Modified bituminous concrete with self-regulating temperature function

A technology of modified asphalt and self-controlling temperature, which is applied in the field of road asphalt to achieve the effects of low production cost, reduction of rutting diseases, and reduction of road surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

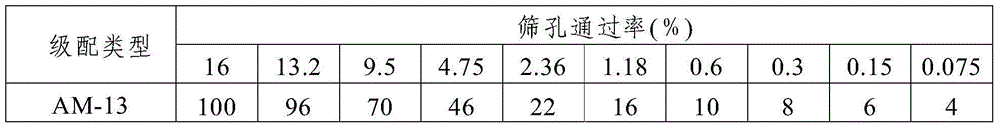

[0030] The modified asphalt concrete with self-temperature control function in this embodiment is made of the following raw materials in parts by weight: 100 parts of mineral aggregate, 4.6 parts of asphalt, 1 part of sepiolite powder, 1.2 parts of palygorskite powder, and 0.03 part of coupling agent; The asphalt is SBS modified asphalt, the coupling agent is a titanate coupling agent, the particle diameters of the sepiolite powder and palygorskite powder are both less than 0.075mm, and the gradation type of the mineral material is AM- Type 13 (see Table 1 for specific gradation composition).

[0031] Table 1 AM-13 type gradation composition

[0032]

[0033] The preparation method of the present embodiment modified asphalt concrete comprises the following steps:

[0034] Step 1. Mix the sepiolite powder and palygorskite powder evenly, add them into the coupling agent and stir evenly, then place them in a drying oven, and dry them at a temperature of 180°C for 3 hours to o...

Embodiment 2

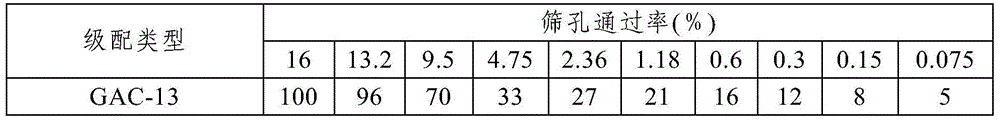

[0038] The modified asphalt concrete with self-temperature control function in this embodiment is made of the following raw materials in parts by weight: 100 parts of mineral aggregate, 3 parts of asphalt, 2.4 parts of sepiolite, 0.1 part of palygorskite, and 0.01 part of coupling agent; The asphalt is road petroleum asphalt, the coupling agent is an aluminate coupling agent, the particle diameters of the sepiolite powder and palygorskite powder are both less than 0.075mm, and the gradation type of the mineral material is GAC-13 type (see Table 2 for specific gradation composition).

[0039] Table 2 GAC-13 type gradation composition

[0040]

[0041] The preparation method of the present embodiment modified asphalt concrete comprises the following steps:

[0042] Step 1. Mix the sepiolite powder and palygorskite powder evenly, add them to the coupling agent and stir evenly, then place them in a drying oven, and dry them for 2 hours at a temperature of 160°C to obtain a mod...

Embodiment 3

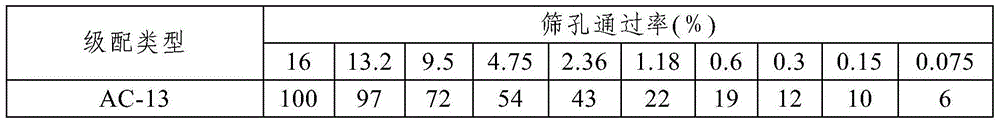

[0046] The modified asphalt concrete with road surface cooling function in this embodiment is made of the following raw materials in parts by weight: 100 parts of mineral aggregate, 7 parts of asphalt, 0.2 part of sepiolite, 2.0 parts of palygorskite, and 0.06 part of coupling agent; The asphalt is coal tar pitch, the coupling agent is an aluminate coupling agent, the particle diameters of the sepiolite powder and palygorskite powder are all less than 0.075mm, and the gradation type of the mineral material is AC-13 type ( The specific gradation composition is shown in Table 3).

[0047] Table 3 AC-13 type gradation composition

[0048]

[0049] The preparation method of the present embodiment modified asphalt concrete comprises the following steps:

[0050] Step 1. Mix the sepiolite powder and palygorskite powder evenly, add them into the coupling agent and stir evenly, then place them in a drying oven, and dry them at a temperature of 180°C for 3 hours to obtain a modifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com