Patents

Literature

660 results about "Pre-preg" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pre-preg is "pre-impregnated" composite fibers where a thermoset polymer matrix material, such as epoxy, or a thermoplastic resin is already present. The fibers often take the form of a weave and the matrix is used to bond them together and to other components during manufacture. The thermoset matrix is only partially cured to allow easy handling; this B-Stage material requires cold storage to prevent complete curing. B-Stage pre-preg is always stored in cooled areas since heat accelerates complete polymerization. Hence, composite structures built of pre-pregs will mostly require an oven or autoclave to cure.

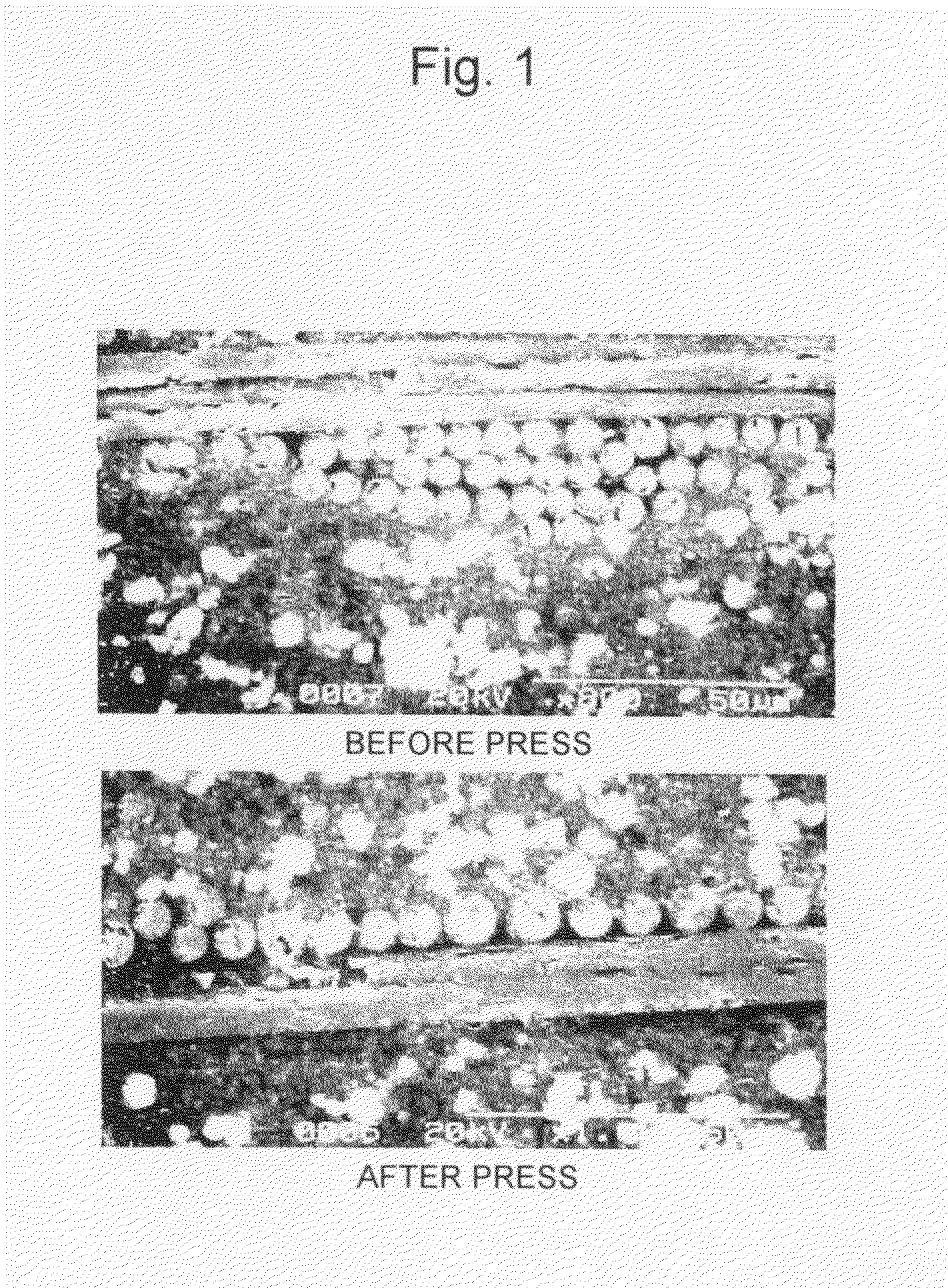

Method for manufacture of minimum porosity, wrinkle free composite parts

A process and associated apparatus used to prepare a thermoplastic composite from a plurality of plies of thermoplastic resin prepregs. The prepregs are formed into a composite structure under two chambers; a rigid outer chamber (of any convenient size or shape) and a second flexible inner chamber containing a prepreg lay-up. The absolute pressures are reduced concurrently in a stepwise method in both chambers. This concurrent, stepped pressure reduction is accomplished at a rate which prevents the vacuum bag from moving far from the prepregs, and prevents wrinkles from forming in the prepregs. Pinching off the diffusion paths required for the removal of unwanted gases is eliminated. The lay-up is then heated and the absolute pressure in the outer rigid chamber is increased. This pressure constrains the flexible inner chamber during out-gassing of the thermoplastic resin, preventing wrinkles from forming in the prepregs. The absolute pressure in the outer rigid chamber is increased to atmospheric pressure or greater causing the prepregs to consolidate. A low absolute pressure is maintained in the flexible inner chamber. The temperature is then increased to the cure temperature of the resin and held for a time sufficient for the resin to cure. The resulting consolidated thermoplastic resin is substantially void free and detectable wrinkles are absent.

Owner:HALE HAROLD P

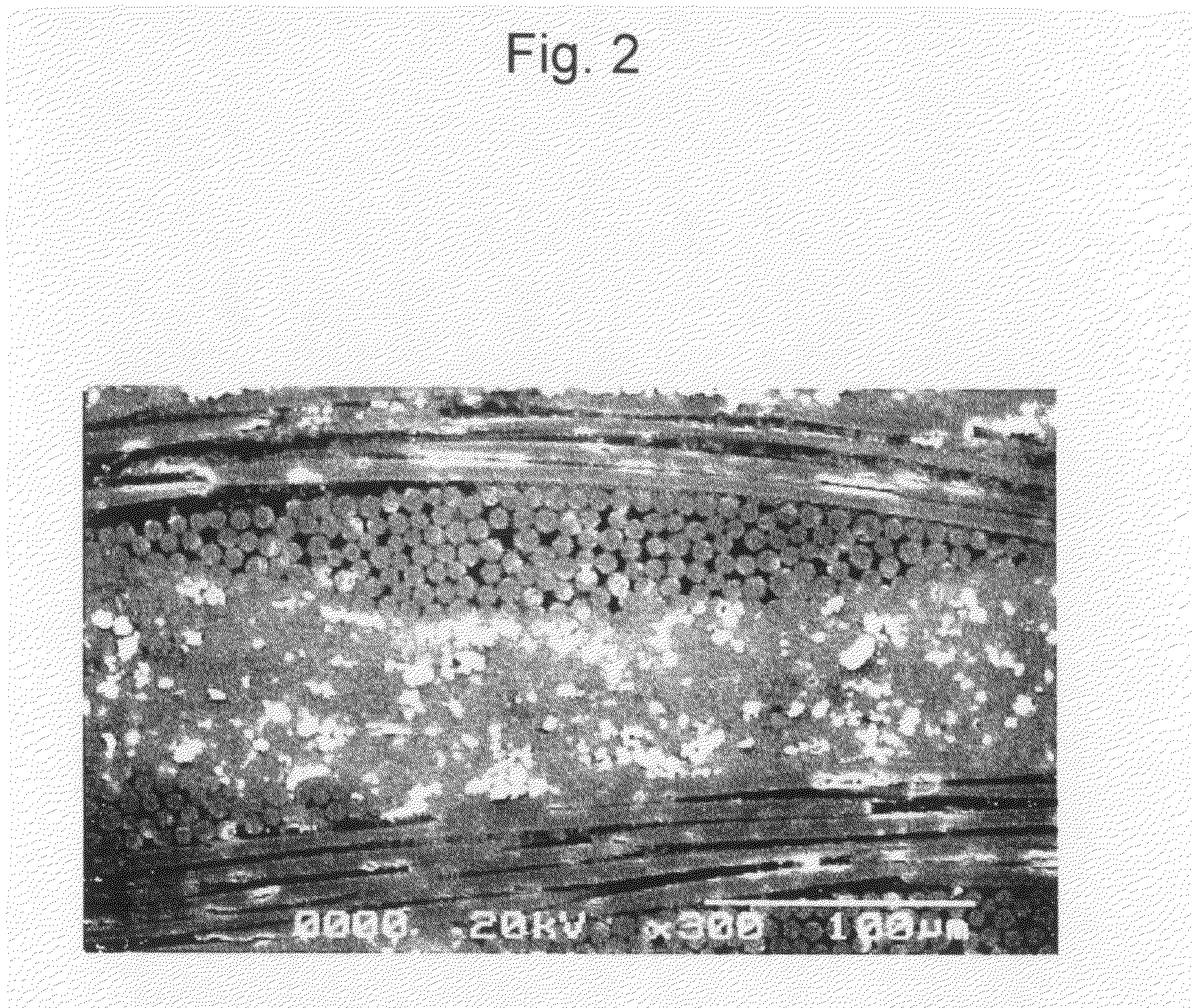

Prepreg fabric and honeycomb sandwich panel

InactiveUS6429157B1Good self-adhesiveReduce porositySynthetic resin layered productsPaper/cardboard layered productsPorosityHoneycomb

A woven fabric prepreg comprising at least [A] a woven fabric as reinforcing fibers, [B] a thermosetting resin or thermosetting resin composition and [C] fine particles of a resin and having a cover factor of 95% or more, and a honeycomb sandwich panel, comprising skin panels fabricated by said woven fabric prepreg and [D] a honeycomb core can be obtained. The woven fabric prepreg little changes in tackiness with the lapse of time and has moderate drapability, being excellent in self adhesiveness to the honeycomb core when used as skin panels of a honeycomb sandwich panel. Furthermore, the honeycomb sandwich panel obtained has a small porosity in the skin panels fabricated by the cured prepreg and has excellent surface smoothness with few pits and depressions on the surfaces of the skin panels.

Owner:TORAY IND INC

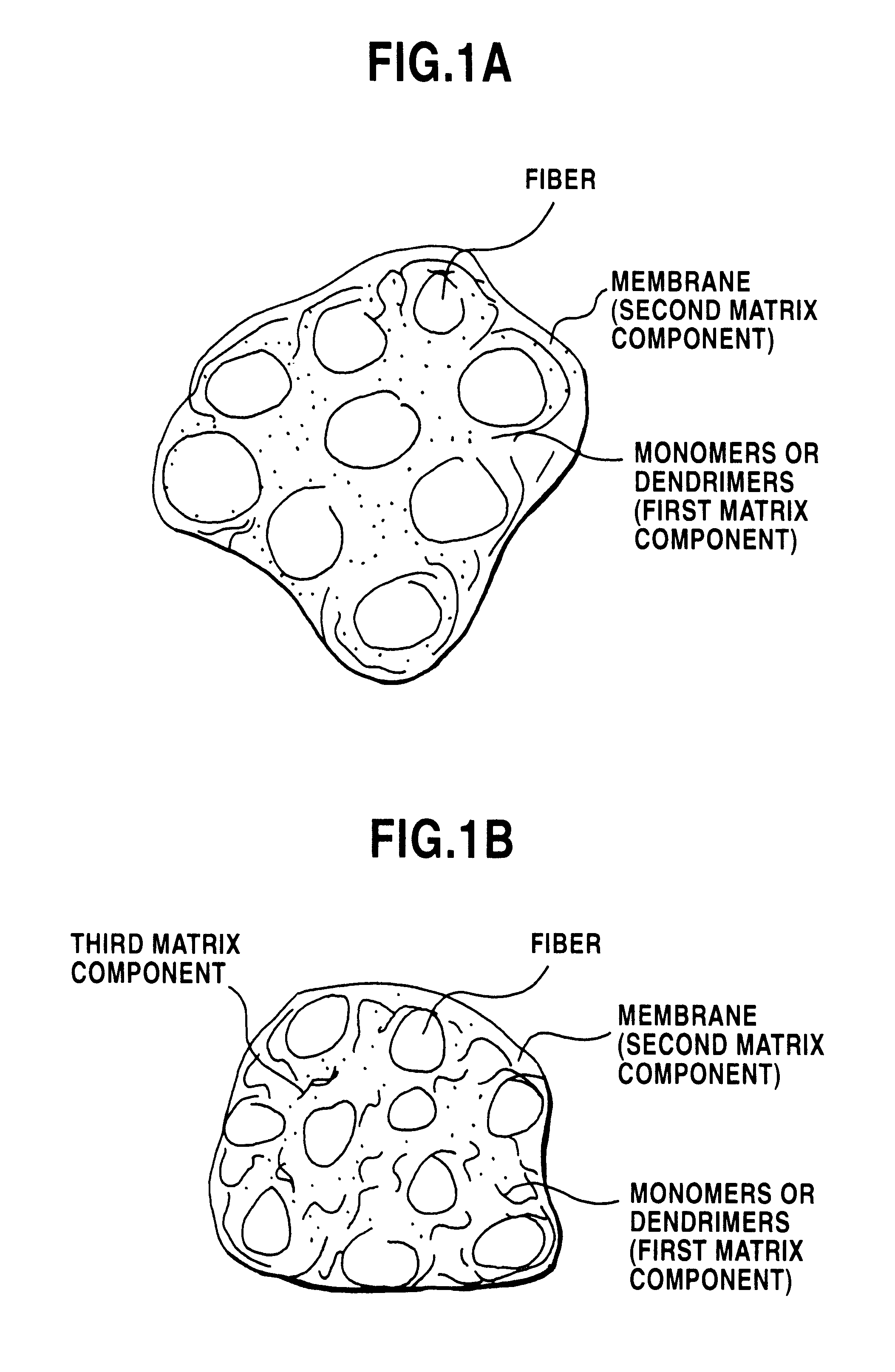

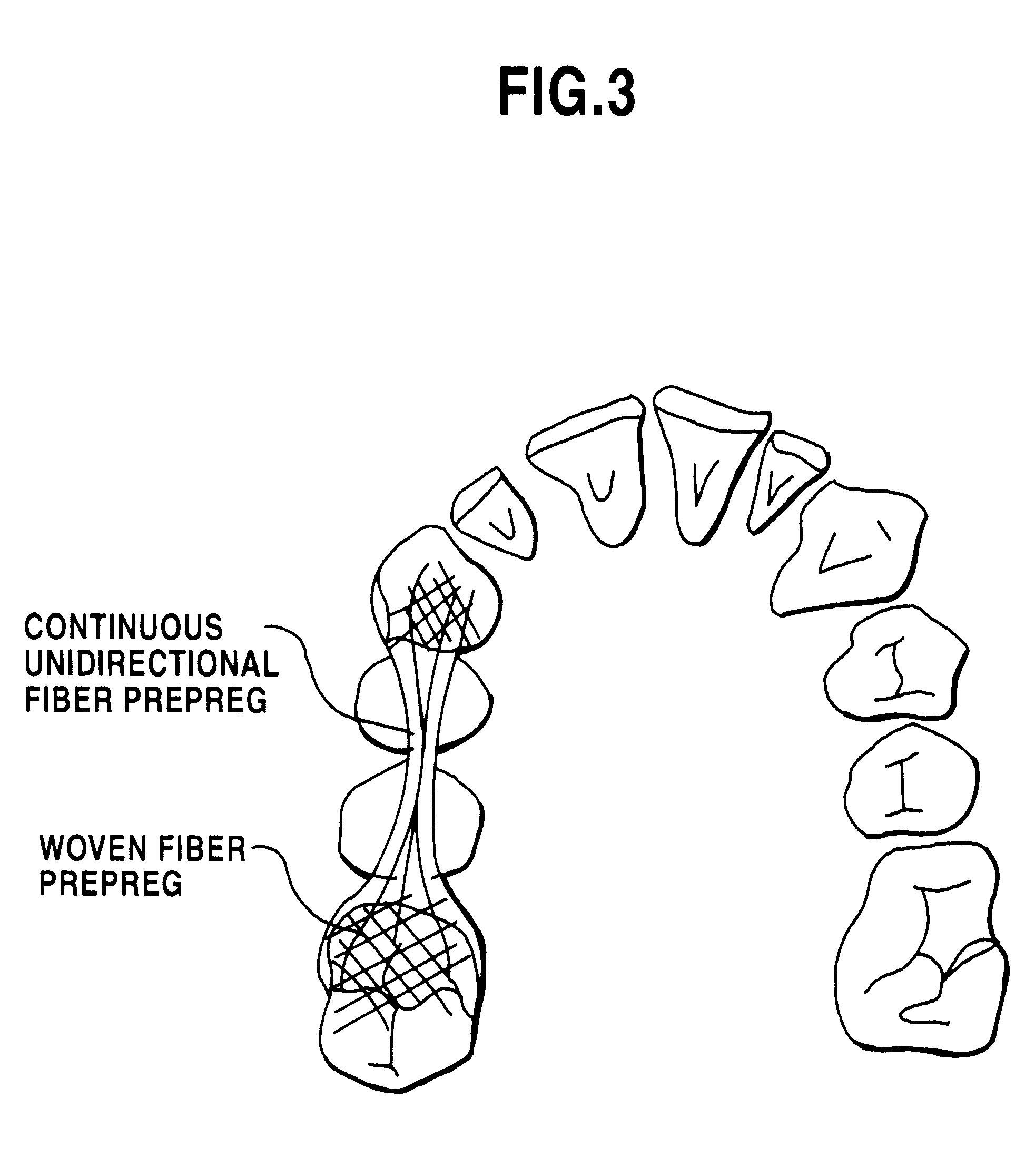

Prepreg

InactiveUS6197410B1Eliminating polymerizationReduce Shrinkage ProblemsImpression capsSurgeryDendrimerInterpenetrating polymer network

This invention relates to a shapable prepreg comprising fibers and a polymeric matrix. The polymeric matrix is a multiphase matrix comprisinga first matrix component consisting of a monomer or a dendrimer, anda second matrix component consisting of high molecular weight organic molecules, said second matrix component forming a sticky membrane of the prepreg with an interpenetrating polymer network (IPN) bonding to the first matrix component. Preferably, the prepreg further comprises a third matrix component consisting of high molecular weight organic molecules, said third component being distributed between the fibers.

Owner:STICK TECH OY

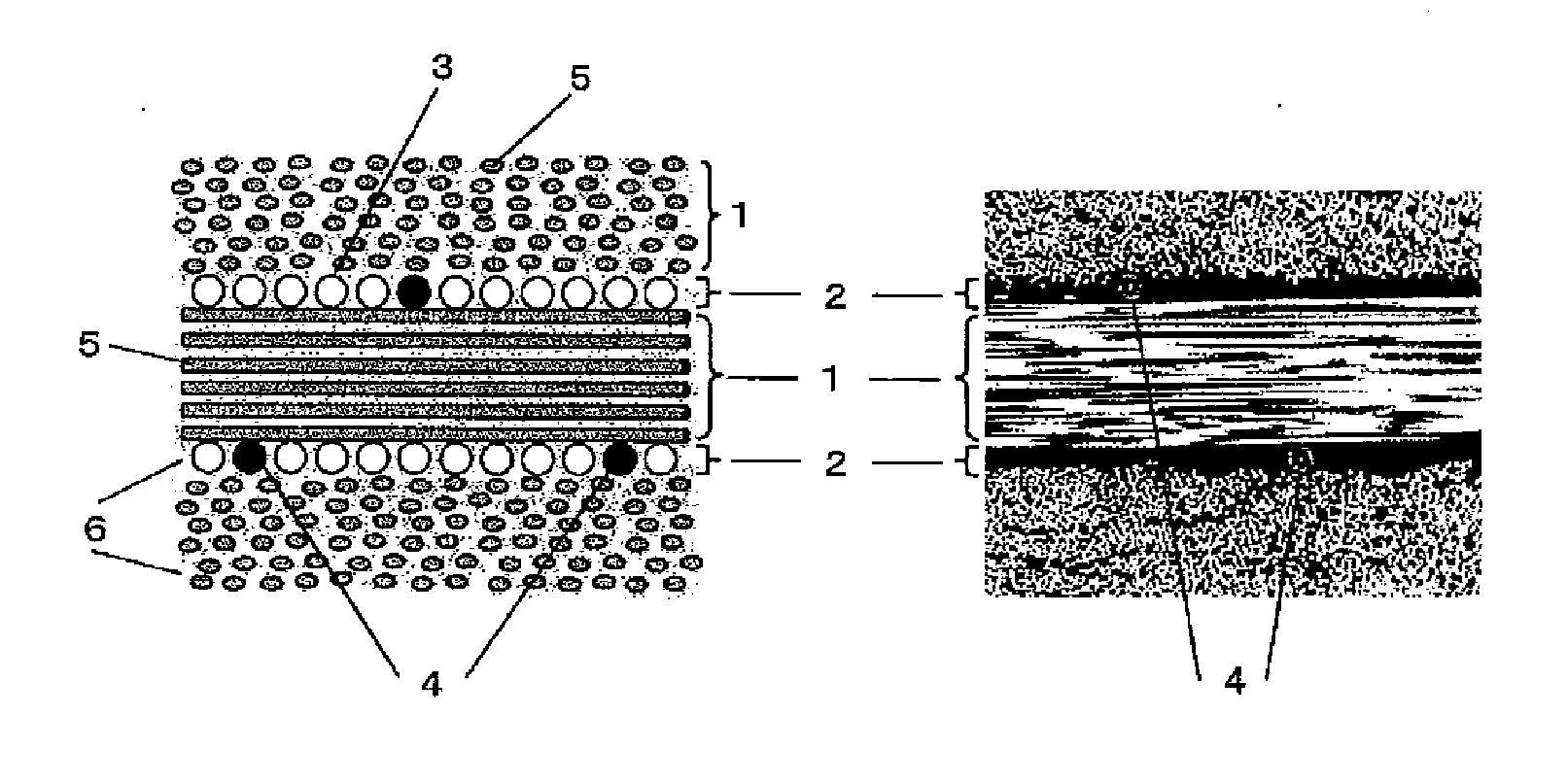

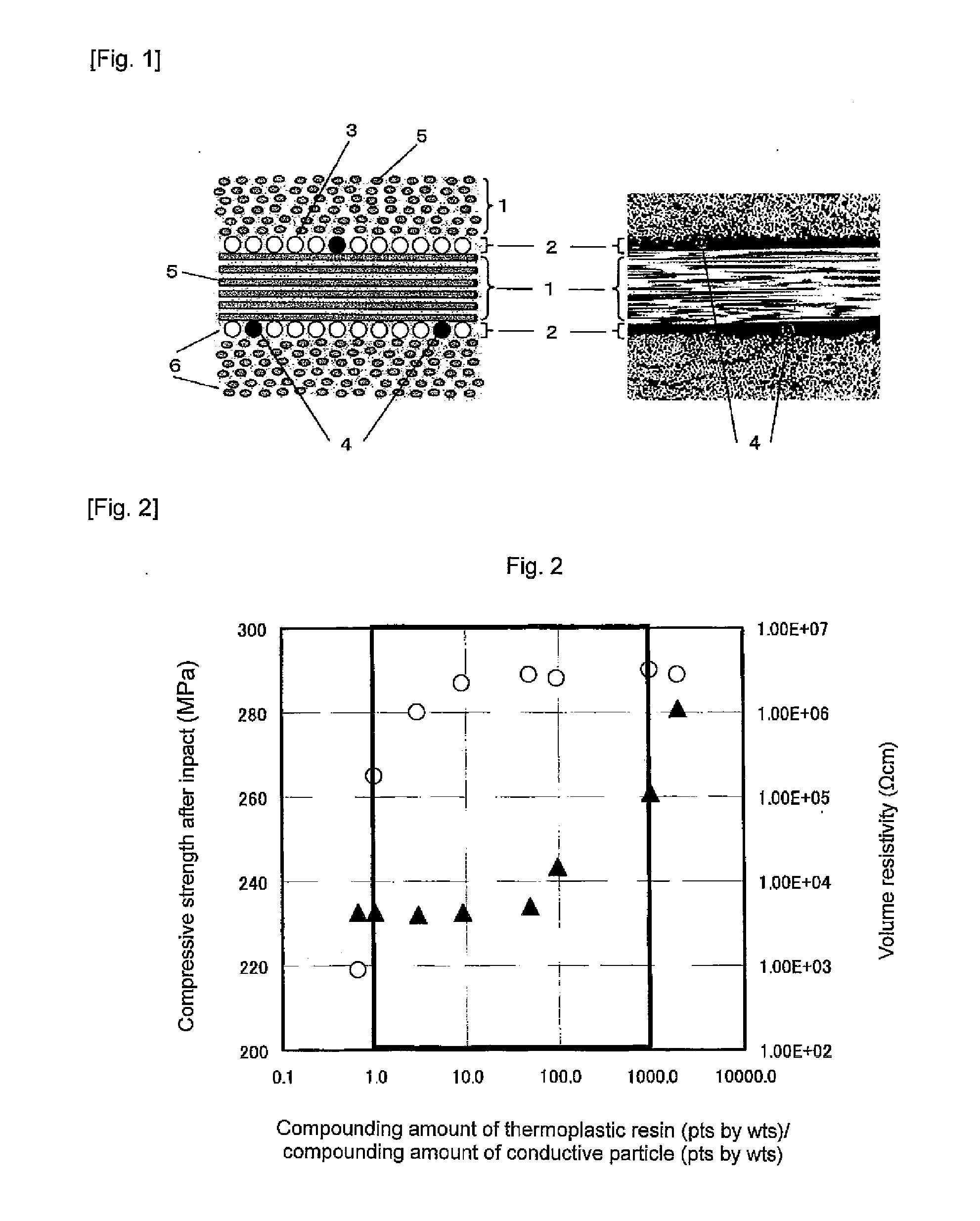

Prepreg and carbon fiber reinforced composite materials

ActiveUS20100178487A1Improve conductivityImprove impact resistanceNon-metal conductorsCarbon fibresCarbon fiber reinforced compositePre-preg

A prepreg containing a carbon fiber [A] and a thermosetting resin [B], and in addition, satisfying at least one of the following (1) and (2).(1) a thermoplastic resin particle or fiber [C] and a conductive particle or fiber [D] are contained, and weight ratio expressed by [compounding amount of [C] (parts by weight)] / [compounding amount of [D] (parts by weight)] is 1 to 1000.(2) a conductive particle or fiber of which thermoplastic resin nucleus or core is coated with a conductive substance [E] is contained.

Owner:TORAY IND INC

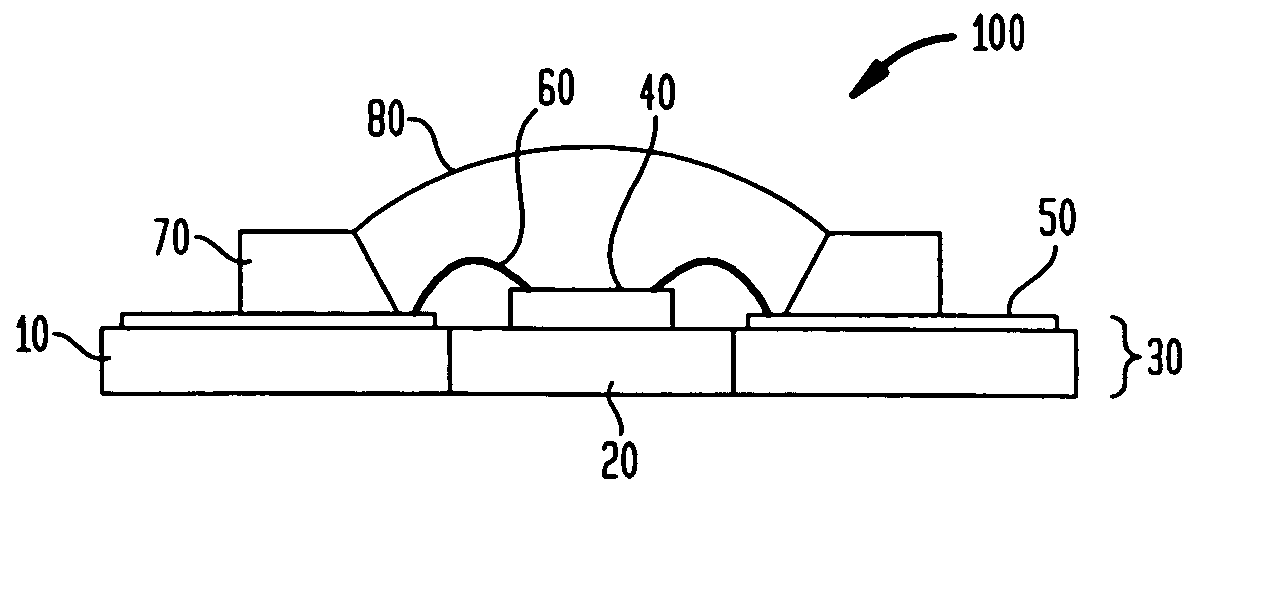

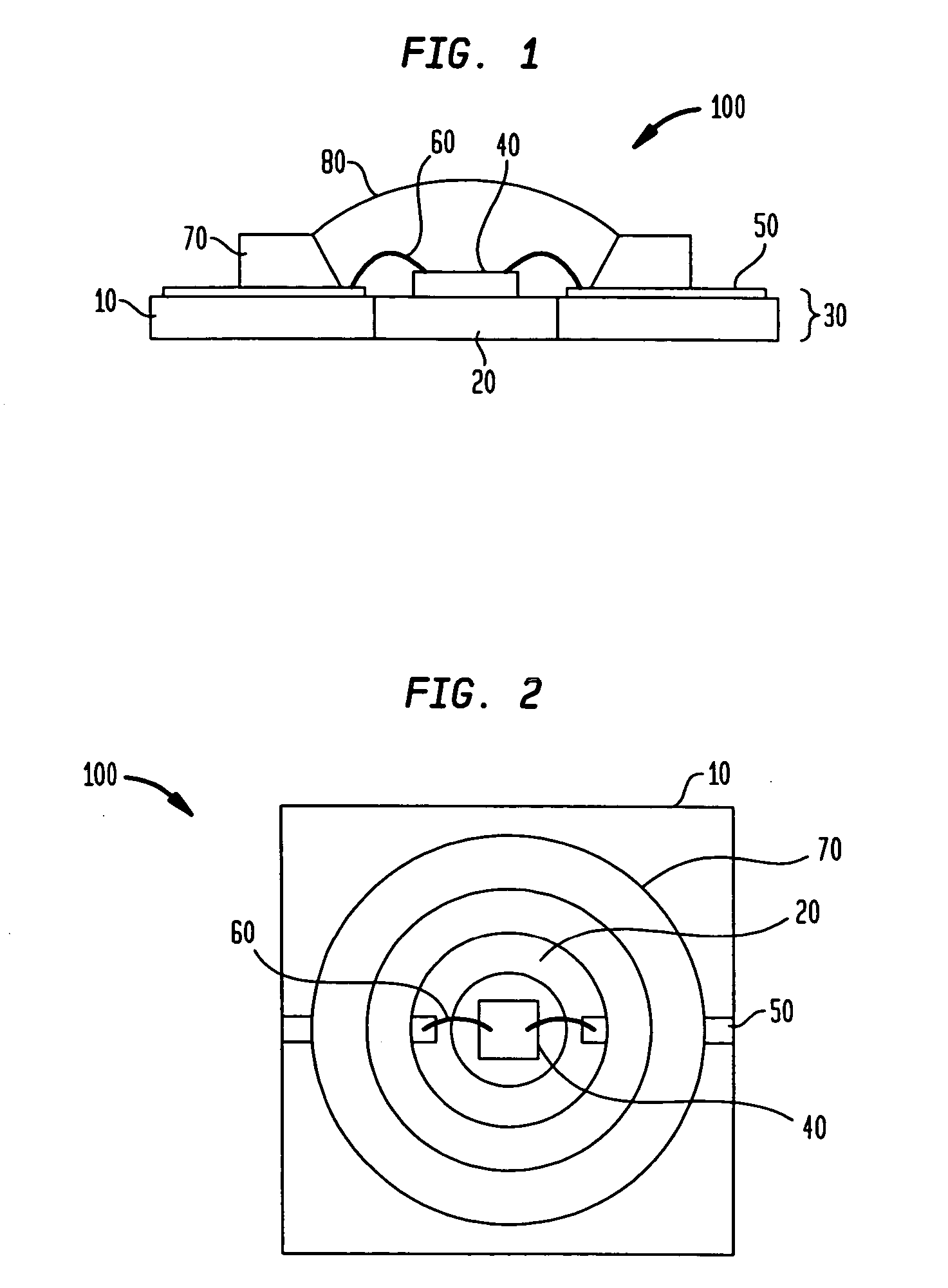

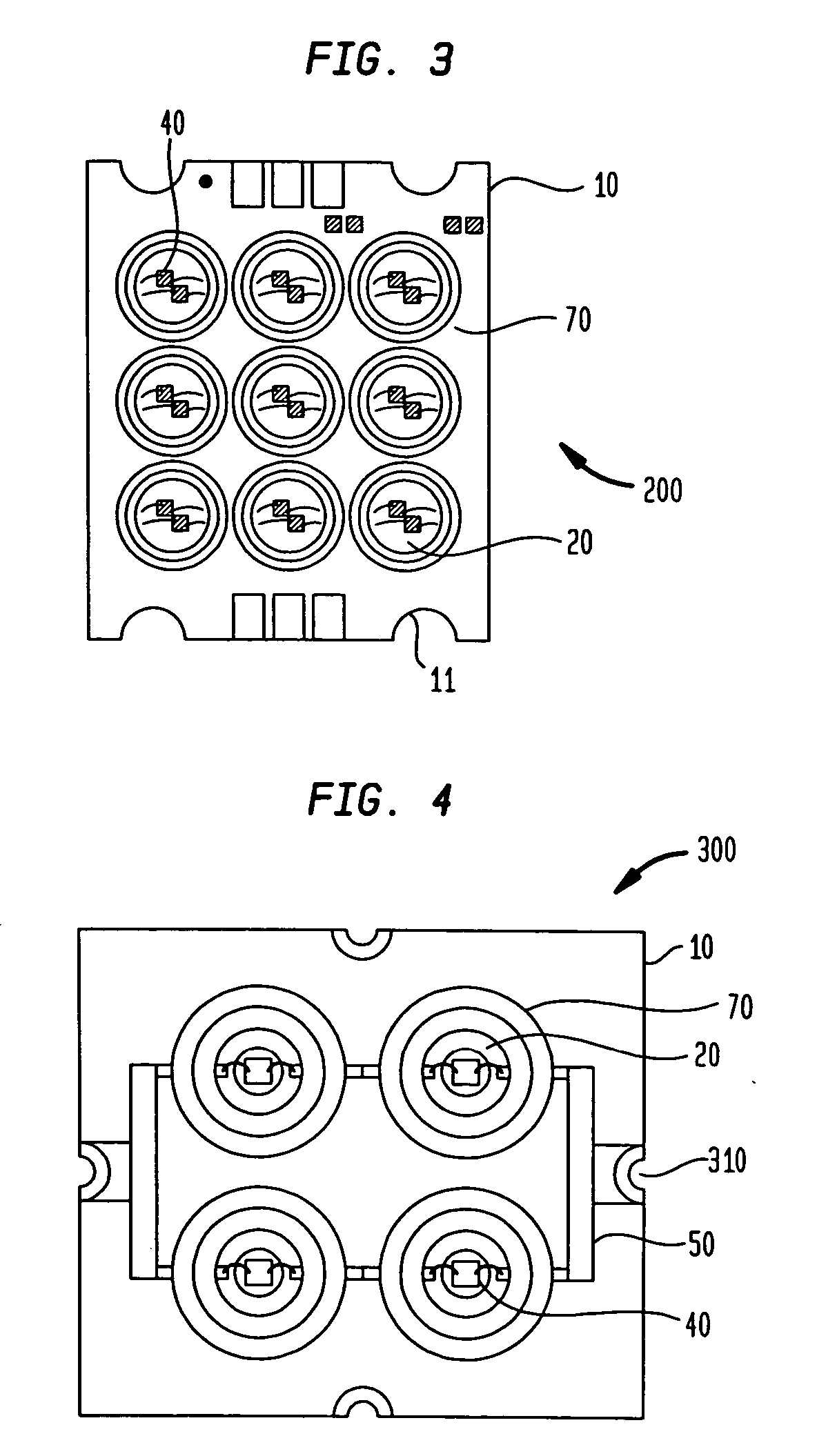

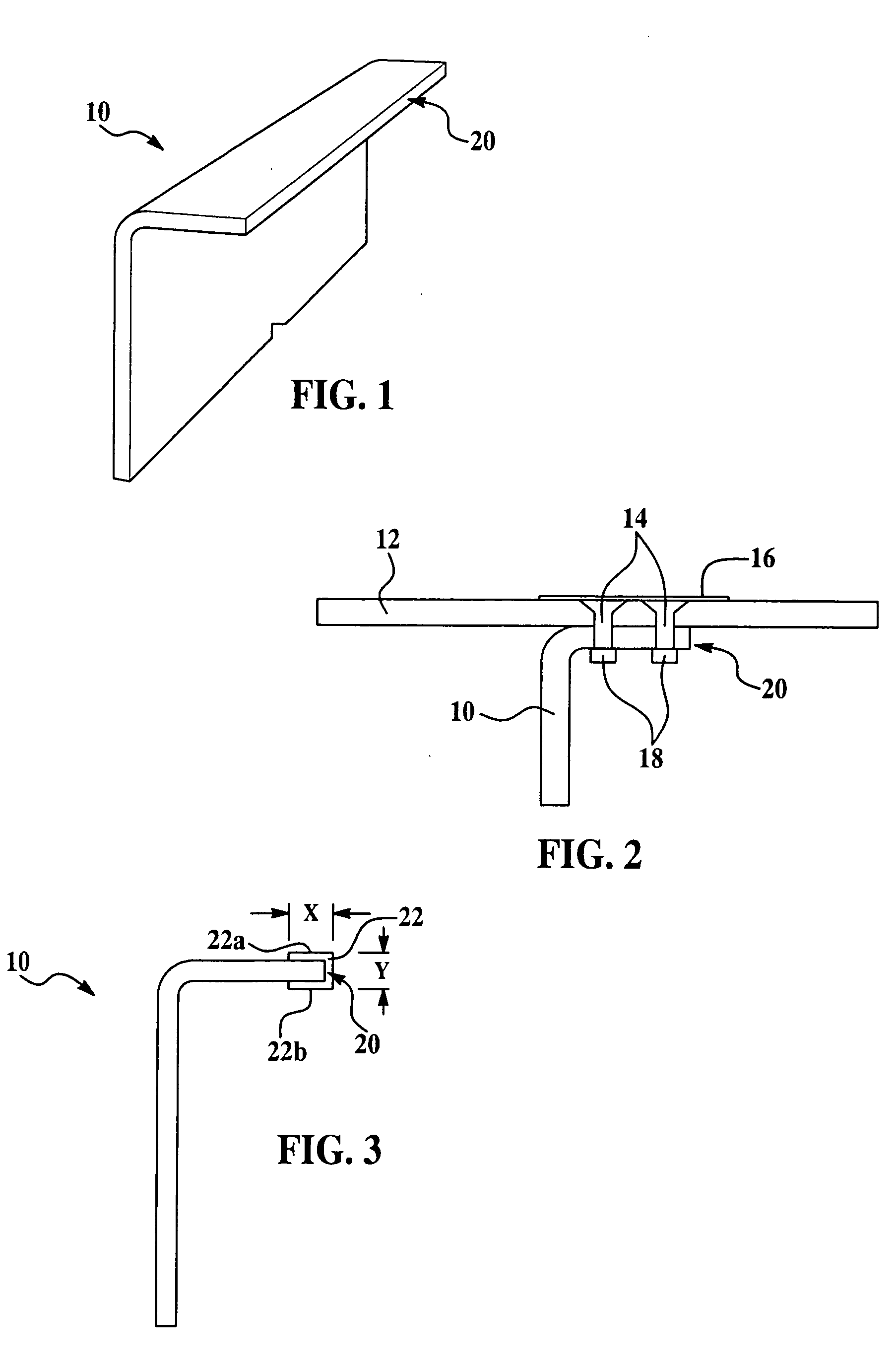

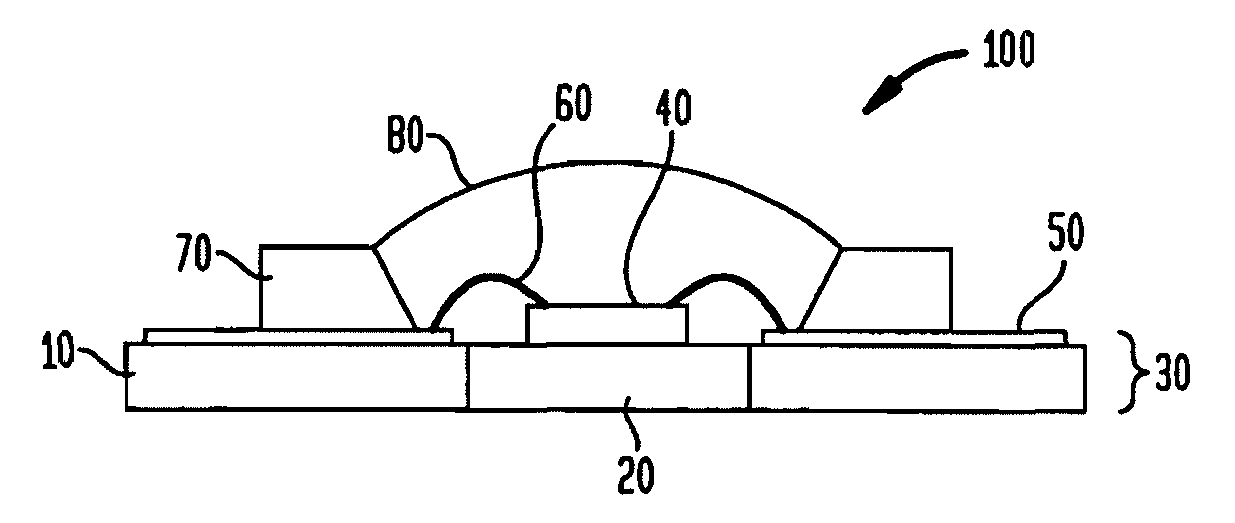

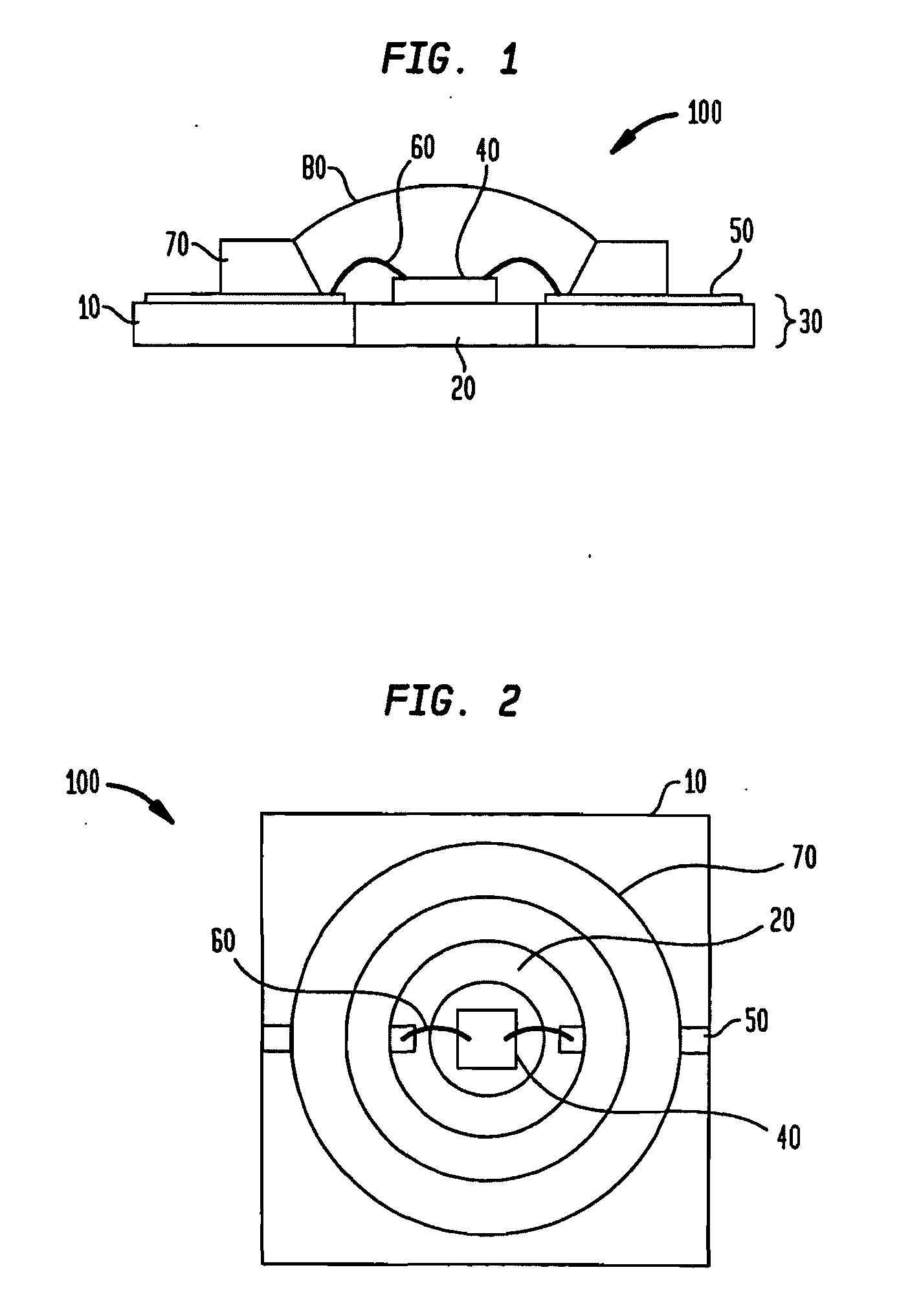

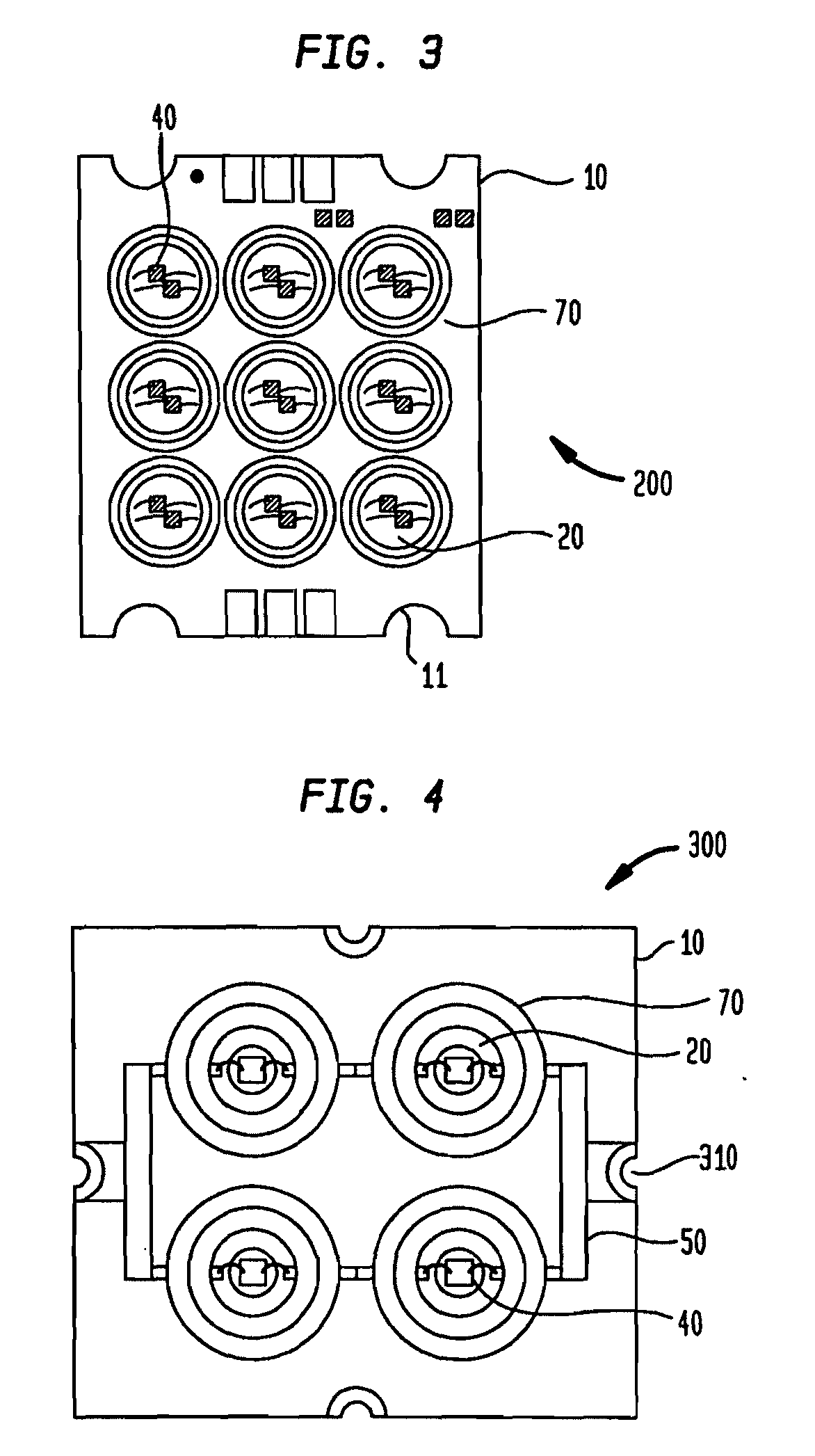

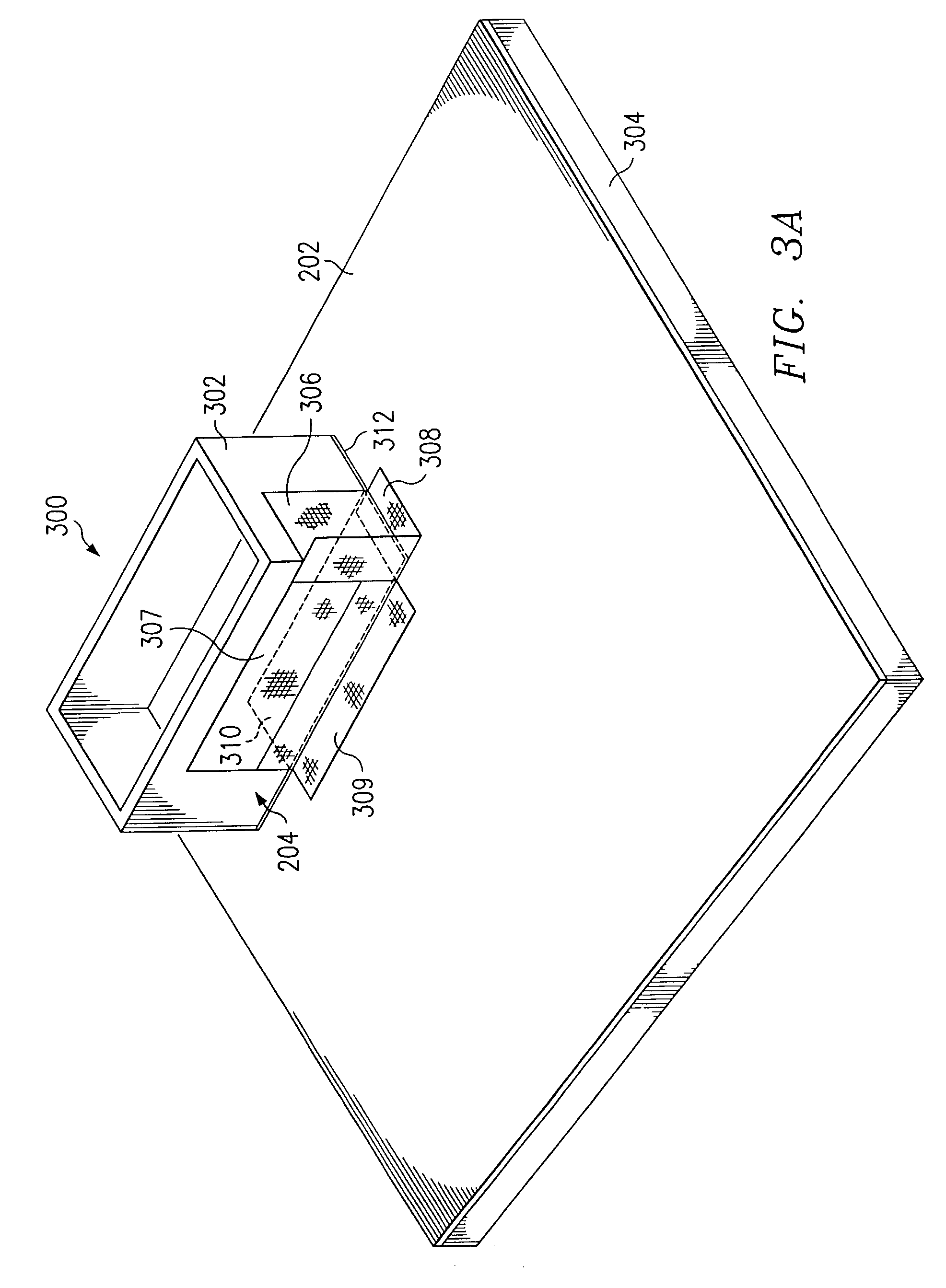

Light emitting diode package and method for making same

InactiveUS20070007558A1Versatile and cost-efficient constructionLow costFinal product manufacturePrinted circuit aspectsSecondary componentEngineering

A light emitting diode (LED) package for high temperature operation which includes a printed wire board and a heat sink. The LED package may include a formed heat sink layer, which may be thermally coupled to an external heat sink. The printed wire board may include apertures that correspond to the heat sink such that the heat sink is integrated with the printed wire board layer. The LED package may include castellations for mounting the package on a secondary component such as a printed wire board. The LED package may further comprise an isolator disposed between a base metal layer and one or more LED die. Optionally, the LED die may be mounted directly on a base metal layer. The LED package may include a PWB assembly having a stepped cavity, in which one or more LED die are disposed. The LED package is advantageously laminated together using a pre-punched pre-preg material or a pressure sensitive adhesive.

Owner:LIGHTING SCI GROUP

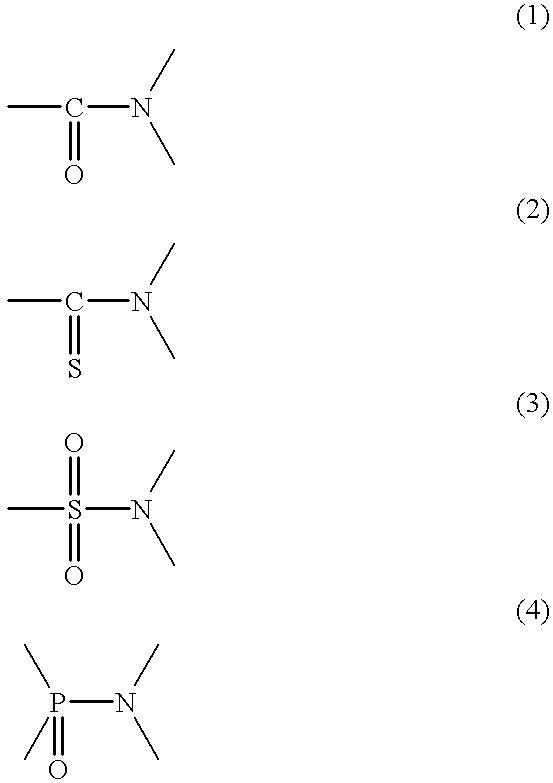

Epoxy resin composition for fiber-reinforced composite material, prepreg, and fiber-reinforced composite material

InactiveUS20020007022A1Synthetic resin layered productsThin material handlingInterlaminar shearFiber-reinforced composite

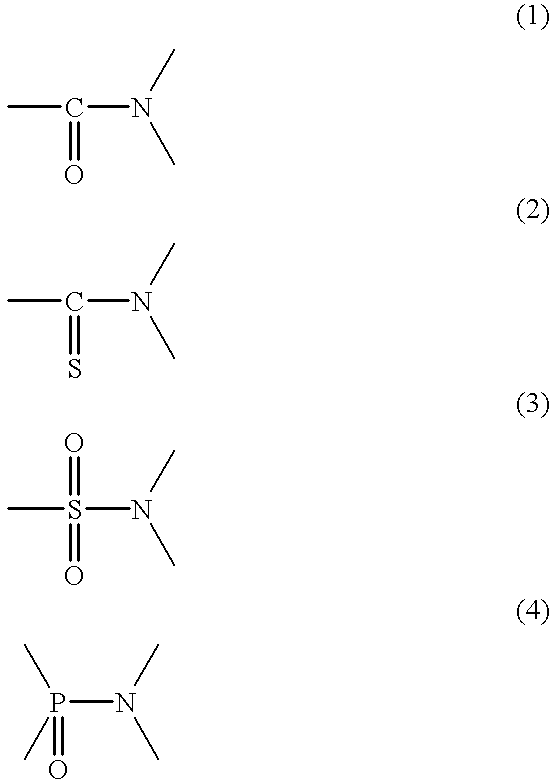

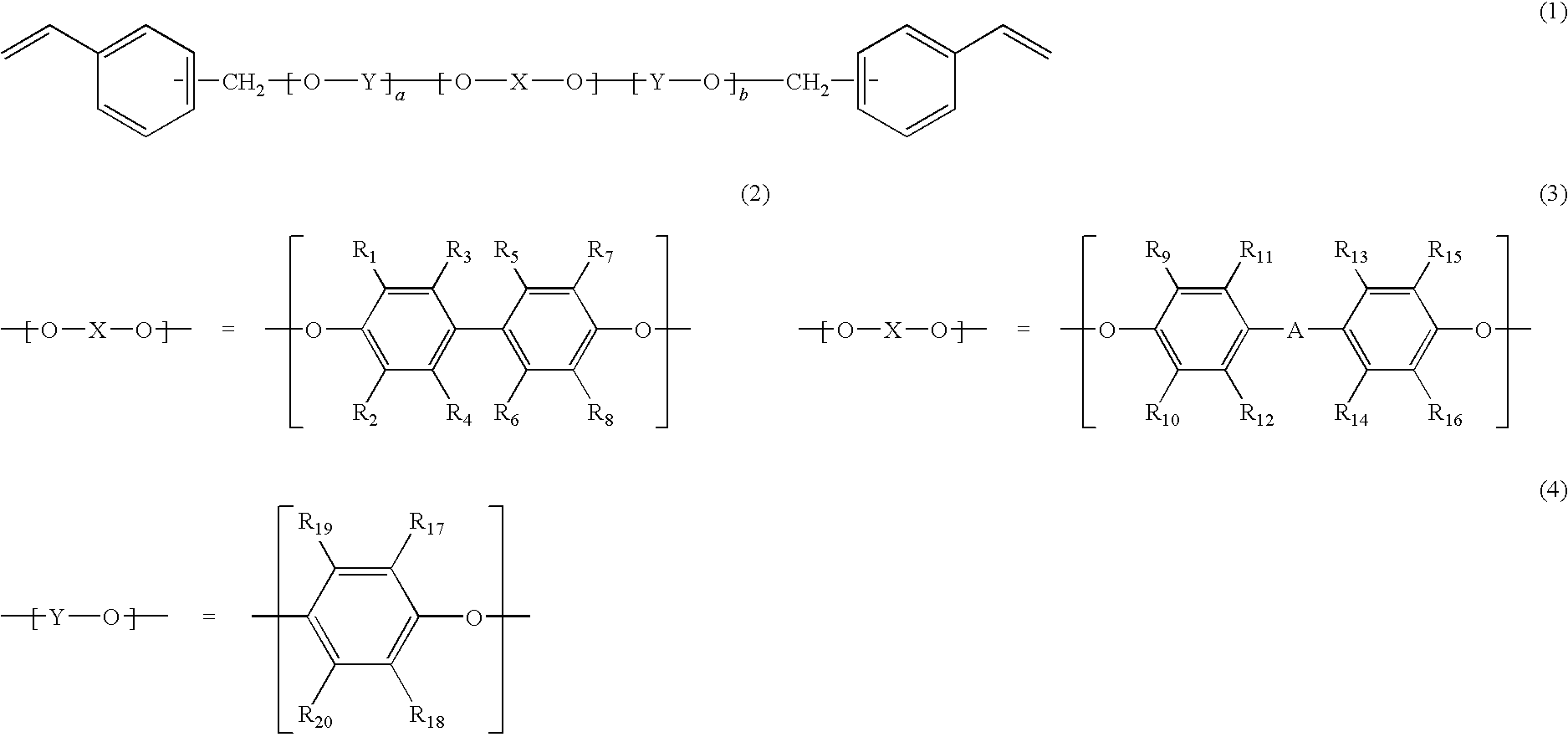

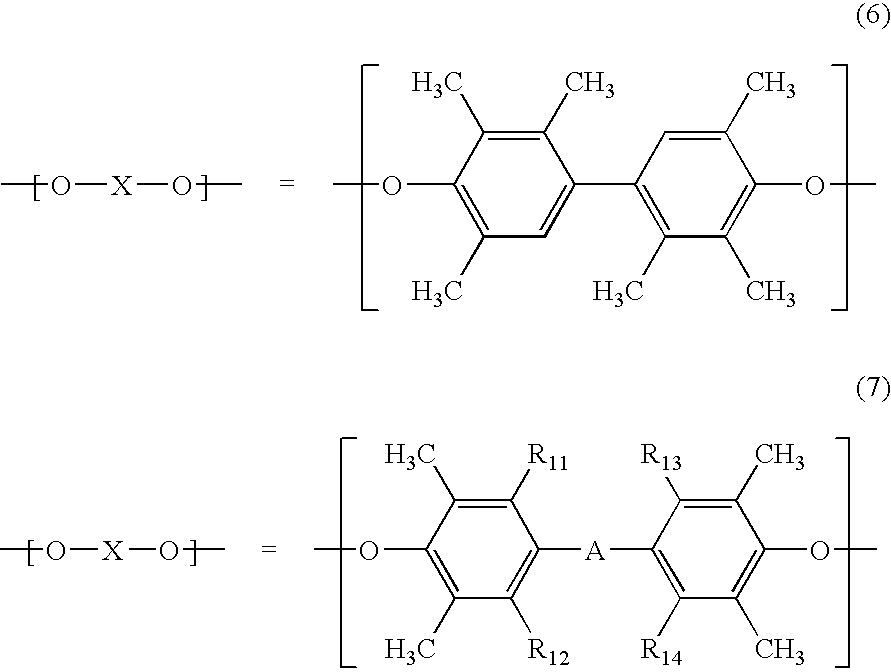

In order to realize the objectives stated above, the thermosetting resin composition for carbon fiber reinforced composite materials of the present invention chiefly comprises the following components. (A) Thermosetting resin (B) Compound containing one functional group which can react with thermosetting resin (A) or its curing agent, and a moiety selected from the following formulae (1) to (4) Furthermore, the present invention also relates to a prepreg formed by impregnating reinforcing fiber with the aforesaid resin composition and to carbon fiber reinforced composite materials comprising reinforcing fiber and a cured aforesaid thermosetting resin composition. In accordance with the present invention, there can be obtained a thermosetting resin composition where the adhesion to reinforcing fiber by the cured material and the elastic modulus of the cured material are excellent, and by using this resin composition there can be obtained carbon fiber reinforced composite materials which are excellent in their 0° compressive strength, 90° tensile strength and interlaminar shear strength, and which also have outstanding impact resistance.

Owner:TORAY IND INC

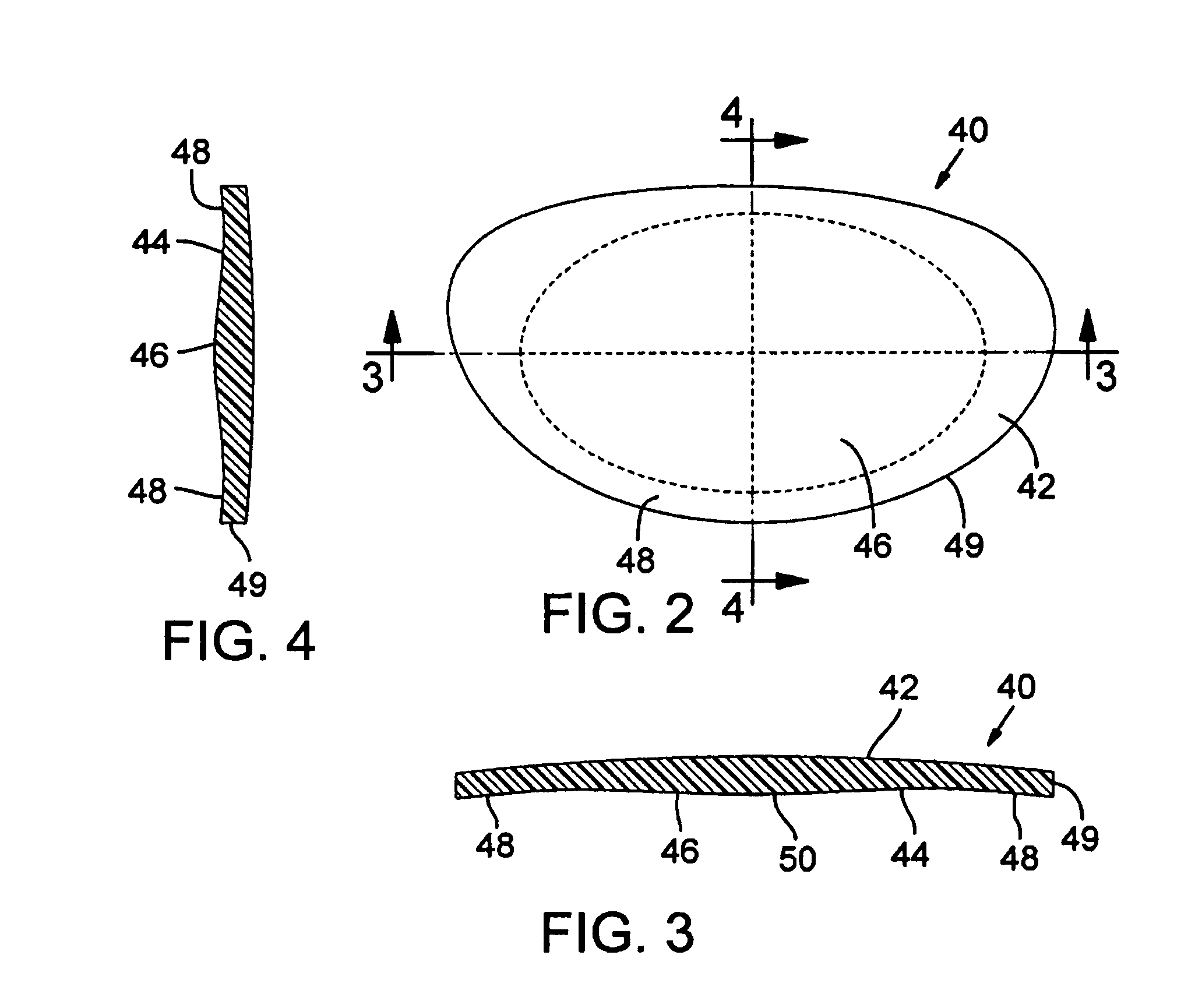

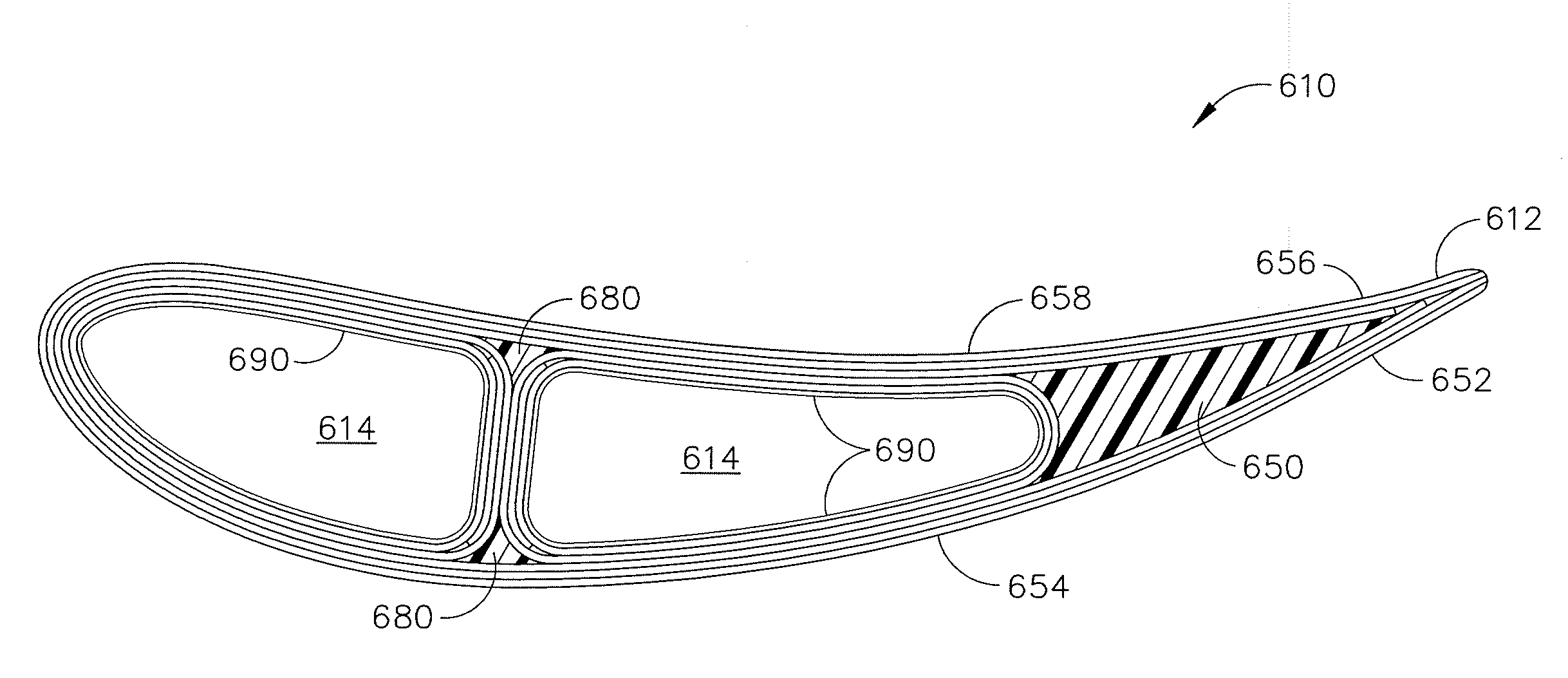

Composite articles and methods for making the same

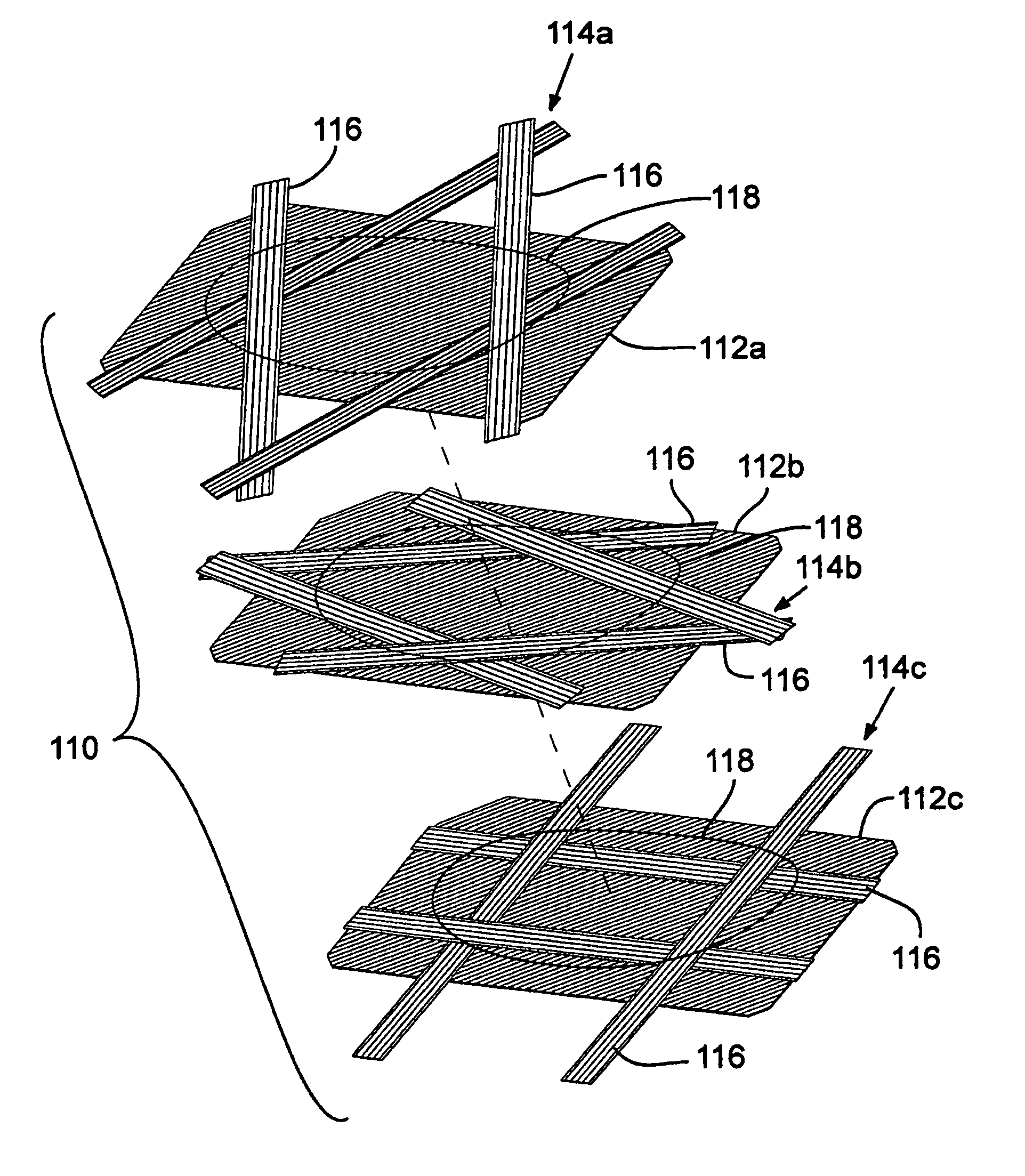

ActiveUS7874938B2Increased durabilityMinimize damageLamination ancillary operationsLaminationEngineeringGolf Ball

The present disclosure pertains to composite articles, and in particular a composite face plate for a golf club-head, and methods for making the same. In certain embodiments, a composite face plate for a club-head comprises a lay-up of multiple, composite prepreg plies. The face plate can be made by first forming an oversized lay-up of multiple prepreg plies having a central portion and a sacrificial portion surrounding the central portion. The lay-up is at least partially cured in a mold under elevated pressure and heat. The lay-up is then removed from the mold and the sacrificial portion is removed from the central portion to form a composite part that is substantially free of defects.

Owner:TAYLOR MADE GOLF

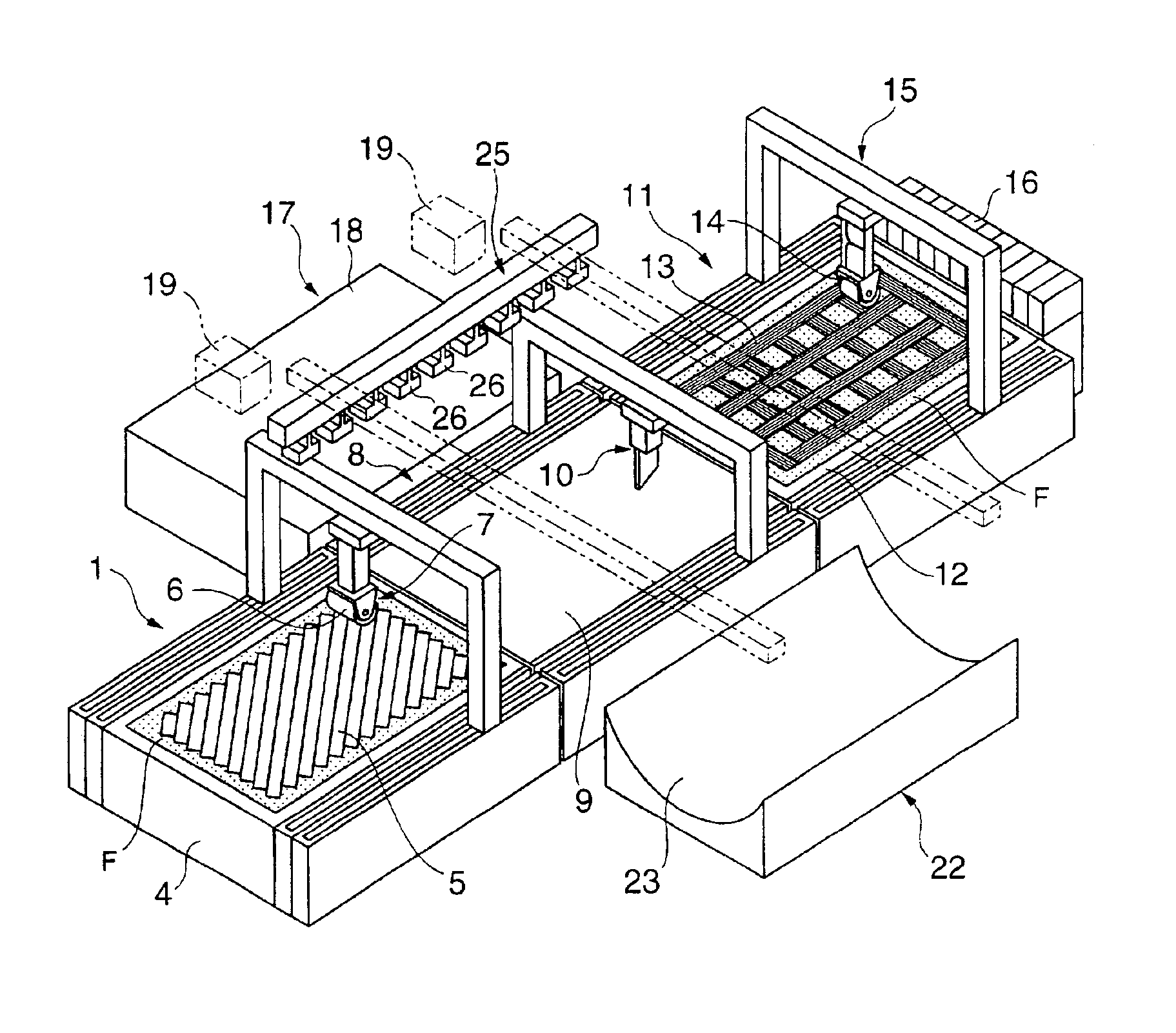

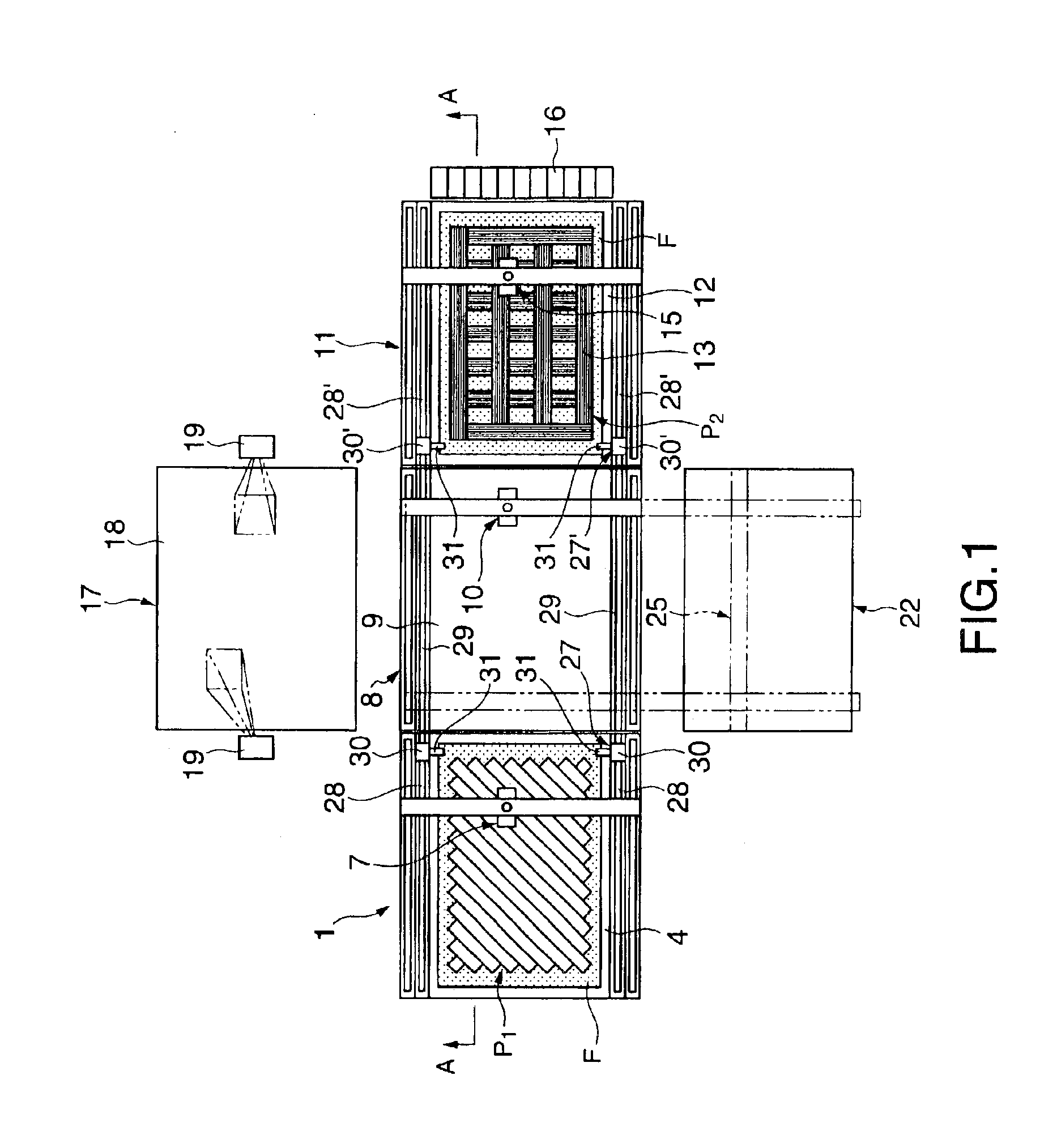

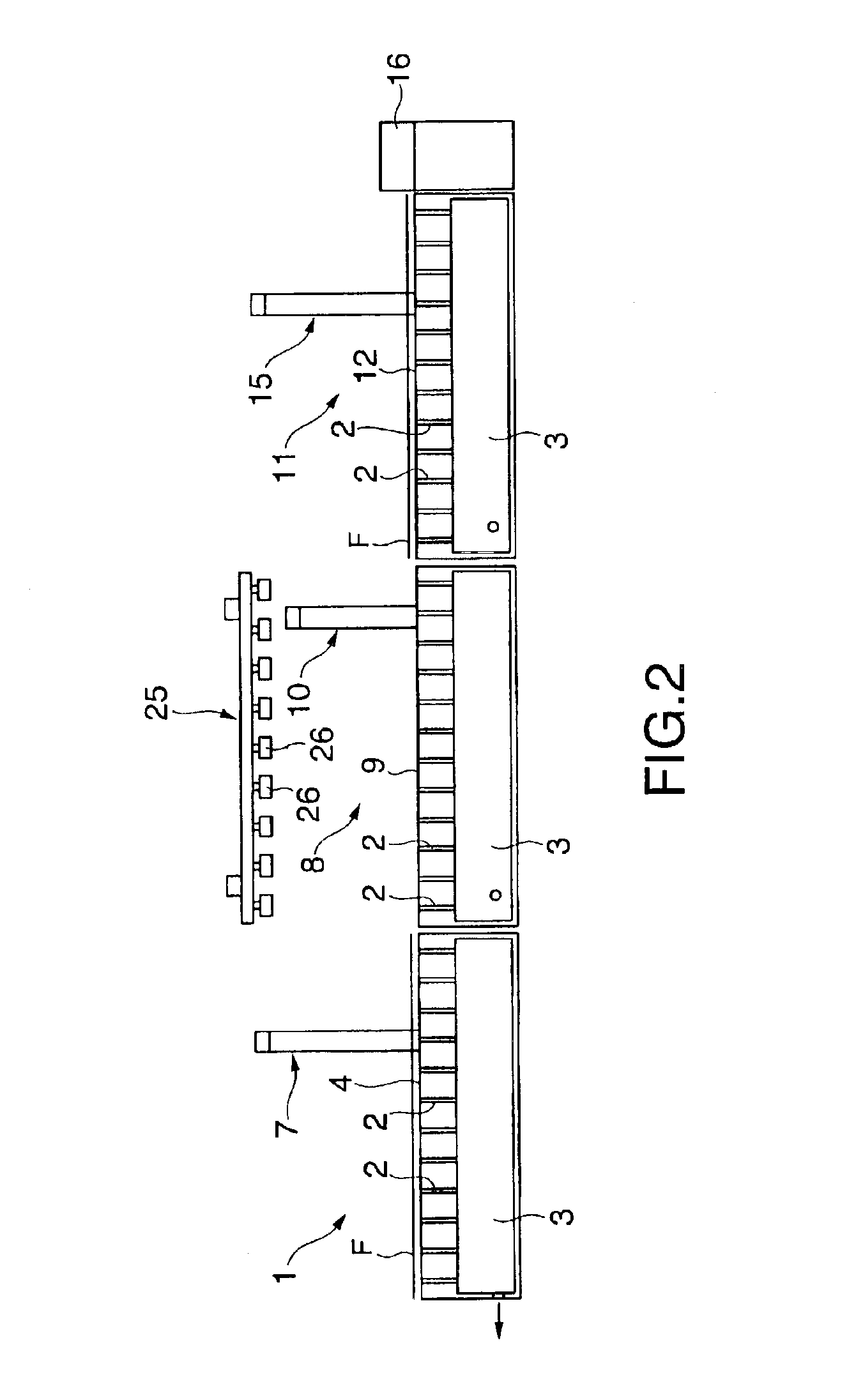

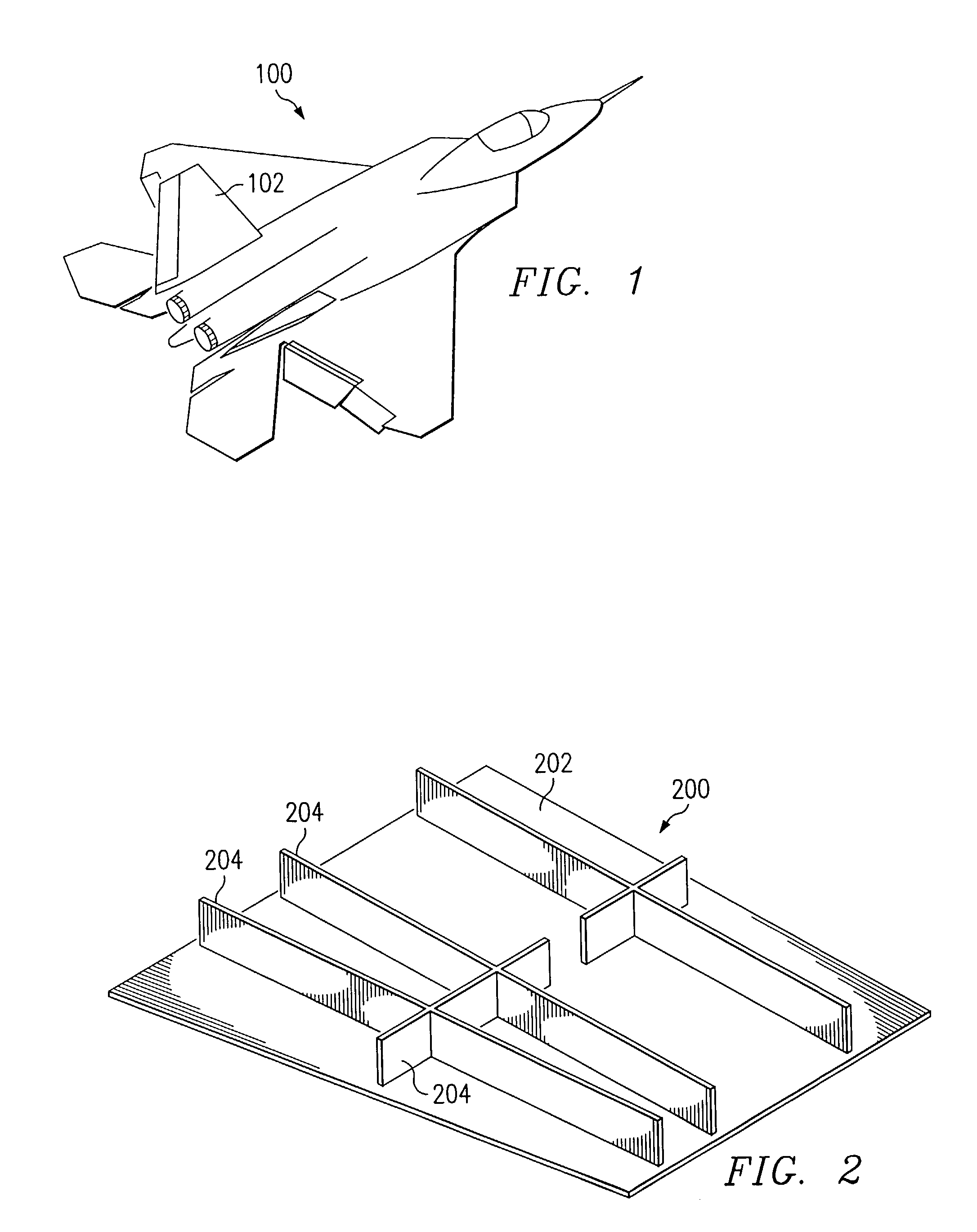

Automatic prepreg laminating method and apparatus for carrying out the same

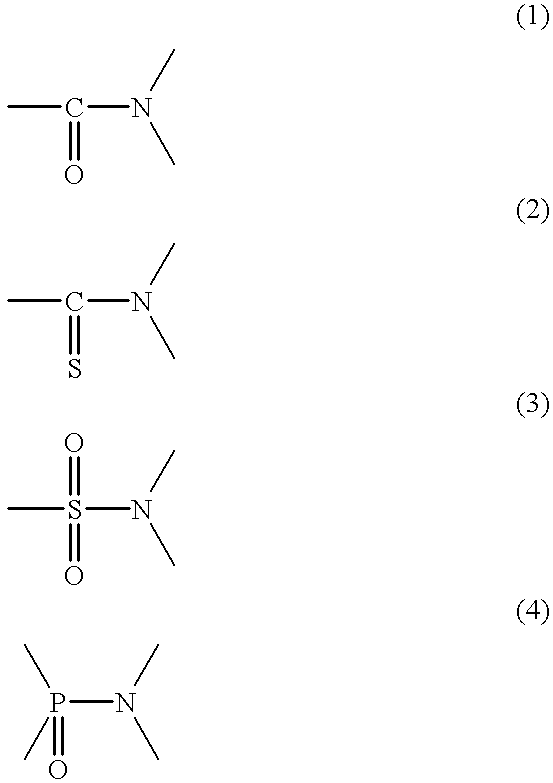

InactiveUS6860957B2Efficiently carrying out prepreg laminationLamination ancillary operationsLaminationEngineeringClose contact

A first parting film is held on a first flat laminating table in close contact with the first flat laminating table, and then wide prepregs are laid for plane lamination on the first parting film to form a large prepreg-laminate having a large area. A second parting film is held on a second flat laminating table in close contact with the second flat laminating table by suction, and then narrow prepregs to form a gridlike prepreg-laminate. The large prepreg-laminate is floated up by jetting air from the first flat laminating table is cut on a cutting table to obtain a prepreg-laminate skin. The gridlike prepreg-laminate is processed similarly to obtain a prepreg-laminate doubler. The prepreg-laminate skin and the prepreg-laminate doubler are carried from the cutting table to a laminating mold having a single-contour laminating surface so as to be superposed and are laminated to form a composite panel.

Owner:KAWASAKI HEAVY IND LTD

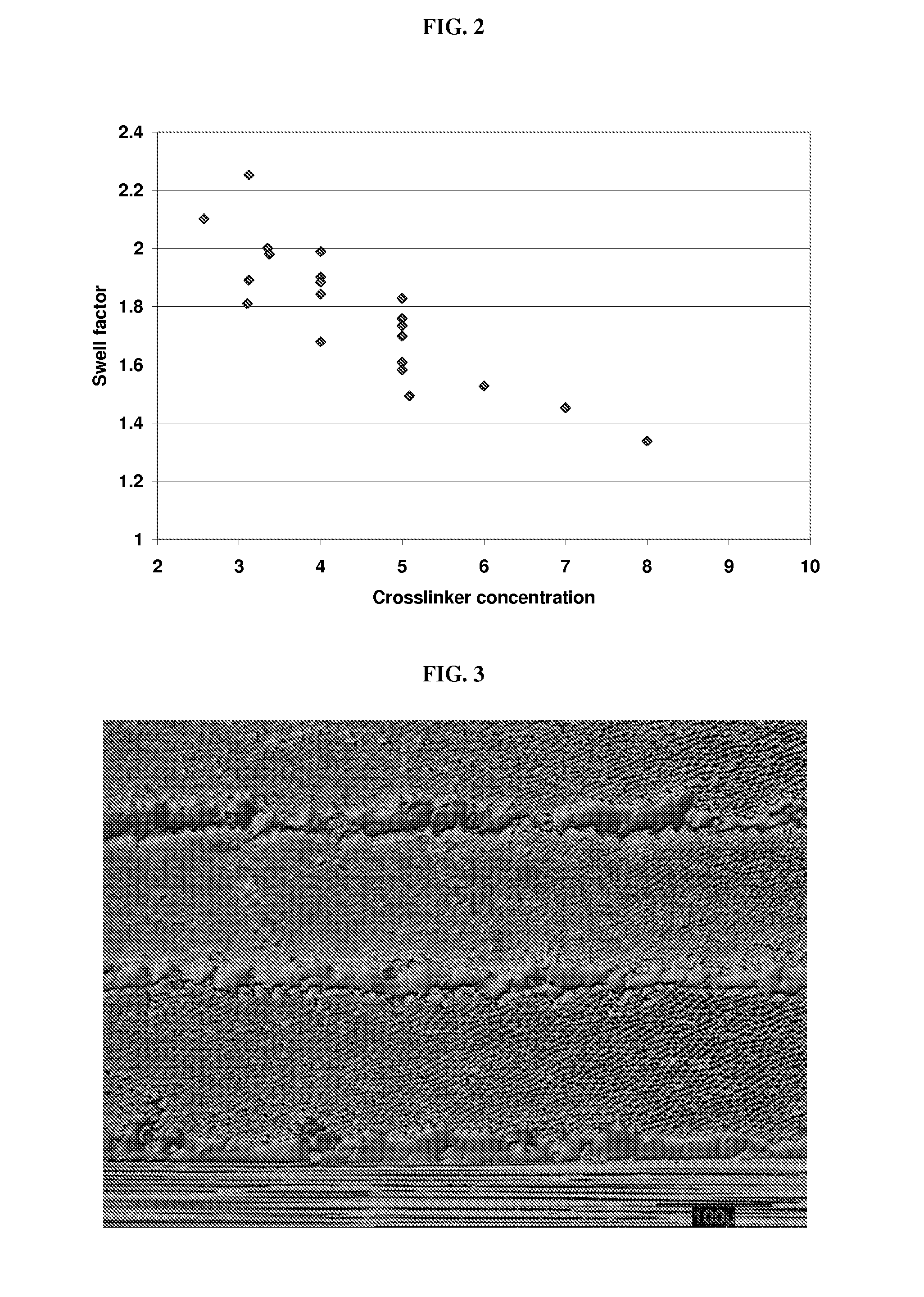

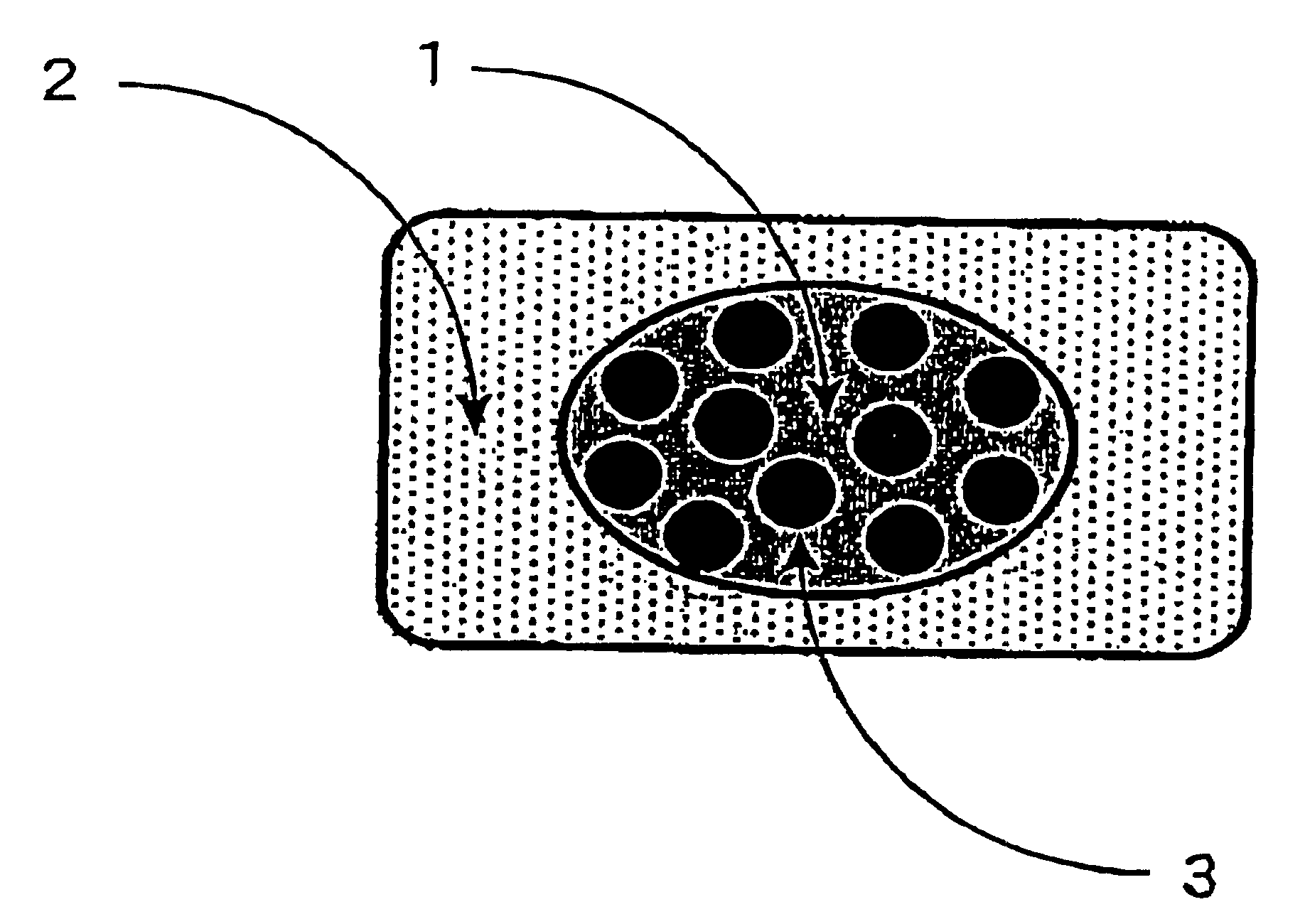

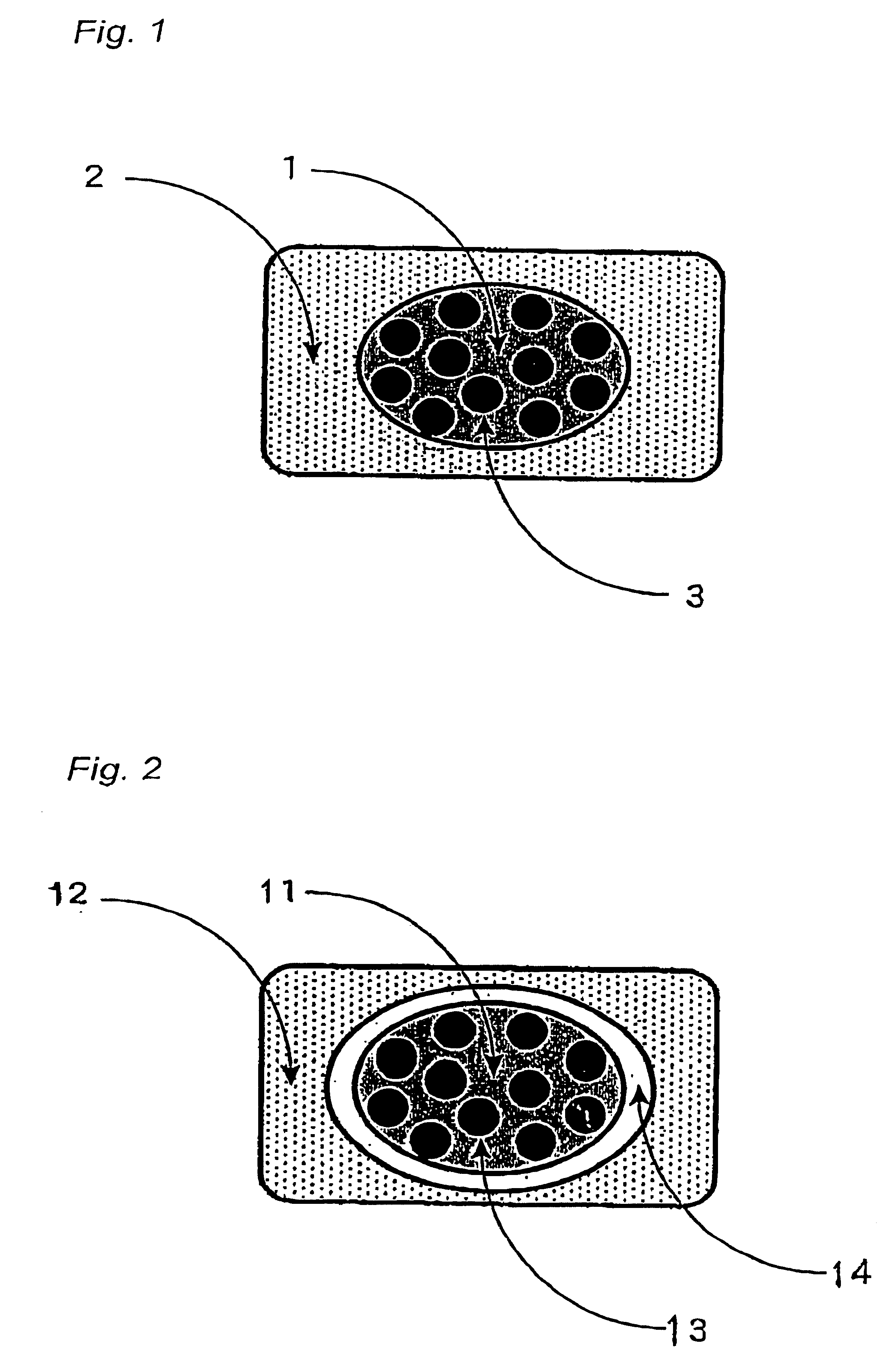

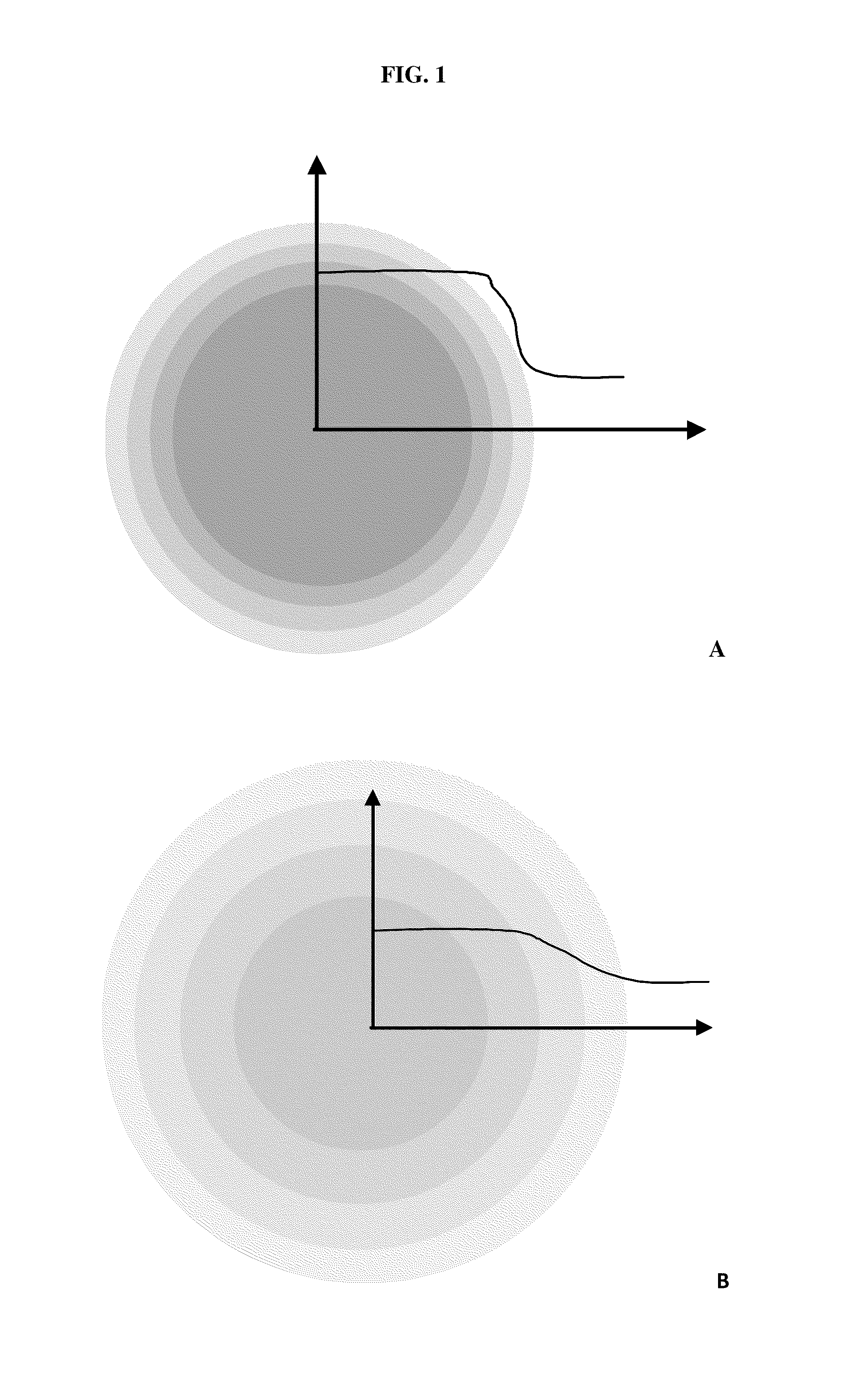

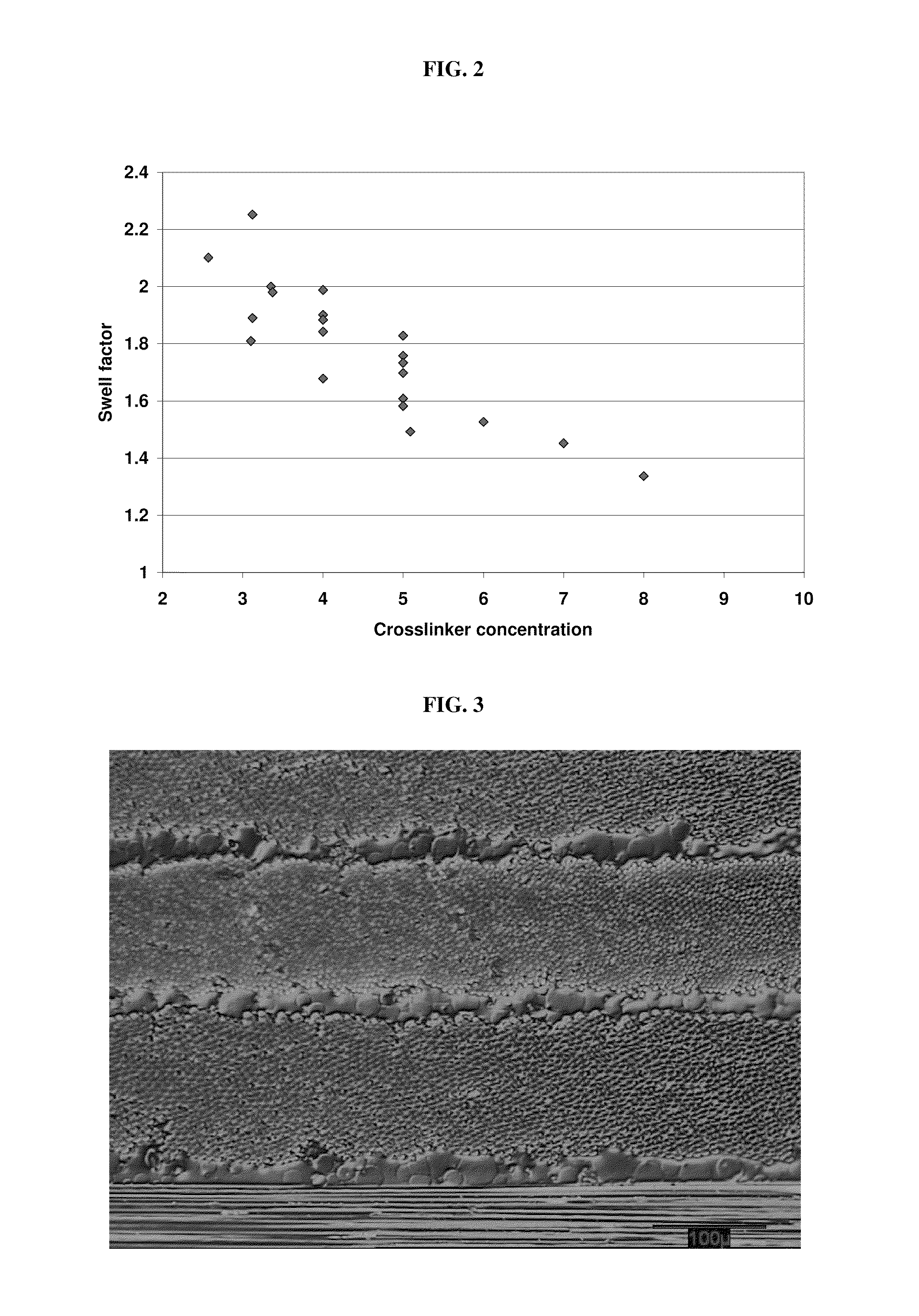

Engineered crosslinked thermoplastic particles for interlaminar toughening

ActiveUS20100304118A1Increase damage toleranceImprove toughnessThin material handlingRubber layered productsTougheningPolymer chemistry

Engineered crosslinked thermoplastic particles are useful for interlaminar toughening of pre-pregs and composite materials.

Owner:CYTEC TECH CORP

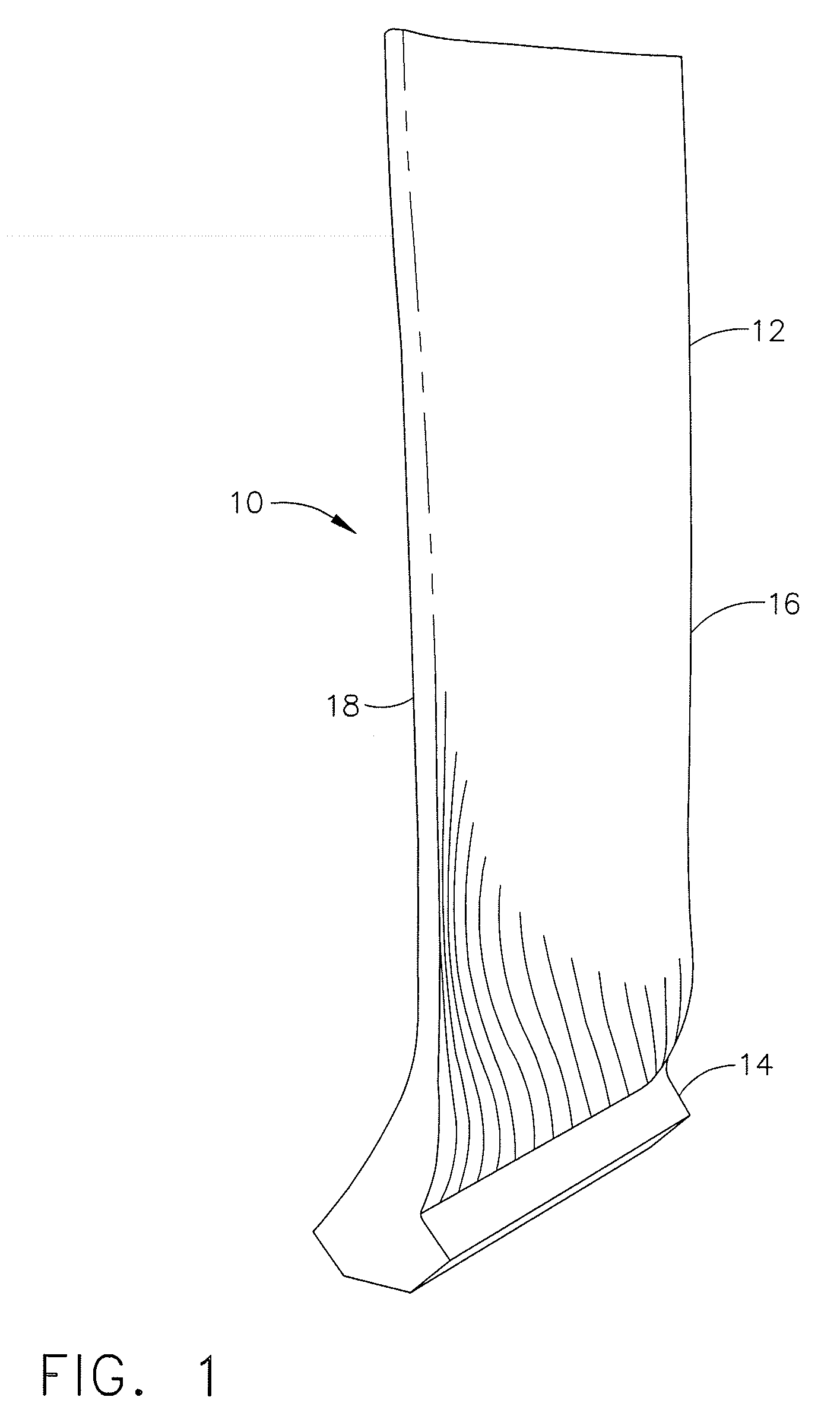

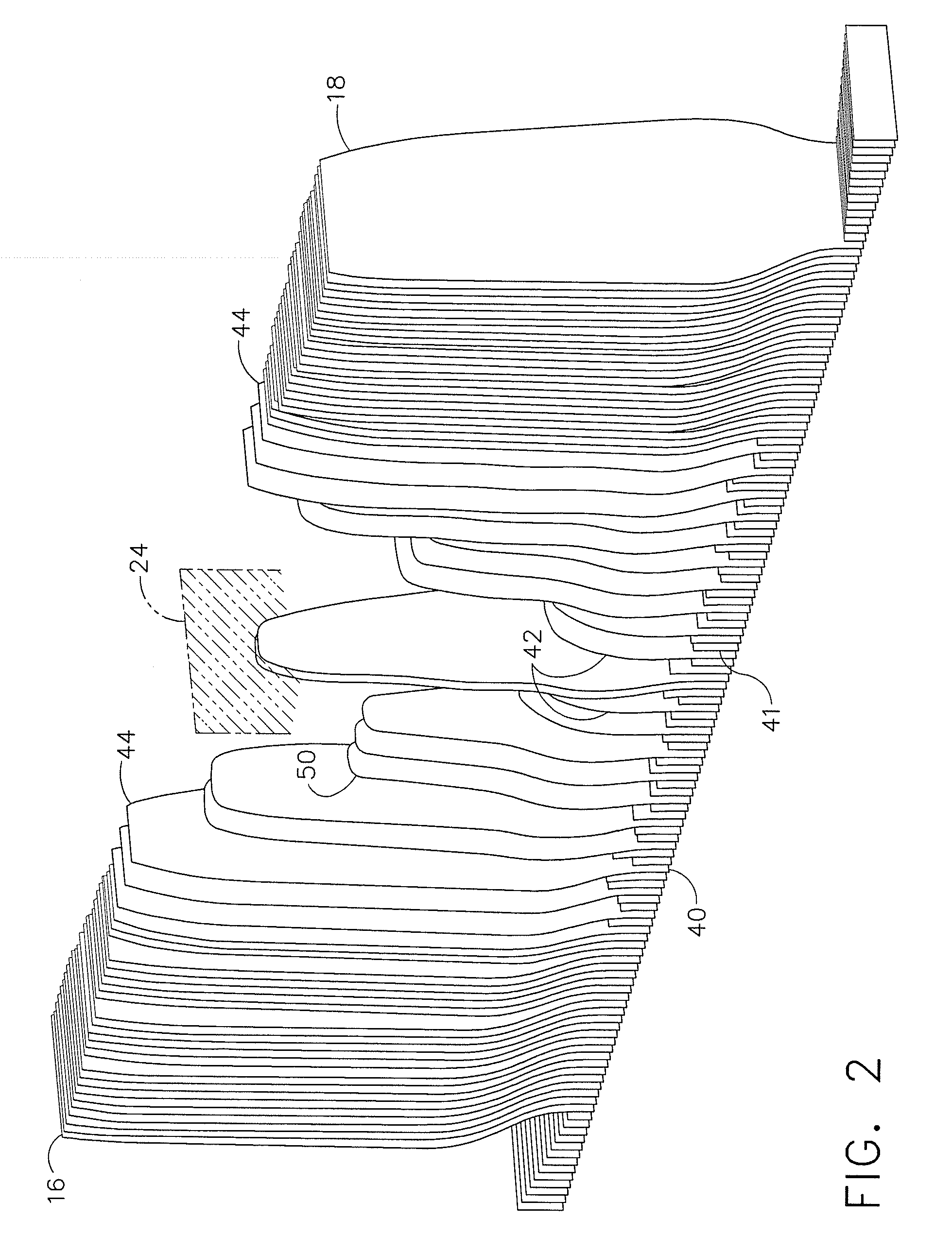

Cmc articles having small complex features

ActiveUS20080124512A1Easy to manufactureEliminate complex processesBlade accessoriesEfficient propulsion technologiesMetallurgyGas turbines

A ceramic matrix composite (CMC) component for gas turbine engines, the component having fine features such as thin edges with thicknesses of less than about 0.030 inches and small radii of less that about 0.030 inches formed using the combination of prepreg plies layed up with non-ply ceramic inserts. The CMC components of the present invention replace small ply inserts cut to size to fit into areas of contour change or thickness change, and replace the small ply inserts with a fabricated single piece discontinuously reinforced composite insert, resulting in fewer defects, such as wrinkles, and better dimensional control.

Owner:GENERAL ELECTRIC CO

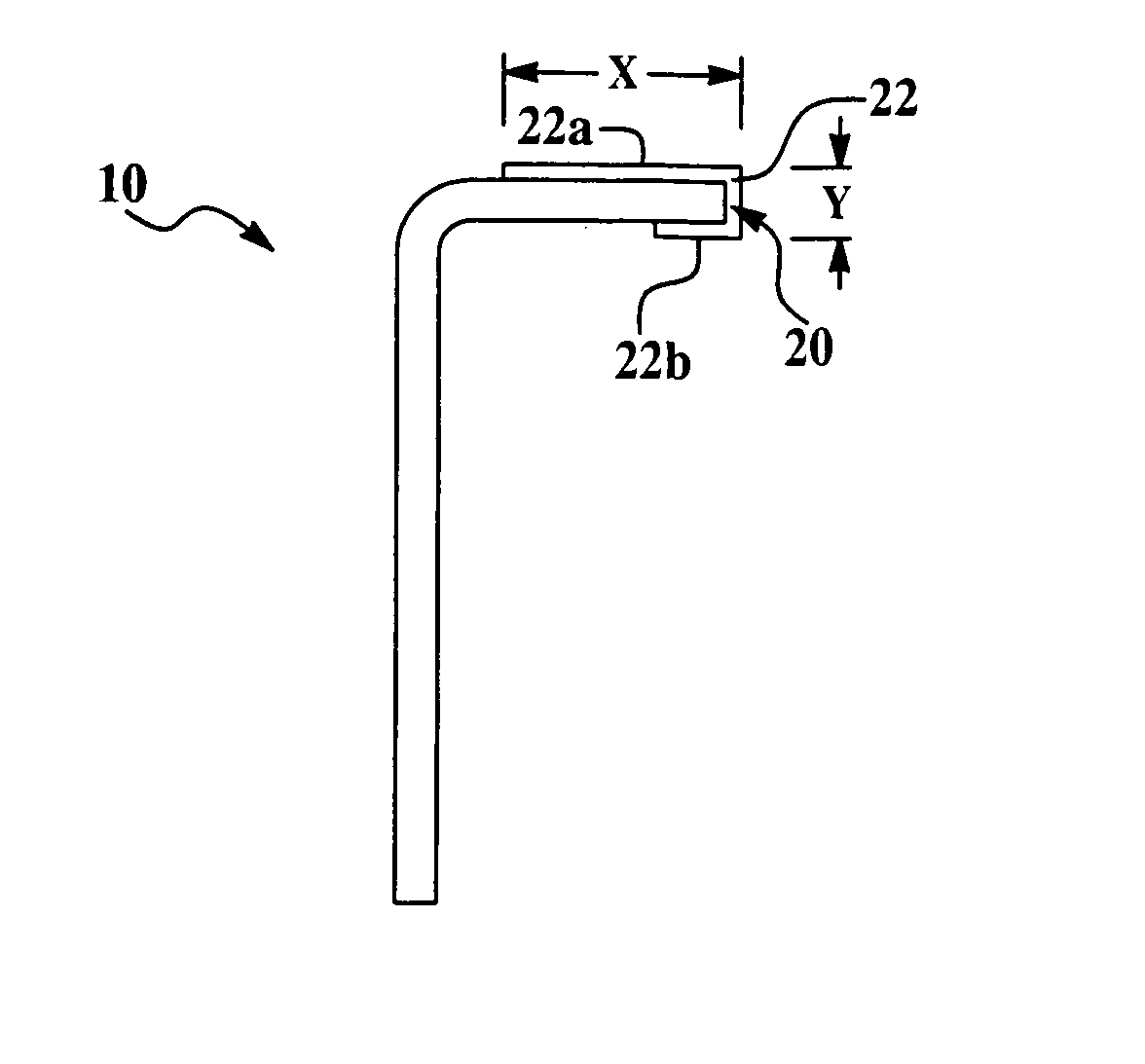

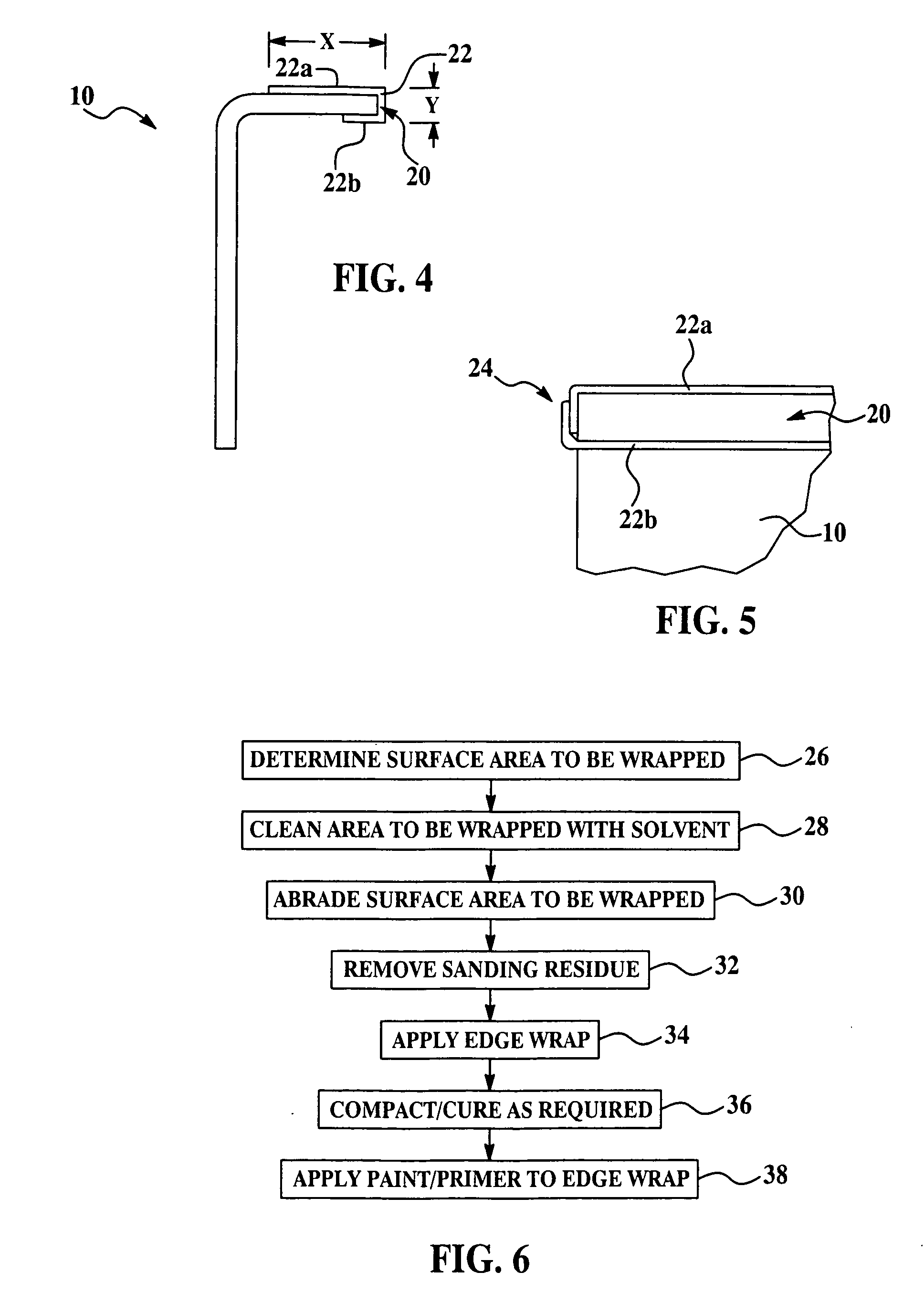

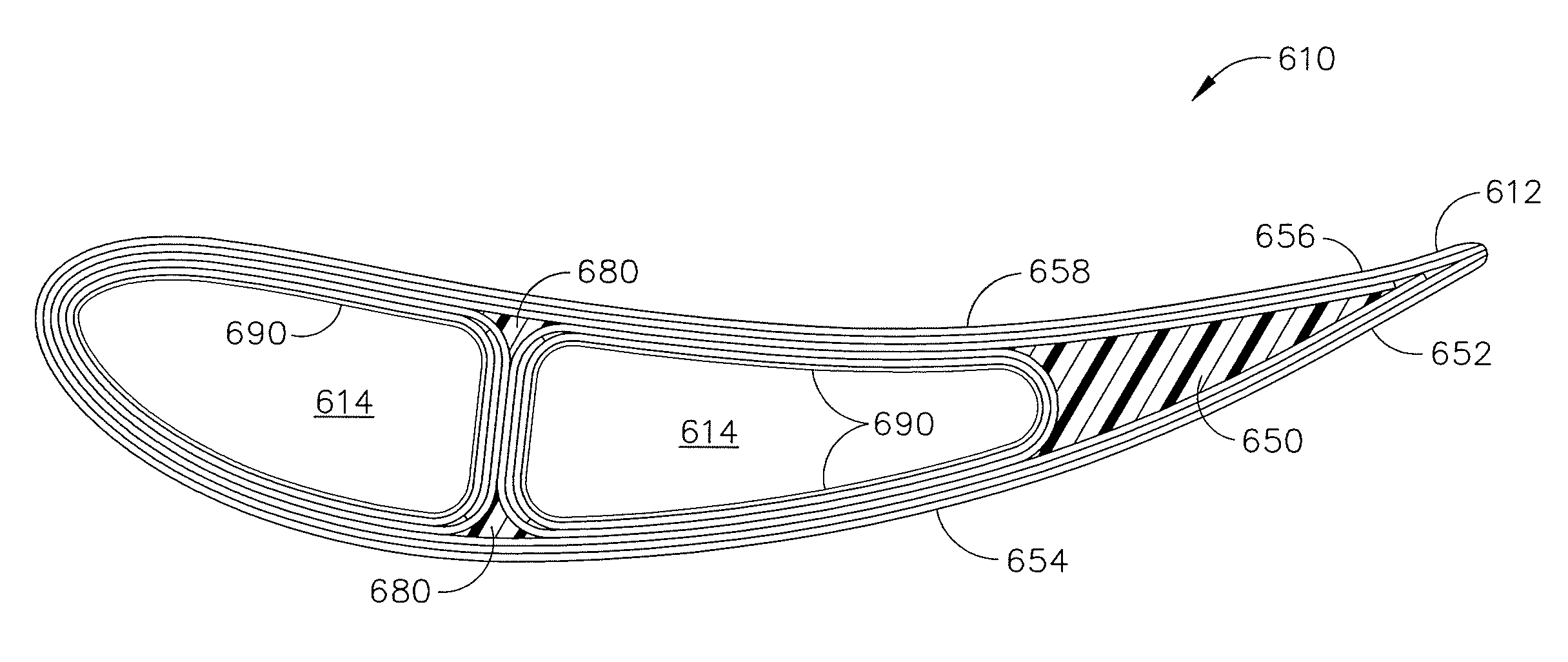

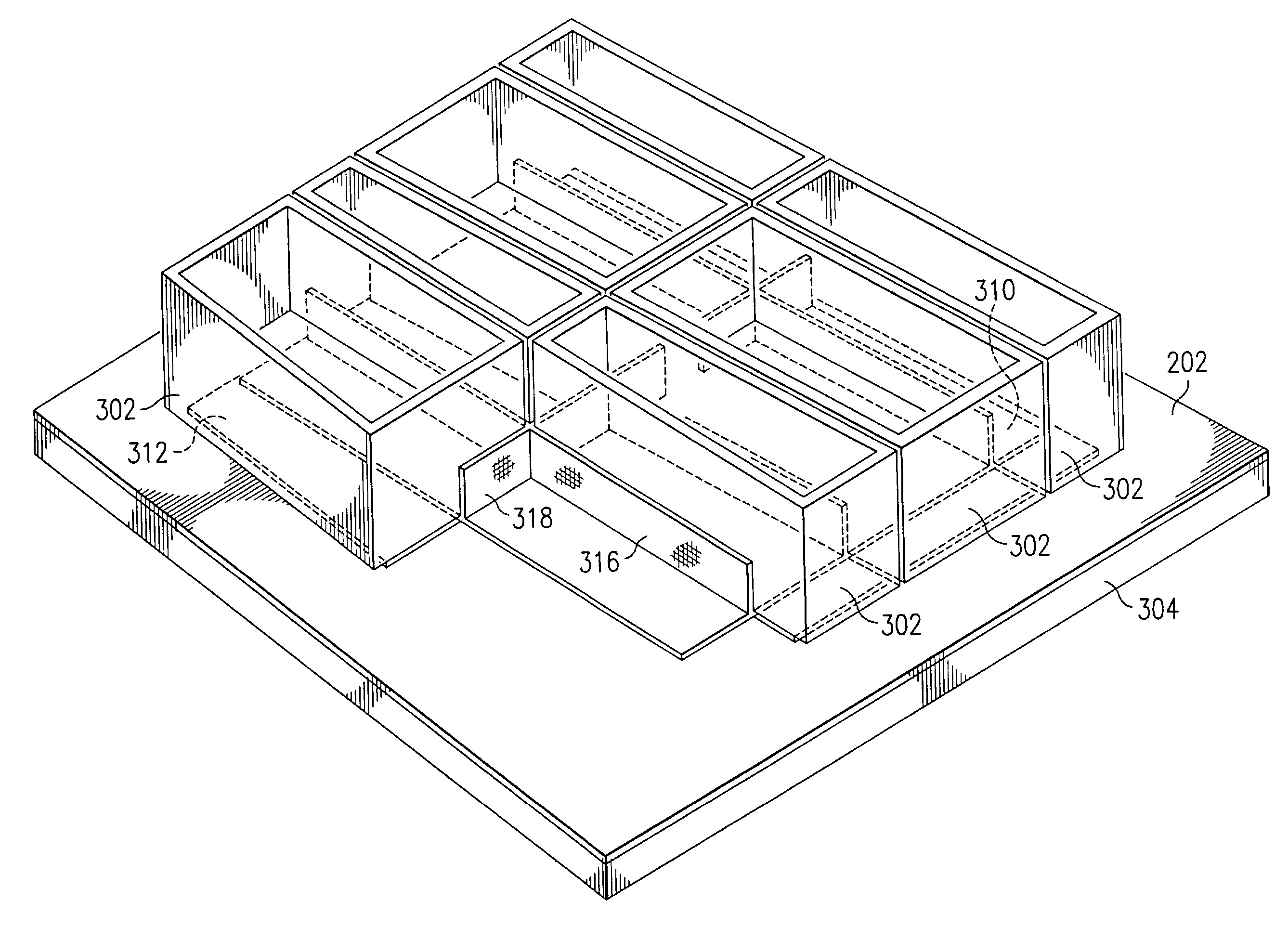

Edge seals for composite structure fuel tanks

ActiveUS20080128430A1Avoid contactPower plant fuel tanksFuel tank safety measuresFuel tankEngineering

The cut laminate edges of aircraft fuel tanks formed of carbon fiber reinforced polymers are sealed to prevent the exposure of carbon fibers to combustible fuel. The edge seal is produced from a prepreg form using a thermosetting resin matched to the characteristics of the resin used in the laminate. The prepreg form can be applied to the cut laminate edges either before or after the laminate is cured. The edge seal acts a dielectric layer that both electrically insulates the cut laminate edges from the fuel and mechanically contains energetic particles produced at the edges due to lighting strikes or other sources of electrical charges.

Owner:THE BOEING CO

Prepreg and fiber-reinforced rubber materials

The object is to provide a carbon fiber-reinforced rubber material which is superior in heat resistance, water resistance, and dimensional stability and exhibits resistance to fatigue from flexing at a practical level. The present invention relates to a prepreg comprising a liquid rubber composition having a viscosity in a range of 0.01 Pa.s to 100 Pa.s at 70° C. and substantially containing no solvent, the liquid rubber being impregnated into a reinforcing fiber, and relates to a fiber-reinforced rubber material comprising the prepreg in which the liquid rubber is crosslinked. Also, the present invention relates to a fiber-reinforced rubber material comprising a substrate comprising a rubber component, the substrate being reinforced by a core material comprising a prepreg of a reinforcing fiber impregnated with the same rubber component.

Owner:TORAY IND INC

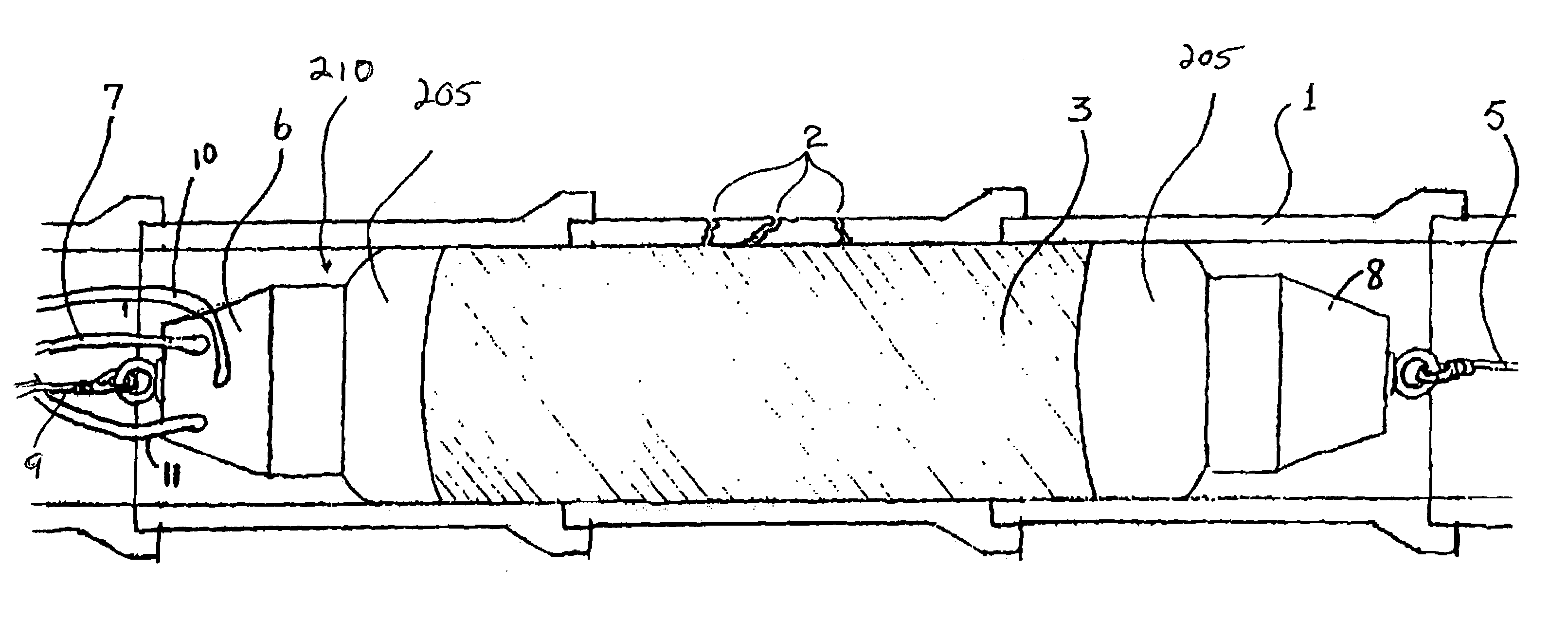

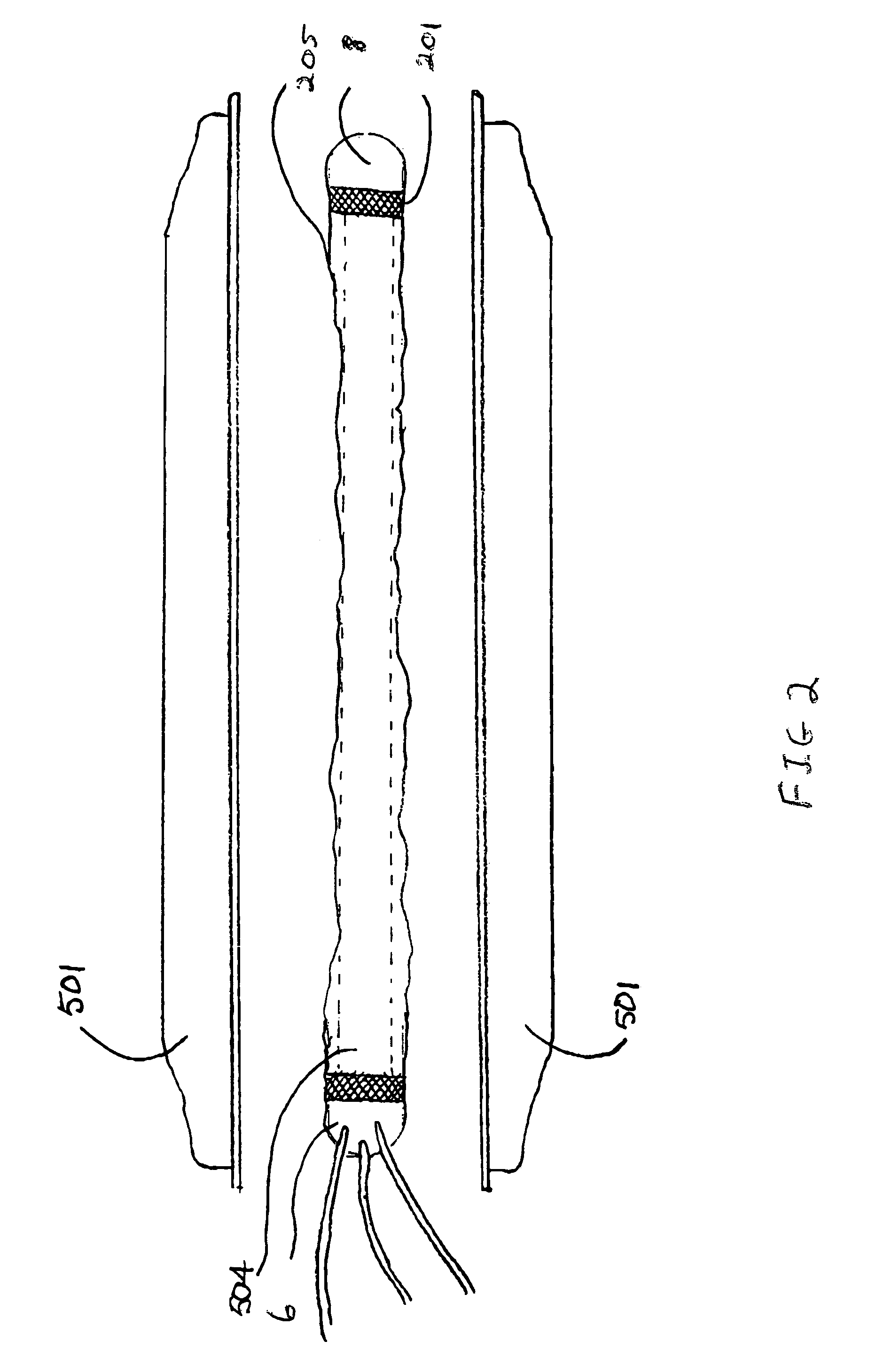

Inflatable heating device for in-situ repair of conduit and method for repairing conduit

InactiveUS7052567B1Extend the life cycleRobust and heatingConfectionerySweetmeatsElastomerResin matrix

The apparatus of the present invention is generally characterized by a heating / inflation module having pressurizable interior and an attached heat curable pre-preg. In particular, an elastomeric, seamless composite is provided that includes a heating element disposed within a thermoset resin matrix. The composite adapted to maintain a consistent temperature profile and an internal air pressure. A first end piece is attached to a first end of the composite and has an air port for communication with a compressed air source, a vacuum port for communication with a vacuum supply source and at least one electrical cable port for communication with a power supply source. A second end piece attached to a second end of the composite. The apparatus further includes a pre-preg removably attached to an outer surface of the composite. The pre-preg includes a structural fiber matrix supporting a heat curable resin. The composite is constructed by applying a liquid silicone matrix to at least one layer of braided or wound and / or tape fibers, wherein a portion of the fibers are electrically conductive. The layer of braided fibers is introduced into a mold, and a removable, expandable inner bladder is then loaded into the mold. The inner bladder is inflated to conform the layer of braided fibers to an interior surface of the mold. An electric current is caused to flow to the conductive fibers to cure the silicone matrix into a stable, elastomeric state. The composite is removed from the mold. A method for repairing a damaged section of a conduit is also disclosed.

Owner:EMS USA HLDG I +1

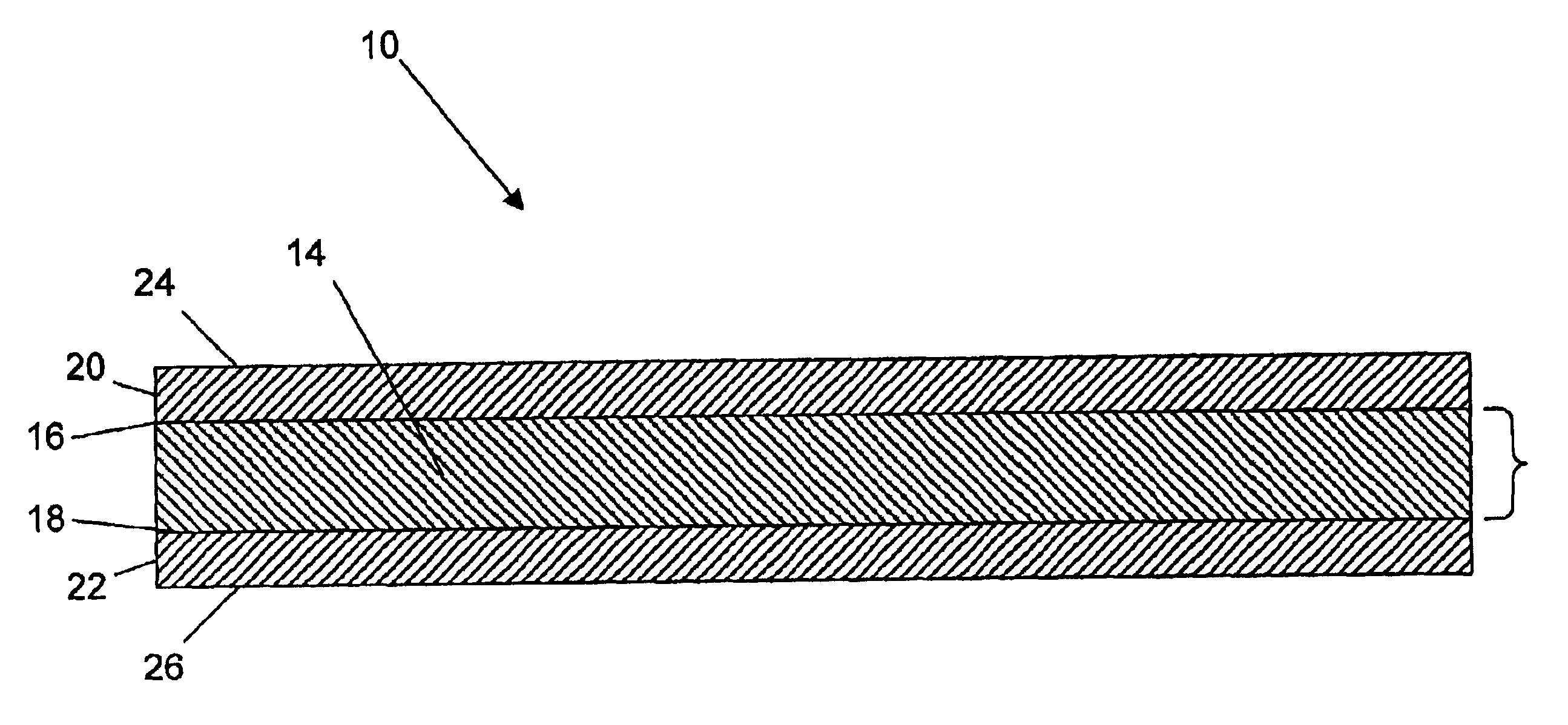

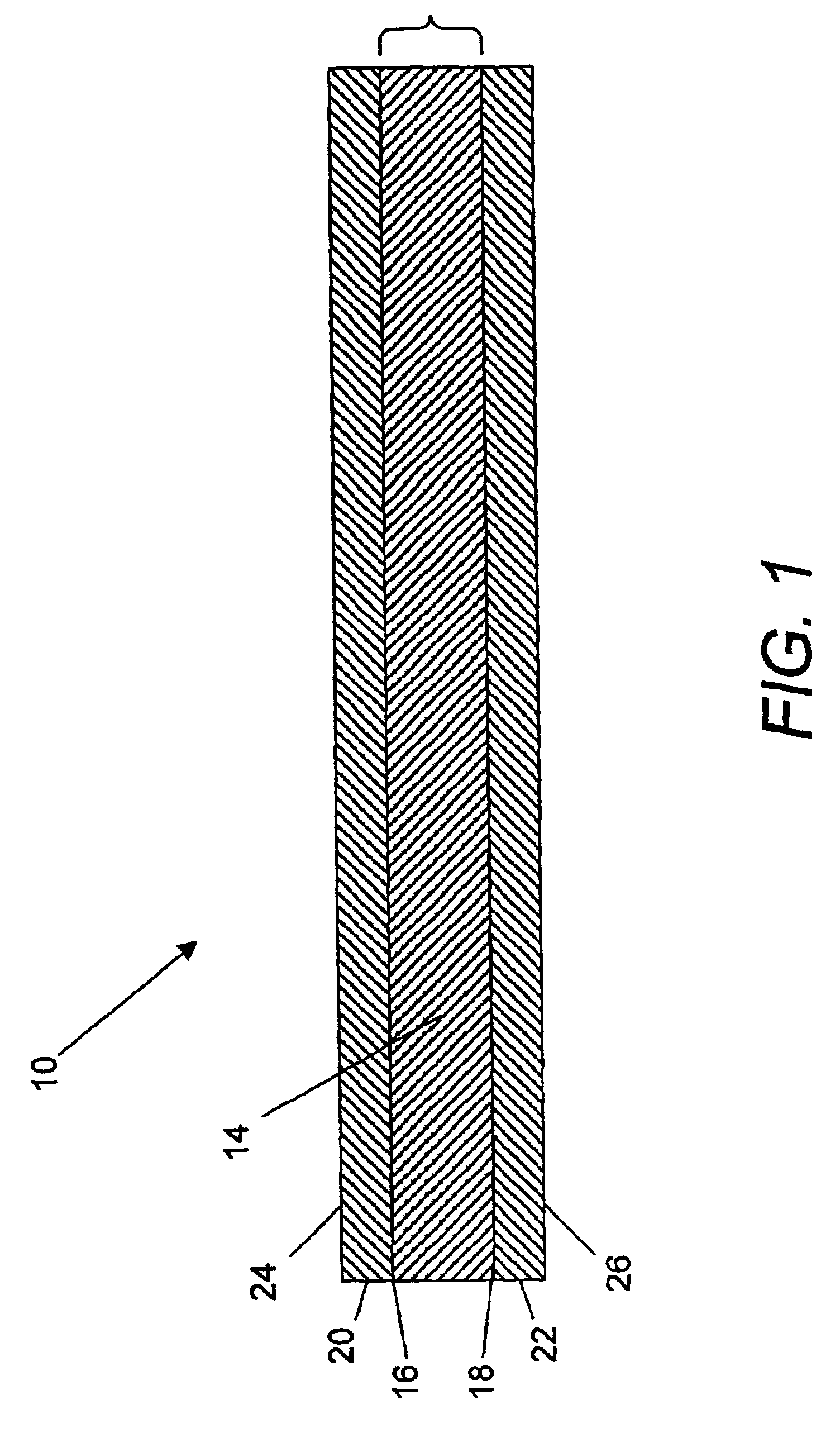

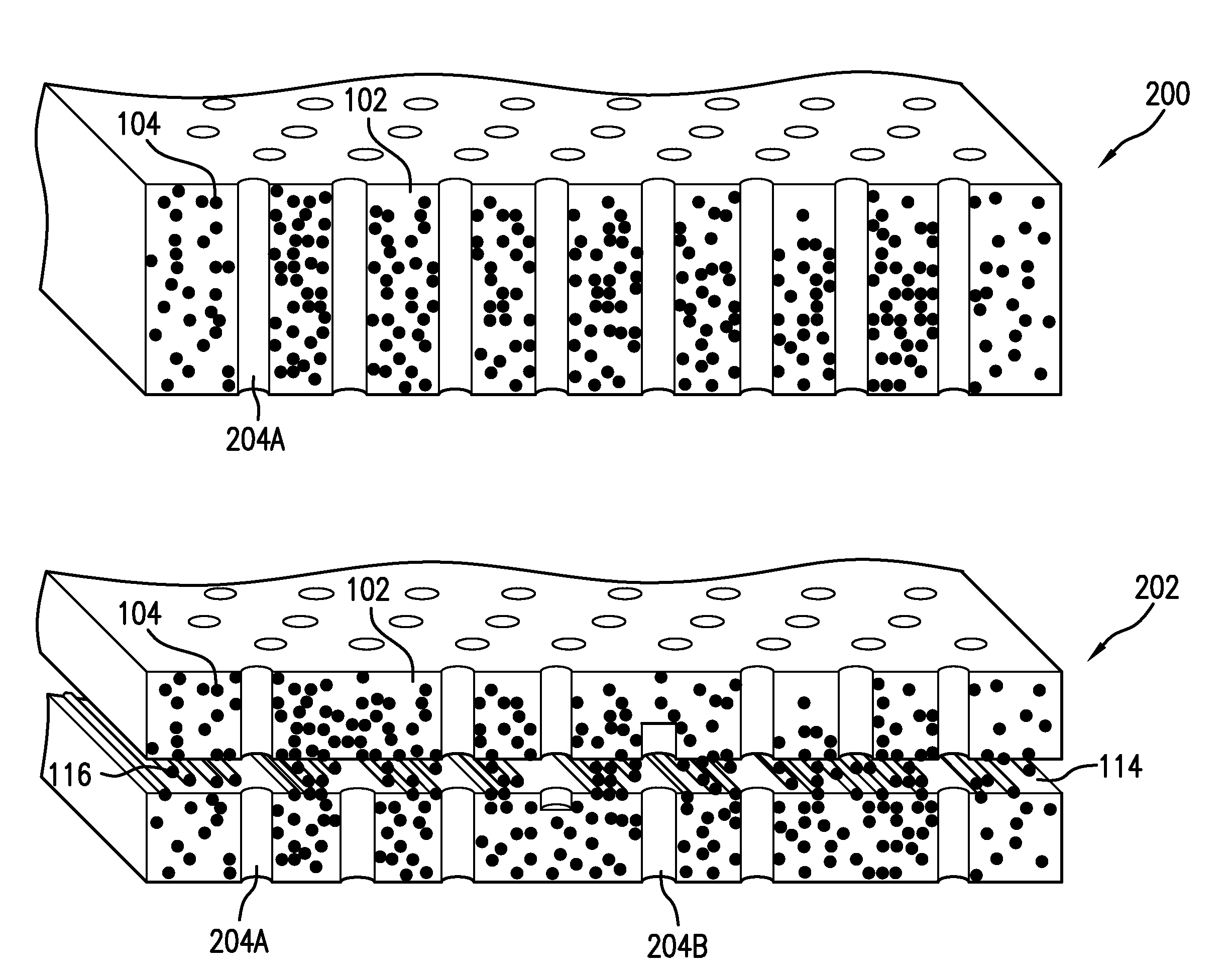

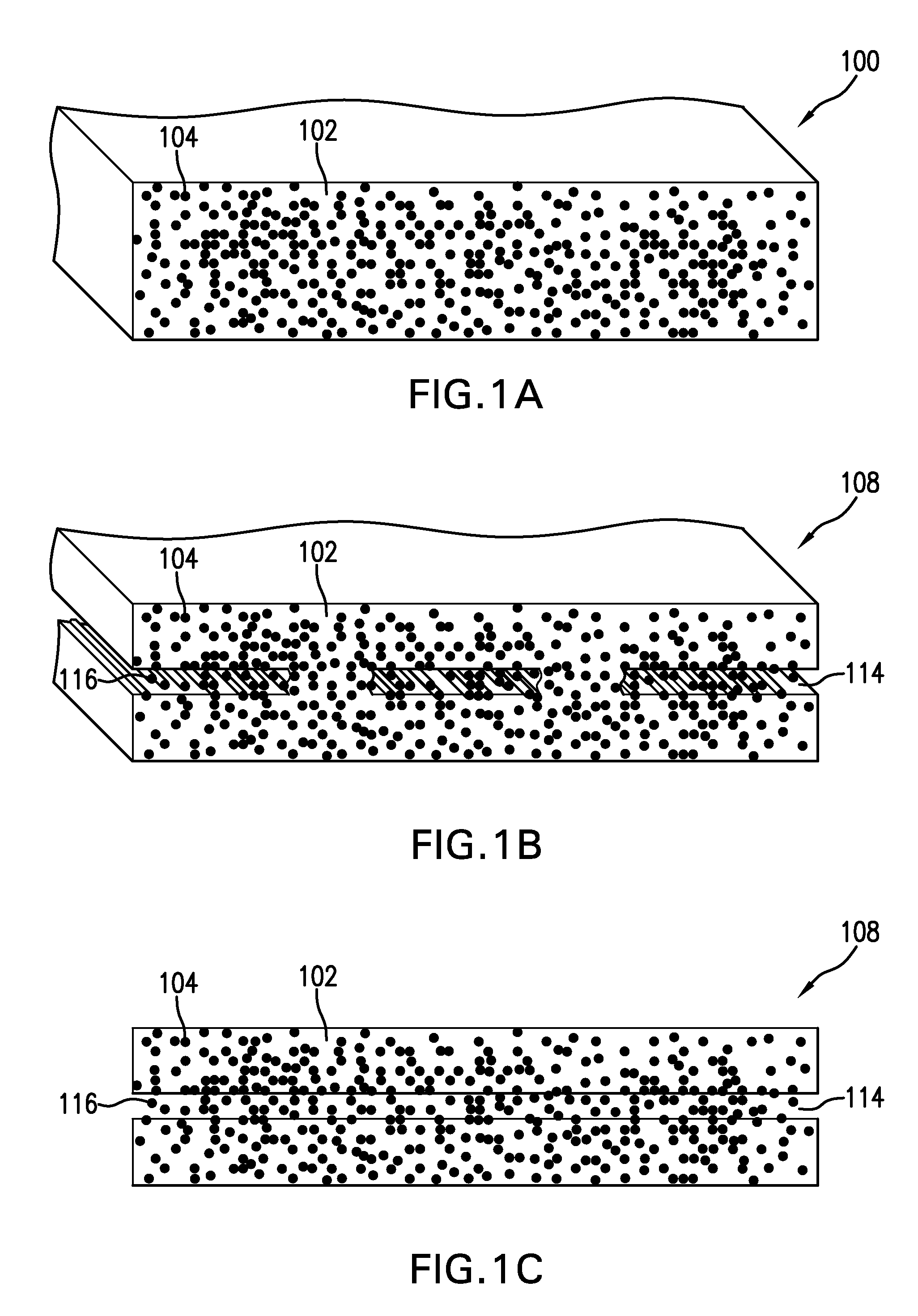

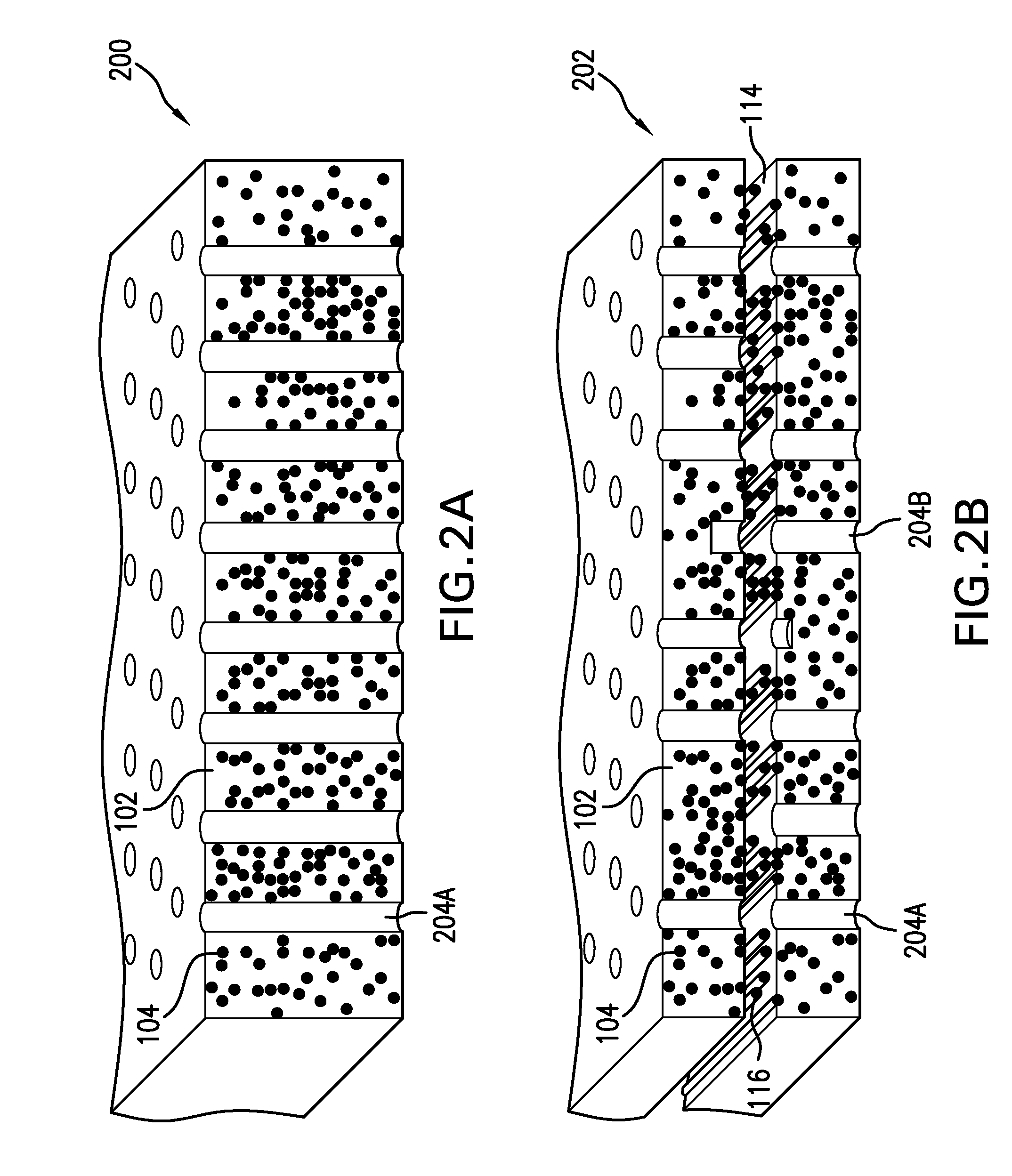

Lightweight circuit board with conductive constraining cores

InactiveUS6869664B2Improve performanceCeramic layered productsElectrical connection printed elementsBoard structureElectrical and Electronics engineering

Prepregs, laminates, printed wiring board structures and processes for constructing materials and printed wiring boards that enable the construction of printed wiring boards with improved thermal properties. In one embodiment, the prepregs include substrates impregnated with electrically and thermally conductive resins. In other embodiments, the prepregs have substrate materials that include carbon. In other embodiments, the prepregs include substrates impregnated with thermally conductive resins. In other embodiments, the printed wiring board structures include electrically and thermally conductive laminates that can act as ground and / or power planes.

Owner:STABLCOR TECH

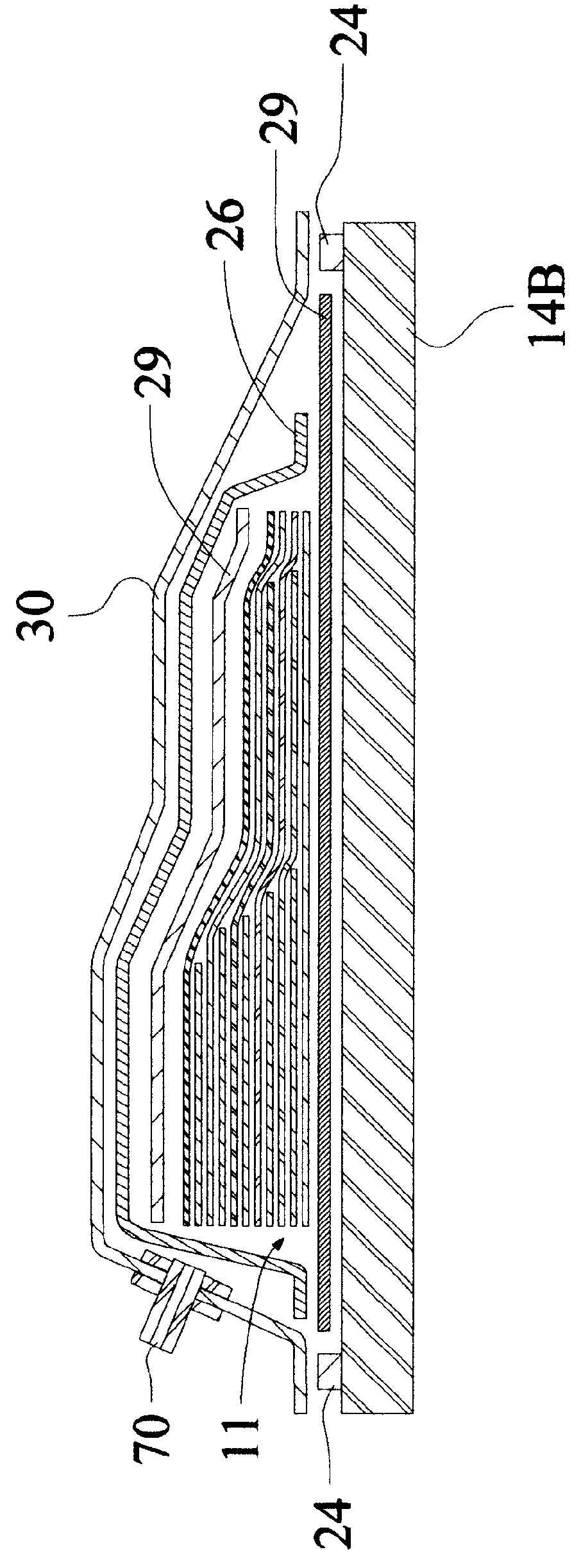

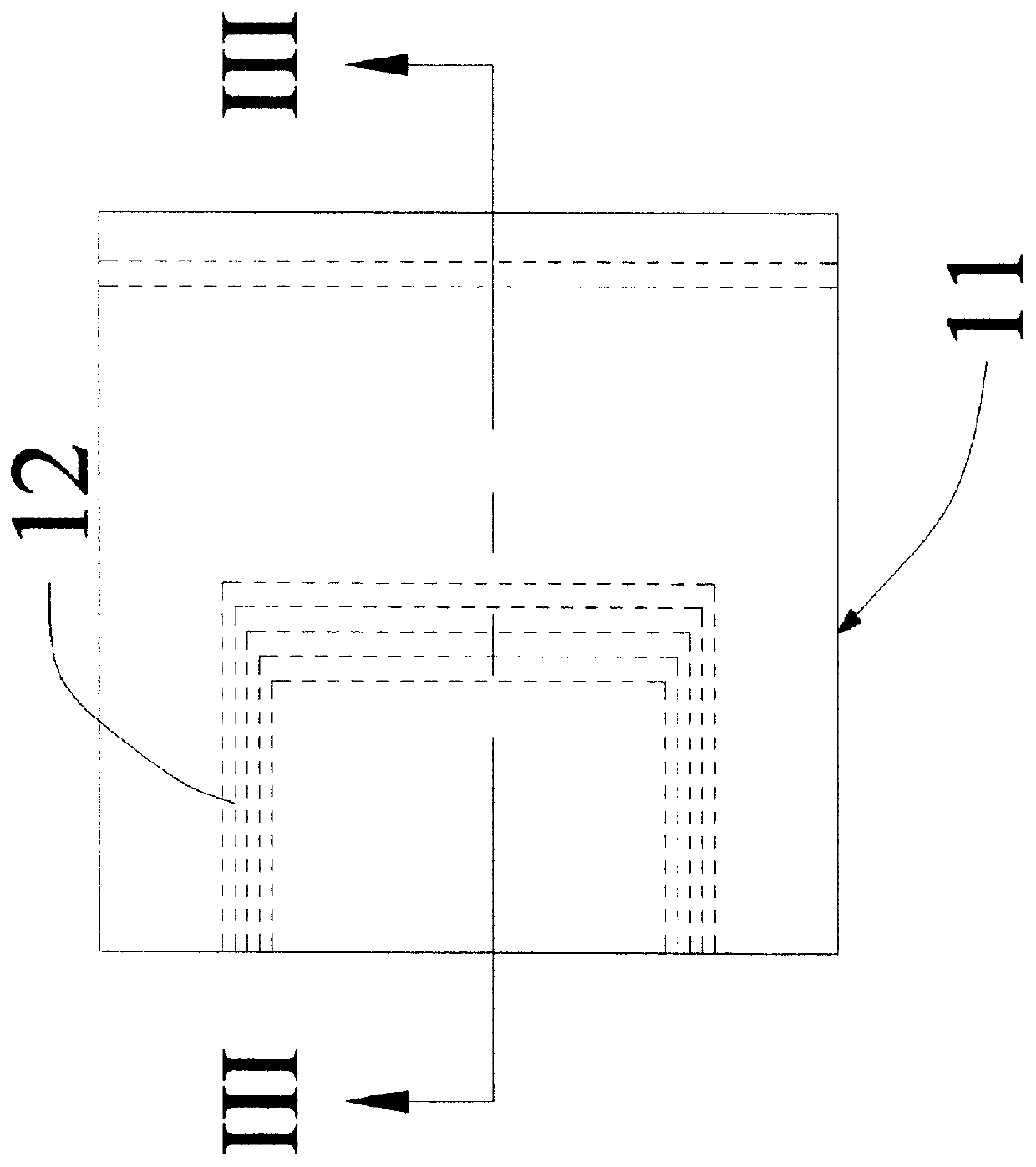

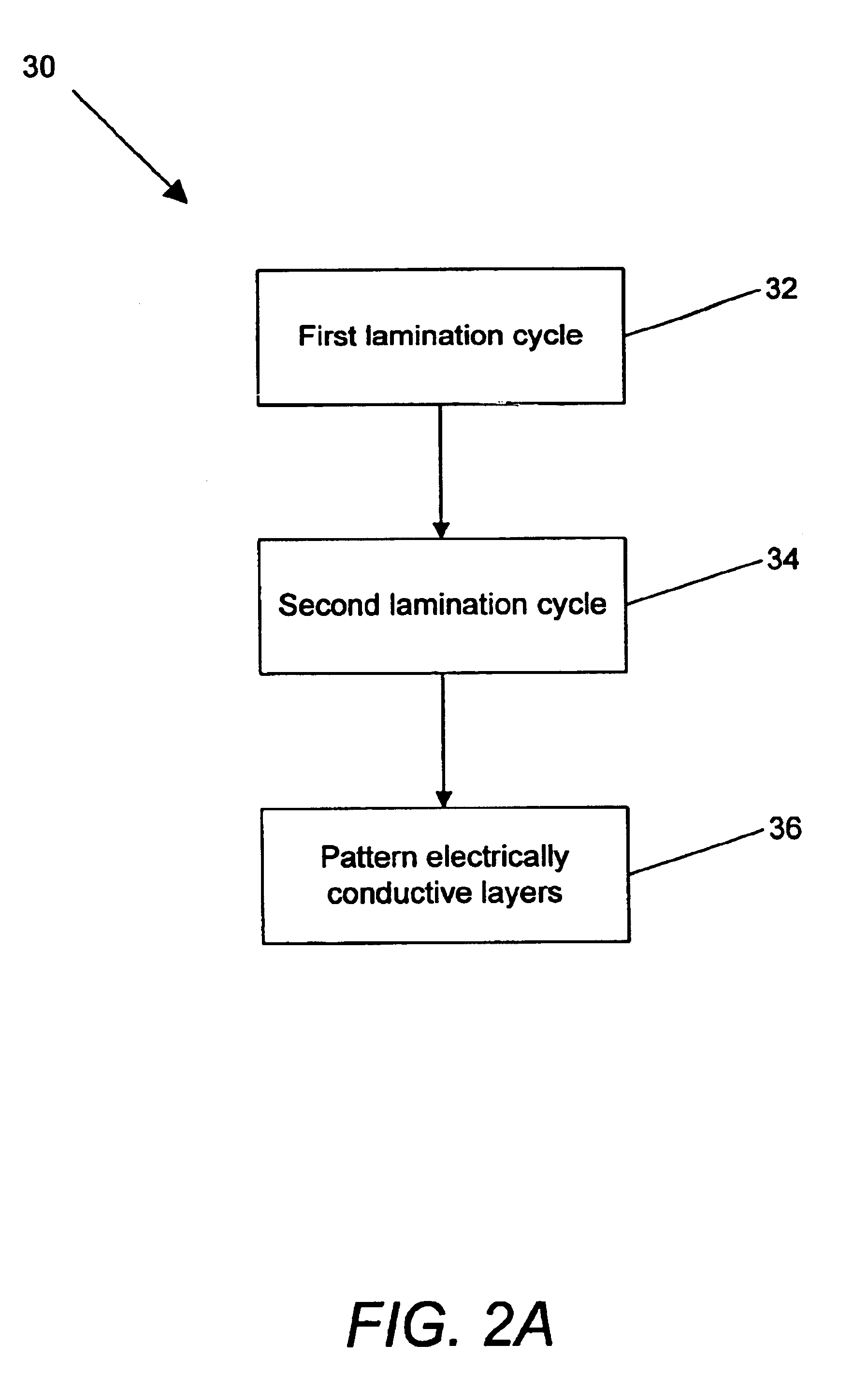

Prepregs with improved processing

ActiveUS20100098906A1Good removal effectLamination ancillary operationsSynthetic resin layered productsMaterial PerforationComposite structure

Systems and methods for the fabrication of prepregs possessing enhanced ability for the removal of gases from within prepregs and prepreg layups prior to and / or during at least a portion of consolidation and cure process to form composite structures are disclosed. In certain embodiments, perforations of selected configurations may be introduced into the prepregs prior to, during, and after layup. The perforations provide routes for gases trapped within and between the perforated prepregs and prepreg lay-ups to escape during consolidation and cure process, reducing the residual porosity within the resulting composite. For example, composites having residual porosities less than 10 vol. %, on the basis of the volume of the composite, may be achieved in this manner.

Owner:CYTEC TECH CORP

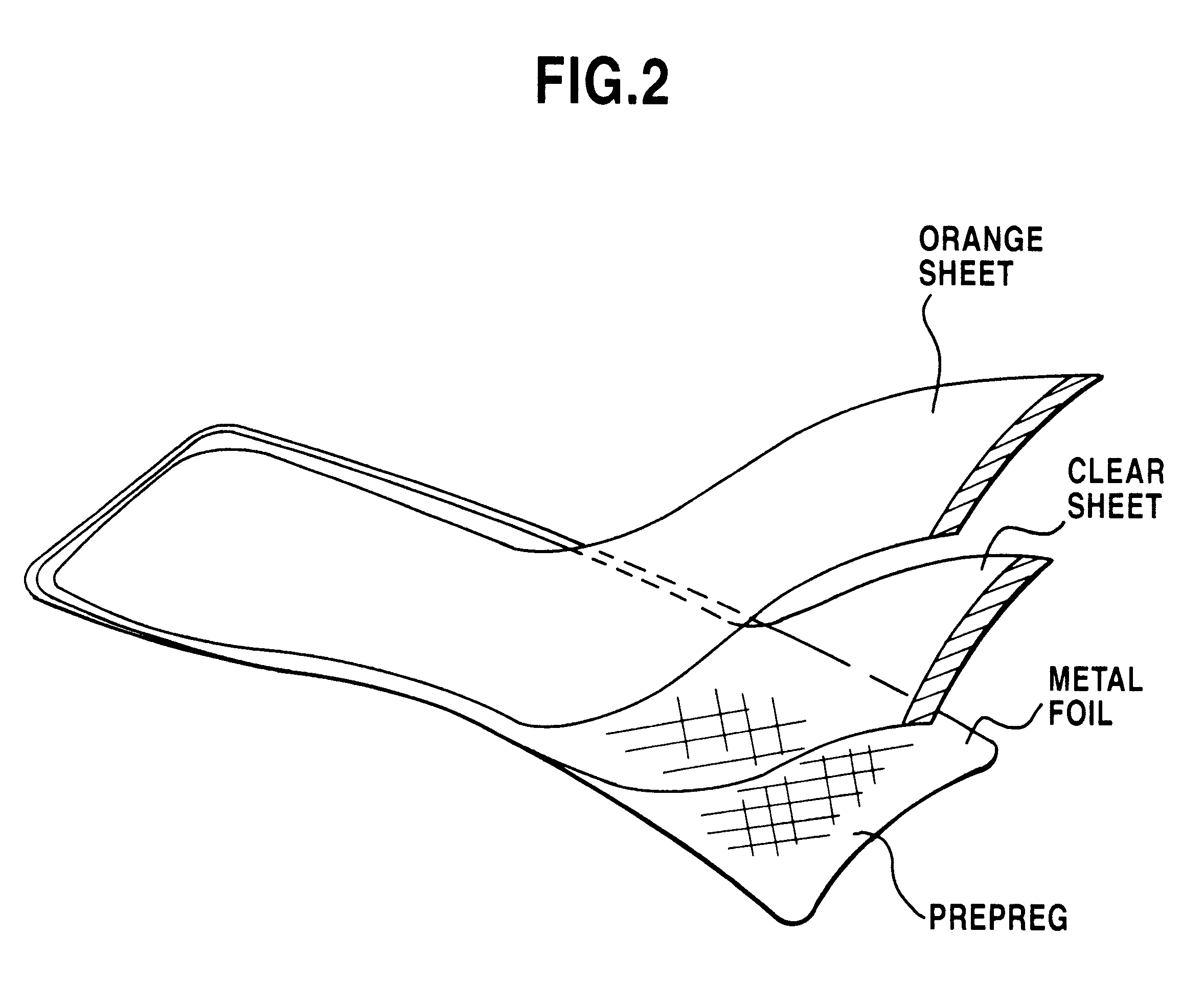

Resin composition, prepreg and metal-foil-clad laminate

ActiveUS20090247032A1Improve suppression propertiesHigh multilayerPrinted circuit aspectsSynthetic resin layered productsMetal foilCopper foil

A vinyl-compound-based resin composition containing a terminal vinyl compound (a) of a bifunctional phenylene ether oligomer having a polyphenylene ether structure, a naphthol aralkyl type cyanate ester resin (b), a bisphenol A cyanate ester resin (c), a brominated flame retardant (d) and an inorganic filler (e), which resin composition is for use in a printed wiring board for high multilayer and high frequency and is improved in moldability and copper foil peel strength, which are conventional problems, without any decrease in electric characteristics and heat resistance after moisture absorption while keeping flame retardancy, a prepreg comprising the above resin composition and a glass woven fabric, a metal-foil-clad laminate obtained by disposing a metal foil on one side or both sides of a stack of at least one prepreg and laminate-molding the resultant set, and a resin sheet obtained by applying a solution of the above resin composition to a surface of a metal foil or a film.

Owner:MITSUBISHI GAS CHEM CO INC

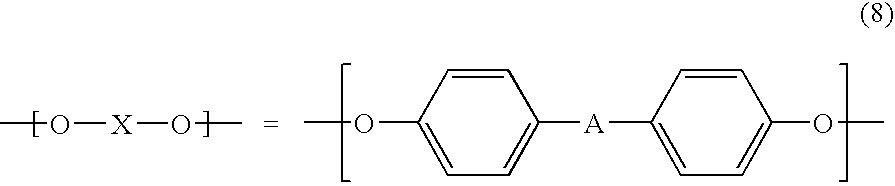

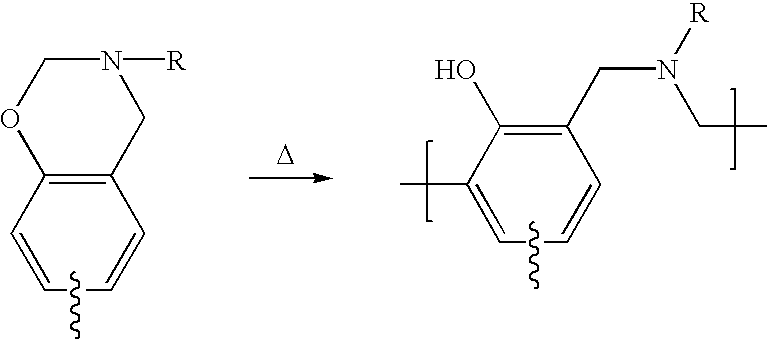

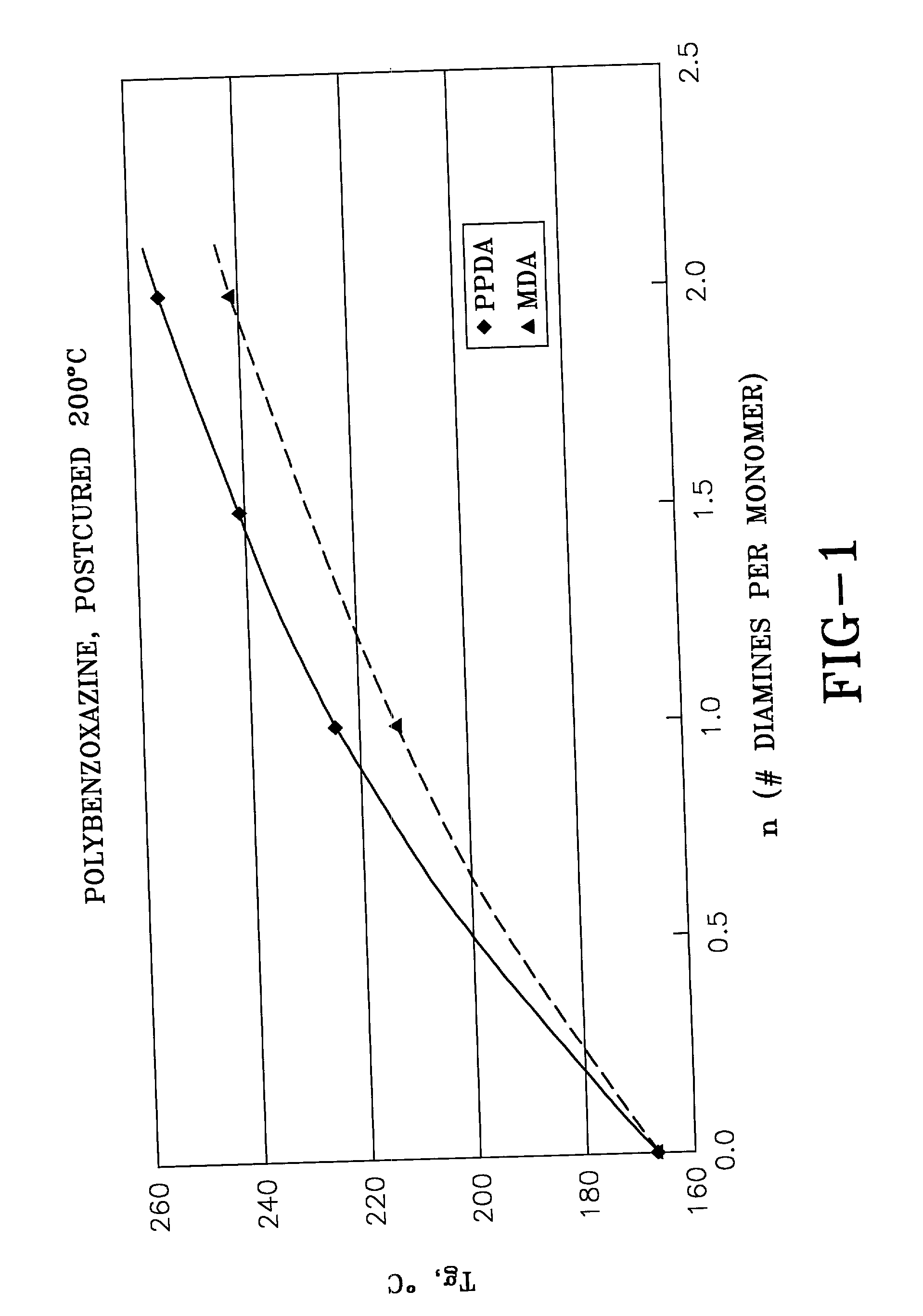

Enhancement of thermal properties of benzoxazine polymers by use of aromatic polyamines to incorporate internal benzoxazine groups within the monomer

A benzoxazine polymer having improved thermal properties. The properties are improved by inserting aromatic polyamines into the monomer, such as phenylenediamine, methylenedianiline, oxydianiline, diaminodiphenylsulfone, 2,2-bis(4-[aminophenoxy]phenyl)propane, 4,4'-oxydianiline, 4,4'-diaminodiphenyl sulfone, and diaminobenzanilide, to introduce internal benzoxazine groups that are crosslinking sites. The improved polymers can be converted into molding compounds, towpregs, and prepregs by being compounded with reinforcing fibers.

Owner:HYCOMP

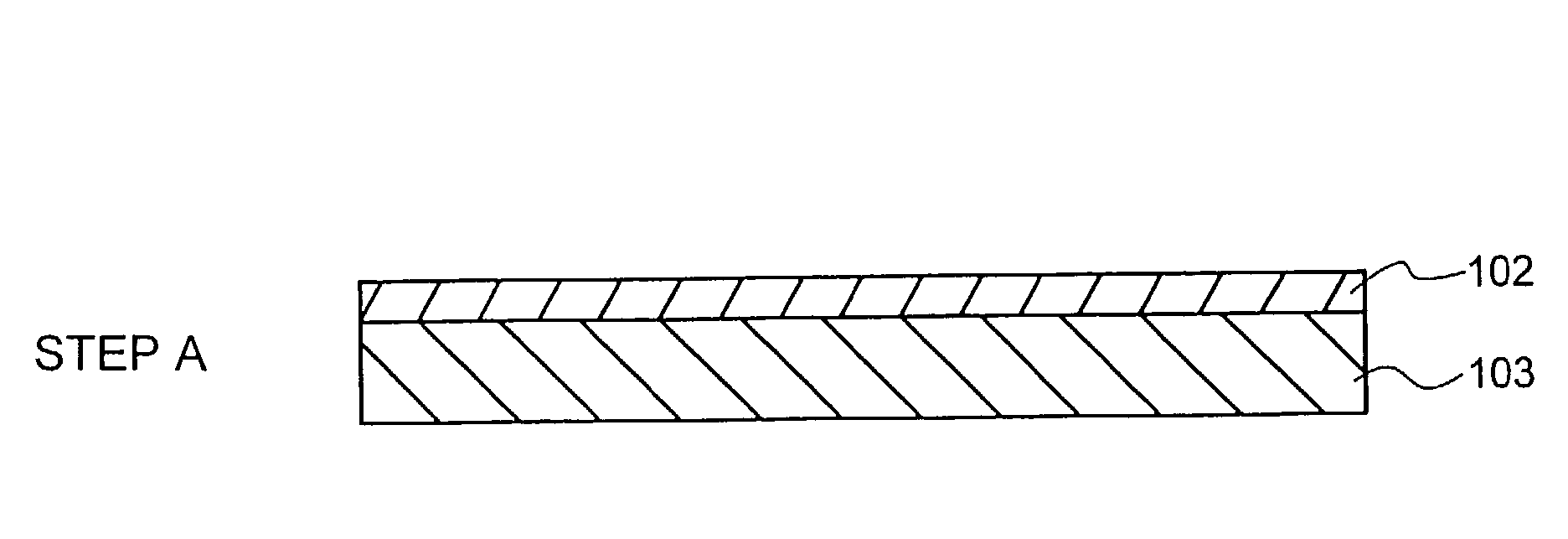

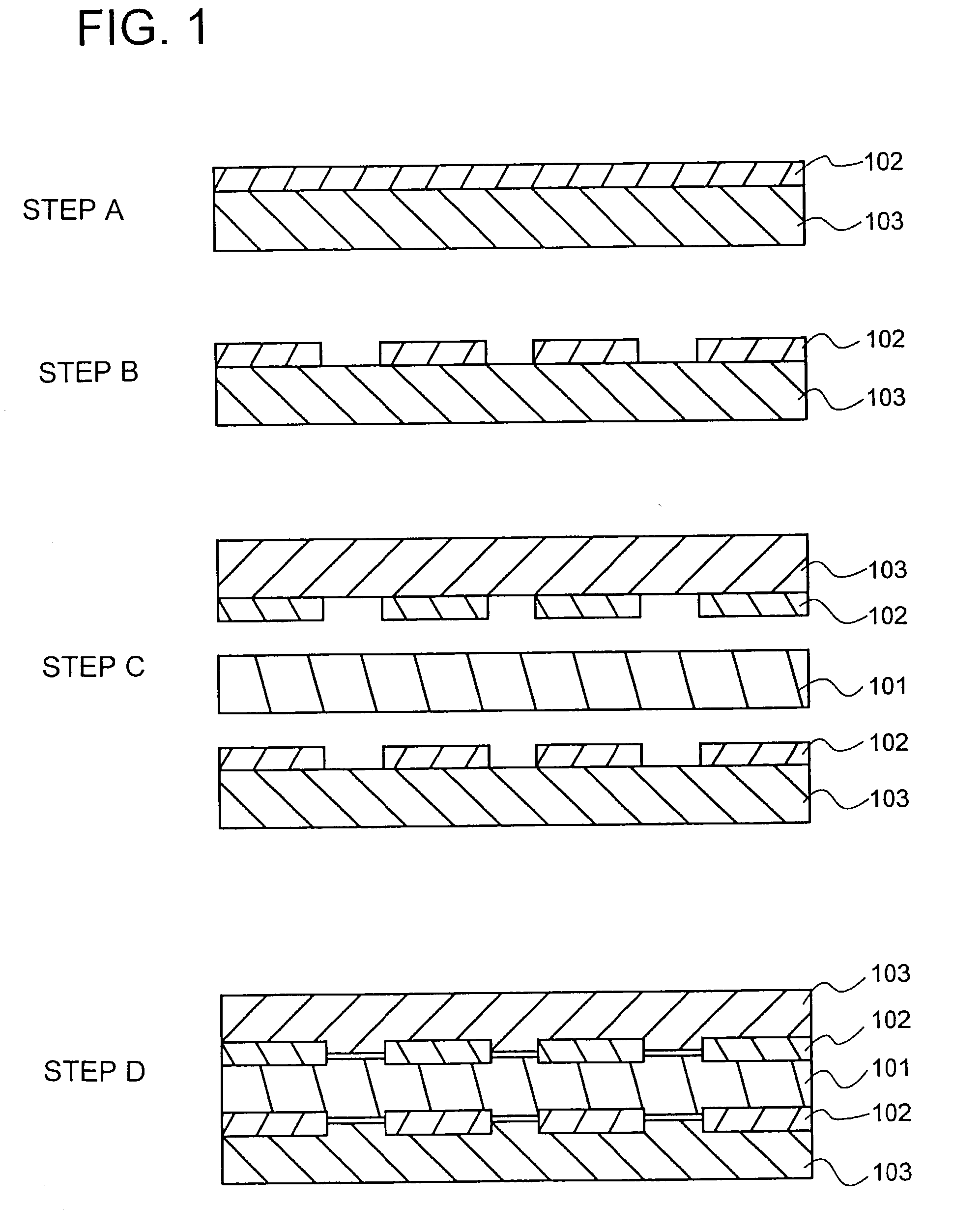

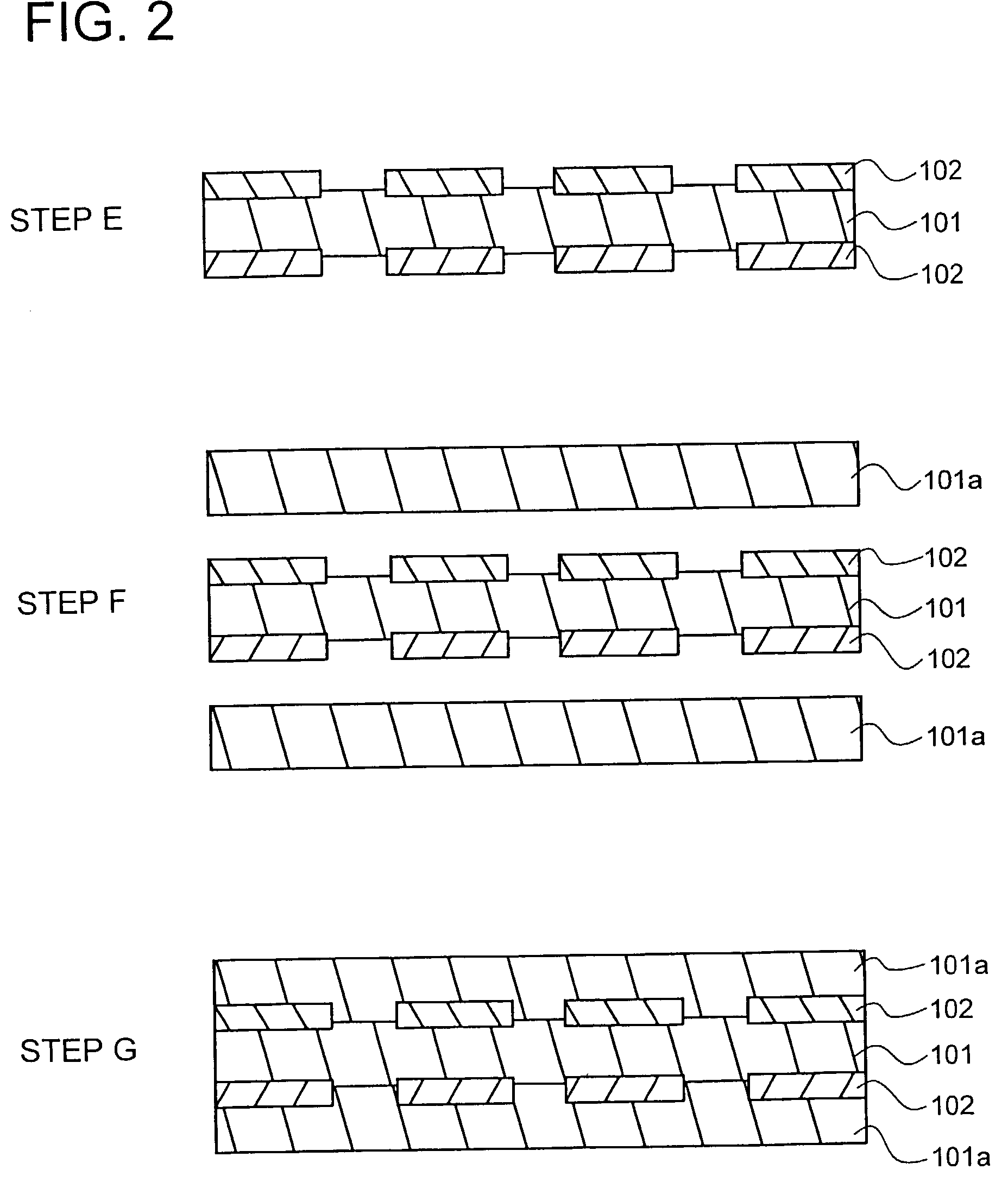

Method for producing multilayer substrate and electronic part, and multilayer electronic part

InactiveUS20030029830A1Reduce thicknessDecorative surface effectsStacked capacitorsElectrical conductorEngineering

Owner:TDK CORPARATION

Epoxy resin composition for carbon-fiber-reinforced composite material, prepreg, integrated molding, sheet of fiber-reinforced composite material and cabinet for electrical/electronic equipment

ActiveCN1946780AIncrease flame retardancyExcellent mechanical propertiesPigmenting treatmentLayered productsCombustionHalogen

A lightweight fiber-reinforced composite material that exhibits excellent flame resistance and mechanical properties and does not emit any halogen gas at combustion; an epoxy resin composition and prepreg suitable for obtaining the above fiber-reinforced composite material; and an integrated molding suitable to electrical / electronic equipment cabinet, in which use is made of the above fiber-reinforced composite material. There is provided an epoxy resin composition for carbon-fiber-reinforced composite material, comprising: [A] epoxy resin, [B] amine curing agent, and [C] phosphorus compound, the component [C] contained in an amount, in terms of concentration of phosphorus atoms, of 0.2 to 15 wt.%.

Owner:TORAY IND INC

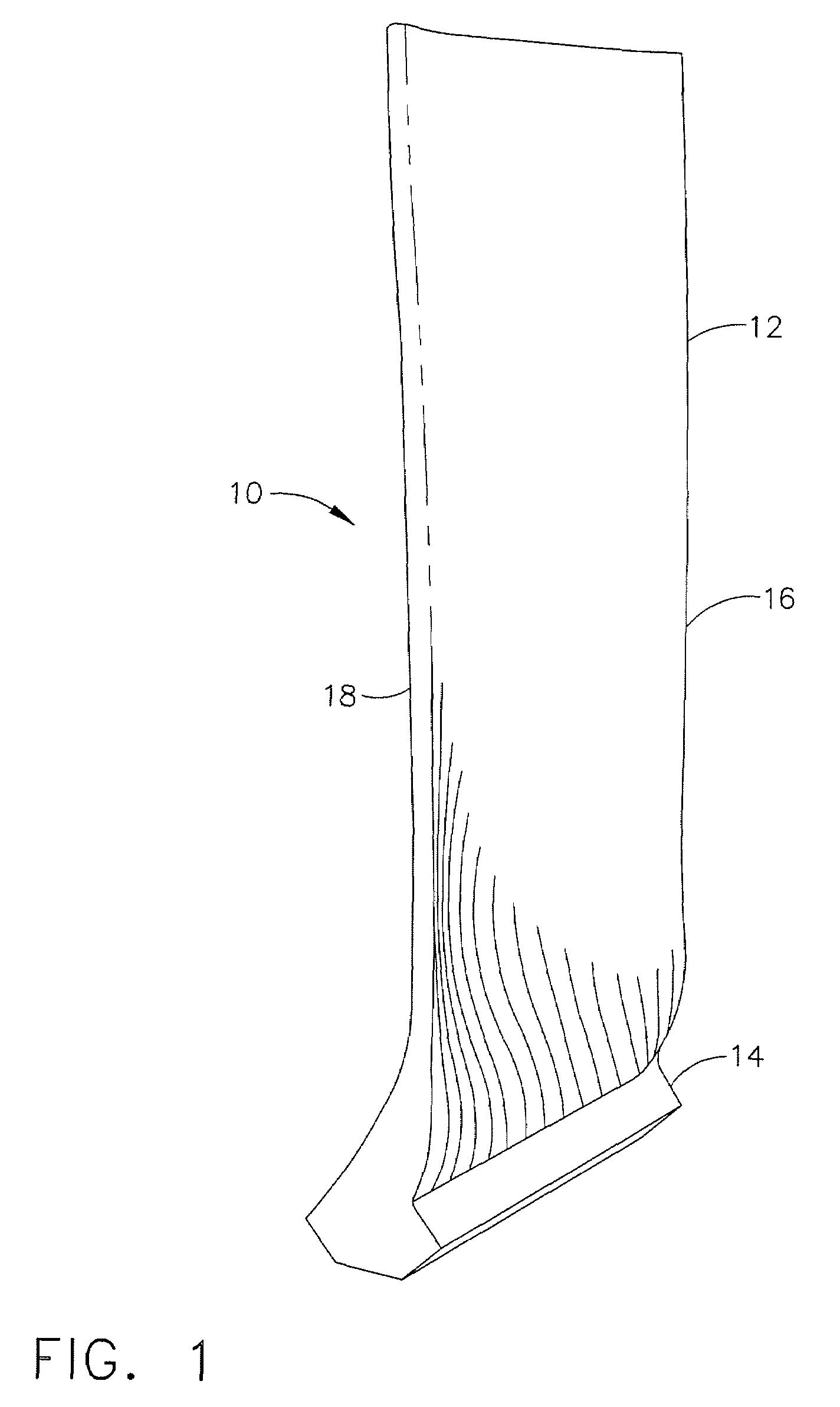

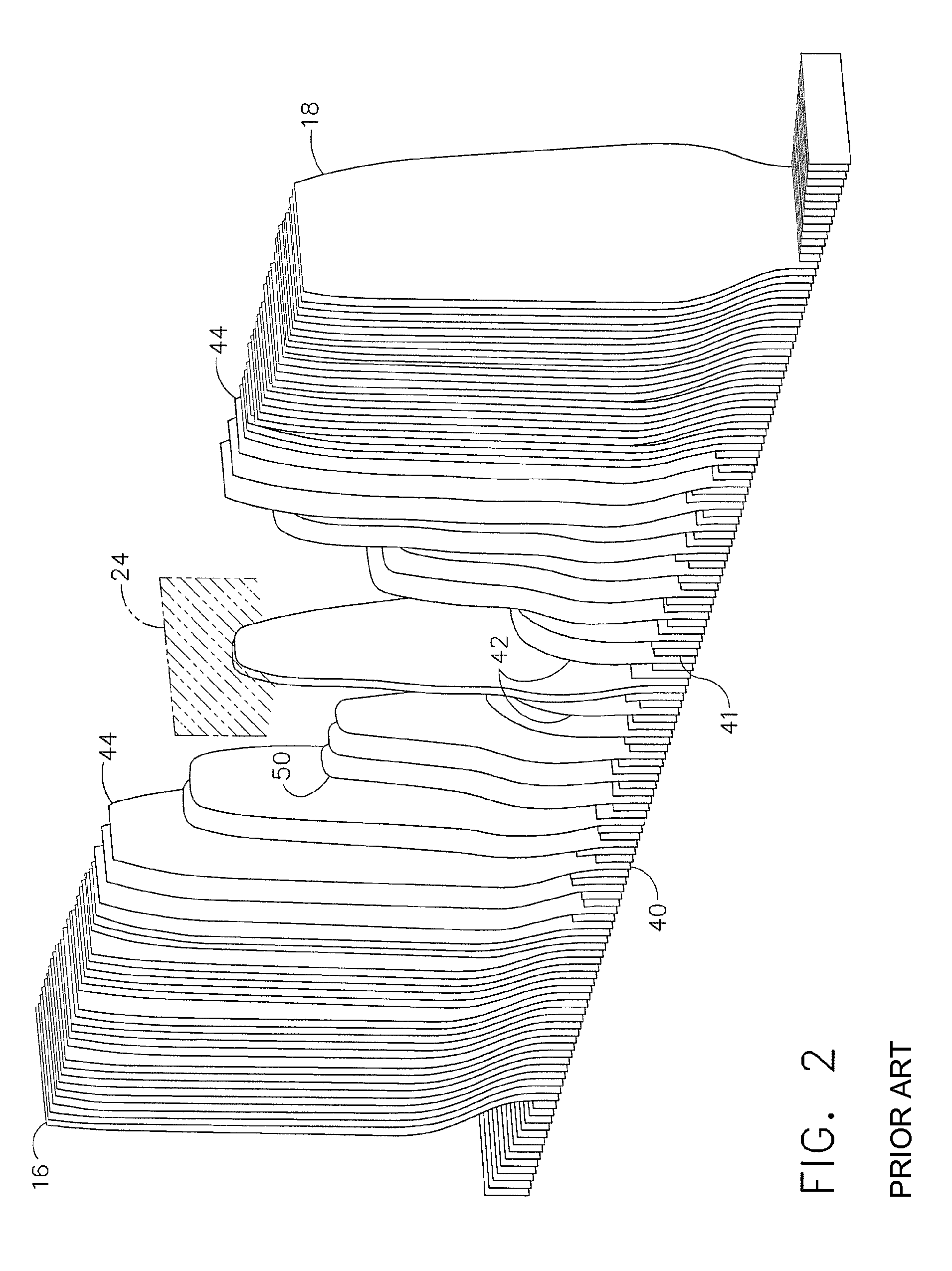

CMC articles having small complex features

ActiveUS7600979B2Easy to manufactureEliminate complex processesBlade accessoriesEfficient propulsion technologiesMetallurgyGas turbines

A ceramic matrix composite (CMC) component for gas turbine engines, the component having fine features such as thin edges with thicknesses of less than about 0.030 inches and small radii of less that about 0.030 inches formed using the combination of prepreg plies layed up with non-ply ceramic inserts. The CMC components of the present invention replace small ply inserts cut to size to fit into areas of contour change or thickness change, and replace the small ply inserts with a fabricated single piece discontinuously reinforced composite insert, resulting in fewer defects, such as wrinkles, and better dimensional control.

Owner:GENERAL ELECTRIC CO

LED Package with Stepped Aperture

ActiveUS20080296599A1Versatile and cost-efficient constructionLow costPoint-like light sourceFinal product manufactureSecondary componentLight-emitting diode

A light emitting diode (LED) package for high temperature operation which includes a printed wire board and a heat sink. The LED package may include a formed heat sink layer, which may be thermally coupled to an external heat sink. The printed wire board may include apertures that correspond to the heat sink such that the heat sink is integrated with the printed wire board layer. The LED package may include castellations for mounting the package on a secondary component such as a printed wire board. The LED package may further comprise an isolator disposed between a base metal layer and one or more LED die. Optionally, the LED die may be mounted directly on a base metal layer. The LED package may include a PWB assembly having a stepped cavity, in which one or more LED die are disposed. The LED package is advantageously laminated together using a pre-punched pre-preg material or a pressure sensitive adhesive.

Owner:LIGHTING SCI GROUP

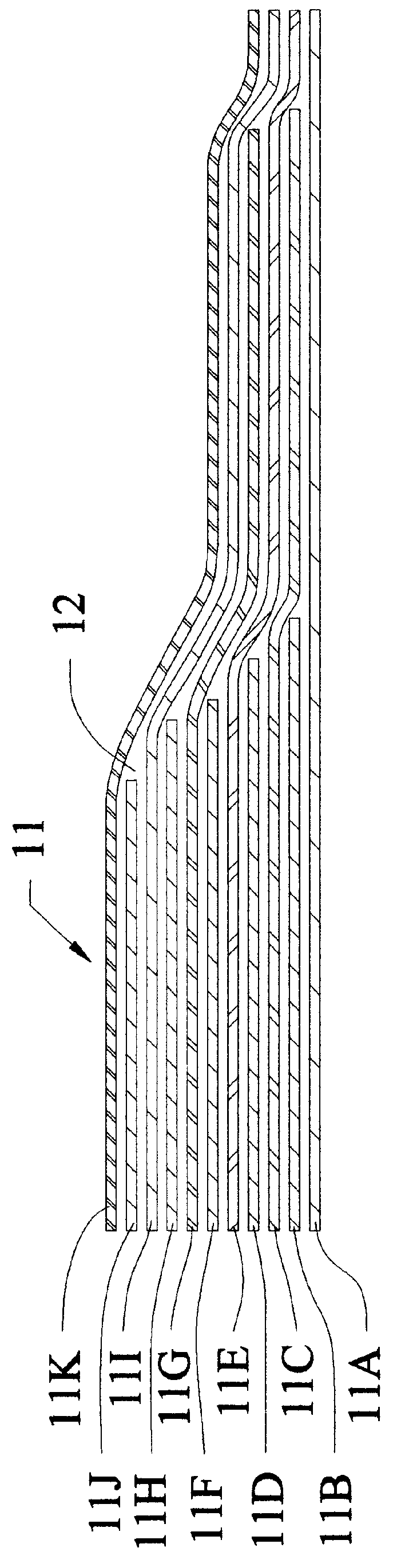

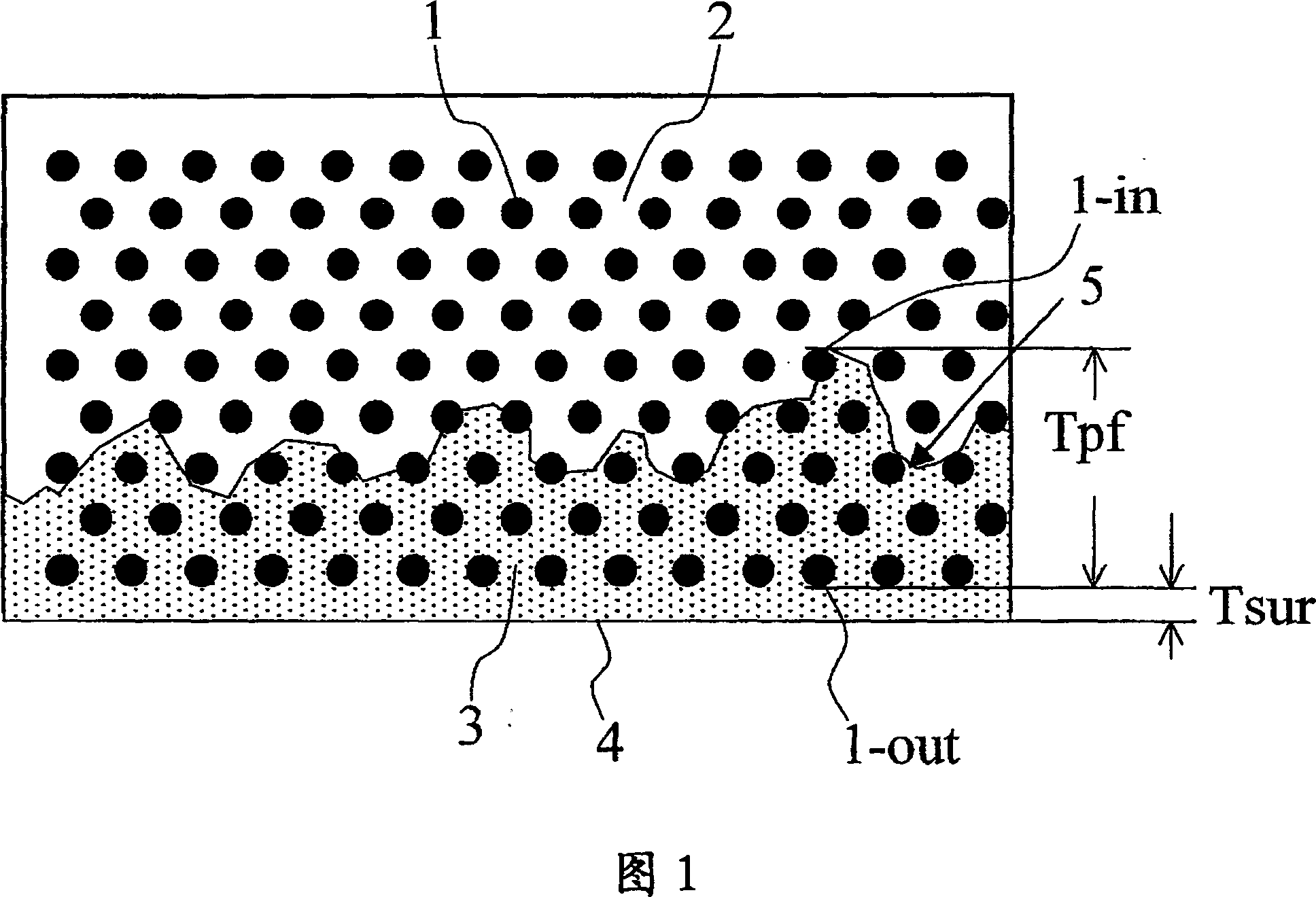

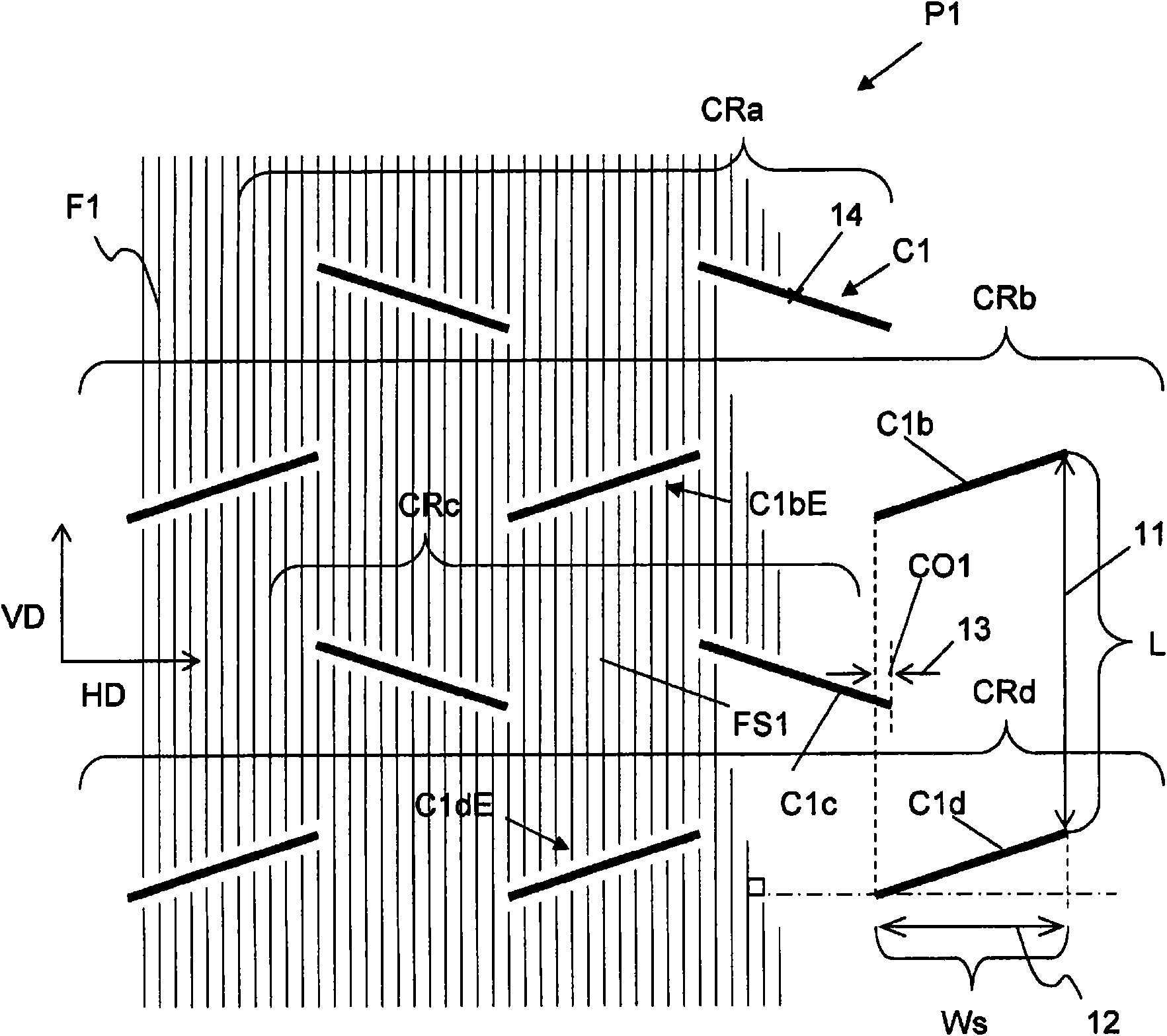

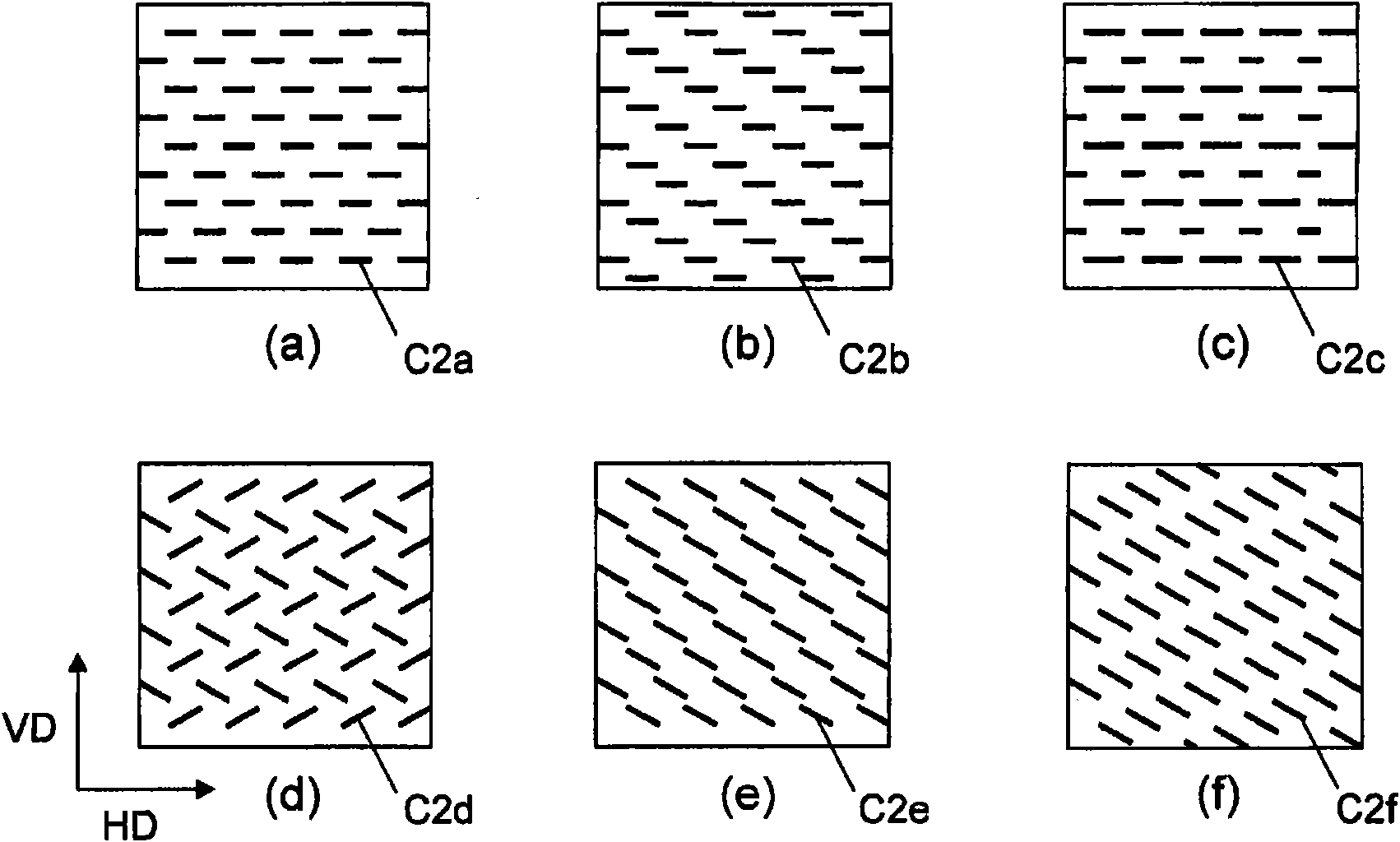

Prepreg base material, layered base material, fiber-reinforced plastic, process for producing prepreg base material, and process for producing fiber-reinforced plastic

ActiveCN101600550AImprove liquiditySpeed up the flowLayered productsVehicle componentsMaterials scienceFibre reinforcement

A prepreg base material which comprises many reinforcing fibers arranged in one direction and a matrix resin present among the many reinforcing fibers. The prepreg base material has, throughout the whole surface, many incisions each extending in a direction crossing the reinforcing fibers, substantially all of the reinforcing fibers having been divided by one or more of the incisions. The reinforcing fiber segments formed by division by the incisions have a length (L) of 10-100 mm. The prepreg base material has a thickness (H) of 30-300 [mu]m, and the content by volume (Vf) of the reinforcingfibers in the prepreg base material is 45-65%.

Owner:TORAY IND INC

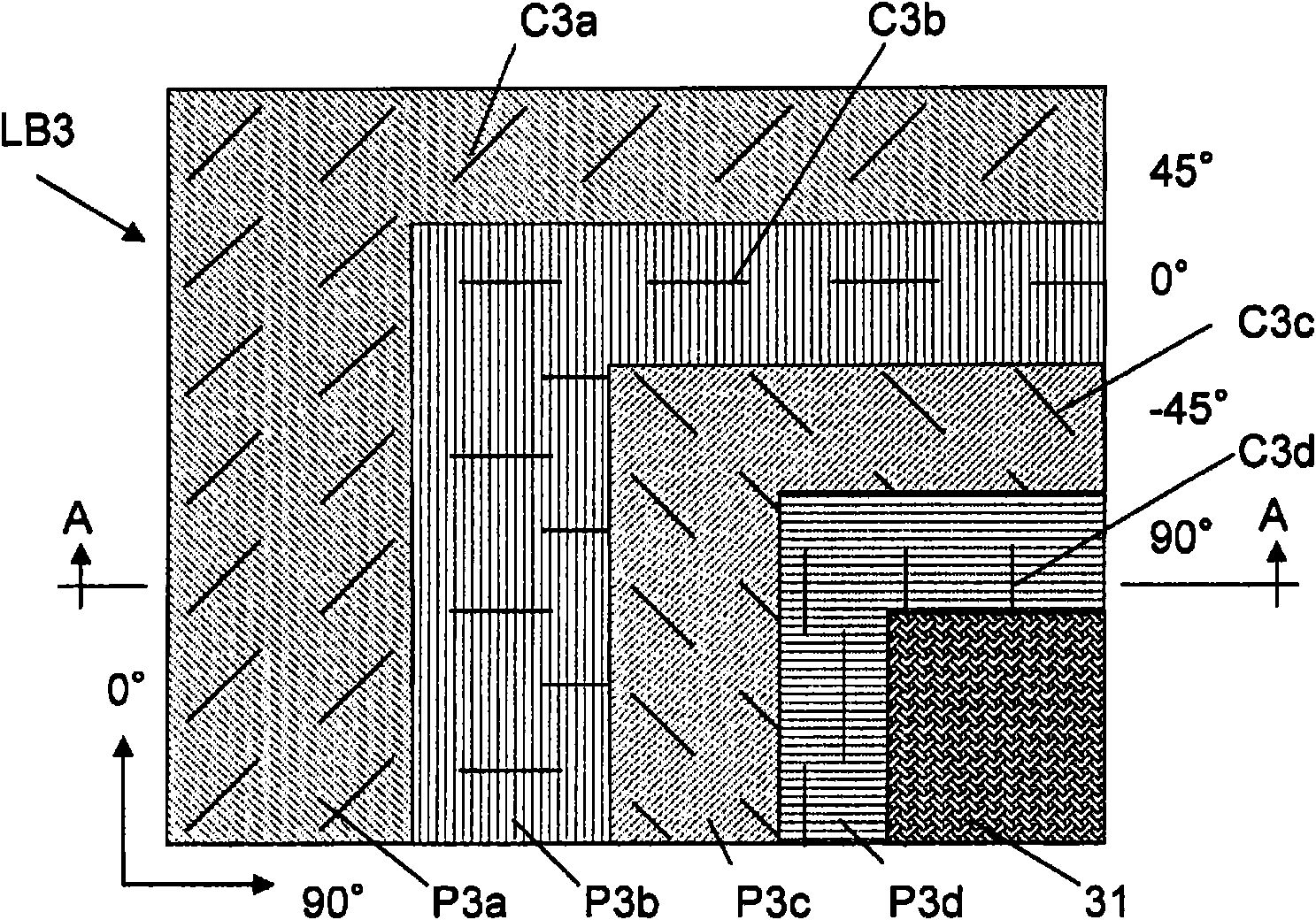

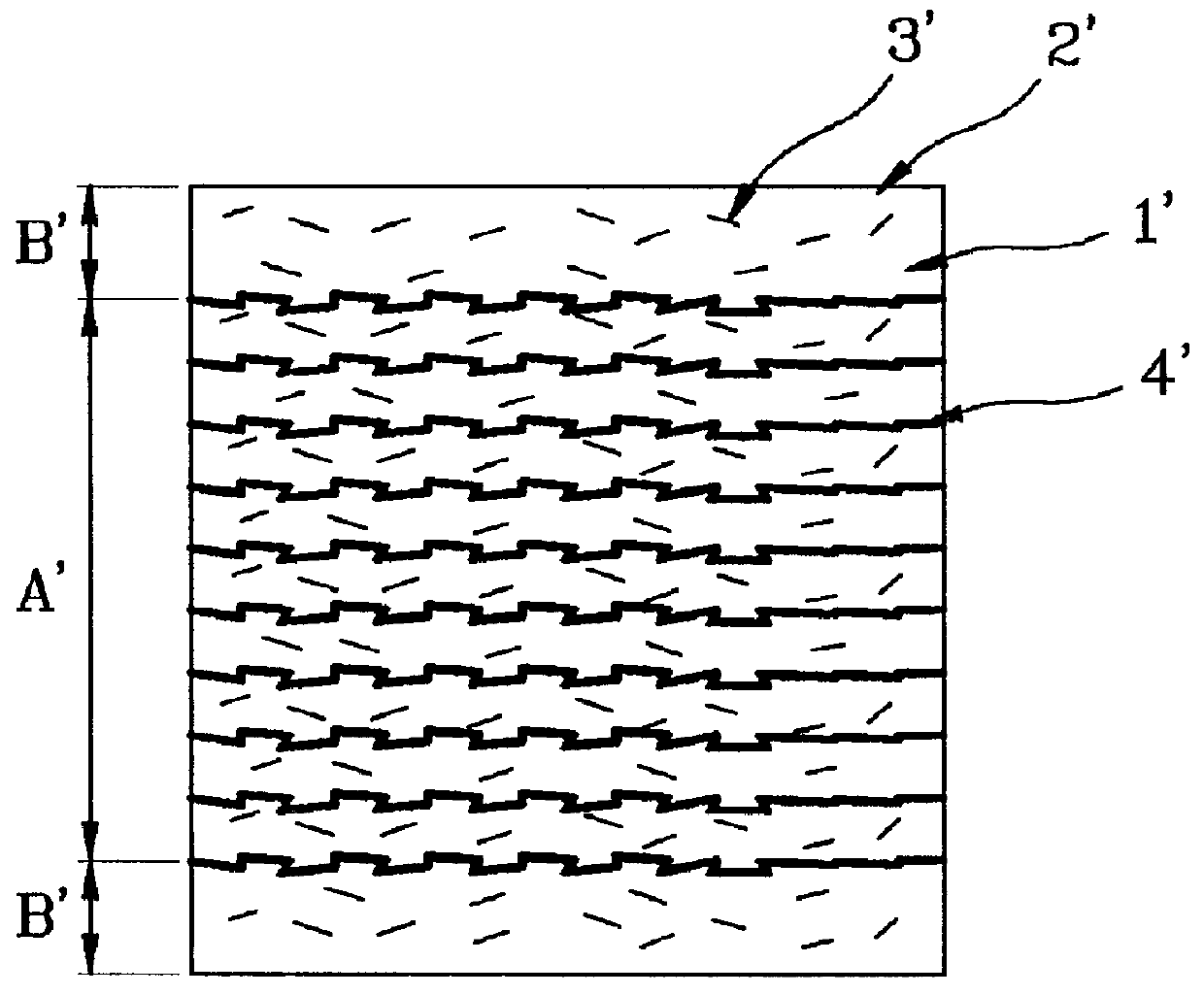

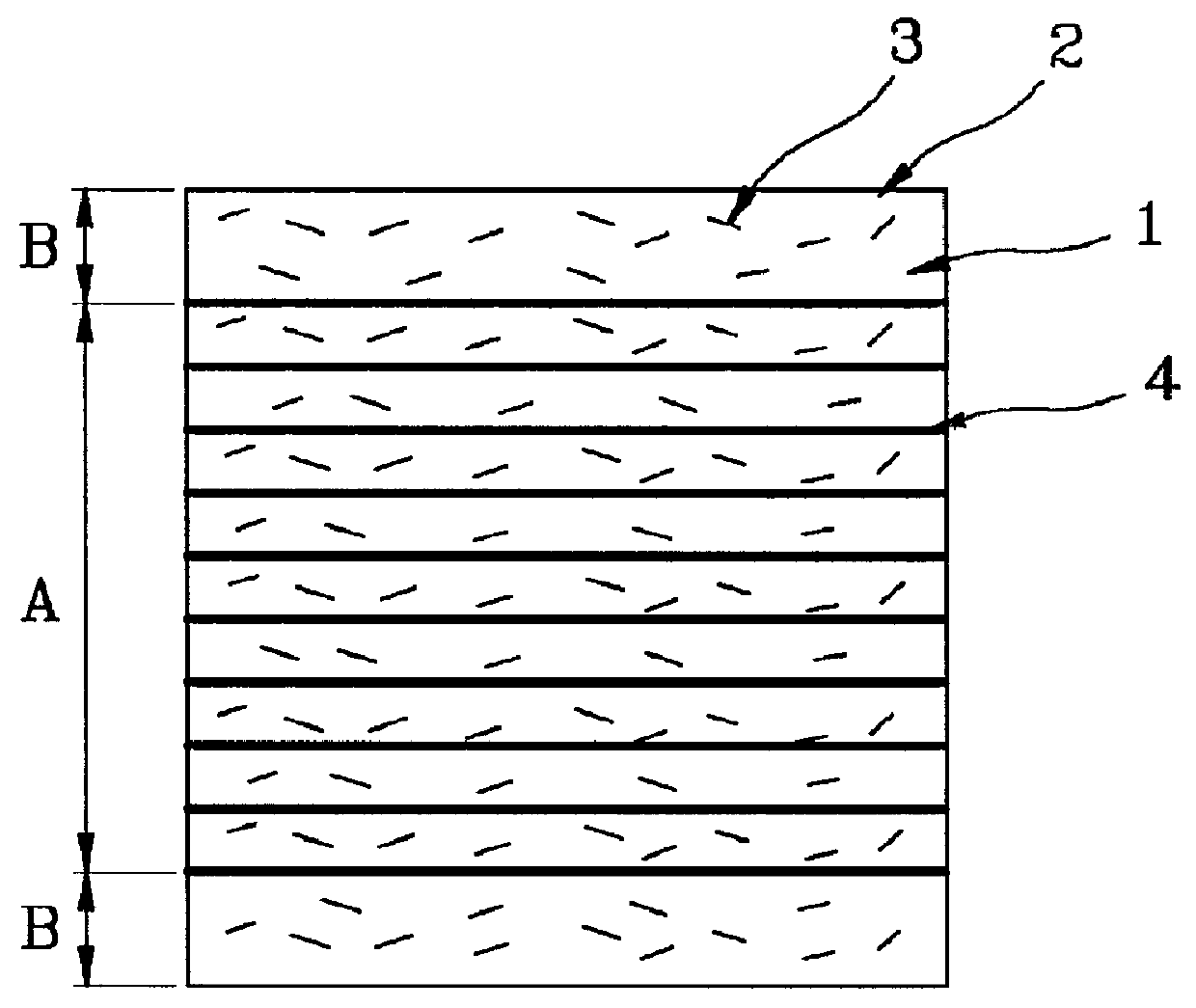

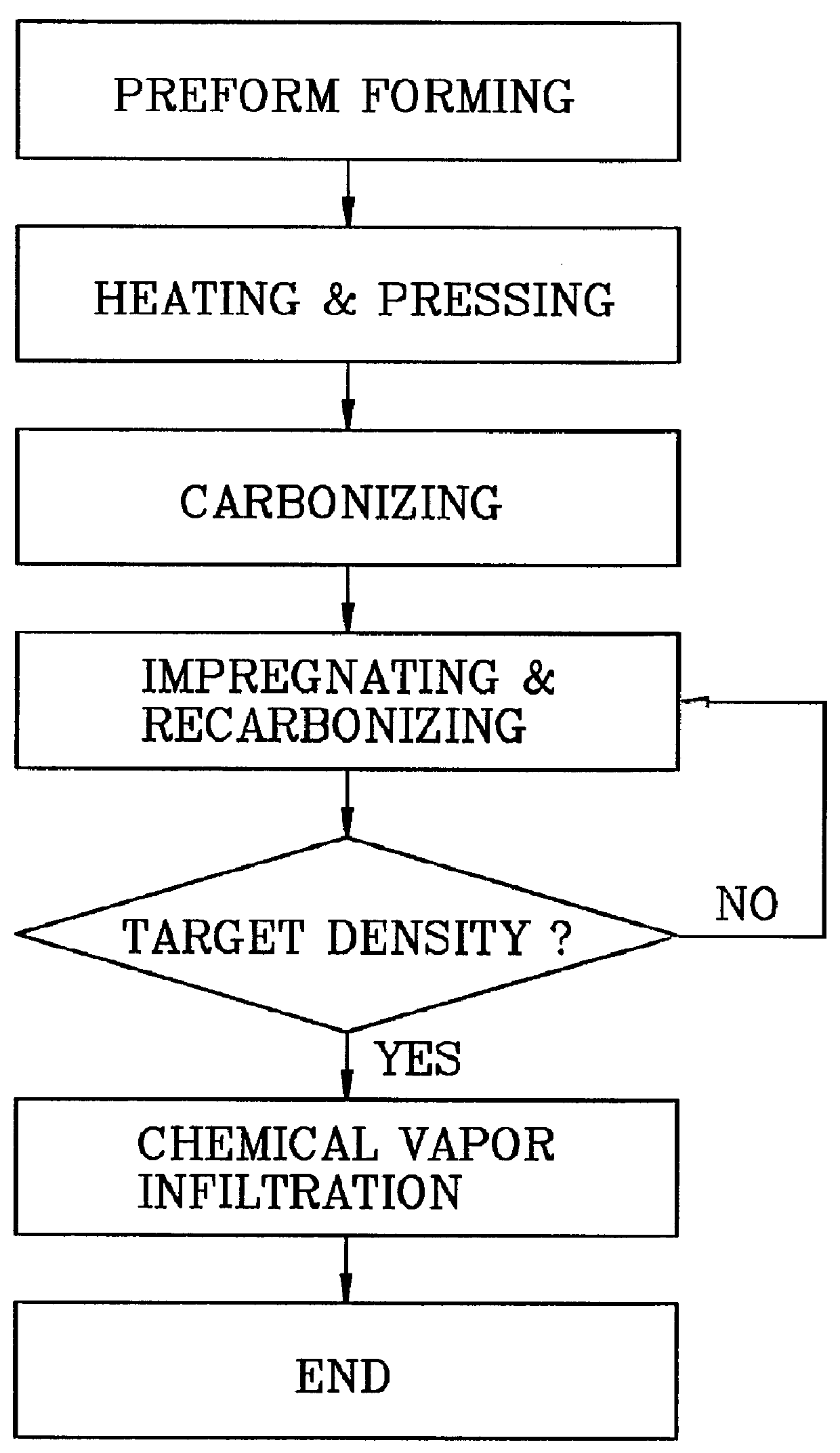

Carbon-carbon composite for friction products and method of making same

InactiveUS6093482AIncreased heat conductivityImprove wear resistanceBearing componentsCeramic layered productsCarbon compositesCarbon fibers

A carbon-carbon composite for friction products comprises an outer friction part and a load bearing structure part supporting the friction part. The friction part contains a mixture of carbon fibers, pitch powder and graphite powder, whereas the structure part is comprised of a pack of alternating layers of the mixture and layers of one member selected from the group consisting of carbon fabrics, carbon-based prepregs and carbon-based, segmented prepregs. The carbon-carbon composite is formed by way of aternatingly piling up layers of a mixture of carbon fibers, pitch powder and graphite powder and layers of one member selected from the group consisting of carbon fabrics, carbon-based prepregs and carbon-based, segmented prepregs one above the other to provide a preform, heating and pressing the preform within a mold to obtain a green body, carbonizing the green body to prepare a carbonized body, impregnating the carbonized body with pitch powder and recarbonizing the impregnated body, and subjecting the impregnated and recarbonized body to chemical vapor infiltration with hydrocarbon gas.

Owner:DACC CARBON

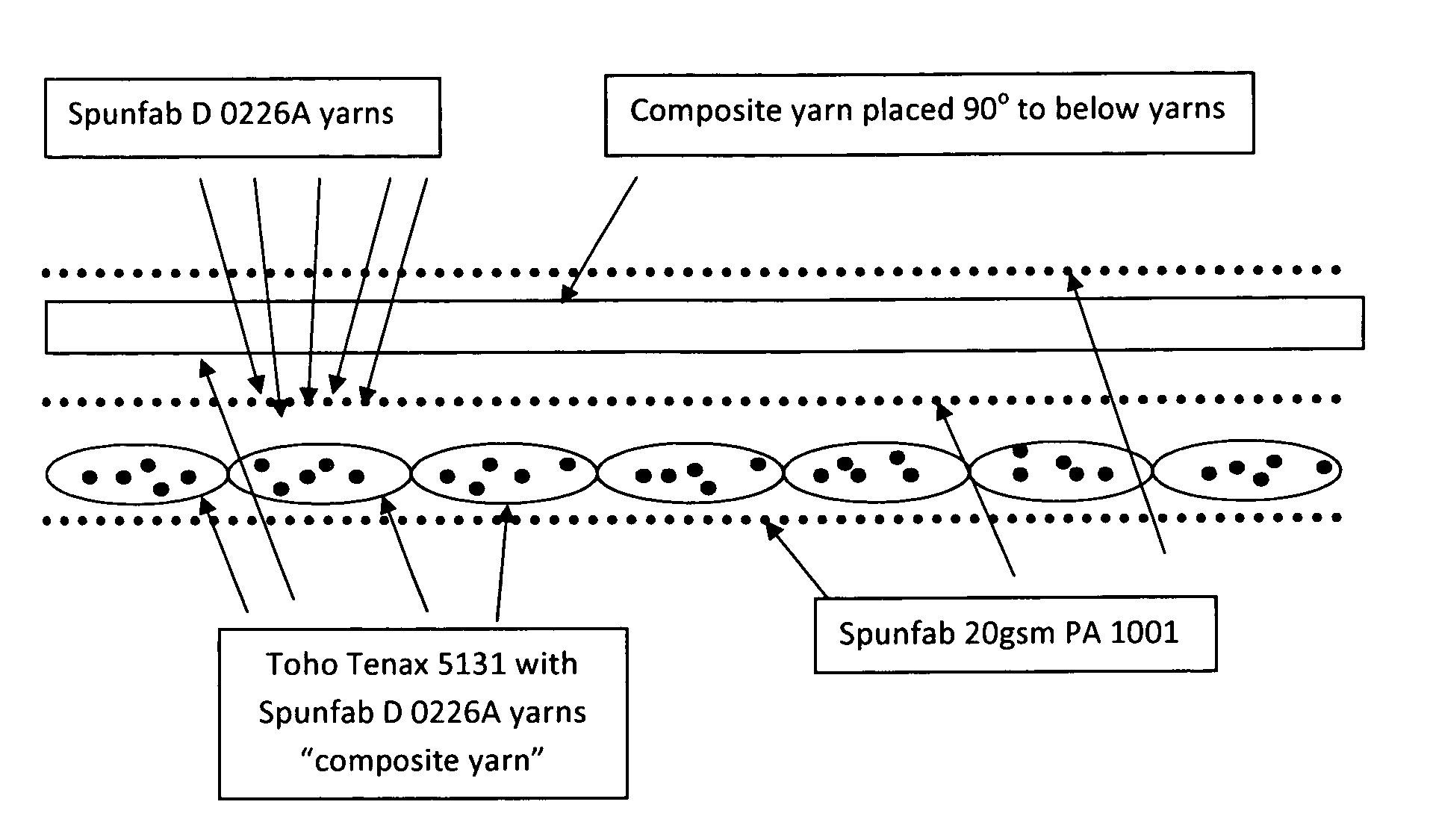

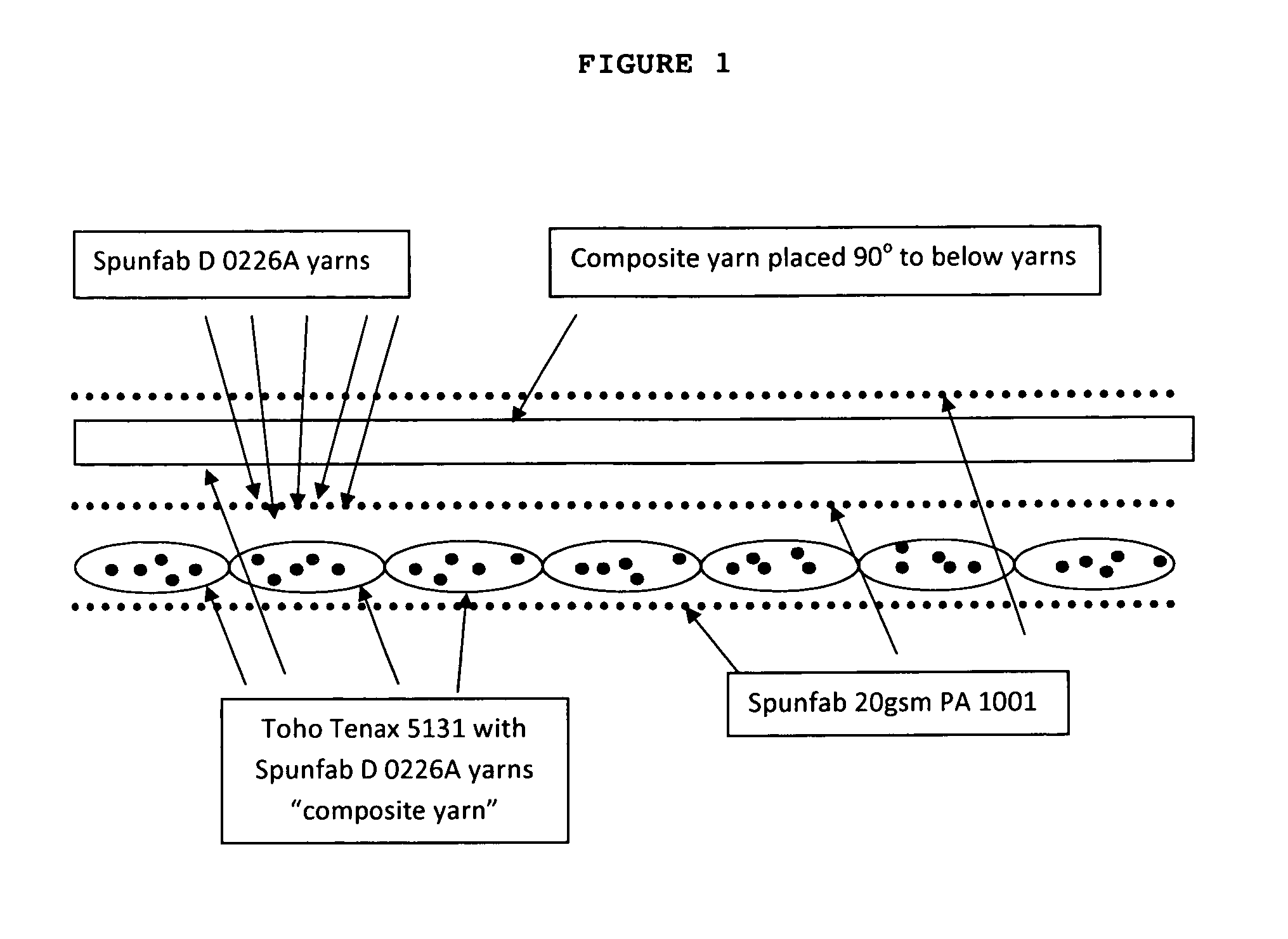

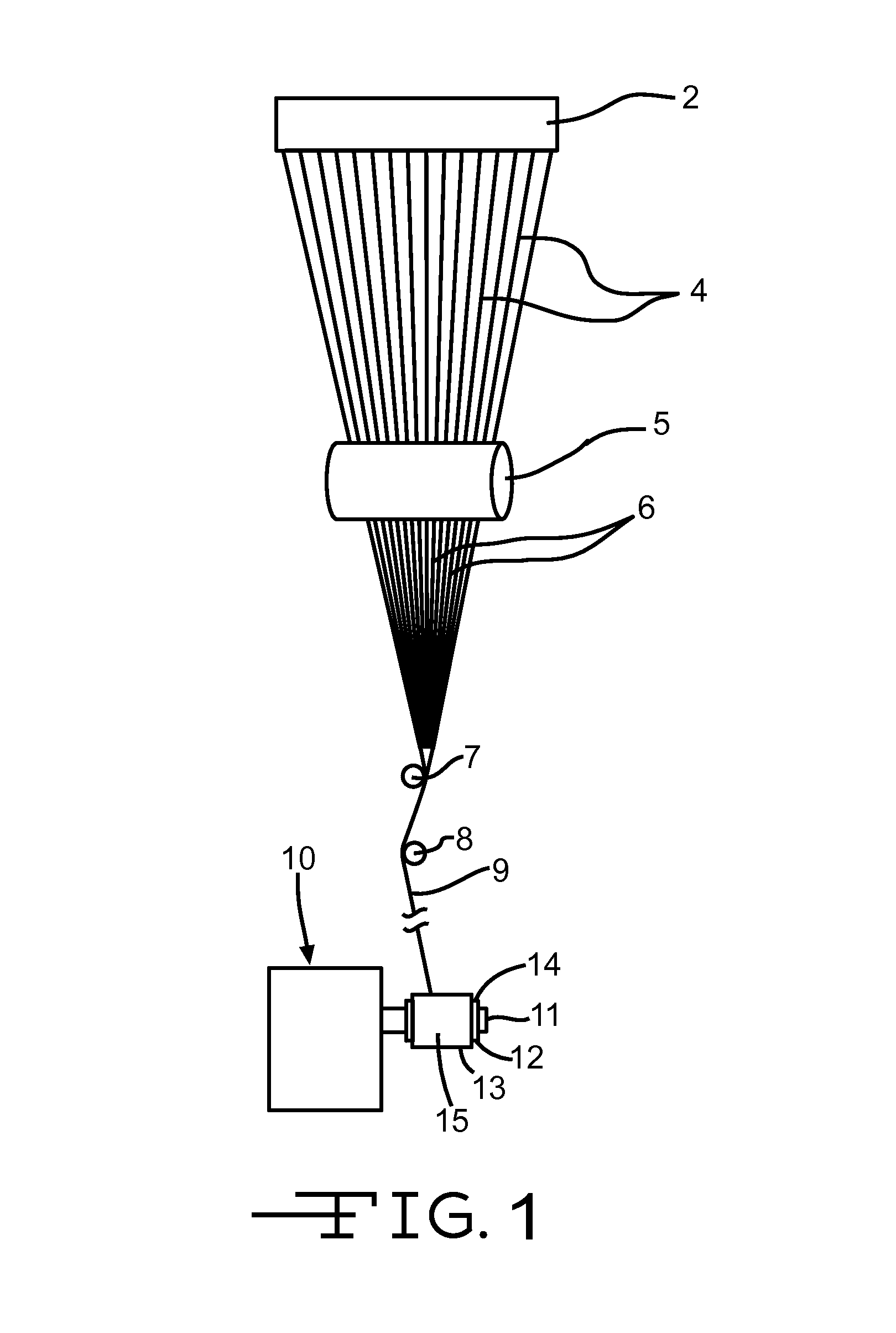

Method of delivering a thermoplastic and/or crosslinking resin to a composite laminate structure

The present invention provides a process for producing a prepreg of high modulus reinforcing fibers, the process comprising the steps of: a) providing a reinforcing fiber bundle layer wherein such bundle contains a thermoplastic and / or crosslinking resin within the fiber bundle; b) providing a layer of a thermoplastic and / or crosslinking material layer on at least one side of the high modulus fiber layer of step a); c) compressing the layers from step b) under an appropriate amount of heat and pressure, and thereby producing a prepreg of high modulus reinforcing fibers.

Owner:KEUCHEL KENNETH HERBERT

Engineered cross-linked thermoplastic particles for interlaminar toughening

ActiveUS8846818B2Improve toleranceImprove toughnessSynthetic resin layered productsCellulosic plastic layered productsCross-linkPolymer network

Owner:CYTEC TECH CORP

Semiconductor device and manufacturing method thereof

InactiveUS20090314527A1Maintain mechanical strengthMaintenanceSemiconductor/solid-state device detailsSolid-state devicesDevice materialFibrous body

To form a conductive region in a prepreg without opening a through hole in a fibrous body. A wiring substrate is provided, including: an organic resin layer and a fibrous body, wherein the fibrous body is impregnated with the organic resin layer; and a wiring with which the fibrous body is impregnated and which is formed by dissolving the organic resin layer. The wiring is exposed on both surfaces of the organic resin layer and penetrates the fibrous body so that the fibrous body is positioned in the through wiring. Further, a semiconductor device is provided by adhering an integrated circuit chip having a bump to the wiring substrate so that the bump is in contact with the wiring.

Owner:SEMICON ENERGY LAB CO LTD

Co-cured vacuum-assisted resin transfer molding manufacturing method

ActiveUS7419627B2Substantial eliminationGood size controlLaminationWood working apparatusShell moldingEngineering

According to one embodiment of the invention, a co-cured vacuum-assisted resin transfer molding manufacturing method includes providing a tool base, disposing a prepreg skin panel outwardly from the tool base, disposing one or more tooling details outwardly from the prepreg skin panel, and disposing one or more preforms proximate the one or more tooling details. The one or more preforms are either dry or binderized. The method further includes disposing a high permeability medium between the one or more tooling details and the one or more preforms, enclosing the prepreg skin panel, the one or more tooling details, the one or more preforms, and the high permeability medium with at least one vacuum bag, pulling a vacuum on the vacuum bag, infusing the one or more preforms with a resin, and curing the one or more preforms and the prepreg skin panel.

Owner:NORTHROP GRUMMAN SYST CORP

Prepreg and printed wiring board using thin quartz glass cloth

ActiveUS20090266591A1Low dielectric constantLoss tangentSynthetic resin layered productsPrinted circuit aspectsGlass fiberDielectric loss

It is an object of the present invention to provide a high frequency-capable printed wiring board material reduced in the dielectric loss tangent, weight, thickness and cost without compromising the workability, and provide electronic components using the same. The present invention provides a prepreg obtained by using a quartz glass cloth composed of low-density quartz glass fibers as a base material and impregnating the cloth with a thermosetting resin composition having a low dielectric loss tangent, and provides electronic components using a cured product of the prepreg as an insulating layer.

Owner:RESONAC CORP

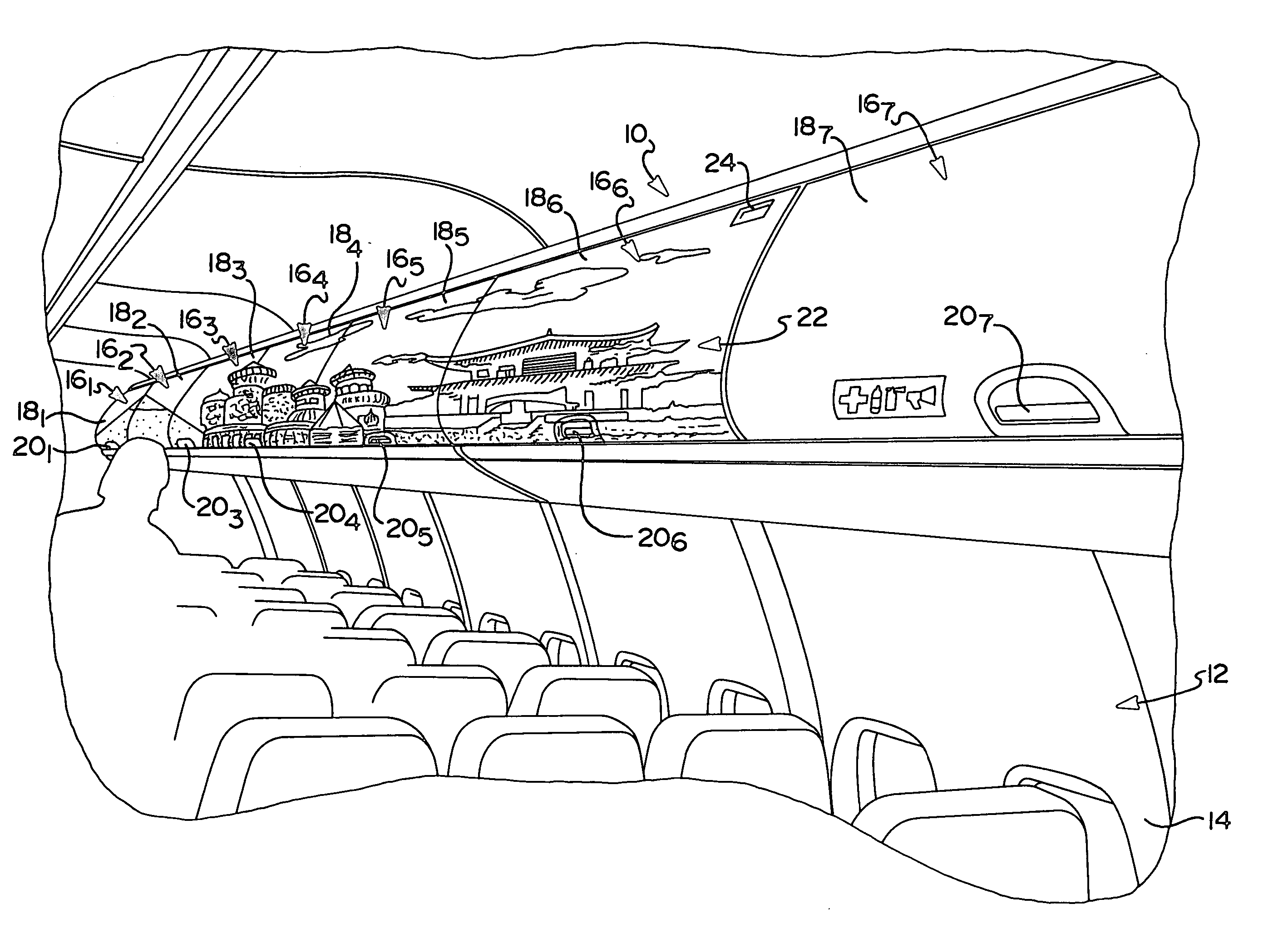

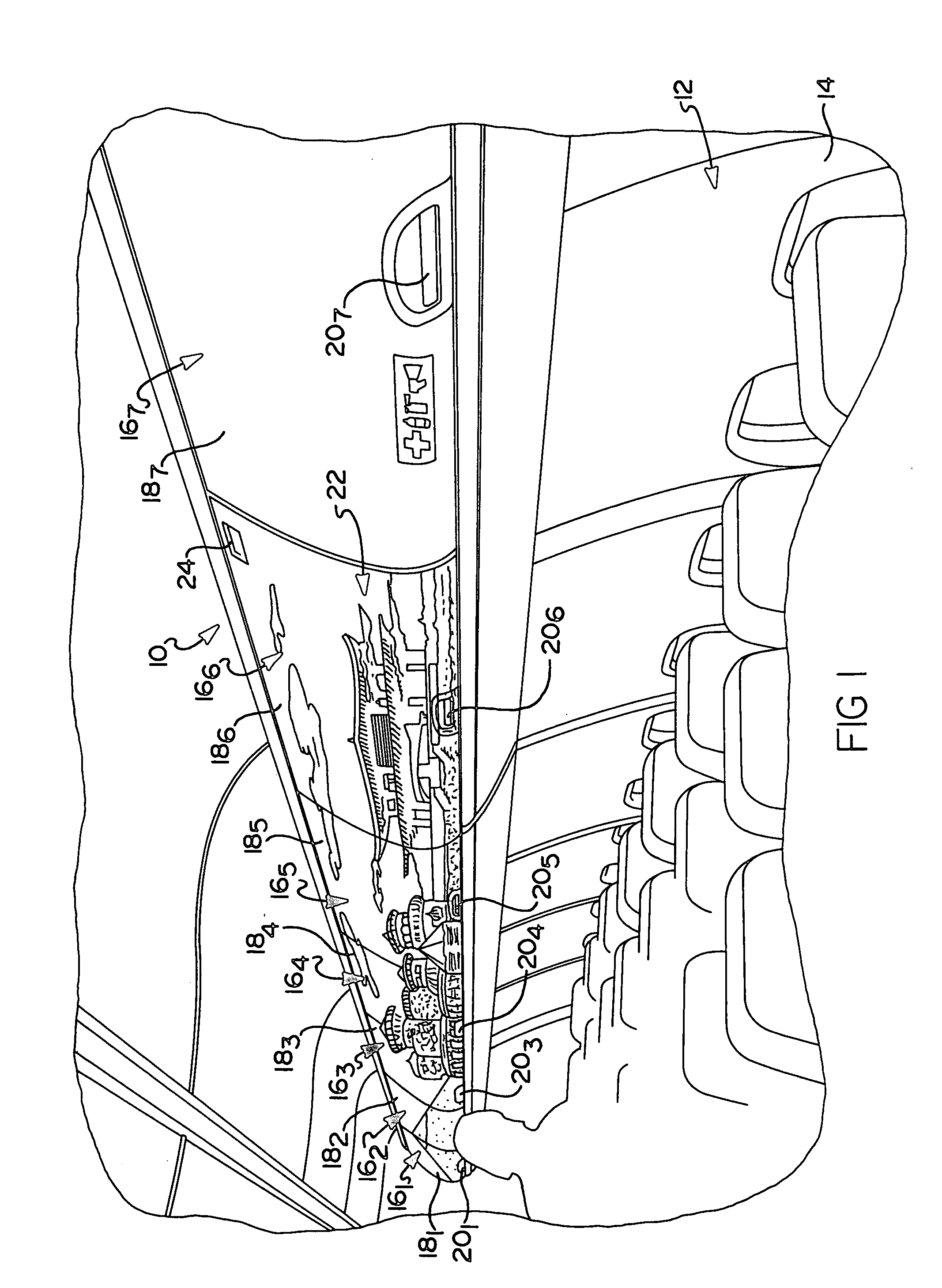

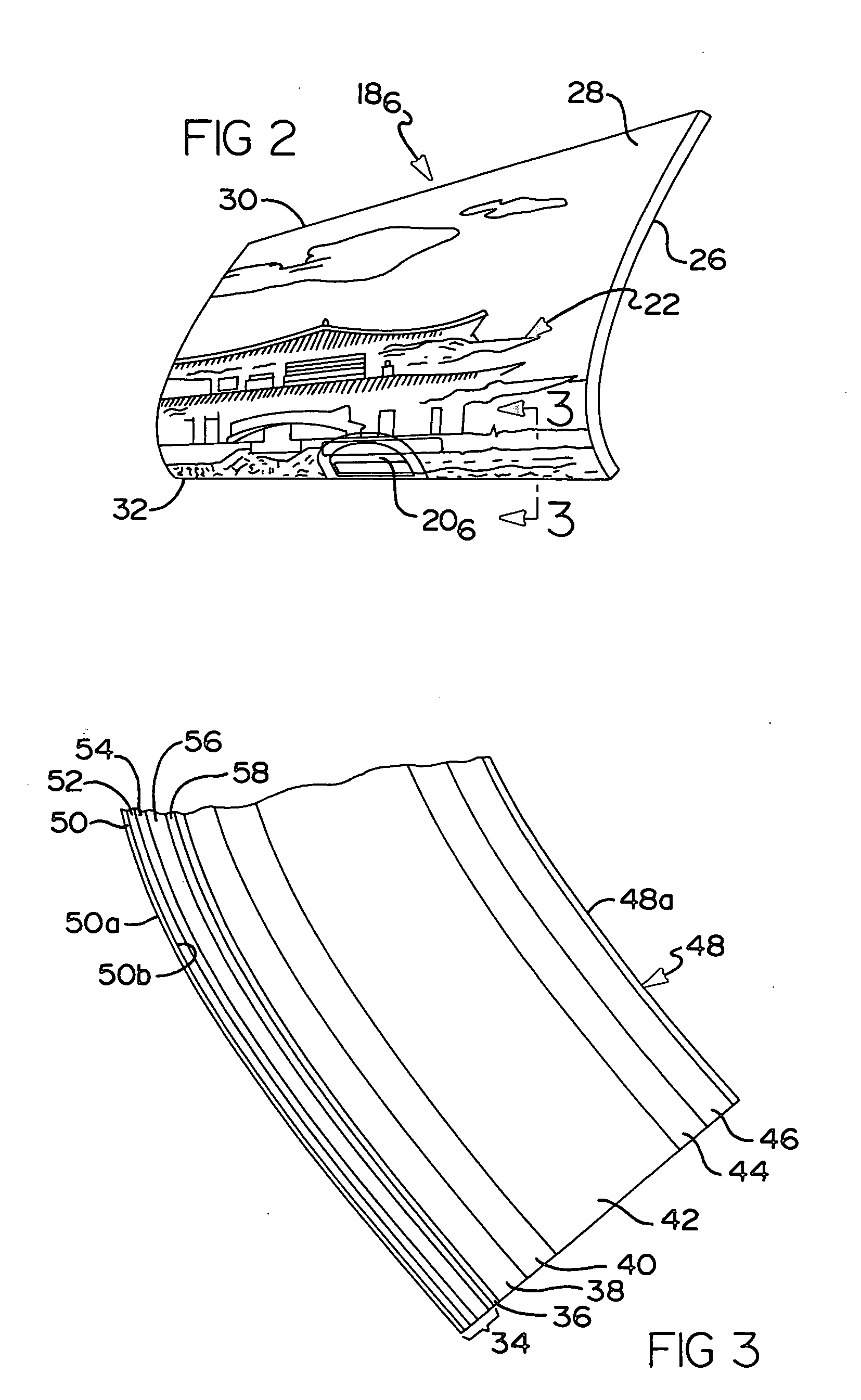

Laminate panel for use in structrual components

InactiveUS20050052516A1Quick and easy changeHigh ink loadingSynthetic resin layered productsGlass/slag layered productsGlass fiberAdhesive

A laminate panel especially well suited to help form an overhead stowage bin door on an aircraft, wherein the door includes a portion of a high contrast color advertising mural or message integrally formed therewith. The door includes a honeycomb support layer on which at least one fiberglass pre-preg layer is formed. A polyvinyl fluoride (PVF) film is used as a substrate for the color mural or message. A ultraviolet (UV) curable ink is deposited directly on the PVF film via an ink jet printing process that produces a high color density, high color contrast image. The PVF film in one form is a Tedlar® PVF film. The ink is cured virtually immediately after it is deposited on the PVF film. An additional layer of PVF film is then secured to a side of the printed-on PVF film opposite to that on which the ink is deposited via a layer of embossing resin to form the laminate panel. The laminate panel is then secured via a suitable adhesive to the fiberglass pre-preg and honeycomb support layer in a subsequent manufacturing step. The stowage bin door and process of making same enable a portion of a high color density, high contrast image, advertising mural or message to be integrally formed with the door.

Owner:THE BOEING CO

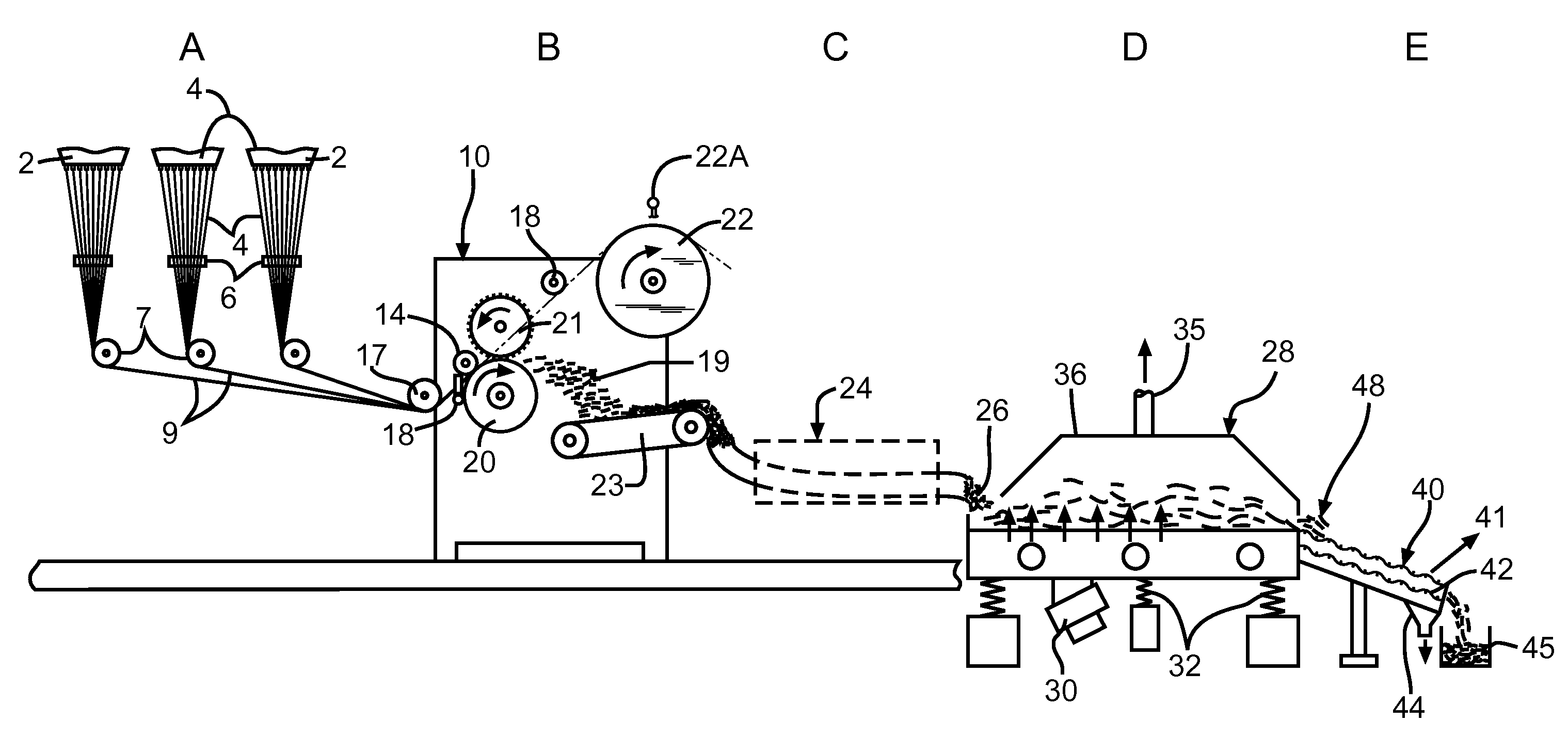

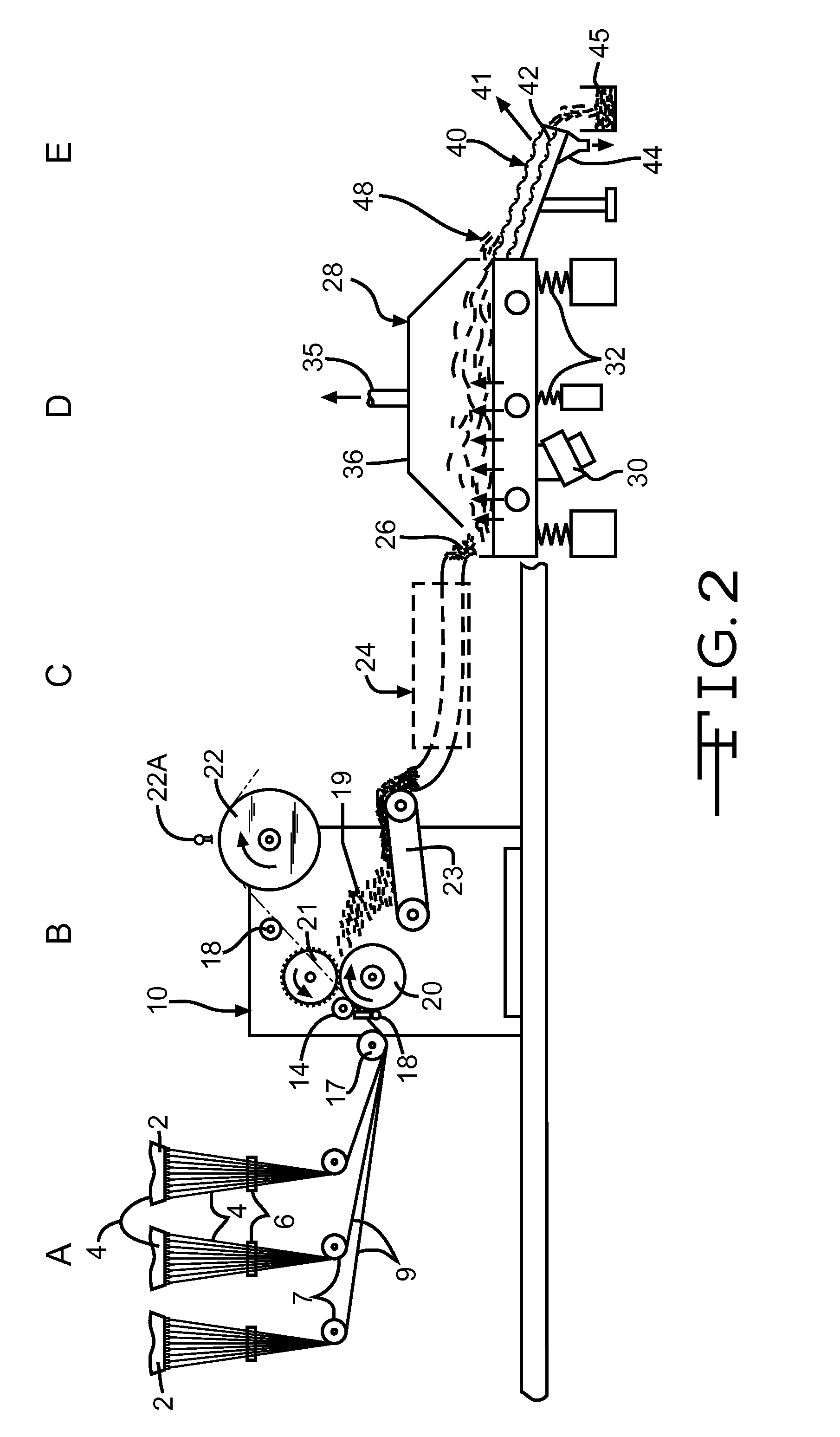

Methods of making reactive fiber/flake prepregs and reactive prepregs

ActiveUS20130165585A1Avoid stickingInhibition of polymerizationWood working apparatusAbsorbent padsOligomerAlternative methods

Prepreg compositions and methods of making them from particles and a binder composition are disclosed. The methods may include placing the particles on a moving conveying belt and applying the binder composition to the particles on the moving conveying belt to form a moving mass. Alternate methods may include first placing the binder composition on the moving conveying belt and then applying the particles to the binding composition to form the moving mass. The methods may further include passing the moving mass through one or more pairs of opposed, compacting rolls, where the particles and the binder composition are pressed into further contact while passing through the compacting rolls to form the prepreg. The binder composition in the prepreg may include monomers and / or oligomers of a polymer that are capable of polymerizing into the polymer under polymerization conditions.

Owner:JOHNS MANVILLE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com