Thermoplastic polymer composite material containing nano diamond ene and preparation method of thermoplastic polymer composite material

A technology of thermoplastic polymer and nanodiamondene, which is applied in the field of thermoplastic polymer composite materials and its preparation, can solve the problems of affecting the working state of parts, low heat dissipation efficiency, small thermal conductivity, etc., achieve low production cost, prolong service life, The effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

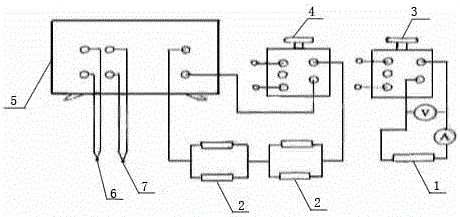

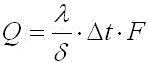

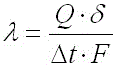

Image

Examples

Embodiment 1

[0022] Embodiment 1 Preparation of nanodiamondene

[0023] The steps are: (1) Preliminary crushing: send the diamond raw material into the ball mill shaping barrel, after passing through the back and forth ball mill crushing and shaping process of steel balls of different particle sizes under high-speed rotation, pass through a certain mesh mesh at the receiving port of the ball mill The mesh of the mesh is not less than 70 mesh, and the ball mill shaping time is generally controlled within 1-5 hours, and the 70 mesh coarse material is automatically returned to the ball mill for ball mill shaping again; the collected particles above 70 mesh are passed through multi-layer The vibrating sieve machine is used for the primary particle size classification, and the sieve meshes are arranged from high to low from 100 mesh to 800 mesh. The time of vibrating sieve is generally 30min-2h. The material can be used for other purposes. At the same time, in order to ensure the accuracy of th...

Embodiment 2

[0029] A thermoplastic polymer composite material containing nanodiamondene, made of the following raw materials in parts by weight: 95 parts of polyethylene, 5 parts of nanodiamondene, the weight percentage of nanodiamondene is composed of nanodiamonds with a particle size of 10-20nm 20% nanodiamondene, 30% nanodiamondene with a particle size of 200-250nm, and 50% nanodiamondene with a particle size of 400-500nm.

[0030] Nanodiamantene is surface functionalized as follows: add nanodiamantene to the mixture of ethanol and acetone, the volume ratio of ethanol to acetone is 1: 1, ultrasonically disperse for 1h, add titanate coupling agent or silane coupling agent, at 40°C, stirring for 48 hours, the addition of titanate coupling agent or silane coupling agent is 1% of nanodiamantene; the weight ratio of nanodiamantene to the mixed solution is 1:1.

[0031] Polyethylene is subjected to the following surface functionalization treatment: the polyethylene raw material is immersed i...

Embodiment 3

[0034] A thermoplastic polymer composite material containing nanodiamondene is made of the following raw materials in parts by weight: 95 parts of polymethyl methacrylate, 5 parts of nanodiamondene, and the weight percentage of nanodiamondene is composed of: the particle size is 10- 10% of 20nm nano-diamantene, 40% of nano-diamantene with a particle size of 200-250nm, and 50% of nano-diamantene with a particle size of 400-500nm.

[0035] Nanodiamantene is surface functionalized as follows: Add nanodiamantene to a mixture of ethanol and acetone, the volume ratio of ethanol to acetone is 1: 1, ultrasonically disperse for 2 hours, add titanate coupling agent or silane coupling agent, at 60 ° C, stirring for 24 hours, the addition of titanate coupling agent or silane coupling agent is 4% of nano-diamantene; the weight ratio of nano-diamantene to the mixed solution is 1.2:1.

[0036] Polymethyl methacrylate is subjected to the following surface functionalization treatment: the poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com