Low density and high strength fiber glass for reinforcement applications

A glass fiber, fiber technology, applied in the field of low density and high strength glass fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

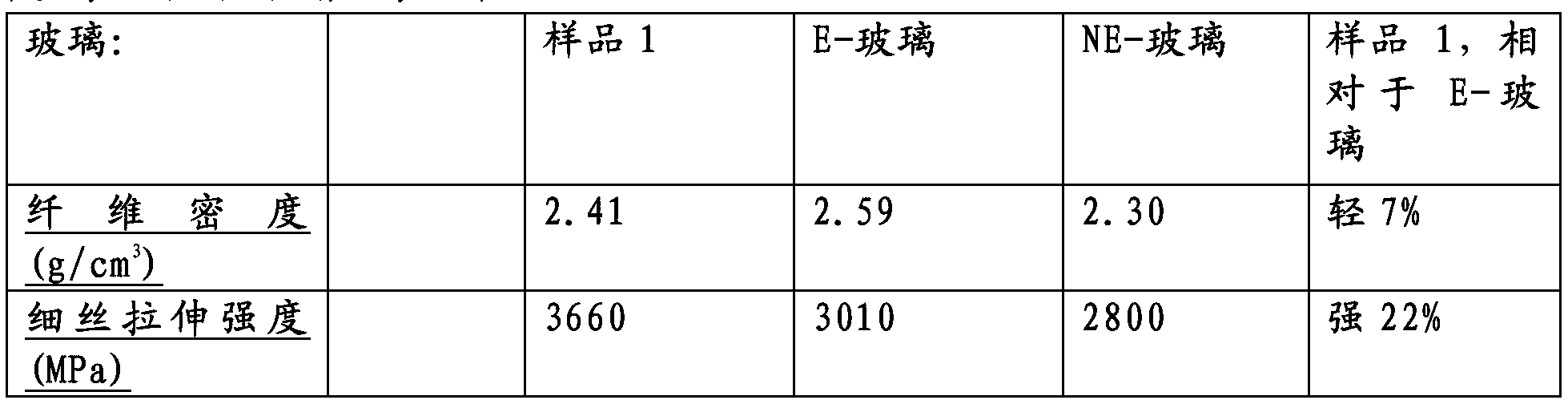

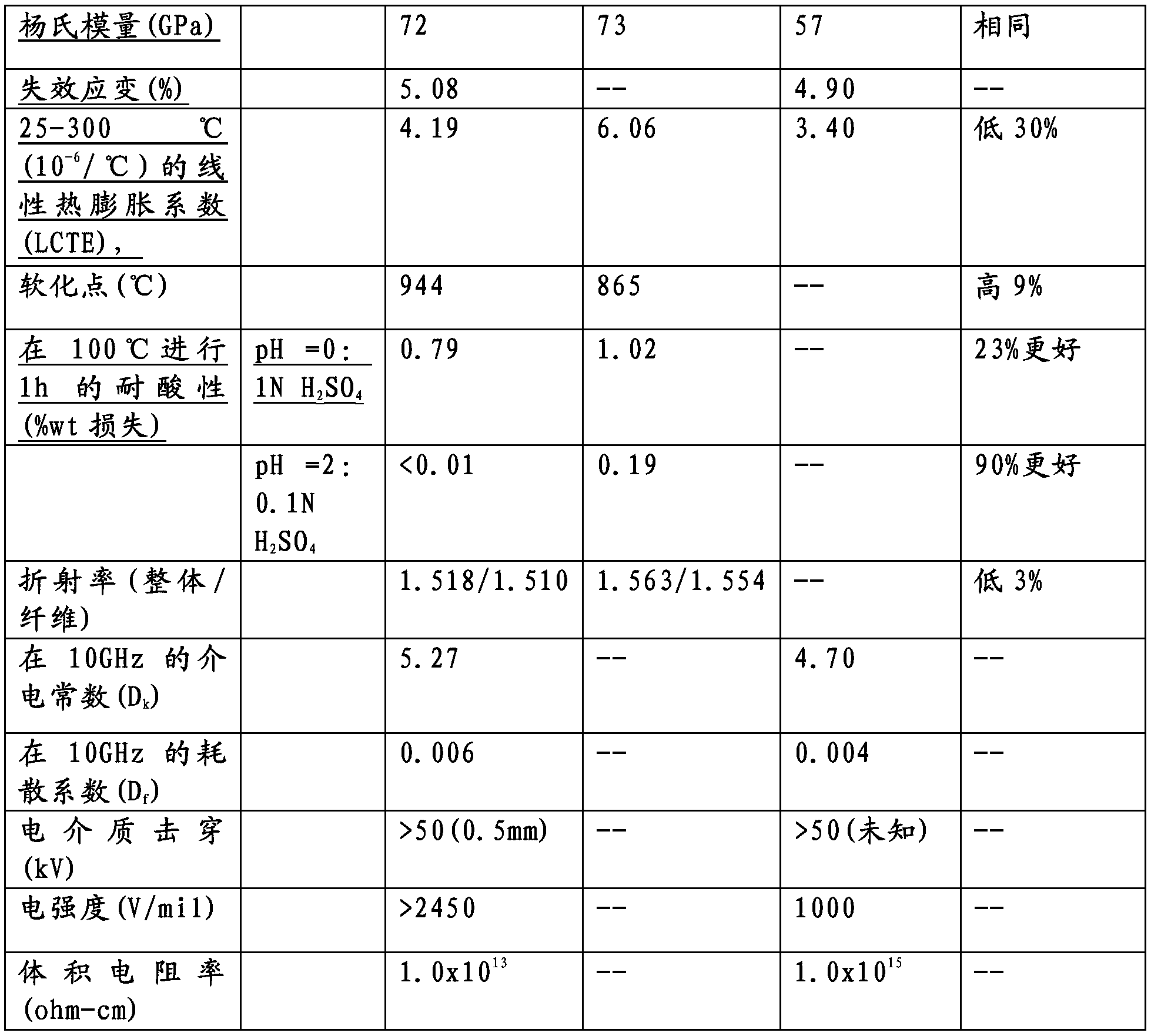

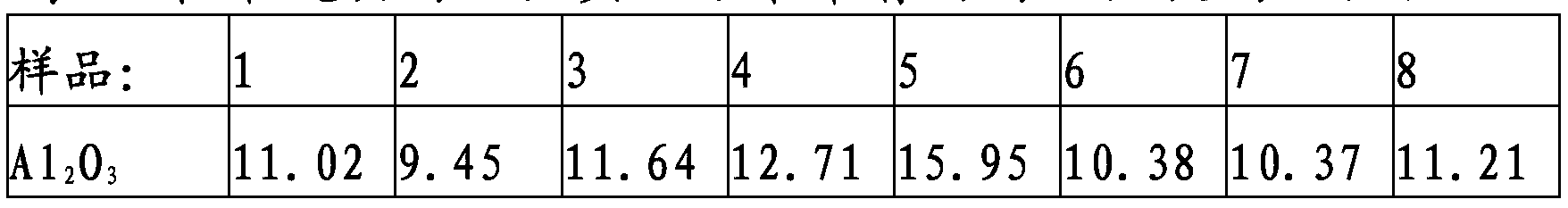

[0405] Certain properties of glass compositions useful in some embodiments of the present invention are measured under controlled processing conditions using routine testing methods known to those skilled in the art. Some measured properties are listed in Table 1. The properties of standard E-glass and commercially available NE-glass are included for reference. The listed properties of commercially available NE-glasses are from literature. The data in Table 1 show that glass fibers suitable for use in the present invention exhibit improved thermal, chemical and mechanical stability compared to E-glass. Glass fibers suitable for use in the present invention are 30% stronger and 25% stiffer than NE-fibres. The glass fibers of Sample 1 of Table 1 comprised a glass composition comprising the following components, as measured by x-ray fluorescence spectroscopy:

[0406] SiO 2 63.02±0.25% by weight;

[0407] B 2 o 3 9.39±0.15% by weight;

[0408] Al 2 o 3 11.60±...

Embodiment 2

[0422] In this example, the yarn breaking load of yarns formed from glass fiber strands of the present invention ("sample yarns") was compared with that of glass fiber strands formed from conventional 621 glass composition. Yarn ("621 Yarn") was compared. Each yarn is formed from a single glass fiber strand (having approximately 200 filaments, nominally 7 microns in diameter). After formation, the glass fibers are coated with a conventional starch-oil sizing composition. The fiberglass strands were dried and then twisted 1 turn / inch in the z direction to form the yarn, which was then woven into a plain weave style fabric with 60 picks / inch in the warp direction and 60 picks / inch in the weft direction. Has 58 picks / inch.

[0423] The breaking load of the fabric was then measured using ASTM5053. Paper signs were mounted on fabric strips 1 inch wide by 6 inches long and loaded on a universal test frame at a rate of 12 inches per minute until failure. A total of 12 breaking lo...

Embodiment 3

[0425] The tensile and impact properties of the laminates of the present invention were compared to those made from glass fibers containing conventional glass compositions. In this example, a fabric was woven using warp and weft yarns made from glass fiber strands having a glass composition of the present invention ("sample fabric"). A comparative fabric was formed from standard E-glass yarns ("E-glass fabric"). Additional details about the fabric are provided in Table 2:

[0426] Table 2

[0427]

sample fabric

fabric style

7781

7781

finishing

1383

497-A

weave pattern

8HS

8HS

warp size

DE79

DE75

Weft size

DE79

DE75

to count

57x61

57x54

base weigh

8.68oz / yd 2

8.73oz / yd 2

thickness

0.008”

0.009”

roll length

60yd

100yd

[0428] The pre-impregnated fabric was then incorporated into the laminate using...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com