Epoxy resin anticorrosive paint based on black talc and preparation method of epoxy resin anticorrosive paint

An epoxy resin and anti-corrosion coating technology, applied in the field of coatings, can solve the problems of poor anti-corrosion performance and easy damage to the anti-corrosion coating structure, and achieve the effects of excellent suspension and dispersibility, improved hardness and rich mineral resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

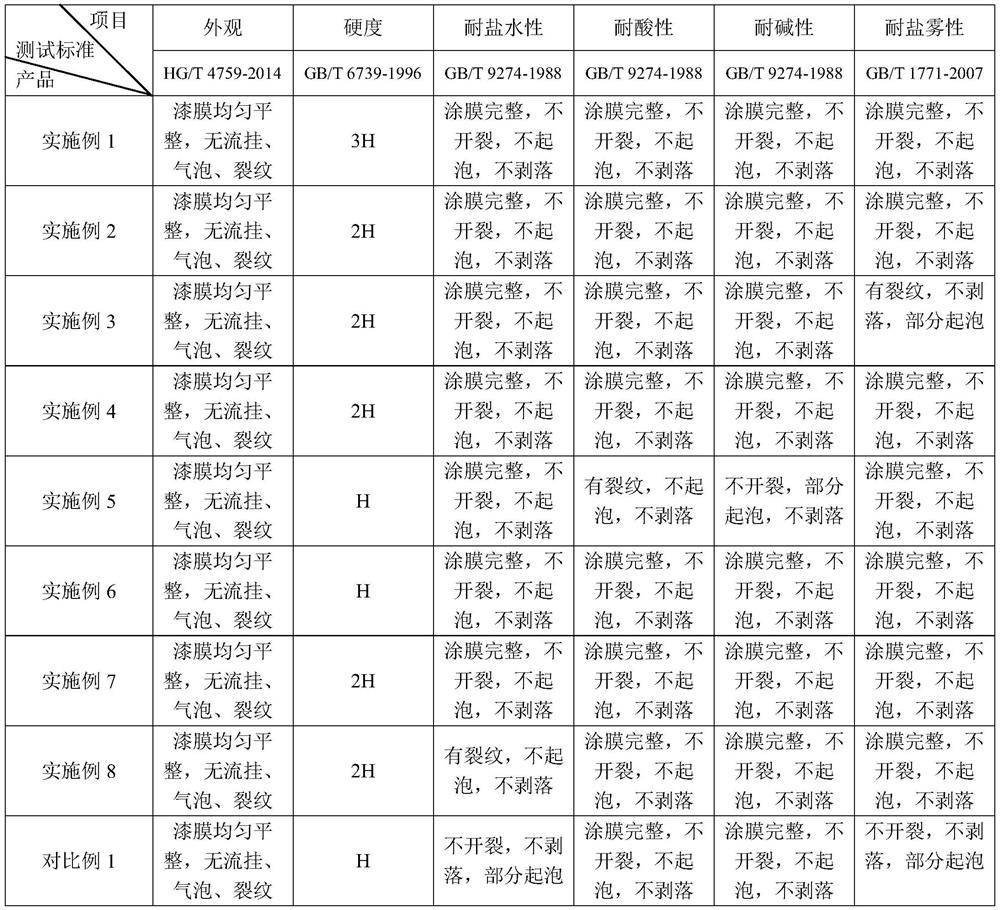

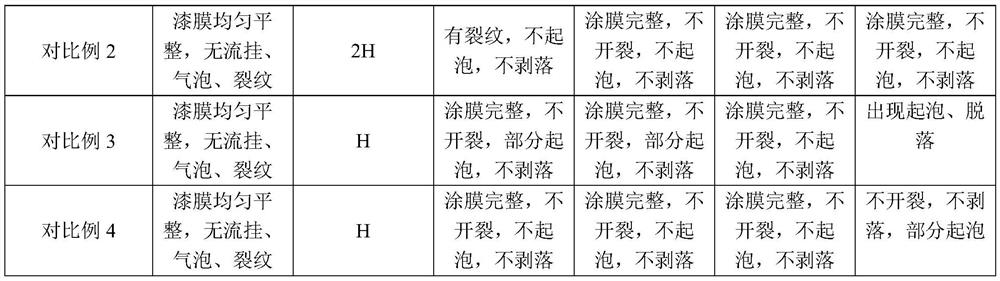

Examples

Embodiment 1

[0038] (1) Preparation of high-temperature carbonized black talc: 30g fineness of 1-2 μm black talc powder in N 2 Carry out high-temperature carbonization treatment with a vacuum tube furnace under the atmosphere. The heating rate is first increased from room temperature to 250 °C at 5 °C / min, and then raised to 1100 °C at 10 °C / min, and kept for 2 hours; after cooling to room temperature, take it out for use. Obtained 28.9g high-temperature carbonized black talc;

[0039] (2) Anti-corrosion coating preparation process: add 175g epoxy resin E-44 (Nantong Xingchen Synthetic Materials Co., Ltd.), 112g xylene and 28g n-butanol (the mass ratio of xylene and n-butanol is 4:1) in the container , then add 25g fineness of 1-2μm high-temperature carbonized black talc, after stirring for 0.5h at a rotating speed of 400r / min, add 25g fineness of 1250 mesh black talc, 1250 mesh 15g mica, 1250 mesh 15g barium sulfate, 1250 mesh 15g calcium carbonate, 30g pigment (20g titanium dioxide and ...

Embodiment 2

[0041] (1) Preparation of high-temperature carbonized black talc: 40g fineness of 1-2 μm black talc powder in N 2 Carry out high-temperature carbonization treatment with a vacuum tube furnace under the atmosphere. The heating rate is first increased from room temperature to 250 °C at 5 °C / min, and then raised to 1100 °C at 10 °C / min, and kept for 2 hours; after cooling to room temperature, take it out for use. Obtained 39.2g high-temperature carbonized black talc;

[0042] (2) Preparation process of anticorrosion coating: add 210g epoxy resin E-44 (Nantong Xingchen Synthetic Materials Co., Ltd.), 84g toluene and 21g ethanol (the mass ratio of toluene and ethanol is 4:1) in the container, then add 30g fine 1-2μm high-temperature carbonized black talc, after stirring at a speed of 400r / min for 0.5h, add 20g of black talc with a fineness of 1250 mesh, 15g of mica of 1250 mesh, 15g of barium sulfate of 1250 mesh, and 15g of calcium carbonate of 1250 mesh , 30g of pigment (15g of ...

Embodiment 3

[0044] (1) Preparation of high-temperature carbonized black talc: 30g fineness of 1-2 μm black talc powder in N 2 Carry out high-temperature carbonization treatment with a vacuum tube furnace under the atmosphere. The heating rate is first increased from room temperature to 250 °C at 5 °C / min, and then raised to 1100 °C at 10 °C / min, and kept for 2 hours; after cooling to room temperature, take it out for use. Obtain 28.5g high-temperature carbonized black talc;

[0045] (2) Anti-corrosion coating preparation process: add 150g epoxy resin E-44 (Nantong Xingchen Synthetic Materials Co., Ltd.), 140g xylene and 35g n-butanol (the mass ratio of xylene and n-butanol is 4:1) in the container , then add 15g fineness of 1-2μm high-temperature carbonized black talc, after stirring for 0.5h at a speed of 400r / min, add 25g fineness of 1000 mesh black talc, 1000 mesh 15g mica, 1000 mesh 15g barium sulfate, 1000 mesh 15g calcium carbonate, 20g pigment (10g iron oxide red and 10g lemon chr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com