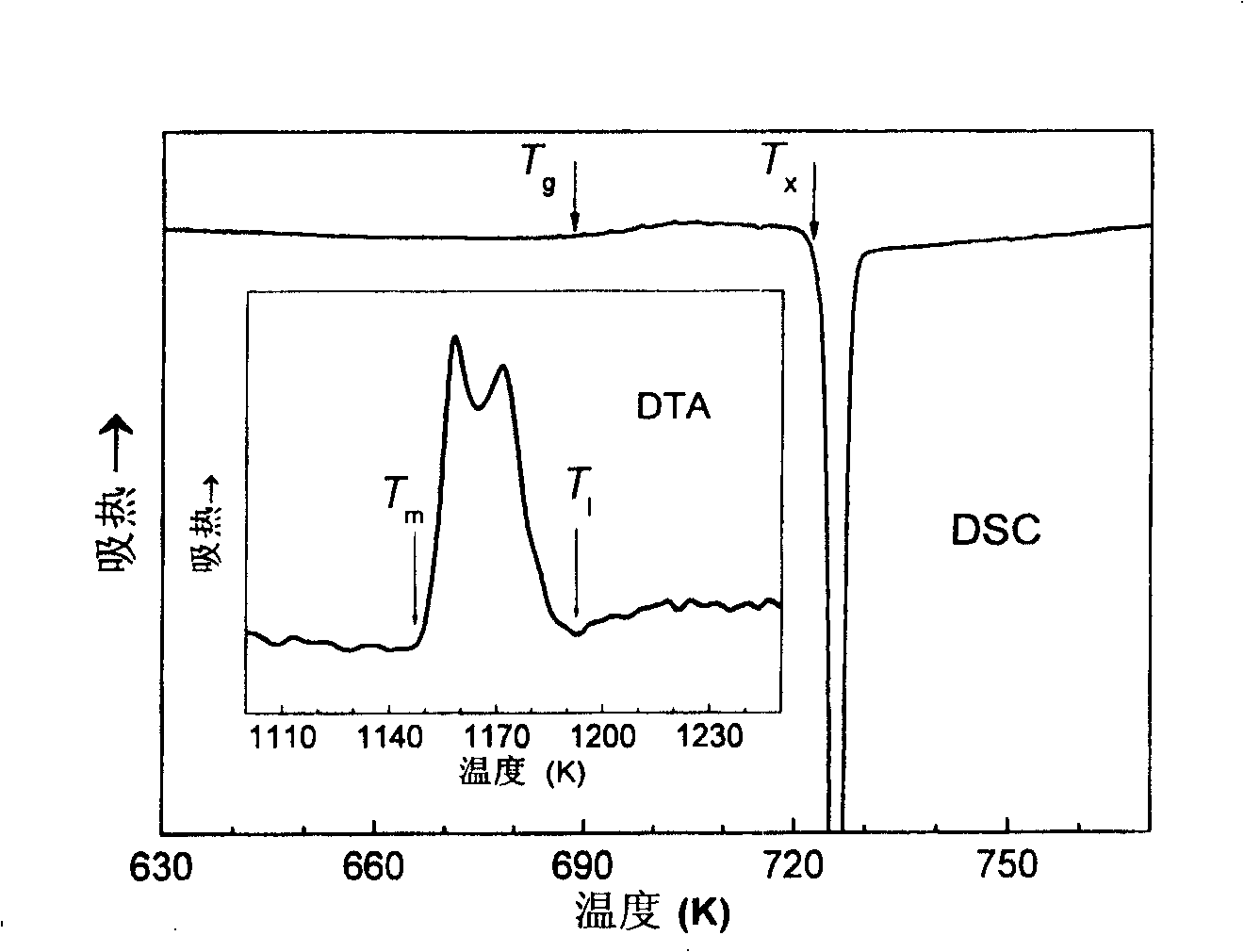

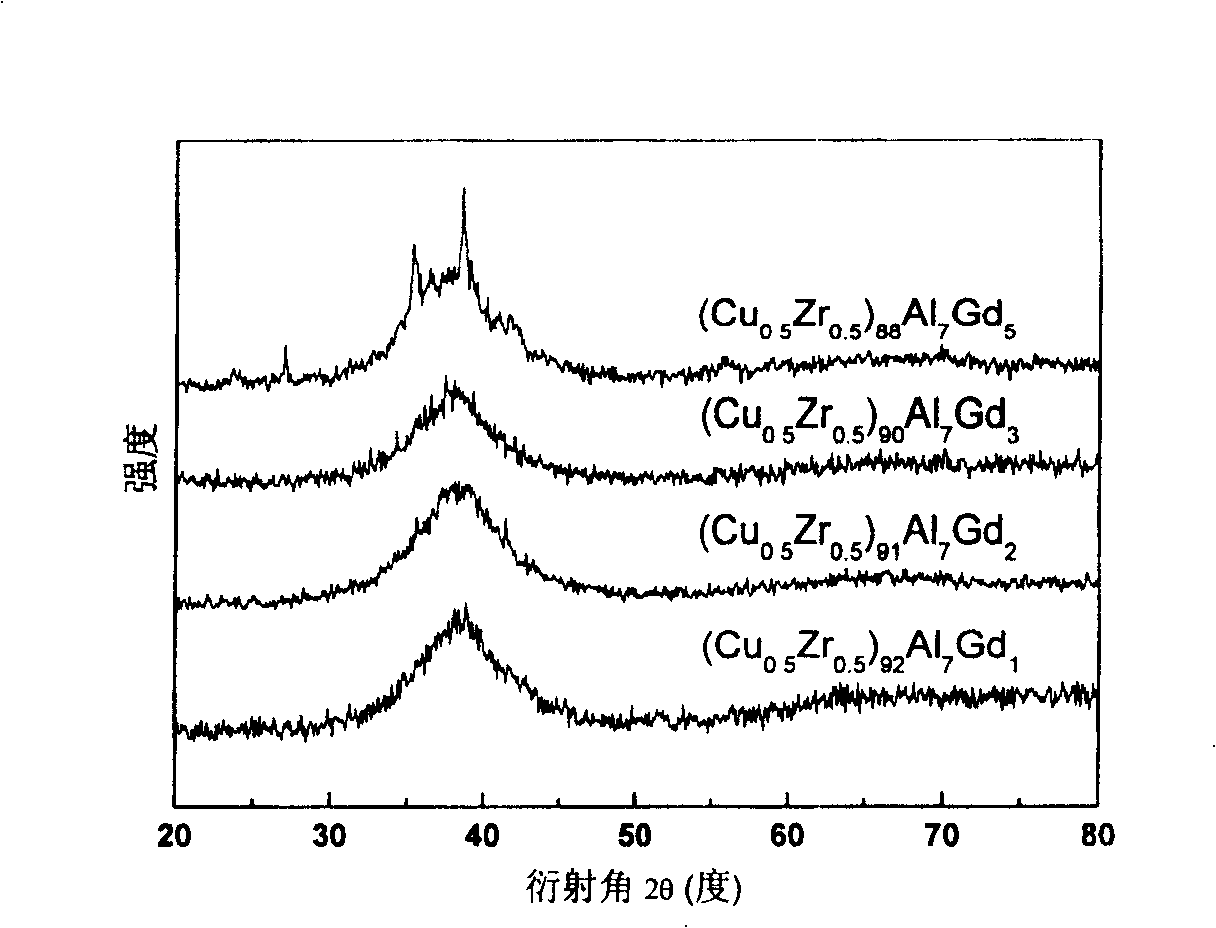

Copper-zirconium based amorphous alloy, and preparation method

InactiveCN1958831AImprove mechanical propertiesHigh plastic deformationMolten metal pouring equipmentsElectric arc furnaceAmorphous metal

This invention relates to a Cu-Zr-based amorphous alloy, whose general formula is (Cu1-xZrx)aAlbMc, where, x is 0.40-0.60; a is 80-100; b is 0-14; c is 0-20; a + b + c is 100; M is Y, La, Ce, Pr, Nd, Gd, Tb, Dy, Ho, Er, Ti, Ag, Ga, Hf, Ta, Nb, Ni, Co or Fe. The preparation method comprises: (1) mixing Cu, Zr, Al and M according to the ratio in Ti-adsorbed Ar atmosphere in an arc furnace, smelting and cooling to obtain mother alloy ingot; (2) re-melting the mother alloy ingot in air, and casting into a water-cooling metal mold to obtain the Cu-Zr-based amorphous alloy. The alloy has high glass formation ability, high crystallization inhibition and large size at a very low cooling speed.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

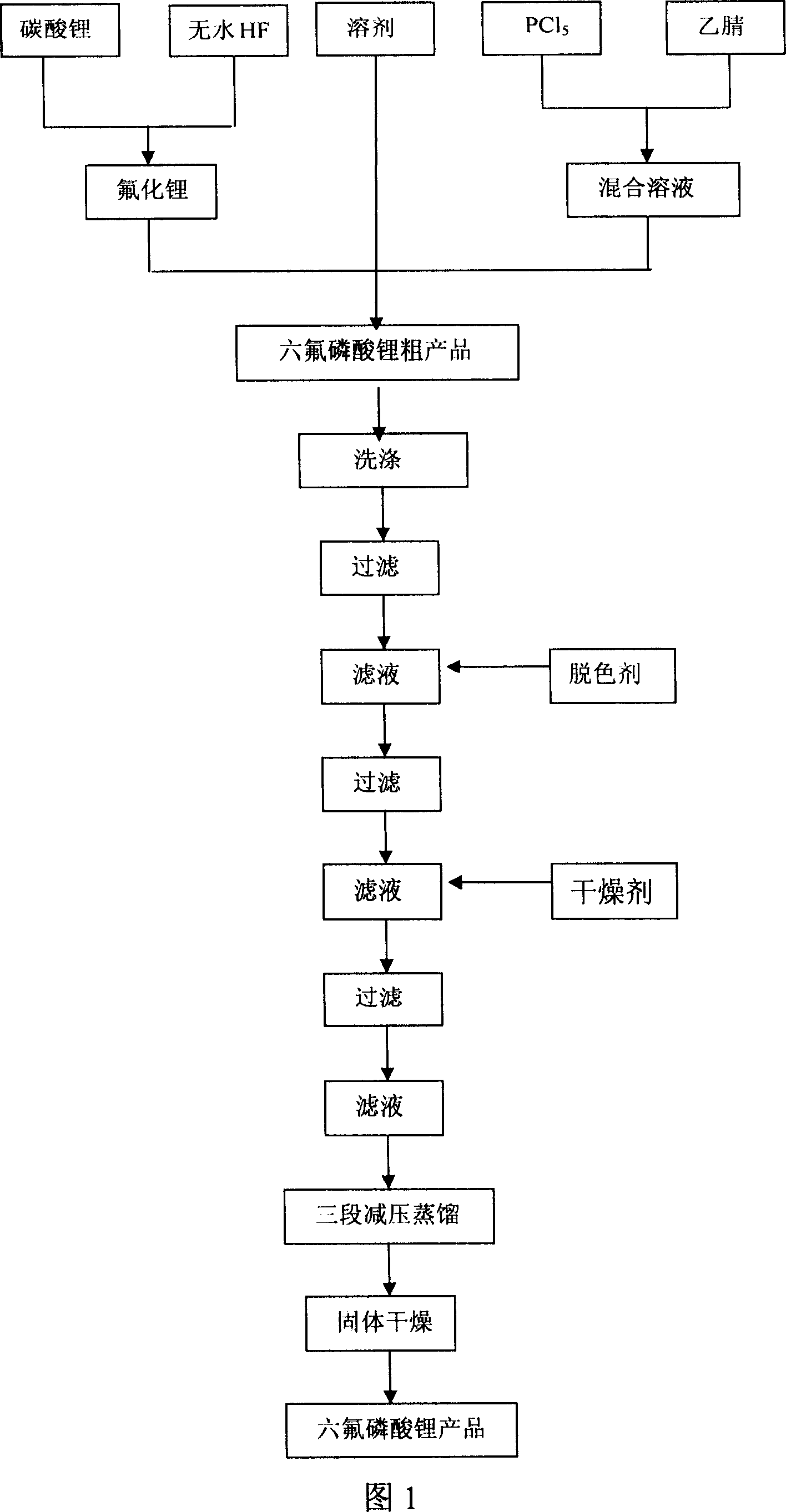

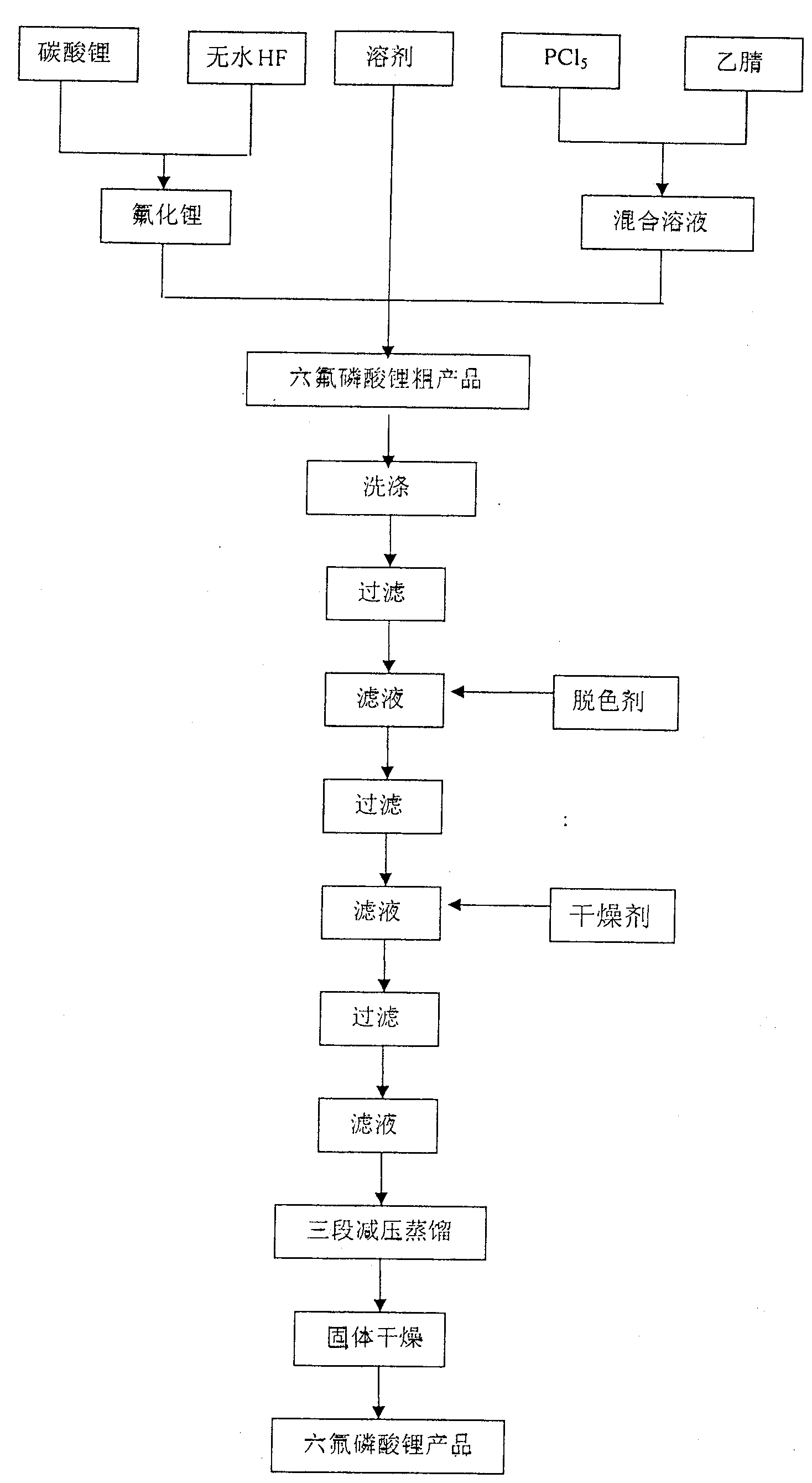

Method for preparing lithium hexafluorophosphate

ActiveCN1962423ARich in mineral resourcesHigh yieldLithium compoundsPhosphorus compoundsWater contentLithium carbonate

The invention discloses a preparing method of lithium hexafluorophosphate, which is characterized by the following: forming lithium fluoride through reacting lithium carbonate and hydrogen fluoride; reacting lithium fluoride and phosphorus source; improving product receiving rate and purity with lower water content and free HF content; possessing 9.7mS / cm conductivity for electrolyte.

Owner:BYD CO LTD

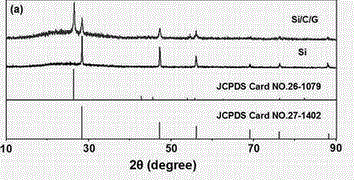

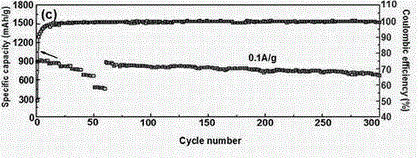

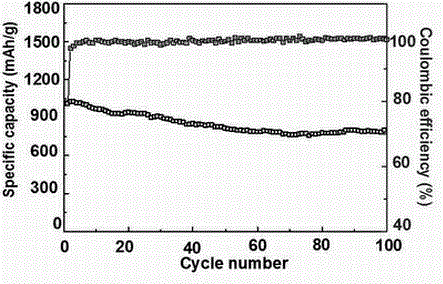

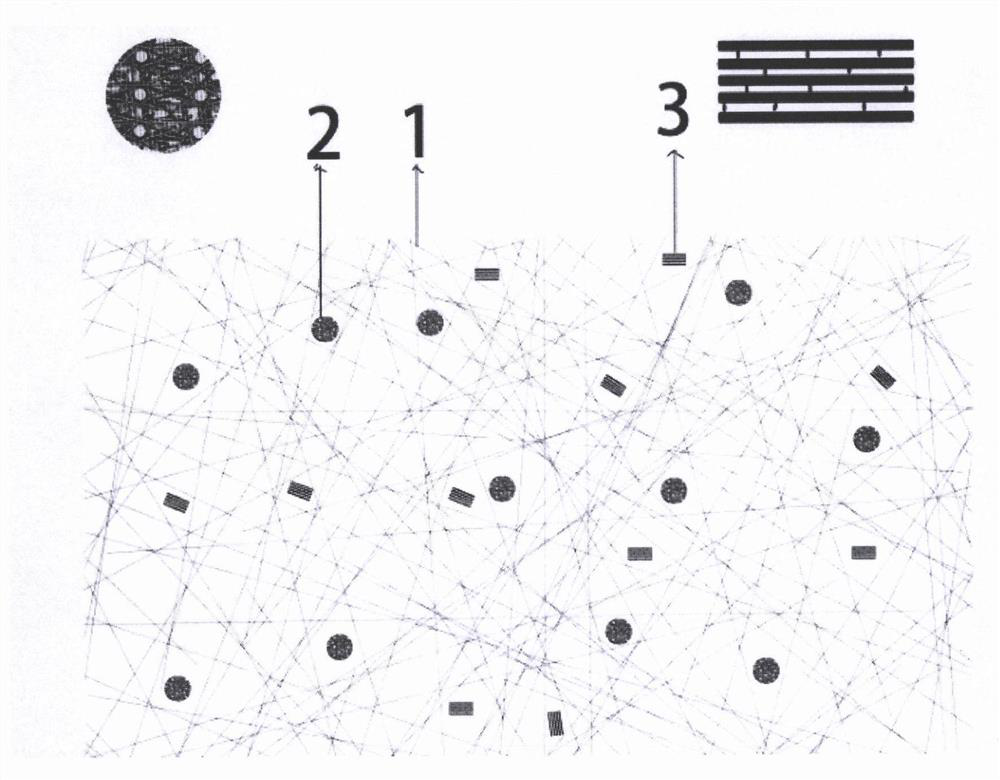

Preparation method and application of bicontinuous-structural nanocomposite material

InactiveCN104979540AHigh specific capacityImprove cycle performanceNegative electrodesSecondary cellsElectrolytic agentNanocomposite

The invention belongs to the technical fields of nanocomposite material and lithium ion battery, and relates to a bicontinuous-structural composite material and a preparation method and an application thereof in a lithium ion battery negative electrode. The problems are solved by selecting two ways. On one hand, silicon having rich pores is used in design of a silicon material morphology; the existence of the pores can increase the specific surface area of the silicon material, and increases the contact area of the silicon material with an electrolyte solution so as to reduce the transmission distance of lithium ions; and in addition, the existence of the pores can relieve huge volume change during lithium de-intercalation of a carbon material, and improves the cycle performance. On the other hand, the silicon material is composited with a material having good electronic conductivity, and the continuous dual-phase silicon composite material is prepared. The bicontinuous-structural composite material not only can overcome damage on a battery due to huge volume change of the silicon material, but also improves the electronic conductivity of the material.

Owner:NORTHEAST NORMAL UNIVERSITY

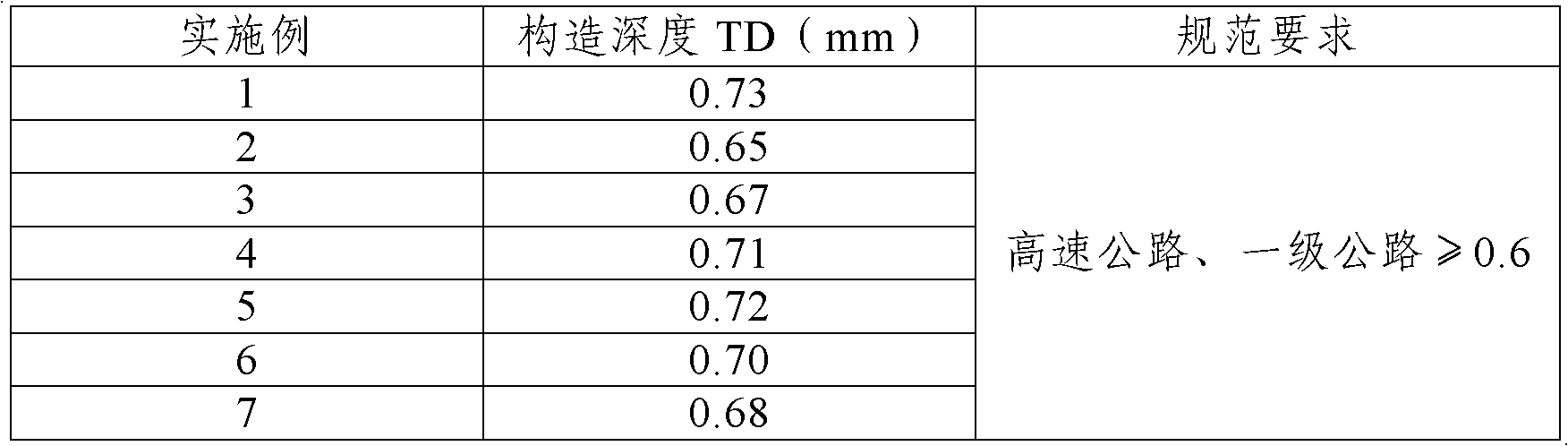

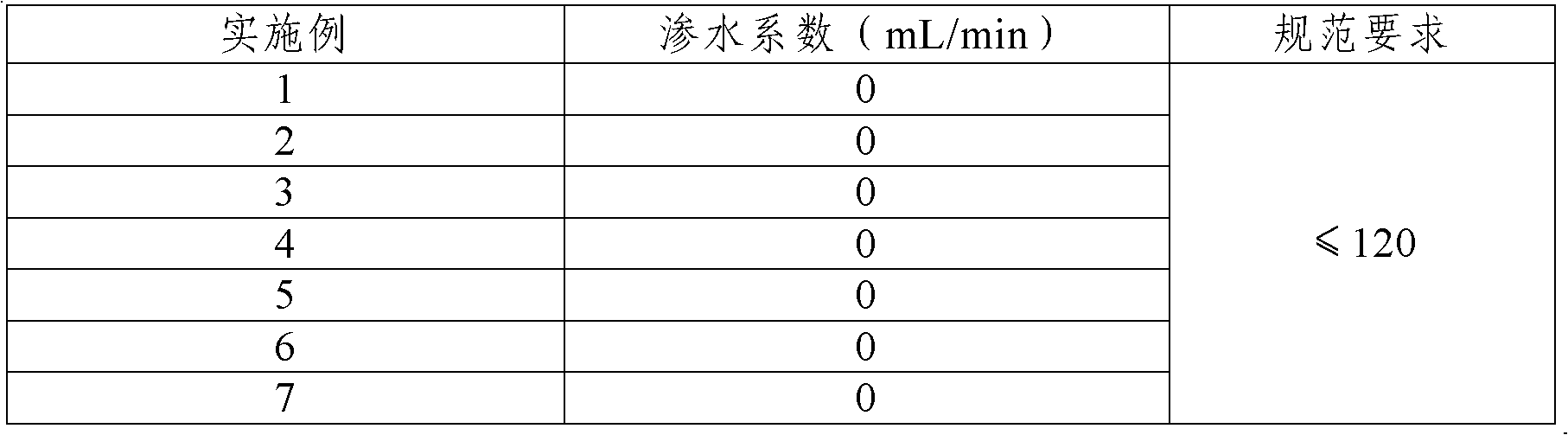

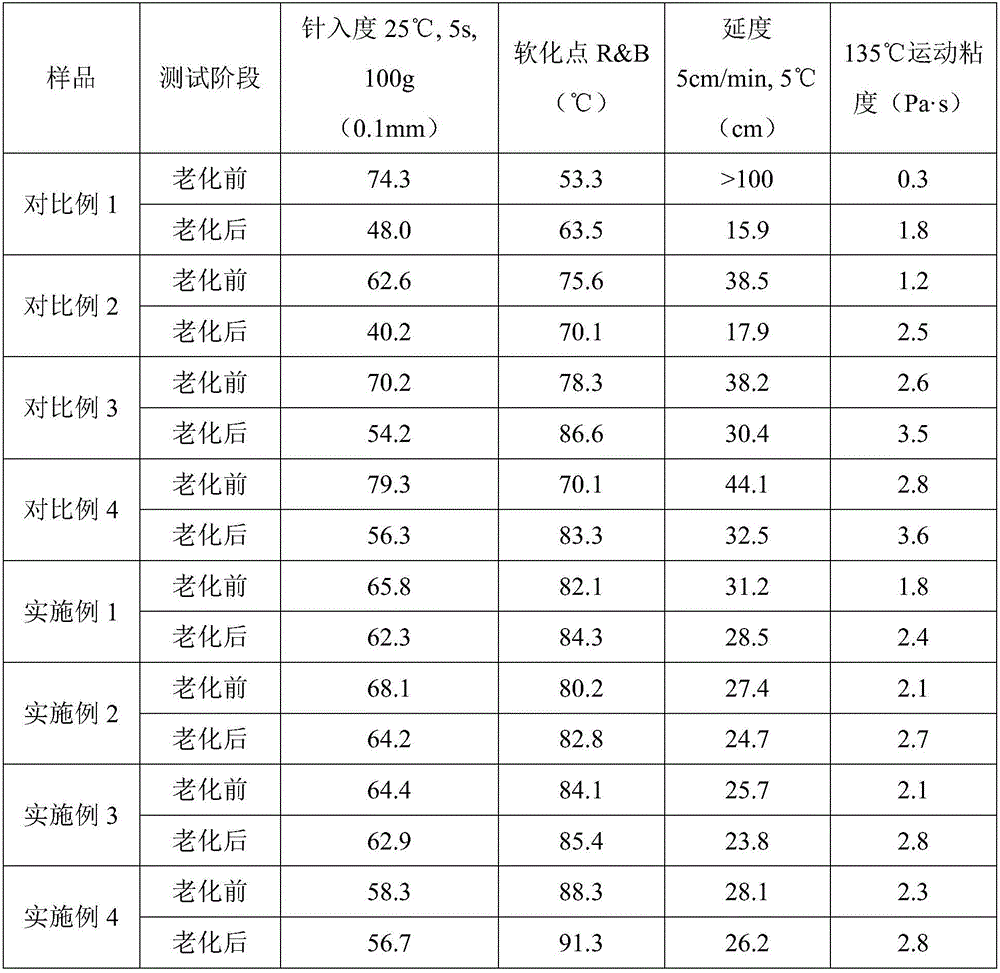

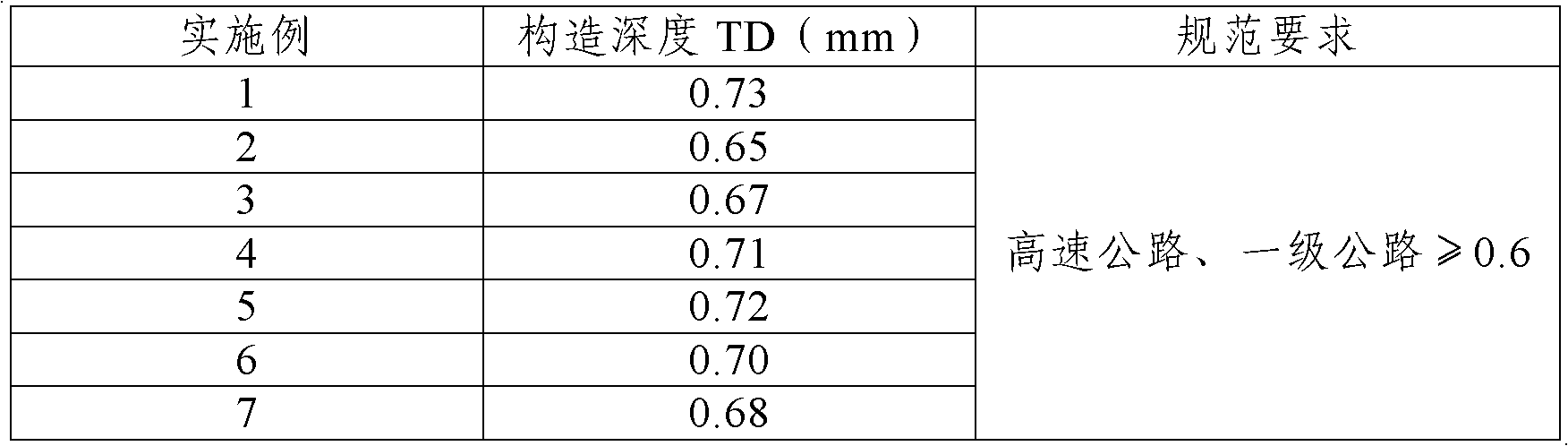

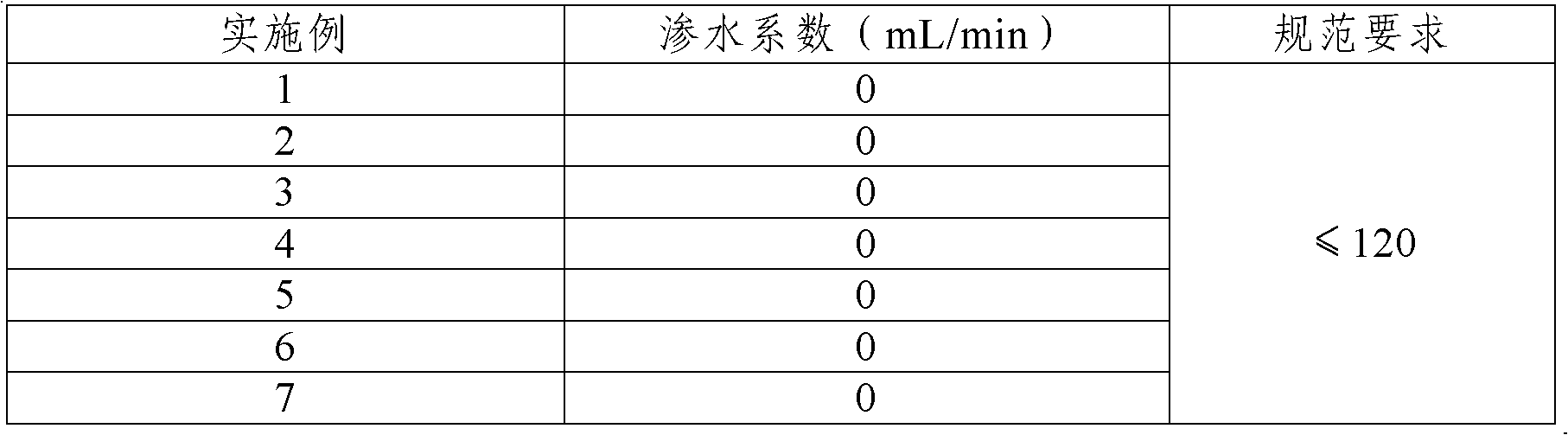

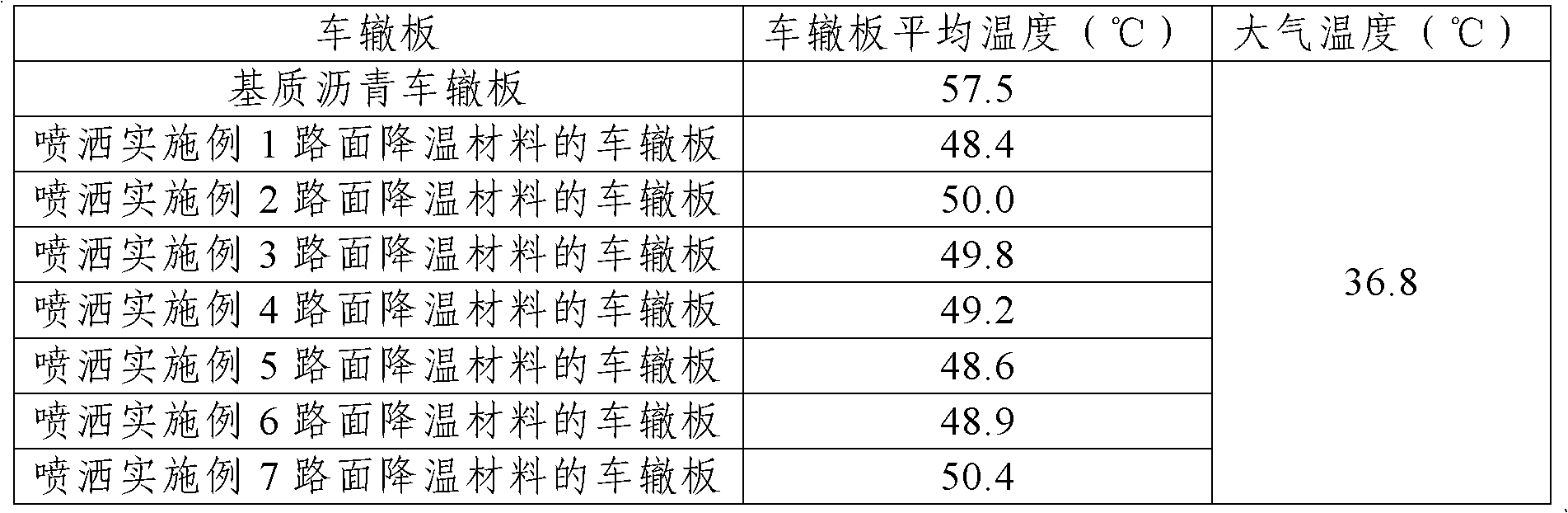

Pavement cooling material

The invention discloses a pavement cooling material which is formed by mixing the following raw materials in part by weight: 45-55 parts of film forming matters, 35-45 parts of tourmaline and 4-8 parts of aids. Each film forming matter is prepared by mixing epoxy resin, polyamide curing agent and methanol diluent according to the mass ratio of 1:(0.3-0.5):(0.05-0.2); the tourmaline is tourmaline powder and / or tourmaline negative ion powder; and each aid is prepared by dispersing agent, defoaming agent and flatting agent according to the mass ratio of (0.5-1.5):(0.5-1.5):1. The pavement cooling material has the advantages that the tourmaline is taken as a main raw material, the excellent characteristics of the tourmaline is reasonably utilized, and the material converts heat energy into electric energy and other energies through a energy conversion principle, not only has a remarkable cooling effect, but also is low in cost, simple in process and convenient in construction and has the most prominent advantages of intelligence and environmental friendliness.

Owner:CHANGAN UNIV

Gunning mix for kiln repair

The invention discloses a gunning mix for kiln repair. The gunning mix is characterized by comprising the following components by mass percent: 37-41% of dead burnt magnesia, 56-61% of forsterite, 1.0-1.4% of borax, 0.4-0.6% of inorganic salt, 0.2-0.4% of sodium tripolyphosphate and 0.4-0.6% of sodium hexametaphosphate. The gunning mix has the beneficial effects that forsterite and dead burnt magnesia are adopted as main raw materials; the gunning mix prepared with the formula has the advantages of high adhesive rate, good antistrip performance, high sintering speed, erosion resistance, anti-scouring performance and low high-temperature expansibility when applied to kilns and thermal equipment, and has more than 95% of adhesive rate; the mineral resources of the raw materials including magnesia and forsterite are abundant and the auxiliary raw materials can be obtained everywhere, so that the formula is simple and the inventory costs of the raw materials are reduced; the high adhesive rate of the product is favorable for not only achieving reduction of the production cost but also reducing the adverse effects of residues on molten steel.

Owner:浙江攀盛冶金材料有限公司

Preparation method of gunning mix for kiln repair

The invention discloses a preparation method of a gunning mix for kiln repair. The preparation method comprises the following steps in sequence: breaking dead burnt magnesia into large dead burnt magnesia particles; grinding the large dead burnt magnesia particles into small dead burnt magnesia particles; grinding part of the small dead burnt magnesia particles into dead burnt magnesia fine powder with a particle size of 0.088mm; breaking forsterite into large forsterite particles; grinding the large forsterite particles into small forsterite particles with particle sizes of 0.1-3mm; weighting borax, inorganic salt, sodium tripolyphosphate and sodium hexametaphosphate, premixing the materials and conveying the materials to a mixing system after premixing; screening the materials according to the difference of particle sizes; filling the small particles and the micro powder into a mixing system tank and conveying the materials to the mixing system after the materials are mixed; stirring dead burnt magnesia, forsterite, borax, inorganic salt, sodium tripolyphosphate and sodium hexametaphosphate in the mixing system simultaneously and then subpackaging the product, thus obtaining a finished product of the gunning mix. The preparation method has the beneficial effects that the formula is simple, thus reducing the inventory costs of the raw materials; the prepared product has a high adhesive rate, thus lowering the production cost.

Owner:浙江攀盛冶金材料有限公司

Attapulgus stone as cut tobacco additive and/or filter tip in to bacco industry

InactiveCN1528214ARich in mineral resourcesAbundant resourcesTobacco treatmentTobacco smoke filtersCellulose acetateTar

The present invention relates to application of attapulgite in tobacco industry. It can be used as additive for tobacco shred, and its added quantity is 0.01-0.5 wt% of weight of tabacco shred in the tobacco shred, it also can be used as additive for filter tip, when it is used as additive for filter tip, firstly, the attapulgite powder glyceride tracetate suspension liquor whose weight ratio is 0.1-10% can be prepared, then the suspension lqiuor can be sprayed on the cellulose acetate fibre bundle by means of filter tip machine so as to obtain qualified filter rod for cigarette. Its invention can reduce tar content and nicotine content in the cigarette.

Owner:盱眙欧佰特粘土材料有限公司

Converter large-face repair material and preparation method thereof

The invention relates to the field of metallurgy and converter repair materials, in particular to a converter large-face repair material and a preparation method thereof. The converter large-face repair material is composed of the following components in percentage by mass: regenerated magnesia carbon 25wt%, high-iron magnesia 30wt%, silicon carbide 25wt%, medium-temperature coal pitch 10wt%, aluminum powder 2wt%, iron scale 4wt%, SD80 3 wt%, and caprolactam 3 wt%. When applied to converter equipment, the converter large-face repair material prepared according to the formula has the advantagesof high adhesion rate, good peeling resistance, fast sintering speed, erosion resistance, scouring resistance and small high-temperature expansion, and the adhesion rate is 97% or more. Mineral resources of the magnesia raw material are rich, auxiliary raw materials are easy to obtain, the formula is simple, and the inventory cost of the raw materials is reduced. The high adhesion of the productnot only reduces the production cost, but also reduces the adverse effects of residue on molten steel. At the same time, the construction progress is accelerated, the converter repair time is shortened, the service life of the converter is prolonged, and the consumption of refractory materials is reduced.

Owner:海城利尔麦格西塔材料有限公司

Attapulgite strengthened and toughened sanitary ceramic green body and preparing method thereof

InactiveCN110105045AImproves Strength and ToughnessSave resources and energyCeramic materials productionClaywaresBall clayNanofiber

The invention discloses an attapulgite strengthened and toughened sanitary ceramic green body and a preparing method thereof. The sanitary ceramic green body is prepared from a green body material andattapulgite mineral nanofibers, wherein the attapulgite mineral nanofibers account for 1-4% of the mass of the green body material. The green body material is prepared from 1-6% of knar clay, 8-16% of Qinyang clay, 9-16% of kaolin, 9-16% of ball clay, 9-16% of Zhangcun clay, 9-16% of porcelain stone, 4-11% of porcelain clay, 4-11% of clay, 14-21% of feldspar, 1-6% of talcum and 1-6% of waste porcelain powder. The developed strengthened and toughened sanitary ceramic green body containing the natural nanofibers has the advantages of being simple in process, low in cost, capable of bringing small environmental loads and the like.

Owner:HEBEI UNIV OF TECH +1

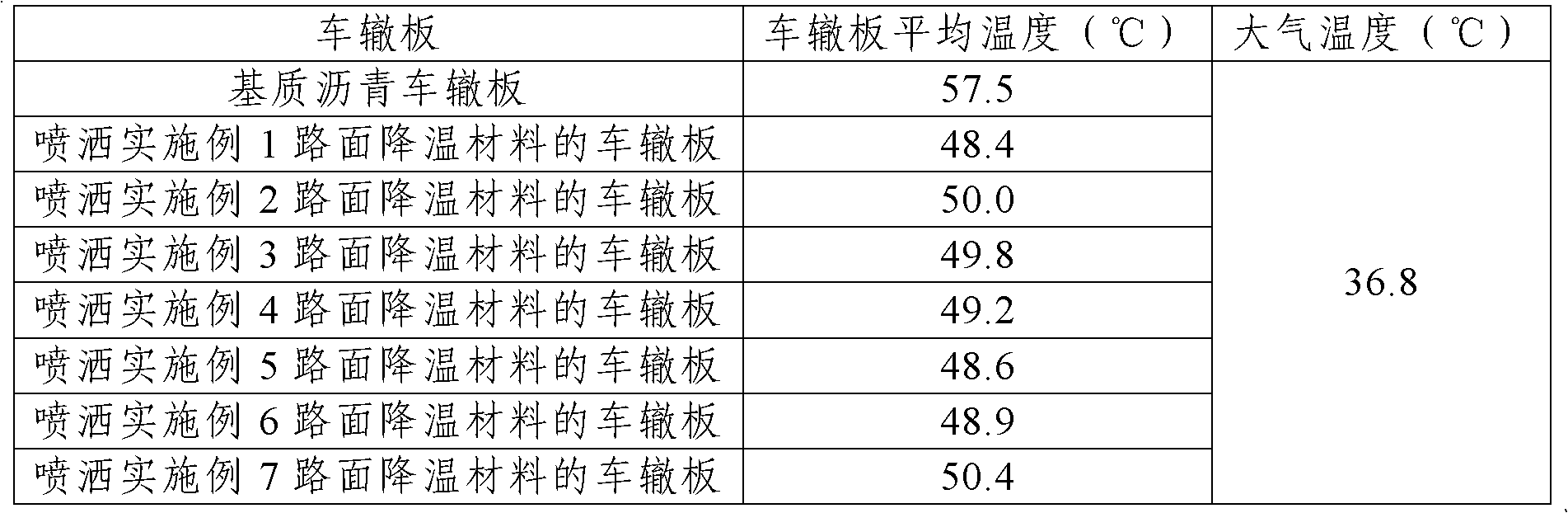

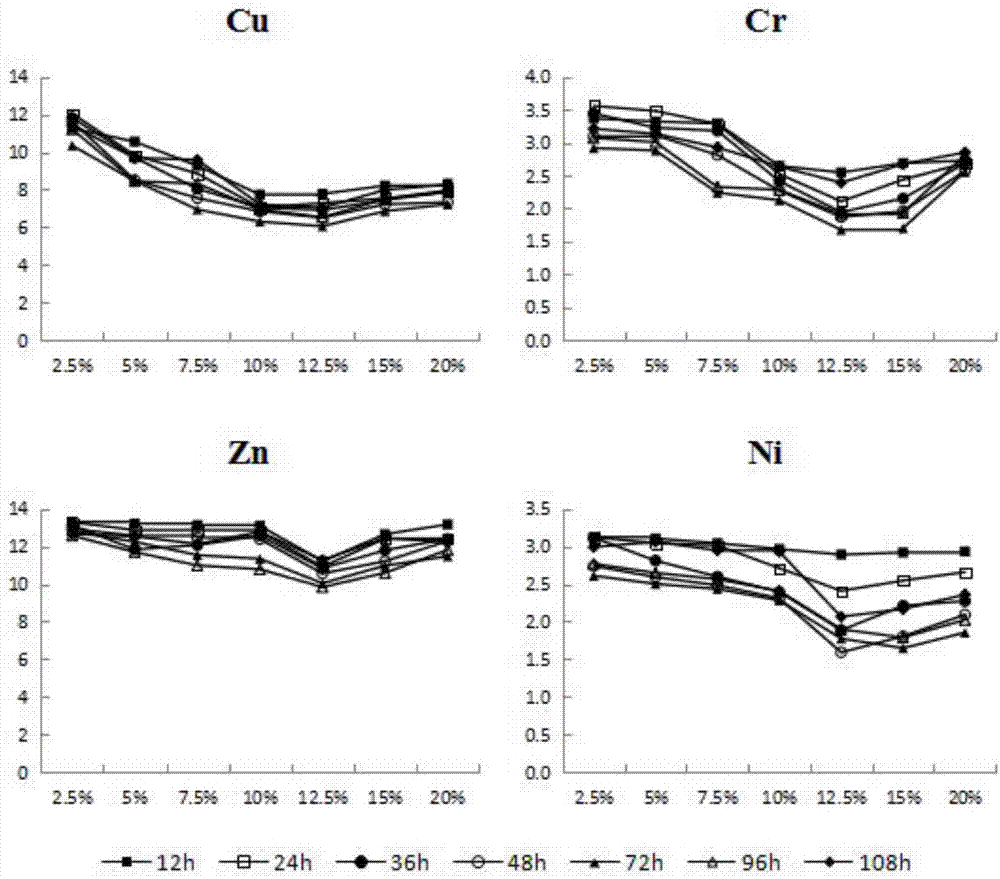

Preparation method of acid activated palygorskite-based soil heavy metal passivation material

InactiveCN106978183AAvoid soakingChemical stabilityAgriculture tools and machinesOrganic fertilisersIon exchangeSoil heavy metals

The invention relates to the technical fields of environmentally friendly materials and preparation methods thereof, and especially relates to a preparation method of an acid activated palygorskite-based soil heavy metal passivation material. Palygorskite clay is widely used nonmetallic clay mineral in heavy metal polluted soil repairing at present, is a rich mineral resource in China, has low price, can adsorb harmful and various organic and inorganic pollutants, does not generate secondary pollution, and has the advantages incomparable to other nonmetallic minerals. After the acidification treatment of the palygorskite clay is carried out, impurities are removed from the palygorskite clay, aggregated crystal beams are dispersed, octahedral cations are gradually dissolved, and microporous channels are expanded, so the purification purpose of the palygorskite clay is reached, the specific surface area is improved, and the adsorption performance and the ion exchange capacity are promoted, thereby the acidified palygorskite clay has more application values and economy values than the untreated palygorskite clay.

Owner:LANZHOU KUNLUN ENVIRONMENTAL PROTECTION TECH

Method for using attapulgite tobacco additive and filter tip additive

InactiveCN1228003CRich in mineral resourcesAbundant resourcesTobacco treatmentTobacco smoke filtersCellulose acetateTar

The present invention relates to application of attapulgite in tobacco industry. It can be used as additive for tobacco shred, and its added quantity is 0.01-0.5 wt% of weight of tabacco shred in the tobacco shred, it also can be used as additive for filter tip, when it is used as additive for filter tip, firstly, the attapulgite powder glyceride tracetate suspension liquor whose weight ratio is 0.1-10% can be prepared, then the suspension lqiuor can be sprayed on the cellulose acetate fibre bundle by means of filter tip machine so as to obtain qualified filter rod for cigarette. Its invention can reduce tar content and nicotine content in the cigarette.

Owner:盱眙欧佰特粘土材料有限公司

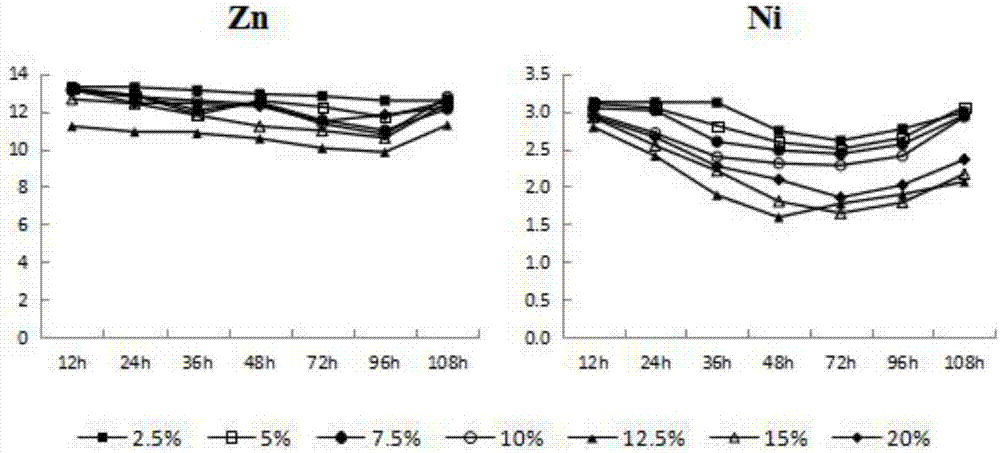

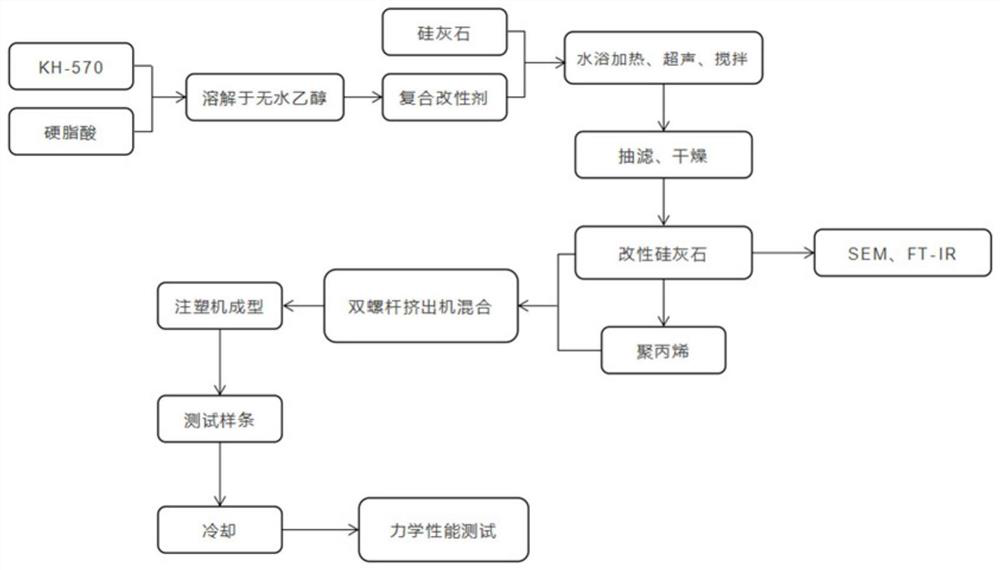

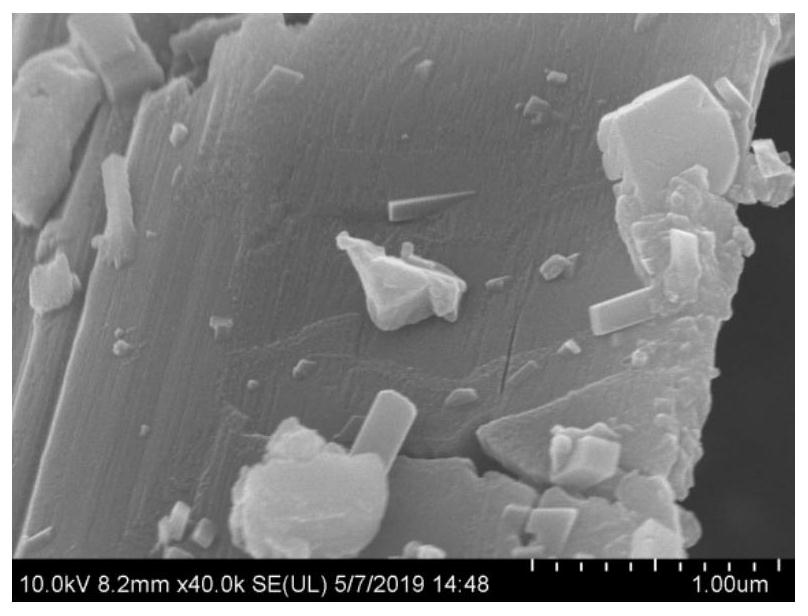

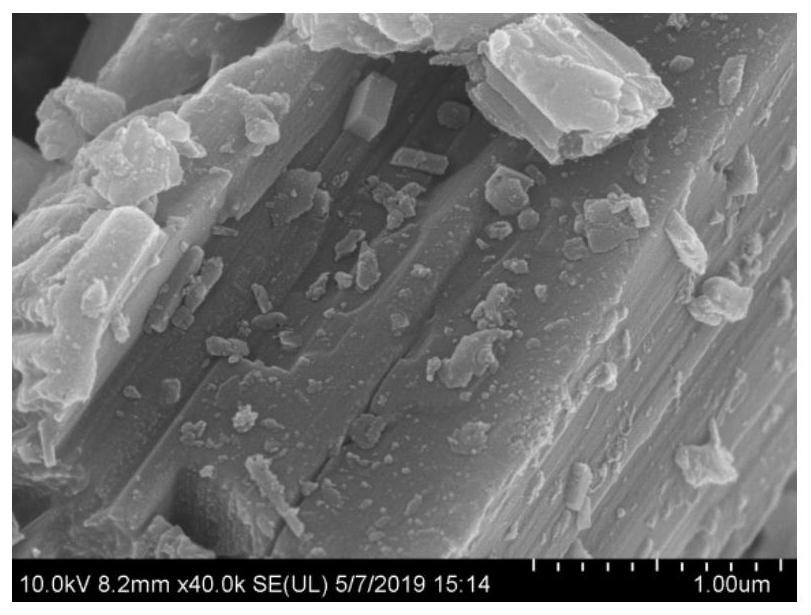

Modifier, modified wollastonite modified by modifier, and preparation method and application of modified wollastonite

InactiveCN112646395AChange surface propertiesRich in mineral resourcesPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsSurface reactionPolymer science

The invention discloses a modifier, modified wollastonite modified by the modifier, and a preparation method and application of the modified wollastonite. The modifier comprises a mixture of stearic acid and a silane coupling agent KH-570, the silane coupling agent KH-570 is hydrolyzed to generate silanol, and then reacts with alkyl on the surface of wollastonite, an organic coating layer is formed on the surface of the wollastonite, and the surface of the wollastonite is organized; stearic acid reacts with the wollastonite to generate stearate which coats the surface of wollastonite; the stearic acid is rich in carboxyl, and an acidic environment provided by ionization of stearic acid is more beneficial to surface reaction of the silane coupling agent KH-570 and the wollastonite, so that the surface organizing effect of the wollastonite is good, the modified wollastonite can be better combined with polypropylene plastic, and the mechanical property of the polypropylene plastic can be improved. The modified wollastonite is simple in modification process and good in modification effect, the polypropylene plastic is filled with the modified wollastonite, the bending property of the polypropylene plastic can be greatly improved, and the application range of polypropylene plasticity is expanded.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Large fabric for repairing furnace

The invention discloses a large fabric for fettling of a converter. The large fabric is prepared from the following components in percentage by mass: 20-25 percent of regenerated magnesia carbon, 28-32 percent of high-iron magnesia, 25-30 percent of regenerated silicon carbide, 12-18 percent of high-temperature asphalt, 1-3 percent of methenamine and 2-5 percent of caprolactam. According to the large fabric for the fettling of the converter, the regenerated magnesia carbon tile, regenerated silicon carbide and high-iron magnesia are used as main raw materials and crushed and screened, and then the high-temperature asphalt, methenamine and caprolactam are added into the former raw materials and fully stirred to obtain the large fabric. The large fabric for the fettling of the converter has the advantages of high adhesive rate, high anti-stripping performance, high sintering speed, high corrosion resistance, high anti-scouring property, small high-temperature expansibility when being used in converter equipment, and the adhesive rate is up to more than 95 percent.

Owner:浙江攀盛冶金材料有限公司

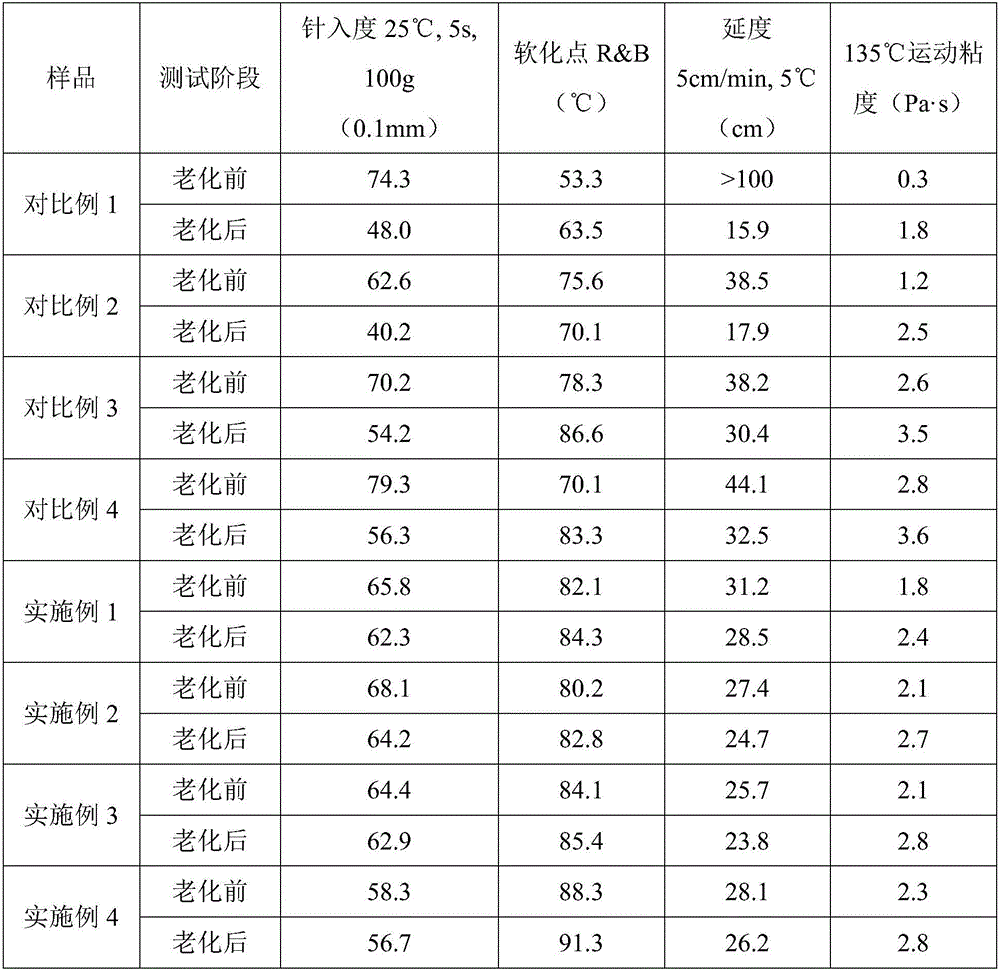

Modified asphalt with high ultraviolet aging resistance

The invention provides modified asphalt with high ultraviolet aging resistance, made from the following materials in percent by weight: 74.8-76.9% of base asphalt, 9.8-13.6% of obsidian, 5.2-7.6% of bauxite, 3.0-4.0% of hydrogenated castor oil, and 2.0-3.2% of aluminum-zirconium coupler, adding up to 100%. Mass researches and experiments show that the modified asphalt produced herein is applied to paving of asphalt pavements and may significantly improve ultraviolet aging resistance of a pavement, reduce cracking speed of active groups, inhibit aging action of ultraviolet upon asphalt to maintain its pavement performance, prevent cracking of the asphalt pavement due to crisping and hardening in later stage, and prolong the maintenance cycle and life of the pavement.

Owner:CHANGAN UNIV

High-temperature wear-resistant sericite pearlescent pigment

InactiveCN105542519ARich in mineral resourcesAbundant resourcesPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsDispersityWear resistant

The invention discloses a high-temperature wear-resistant sericite pearlescent pigment which comprises the following raw materials in parts by weight: 100-120 parts of sericite powder body, 30-38 parts of titanium powder, 30-38 parts of zinc powder, 22-30 parts of chrome yellow, 22-30 parts of cobalt blue, 12-20 parts of iron powder, 12-20 parts of methyl hydrogen-containing silicon oil, 10-18 parts of polyvinyl alcohol, 10-18 parts of colorant and 5-7 parts of coupling agent. By using the sericite as the main raw material to manufacture the pearlescent pigment, the pearlescent pigment has the advantage of available raw materials and is easy to manufacture. The titanium powder and zinc powder are added and mixed to coat the sericite surface, thereby obviously improving the pearlescent effect. The added colorant and coupling agent can obviously enhance the dispersity of the pearlescent pigment and greatly enhance the wear resistance, and the pearlescent pigment has high temperature resistance. The added cobalt blue, iron powder and methyl hydrogen-containing silicon oil can change the physical properties of various raw materials. The brightness and chroma of the pearlescent pigment are greatly enhanced, the wear resistance of the pearlescent pigment is greatly enhanced, and the pearlescent pigment has high temperature resistance and is suitable for popularization.

Owner:ANHUI HENGHAO SCI & TECH

Pavement cooling material

The invention discloses a pavement cooling material which is formed by mixing the following raw materials in part by weight: 45-55 parts of film forming matters, 35-45 parts of tourmaline and 4-8 parts of aids. Each film forming matter is prepared by mixing epoxy resin, polyamide curing agent and methanol diluent according to the mass ratio of 1:(0.3-0.5):(0.05-0.2); the tourmaline is tourmaline powder and / or tourmaline negative ion powder; and each aid is prepared by dispersing agent, defoaming agent and flatting agent according to the mass ratio of (0.5-1.5):(0.5-1.5):1. The pavement cooling material has the advantages that the tourmaline is taken as a main raw material, the excellent characteristics of the tourmaline is reasonably utilized, and the material converts heat energy into electric energy and other energies through a energy conversion principle, not only has a remarkable cooling effect, but also is low in cost, simple in process and convenient in construction and has the most prominent advantages of intelligence and environmental friendliness.

Owner:CHANGAN UNIV

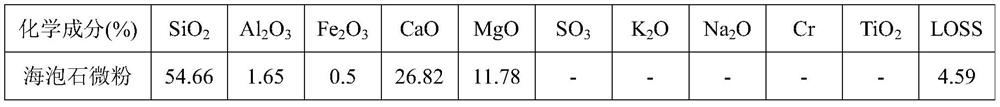

Sepiolite aerated concrete block and preparation process thereof

The invention discloses a sepiolite aerated concrete block which is prepared by adopting an non-autoclaved process. The concrete block comprises the following raw materials: a cementing material, an additive and water, wherein the cementing material is selected from sepiolite, slag, kaolin and cement, and the cement is a mixture of Portland cement and calcium aluminate cement. The invention also discloses a preparation method, which comprises the steps of mixing and stirring the cementing material, preparing a mixture for later use, preparing a suspension with the aluminum powder paste contentof 1-3%, preparing a sodium silicate and sodium hydroxide mixed solution, pouring the sodium silicate and sodium hydroxide mixed solution into the cementing material mixture, adding the aluminum powder paste suspension into the obtained slurry, carrying out casting molding on the obtained slurry, and curing to obtain the finished product building block. According to the sepiolite aerated concretebuilding block and the preparation process thereof, the building block with high compressive strength is prepared under the non-autoclaved condition.

Owner:HUNAN INSTITUTE OF ENGINEERING

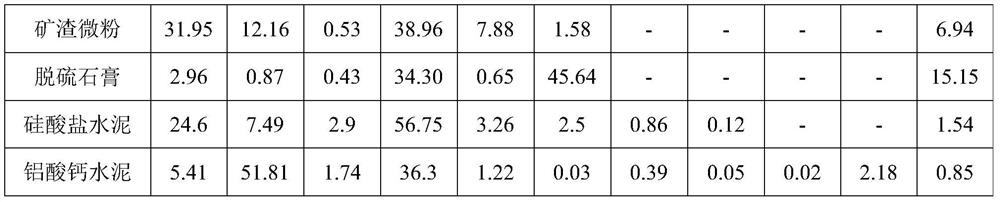

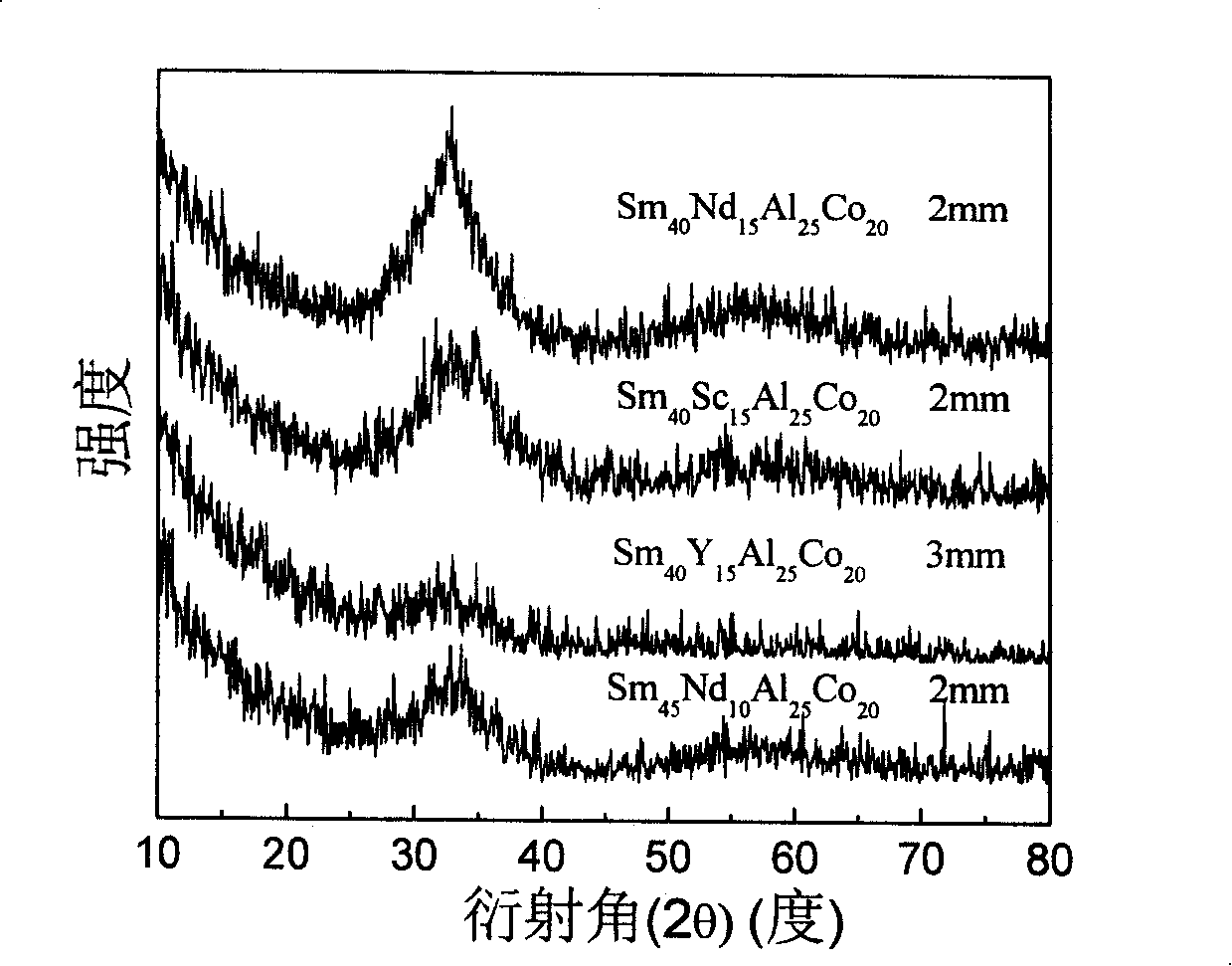

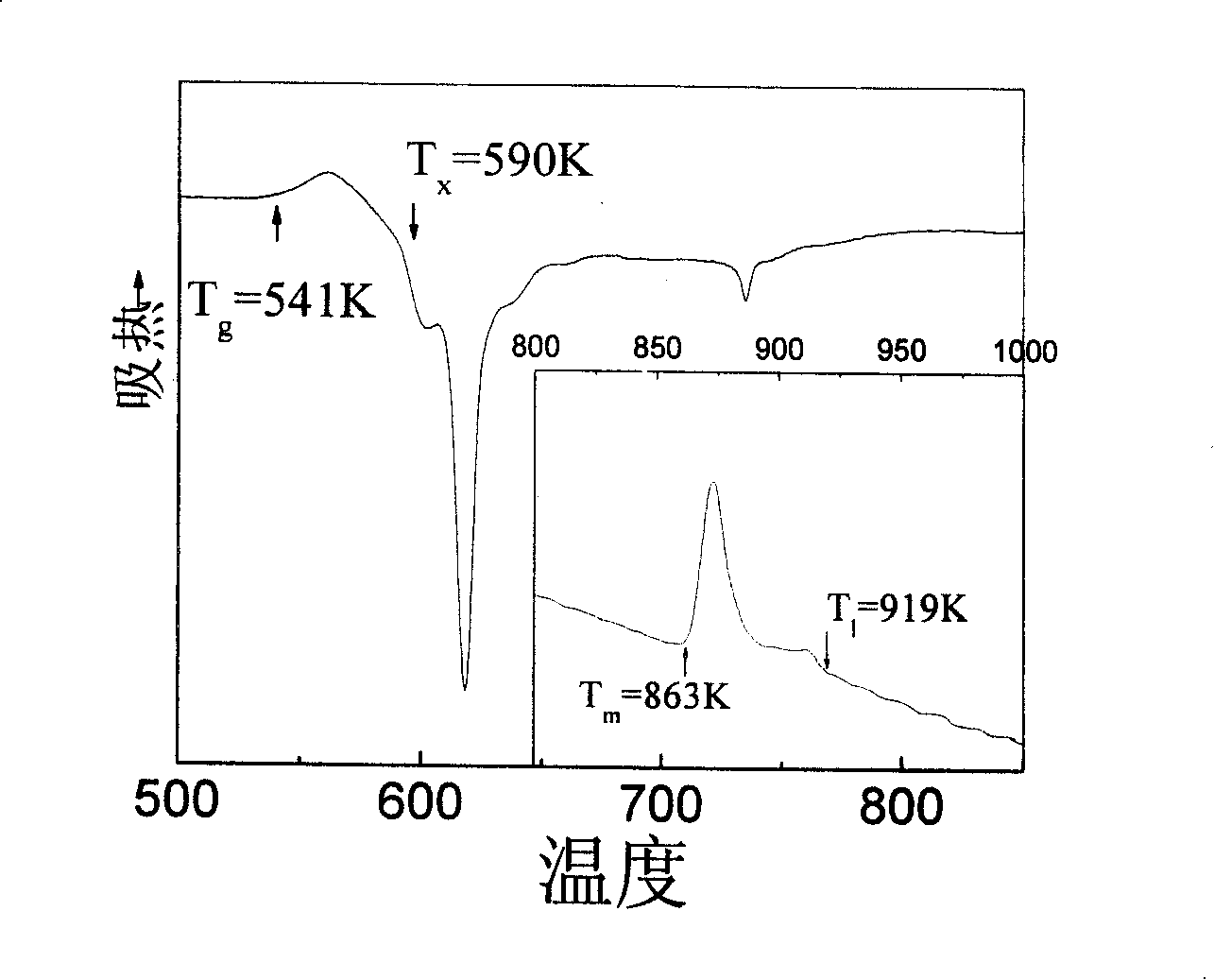

Samarium based amorphous alloy and preparation method thereof

InactiveCN100398687CHigh glass forming abilityImprove thermal stabilityCrystal structureHeat stability

The invention discloses a samarium-based amorphous alloy, which is based on samarium as main component with SmaMbAlcCod as component, wherein metal element M is Y, Sc or Nd (40<=a<=55,0<=b<=16,22<=c<=25,20<=d<=22, a+b+c+d=100); the alloy possesses higher glass forming ability and heat stability with glass transition temperature at 541-584K and crystallizing temperature at 590-652K, whose breadth of cool liquid phase area is 49-89K; the alloy is easy to form large-size amorphous alloy with each dimension not less than 1mm, whose critical diameter is not less than 1mm.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

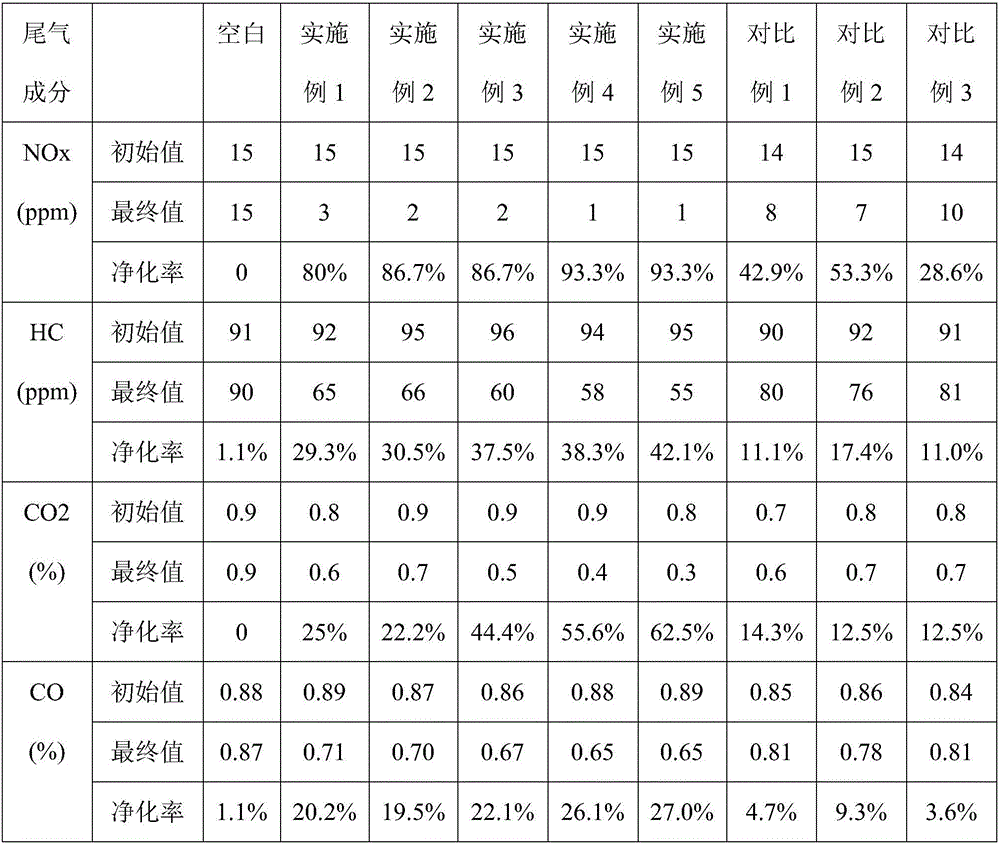

Road coating capable of adsorbing tail gas as well as preparation method and application thereof

InactiveCN106747257AImprove the road environmentHigh mechanochemical stabilityGas treatmentOther chemical processesGreenhouse gasTriethanolamine

The invention discloses a road coating capable of adsorbing tail gas as well as a preparation method and an application thereof. The road coating material is prepared from raw materials in parts by weight as follows: 42-50 parts of seaweed clay, 17-25 parts of vermiculite, 5-13 parts of cocamidopropyl betaine, 11-19 parts of triethanolamine and 3-7 parts of citric acid. The road coating material takes the seaweed clay and the vermiculite as main raw materials, after treatment with other substances, excellent characteristics of all raw materials are reasonably utilized, and the road coating can purify NOX, HC compounds, CO and other harmful gas in the air, has a certain effect on absorbing greenhouse gas, namely, CO2 and significantly improves the road environment. The road coating is pollution-free and high in mechanical and chemical stability and durability. The road coating is simple and convenient to construct and has excellent pavement performance, the construction process is simple, raw materials are non-toxic and harmless, and the road coating has great social benefit in improving road use quality and protecting the environment.

Owner:ZHENGZHOU CHENGHE INFORMATION TECH CO LTD

Method for preparing swelled fluorine mica by kaoline

InactiveCN100436318CRich in mineral resourcesExpand the New Way of Comprehensive Utilization of ResourcesSilicon compoundsKaolin clayBrucite

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Grinding waste perforated brick

InactiveCN106242607AHigh strengthImprove the authenticity rateCeramic materials productionCeramicwareBrickSlag

The invention discloses a grinding waste perforated brick. The grinding waste perforated brick comprises, by weight, 10-25 parts of grinding wastes, 5-10 parts of basalt, 35-50 parts of furnace slag, 2-6 parts of manganese dioxide, 1-2 parts of borax, 2-4 parts of perlite, 10-20 parts of river sands, 1-5 parts of wood chips and 80-100 parts of water. The perforated brick has the advantages of scientific production technology, convenience in manufacturing, realization of waste utilization, low production cost, compactness, high strength, high hardness, good binding property, good wear resistance, no desertification, no cracks caused by rapid change of the temperature, no porcelain formation, no fragmentation, strong water absorption property, small shrinkage, wear, pressure, acid-alkali and ageing resisting functions and long service life.

Owner:安徽琮玥工程项目管理有限公司

A kind of attapulgite composite glass fiber core material and preparation method thereof

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for preparing lithium hexafluorophosphate

ActiveCN100567141CRich in mineral resourcesHigh yieldLithium compoundsPhosphorus compoundsHydrogen fluorideLithium carbonate

A method for preparing lithium hexafluorophosphate, the method comprises reacting lithium fluoride with a phosphorus source, wherein the lithium fluoride is prepared by reacting lithium carbonate and hydrogen fluoride. Since lithium carbonate is a form in which lithium element exists in large quantities in nature, the raw material is easy to obtain and the price is cheap. Moreover, the lithium hexafluorophosphate product prepared by the method of the present invention has high yield, good purity, low water content and low free HF content, and the conductivity of the prepared electrolyte is as high as 9.7mS / cm.

Owner:BYD CO LTD

Preparation method of gunning mix for kiln repair

The invention discloses a preparation method of a gunning mix for kiln repair. The preparation method comprises the following steps in sequence: breaking dead burnt magnesia into large dead burnt magnesia particles; grinding the large dead burnt magnesia particles into small dead burnt magnesia particles; grinding part of the small dead burnt magnesia particles into dead burnt magnesia fine powder with a particle size of 0.088mm; breaking forsterite into large forsterite particles; grinding the large forsterite particles into small forsterite particles with particle sizes of 0.1-3mm; weighting borax, inorganic salt, sodium tripolyphosphate and sodium hexametaphosphate, premixing the materials and conveying the materials to a mixing system after premixing; screening the materials according to the difference of particle sizes; filling the small particles and the micro powder into a mixing system tank and conveying the materials to the mixing system after the materials are mixed; stirring dead burnt magnesia, forsterite, borax, inorganic salt, sodium tripolyphosphate and sodium hexametaphosphate in the mixing system simultaneously and then subpackaging the product, thus obtaining a finished product of the gunning mix. The preparation method has the beneficial effects that the formula is simple, thus reducing the inventory costs of the raw materials; the prepared product has a high adhesive rate, thus lowering the production cost.

Owner:浙江攀盛冶金材料有限公司

Modified bituminous concrete with self-regulating temperature function

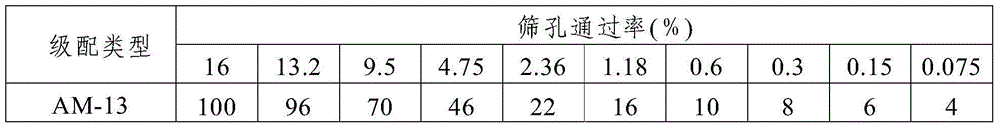

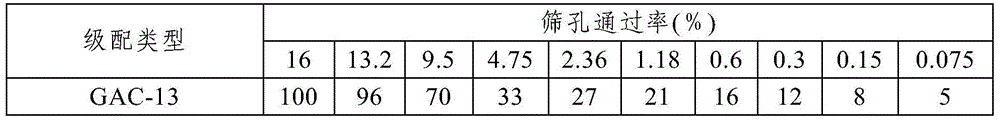

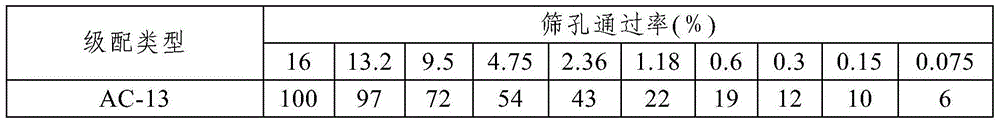

The invention provides modified bituminous concrete with a self-regulating temperature function. The modified bituminous concrete is prepared from the following raw materials in parts by weight: 100 parts of mineral aggregate, 3-7 parts of asphalt, 0.2-2.4 parts of sepiolite powder, 0.1-2.0 parts of palygorskite powder, and 0.01-0.06 part of coupling agent, wherein the coupling agent is a titanate coupling agent or an aluminate coupling agent; the aggregate grading type of the mineral aggregate is AM-13, GAC-13, AC-13, SMA-13 or OGFC-13. According to the modified bituminous concrete provided by the invention, excellent characteristics of sepiolite and palygorskite are reasonably utilized; the usability of a bituminous concrete pavement can be effectively improved; the temperature of the bituminous concrete pavement can be reduced under a high-temperature condition; a track disease is reduced; the bituminous concrete pavement can keep high temperature to resist a low-temperature disease under a low-temperature condition.

Owner:CHANGAN UNIV

A modified asphalt with high anti-ultraviolet aging function

InactiveCN106046811BGood chemical stabilityLow thermal conductivityBuilding insulationsAging resistanceUltraviolet

The invention provides modified asphalt with high ultraviolet aging resistance, made from the following materials in percent by weight: 74.8-76.9% of base asphalt, 9.8-13.6% of obsidian, 5.2-7.6% of bauxite, 3.0-4.0% of hydrogenated castor oil, and 2.0-3.2% of aluminum-zirconium coupler, adding up to 100%. Mass researches and experiments show that the modified asphalt produced herein is applied to paving of asphalt pavements and may significantly improve ultraviolet aging resistance of a pavement, reduce cracking speed of active groups, inhibit aging action of ultraviolet upon asphalt to maintain its pavement performance, prevent cracking of the asphalt pavement due to crisping and hardening in later stage, and prolong the maintenance cycle and life of the pavement.

Owner:CHANGAN UNIV

A preparation method of large fabric for converter repairing

The invention discloses a preparation method of a large-area material for converter fettling, which adopts regenerated magnesia carbon bricks, regenerated silicon carbide and high-iron magnesia as main raw materials, and prepares the material by crushing and sieving regenerated magnesia carbon bricks, regenerated silicon carbide and high-iron magnesia, adding high temperature asphalt, urotropine and caprolactam, and fully stirring. When used in converter equipment, the large-area material for converter fettling prepared by the formula has the advantages of high adhesive rate, good anti-stripping performance, high sintering speed, erosion resistance, scouring resistance, and low high temperature expansion, and has an adhesive rate of more than 95%. The raw material of magnesia is rich in ore resources; the auxiliary raw materials are available everywhere; the formula is simple; the raw material stock-holding cost is decreased; the high adhesive rate of the product not only realizes the reduction of production cost, but also reduces adverse influence of residues on molten steel. Meanwhile, the work intensity is decreased; the construction progress is accelerated; the fettling time is shortened; the furnace service life is prolonged; and the consumption of refractory materials is reduced.

Owner:浙江攀盛冶金材料有限公司

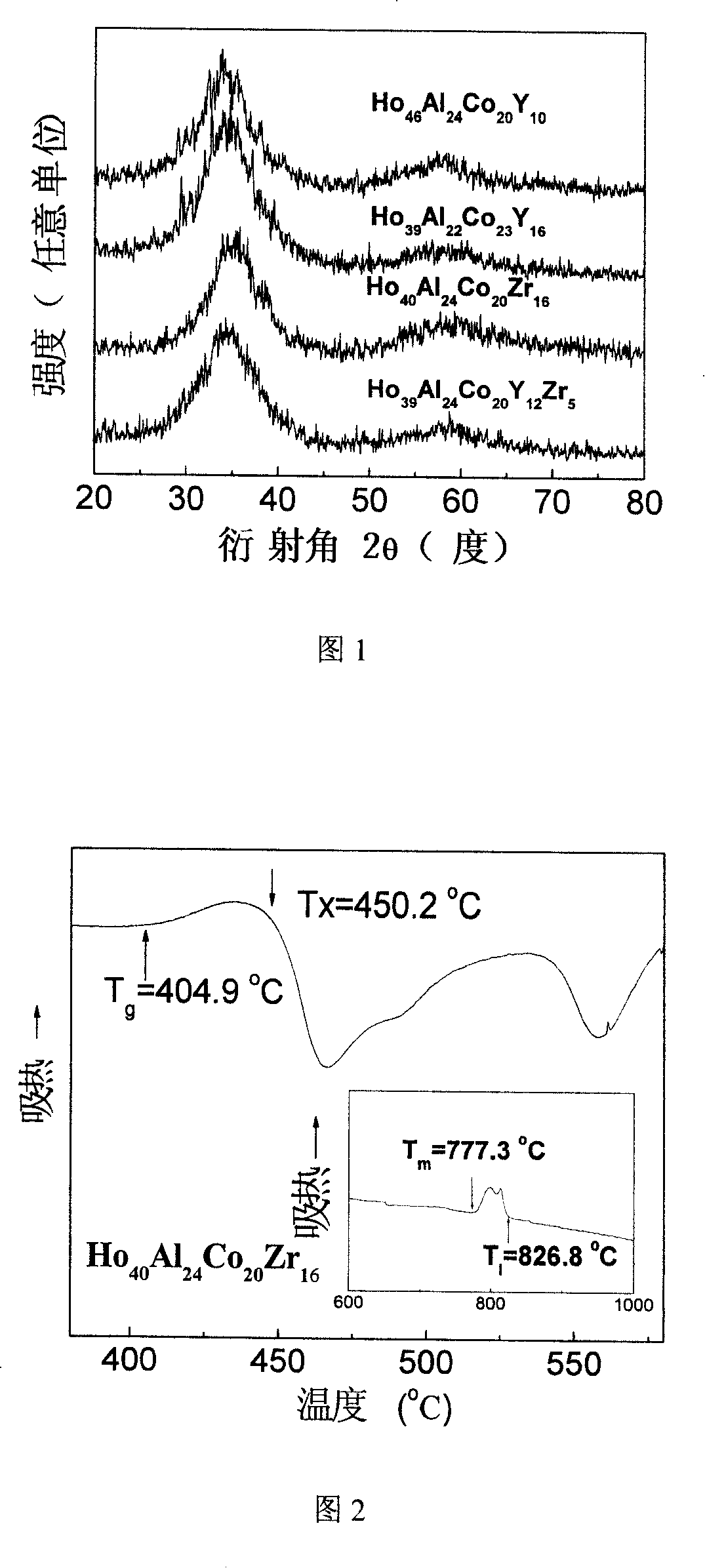

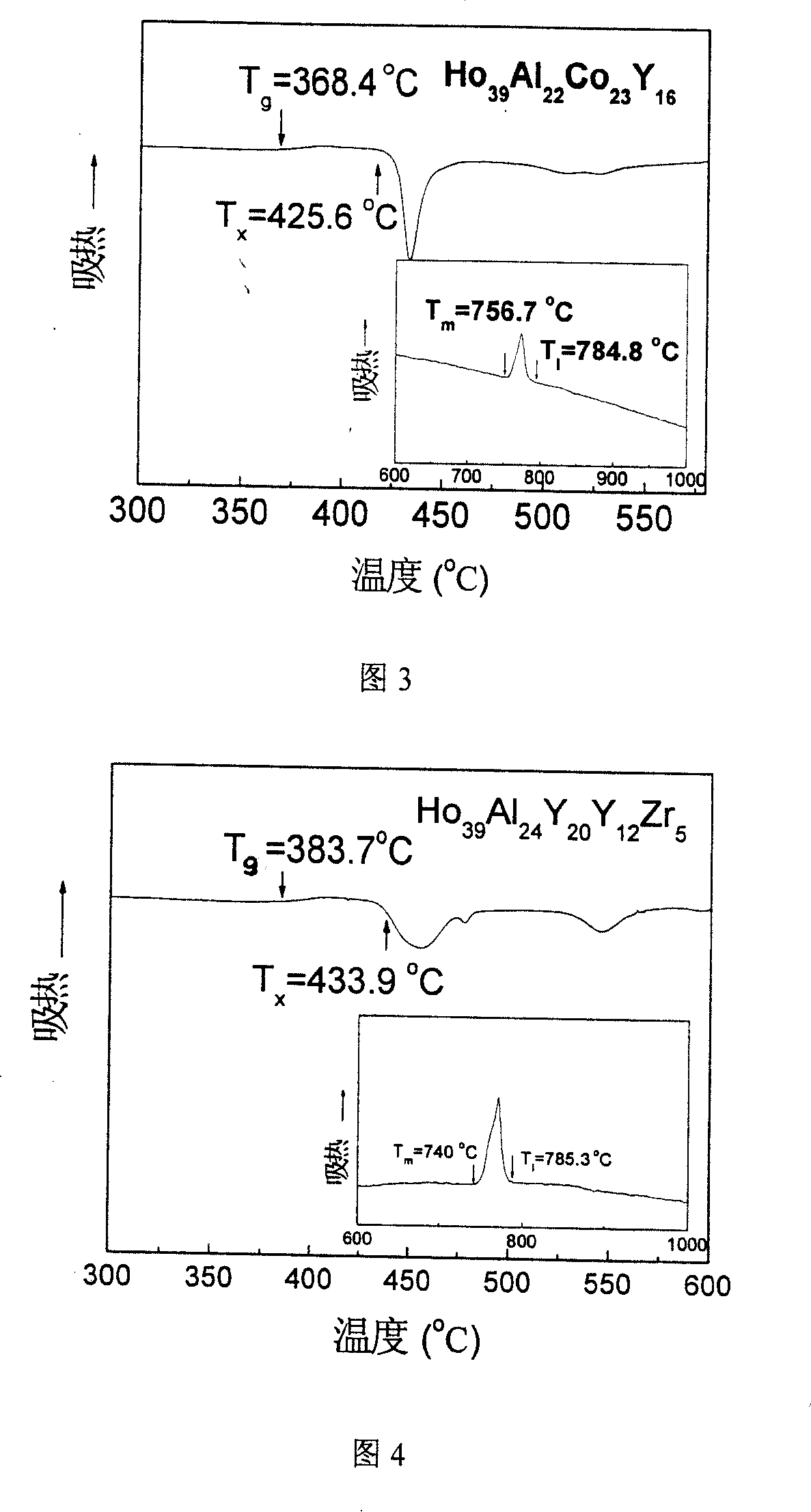

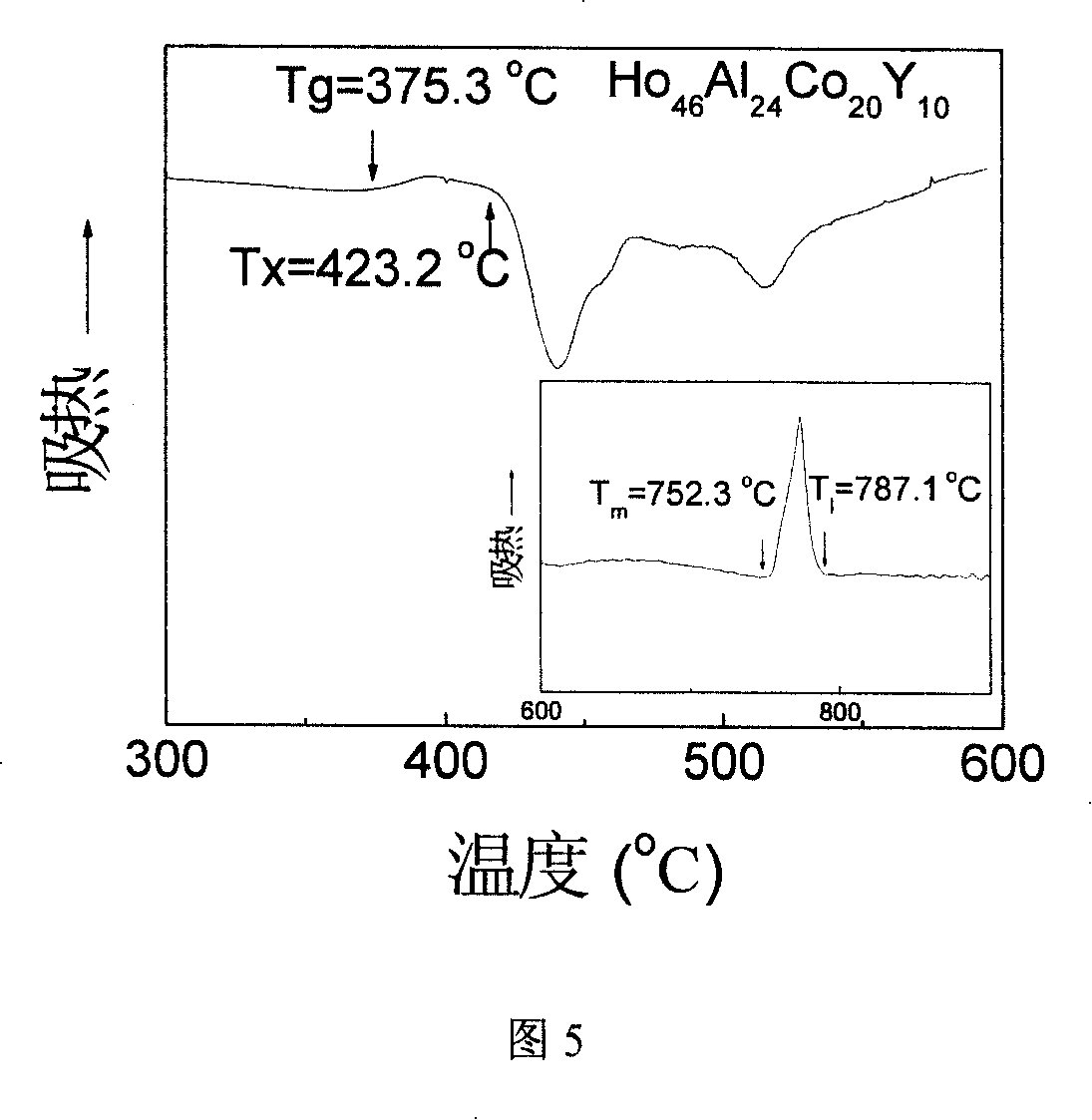

Holmium base amorphous alloy and its preparation method

InactiveCN100378243CHigh glass forming abilityImprove thermal stabilityElectric arc furnaceRare earth

The invention relates to a holmium radical bulk non-crystal body alloy that the expression is HoaMbAlcCodTe, and 30 greater than or equal to a greater than or equal to 56, 0 greater than or equal to b greater than or equal to 26, 22 greater than or equal to c greater than or equal to 25, 20 greater than or equal to d greater than or equal to 23, 0 greater than or equal to e greater than or equal to 25, and a+b+c+d+e=100, M is Zr or / and Y, element T is Fe, Ni, Nb, Pd, Mo, Hf, Ta, or rare earth Ce, Tb, Dy, Gd, Er, and Sm. The alloy is made up from mixing the elements with purity over 99.9wt% according to the ratio, and taking multi times melting to gain mother alloy ingot bar, and re-melting the mother alloy, using casting adsorbing device in arc furnace to adsorb the melt into water cooledcopper mould. The invention has low critical cooling speed, strong anti oxygen ability, and strong anti crystallizing ability. It is easy to make and low cost, and has high thermal stability.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

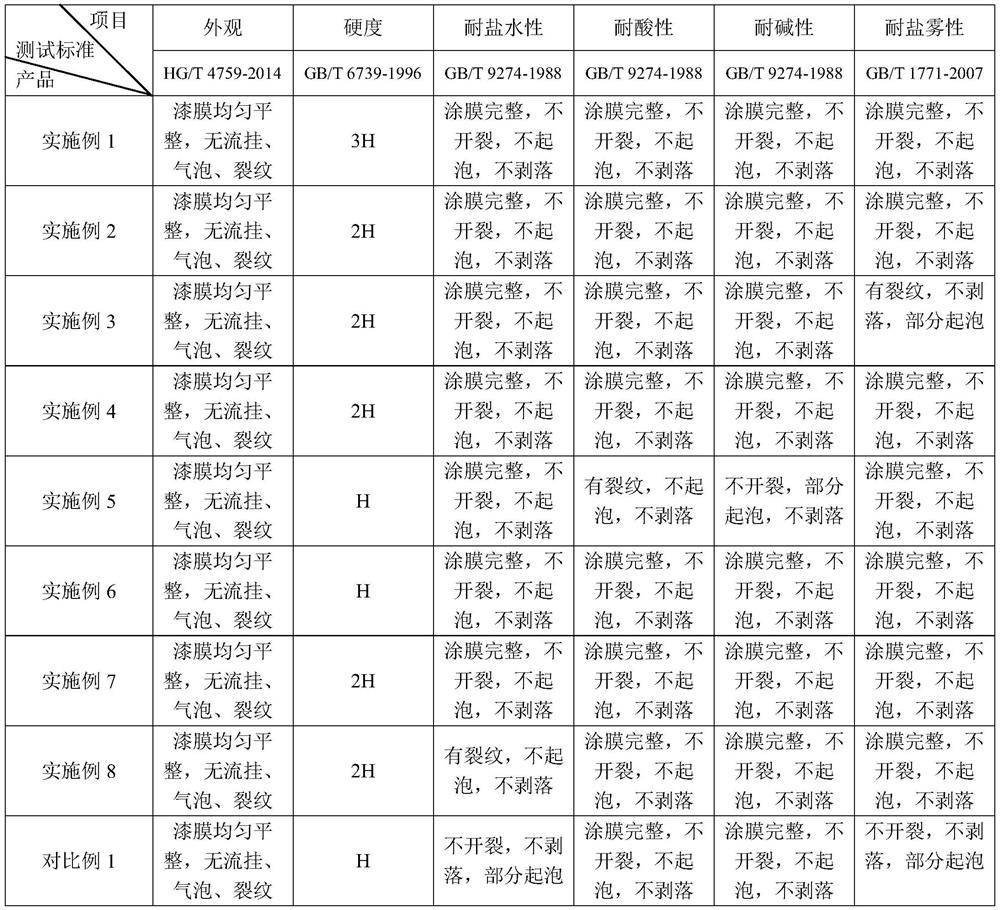

Epoxy resin anticorrosive paint based on black talc and preparation method of epoxy resin anticorrosive paint

InactiveCN112961578ARich in mineral resourcesLow priceAnti-corrosive paintsEpoxy resin coatingsEpoxyPolymer science

The invention discloses an epoxy resin anticorrosive paint based on black talc and a preparation method of the paint, and the anticorrosive paint comprises the following raw materials by weight: 25-55 wt% of epoxy resin, 20-40 wt% of a solvent, 8-20 wt% of a filler, 8-15 wt% of zinc powder with fineness of 800-1250 meshes, 1-6 wt% of high temperature carbonized black talc with fineness of 1-2 [mu]m, 3-6 wt% of a pigment, 0.2-2 wt% of a dispersant, 0.2-2 wt% of an antifoaming agent, and 0.2-2 wt% of a leveling agent. The preparation process of the anticorrosive paint is simple and easy to operate; and the product is good in wear resistance, salt water resistance, acid resistance, alkali resistance and other corrosion resistance, and the surface of the coating does not blister or fall off.

Owner:ZHEJIANG UNIV OF TECH

Copper-zirconium based amorphous alloy, and preparation method

InactiveCN100445413CImprove mechanical propertiesHigh plastic deformationMolten metal pouring equipmentsElectric arc furnaceArgon atmosphere

The invention relates to a copper-zirconium-based amorphous alloy, which is mainly composed of copper and zirconium, and whose composition is expressed by the following formula: (Cu1-xZrx)aAlbMc, wherein, 0.40≤x≤ 0.60, 80≤a≤100, 0≤b≤14, 0≤c≤20, and a+b+c=100; metal element M is Y, La, Ce, Pr, Nd, Gd, Tb, Dy, Ho , Er, Ti, Ag, Ga, Hf, Ta, Nb, Ni, Co, or Fe. The preparation of the alloy is to mix the above-mentioned components Cu, Zr, Al and M according to the required atomic ratio in an electric arc furnace with an argon atmosphere adsorbed by titanium, and then melt and cool to obtain a master alloy ingot; then use conventional The metal mold casting method is to remelt the master alloy ingot in the air and cast it in a water-cooled metal mold to obtain the alloy. The alloy has high glass-forming ability, strong ability to inhibit crystallization, and can be made into larger sizes at very low cooling rates.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com