Fiber-reinforced composite material-wood-steel combined buckling-restrained brace

A technology of anti-buckling energy consumption and composite materials, applied in the direction of earthquake resistance, building components, etc., can solve the problems of difficult transportation, installation and replacement, limited energy consumption capacity, long production cycle, etc., and achieve convenient wrapping of fiber-reinforced composite materials, The effect of suppressing the overall buckling, easy installation and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

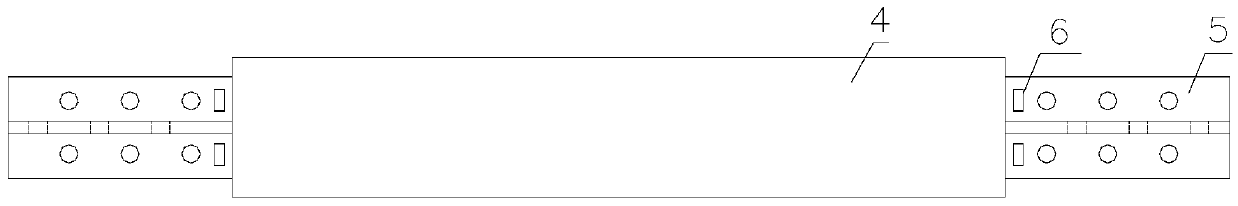

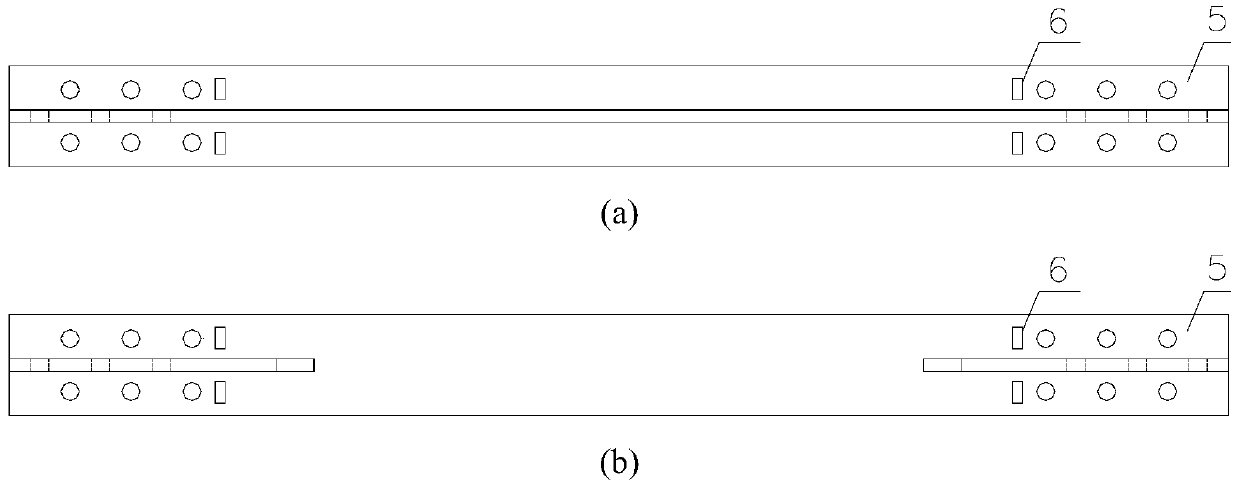

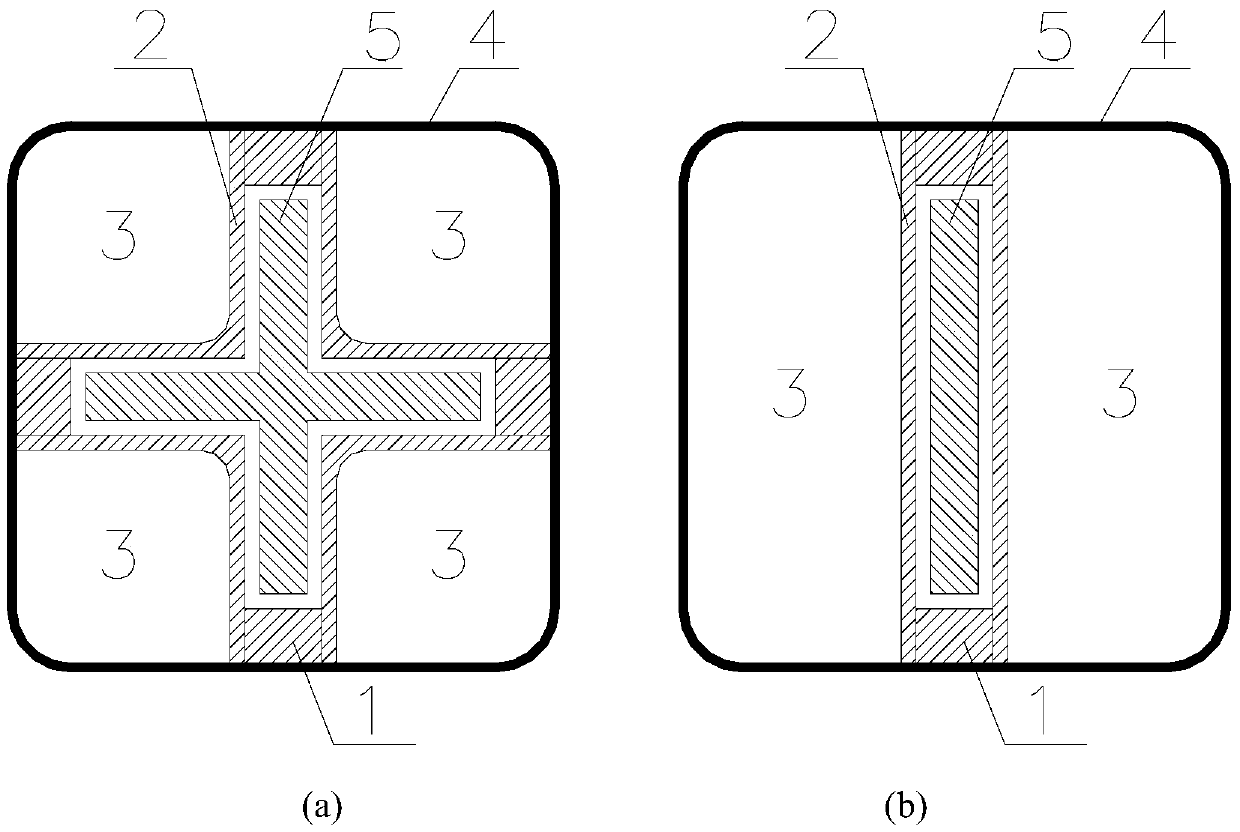

[0020] Since the anti-buckling energy-dissipating support of the inline cross-section inner core is similar to the specific implementation of the buckling-resistant energy-dissipating support of the cross-section inner core, the present invention will be further described below in conjunction with an embodiment of a cross-section inner core and the accompanying drawings.

[0021] see figure 1 , figure 2 (a) and image 3 (a), an embodiment of the anti-buckling energy-dissipating support consists of four spacers 1, four protective plates 2, four wooden blocks 3, fiber-reinforced composite materials 4, an inner core 5 and 8 limit blocks 6, The inner core 5 can adopt a steel plate member. Wherein the specific shape of each part, the connection of interrelationship and the purpose thereof are as follows.

[0022] see image 3 (a), in this embodiment, the protective plate 2 is an angle steel, the cross section of the wooden block 3 is a square processed by chamfering, and holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com