Integrated forming method and device for segmented blade

A molding method and blade technology, which can be applied to other household appliances, household appliances, household components, etc., can solve the problems of low structural strength of segmented blade joints, low blade bearing capacity, low production efficiency, etc., to shorten the production cycle, The effect of improving blade quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In the following, the present invention will be described in detail with reference to the accompanying drawings and specific implementation examples. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. After reading the present invention, those skilled in the art all fall into the appended claims of the present application to the amendments of various equivalent forms of the present invention limited range.

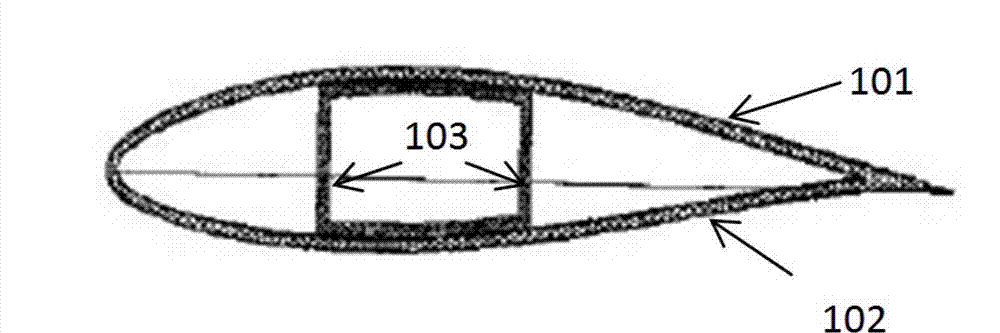

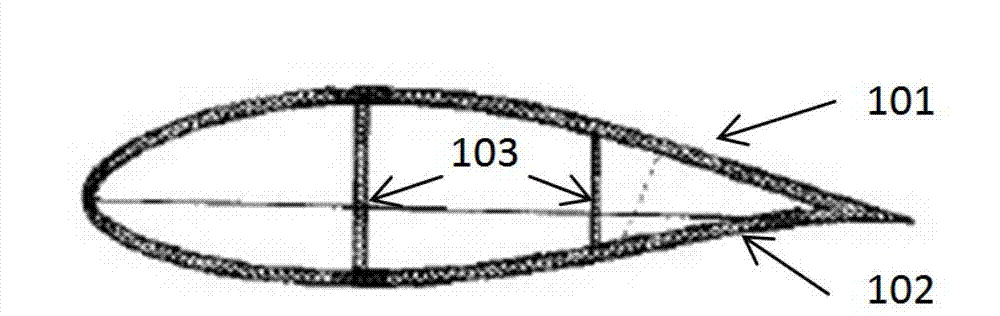

[0050] figure 1 , figure 2 It is the cross-sectional structure of common blades. The upper and lower shells 101, 102 are made respectively by using the traditional manufacturing method, and then the shear web 103 is bonded with an adhesive.

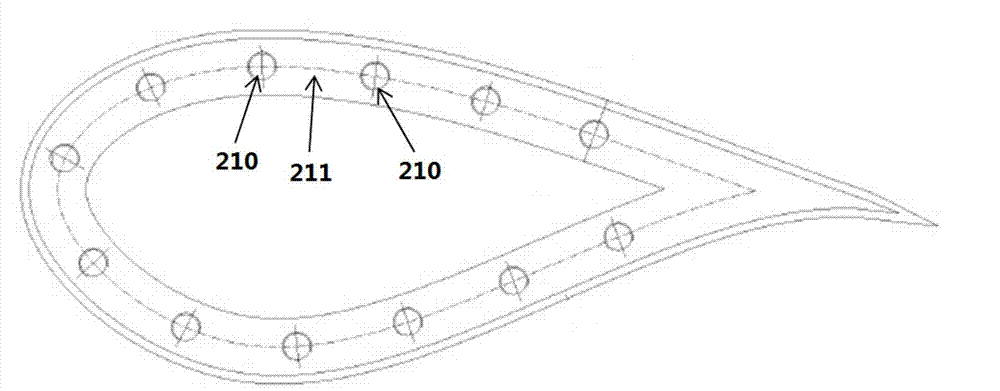

[0051] image 3 It is an end view of the connecting parts of the segmented blades of the present invention, metal bolt sleeves 210 are pre-embedded inside the upper and lower shells.

[0052] Figure 4 It is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com