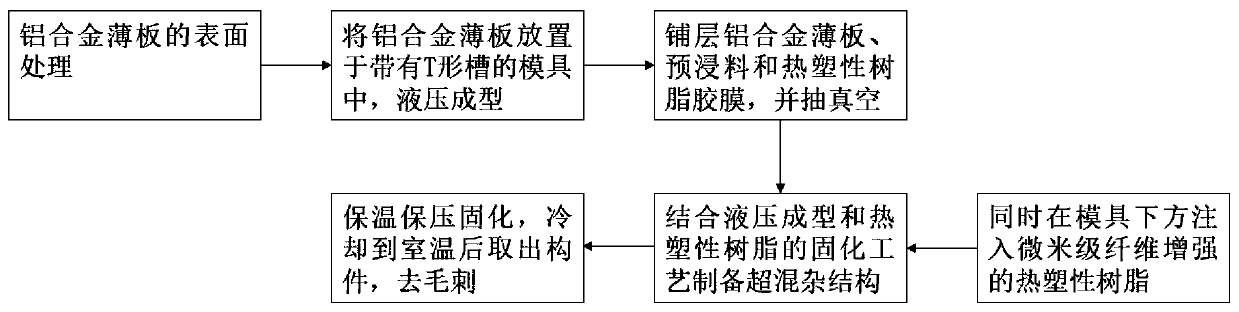

Integrated forming die and method of fiber-metal super-hybrid T-shaped reinforcing rib structure

A fibrous metal and ultra-hybrid technology, applied in chemical instruments and methods, household appliances, and other household appliances, can solve the problems of unfavorable civil transportation tools such as efficient integrated molding, and achieve high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The first step is aluminum alloy thin plate (AA7475-T6, 0.4mm×250mm×250mm) blank preparation and surface treatment. The aluminum alloy surface treatment method includes two steps: the first step is the surface nano treatment, including: (1) alkali washing: NaOH and Na 2 CO 3 Each 30g / L mixed solution, the temperature is 50-60°C, the treatment time is 0.5-1min, and the tap water is rinsed for 2-5min; (2) pickling: HNO 3 The concentration is 300-500g / L, the treatment time is 2-5min, rinse with tap water for 2-5min; (3) 25% ammonia solution, the treatment time is 20min; the second step is nitrogen plasma surface treatment, where the voltage is 5000w, nitrogen gas flow The temperature is 600sccm, the temperature is 40°C, the working vacuum is 30Pa, and the processing time is 10min;

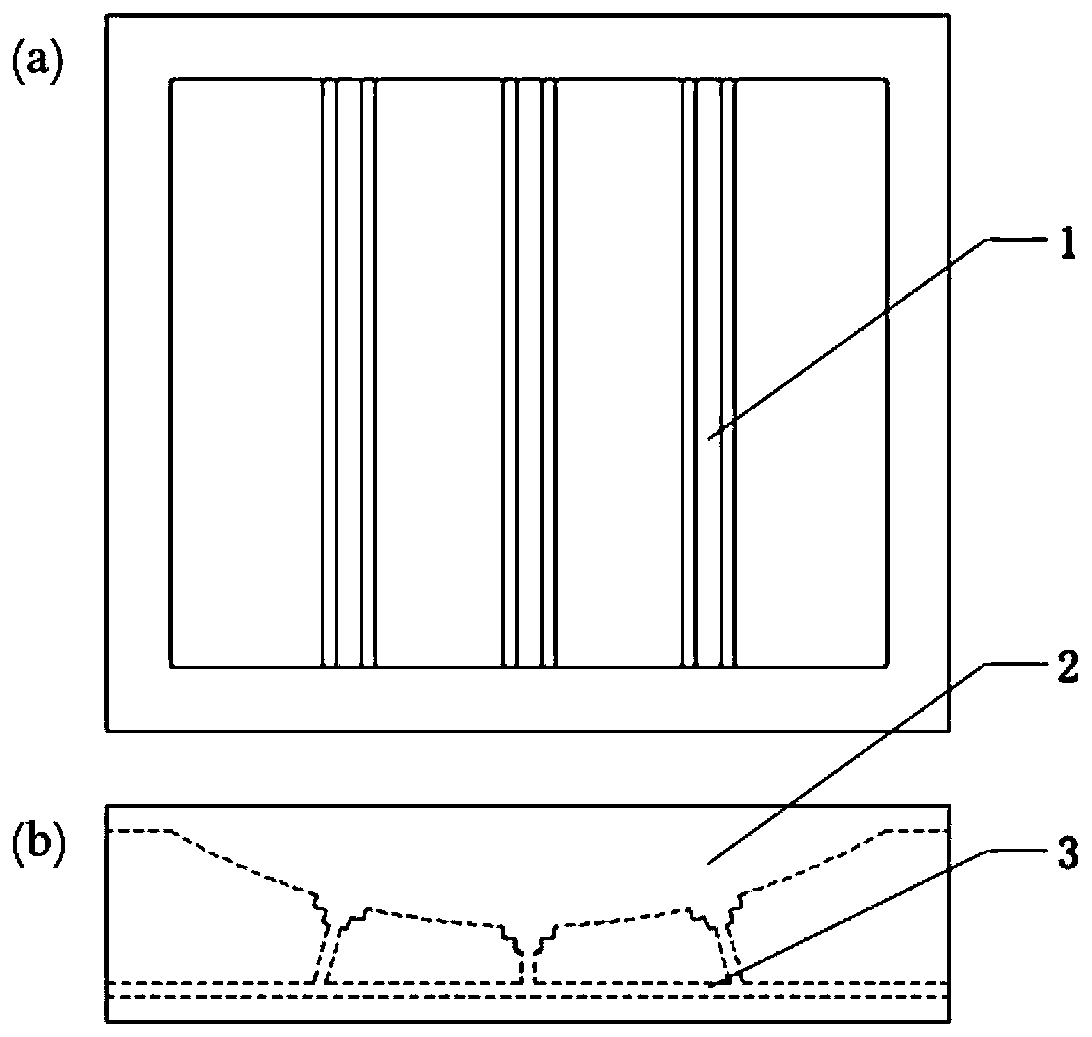

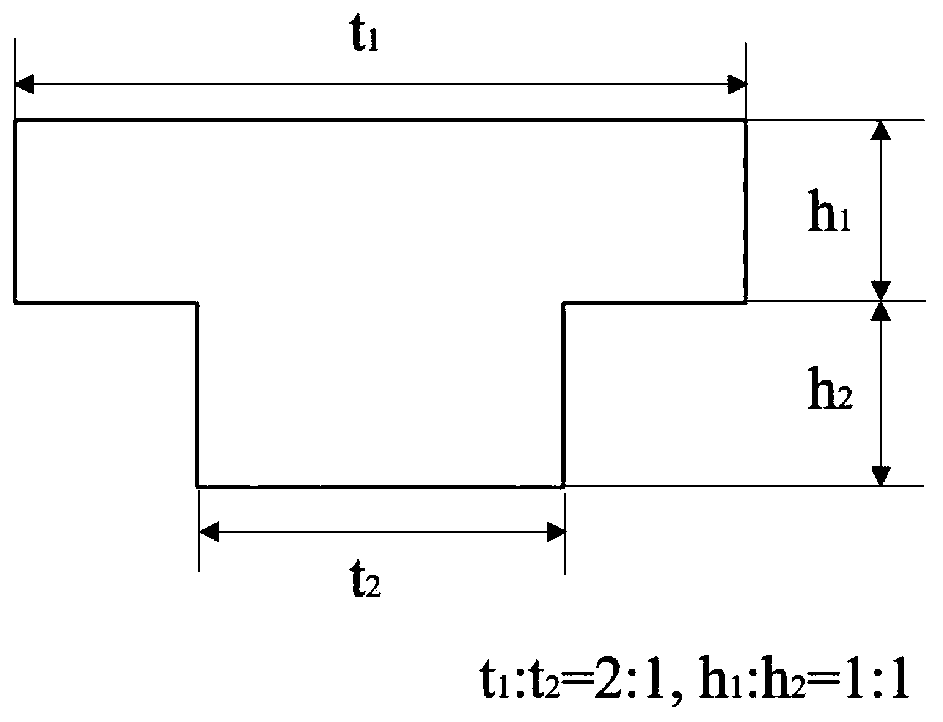

[0038] In the second step, a surface-treated aluminum alloy sheet is placed in a mold with a T-shaped groove (width 2.5mm). The length of the T-shaped reinforcement is the same, the bottom o...

Embodiment 2

[0044] The first step is aluminum alloy thin plate (AA2024-T3, 0.3mm×200mm×200mm) blank preparation and surface treatment. The aluminum alloy surface treatment method includes two steps: the first step is the surface nano treatment, including: (1) alkali washing: NaOH and Na 2 CO 3 Each 30g / L mixed solution, the temperature is 50-60°C, the treatment time is 0.5-1min, and the tap water is rinsed for 2-5min; (2) pickling: HNO 3 The concentration is 300-500g / L, the treatment time is 2-5min, rinse with tap water for 2-5min; (3) 25% ammonia solution, the treatment time is 20min; the second step is nitrogen plasma surface treatment, where the voltage is 5000w, nitrogen gas flow The temperature is 600sccm, the temperature is 40°C, the working vacuum is 30Pa, and the processing time is 10min;

[0045] In the second step, a surface-treated aluminum alloy sheet is placed in a mold with a T-shaped groove (width 2mm). The length of the shaped reinforcement is the same, the bottom of th...

Embodiment 3

[0051] The first step is aluminum alloy thin plate (AA6061-T6, 0.5mm×300mm×300mm) blank preparation and surface treatment. The aluminum alloy surface treatment method includes two steps: the first step is the surface nano treatment, including: (1) alkali washing: NaOH and Na 2 CO 3 Each 30g / L mixed solution, the temperature is 50-60°C, the treatment time is 0.5-1min, and the tap water is rinsed for 2-5min; (2) pickling: HNO 3 The concentration is 300-500g / L, the treatment time is 2-5min, rinse with tap water for 2-5min; (3) 25% ammonia solution, the treatment time is 20min; the second step is nitrogen plasma surface treatment, where the voltage is 5000w, nitrogen gas flow The temperature is 600sccm, the temperature is 40°C, the working vacuum is 30Pa, and the processing time is 10min;

[0052] In the second step, a surface-treated aluminum alloy sheet is placed in a mold with a T-shaped groove (width 3mm). The length of the shaped reinforcement is the same, the bottom of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com