Patents

Literature

162results about How to "Play a skeleton role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

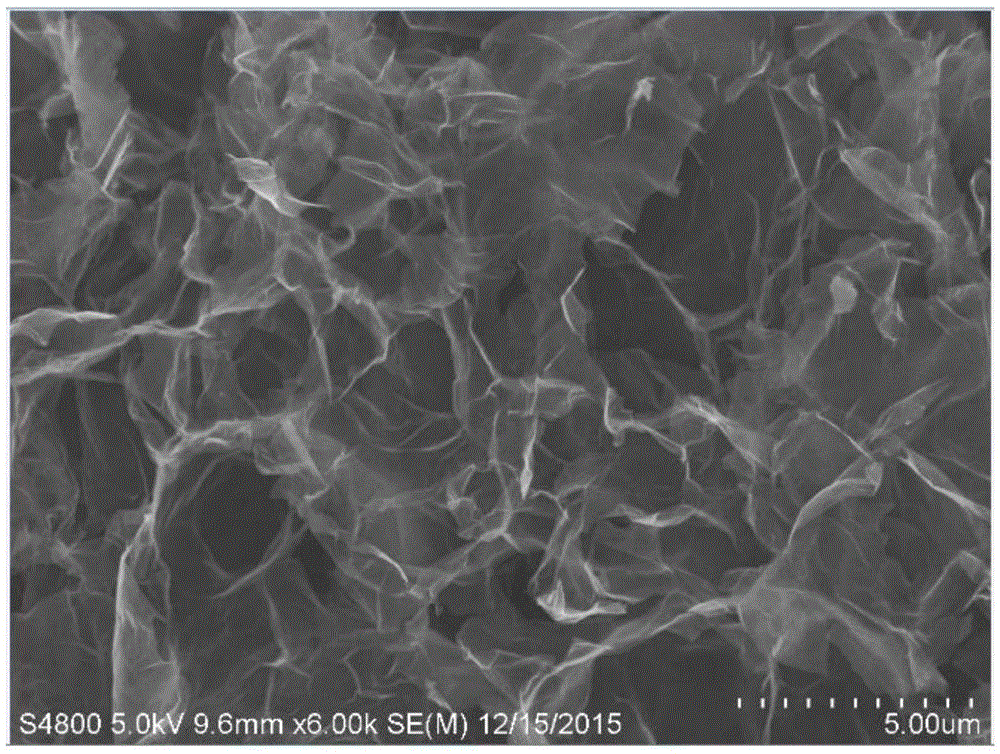

Preparation method of high-performance nitrogen-doped three-dimensional graphene

ActiveCN105645403AHigh nitrogen contentPlay a skeleton roleHybrid capacitor electrodesGrapheneNitrogen gasNitrogen doped graphene

The invention relates to the technical field of synthesizing of graphene materials and provides a preparation method of nitrogen-doped graphene. The preparation method includes: using an improved Hummers method to prepare continuous large-piece graphene oxide; using a hydrothermal method to prepare the graphene oxide into graphene of a porous three-dimensional structure; ultrasonically dispersing the graphene of the porous three-dimensional structure into an acid solution with the pH being 1-5, adding aniline, well mixing, adding ammonium persulfate, well mixing, and transferring the obtained mixed liquid into a teflon container for hydrothermal reaction so as to obtain a porous three-dimensional graphene-polyaniline compound; performing high-temperature treatment under nitrogen protection to allow polyaniline to decompose out nitrogen sources so as to obtain the nitrogen-doped porous three-dimensional graphene. The method has the advantages that the nitrogen-doped graphene with high nitrogen content can be prepared, the structure of the three-dimensional graphene can be kept, the obtained nitrogen-doped porous three-dimensional graphene is good in electrochemical performance and quite suitable for being used for producing a super capacitor, and the method is convenient to operate and beneficial to industrial popularization.

Owner:NANJING UNIV OF POSTS & TELECOMM

Formula of ceramic for insulator ceramic body and preparation method of the insulator ceramic body

InactiveCN102241506AHigh mechanical strengthImprove electrical performanceCeramicsPotassium dioxideMullite

The invention discloses a formula of a ceramic for an insulator ceramic body and a preparation method of the insulator ceramic body. Beneficial effects of a technical scheme of the invention comprise that the formula contains specific proportions of silicon oxide and alumina and the silicon oxide and the alumina are sintered into mullite to improve a mechanical strength and a hot and cold performance of a ceramic material, and silica can reduce a dry degree, a firing shrinkage degree and a bending deflection degree of a ceramic blank, play a supportive role in a ceramic blank and improve a mechanical strength of a ceramic blank; alumina can improve greatly a mechanical strength of ceramic blank; added potassium dioxide can reduce a sintering temperature, fill gaps of a ceramic blank and improve a compactness of a ceramic material, and a mechanical strength and an electrical performance of a ceramic blank; and through a cooperation with a preparation method, an insulator ceramic body obtains improved greatly hydrophobic properties, anti-fouling properties, insulating properties and mechanical properties.

Owner:SUZHOU AIJIAN ELECTRICAL PORCELAIN

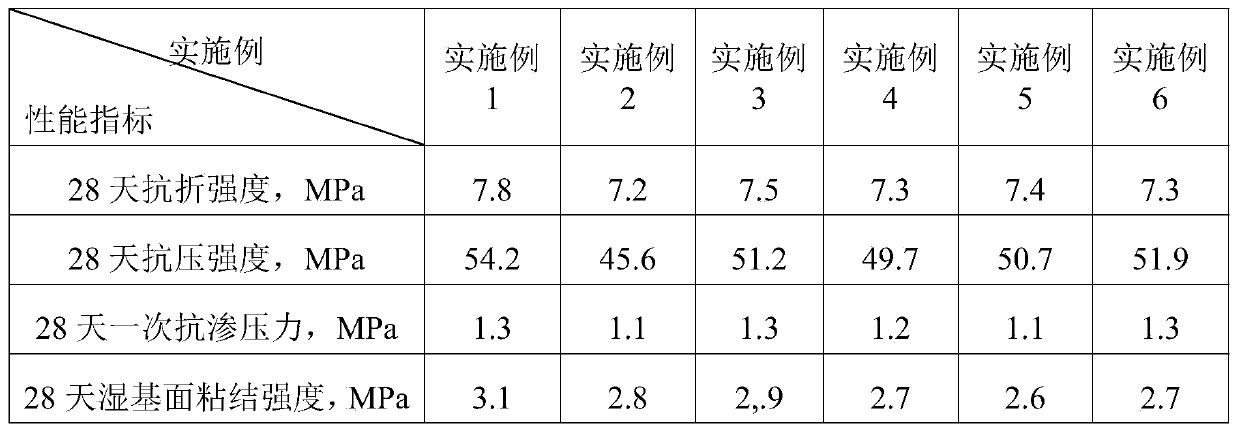

Waterproof and anti-corrosion repair mortar for polymer cement-based concrete structure

The invention relates to a waterproof and anti-corrosion repair mortar for a polymer cement-based concrete structure, in particular to a cement concrete repair material for a cement concrete structure, which is used for carrying out bonding reinforcement and repair on defects of municipal roads, municipal services, bridges and water conservancy projects (dams and gates). The waterproof and anti-corrosion repair mortar is prepared by mixed materials and water, and the mixed materials comprise the following components in parts by weight: 20-30 parts of portland cement, 0.01-0.05 part of high-performance water-reducing agent, 1-5 parts of high-aluminum cement, 15-30 parts of quartz sand, 25-60 parts of gravel and 1-3 parts of acrylic adhesive powder, 1-3 parts of fiber material, while the using amount of water accounts for 5-14% of the total parts of the mixed materials. Due to the adoption of the technical scheme, the waterproof and anti-corrosion repair mortar has the characteristics of good pressure resistance, high flexural strength, high bonding strength, good durability, convenient and fast construction, fast setting and early strength shrinkage control, and can greatly shorten the repair time and quickly resume the traffic in particular to roads.

Owner:卢建华

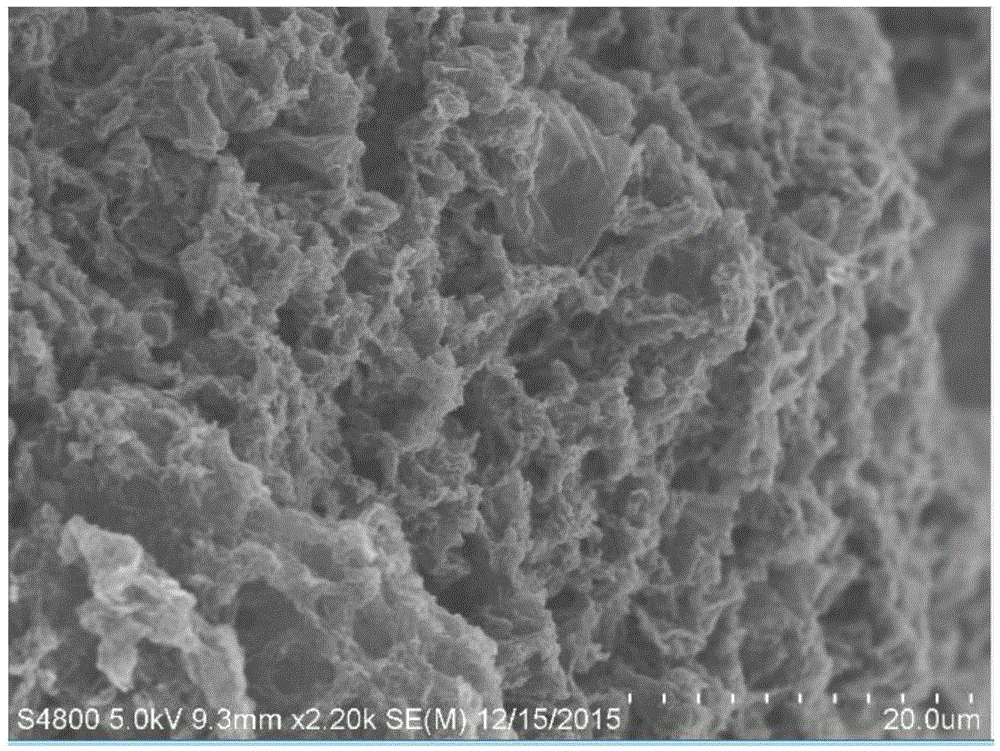

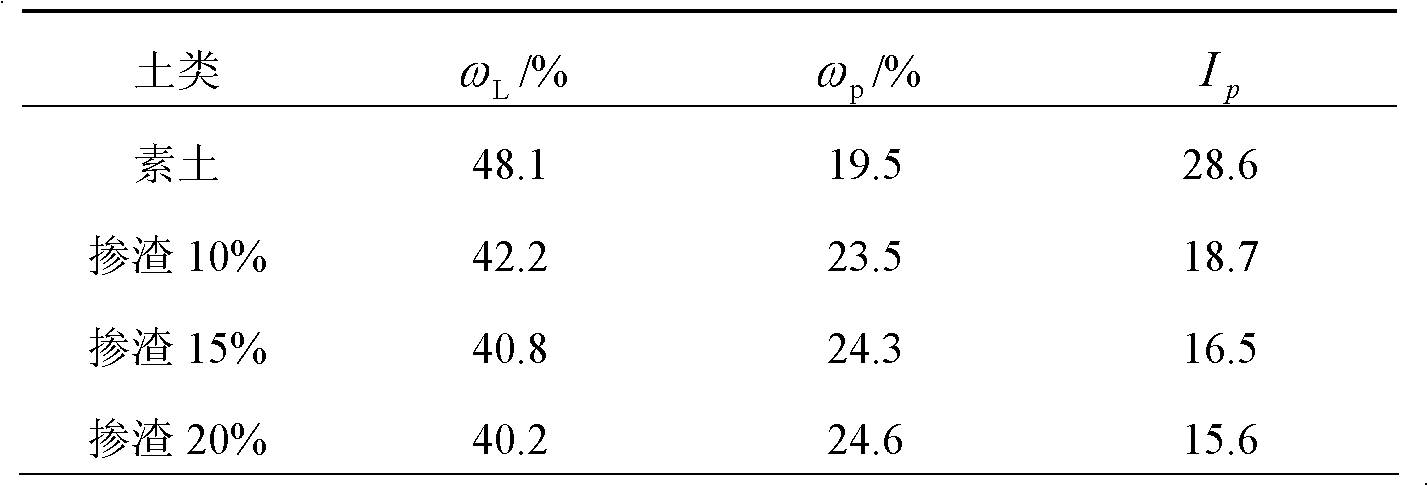

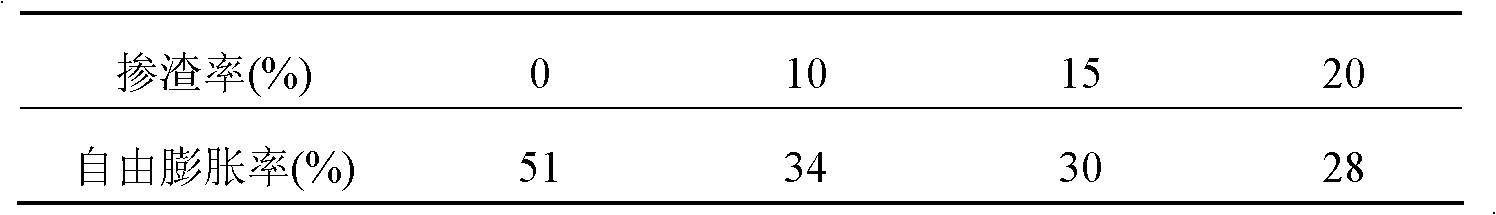

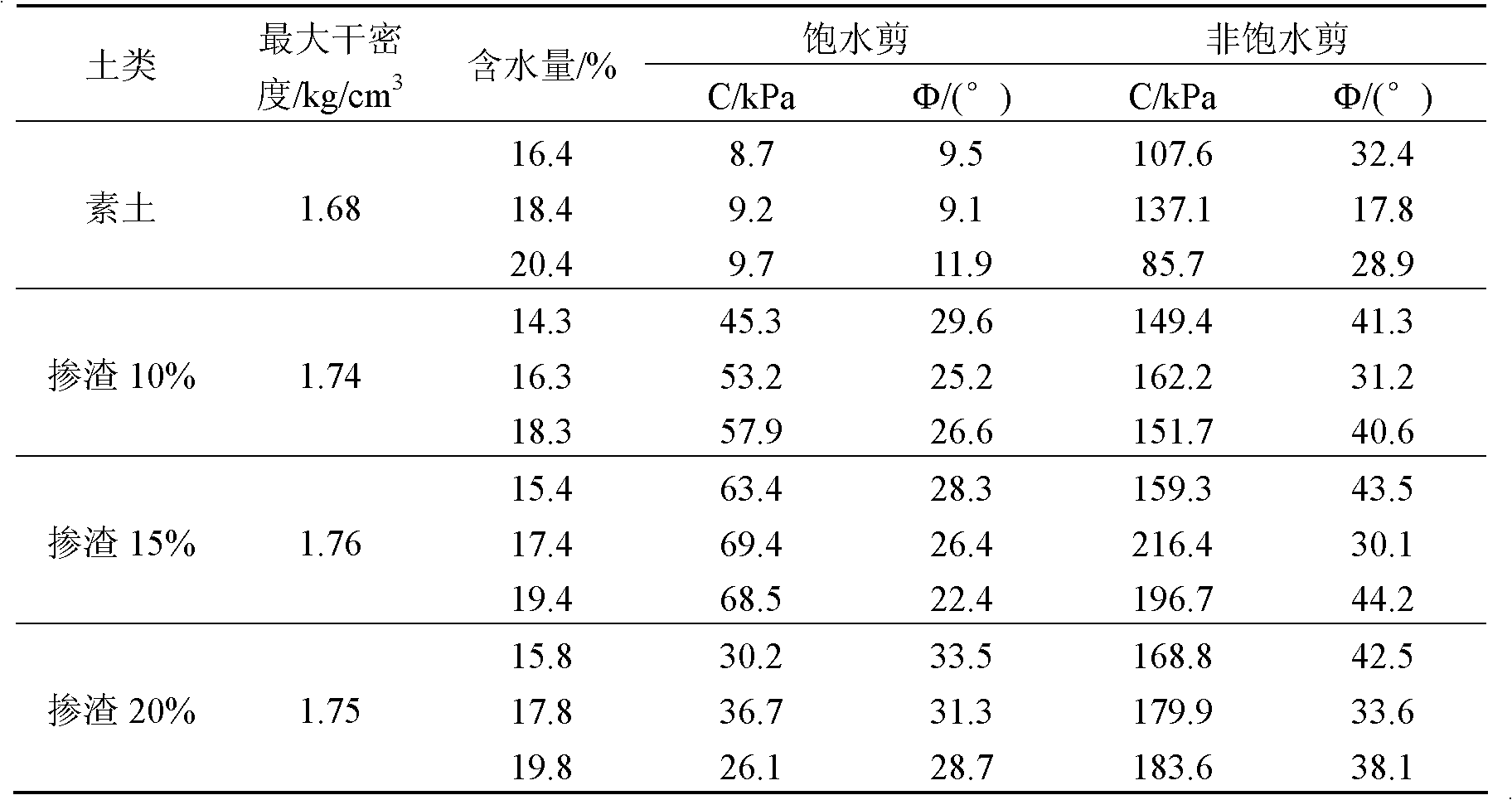

Method for improving expansive soil and construction method thereof

InactiveCN103184733AReduce swelling effectImprove water stabilityBuilding constructionsOrganic fertilisersSoil scienceSlag

The invention discloses a method for improving expansive soil and a construction method thereof. The method for improving expansive soil comprises the following steps of: 1) at the mass ratio of 15-20% of modifying agent and dry soil, evenly stirring the modifying agent and expansive soil to obtain composite soil; 2) determining the optimal moisture content of the composite soil; 3) regulating the moisture content of the composite soil obtained in step 1) to keep at the optimal moisture content; and under the natural condition, tightly covering materials to obtain the improved expansive soil. The method is characterized in that the modifying agent is blast furnace grain slag, and the blast furnace grain slag comprises the following main chemical ingredients in parts by mass: 38-43% of CaO, 33-38% of SiO2, 15-16% of Al2O3 and 4-8% of MgO. According to the improved expansive soil, the expansibility of the expansive soil can be eliminated, the water stability of the expansive soil is improved, and the strength required by the engineering is satisfied.

Owner:HOHAI UNIV

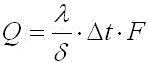

Concrete materials having functions of heat conduction and heat storage, and preparation method thereof

ActiveCN104386981AGood thermal conductivityConsistent granularityHeat-exchange elementsMicroballoon preparationHeat conductingGraphite

The invention discloses a concrete material having the functions of heat conduction and heat storage, and a preparation method thereof, and belongs to the technical field of building materials. The concrete material having the function of heat conduction and heat storage, disclosed by the invention, comprises 15-25 parts of cement, 15-25 parts of quartz sand, 15 -25 parts of natural pebbles, 10-15 parts of graphite, 20-30 parts of water, 1-3 parts of water reducing agents, 1-3 parts of expanding agents, 5-10 parts of phase-change polyethylene microcapsules and1-5 parts of aramid fibers. The preparation method comprises three steps: step 1) preparing cement slurry and performing the heat conduction on the cement slurry; step 2) preparing hot concrete slurry; step 3) pouring concrete. The working procedures are simple. Through the adoption of the concrete material and the preparation method, disclosed by the invention, the double purposes of good heat conducting effect and good heat storing effect for the concrete material having the functions of heat conduction and heat storage can be realized.

Owner:MAANSHAN NBWAVE HEAT ENERGY SCI

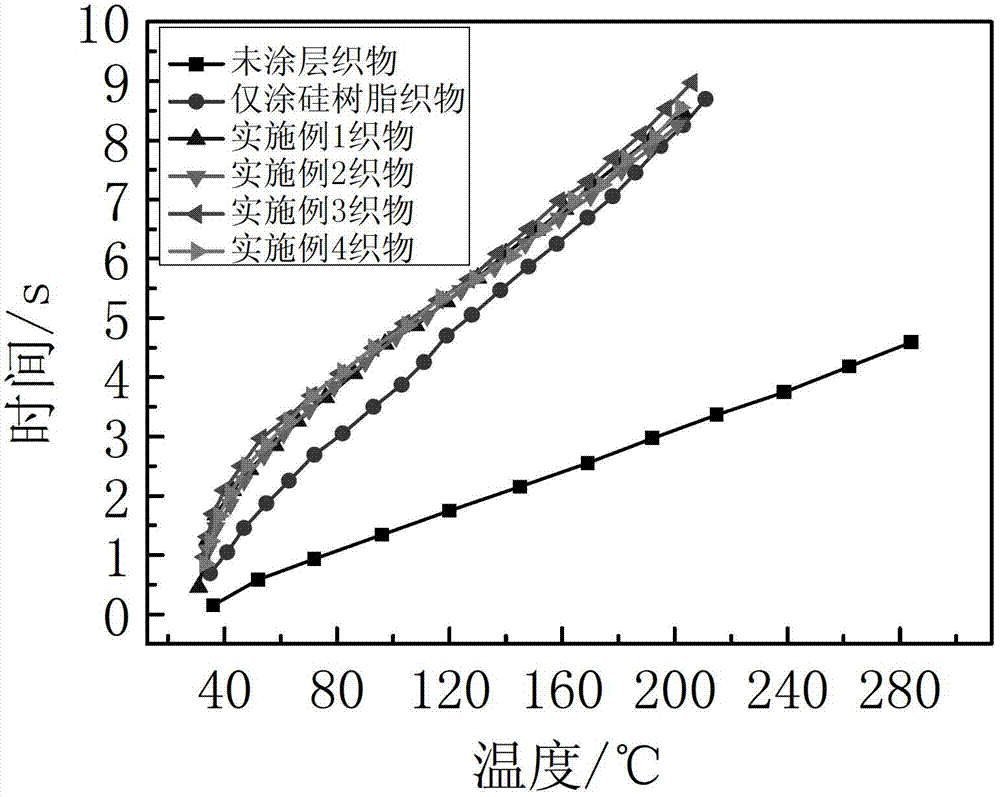

Heat-insulating and ablation-resistant glass fiber fabric and preparation method thereof

ActiveCN103205896AImprove heat resistanceImprove crack resistanceFibre treatmentResin coatingEngineering

The invention provides a heat-insulating and ablation-resistant glass fiber fabric and a preparation method thereof, belonging to the technical field of thermal protection fabrics and preparation thereof. The heat-insulating and ablation-resistant glass fiber fabric product comprises a fabric layer and coating layers on the front and back surfaces of the fabric layer, wherein the thicknesses of the coating layers on the front and back surfaces of the fabric layer are controlled at 30-80 micros; the fabric layer is made from glass fiber fabrics; the coating layers are composite organic silicon resin coating layers which are prepared by mixing an organic silicon resin solution, white carbon black, mica powder and the like in certain percentage by weight; a solute of the organic silicon resin solution is phenyl methyl silicone, a solvent of the organic silicon resin solution is dimethylbenzene, toluene or a mixture of the two, and the mass ratio of the solvent to the solute is 1:1; and a preparation method of a composite organic silicon resin coating layer solution comprises the following steps of: sequentially adding the white carbon black, the mica powder, wollastonite in powder and metallic oxide into the organic silicon resin solution, and stirring to ensure that the substances are uniformly dissolved. The heat-insulating and ablation-resistant glass fiber fabric is simple in process, easy to operate, and excellent in heat resistance, weather resistance, insulating property, reinforcement performance, scrubbing resistance and weathering resistance.

Owner:赵晓明 +1

Binder for micro-powder injection molding and application method thereof

The invention discloses binder for micro-powder injection molding and an application method thereof. The binder comprises the following components by mass percentage: 15% to 25% of industrial paraffin, 20% to 30% of Brazilian wax, 15% to 32% of high-density polyethylene, 10% to 20% of low-density polyethylene, 5% to 20% of vegetable oil and 1% to 7% of stearic acid. The application method of the binder comprises the following steps: mixing the binder and metal powder by a volume ratio of (50-58):(50-42); injection molding; de-fatting; and sintering to obtain a micro-metal part. The binder of the invention has lower viscosity but enough strength, and the binder has better injection molding capacity and green-pressing stability; the binder, due to the flowability, facilitates the micro-injection molding process and avoids the damage caused by demolding green bodies; the density of injection-molded green bodies is uniform; and the de-bound micro-metal parts resistant to cracks and deformation can be produced through the thermal de-binding process at low temperature and at a low heating rate.

Owner:CHANGSHA UNIVERSITY

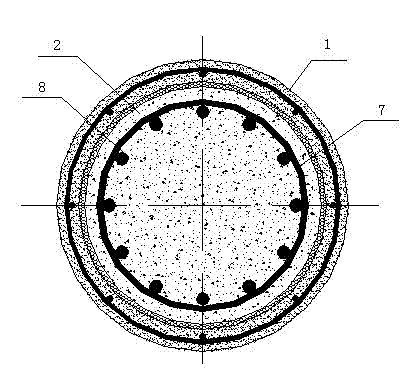

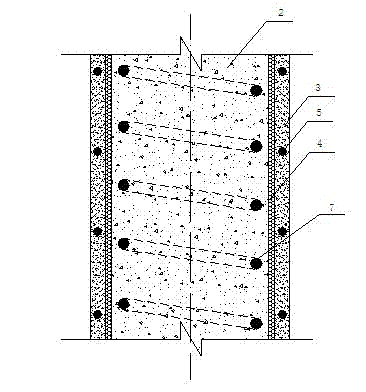

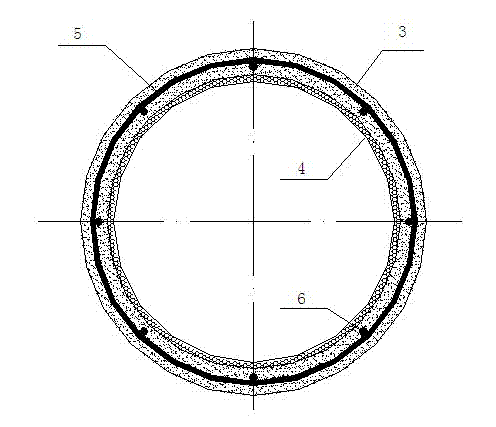

Composite casing pipe restrained reinforced concrete column

InactiveCN102776985AImprove the axial bearing capacityImprove bearing capacityStrutsBuilding reinforcementsReinforced concrete columnRebar

The invention discloses a composite casing pipe restrained reinforced concrete column which is characterized in that a composite casing pipe of the reinforced concrete column (2) is a combined body of a precast active power concrete outer casing pipe (3) and a precast active power concrete inner casing pipe (4). The composite casing pipe restrained reinforced concrete column provided by the invention has the characteristics of convenience in construction, low cost, high bearing force, shock-resistant property, obvious fireproof performance, excellent durability and the like, meanwhile, the composite casing pipe restrained reinforced concrete column can be used for saving resources and energy sources, and conforms to the sustainable development requirement.

Owner:HUNAN UNIV

Compound nylon diaphragm, and manufacturing method

InactiveCN1917255AHigh moisture absorptionStrong hydrophilic liquid retention performanceCell component detailsNon-woven fabricsNickel cadmiumHot melt

The diaphragm is a hot melted and rolled product from non-woven fabrics of nylon backing material in one, two or three layers. In total weight of raw fiber, nylon fiber is in 40-60 wt%, and hot melted composite fiber with dual constituents in low melting point is in 40-60 wt%; or, nylon fiber is in 40-60 wt%, hot melted composite fiber with dual constituents in low melting point is in 30-45 wt%, superfine vinylon fiber is in 10-15 wt%. The method includes steps: using different techniques prepares non-woven fabrics of nylon backing material in different structures; using hot rolling machine with three rollers rolls non-woven fabrics of nylon backing material in one, two or three layers. Features are: simple method, small investment easy of obtaining materials and low cost. The diaphragm is accorded with requirements of nickel cadmium SC cell: high capacitance 1500man-2000man, and discharging in 10C-15C high multiplying factors.

Owner:CHANGZHOU KANGJIE SPECIAL NON WOVEN FABRICS CO LTD

Method for improving swelling soil by using alkali residue and construction method for alkali- residue-modified soil

InactiveCN102352622AReduce engineering costsEngineering Disaster ReductionBuilding constructionsOrganic fertilisersSoil scienceEnvironmental engineering

The invention discloses a method for improving swelling soil by using alkali residue and a construction method for the alkali residue modified soil. The method for improving the swelling soil by using the alkali residue comprises the following steps of: 1, mixing the alkali residue and the swelling soil uniformly in a mass ratio of the alkali residue to dry soil of 30 to 40 percent to obtain mixed soil; 2, determining the best moisture content of the mixed soil through a heavy compaction test in 'Road Geotechnical Test Regulation' JTJ-051-93; and 3, adjusting the moisture content of the mixed soil obtained in the step 1 to maintain the moisture content to be the best moisture content, mixing uniformly, and enclosing the materials under the natural condition for 5 to 7 days to obtain the alkali residue modified soil. The construction method comprises the following steps of: unloading the alkali residue modified soil after improvement into an appointed place; paving uniformly, wherein the paving thickness is 30 to 35 cm; after detecting that the moisture content meets the best moisture content requirement, statically pressing the soil quickly and leveling accurately by using a road roller; and rolling the road surface to the required compactedness. The improved swelling soil can eliminate expansibility of the swelling soil, improve water stability of the swelling soil and meet strength required by engineering.

Owner:HOHAI UNIV

Fast maintenance method for furnace lining of deslagging surface of converter

InactiveCN108660282AImproves washout propertiesEasy dischargeManufacturing convertersProcess efficiency improvementSmelting processTemperature difference

The invention provides a fast maintenance method for a furnace lining of a deslagging surface of a converter. The fast maintenance method for the furnace lining of the deslagging surface of the converter is applied to the technical field of iron and steel smelting processes, and comprises the maintenance steps of deslagging the converter, and remaining high-temperature residual furnace slags in the converter; adding bar steel scraps having temperature difference with the residual furnace slags into the converter, precipitating and condensing high-melting-point mineral substances in the furnaceslags under the action of the temperature difference of the bar steel scraps and the residual furnace slags, and adhering to the deslagging surface of the converter so as to replace a fettling material; and statically cooling the converter, and after finishing cooling, accomplishing the fast maintenance operation for the furnace lining of the deslagging surface of the converter. According to thefast maintenance method for the furnace lining of the deslagging surface of the converter provided by the invention, no cost input of the fettling material is required, the problems of the adverse effect on fettling and the environment pollution due to too long or too short sintering time are avoided, the molten steel end point components are ensured, the fettling time is effectively shortened, the converter operability is improved, and meanwhile, the fast maintenance method for the furnace lining of the deslagging surface of the converter has the characteristics of fast maintenance speed, good fettling effect, low fettling cost, safety, environment protection and the like.

Owner:MAANSHAN IRON & STEEL CO LTD

Method for improving expansive soil by waste foundry sand and construction method

InactiveCN101423353AReduce engineering costsEngineering Disaster ReductionSoil preservationFoundryChemical reaction

The invention discloses a method for modifying expansive soil by waste foundry sand, which comprises the following steps: step one, according to the proportion of between 1 to 5 and 1 to 3 of the mass of the waste foundry sand to the mass of dry soil of a soil body needing to be improved, weighing the waste foundry sand and the soil body to be improved, and mixing the waste foundry sand and the soil body evenly, wherein the components of the waste foundry sand in mass percentage are: 41 percent of quartz sand, 37 percent of coal dust, 19 percent of clay and 3 percent of iron; step two, determining the optimum moisture content; and step three, adding water to the mixed soil obtained in the step one, and stirring the mixture evenly to obtain waste foundry sand improved expansive soil. The method for using the waste foundry sand to improve the expansive soil is utilized to obtain a construction method for using the waste foundry sand to improve the expansive soil. With a method for constructing the waste foundry sand improved expansive soil which is obtained by the method for improving the expansive soil by the waste foundry sand, the obtained waste foundry sand improved expansive soil is paved as a surface improved layer the thickness of which is between 30 and 60 centimeters on the construction surface; and then the surface improved layer is kept for 3 to 7 days under natural condition, and the improved soil body has a chemical reaction with the components of the waste foundry sand to eliminate or reduce the swell-shrink characteristics of the soil body in the improved layer, thus the strength required by an engineering can be achieved.

Owner:HOHAI UNIV

Cement-based capillary crystalline waterproof coating and preparation method thereof

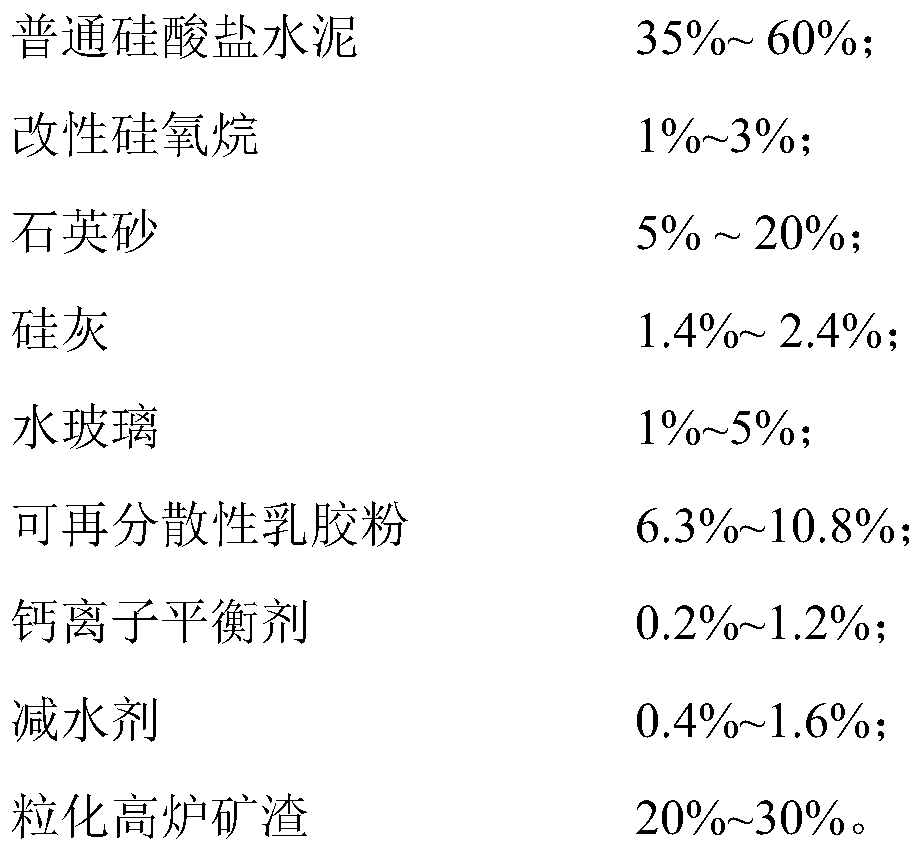

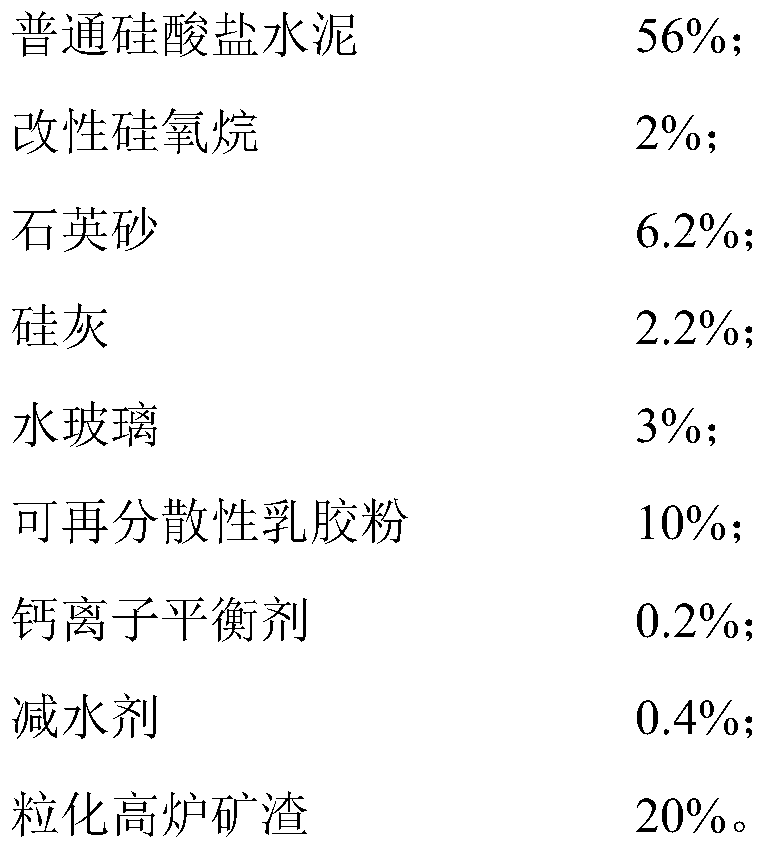

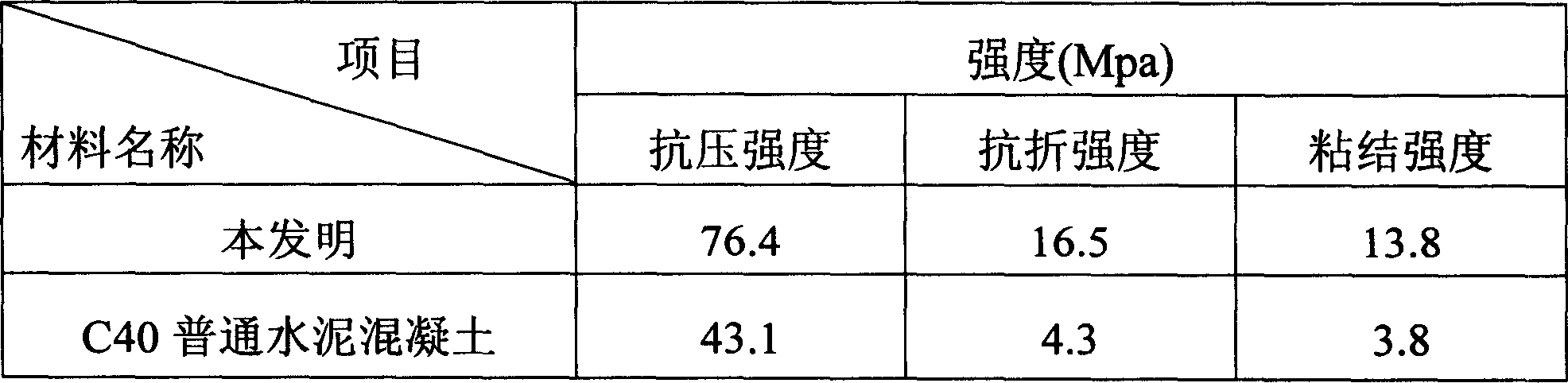

InactiveCN110922134AImprove impermeabilityImprove anti-seepage and waterproof effectSolid waste managementSilica fumeSiloxane

The invention discloses a cement-based capillary crystalline waterproof coating and a preparation method thereof, and belongs to the technical field of building waterproof materials. The cement-basedcapillary crystalline waterproof coating is composed of, by weight, 35%-60% of ordinary Portland cement; 1%-3% of a modified siloxane, 5%-20% of quartz sand, 1.4%-2.4% of silica fume, 1%-5% of water glass, 6.3%-10.8% of redispersible latex powder, 0.2%-1.2% of a calcium ion balancing agent, 0.4%-1.6% of a water reducing agent and 20%-30% of granulated blast furnace slag. By adopting the technicalscheme, the anti-permeability and waterproof performance, the bonding performance and the flexural and compressive strength of the obtained cement-based capillary crystalline waterproof coating can beeffectively improved, the anti-permeability and waterproof effects can be further improved when the cement-based capillary crystalline waterproof coating is applied to the surface of concrete, and therefore the service life of the concrete can be prolonged.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

Method for preparing plaster evacuated mould

InactiveCN101531026AReduce water-cement ratioReduce solubilitySolid waste managementMixing operation control apparatusWater basedTime extension

This invention discloses a method for preparing plaster evacuated mould, including following steps: weighting and mixing the raw material based on that the mass ratio of plaster: inorganic filling material: glass fiber: high efficiency water reducing agent (mass ratio) is 80-90:10-20:3-4:0.5:2.5; weighting water based on the cement water ratio of o.45 to 0.65 by calculating with mass, then pouring the prepared raw materials into a stirring pot, at the same time, opening the stirrer, quickly stirring for 1 to 3 min with the rotating speed of 100 to 300 r / min; coating mineral oil at the four sides and the bottom of the module, then pouring the mixed ground paste into the mould, screeding the upper surface of the plaster evacuated mould, fetching out the concretionary plaster evacuated mould from the module, finally naturally drying the mould. The product prepared by this invention has short time for drying, enlarged delayed coagulation time and can improve the intensity and the hard wearing performance.

Owner:贵州金三利科技建材有限公司

Repairing material for cement concrete structure

The invention relates to a cement concrete patching material which is prepared from mixture and water, the weight portions of the mixture include silicate cement 13-17, high efficiency water reducing agent 0.06-0.2, exciting agent 0.6-5.3, yellow sand 13-28, crushed stone 26-50, polyvinyl alcohol 0.1-0.2, fibrous material 0.4-3.3, the amount of water accounts to 5-14% of the total weight parts of the mixture.

Owner:芮志平

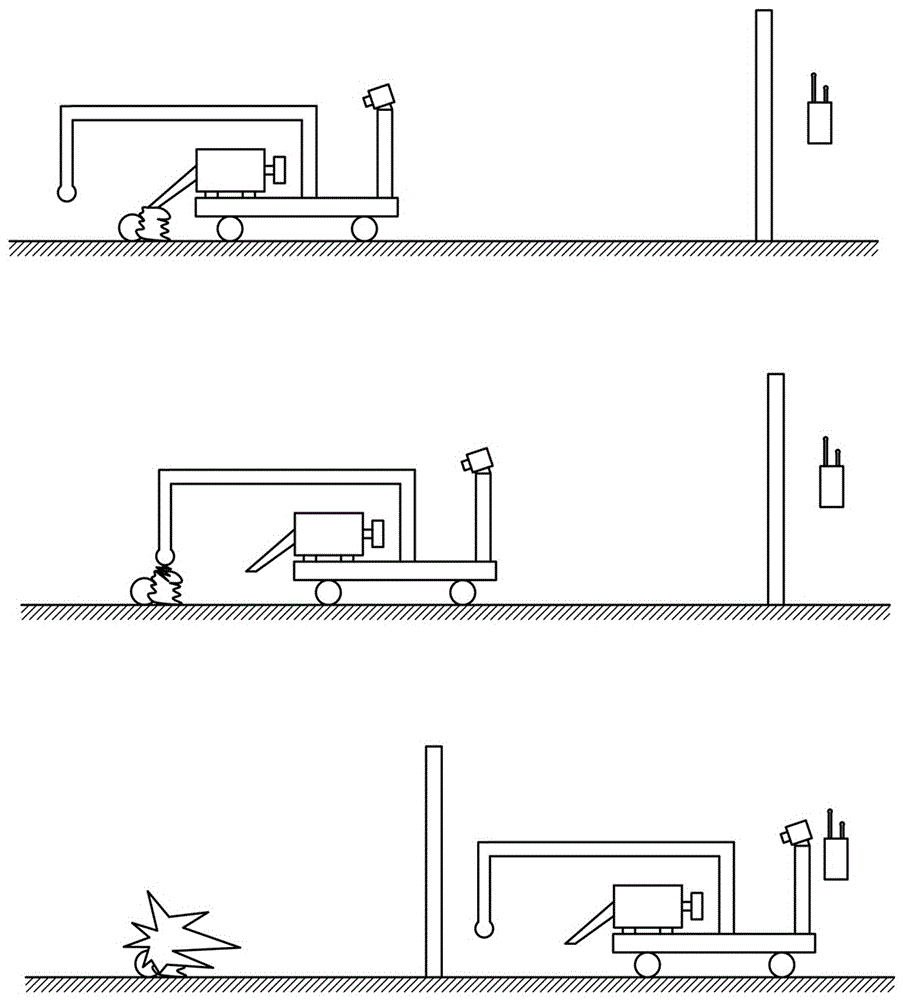

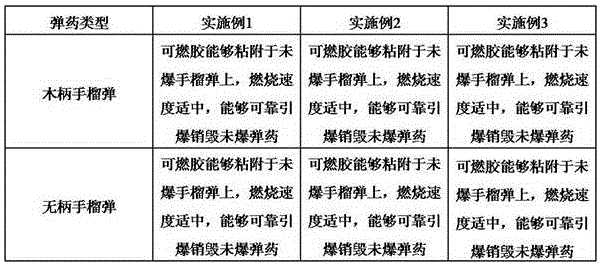

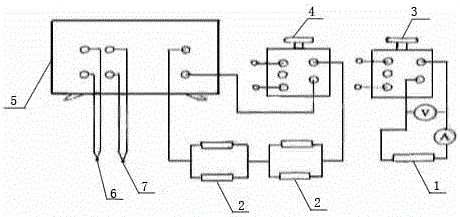

Combustible glue used for destroying unexploded ordnance and preparation method and application thereof

The invention provides combustible glue used for destroying unexploded ordnance and a preparation method and application thereof. The combustible glue is prepared through the following steps that Al powder and Fe3O4 powder are evenly mixed to obtain Al / Fe3O4 mixed powder; lac is dissolved in absolute ethyl alcohol to obtain a lac absolute ethyl alcohol solution with the mass concentration being 5%-6%; the Al / Fe3O4 mixed powder is added into the lac absolute ethyl alcohol solution, and the Al / Fe3O4 mixed powder and the absolute ethyl alcohol solution are stirred to be evenly mixed; glass fiber powder is added and stirred to be evenly mixed; and expandable graphite is added and stirred to be evenly mixed to obtain the combustible glue. The mass ratio of the Al powder to the Fe3O4 powder is 7-8 to 15. The massic volume ratio of the Al / Fe3O4 mixed powder to the lac absolute ethyl alcohol solution is 1g to 2-3 mL. The adding amount of the glass fiber powder is 1%-3% of the Al / Fe3O4 mixed powder by mass. The adding amount of the expandable graphite is 1%-3% of the Al / Fe3O4 mixed powder by mass. The combustible glue is low in combustion speed, large in combustion heat output and long in combustion duration, and can heat explosives in the unexploded ordnance once being ignited, and it can be ensured that the explosives in the unexploded ordnance are reliably detonated.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

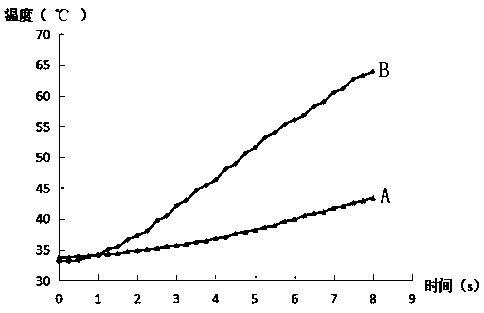

Thermoplastic polymer composite material containing nano diamond ene and preparation method of thermoplastic polymer composite material

The invention discloses a thermoplastic polymer composite material containing nano diamond ene, and belongs to the technical field of high polymer materials. The thermoplastic polymer composite material is prepared from, by weight, 90-95 parts of a thermoplastic polymer and 5-10 parts of nano diamond ene. A corresponding preparation method of the thermoplastic polymer composite material comprises the following steps that 1, the thermoplastic polymer and nano diamond ene are mixed in proportion; 2, melt extruding, drawing, cooling, pelletizing and drying are conducted on a double-screw extruder, and then the thermoplastic polymer composite material is obtained. According to the thermoplastic polymer composite material, nano diamond ene is added into the thermoplastic polymer, the heat conductivity coefficient of the polymer material is 5-10 W / (m.K), and the heat conductivity of the overall polymer material is improved; the composite material has a lamellar single crystal structure and is high in strength and good in wear resistance, the strength of the polymer material is improved, and the service life of the polymer material is prolonged; the preparation method of the composite material is simple and low in production cost, and only the double-screw extruder is utilized as the equipment.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

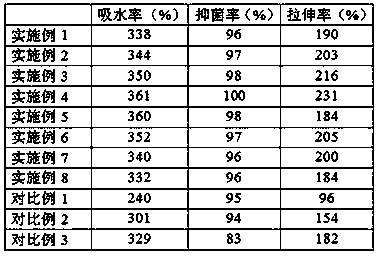

Hemostatic antibacterial dressing for vascular surgery department

ActiveCN109453418ANo secondary traumaImprove mechanical propertiesAbsorbent padsBandagesPolyvinyl alcoholMedicine

The invention discloses a hemostatic antibacterial dressing for vascular surgery department, belonging to the technical field of medical dressing. The hemostatic antibacterial dressing concretely comprises a fiber layer I and a gel layer from outside to inside, and a fiber layer II is arranged in the gel layer; the gel layer is prepared from the following raw materials in parts by weight: 50-60 parts of acrylic acid, 40-50 parts of N-methylol acrylamide, 10-20 parts of polyvinyl alcohol, 1-2 parts of aluminium glycinate, 3-8 parts of talcum powder, 0.5-1 part of nano silver, 1-2 parts of polypropylene fibers, 5-8 parts of gelatin, 5-12 parts of polyvinylpyrrolidone, 0.5-1.2 parts of N, N-methylenebisacrylamide, 0.5-1 part of sodium persulfate and 200-260 parts of water. The antibacterial dressing is excellent in performance and long in service life.

Owner:NANYANG FIRST PEOPLES HOSPITAL

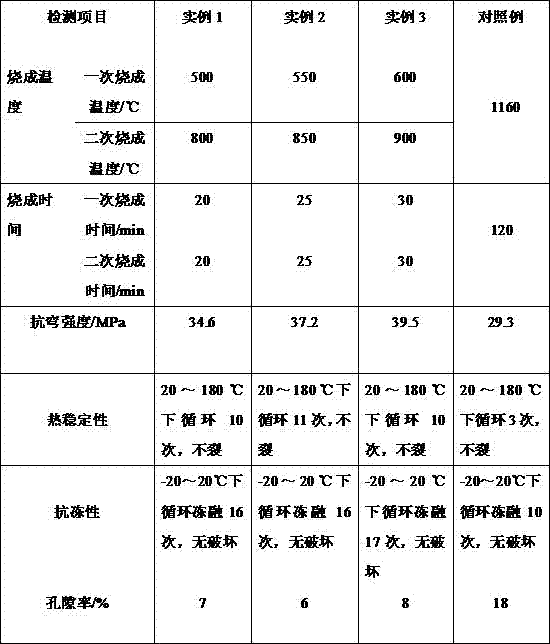

Low-temperature-fired antique glazed tile and its preparation method

InactiveCN107417254ALow melting pointEvenly heatedCeramic materials productionClaywaresFree coolingRoom temperature

The invention discloses a low-temperature-fired antique glazed tile and a preparation method thereof, belonging to the field of building materials. The method comprises the following steps: weighing the raw materials of the low-temperature-fired antique glazed tile, adding water for batch mixing and carrying out aging so as to obtain an aged mixture; compacting the aged mixture to form a blank and carrying out demolding so as to obtain a tile blank; subjecting the tile blank to drying and pre-firing so as to obtain a pre-fired tile blank; then carrying out fumigation, cooling and drying so as to obtain a fumigated tile blank; weighing raw materials for a glaze of the low-temperature-fired antique glazed tile and carrying out batch mixing so as to obtain the glaze; coating the surface of the fumigated tile blank with the obtained glaze and carrying out drying so as to obtain a glazed tile blank; and carrying out heating and heat preservation twice and then carrying out natural cooling to room temperature so as to obtain the low-temperature-fired antique glazed tile. The invention has the beneficial effects that the low-temperature-fired antique glazed tile is low in firing temperature, short in firing time, low in energy consumption, high in product density and good in mechanical properties, has excellent application prospects, and is worthy of promotion and application.

Owner:YUHUAN DEGU NEW MATERIAL TECH CO LTD

Baking-free antique black brick and preparation method thereof

The invention relates to a baking-free antique black brick and a preparation method thereof. The baking-free antique black brick comprises a basic layer and a surface layer, wherein the basic layer iscomprises clay residues, recycled aggregates and cement; the surface layer comprises white portland cement, slag powder, recycled fine aggregates, black iron oxide and green iron oxide. The clay residues are adopted to serve as one of the production raw materials of the baking-free antique black brick, the utilization rate and the additional value of the clay residues are improved, and the utilization of building waste resources is improved; moreover, the baking-free antique black brick prepared from the method can meet various performance indexes, and is suitable for masonry engineering anddecoration engineering; the production process is simple, the disposal efficiency is high, the treatment capacity is high, the field application effect is good, and the baking-free antique black brickhas good economic benefits and social benefits.

Owner:深圳市绿志新型建材研究院有限公司

Corrosion resistant paint for hydraulic cylinder and preparation method of corrosion resistant paint

InactiveCN104804642AStrong adhesionNot easy to fall offAnti-corrosive paintsEpoxy resin coatingsCross linkerTrichloroethylene

The invention discloses corrosion resistant paint for a hydraulic cylinder and a preparation method of the corrosion resistant paint. The corrosion resistant paint for the hydraulic cylinder, provided by the invention includes the following components in parts by weight: 60-63 parts of epoxy-modified organic silicone resin, 40-45 parts of trichloro ethylene, 20-30 parts of bisphenol A epoxy resin, 12-14 parts of mica powder, 10-13 parts of an amino resin cross-linking agent, 7-9 parts of polydimethylsiloxane, 12-14 parts of silicone resin, 3-5 parts of rust-proof lubricating oil, 5-7 parts of copper powder, 2-4 parts of clay, 1-3 parts of ceramic powder, 2-5 parts of beryllium oxide, 1-3 parts of triethylene tetramine, 5-7 parts of zirconium oxide and 3-5 parts of auxiliaries.

Owner:SUZHOU JIN YUAN OIL MACHINERY

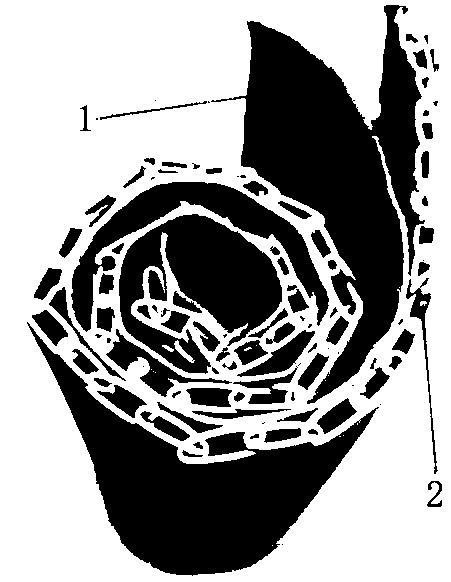

Aerogel composite aramid non-woven fabric thermal protection material and preparation method thereof

The invention discloses an aerogel composite aramid non-woven fabric thermal protection material and a preparation method thereof. The preparation method of the aerogel composite aramid non-woven fabric thermal protection material comprises the following steps of uniformly mixing a silicon source, organic solvent and water, dropwise adding in acid catalysts to regulate the pH, and then heating, mixing and temperature-keeping the mixture to obtain a silicon sol; regulating the temperature of the silicon sol, adding in alkali catalysts to regulate the pH, spraying the pH-regulated silicon sol onto an aramid non-woven fabric, standing the sprayed aramid non-woven fabric to obtain a wet gel-aramid non-woven fabric complex; lining macrocyclic polyester spiral drying screens into the wet gel-aramid non-woven fabric complex, rolling the lined wet gel-aramid non-woven fabric complex, immersing the fabric roll into ageing solution for ageing, performing supercritical drying on the aged fabric roll inside a supercritical drying device to obtain the aerogel composite aramid non-woven fabric thermal protection material. The prepared aerogel composite aramid non-woven fabric thermal protectionmaterial is excellent in properties such as thermal insulation, fire resistance, light weight and breathability.

Owner:浙江鹏辰造纸研究所有限公司

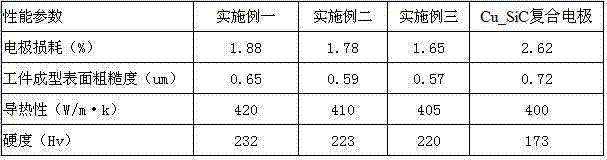

Composite material tool electrode for electrolytic deposition and electric spark and preparation method thereof

ActiveCN103878455AHigh specific heat capacityHigh hardnessElectrical-based machining electrodesMachined surfaceHardness

The invention discloses a composite material tool electrode for electrolytic deposition and electric spark and a preparation method of the composite material tool electrode, and belongs to the technical field of electrical discharge machining of electric spark. The composite material tool electrode for electrolytic deposition and electric spark is characterized by comprising, by weight, 16-18% of SiC particles, 14-16% of TiB2 particles, and the balance copper as a base body, and the SiC particles and the TiB2 particles are embedded in the base body. Due to the fact that the SiC particles and the TiB2 particles are added to the copper base body, compared with the method that only the SiC particles are added in the initial research stage, on the premise of not changing the total adding amount, the specific heat capacity of the tool electrode is improved by 10%, the coefficient of thermal expansion is lowered by 3%, the hardness is improved by 5%, and therefore the loss of the electrode under same electrical discharge machining parameters is lowered by 7%, and the roughness of a machined surface is lowered by 2%.

Owner:SHANDONG UNIV OF TECH

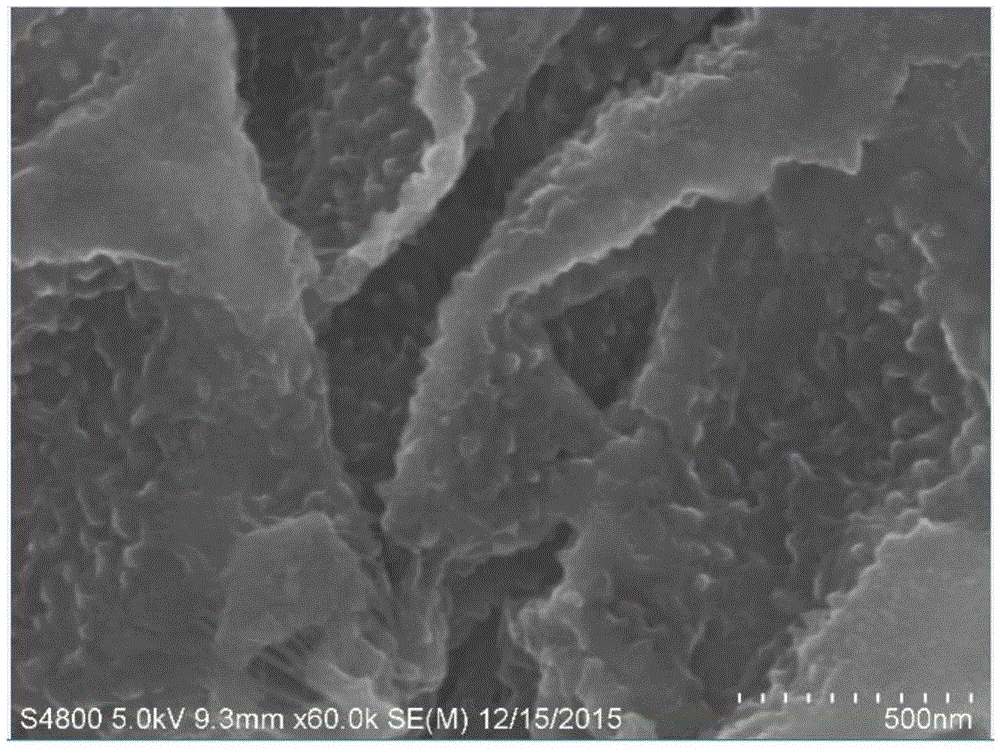

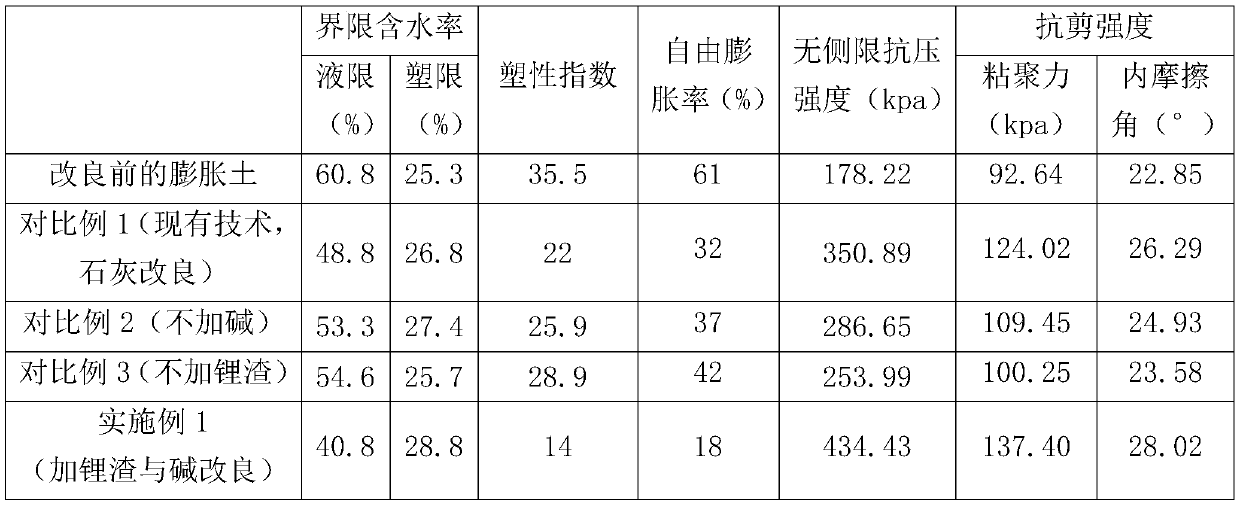

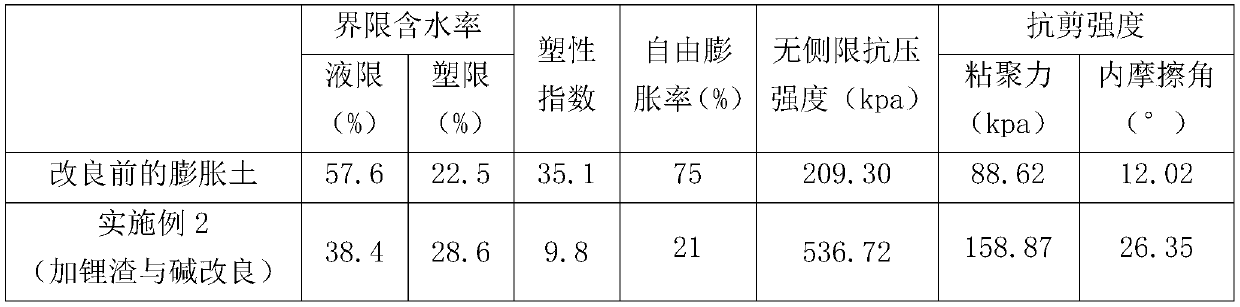

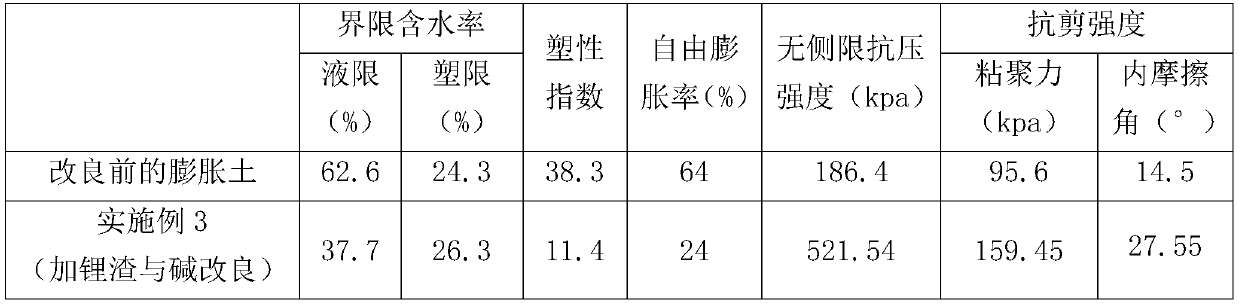

Improved expansive soil, and preparation method, construction method and application thereof

ActiveCN111139078AEvenly distributedGood physical propertiesRoadwaysBuilding constructionsSoil scienceEnvironmental engineering

The invention relates to improved expansive soil, and a preparation method, a construction method and application thereof. The improved expansive soil comprises 12-16% by mass of lithium slag, 4% by mass of alkali and 80-84% by mass of expansive soil of a to-be-improved soil body, and the improved expansive soil is formed by uniformly mixing the lithium slag, the alkali and the expansive soil. According to the invention, the waste lithium slag is used for improving the expansive soil under the condition of alkali doping, so engineering cost is saved, the lithium slag is reutilized, environmentis protected, and a novel improvement method is developed for reducing engineering disasters caused by expansive soil; the waste lithium slag is added as coarse aggregate to function as a skeleton effect and to improve mixture gradation, and can be uniformly distributed in the expansive soil, so excellent physical performance is obtained and physical improvement is realized; and the improved expansive soil is substantially reduced in expansibility, cracks caused by a dry-wet cycle can be eliminated, water stability can be improved, and strength required by engineering can be met.

Owner:HOHAI UNIV

Scratch-resistant self-cleaning silicon PU finish paint and preparation method thereof

InactiveCN113072851AImprove adhesionGood suspensionPolyurea/polyurethane coatingsPolymer scienceAcrylic resin

The invention provides a scratch-resistant self-cleaning silicon PU finish paint. The scratch-resistant self-cleaning silicon PU finish paint comprises a component A and a component B in a mass ratio of 10:1. The component A comprises the following components in parts by weight: 20-25 parts of water-based hydroxy acrylic resin, 8-12 parts of water-based polyurethane resin, 3-8 parts of silicon modified polyurethane resin, 3-8 parts of silicon modified acrylic resin, 0.2-1 part of a water-based wetting dispersant, 0.2-1 part of a water-based defoaming agent, 0.2-1 part of an adhesive, 4-12 parts of filler and 25-30 parts of water. The component B comprises a curing agent, mamely, 10 parts of a hexamethylene diisocyanate (HDI) tripolymer. The scratch-resistant self-cleaning silicon PU finish paint is flexible and good in adhesive force, and can resist friction for more than 100 thousand times. The surface of the silicon PU finish paint is hydrophobic and oleophobic, so that dirt can hardly remain on the surface of the finish paint, and a court is in a new state after being washed by rainwater.

Owner:湖南盛天新材料有限公司

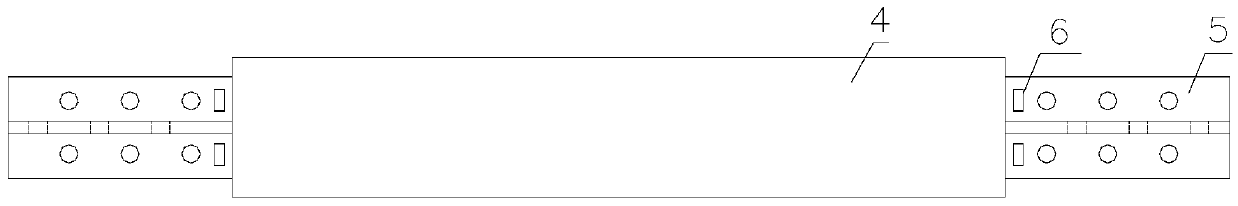

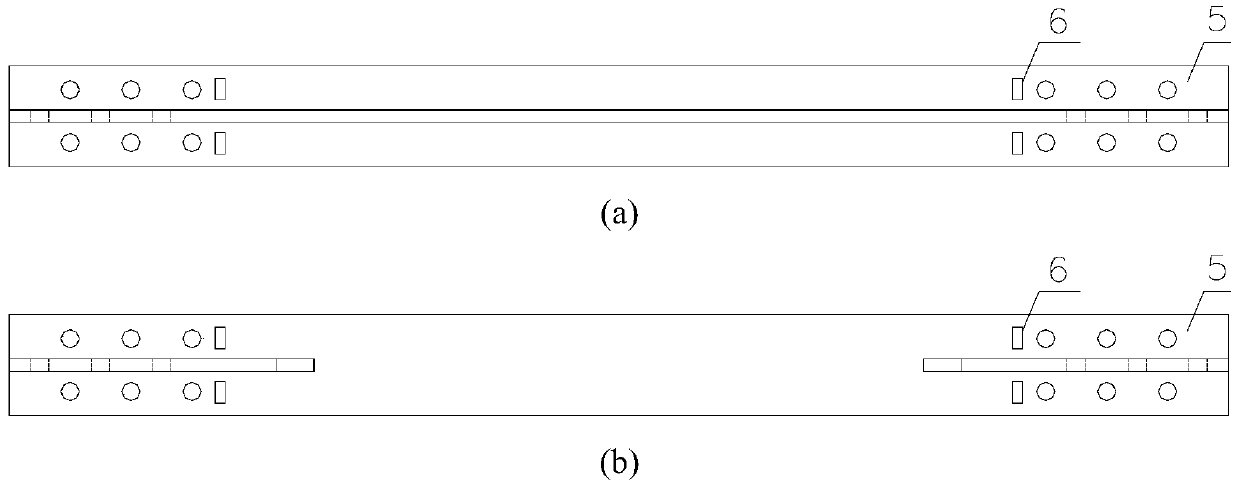

Fiber-reinforced composite material-wood-steel combined buckling-restrained brace

InactiveCN105507441AShort manufacturing cycleSmall additional weightShock proofingConstruction engineeringFiber-reinforced composite

The invention discloses a fiber-reinforced composite material-wood-steel combined buckling-restrained brace. The fiber-reinforced composite material-wood-steel combined buckling-restrained brace comprises an inner core and an outer combined restraint sleeving the inner core, wherein the outer combined restraint comprises cushion blocks, a plurality of protecting plates, wood blocks and a fiber-reinforced composite material, the protecting plates are arranged on the periphery of the inner core longitudinally, each two adjacent protecting plates are connected through the cushion block arranged at the outer ends of the cushion blocks so as to form an enclosed structure accommodating the inner core, the wood blocks are arranged on the outer surfaces of the protecting plates connectively, and the fiber-reinforced composite material is wound on the integral outside of the cushion blocks, the protecting plates and the wood blocks longitudinally. The fiber-reinforced composite material-wood-steel combined buckling-restrained brace has the advantages of low self weight, short manufacturing period, convenience in transportation, simplicity in mounting and replacement and the like while bearing and energy-dissipating capabilities are guaranteed, can be applied to multi-story buildings and high-rise buildings with concrete structures and steel structures and can solve the problem of safety of building structures under the action of earthquakes.

Owner:SOUTHEAST UNIV

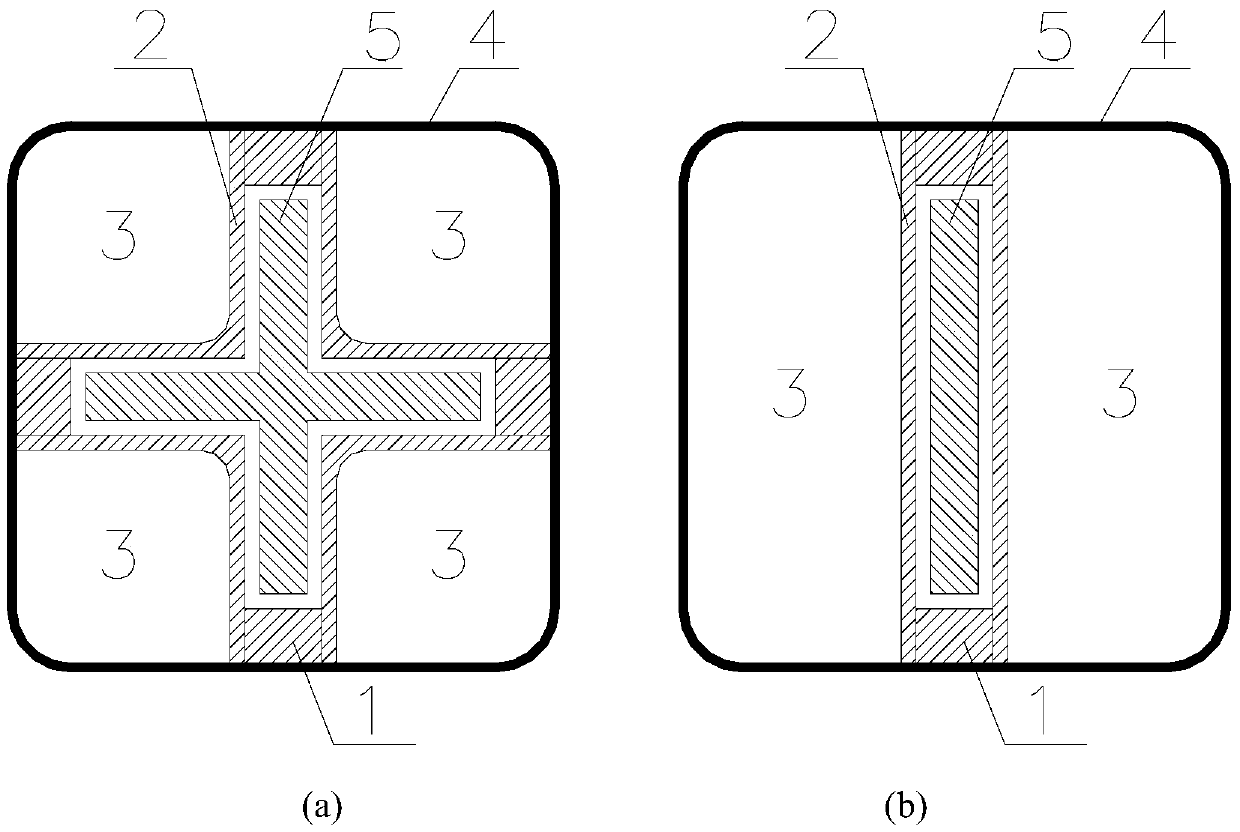

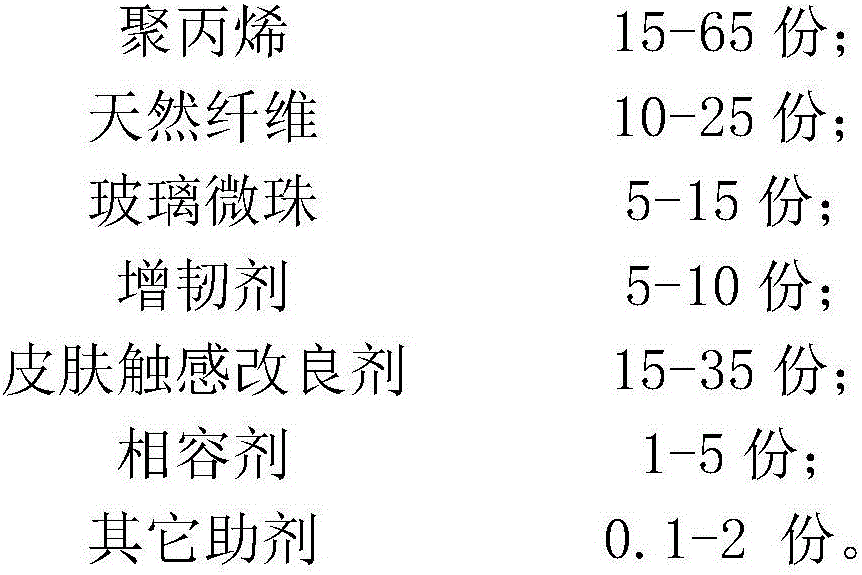

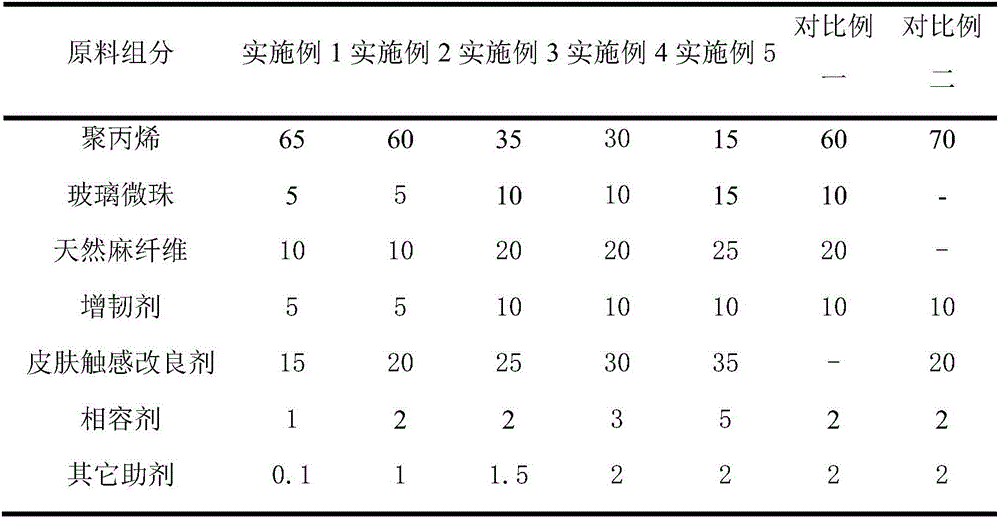

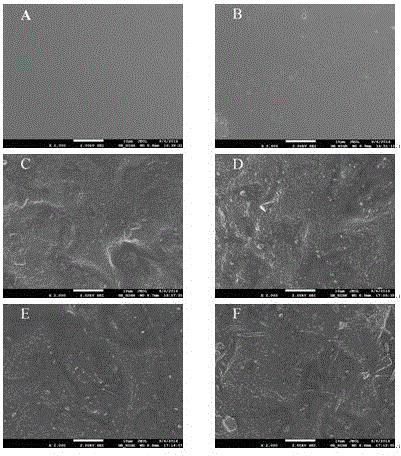

Low-density super-matte bionic polypropylene composite and preparation method thereof

The invention relates to the technical field of polymers, in particular to low-density super-matte bionic polypropylene composite and a preparation method thereof; the low-density super-matte bionic polypropylene composite is made from polypropylene, a flexibilizer, natural fibers, a skin tactility improver, glass beads, a compatibilizer, and other aids; the materials are mixed well and added into a parallel twin-screw extruder for melting, and the low-density super-matte bionic polypropylene composite is prepared via extruding and granulating. By adding the natural fibers, the glass beads, the compatibilizer, the skin tactility improver and the like during preparation, the prepared polypropylene composite is given the features such as ultralow gloss, low density, scratch resistance, good skin tactility and low shrinkage; in addition, the low-density super-matte bionic polypropylene composite retains the skin tactility, exhibits good rigidity and toughness, has a density of less than 1.02 g / cm<3>, and meets the development trend to light weight.

Owner:ORINKO NEW MATERIAL CO LTD

Water-permeable floor tiles

InactiveCN104909712AGood water permeabilityImprove hydrophilic abilityCeramic materials productionClaywaresMontmorilloniteMetal fibers

The invention discloses water-permeable floor tiles and relates to the technical field of building materials. The water-permeable floor tiles are prepared from the following raw materials in parts by weight: 25-35 parts of coal cinder, 25-35 parts of calcium carbonate, 5-10 parts of montmorillonite clay, 5-10 parts of diatomite and 1-2 parts of metal fiber. The length of the metal fiber is 0.8-1mm, the fineness of the coal cinder is 7-20 meshes, the fineness of the diatomite is 36-40 meshes, and the fineness of the montmorillonite clay and calcium carbonate is 120-220 meshes respectively. The water-permeable floor tiles can be used for solving the problem of the existing floor tiles that the water permeability is poor.

Owner:LIUZHOU PUYA TRADE

Heat insulation coating for building and preparation method of heat insulation coating

InactiveCN107141902AImprove insulation effectStrong adhesionFireproof paintsAntifouling/underwater paintsThermoplasticFiber

The invention discloses a heat insulation coating for a building and a preparation method of the heat insulation coating, and relates to the field of building materials. The heat insulation coating is prepared from the following raw materials in parts: 90 to 100 parts of styrene-acrylic emulsion, 55 to 65 parts of glass wool, 45 to 55 parts of short fiber, 40 to 45 parts of thermoplastic expanded hollow microspheres, 25 to 30 parts of nano aluminium silicate, 20 to 25 parts of nano calcium carbonate, 10 to 20 parts of nano titanium dioxide, 10 to 20 parts of a filler, 10 to 15 parts of an auxiliary and 150 to 180 parts of water. A coating film formed by the coating is good in heat insulation and preservation effect, high in bonding strength, difficult to crack and high in abrasion resistance; furthermore, the preparation method is scientific and simple; the energy consumption is greatly reduced; meanwhile, the heat insulation coating is free of pollution to the environment.

Owner:HEFEI YAKELI NEW BUILDING MATERIAL CO LTD

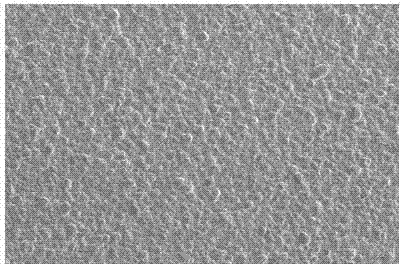

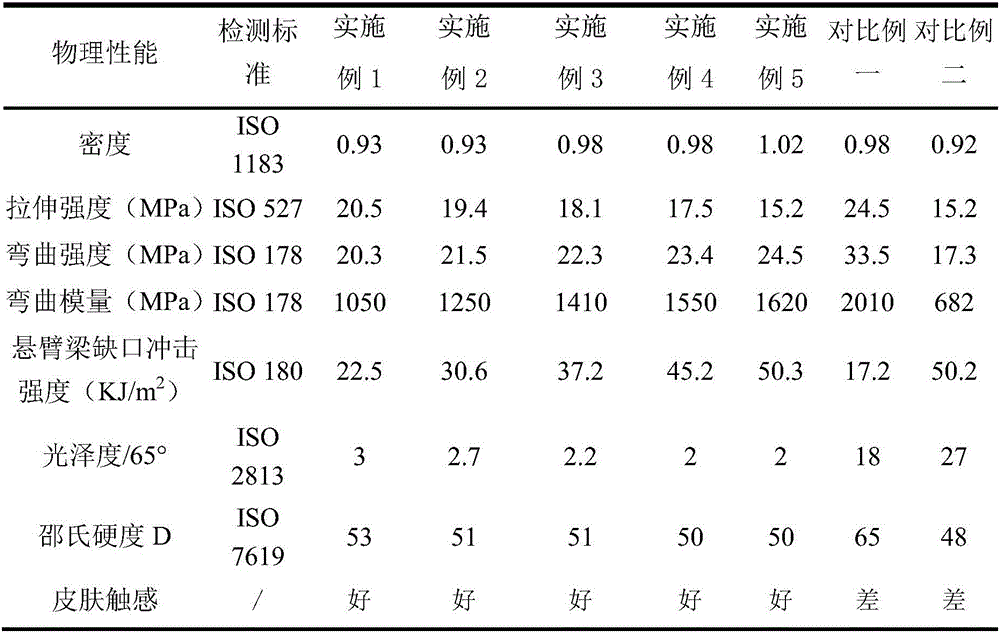

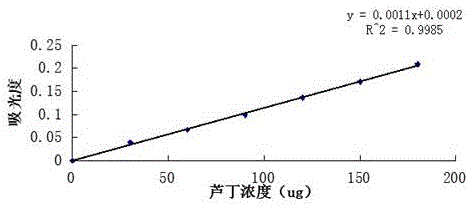

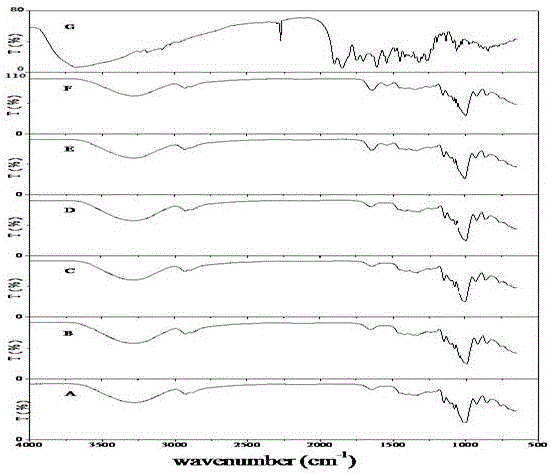

Corn starch film containing rutin composite nanoparticles and preparation method of corn starch film

The invention provides a corn starch film containing rutin composite nanoparticles and a preparation method of the corn starch film. The rutin composite nanoparticles in the corn starch film are prepared by embedding rutin in corn prolamine. The rutin composite nanoparticles have the performance of slowly releasing the rutin, so that the corn starch film prepared by the method has long-acting oxidation resistance. According to the corn starch film disclosed by the invention, instruments of a physical property determinator, a Fourier transform infrared spectrum analyzer, a scanning electron microscope and the like are adopted for analyzing the representational structure of the corn starch film, and the light transmittance, the water solubility, the moisture permeability, the surface color, the mechanical performance, the slow release efficiency and the oxidation resistance of the corn starch film are determinated. A result shows that after the rutin composite nanoparticles are added in the corn starch film, the property of the corn starch film is improved to some extent; discovered by determination on the property of the corn starch film, hydrogen bonds and electrostatic interaction can be formed by the rutin composite nanoparticles and a starch substrate, the property of the corn starch film is strengthened to a certain degree, and the corn starch film is enabled to have a certain slow release ratio and stronger oxidation resistance.

Owner:QINGDAO AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com