Patents

Literature

80 results about "Fiber metal laminate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

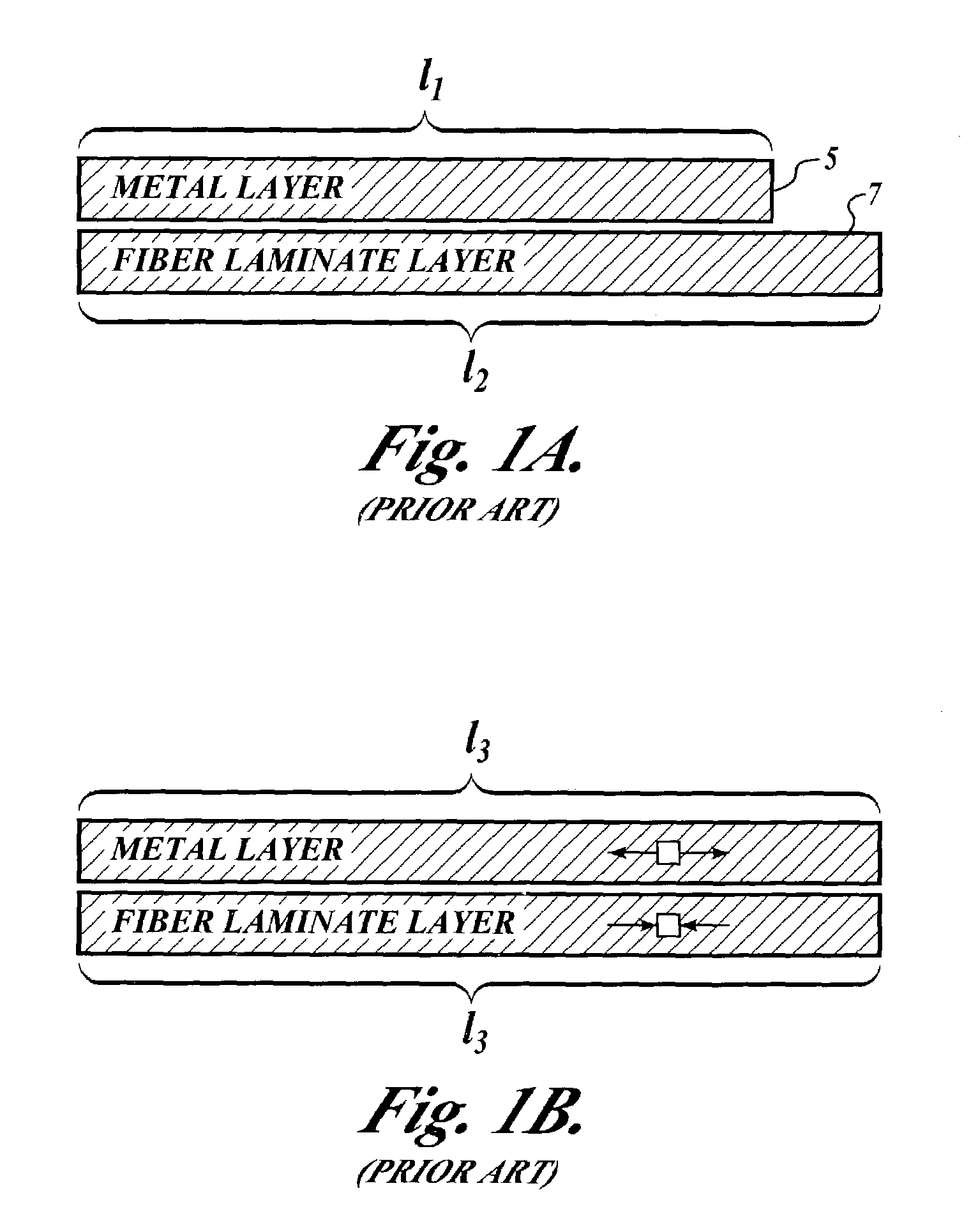

Fiber metal laminate (FML) is one of a class of metallic materials consisting of a laminate of several thin metal layers bonded with layers of composite material. This allows the material to behave much as a simple metal structure, but with considerable specific advantages regarding properties such as metal fatigue, impact, corrosion resistance, fire resistance, weight savings, and specialized strength properties.

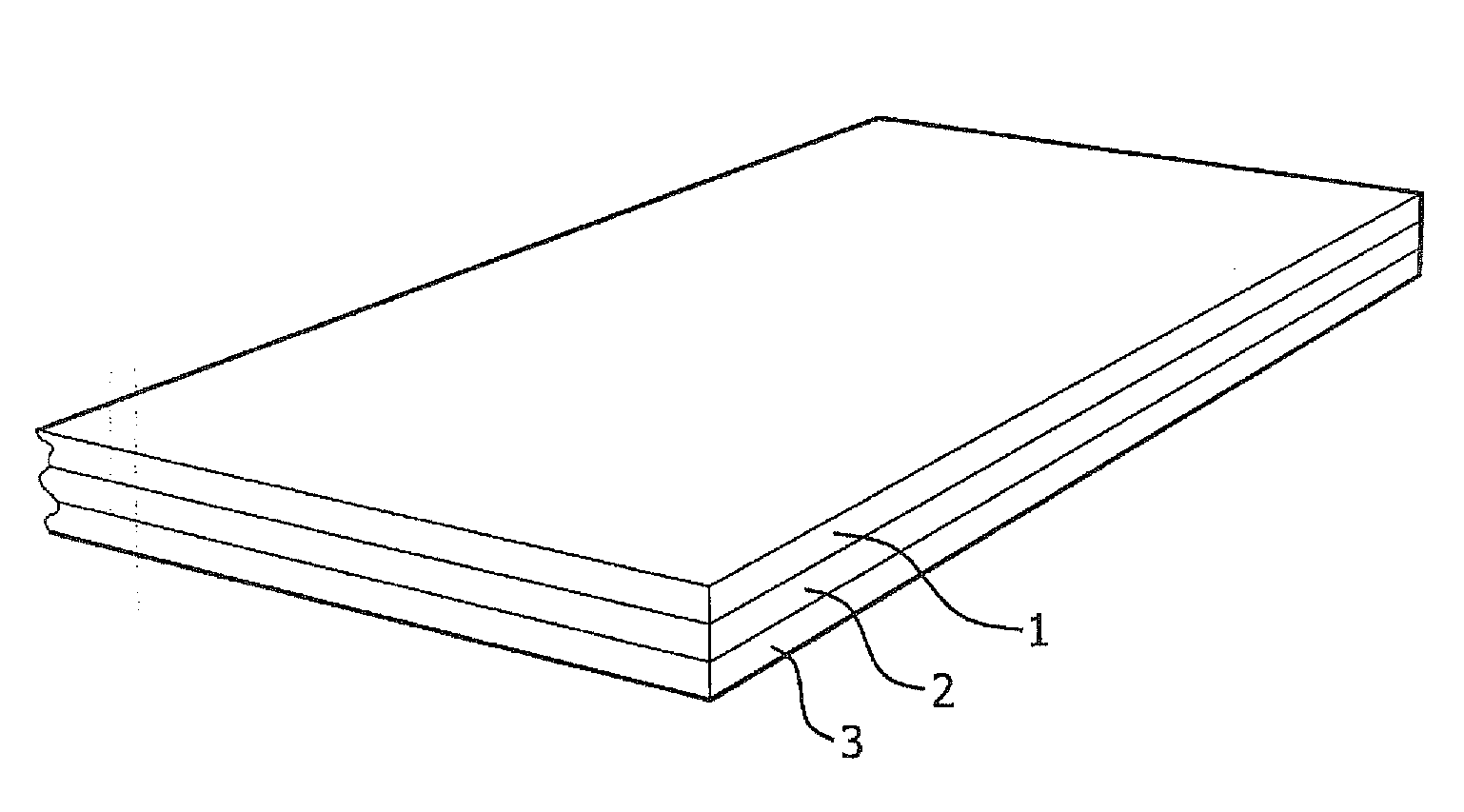

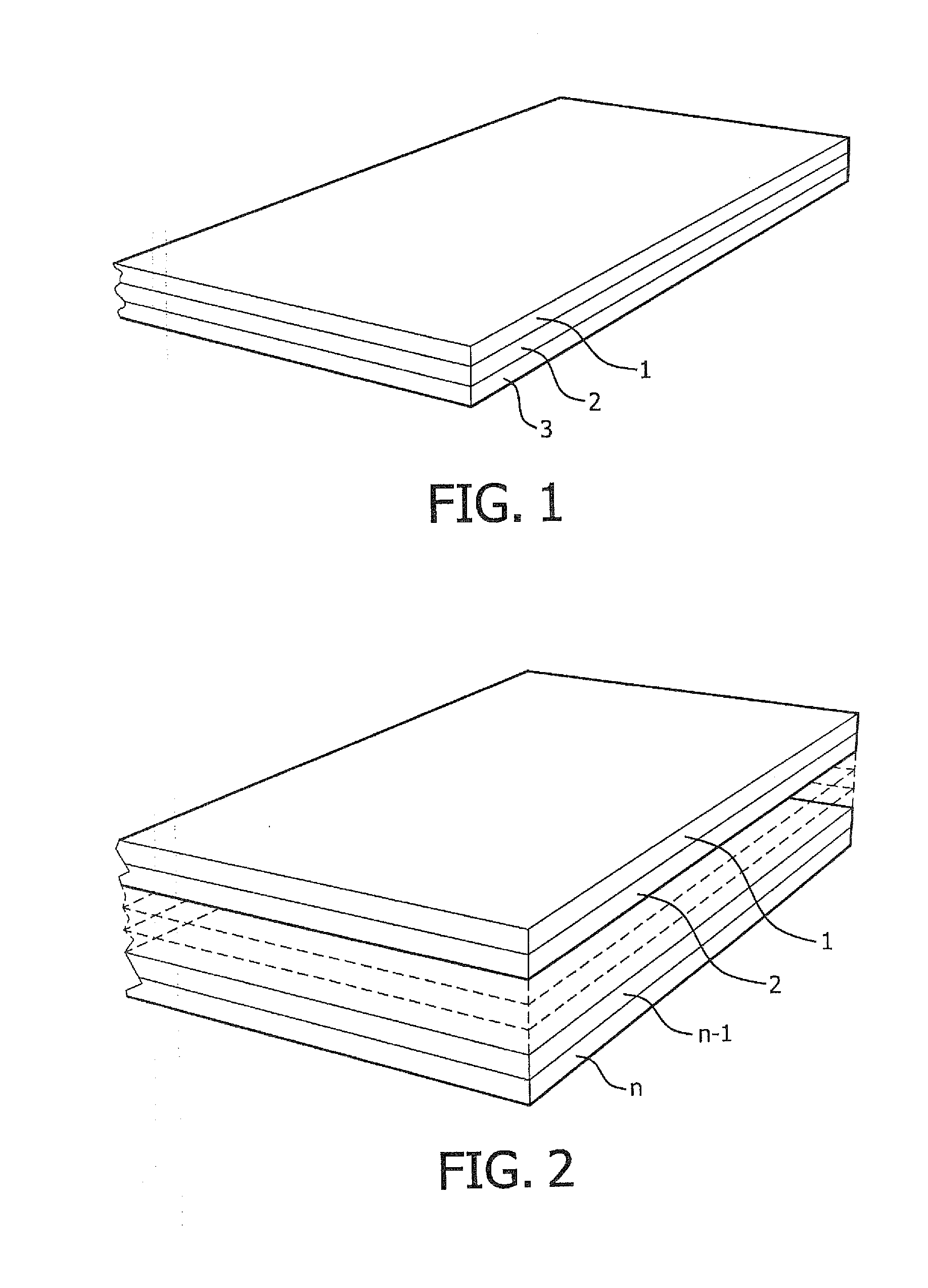

High toughness fiber-metal laminate

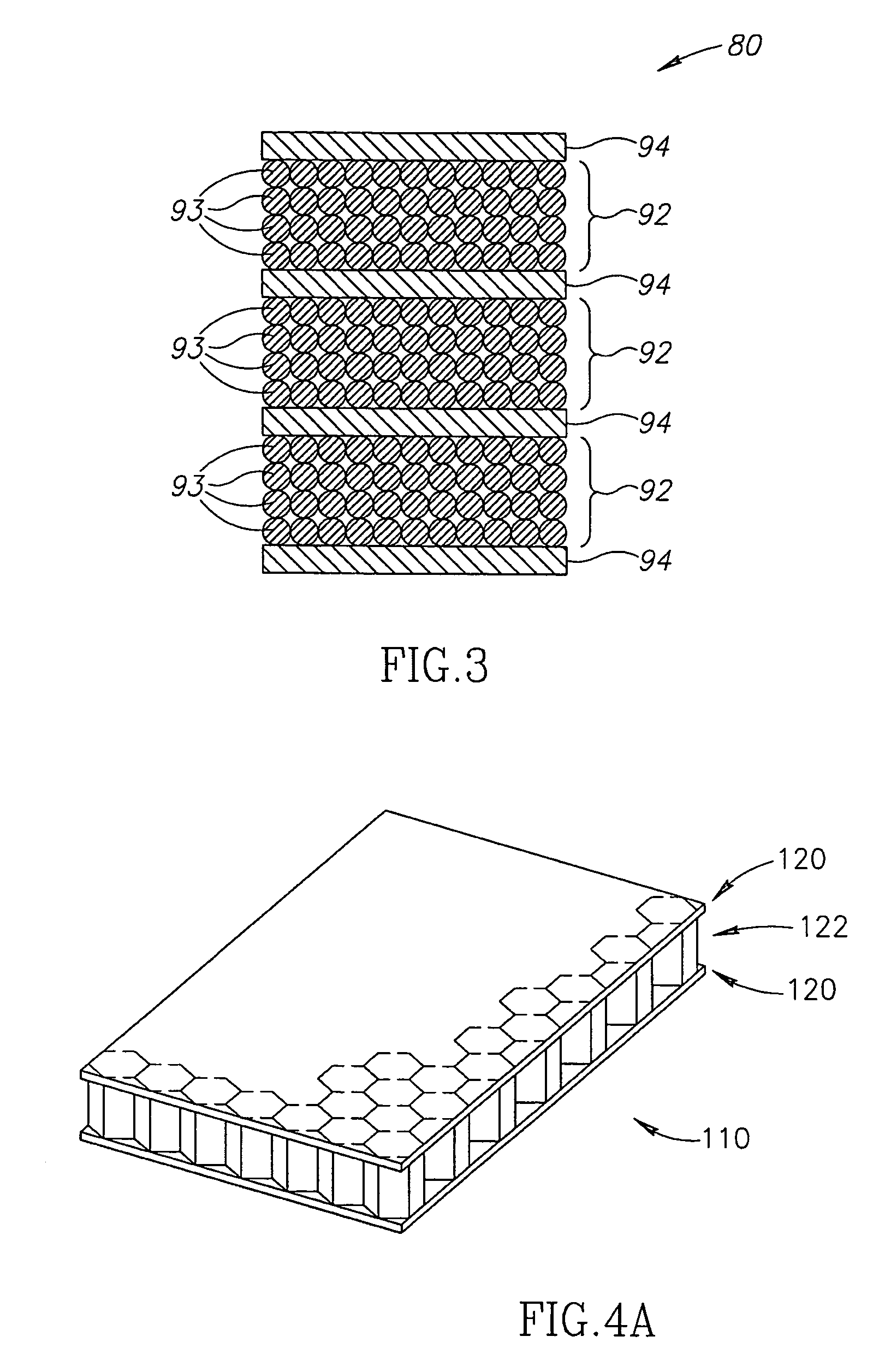

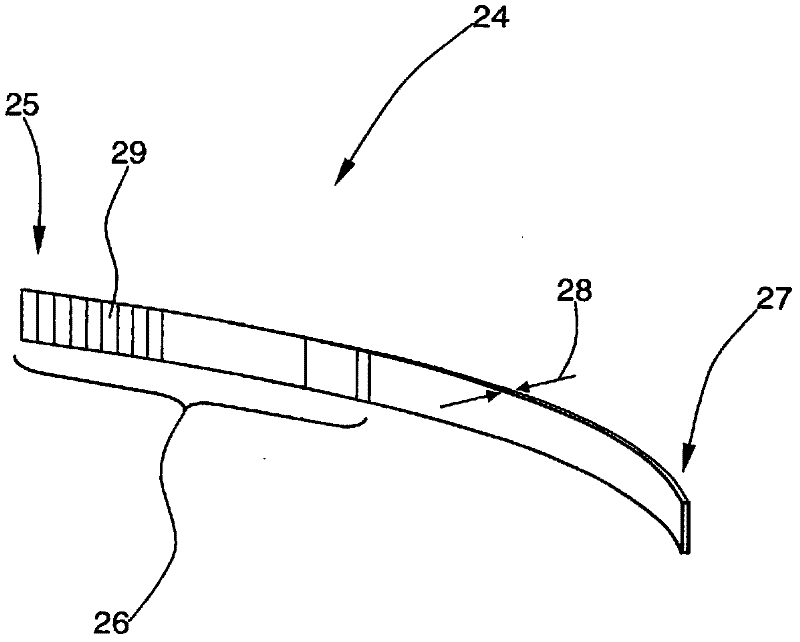

InactiveUS20110052910A1Good explosion resistanceReduce weightFilm/foil adhesivesAnimal housingThin metalLeading edge

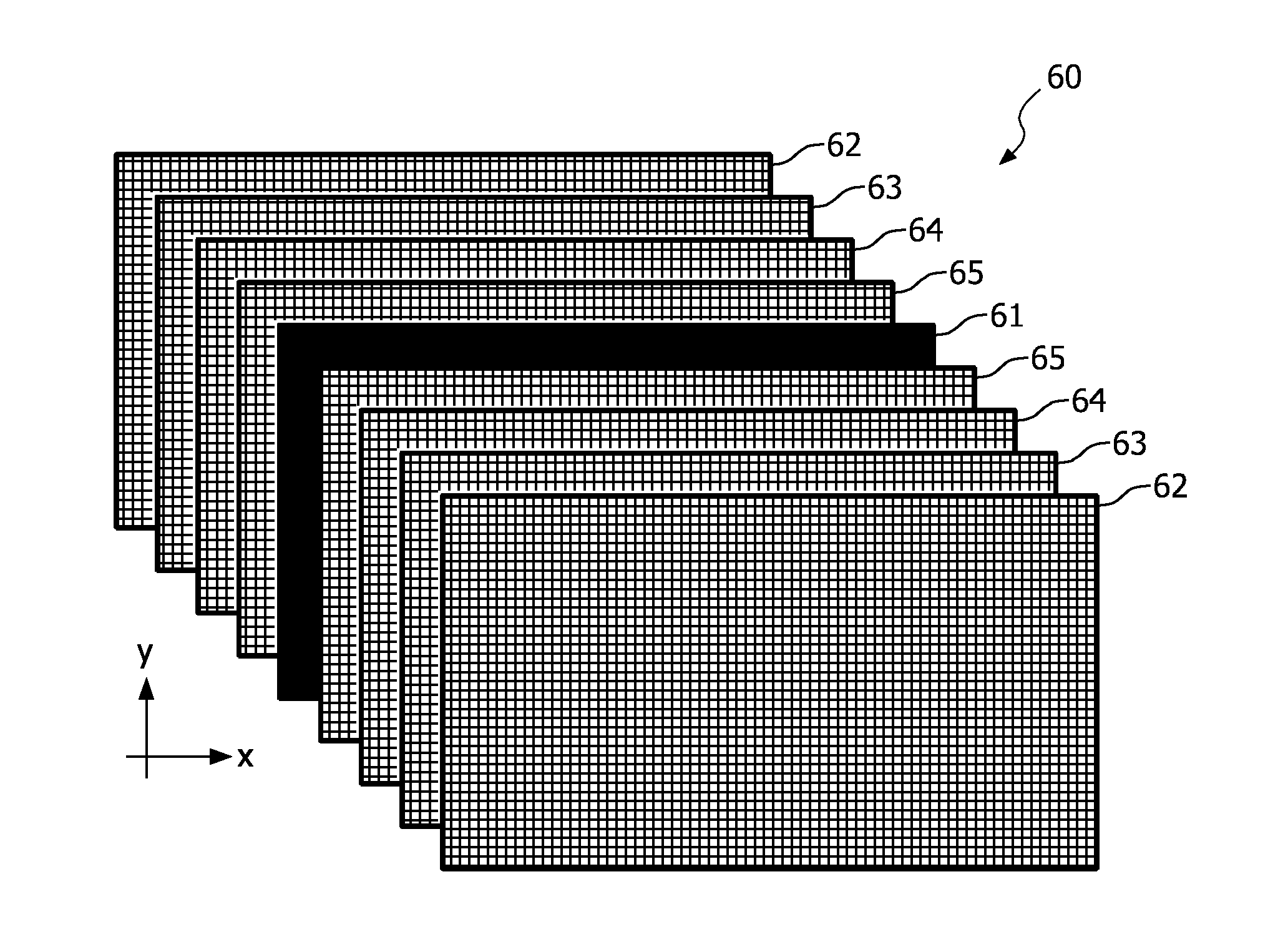

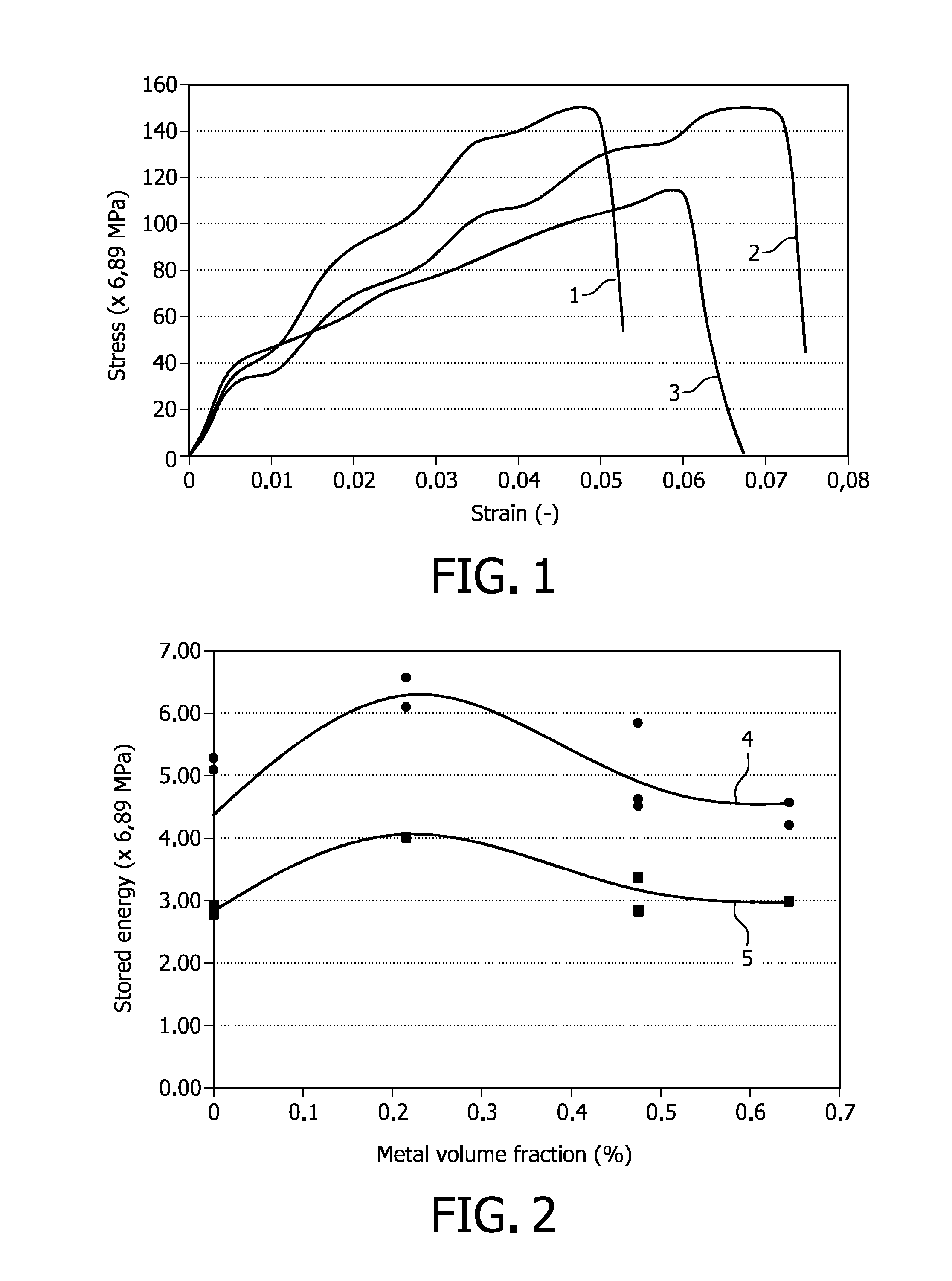

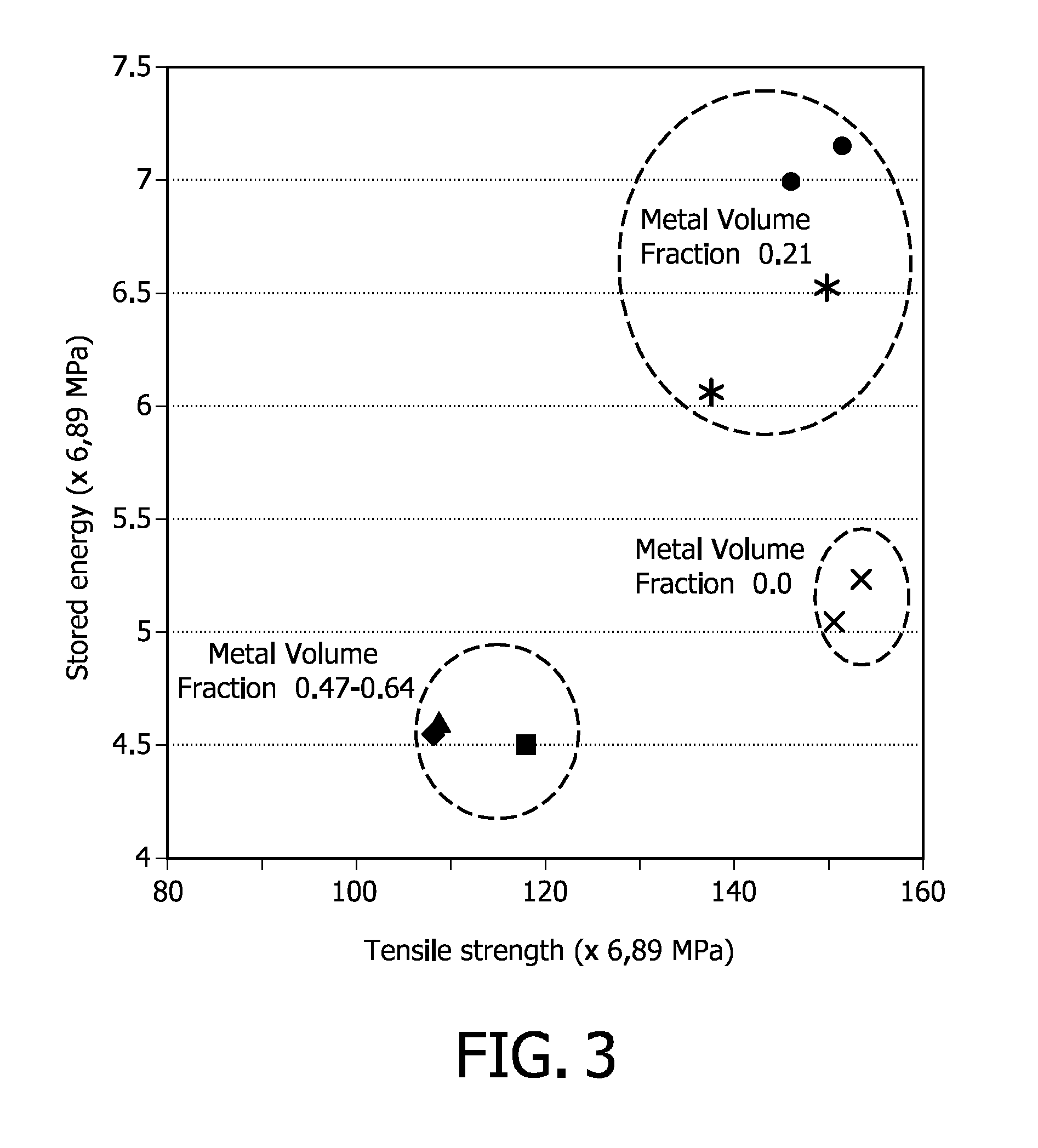

The invention relates to a fiber-metallaminate comprising fiber-reinforced composite layers and thin metal sheets, wherein the total metal volume fraction of the laminate is between 0 vol. % and 47 vol. %. The fiber-metal laminate according to the invention shows an unprecedented combination of toughness and tensile strength. The laminate is advantageously used in constructing impact resistant objects, such as explosion resistant aircraft luggage containers and wing leading edges.

Owner:GTM HLDG +1

Aluminum-fiber laminate

InactiveUS20050175813A1Improve corrosion resistanceGood physical propertiesVehicle componentsThin material handlingFiber metal laminateResin matrix

An exemplary fiber metal laminate includes at least two metallic layers and at least one fiber layer bonded between the two metallic layers. The fiber layer includes a resin matrix and organic polymeric fibers with a modulus of elasticity greater than 270 GPa. The polymeric fibers may include poly diimidazo pyridinylene fibers. The metallic layers may include pre-treated aluminum alloy layers.

Owner:THE BOEING CO

Nanostructure aluminum fiber metal laminates

InactiveUS20050271859A1Reduce property damageEffective solution to strength character issuesVehicle componentsThin material handlingFiber metal laminateAluminum metal

Owner:THE BOEING CO

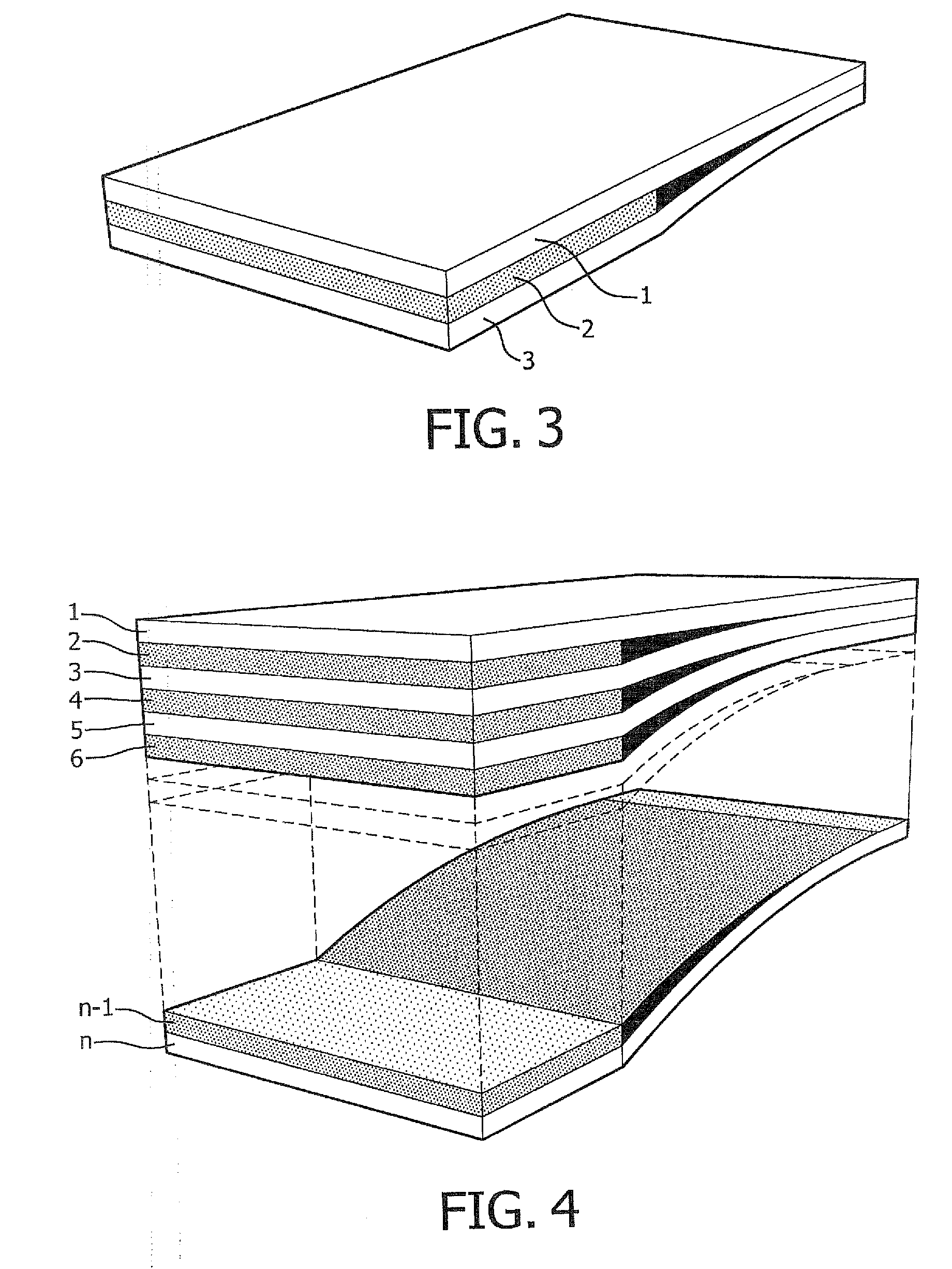

Carbon fiber metal laminate

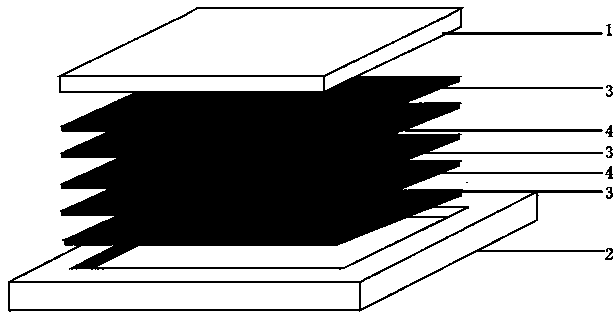

InactiveCN101524903AImpact resistantImprove fatigue performanceSynthetic resin layered productsMetal layered productsHigh fractureFiber metal laminate

The invention relates to a carbon fiber metal laminate. The invention aims at the problem that, so far, flight vehicle structure materials, which not only has high specific strength and high specific stiffness, but also has high fracture toughness and processability, are non-existent. The inventive laminate is composed of at least two metal plates and at least one carbon fiber composite material layer; at least two metal plates are superposed together, a carbon fiber composite material layer which is adhesively bonded with the two adjacent metal plates are laid between the two adjacent metal plates; the thickness of the metal plate is 0.2m-0.4m and the thickness of the carbon fiber composite material layer is 0.15mm. The inventive laminate has high specific strength and specific stiffness, high fracture toughness and processability, and is also excellent in fatigue property and loss tolerance property. The invention can be used as a structure material for aerospace flights, such as a skin material of large civil planes, and can also be used as alternative material of metal auto panels, magnetically levitated train, light bulletproof armor and ship, etc.

Owner:HARBIN INST OF TECH

Metal sheet-fiber reinforced composite laminate

InactiveUS20130316148A1Optimal structural responseImprove responseFuselage framesSynthetic resin layered productsTensile strainFiber metal laminate

Owner:GTM ADVANCED PROD

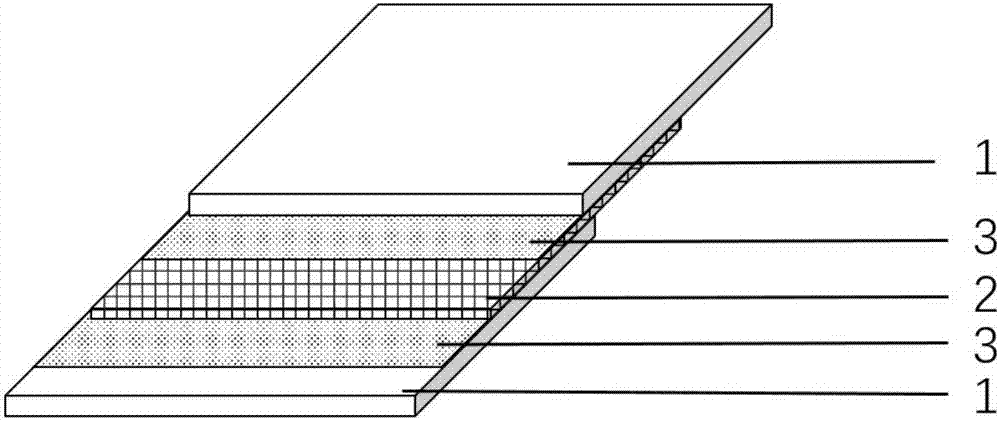

Ultrahigh molecular weight polyethylene fiber reinforced fiber metal laminate and preparation method thereof

InactiveCN106965505AStrong toughnessStrong processing and winding performanceSynthetic resin layered productsLaminationCarbon fibersAdhesive

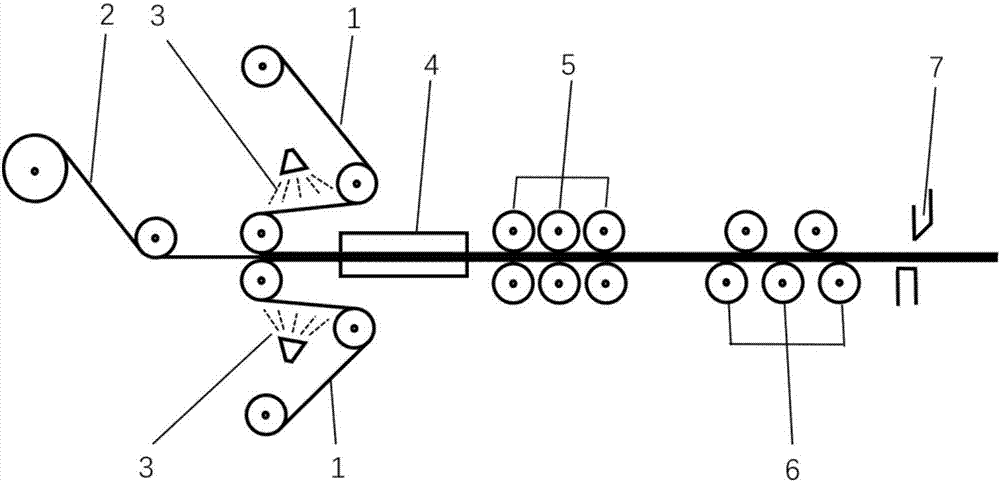

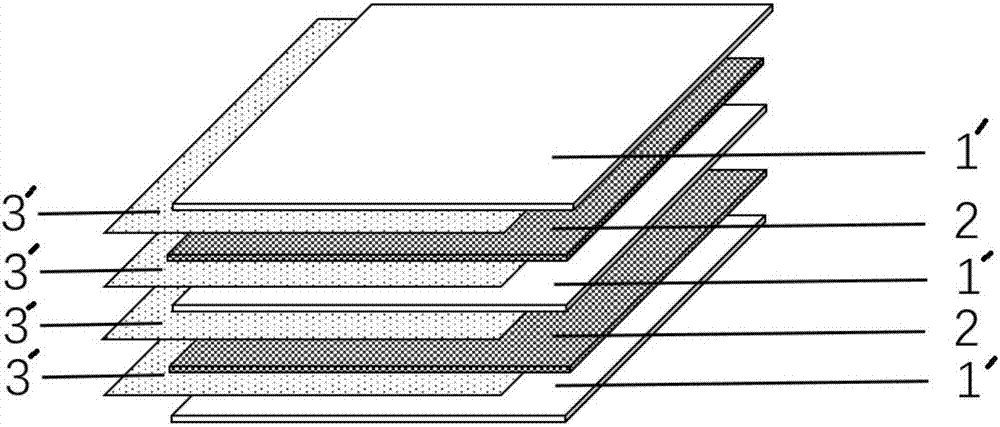

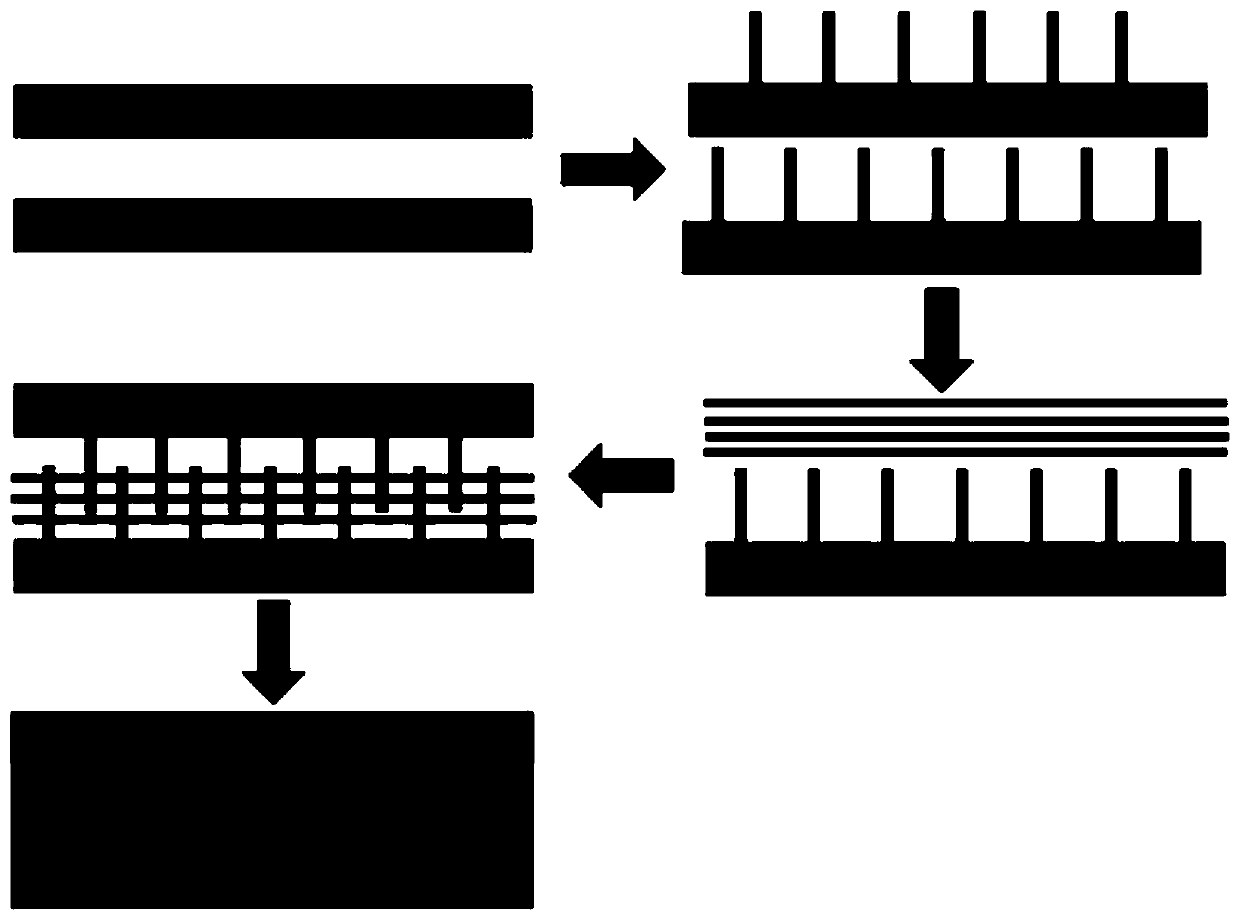

The invention relates to an ultrahigh molecular weight polyethylene (UHMWPE) fiber reinforced fiber metal laminate. The UHMWPE fiber reinforced fiber metal laminate is formed by alternately superposing metal thin plates and UHMWPE fiber reinforced prepregs; and the metal thin plates and the UHMWPE fiber reinforced prepreg sheet materials are formed through adhesion of adhesive and rolling. The UHMWPE fiber reinforced fiber metal laminate is high in tensile strength, not liable to wear, high in fiber tenacity, high in processing, weaving and winding properties and high in skin friendliness; the fiber is high in shear strength and not liable to break, and the cost of the fiber is greatly reduced as compared with that of carbon fiber; preparation equipment is high in work efficiency and can be competent for a mass and high-efficiency production task, and the total preparation cost of the laminate is low; manufacturing devices are clever in design, and a metal thin plate guide device, a prepreg guide device and an adhesive spray-coating device cooperate with each other to complete high-efficiency and high-quality production work.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

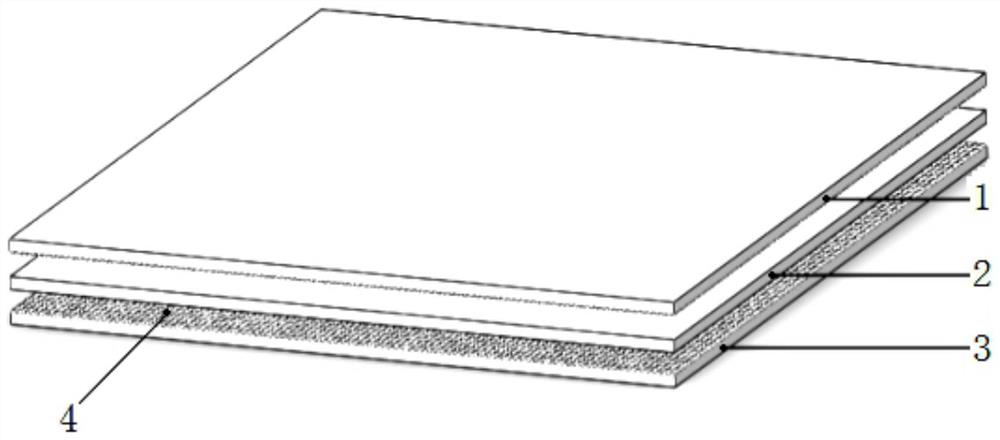

Fiber-metal laminated plate and preparation method thereof

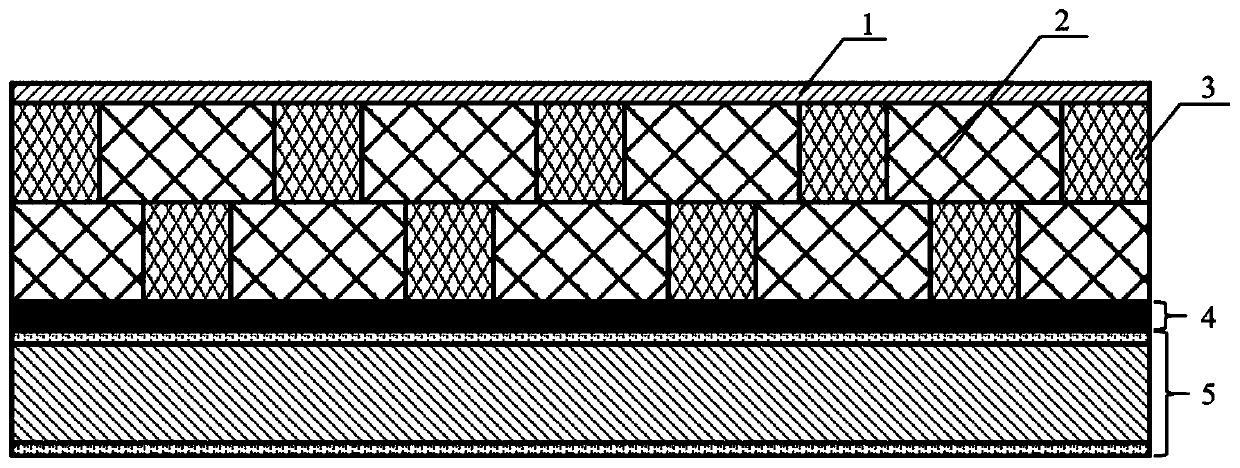

ActiveCN105522788AImprove bindingLayered product treatmentProtective equipmentFiber metal laminateWeak binding

The invention provides a fiber-metal laminated plate. The fiber-metal laminated plate solves the problem of a weak binding force between a metal layer and a fiber cloth in the existing fiber-metal laminated plate. The fiber-metal laminated plate comprises a metal layer, a resin binder layer and a fiber cloth and the metal layer, the resin binder layer and the fiber cloth are orderly stacked, chopped fibers are arranged between the resin binder layer and the fiber cloth and each one of the chopped fibers has a first part inserted in the fiber cloth and a second part fixed in the resin binder layer. The invention also discloses a preparation method of the fiber-metal laminated plate. The fiber-metal laminated plate has a strong binding force between the metal layer and the fiber cloth.

Owner:BYD CO LTD

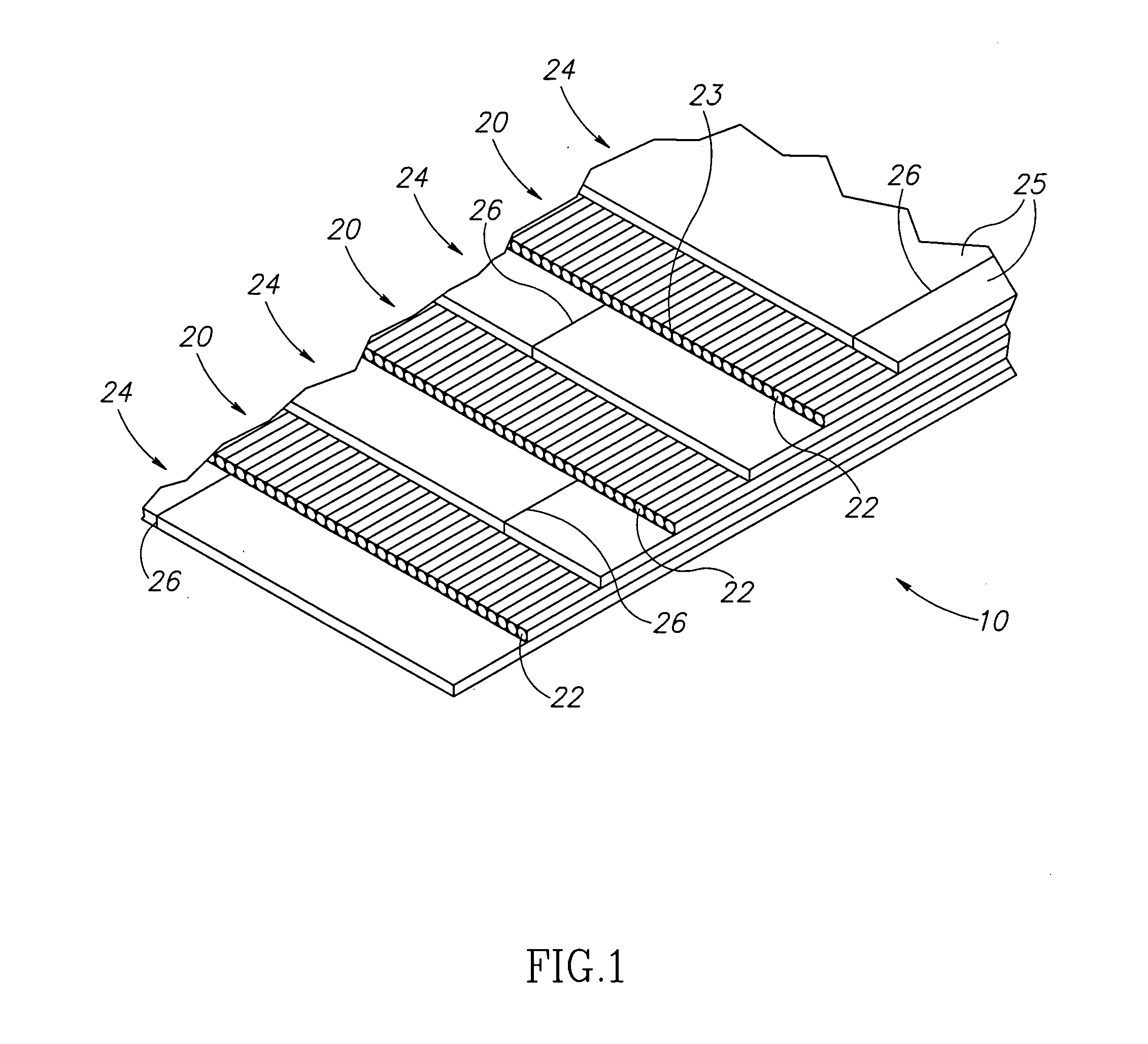

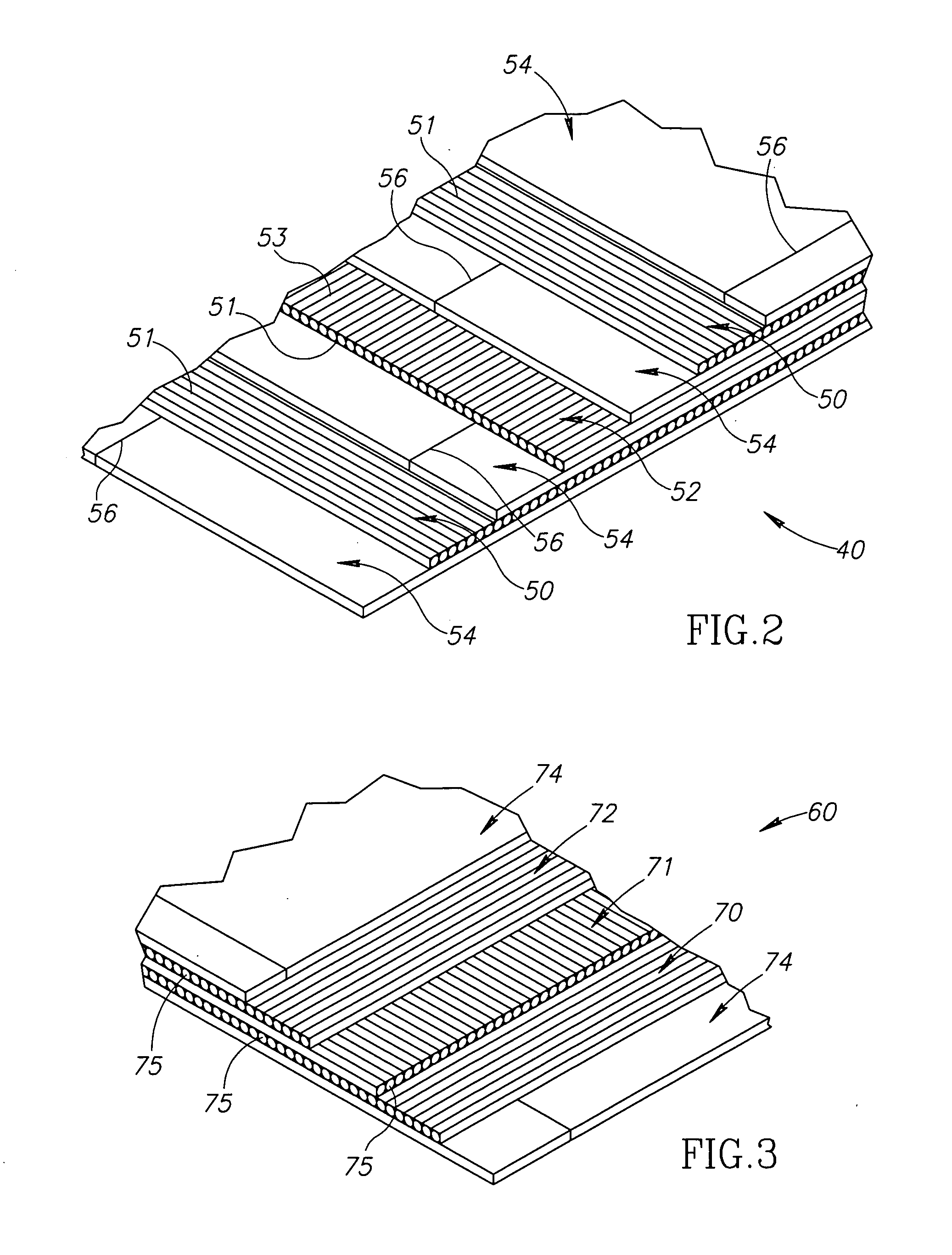

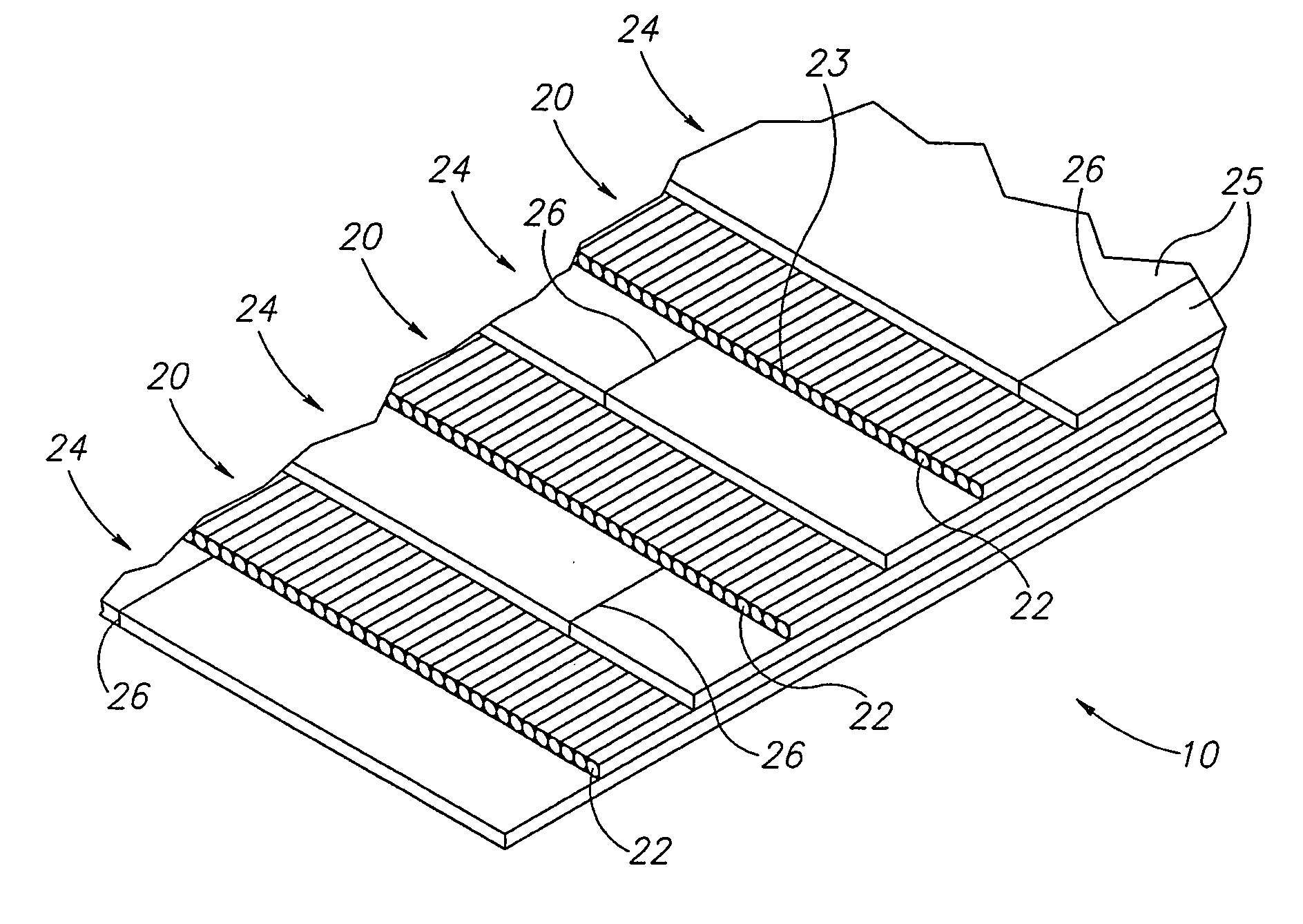

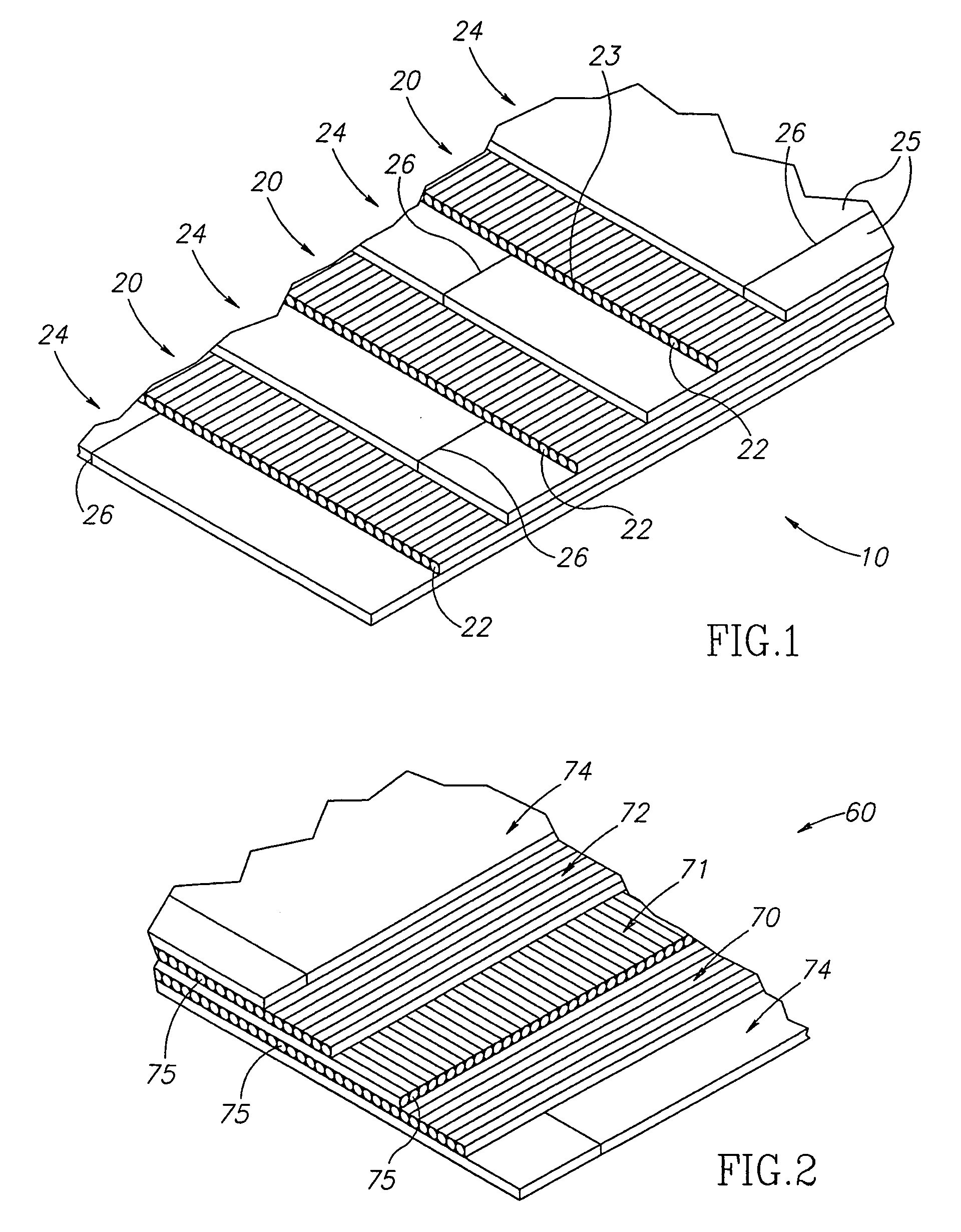

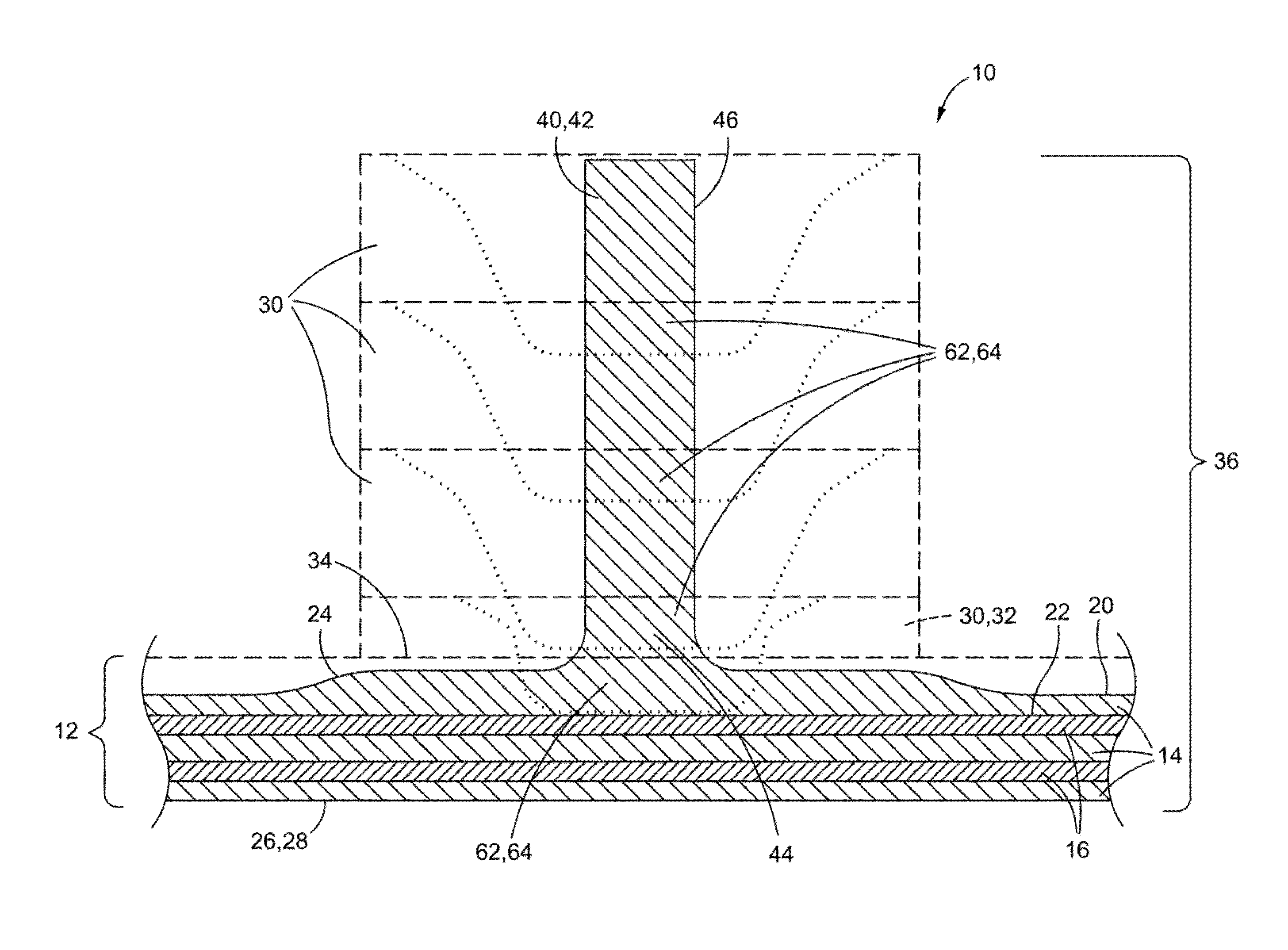

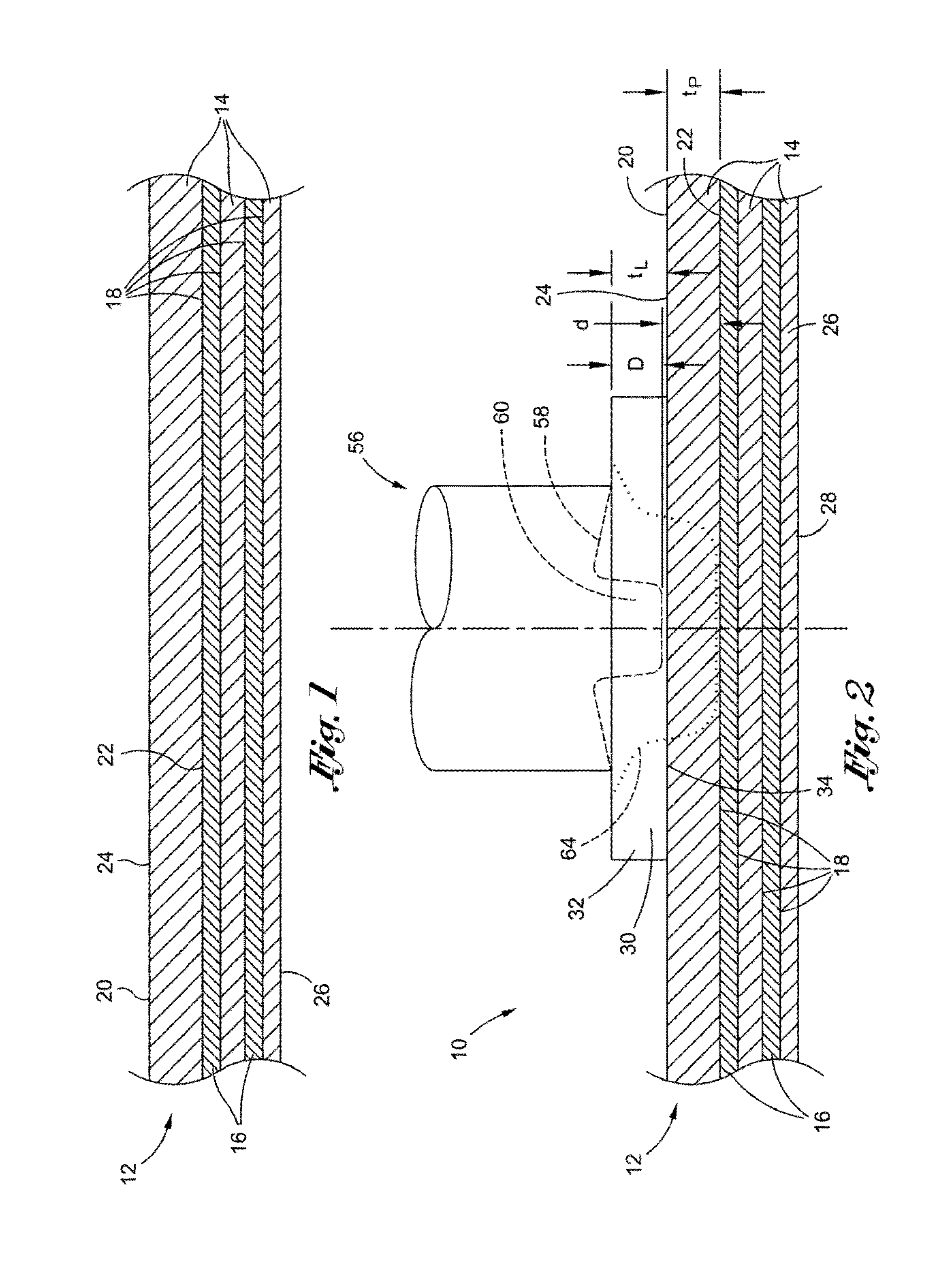

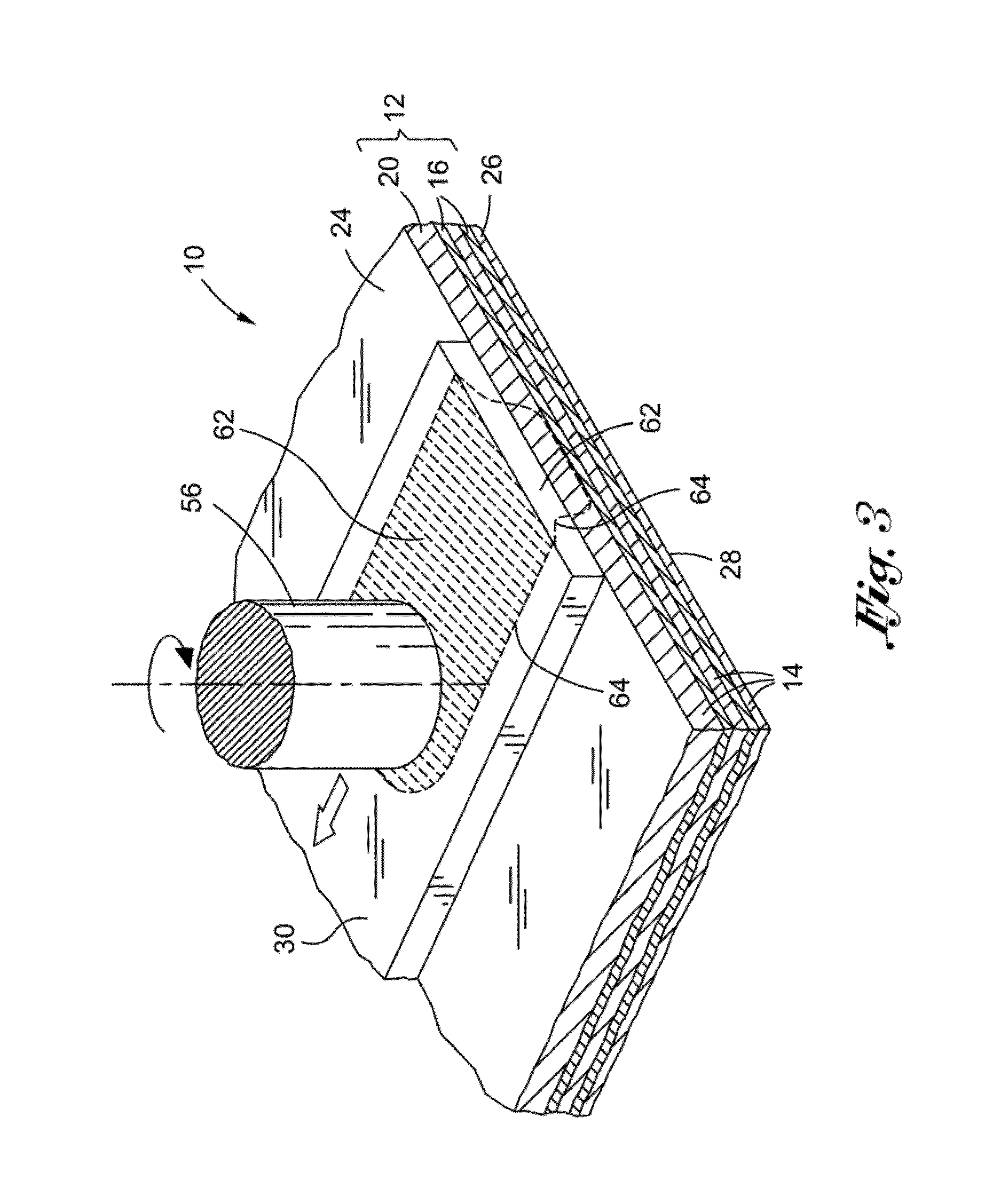

System and method for integrally forming a stiffener with a fiber metal laminate

ActiveUS20100092789A1Extended service lifeImpact-resistance is enhancedTurbinesFuselage bulkheadsThermal energyFiber metal laminate

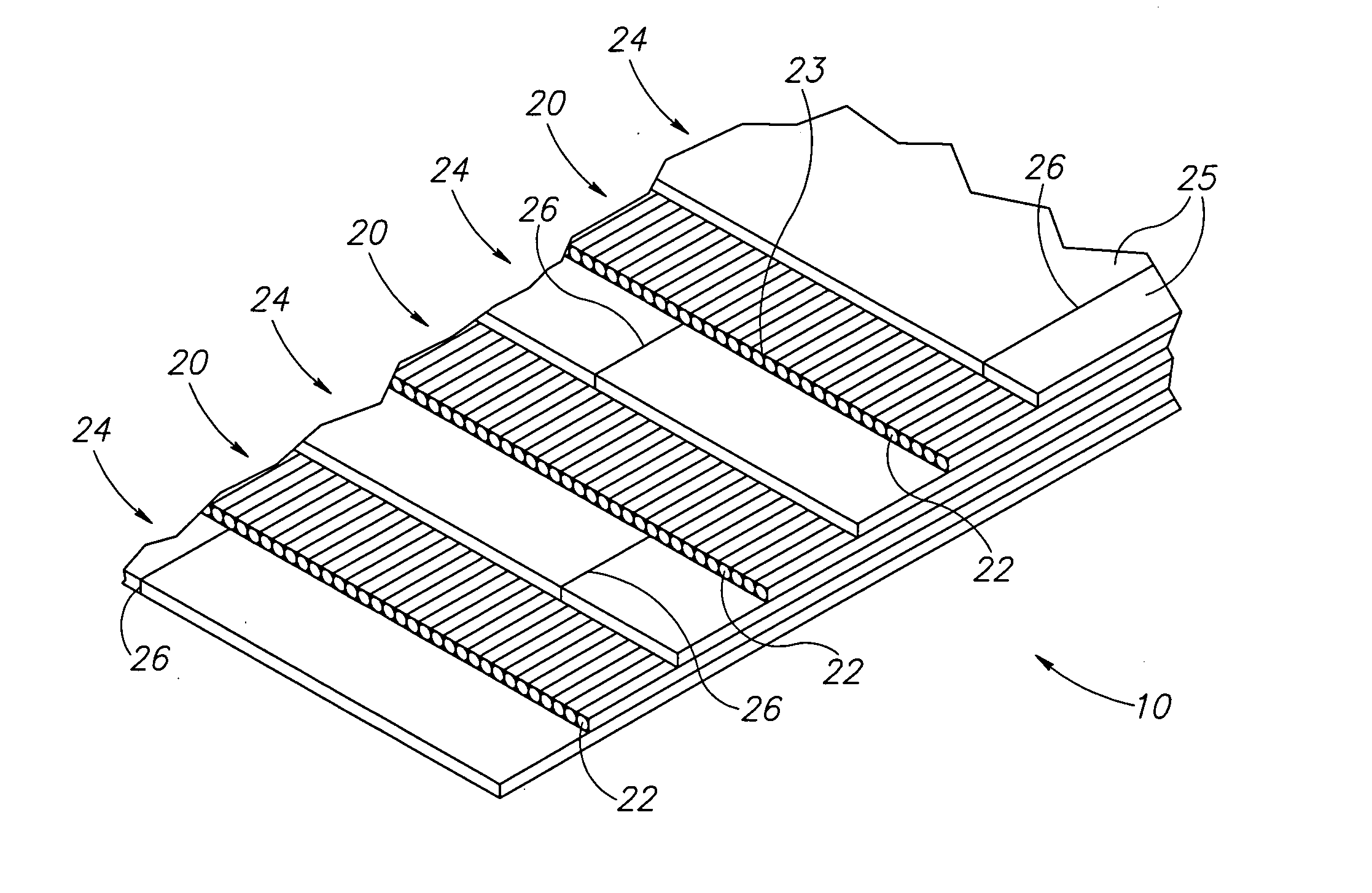

A unitized assembly comprises a fiber metal laminate having at least one additive layer deposited thereonto such as by friction stir welding. The fiber metal laminate comprises metallic and non-metallic plies and having an innermost metallic ply. The innermost metallic ply and the additive layer are each sized and configured to facilitate the generation of thermal energy sufficient to deposit the first additive layer to the innermost metallic ply during the friction stir welding process. The additive layer is sized and configured to minimize thermal loads in the innermost metallic ply during deposition thereof. The unitized assembly may be formed using a stock member such as a metallic plate from which the innermost metallic ply may be machined. The metallic and non-metallic plies may be laid up over the innermost metallic ply. The substructure elements may be machined from the metallic plate.

Owner:THE BOEING CO

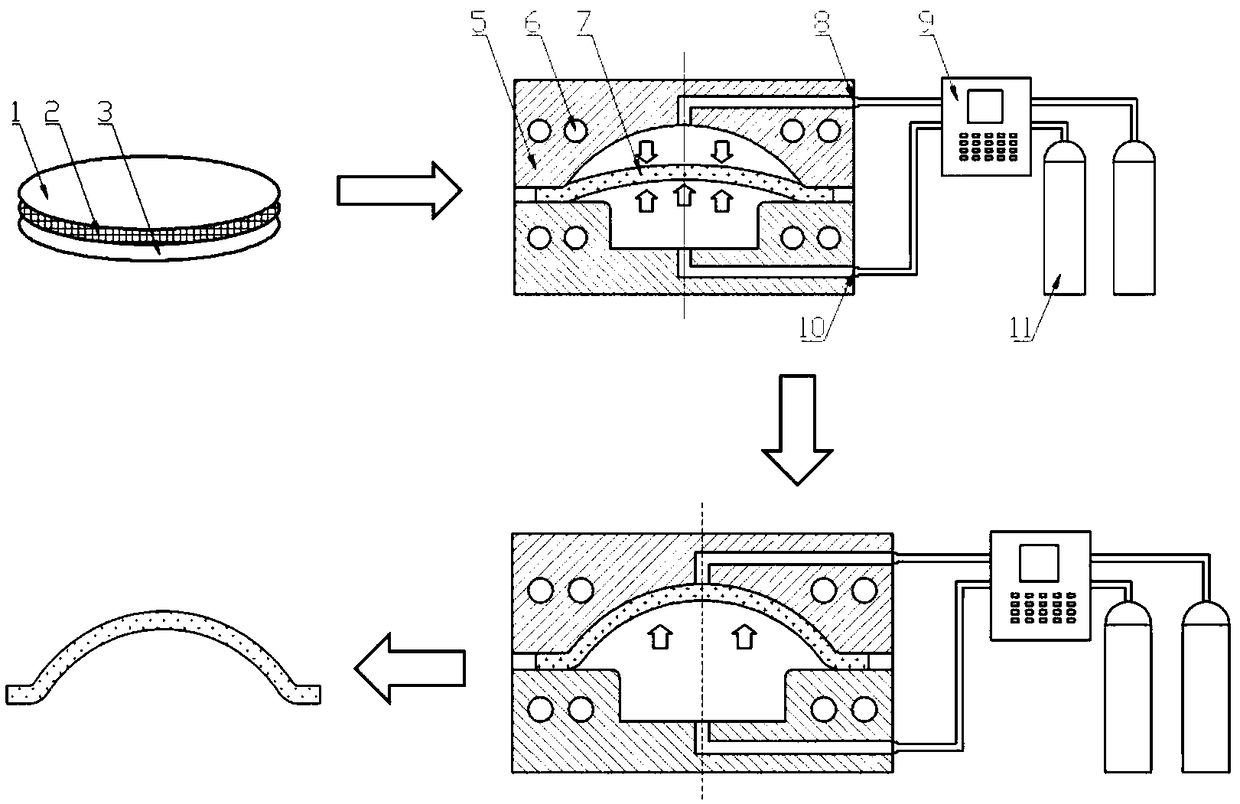

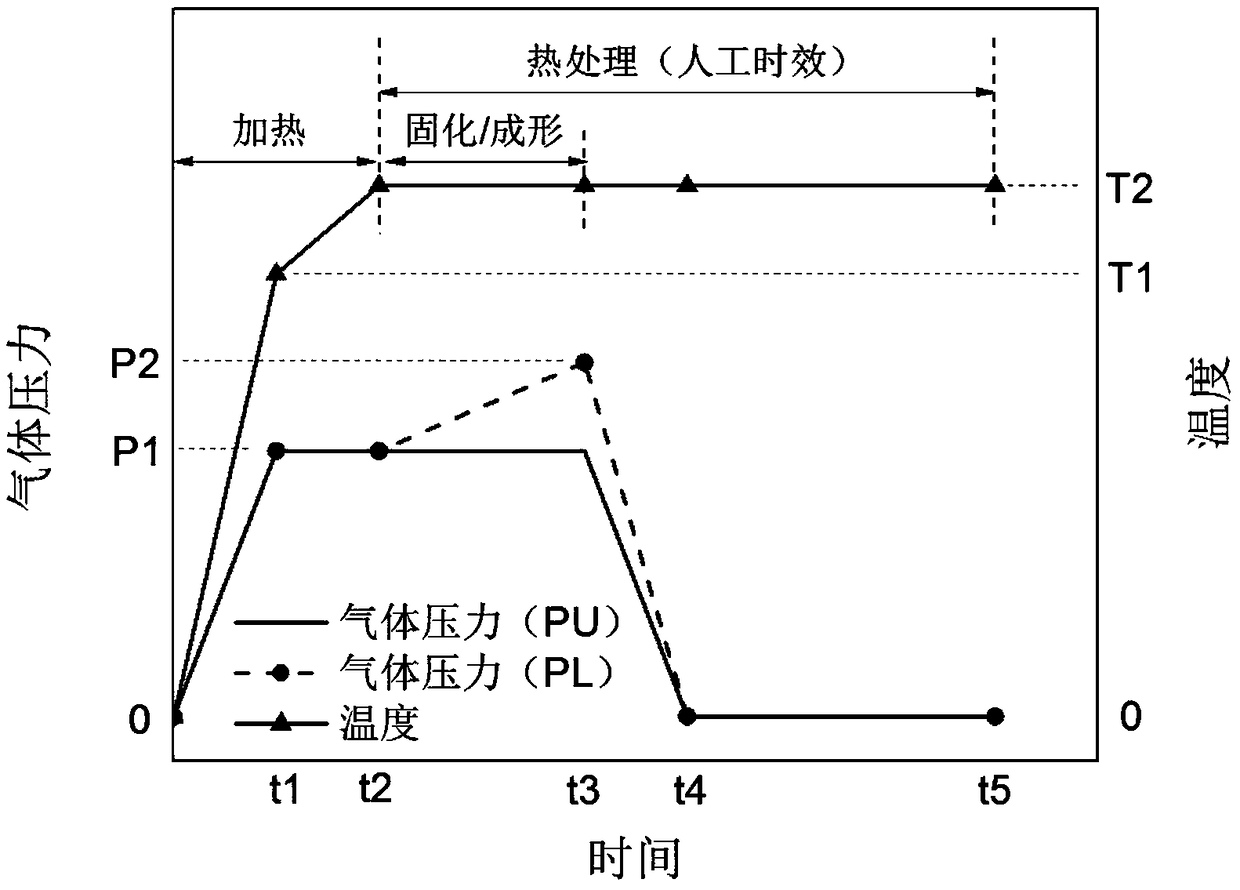

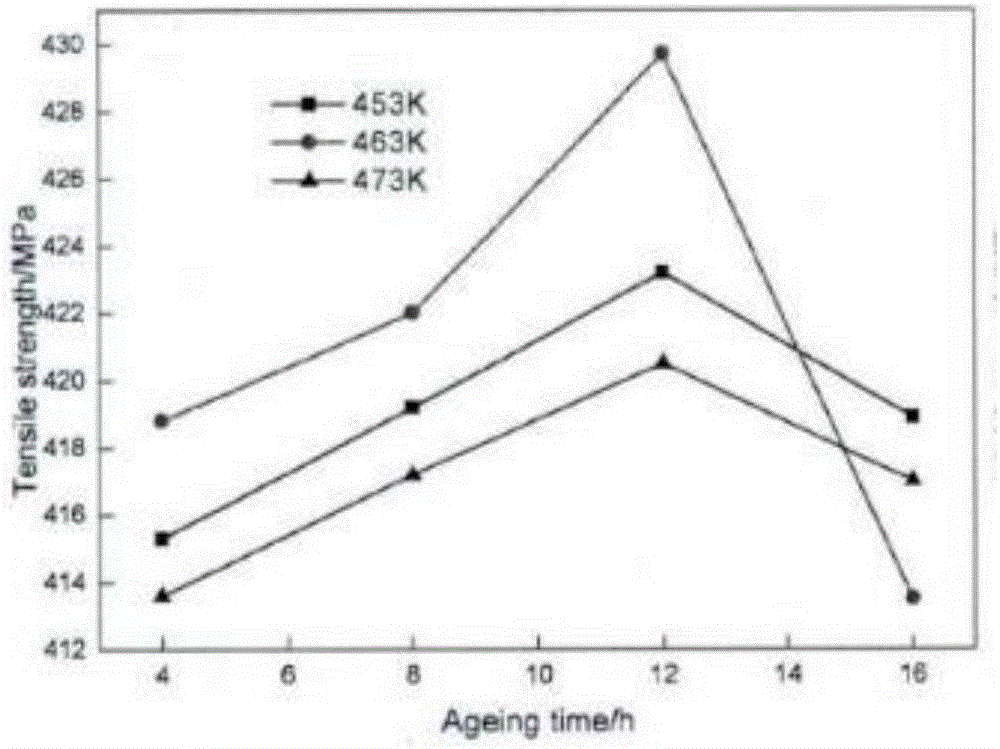

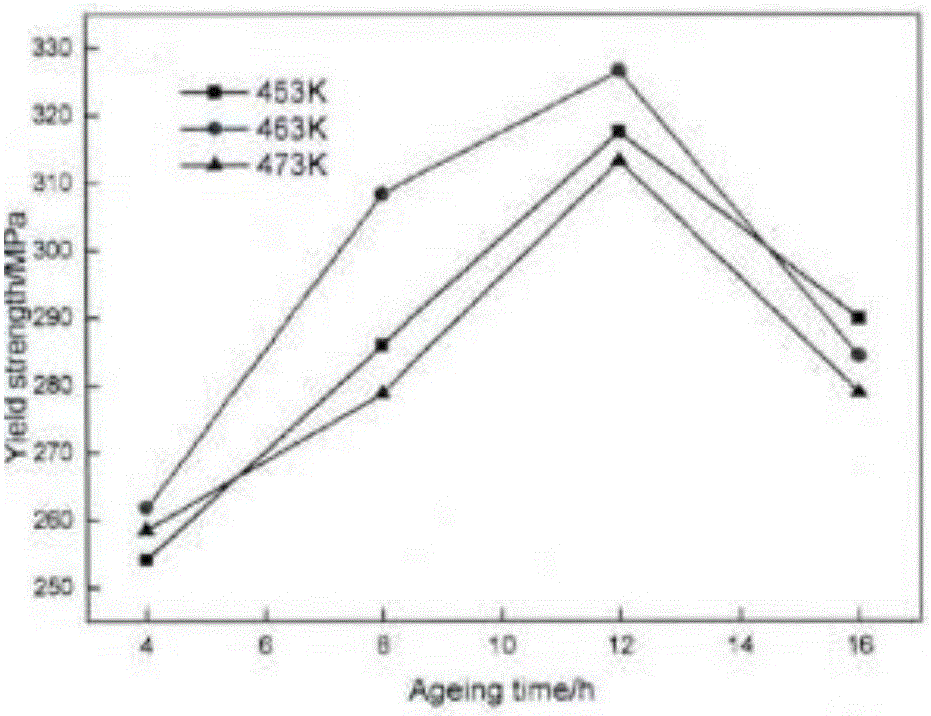

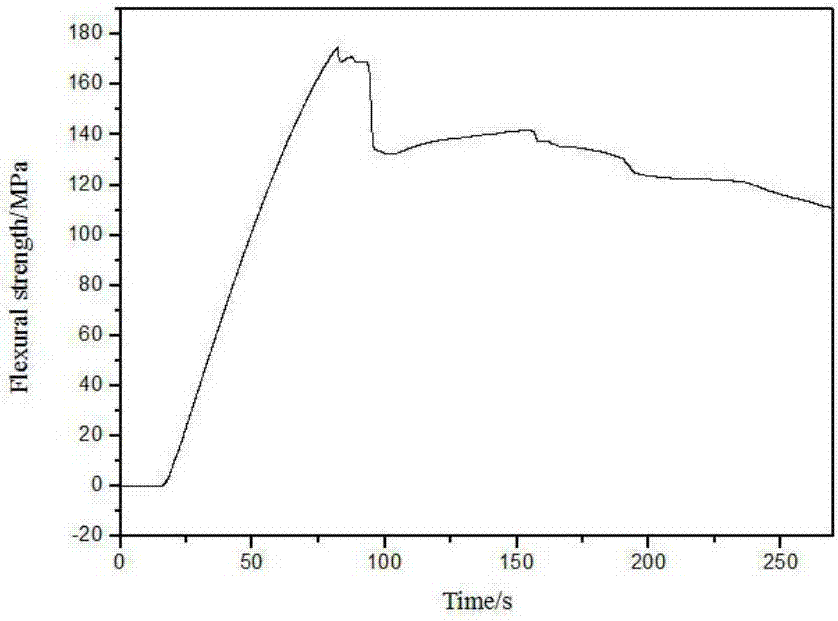

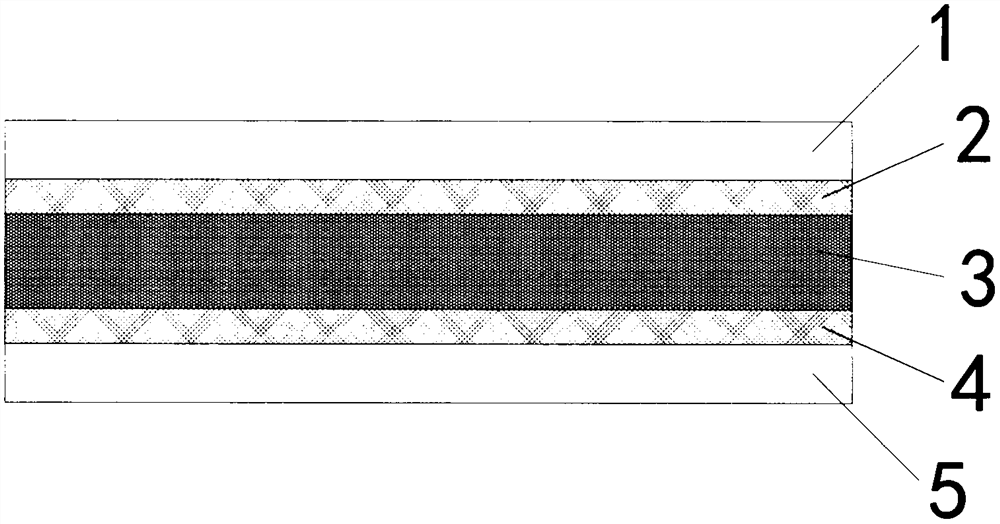

Solidification/forming/heat treatment integrated preparation method of carbon fiber metal laminate curved surface piece

ActiveCN109334164AIncreased shear strengthImprove plasticitySynthetic resin layered productsLaminationCarbon fibersFiber metal laminate

The invention provides a solidification / forming / heat treatment integrated preparation method of a carbon fiber metal laminate curved surface piece, and belongs to the technical field of multi-layer plate preparation and forming. According to the method, carbon fiber resin composite materials and solid solution-state aluminum alloy plates are alternately laminated to obtain a non-solidified fiber metal laminate; and the non-solidified fiber metal laminate undergoes heating, double-side pressing, heat preservation, solidification, forming and aging treatment to obtain the carbon fiber metal laminate. By adopting the process, the solidification / forming / heat treatment process of the fiber metal laminate can be integrated to significantly improve the processing efficiency; under the action of normal stress, the shear strength between the fiber layers and the aluminum alloy layers is higher and the plasticity of the aluminum alloy plates is better; and double-side gas pressure forming is adopted, so that the rigid contact of molds is avoided and the surface quality of components is better.

Owner:WUHAN UNIV OF TECH

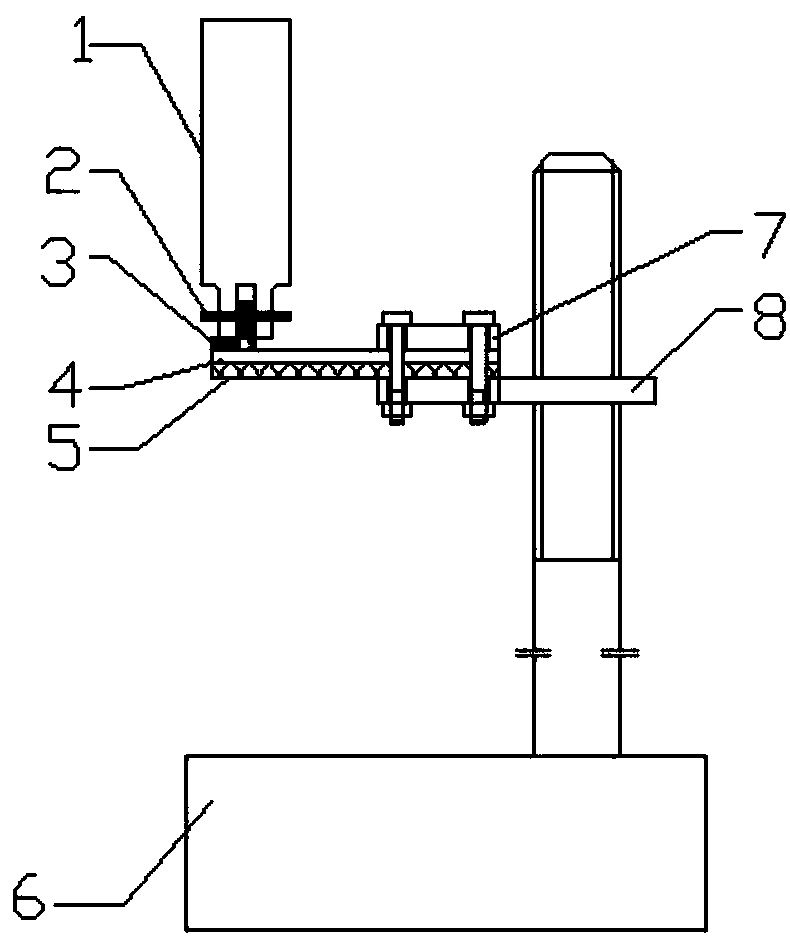

Method for manufacturing fiber metal laminate component and device adopted in method

ActiveCN106183328AReduce residual stressEvenly distributedLayered product treatmentLaminationFiber metal laminateFiber-reinforced composite

The invention provides a method for manufacturing a fiber metal laminate component. The method comprises the following steps: first, manufacturing a fiber metal laminate component prefabricated part; secondly, putting a mold laminated with the fiber metal laminate component prefabricated part in an autoclave for creeping-curing compound molding to obtain a component; and thirdly, cooling the component, removing the mold, and rebounding to obtain the fiber metal laminate component. According to the method, the process flow is simplified, the process parameters are reasonably selected, appearance and performance synergistic manufacture is realized in the autoclave by utilizing the creep aging characteristic of metal and the cure molding characteristic of the carbon fiber composite material, and the problem that metal and a fiber enhanced composite material are not matched in deformation due to different rigidities after resin is cured can be effectively avoided; the fiber metal laminate component has small residual stress, uniform distribution and small rebound deformation after molding; and the defects, such as cracking, layering and the like, cannot be easily generated inside the fiber metal laminate component. The invention further provides a device adopted in the method. The device is concise in structure and convenient to manufacture.

Owner:CENT SOUTH UNIV

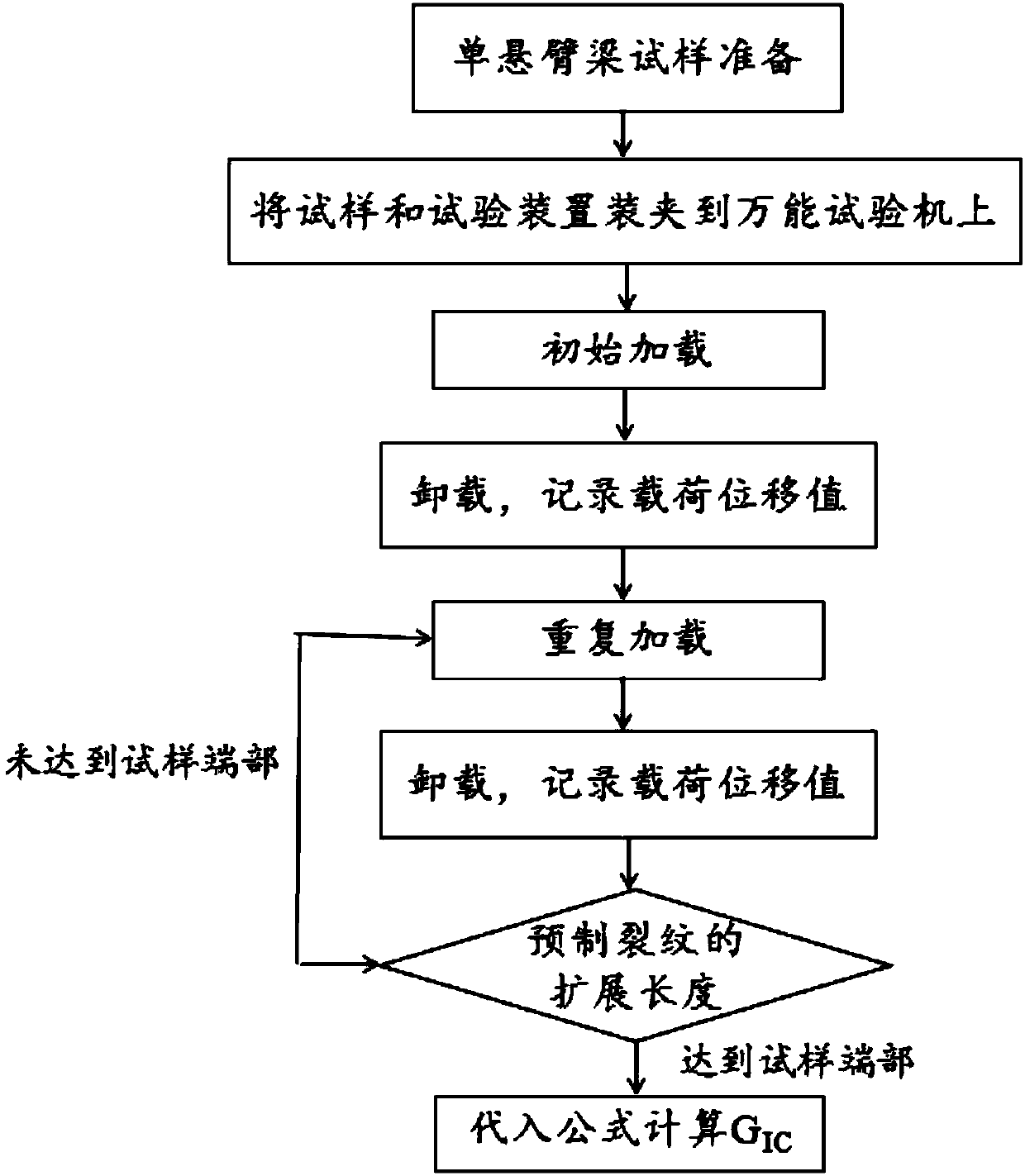

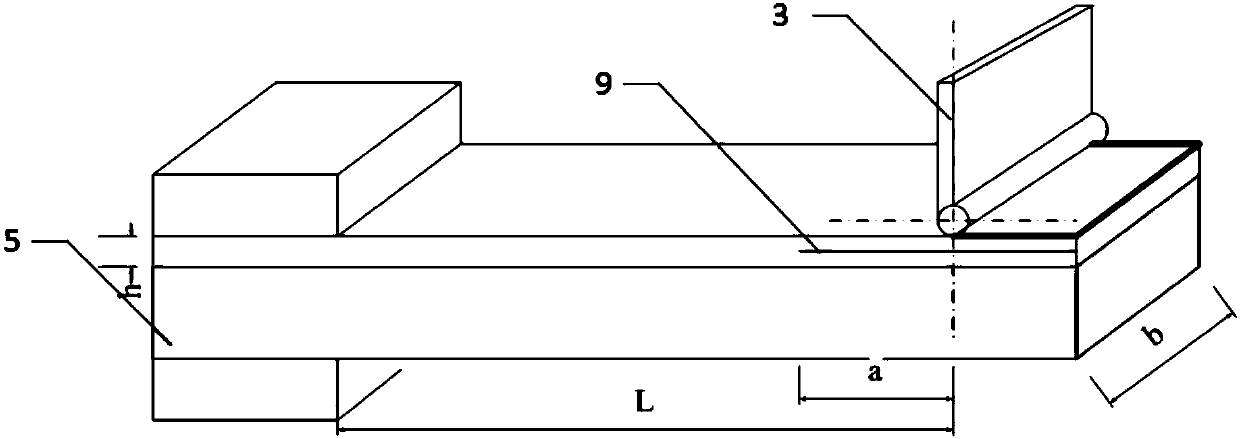

Assessment and test method and device for I-type interlaminar fracture toughness GIC of fiber-metal laminates (FMLs)

InactiveCN107621408AAddressing performance testing needsSimple structureMaterial strength using tensile/compressive forcesCantilevered beamFiber metal laminate

The invention discloses an assessment and test method and device for I-type interlaminar fracture toughness GIC of fiber-metal laminates (FMLs). The device comprises a pedestal (6), a supporting unit,a clamping unit, a universal tester and a fiber metal laminate sample; the fiber metal laminate sample is of a bar-cuboid single-cantilever beam sample, a sheet or a thin film is placed in the material interface at one end of each fiber metal laminate to serve as a precrack, a strengthening block is adhesively fixed on the lower underside of the fiber metal laminate, and an upper padding plate (7) and a lower padding plate (8) are adhesively fixed to the upper and lower sides of the other end of the fiber metal laminate. With the method, reference is provided for formulating test standard ofthe I-type interlaminar fracture toughness of the FMLs in China, and the effective method is provided for assessment of other interlaminar properties.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

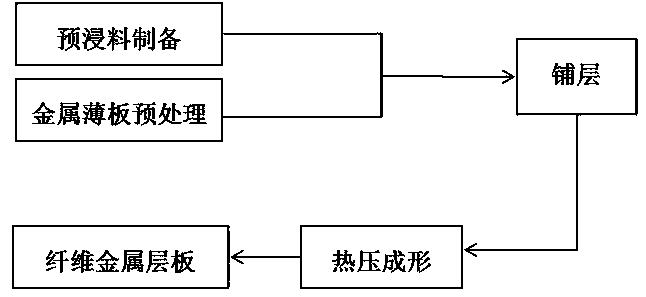

Method for preparing continuous carbon fiber enhanced polyether-ether-ketone matrix fiber metal laminates

InactiveCN104191753AHigh strengthHigh elastic modulusSynthetic resin layered productsLaminationCarbon fibersPoly ether ether ketone

The invention discloses a method for preparing continuous carbon fiber enhanced polyether-ether-ketone matrix fiber metal laminates and belongs to the field of preparation of composite materials. The method comprises the following steps: by utilizing continuous carbon fibers and a modified polyether-ether-ketone resin solution, preparing a continuous carbon fiber enhanced polyether-ether-ketone prepreg; sequentially performing degreasing treatment, acid pickling and anodic oxidation treatment on metal plates; alternatively laying the treated metal plates and the continuous carbon fiber enhanced polyether-ether-ketone prepreg, performing hot-press curing and forming on the metal plates and the prepreg in a mold, and naturally cooling, thereby obtaining the carbon fiber enhanced polyether-ether-ketone matrix fiber metal laminates. The fiber metal laminates prepared by the invention have the advantages of high toughness, high strength, difficulty in processing, environmental friendliness and no pollution.

Owner:JIANGSU CHENGFEI PRECISION ALLOY +1

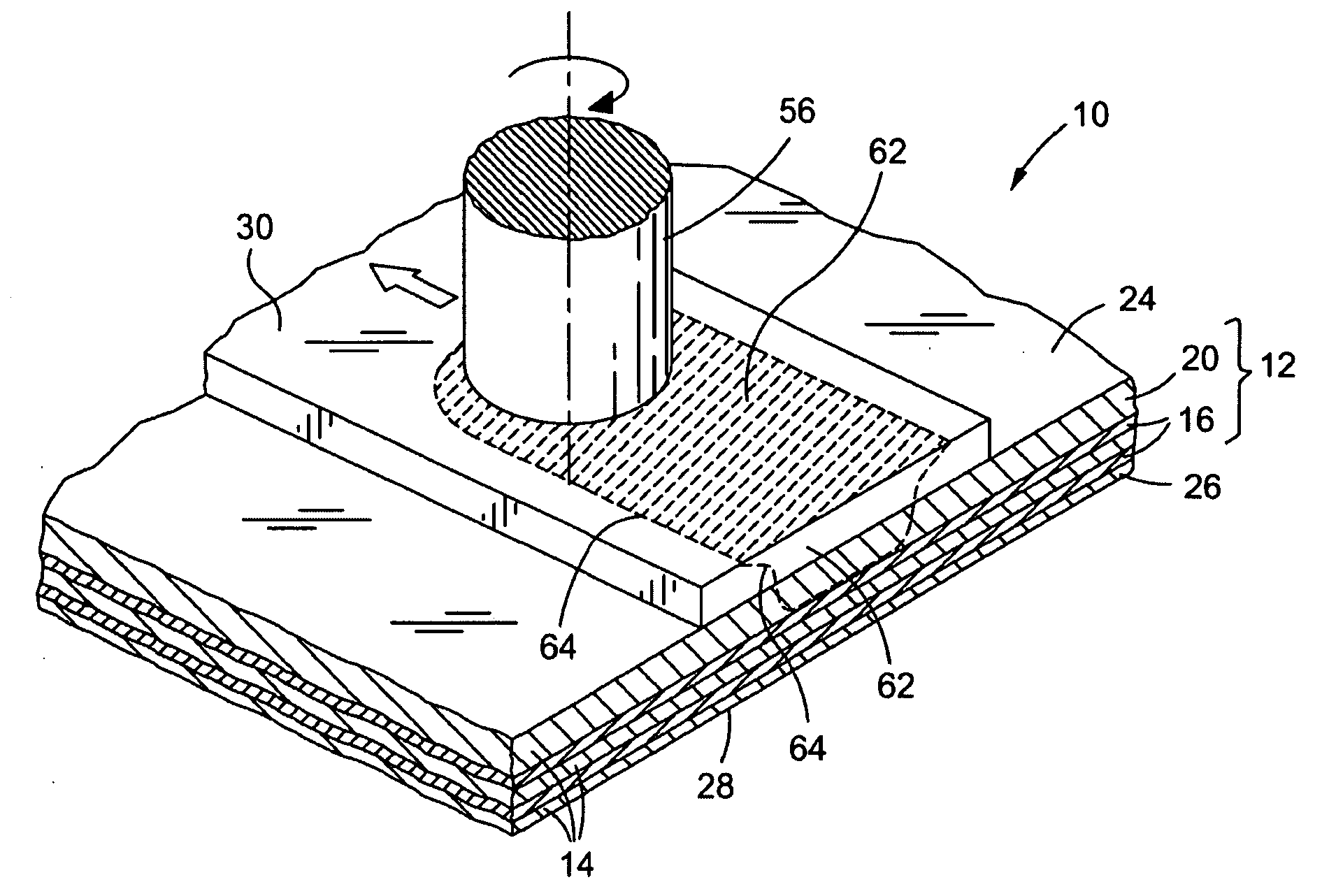

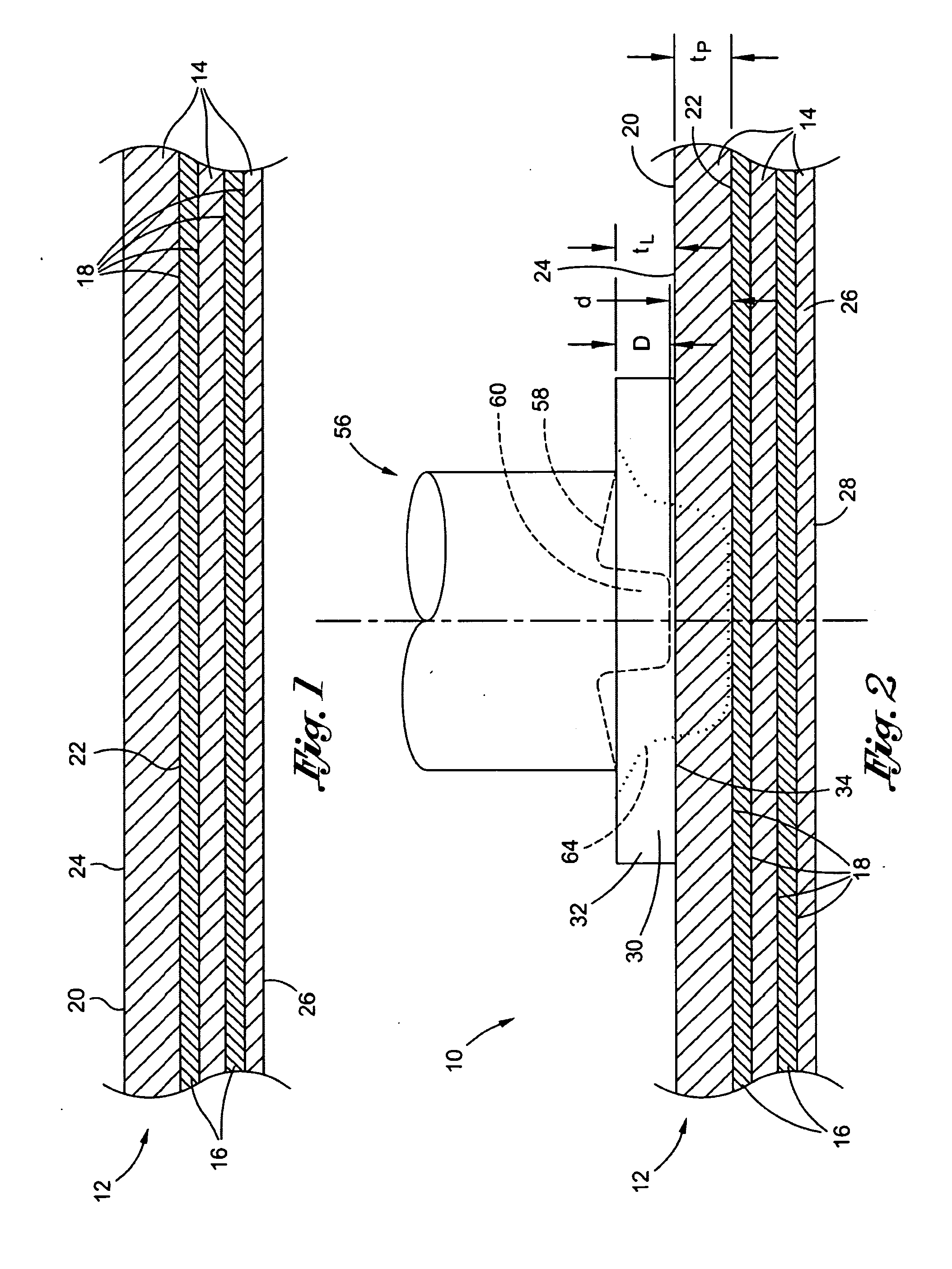

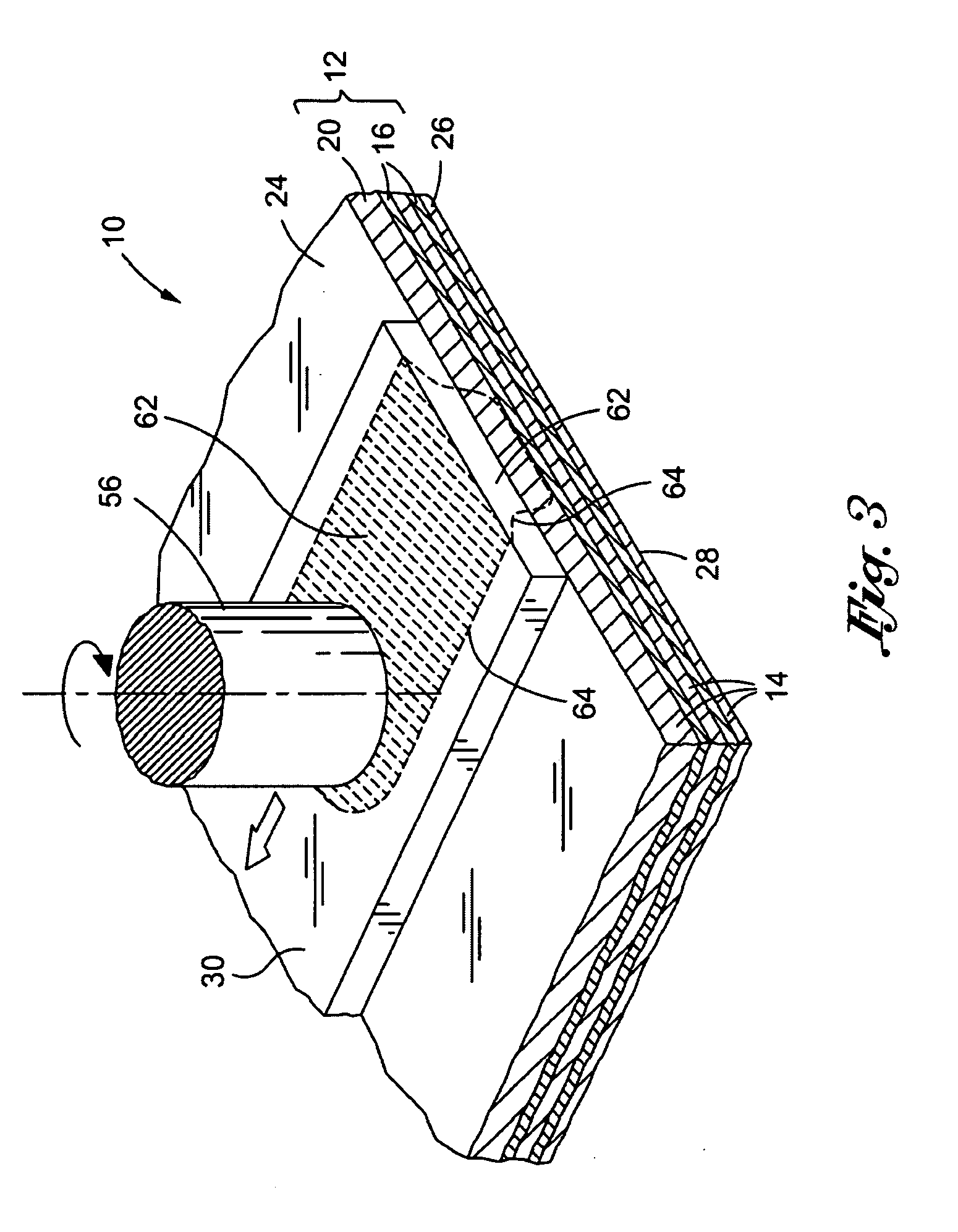

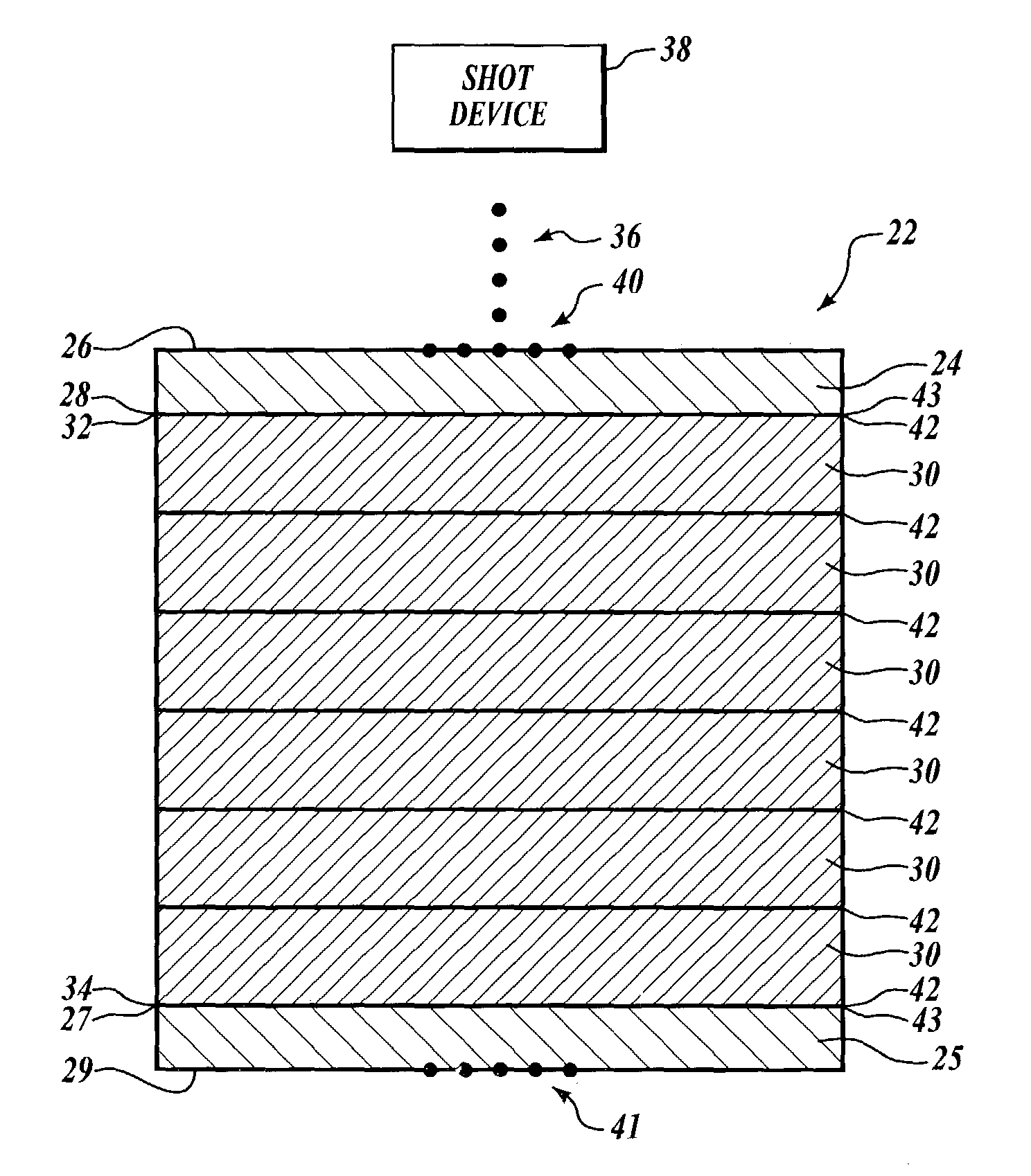

Method for improving crack resistance in fiber-metal-laminate structures

InactiveUS7192501B2Reduce crackingLow costOrnamental structuresSpecial ornamental structuresCrack resistanceFiber metal laminate

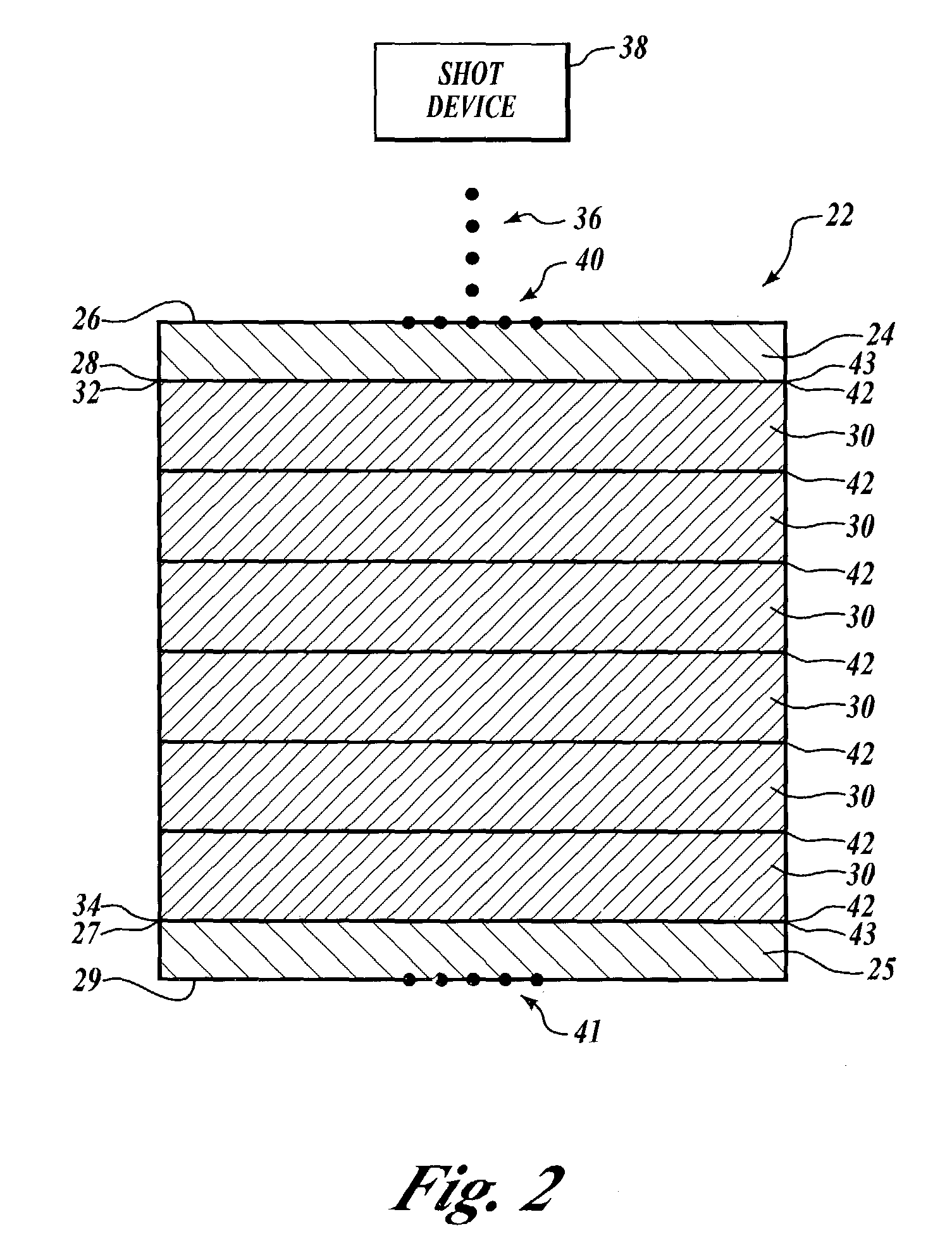

A method is provided for altering residual stresses in a fiber-metal-laminate structure. At least a first fiber laminate substrate layer having first and second surfaces is provided. At least a first outer metallic laminate layer having third and fourth surfaces is provided, and the first and fourth surface is provided, and the first and fourth surfaces are bonded together. The third surface is peened, such that the at least first fiber laminate substrate layer is subjected to residual tensile stresses and the at least first outer metallic laminate layer is subjected to residual compression stresses. Peening defines a peened region that extends from the third surface into the at least first outer metallic laminate layer a finite distance that is closer to the third surface than the fourth surface.

Owner:THE BOEING CO

Composite bulletproof armor plate and preparation method thereof

ActiveCN109855473AHigh compressive strengthIncrease elasticitySynthetic resin layered productsLaminationInterference fitCeramic composite

The invention discloses a composite bulletproof armor plate and a preparation method thereof. The composite bulletproof armor plate comprises a protective cover plate, ceramic plates, metal restraining plates, a fiber metal laminated plate and a porous metal sandwich plate; and the ceramic plates and the metal restraining plates are assembled and connected in an interference fit mode, the ceramicplates are supported through the fiber metal laminated plate and the porous metal sandwich plate, and the bullet resistance of a bulletproof armor plate is improved. The preparation technology is simple, the cost is low, compared with a traditional ceramic composite armor plate, the composite bulletproof armor plate is higher in impact resistance at a time and has the multi-time impact resistance,and the composite bulletproof armor plate has the wide application prospects in the bulletproof fields of armed helicopters, armored cars, vessels and the like.

Owner:XI AN JIAOTONG UNIV

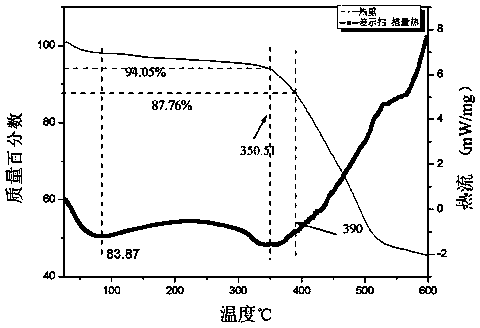

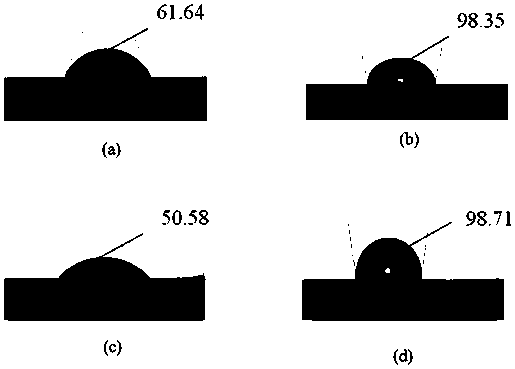

Method for significantly improving metal joint strength by using metal complex

ActiveCN107815677AImprove interface performanceAct as a bridgeAnodisationMetallic material coating processesMicro nanoSalicylaldehyde

The invention relates to a method for significantly improving the metal joint strength by using a metal complex, in particular to influence of a schiff base metal complex on the metal joint strength.According to the design method, a micro-nano structure is constructed on a clean metal plate firstly, the surface of the metal plate is subjected to hydroxylation, and a bis-salicylaldehyde schiff base ligand and the metal complex thereof are prepared; and the schiff base metal complex is self-assembled on the surface of the metal plate, hot pressing is conducted for making a single-lap shearing sample, and the influence of the schiff base metal complex on the joint strength of metal / resin is researched. According to the method for significantly improving the metal joint strength by using themetal complex, the interfacial strength between the metal and resin is improved through actions such as mechanical meshing force, chemical bonds and molecular winding; anodic oxidation is combined with a schiff base titanium complex process, and the single-lap shearing strength of TC4 / PEEK reaches 47.5 MPa and is improved by 54.2% compared with a pure anodic oxidation sample (30.8 MPa); and the problems of interfacial stratification and damp-heat aging in fiber metal laminated plates are advantageously solved, the preparation process is simple, reaction conditions are controllable, and large-scale production and application can be achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

System and method for integrally forming a stiffener with a fiber metal laminate

ActiveUS8678267B2Extended service lifeImpact-resistance is enhancedTurbinesWelding/cutting auxillary devicesThermal energyFiber metal laminate

A unitized assembly comprises a fiber metal laminate having at least one additive layer deposited thereonto such as by friction stir welding. The fiber metal laminate comprises metallic and non-metallic plies and having an innermost metallic ply. The innermost metallic ply and the additive layer are each sized and configured to facilitate the generation of thermal energy sufficient to deposit the first additive layer to the innermost metallic ply during the friction stir welding process. The additive layer is sized and configured to minimize thermal loads in the innermost metallic ply during deposition thereof. The unitized assembly may be formed using a stock member such as a metallic plate from which the innermost metallic ply may be machined. The metallic and non-metallic plies may be laid up over the innermost metallic ply. The substructure elements may be machined from the metallic plate.

Owner:THE BOEING CO

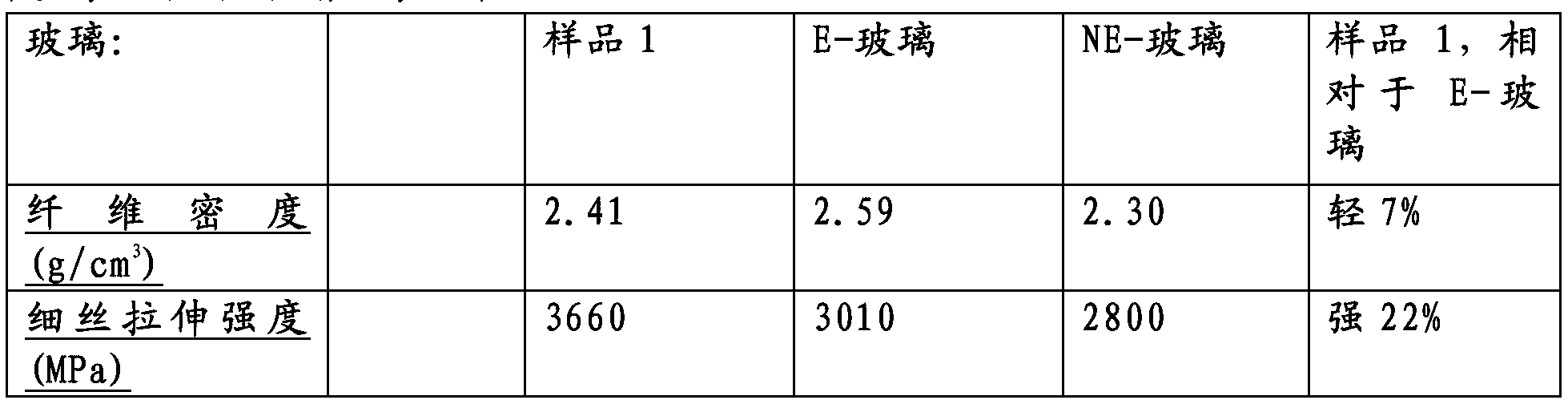

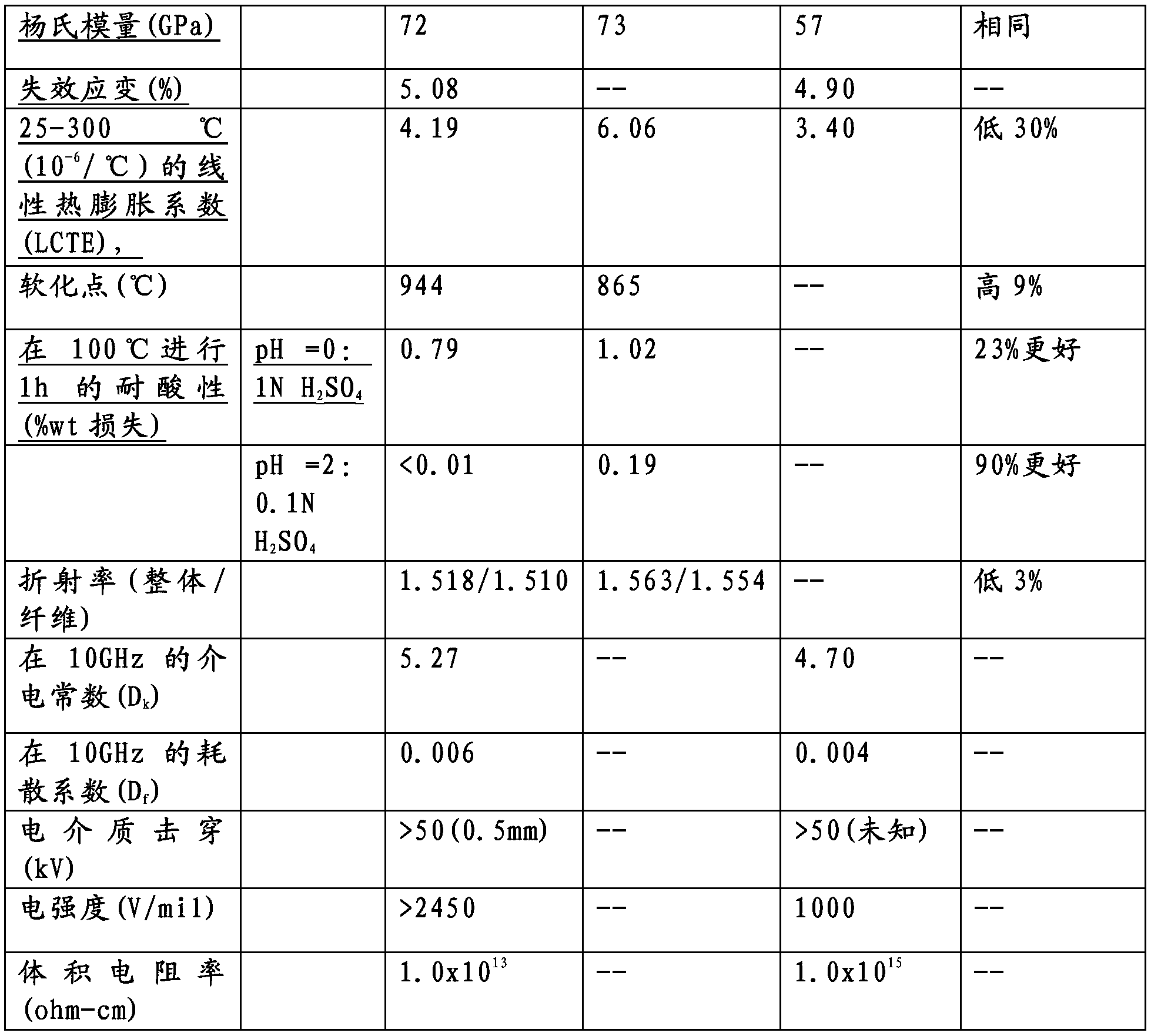

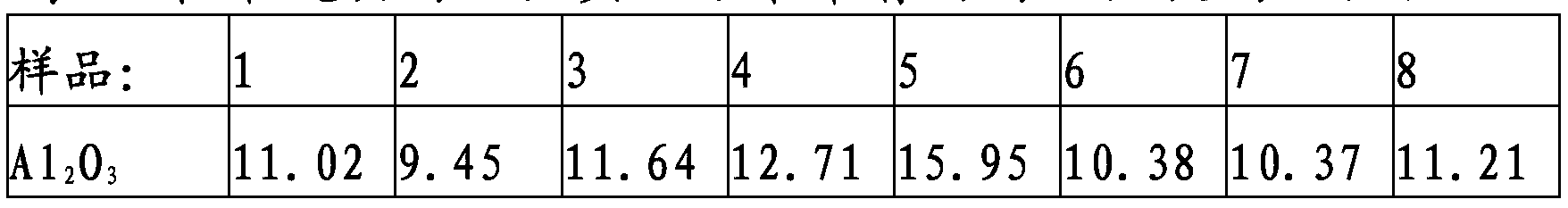

Low density and high strength fiber glass for reinforcement applications

The present invention relates to fiber glass strands, yarns, fabrics, composites, prepregs, laminates, fiber-metal laminates, and other products incorporating glass fibers formed from glass compositions. The glass fibers, in some embodiments, are incorporated into composites that can be used in reinforcement applications. Glass fibers formed from some embodiments of the glass compositions can have certain desirable properties that can include, for example, desirable electrical properties (e.g. low Dk) or desirable mechanical properties (e.g., specific strength).

Owner:PPG IND OHIO INC

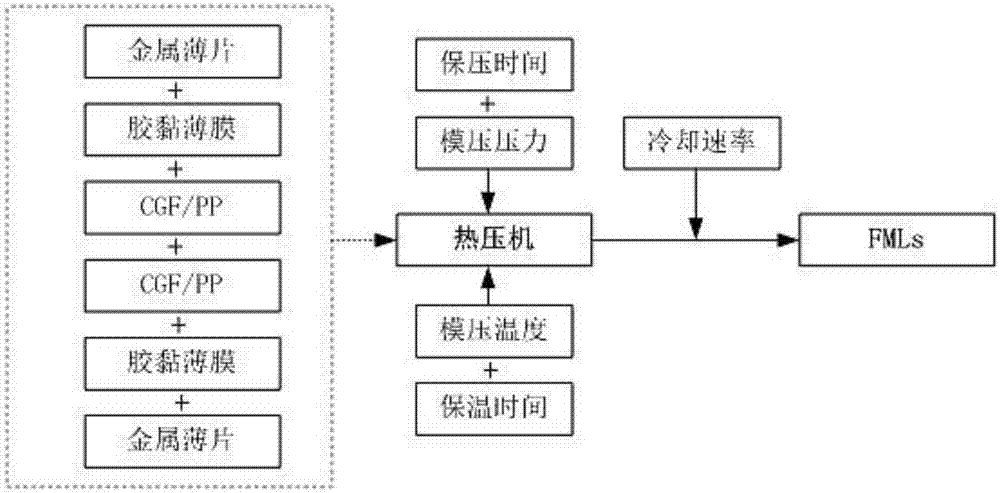

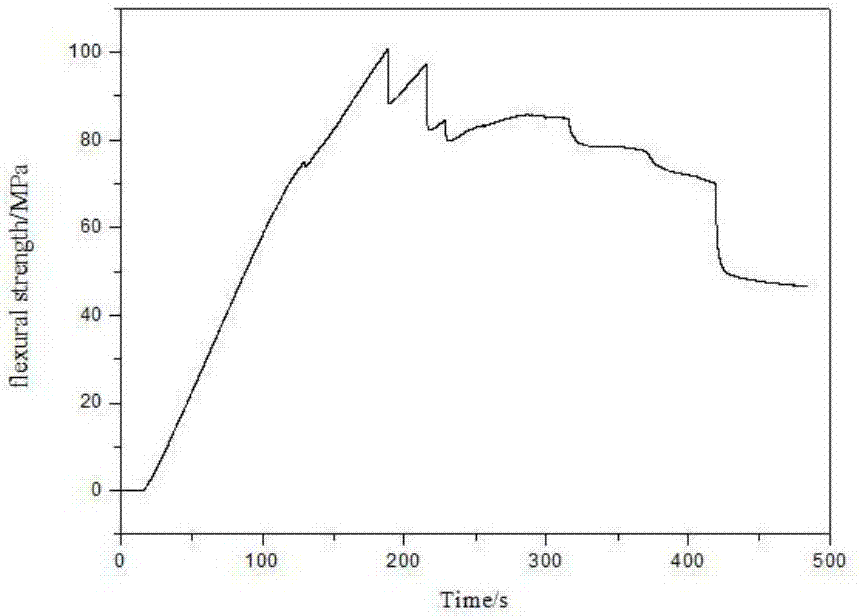

Preparation method of fiber metal laminate and fiber metal laminate

The invention discloses a preparation method of a fiber metal laminate, which comprises the following steps of: coating a die in a hot press with mould release wax / a mould release agent; sequentially placing a layer of metal sheet, at least one layer of interface thin film, at least two layers of fiber prepreg tape fabrics, at least one layer of interface thin film and one layer of metal sheet in the die; setting process parameters of the hot press and starting the hot press, carrying out heat preservation after a temperature of the die in the hot press reaches a preset temperature, carrying out pressure maintaining at the preset temperature, and finally, carrying out cooling at a preset cooling rate to obtain the fiber metal laminate. Composite molding of the fiber prepreg tape fabrics and the metal sheets is implemented by the hot press through adopting a hot die-pressing method, so that a workpiece is smooth and flat in surface and has high mechanical performance, and compared with a steel workpiece with the same thickness, the workpiece is greatly reduced in weight; the mould release agent or the mould release wax is brushed, and release cloth is laid, so that the formed composite material is easy to demould; in comparison with a pure composite material, the fiber metal laminate is low in cost and more superior in performance.

Owner:HUNAN UNIV

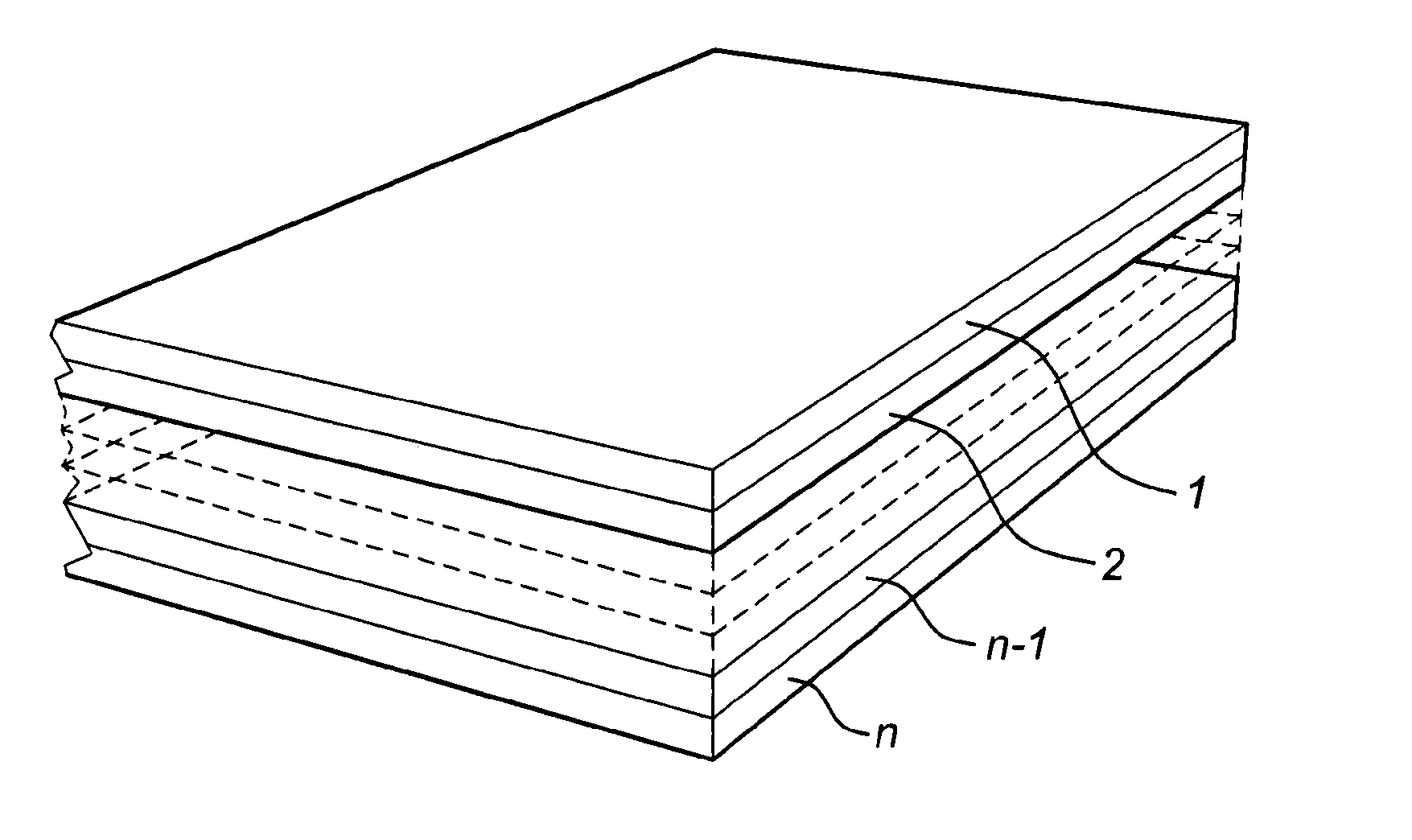

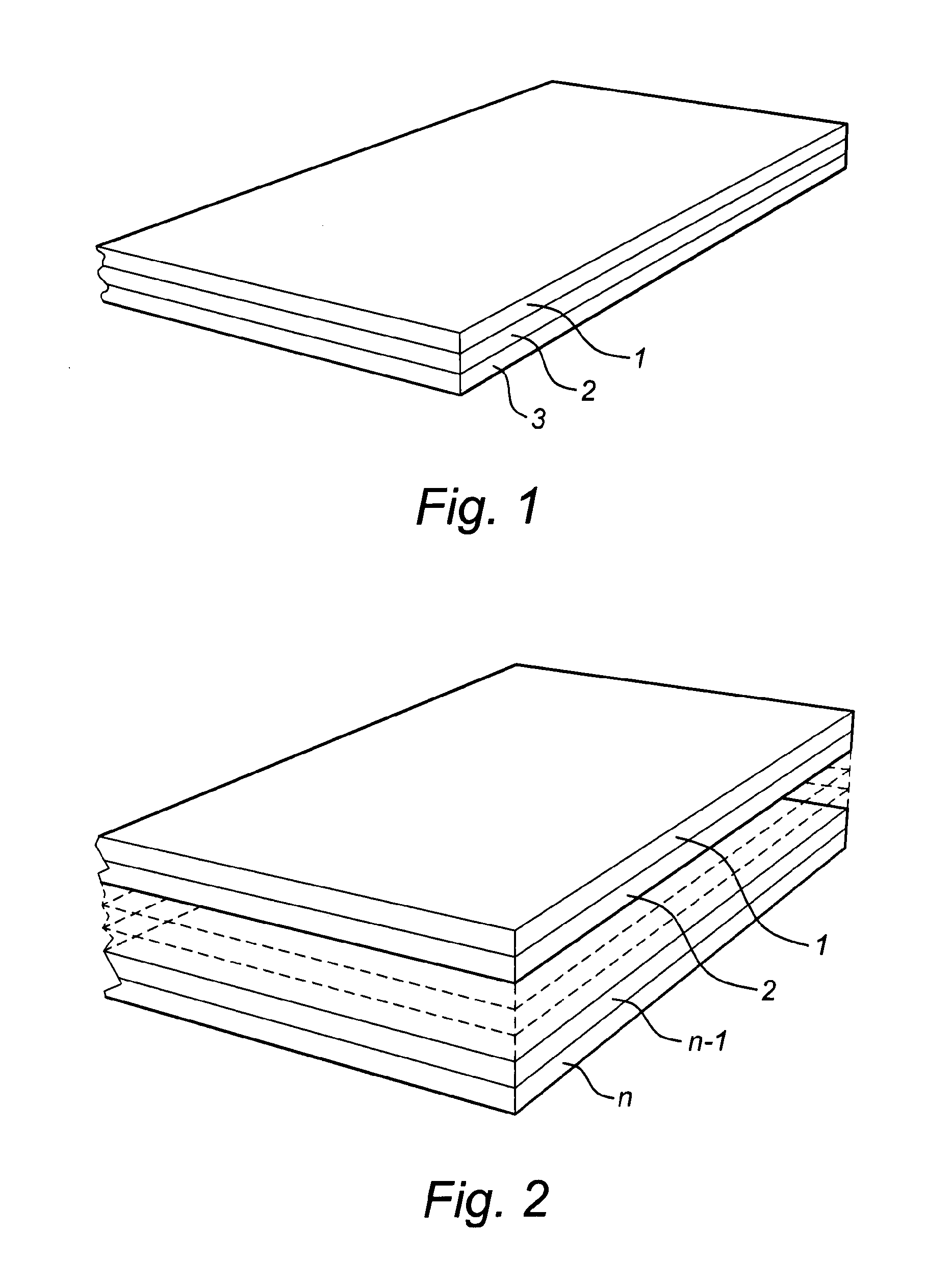

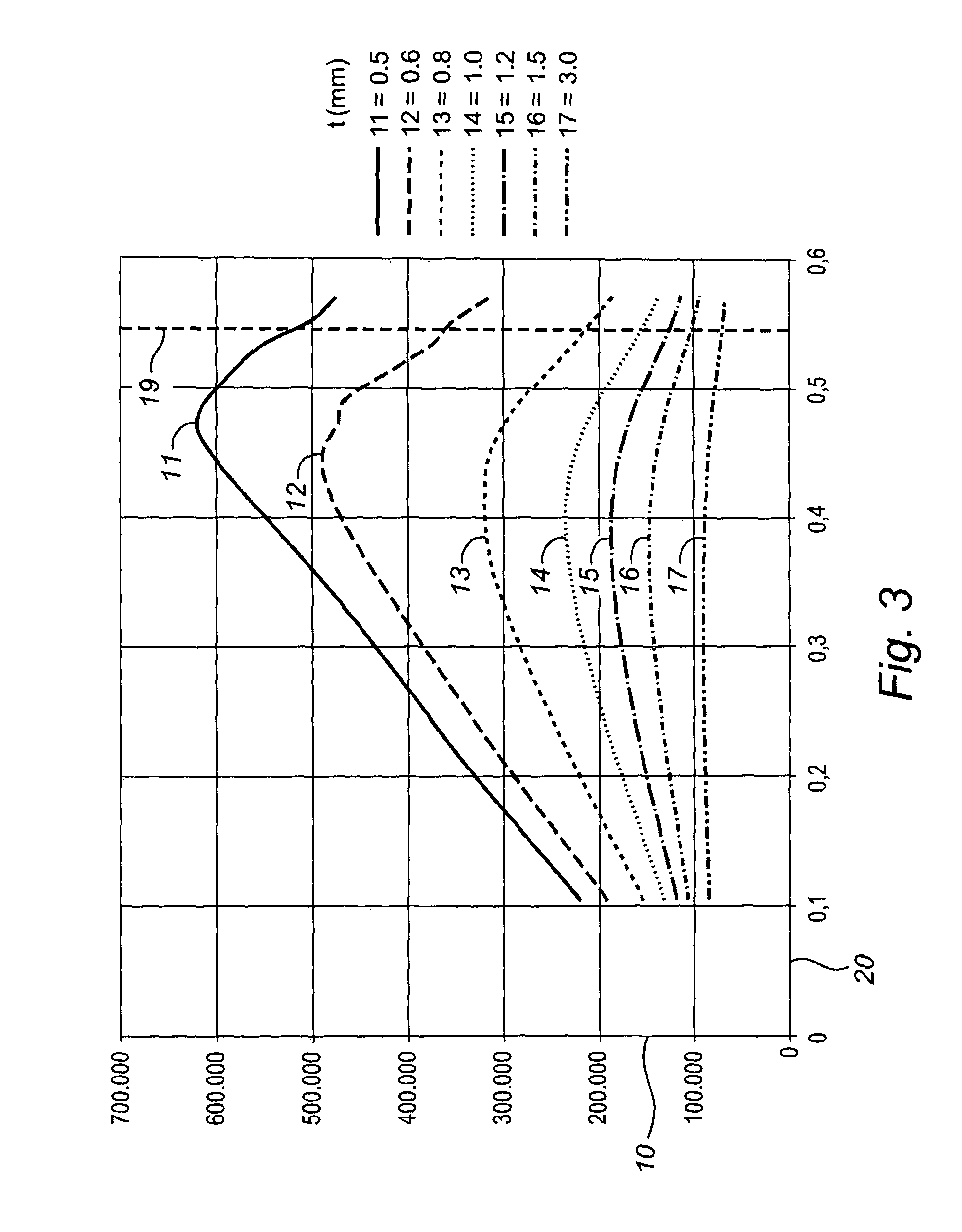

Fiber-Metal Laminate

ActiveUS20140329069A1Mechanical area measurementsSynthetic resin layered productsHigh stiffnessFiber metal laminate

A fiber-metal laminate of mutually bonded fiber-reinforced composite layers and metal sheets comprises a combination of a fiber-reinforced composite layer and an adjacent metal sheet, in which combination the properties satisfy the following relations:Elam*Ecomp / (Emetal*tmetal2) has a value between a lower bound given bya*(Vf−c)(b / (Vf−c)) with b=0.36 and c=0.3 (1a)and zero when Vf≦0.3, (1b)and an upper bound given bya*(Vf−c)(b / (Vf−c)) with b=0.88 and c=0 (1c)0.10≦Vf<0.54 (2)0<Elam*Ecomp / (Emetal*tmetal2)<400*Vf kN / mm4 (3)wherein a=1200 kN / mm4; andEcomp=tensile Young's modulus of the fiber-reinforced composite layer in kN / mm2 in the combination, taken in the direction of highest stiffness of the composite layerElam=tensile Young's modulus of the total fiber-metal laminate in kN / mm2, taken in the same direction as for Ecomp Emetal=tensile Young's modulus of the metal sheet in kN / mm2 in the combinationtmetal=thickness of the metal sheet in mm in the combinationVf=fiber volume fraction of the fiber-reinforced composite layer in the combination.

Owner:GTM ADVANCED PROD

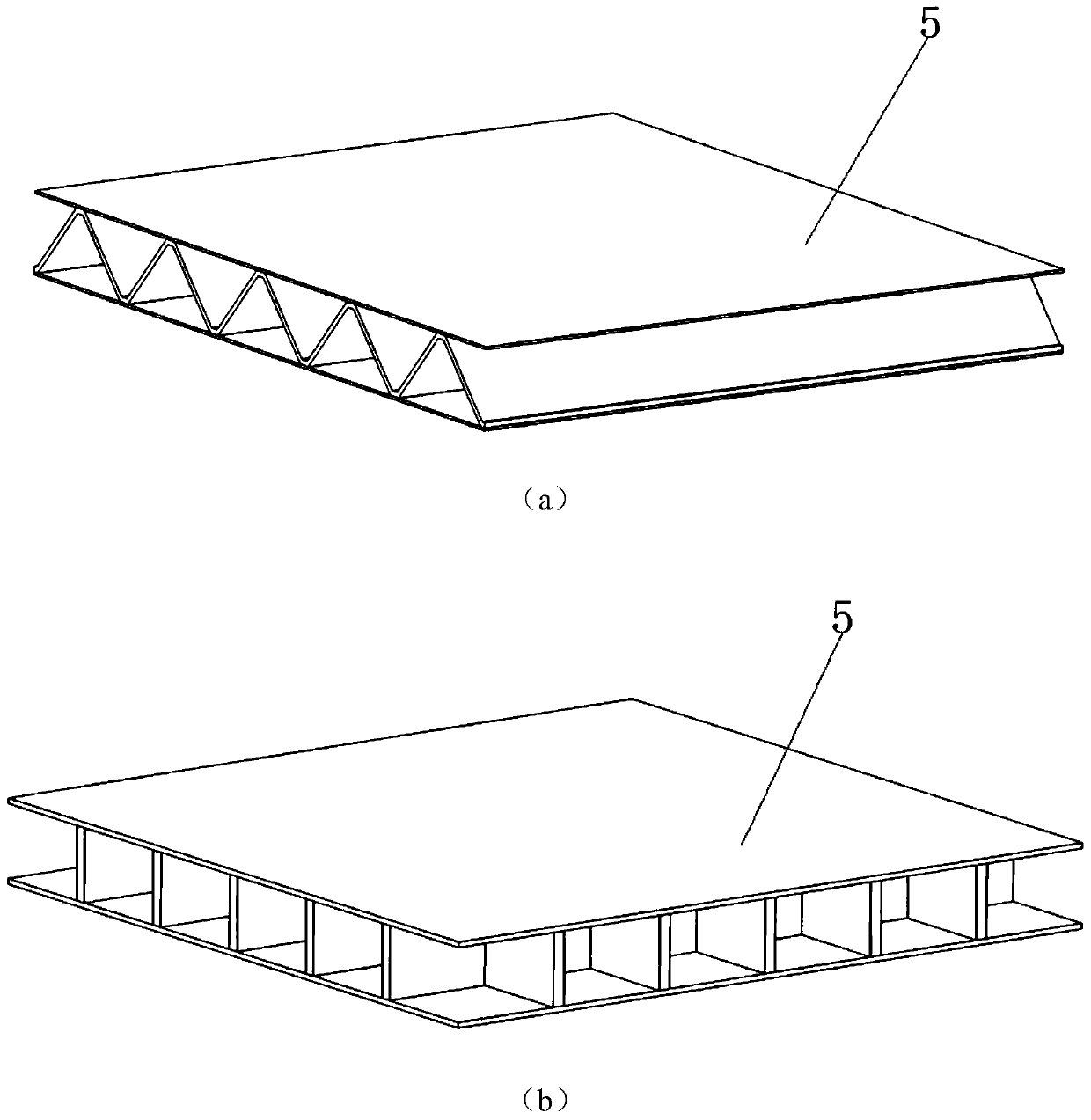

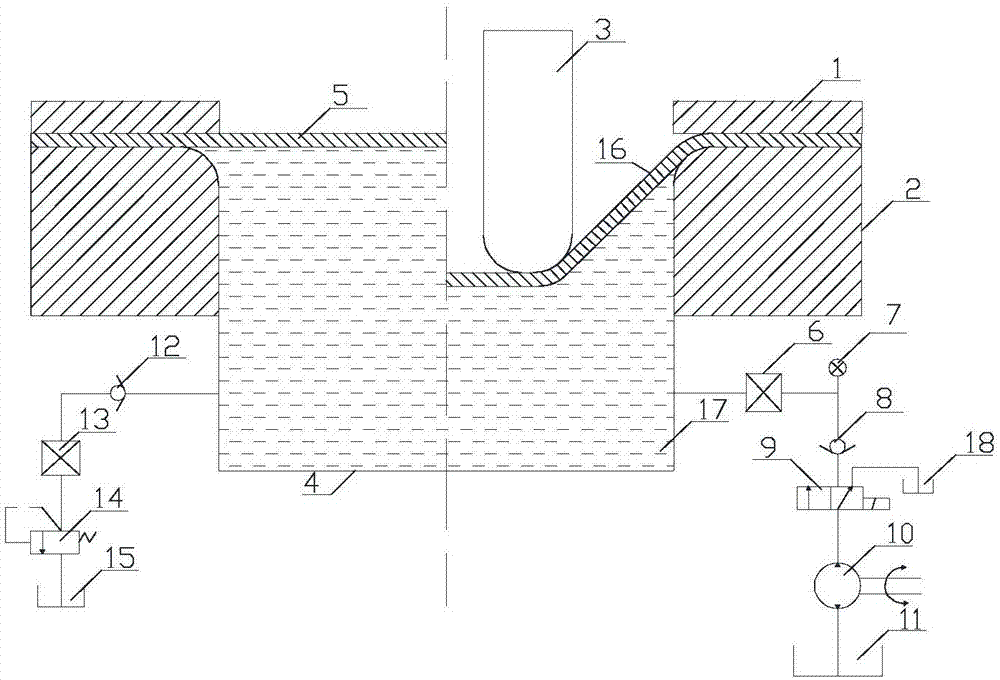

Fiber metal laminated plate forming device and method

InactiveCN107570585ASupport pressure is the sameImprovement accuracy is not highShaping toolsMetal-working feeding devicesTemperature controlNumerical control

The invention provides a fiber metal laminated plate forming device and method. A fiber metal laminated plate is processed by means of the hydraulic supporting and auxiliary heating numerical controlincremental forming technology. On a numerical control incremental forming machine tool, a forming tool head controlled through a mechanical program is arranged above a frame-shaped upper forming fixture and a frame-shaped lower forming fixture in advance. A box with an upward opening is additionally arranged in a cavity of the lower forming fixture. The laminated plate is clamped between the upper forming fixture and the lower forming fixture. The box is connected with a pressure control system and a temperature control system through a pipeline. In the process of incremental forming, a hydraulic control system is used for controlling ingoing, outgoing, heating and cooling of hydraulic oil to guarantee that the pressure and temperature borne by the laminated plate to be uniform and constant in the forming process. Accordingly, the good mechanical performance of the laminated plate is guaranteed, and the forming quality of products is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

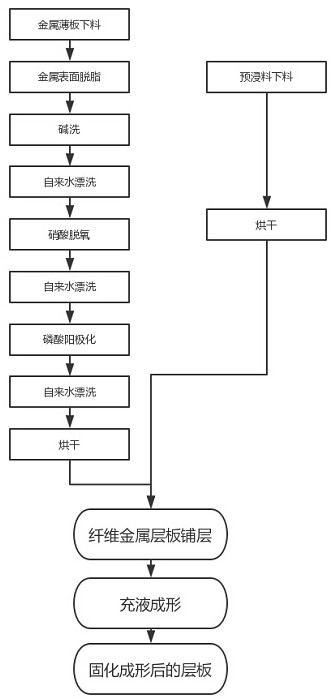

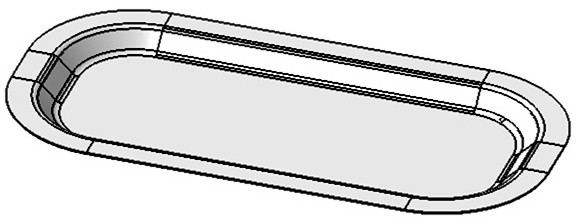

Semi-curing forming process for thermosetting fiber metal laminate

InactiveCN112092479ALight in massLight damage toleranceAnodisationLamination ancillary operationsGlass fiberFiber metal laminate

The invention discloses a semi-curing forming process for a thermosetting fiber metal laminate. The semi-curing forming process comprises the following steps: pretreating a metal plate; coating a layer of adhesive on the surface of the metal plate, and laying a cut glass fiber prepreg on the surface of the metal plate; sealing the periphery of the laid fiber metal plate; placing the fiber metal plate on a lower die of a hydraulic forming machine and positioning descending the upper die, closing the dies and forming; putting a formed part into a vacuum bag, vacuumizing, heating to a curing temperature, and keeping the temperature and the pressure for 3 hours; furnace cooling. The thermosetting fiber metal laminate is formed before being cured, and adverse factors such as large deformation and difficult forming after curing are solved to a certain extent by utilizing a certain flowing property between the resin and the metal plate. And meanwhile, liquid filling forming is adopted, so that the plate is stressed in the thickness direction and bears the three-way compressive stress state, the forming performance of the fiber laminate is improved, and forming of multi-curvature complex-shaped parts is achieved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

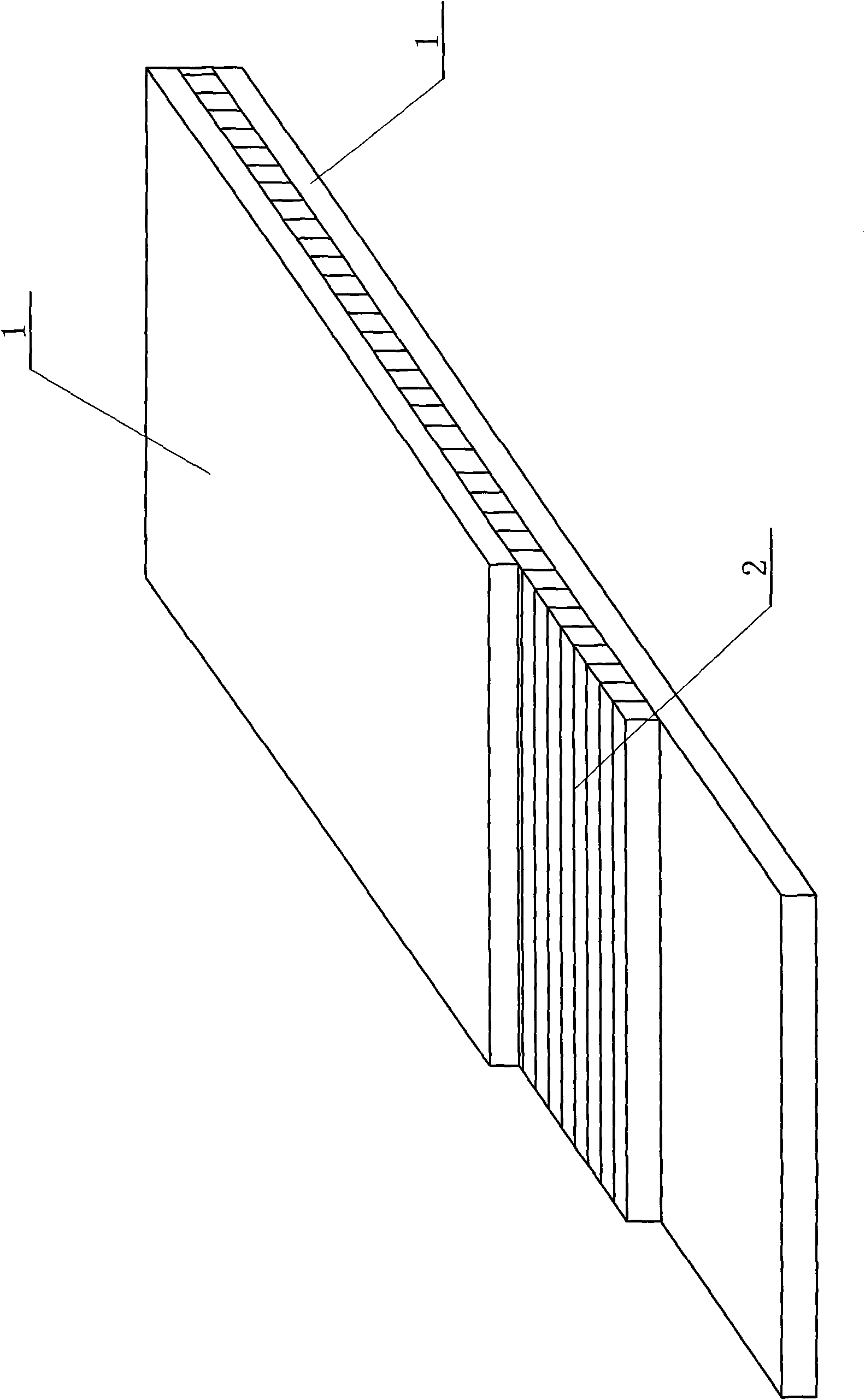

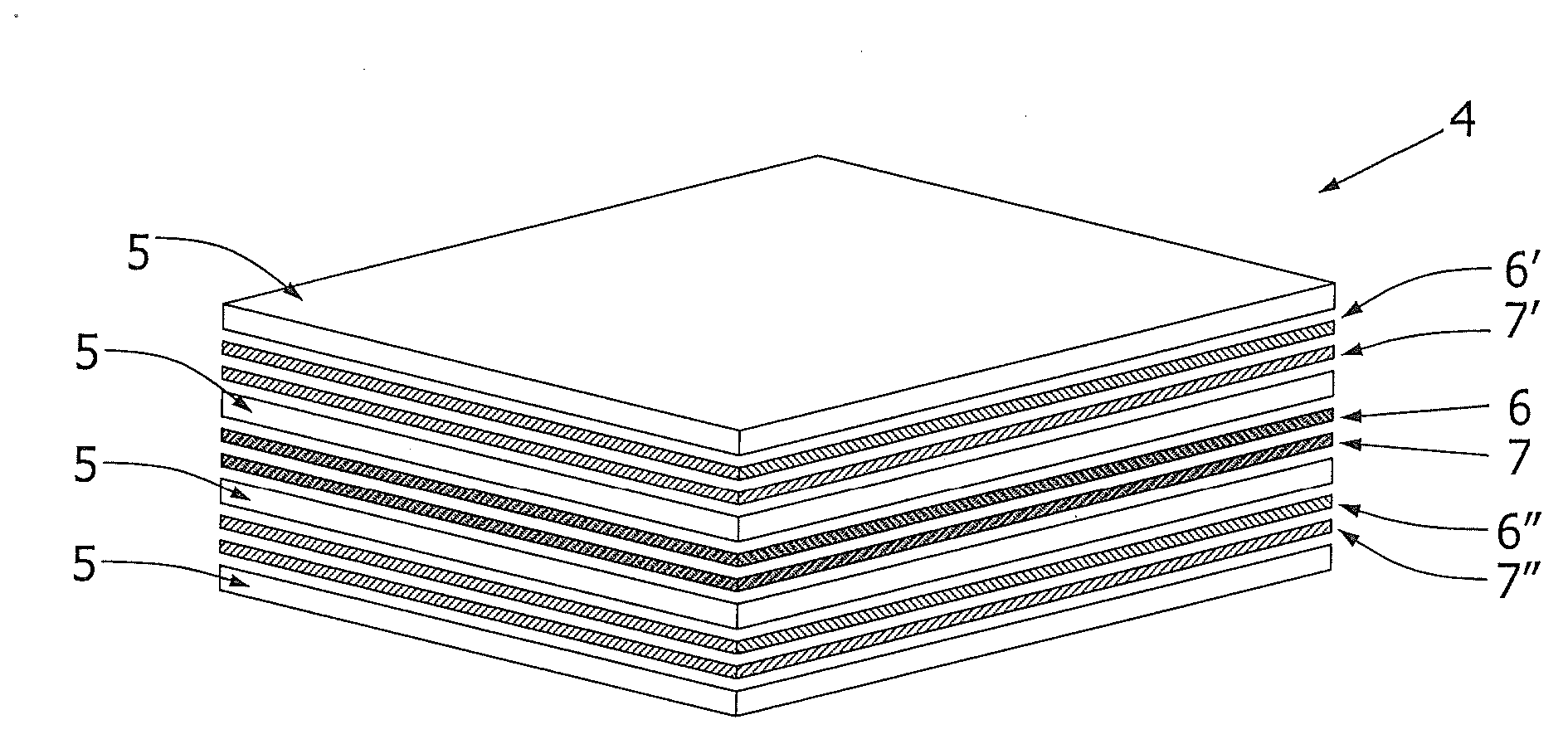

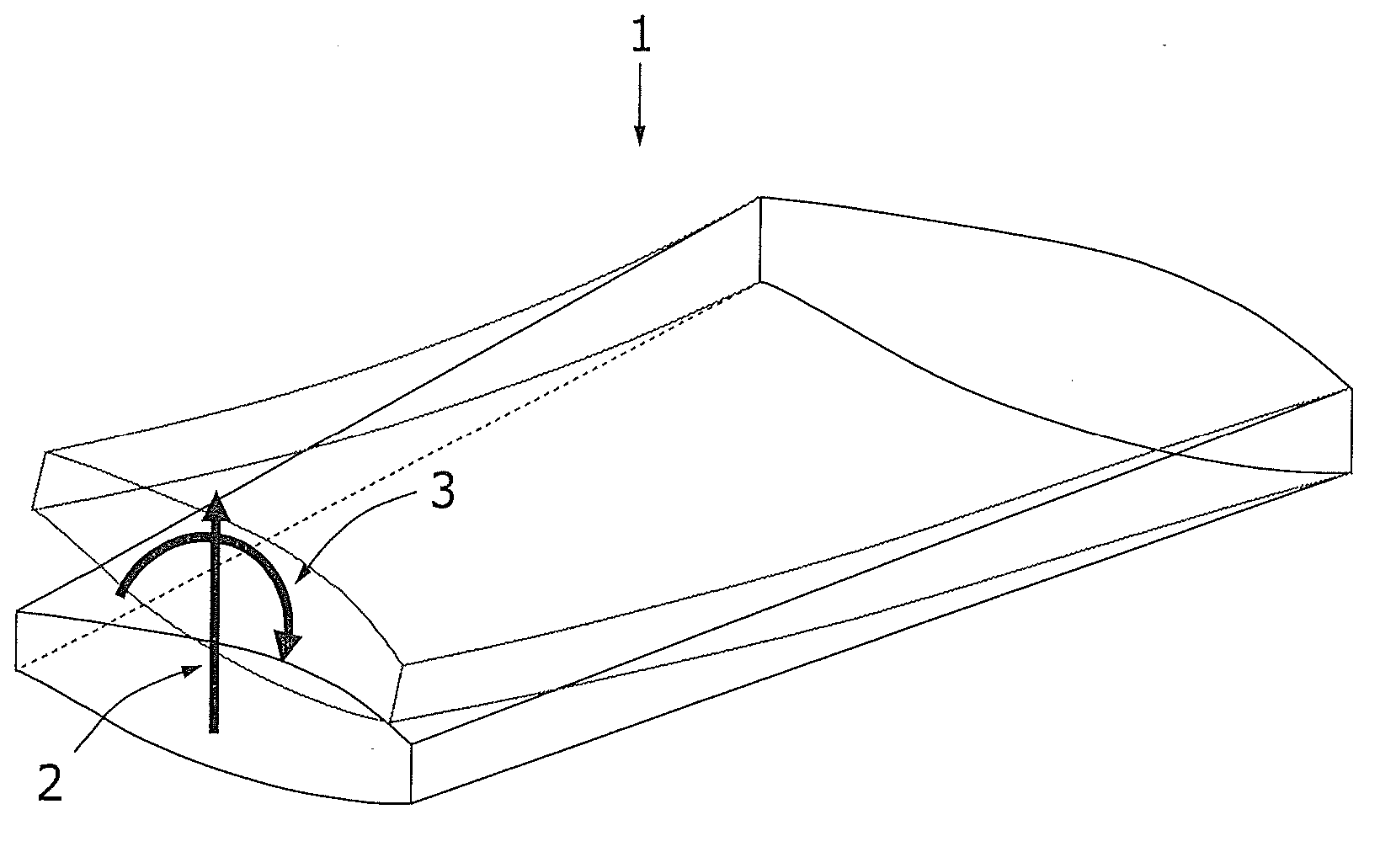

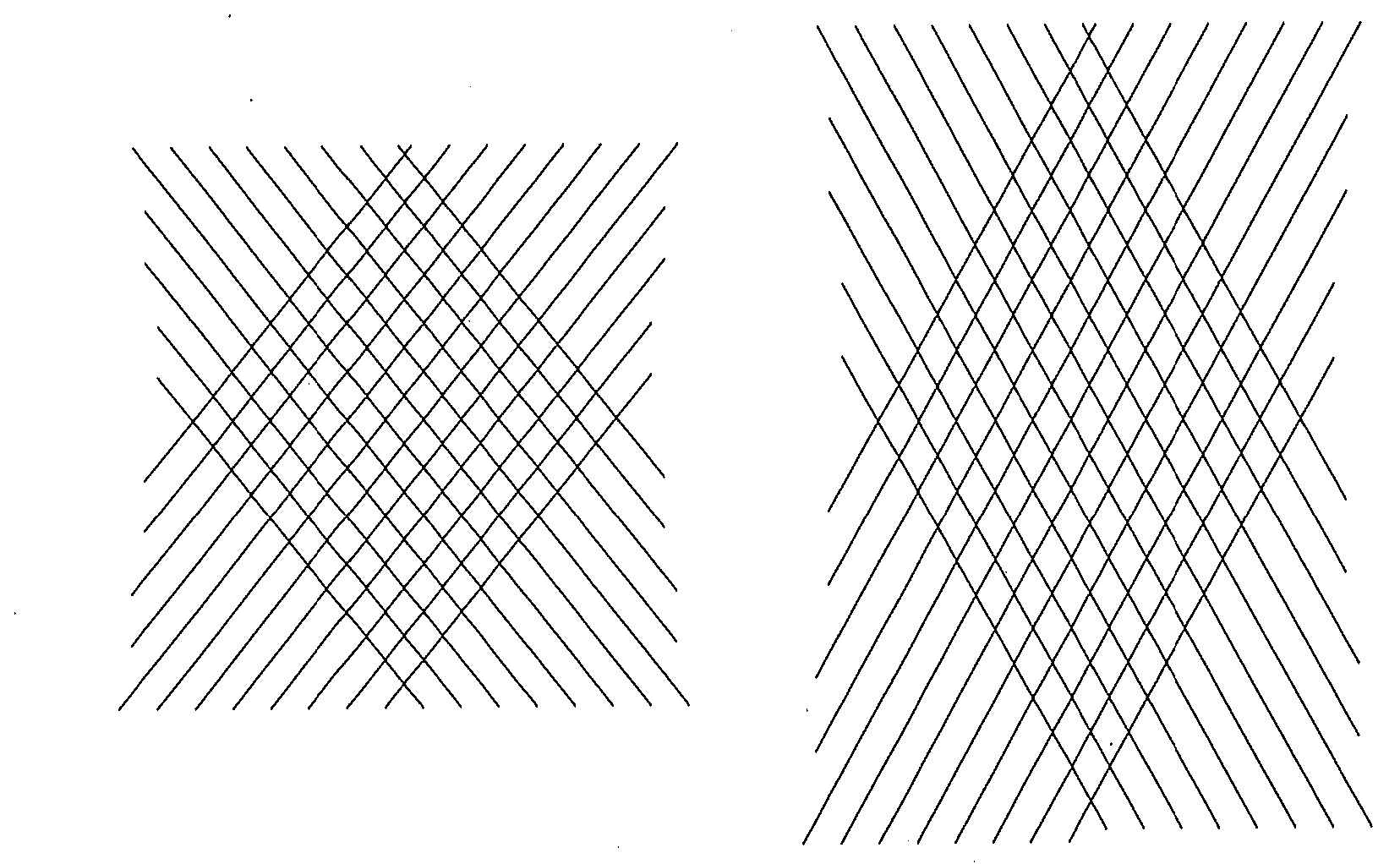

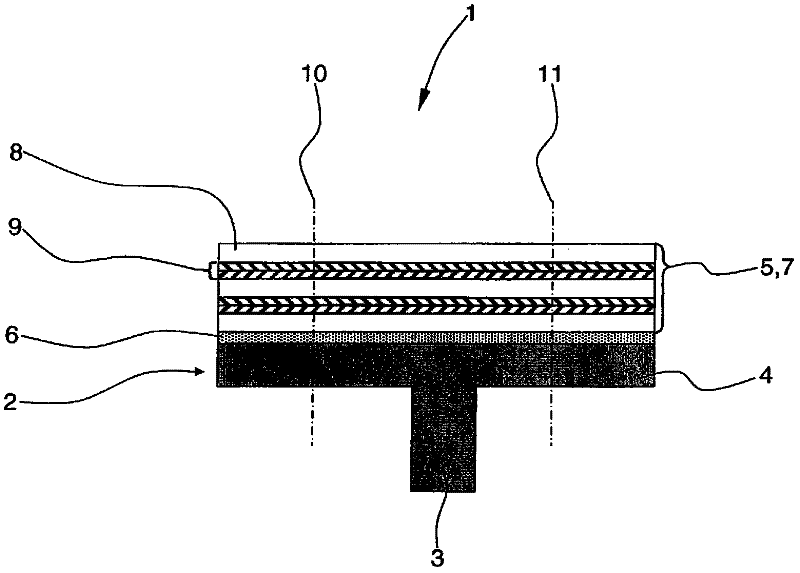

Aircraft wing and fiber metal laminate forming part of such an aircraft wing

InactiveCN103140349AEfficient propulsion technologiesWeight reductionFiber metal laminateOptoelectronics

Fiber metal laminate (4)and an aircraft wing (1) having a longitudinal direction, comprising metal layers (5) and fiber reinforced plastic layers (6, 7, 6', 7'; 6'', 7'') in between said metal layers (5),wherein the metal layers (5) and the fiber reinforced plastic layers (6, 7, 6', 7'; 6'', 7'') are bonded together, and wherein the fibers of at least some of the fiber reinforced plastic layers (6, 7, 6', 7'; 6'', 7'') are arranged in a first group in a first plastic layer (6) and in a second group in a second plastic layer (7) whereby the fibers of the first group are at an angle with respect to the fibers of the second group, whereinsaid laminate (4) exhibits fibers of a first type and fibers of a second type, wherein the fibers of the first type being arranged in the said longitudinal direction of the laminate (4) in one or more of its fiber reinforced plastic layers (6', 7'; 6'', 7''), and that it has adjacent fiber reinforced plastic layers (6, 7) at or near a symmetry-plane of the laminate (4) that are provided with the fibers of the second type.

Owner:CONSTELLIUM ISSOIRE

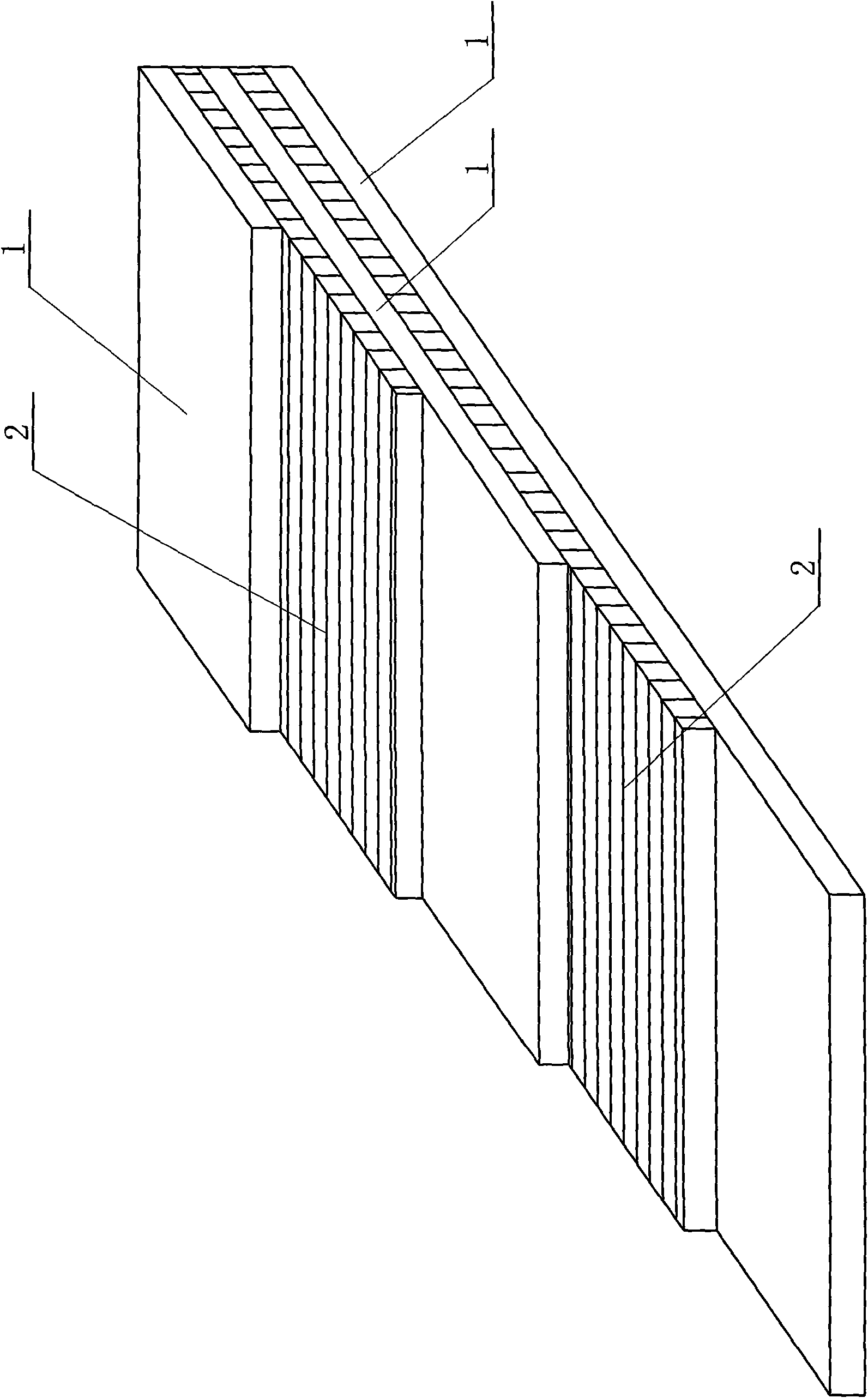

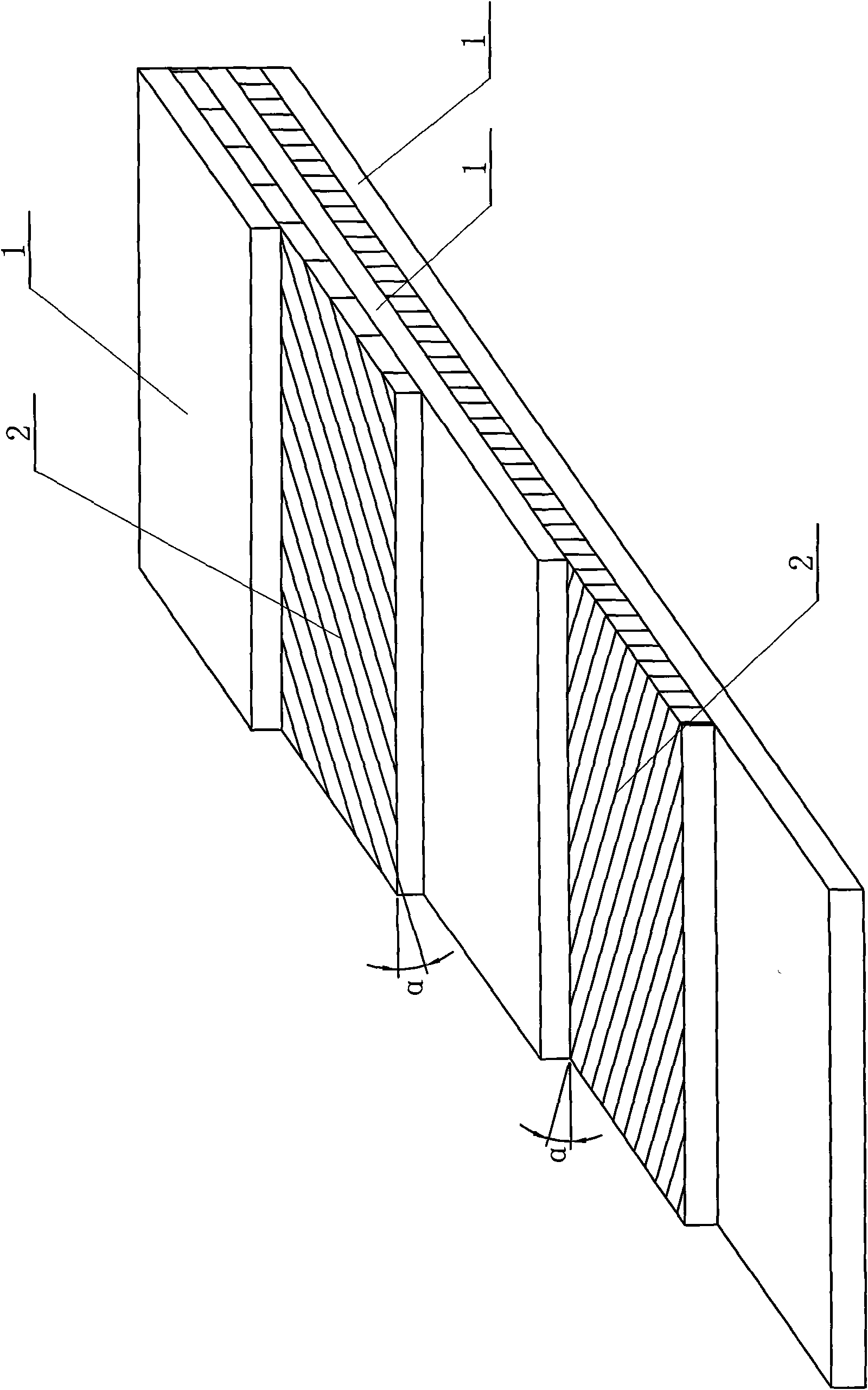

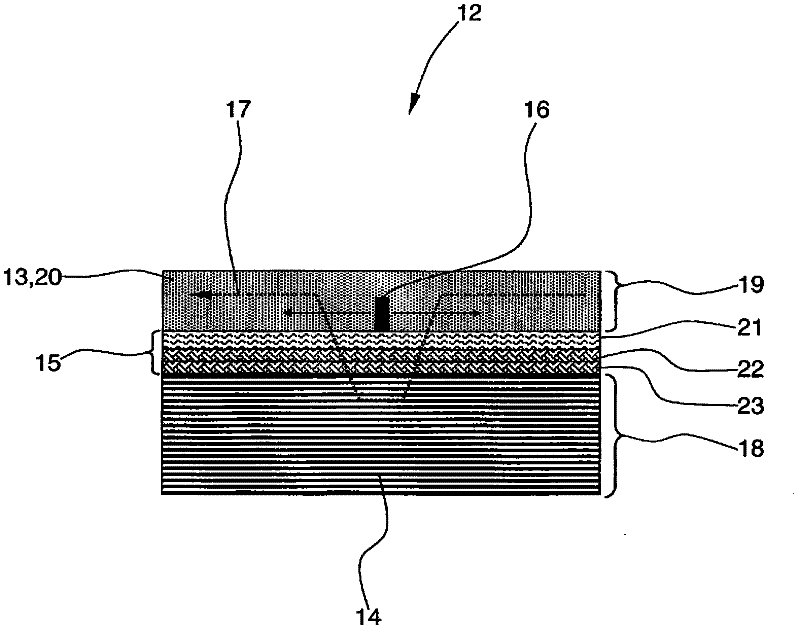

Structural element for reinforcing a fuselage of an aircraft

InactiveCN102186722AHigh damage toleranceFuselage framesEfficient propulsion technologiesFiber metal laminateMetallic materials

The invention relates to a structural element (1,12,30) for reinforcing a fuselage of an aircraft, wherein the structural element comprises a reinforcement profile (2,13) which is made of a metallic material, particularly an aluminum alloy material or a titanium alloy material, as a single piece. According to the invention, the reinforcement profile is provided with a tab (5,14,24) at least in some areas. As a result of the tab, which is made of a fiber-reinforced layer material (7) or a fiber metal laminate and glued to a flange (20, 32) of the reinforcement profile at least in some areas, the structural element has a high damage tolerance and advantageous fatigue properties.; The fiber metal laminate or the layer material comprises a plurality of metal layers (8,34,43) and fiber-reinforced plastic layers (9,35,41) stacked in alternating fashion, said layers being glued to each other over the entire area. The reinforcement profile is joined to the tab through a joining layer (6,15,36). Said joining layer is constructed with preferably two prepreg layers (20,23,37,38) and a non-fiber-reinforced adhesive layer (21). The reinforcement profile is, for example, a curved rib segment (31) or a straight beam, both of which can be used particularly to brace a central and highly loaded fuselage section of a high wing aircraft. A crack (16) which forms in the area of an inner flange or an outer flange of the rib segment or of a reinforcement profile is bridged by the effect of the tab so that further propagation, if not completely prevented, is at least greatly slowed.

Owner:AIRBUS OPERATIONS GMBH

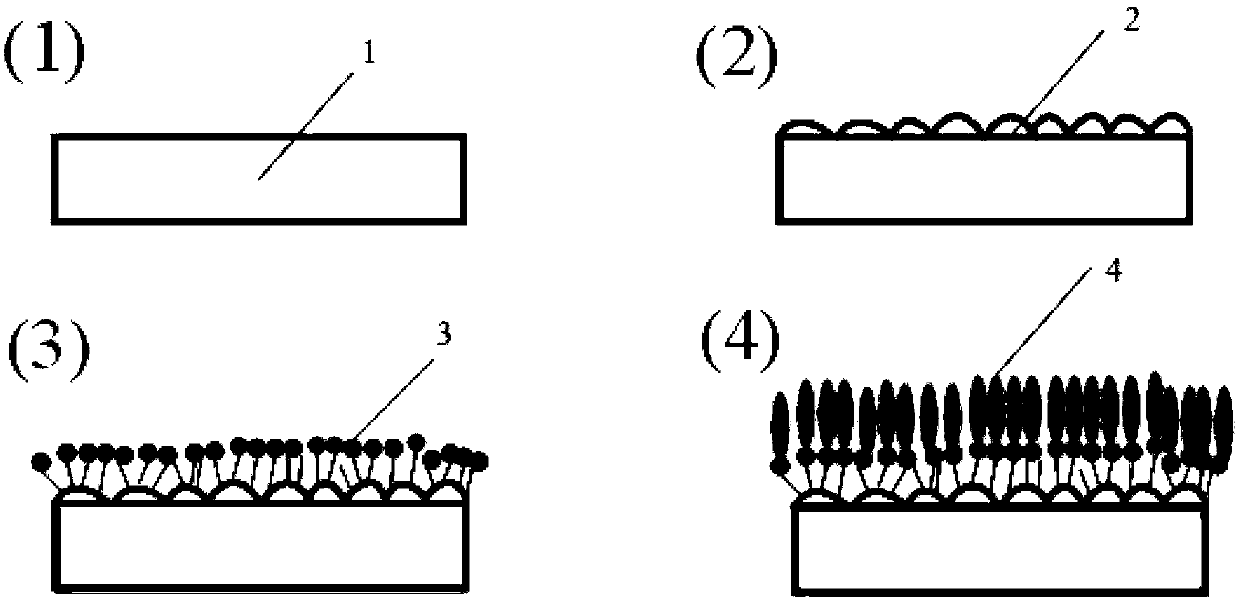

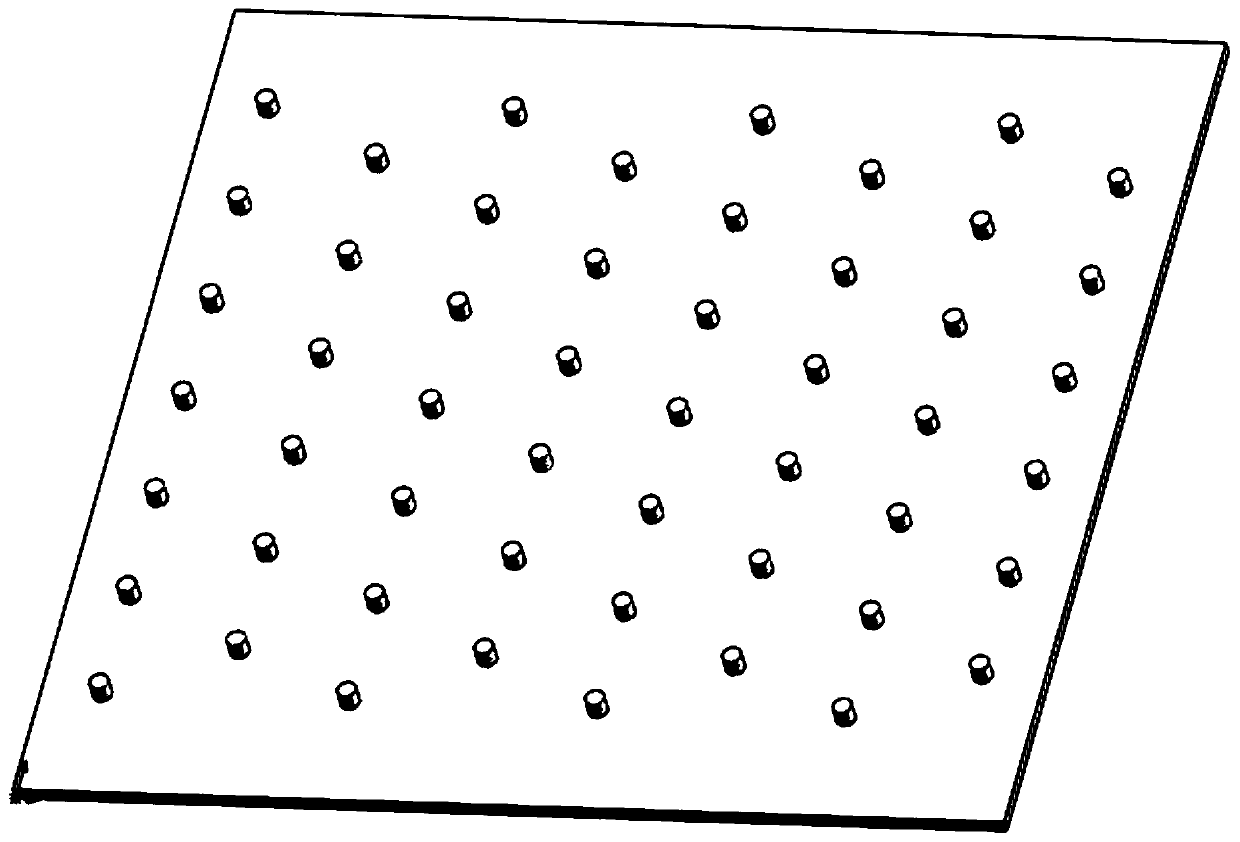

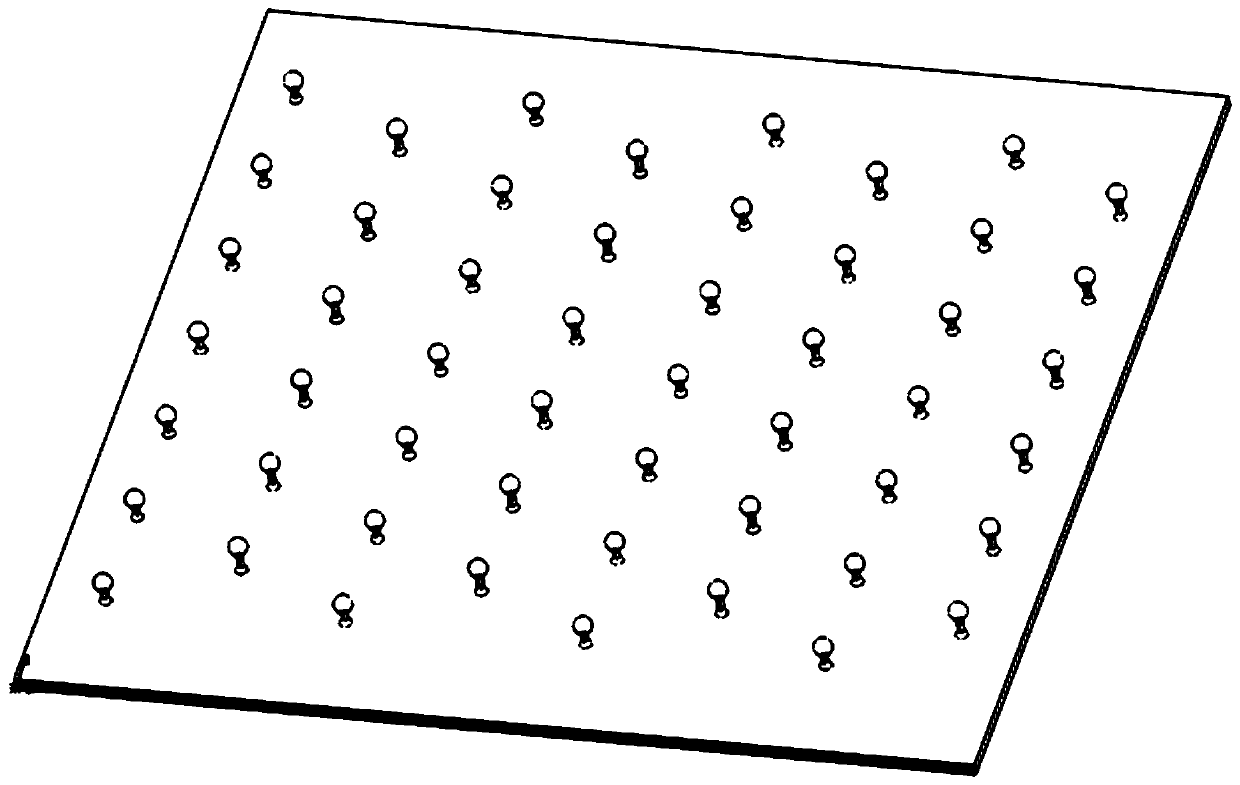

Novel fiber metal laminate and preparation method thereof

ActiveCN110466217AEnhanced interface bindingImprove performanceLamination ancillary operationsLaminationMaterials preparationManufacturing technology

The invention provides a novel fiber metal laminate and a preparation method thereof, and belongs to the technical field of composite material preparation, wherein a metal plate and a prepreg are laminated, and curing is performed at a certain temperature under a certain pressure to form an ultra-hybrid composite material, ie., the novel fiber metal laminate. The preparation method comprises: (1)preparing a projection structure with a certain height on the surface of a metal plate by using an additive manufacturing technology, and pre-treating the surface of the metal plate; (2) cutting a prepreg, and laying in a mold; (3) pre-pressing the prepreg layer, carrying out surface piercing, and carrying out secondary cutting; and (4) carrying out laminating paving and hot pressing molding on the metal layer and the prepreg layer. According to the present invention, the novel fiber metal laminate prepared by the method can increase the interface connection strength between the metal and thecomposite material, inhibit the delamination, improve the interlayer performance of fiber metal laminates, and increase the interlaminar shear strength and the damage tolerance.

Owner:DALIAN UNIV OF TECH

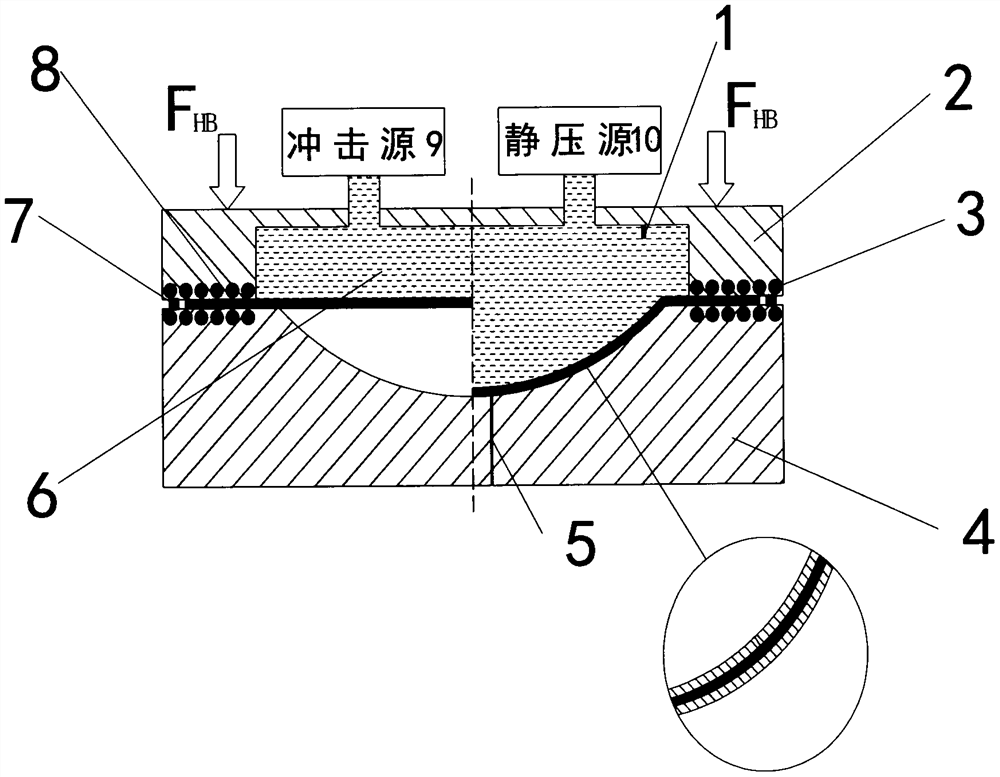

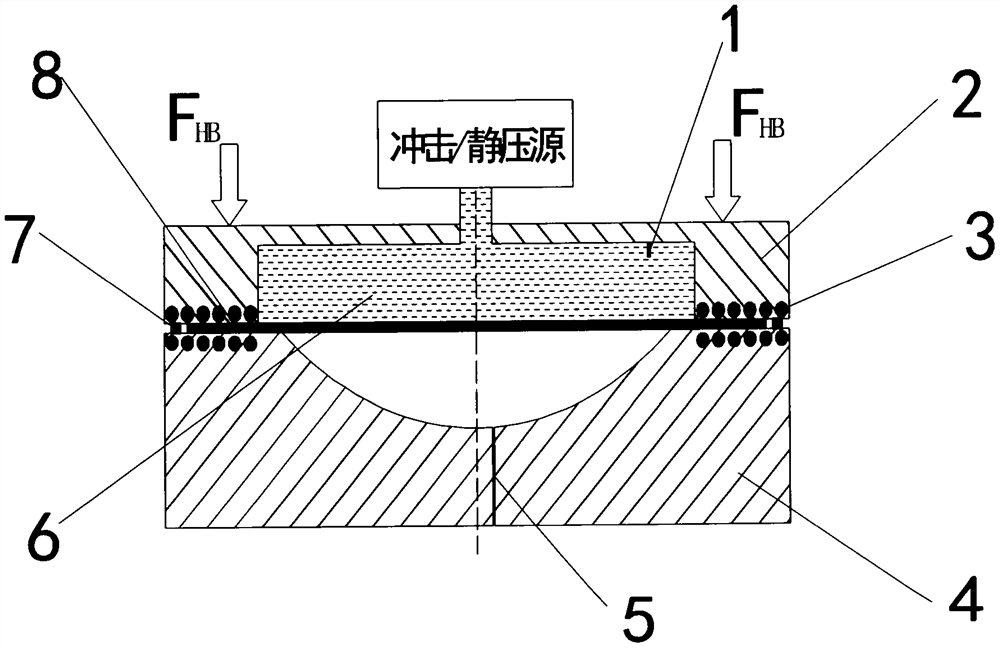

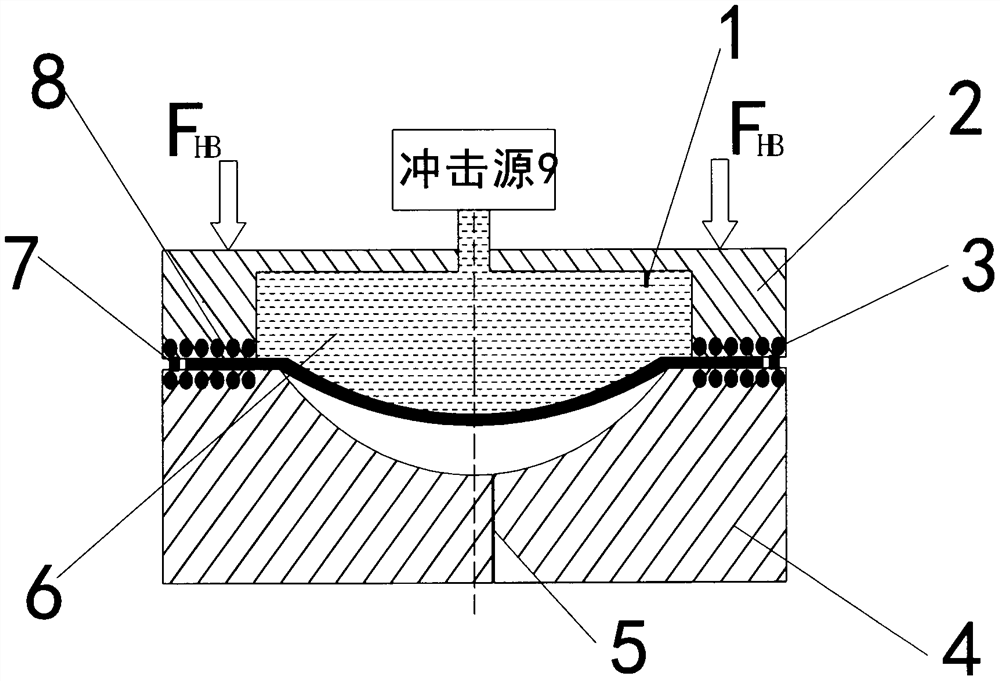

Thermal medium variable energy rate surface force loading forming method for fiber metal laminate

The invention provides a fiber metal laminate thermal medium variable energy rate surface force loading forming method, and belongs to the field of composite material forming. The novel method is a novel technology integrating high-energy-rate impact forming and liquid-filling static pressure forming in a crossed mode, and has the advantages of the two. The problems that in traditional forming, fiber materials are stacked and distributed unevenly, and in the material curing process, interlayer residual stress is large, and resilience is large are solved. The part rigidity can be enhanced, the die number is reduced, the equipment tonnage is reduced, and the forming efficiency is improved. The forming process mainly comprises the steps that a mold is cleaned, the surface of a metal layer is treated, a blank layer is placed on the forming mold, the mold is closed downwards, liquid is loaded, heating is conducted till thermoplastic resin enters a viscous state and high-elastic state mixed state, and at the moment, high-energy-rate fluid impact forming is conducted on the composite blank. And after forming, solidification is carried out under the synergistic effect of fluid high-pressure variable-path loads and gradient cooling, and interlayer tight combination of laminates is achieved. The method is mainly used for accurate forming of large complex thin-wall components in the aerospace manufacturing field.

Owner:HEBEI UNIV OF TECH

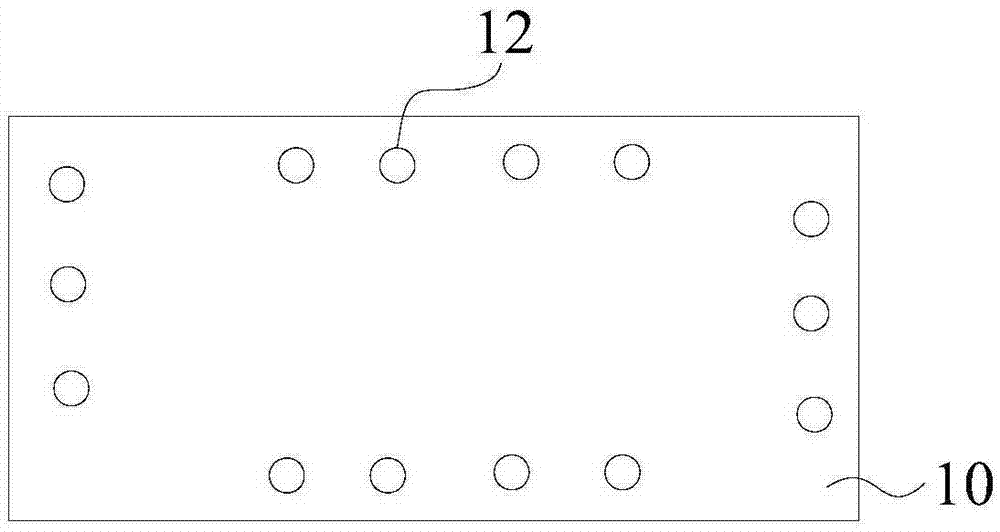

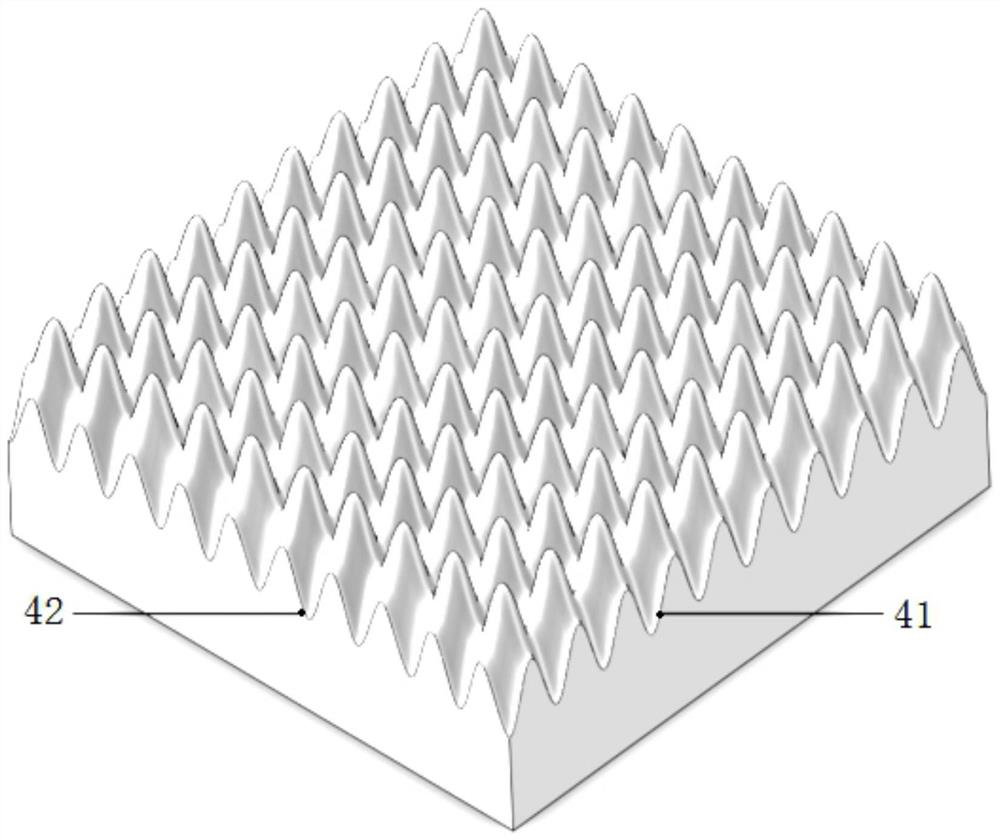

Metal layer bionic microstructure fiber metal laminate capable of realizing resin self-infiltration

ActiveCN113043682ASolving Infiltration Outgassing ProblemsSolve Exhaust ProblemsSynthetic resin layered productsVehicle componentsAviationFiber metal laminate

The invention discloses a metal layer bionic microstructure fiber metal laminate capable of achieving resin self-infiltration, and belongs to the field of plate composite materials. The structure can effectively solve the problem of difficulty of infiltration of resin into deeper blind hole or blind pit microstructures in the surface of the metal layer of the fiber metal laminate, and the interlayer bonding performance of the metal matrix and the fiber prepreg is enhanced. The structure is composed of a vertical conical hole dense array structure which is of a spatial geometry asymmetric structure and is spaced by a certain distance, a multi-stage structure composed of a conical hole main hole and conical hole auxiliary holes, or a pit structure of an Archimedes spiral or logarithmic spiral track with different spatial curvatures, and a groove microstructure provided with an Archimedes spiral or logarithmic spiral track. The structure is mainly used for infiltrating resin into deeper blind hole or blind pit microstructures inthe surface of a metal layer of the fiber reinforced metal laminate, and the laminate is mainly used for manufacturing aviation covering parts such as fuselages, skins and the like of large aircrafts and high-speed aerospace vehicles in the field of aerospace manufacturing.

Owner:HEBEI UNIV OF TECH

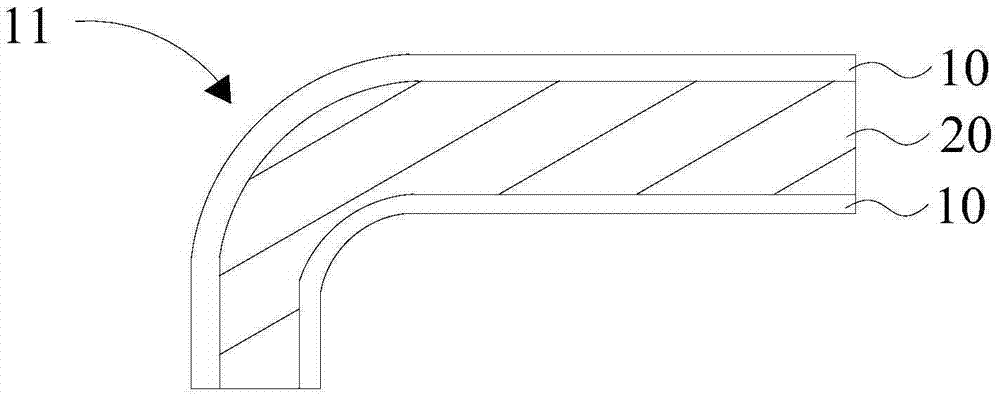

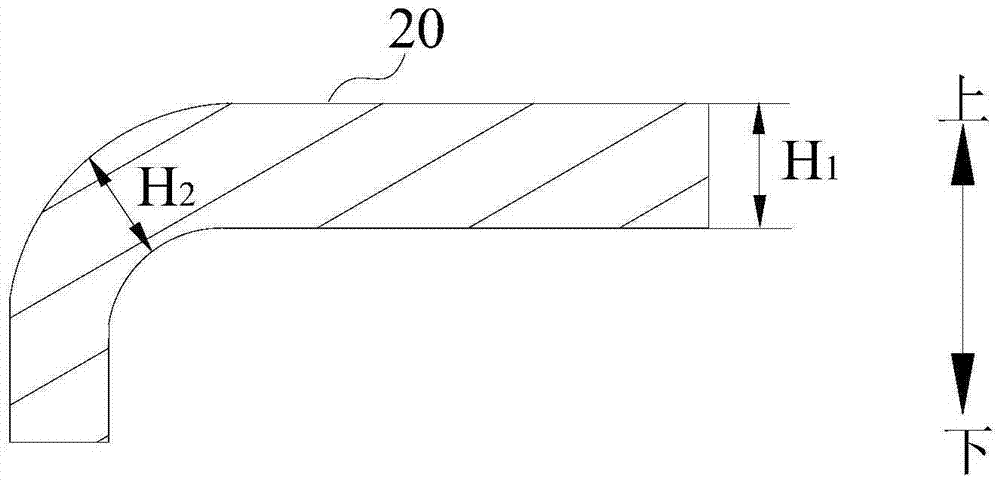

Fiber metal laminate, preparation method and electronic equipment

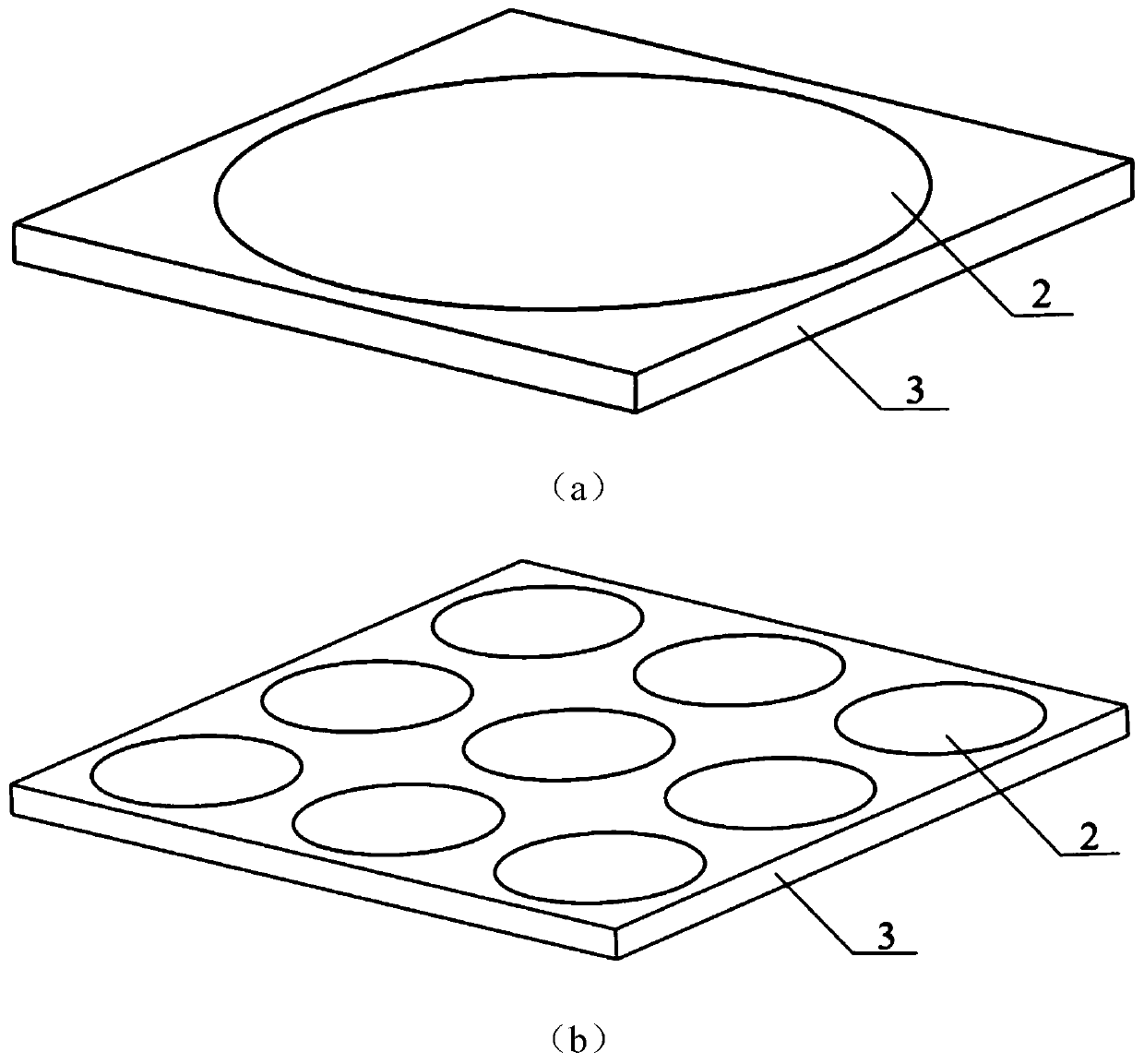

InactiveCN106891579AImprove yield rateUniform thicknessLaminationLamination apparatusFiber metal laminateOptoelectronics

The invention provides a fiber metal laminate, a preparation method and electronic equipment. The fiber metal laminate comprises at least two metal plates which are arranged in parallel and are provided with at least one bent part, and a fiber layer which is arranged between two adjacent metal plates, wherein the relative error of the thickness of the fiber layer does not exceed 5 percent. Therefore, low product yield caused by uneven thickness of bent part and fiber layer can be avoided.

Owner:BYD CO LTD

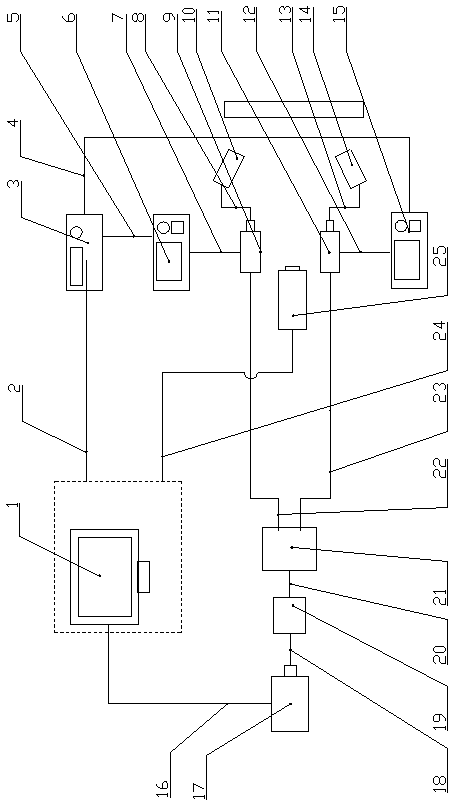

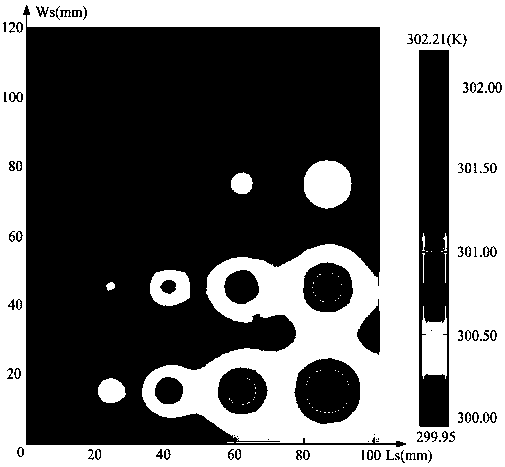

Infrared thermal wave destructive interference detecting device and method for fiber metal laminate defect using linear frequency modulation pulse coherent laser excitation

PendingCN109211975AExtended depth rangeLower performance requirementsMaterial flaws investigationBeam expanderBeam splitter

The invention discloses an infrared thermal wave destructive interference detecting device and method for a fiber metal laminate defect using linear frequency modulation pulse coherent laser excitation. The device comprises a modulator, a second beam expander, an infrared camera. A computer is connected to a dual channel function generator. The dual channel function generator is respectively connected to a first RF driving source and a second RF driving source. The first RF driving source is connected to a first acousto-optic modulator. The first acousto-optic modulator is connected to a firstbeam expander. The second RF driving source is connected to a second acousto-optic modulator. The second acousto-optic modulator is connected to the second beam expander. The computer is connected toa laser. The laser is connected to an amplifier. The amplifier is connected to a fiber optic beam splitter. The fiber optic beam splitter is respectively connected to the first acousto-optic modulator and the second acousto-optic modulator. The computer is connected to the infrared camera. The infrared thermal wave destructive interference detecting device and method can significantly improve thesignal to noise ratio of the infrared thermal wave characteristic image. Moreover, the detection capability of the infrared thermal wave detecting technology is improved.

Owner:HARBIN UNIV OF COMMERCE

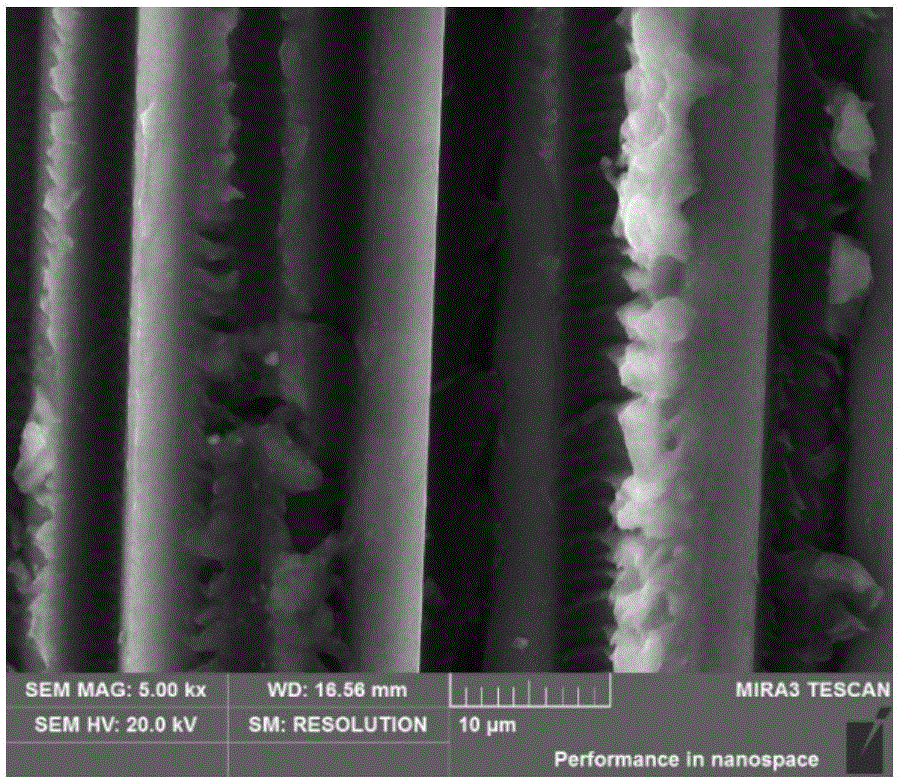

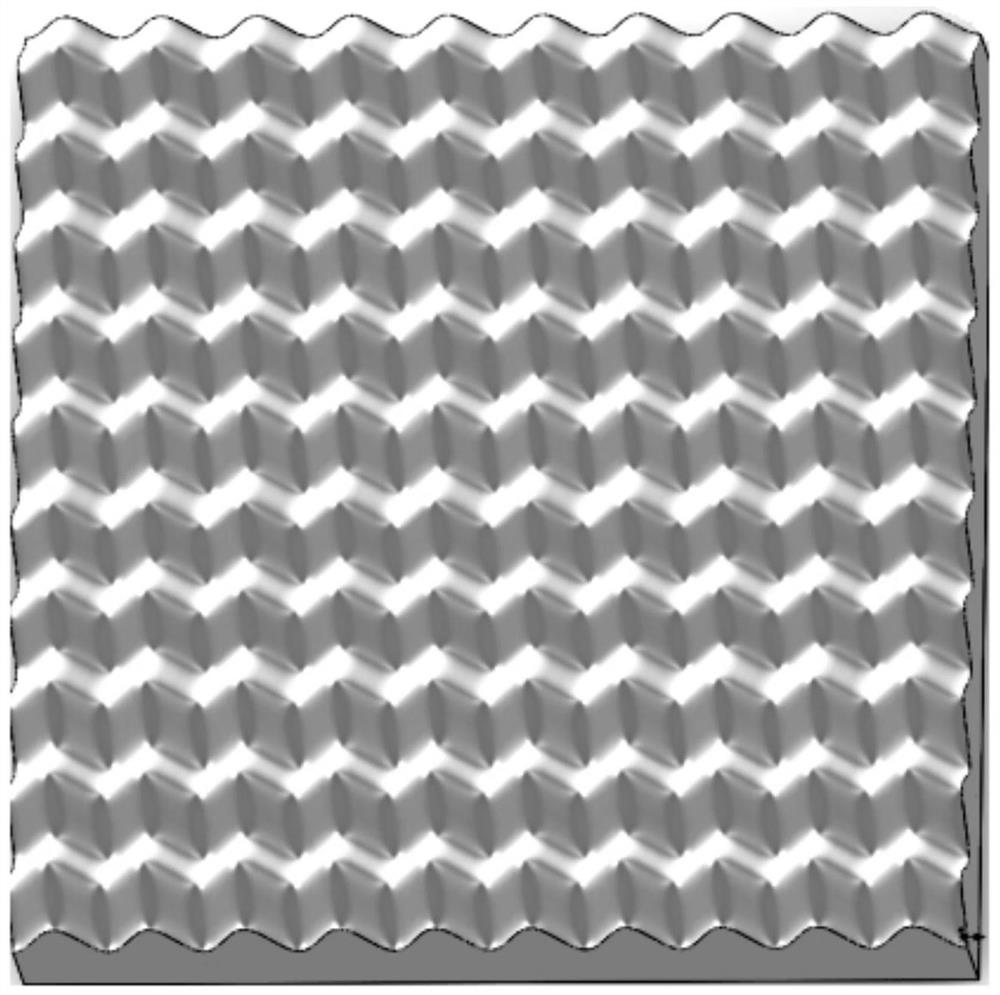

Fiber metal laminate for enhancing composite interface connection and preparation method thereof

ActiveCN114103303AReduce composite interface connection performanceComposite interface connection performance enhancementLamination ancillary operationsSynthetic resin layered productsAdhesion forcePolymer science

The invention relates to a fiber metal laminate for enhancing composite interface connection and a preparation method thereof. The fiber metal laminate comprises a metal laminate and a fiber prepreg tape layer, the metal matrix surface microstructure is composed of micron-sized bidirectional corrugations similar to a human intestinal villus structure and a seta structure on a gecko foot and nano-sized corrosion holes connected with the corrugations. According to the structure, the defects of a traditional physical surface treatment mode of a metal matrix of the fiber metal laminate can be overcome, the connection performance of a composite interface between the metal laminate and the fiber prepreg tape is enhanced, and the problems of layering and degumming easily occurring in the preparation and forming process of the fiber metal laminate are solved. According to the invention, a human intestinal villus structure and a seta structure on a gecko foot are used for reference, large-area molecular contact can be realized when the metal laminate is in contact with any surface by utilizing the micron-sized bulges, and weak Van der Waals interaction is converted into huge adhesive force, so that the composite interface connection performance between the metal laminate and the fiber resin layer is improved, and the service life of the metal laminate and the fiber resin layer is prolonged. And the glue failure or layering defect is effectively improved.

Owner:YANSHAN UNIV

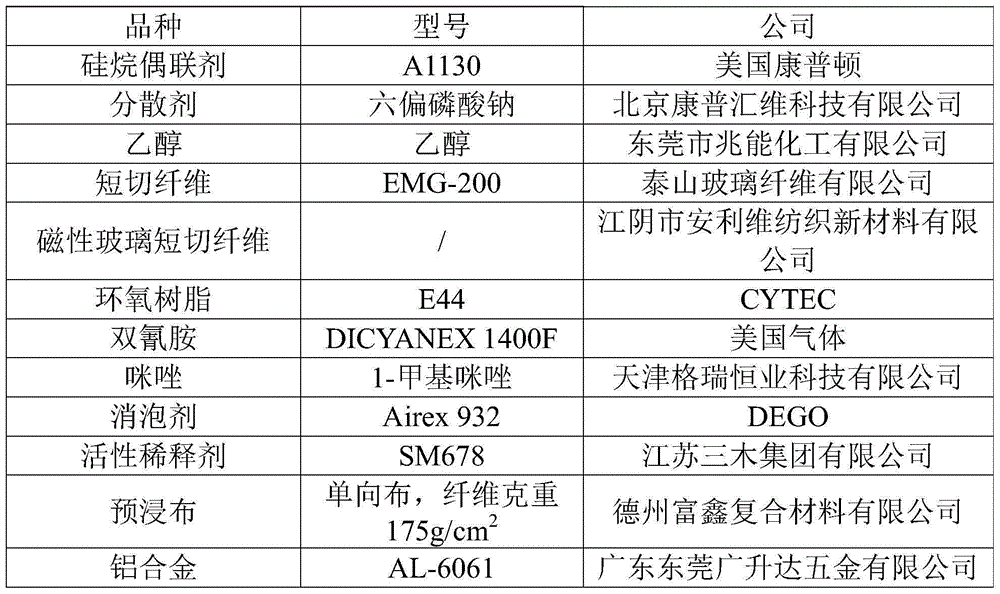

Fiber metal laminated plate and preparation method thereof

InactiveCN106696392AImprove bindingSynthetic resin layered productsLaminationFiber metal laminateResin bonding

The invention relates to the field of fiber metal laminated plates, and discloses a fiber metal laminated plate and a preparation method thereof. The fiber metal laminated plate includes a metal layer, a resin bonding layer and a fiber layer which are sequentially stacked, magnetic chopped fiber is between the resin bonding layer and the fiber layer, and the included angle between the magnetic chopped fiber and the fiber layer is greater than 0 degree. The bonding force between the metal layer of the metal laminated plate and fiber cloth is stronger.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com