Patents

Literature

89 results about "Carbon fiber reinforced polymers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon Fiber-Reinforced Polymer (CFRP) Definition - What does Carbon Fiber-Reinforced Polymer (CFRP) mean? A carbon fiber-reinforced polymer (CFRP) refers to a type of durable and strong material that is composed of linked-chain carbon atoms in a matrix structure of polymer resin. These polymers are highly corrosion resistant.

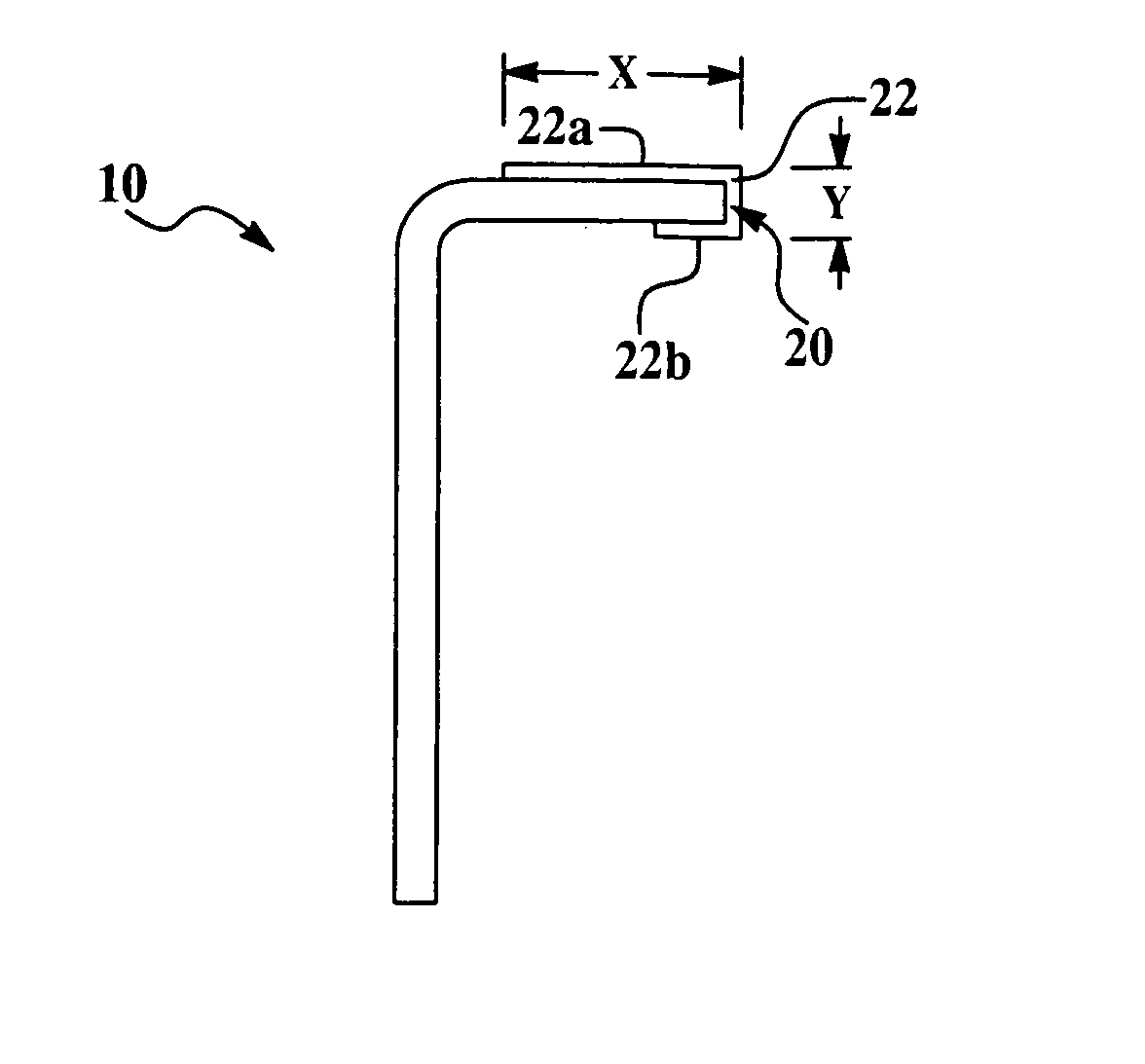

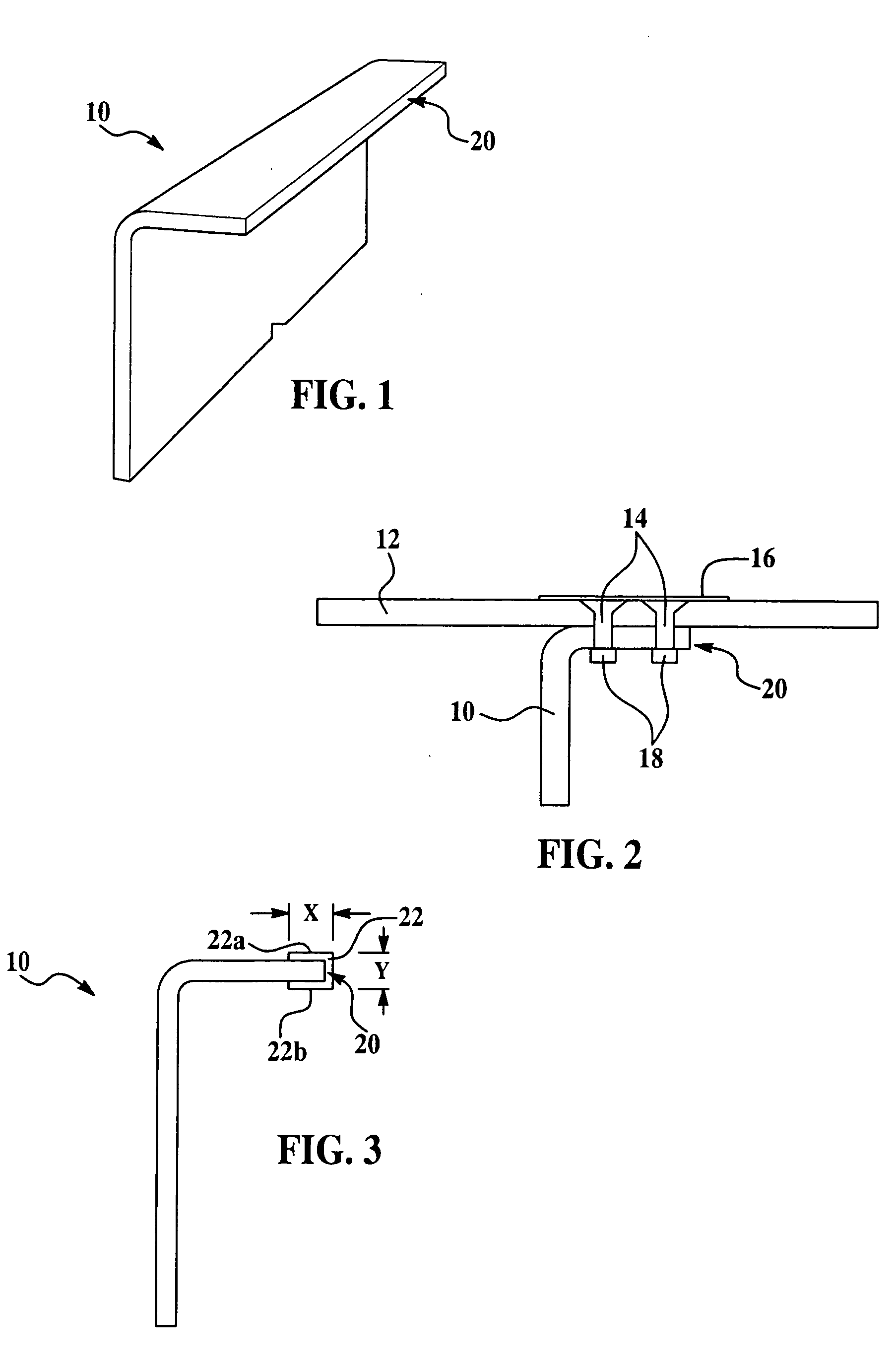

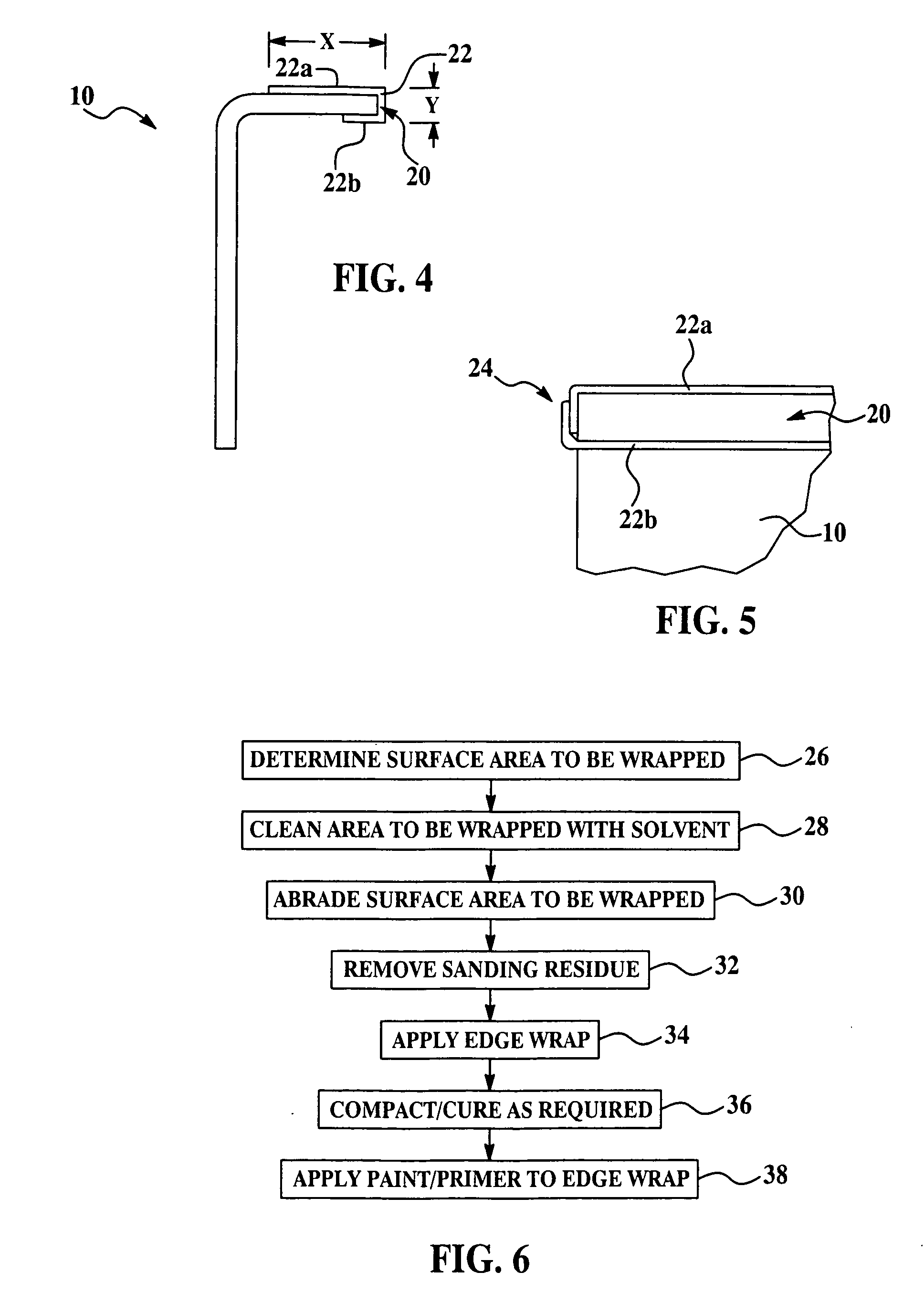

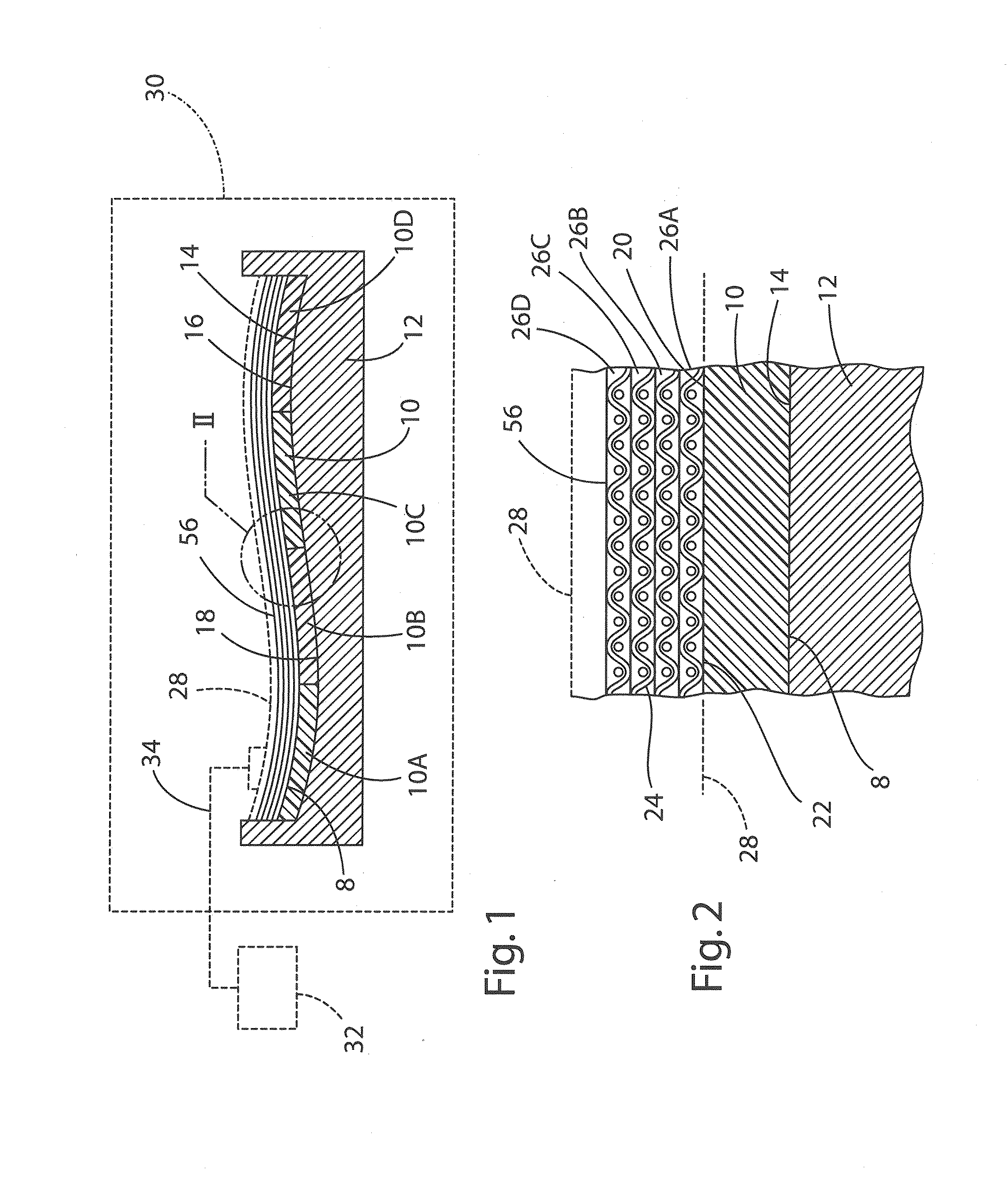

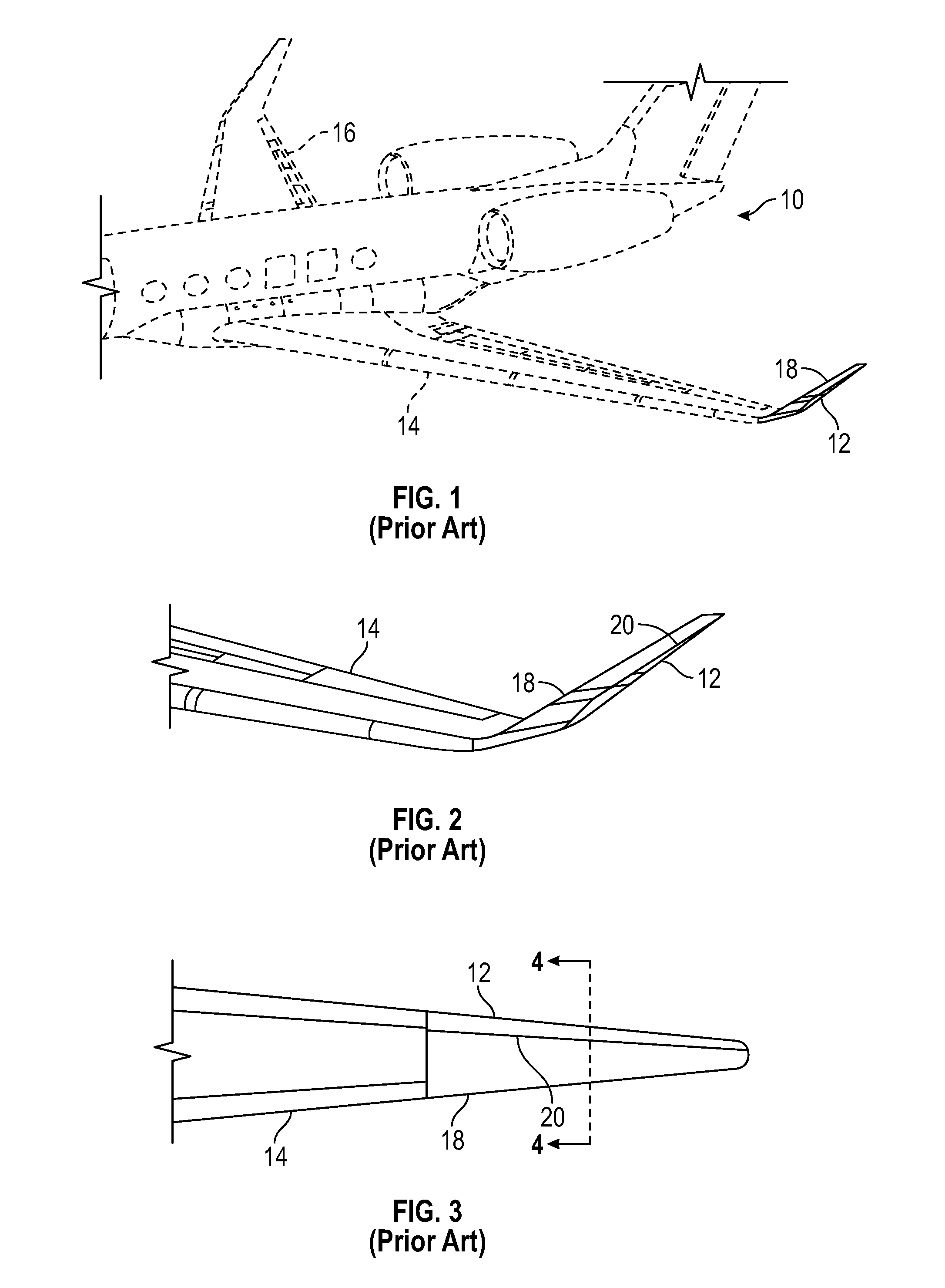

Edge seals for composite structure fuel tanks

ActiveUS20080128430A1Avoid contactPower plant fuel tanksFuel tank safety measuresFuel tankEngineering

The cut laminate edges of aircraft fuel tanks formed of carbon fiber reinforced polymers are sealed to prevent the exposure of carbon fibers to combustible fuel. The edge seal is produced from a prepreg form using a thermosetting resin matched to the characteristics of the resin used in the laminate. The prepreg form can be applied to the cut laminate edges either before or after the laminate is cured. The edge seal acts a dielectric layer that both electrically insulates the cut laminate edges from the fuel and mechanically contains energetic particles produced at the edges due to lighting strikes or other sources of electrical charges.

Owner:THE BOEING CO

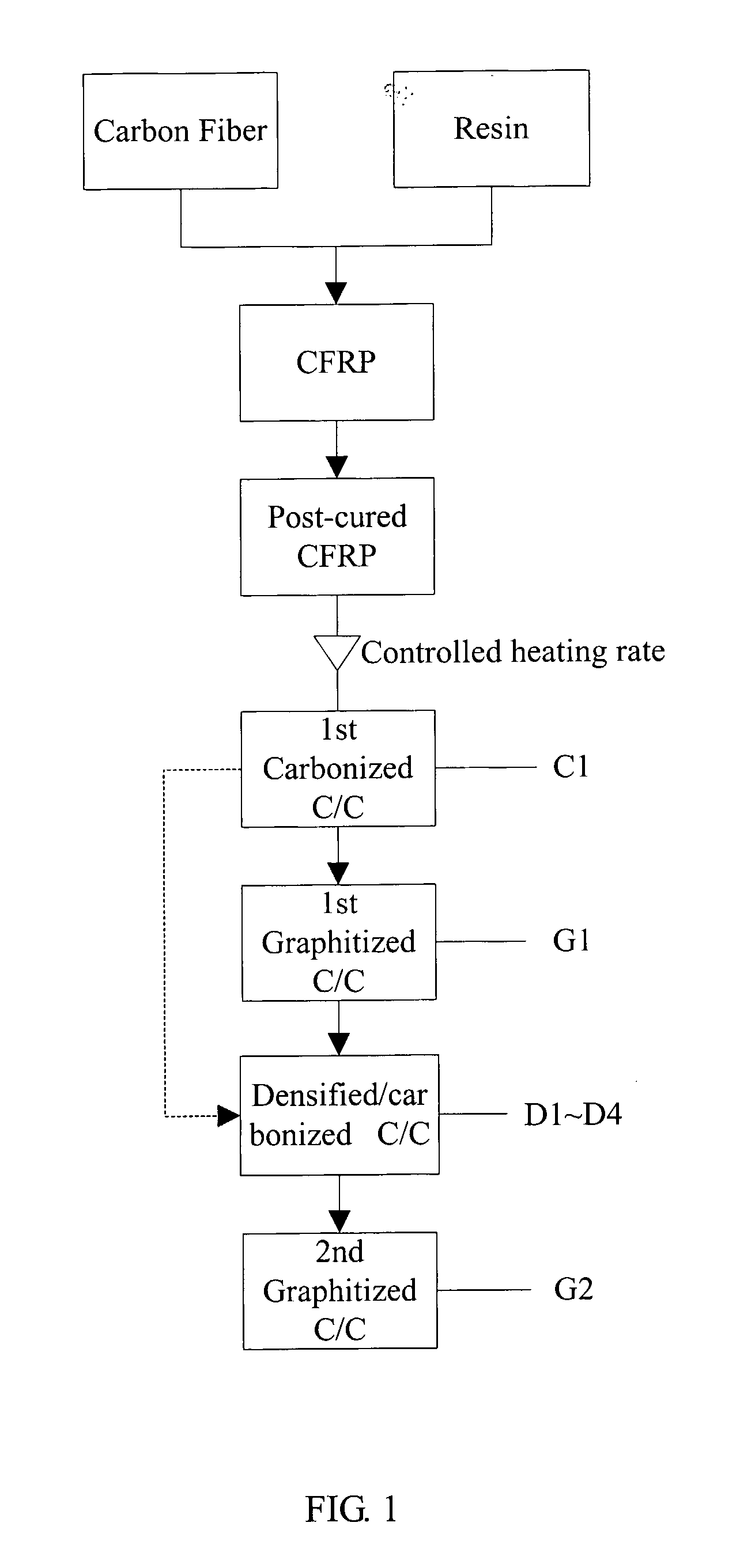

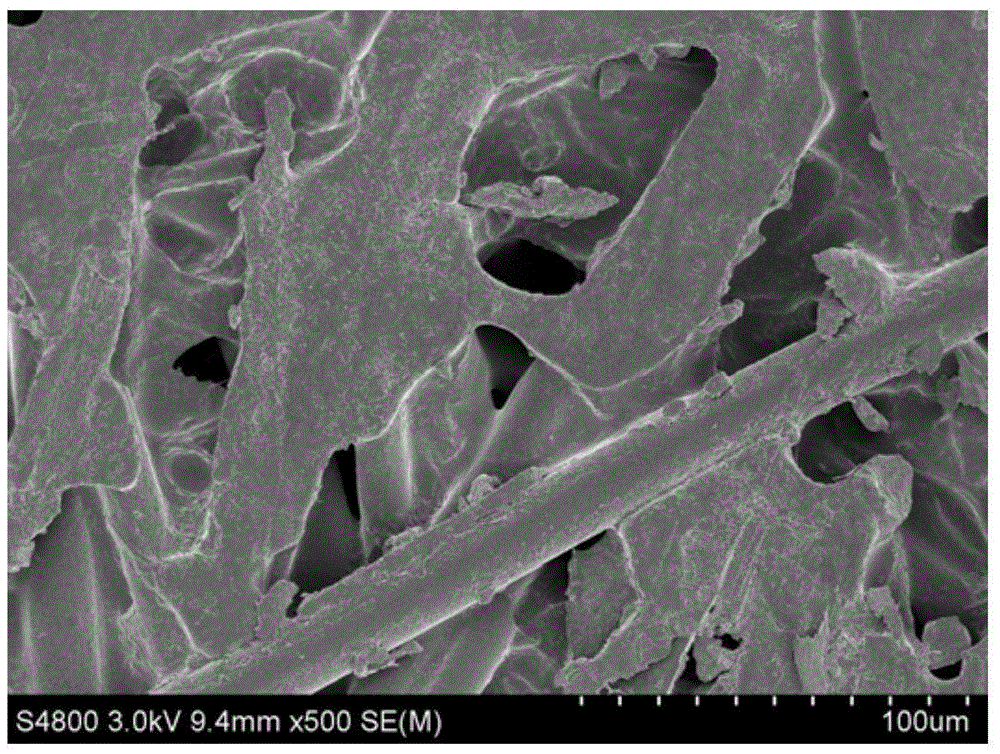

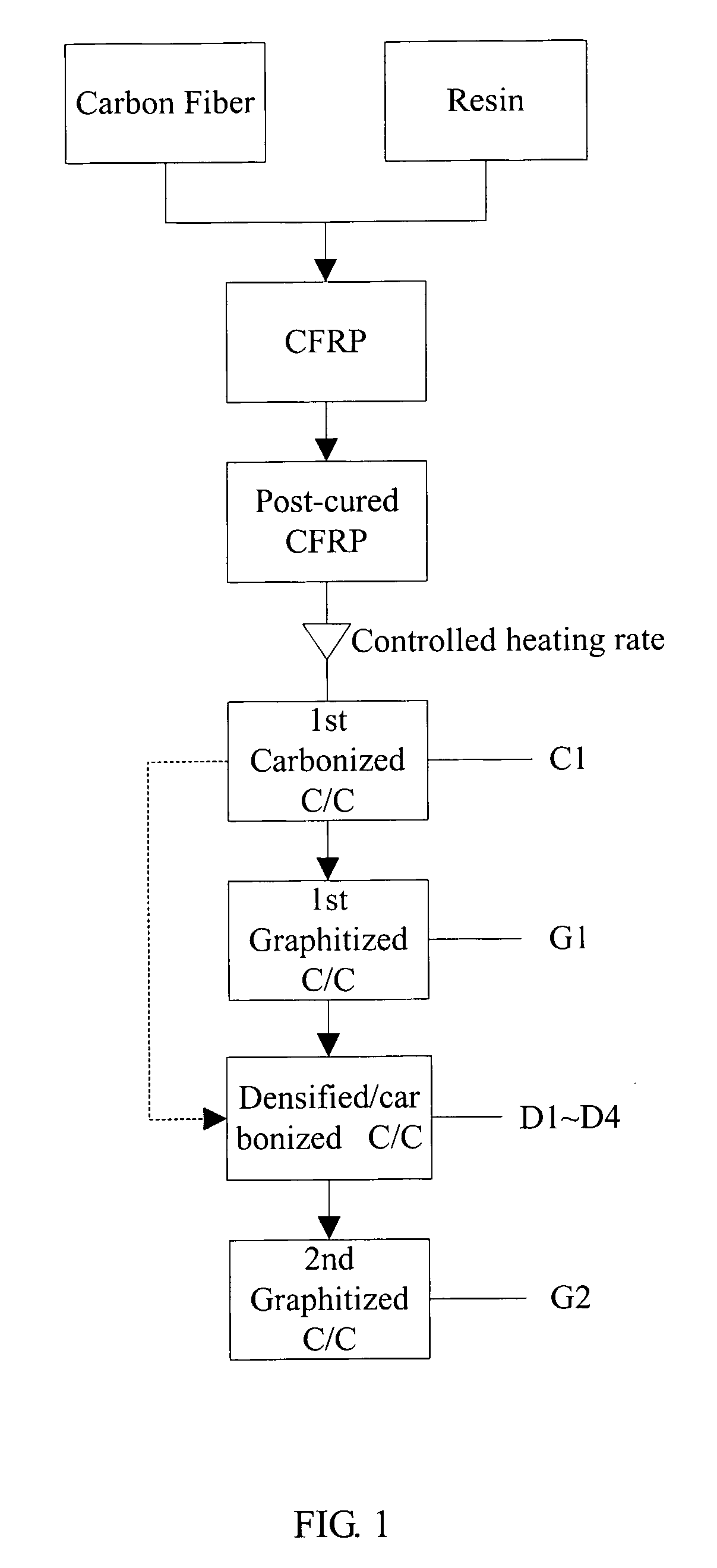

Method for Preparing a Carbon/Carbon Composite

InactiveUS20080025906A1Comparable mechanical propertyAcceptable tribological performanceMaterial nanotechnologyAlkali metal halidesCarbon compositesMaterials science

A method for preparing a carbon / carbon (C / C) composite comprising carbonizing a carbon fiber-reinforced polymer matrix composite precursor by heating the precursor in an inert atmosphere with a heating rate greater than 20° C. / min up to 1500° C. / min.

Owner:NAT CHENG KUNG UNIV

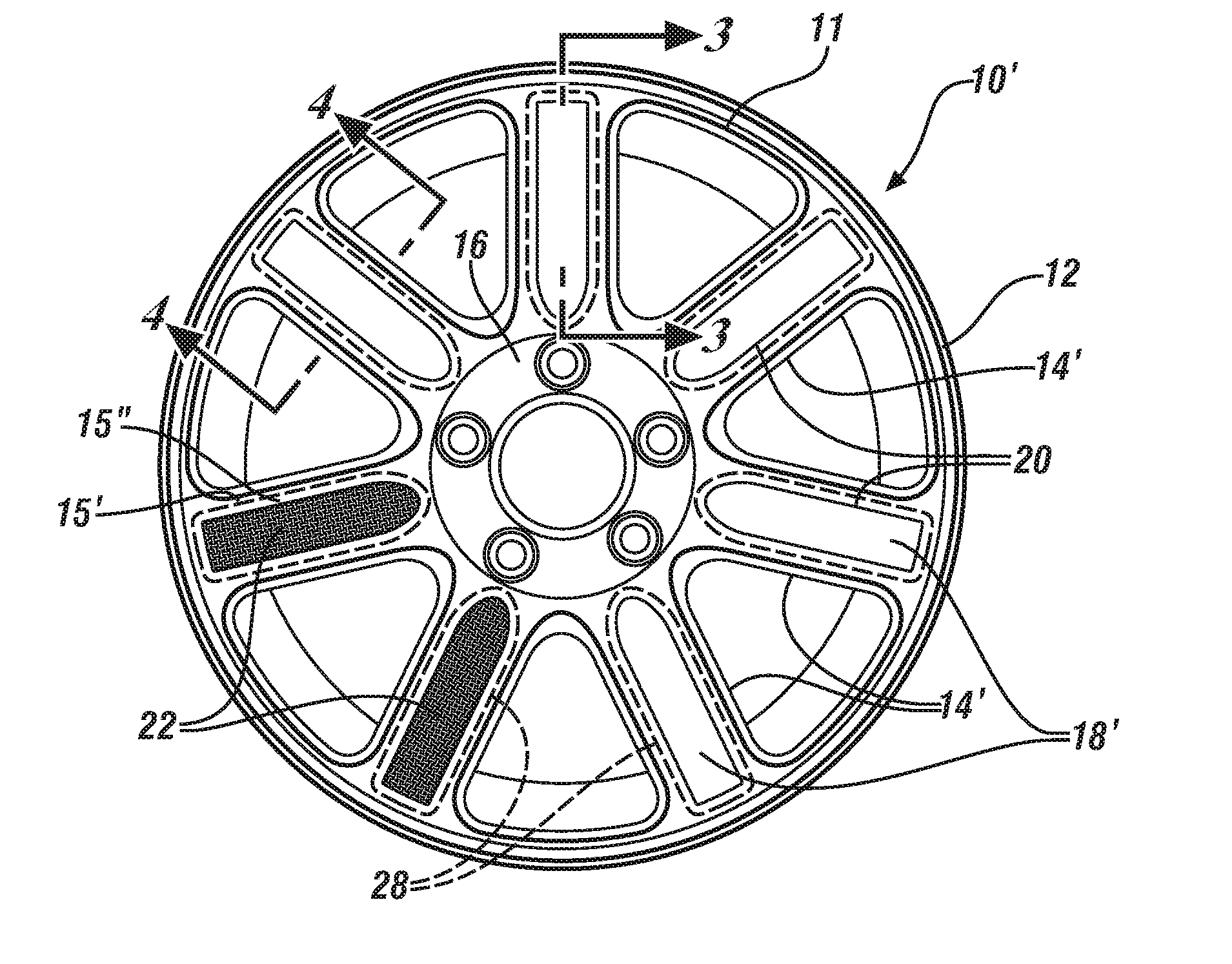

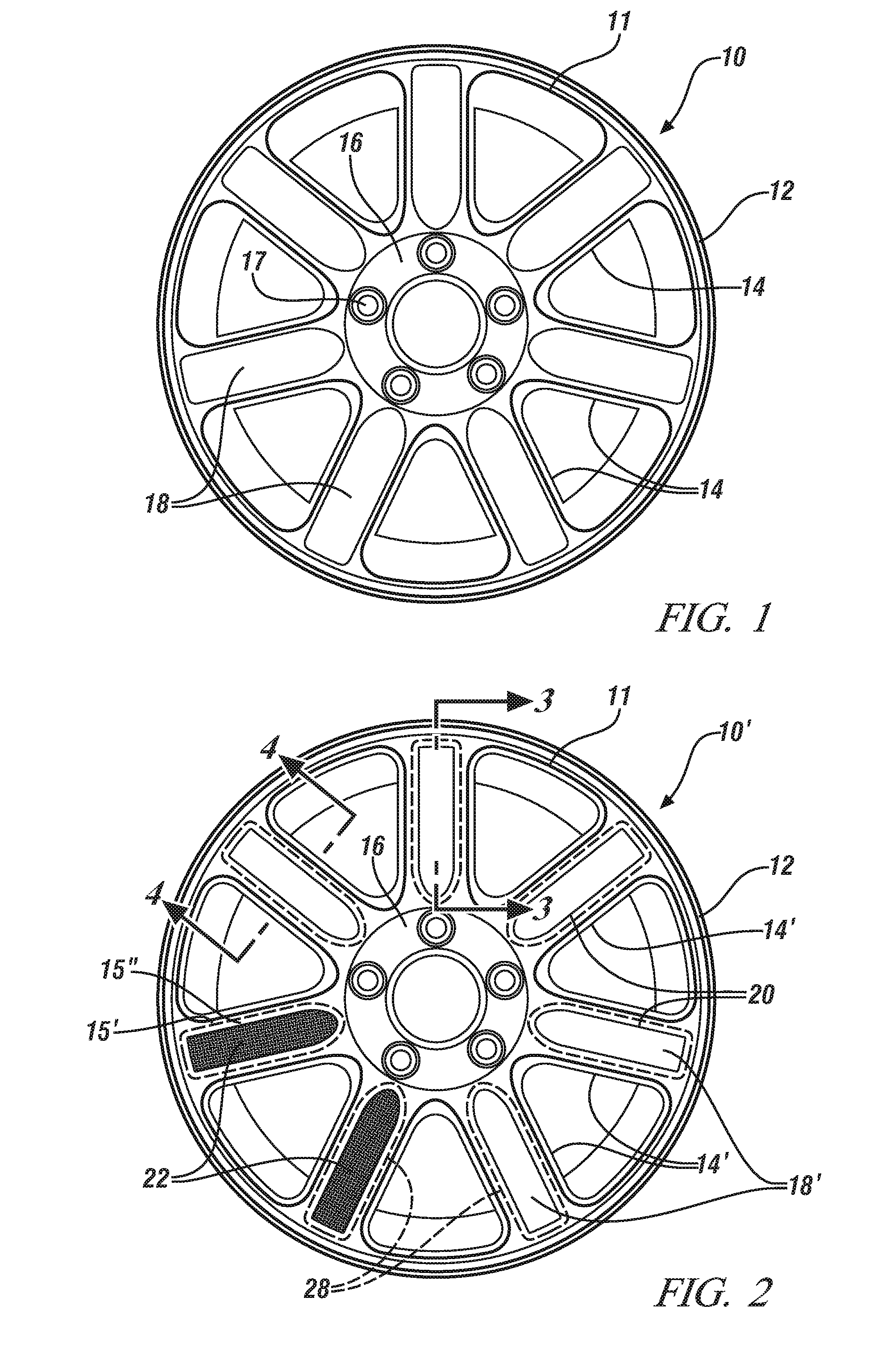

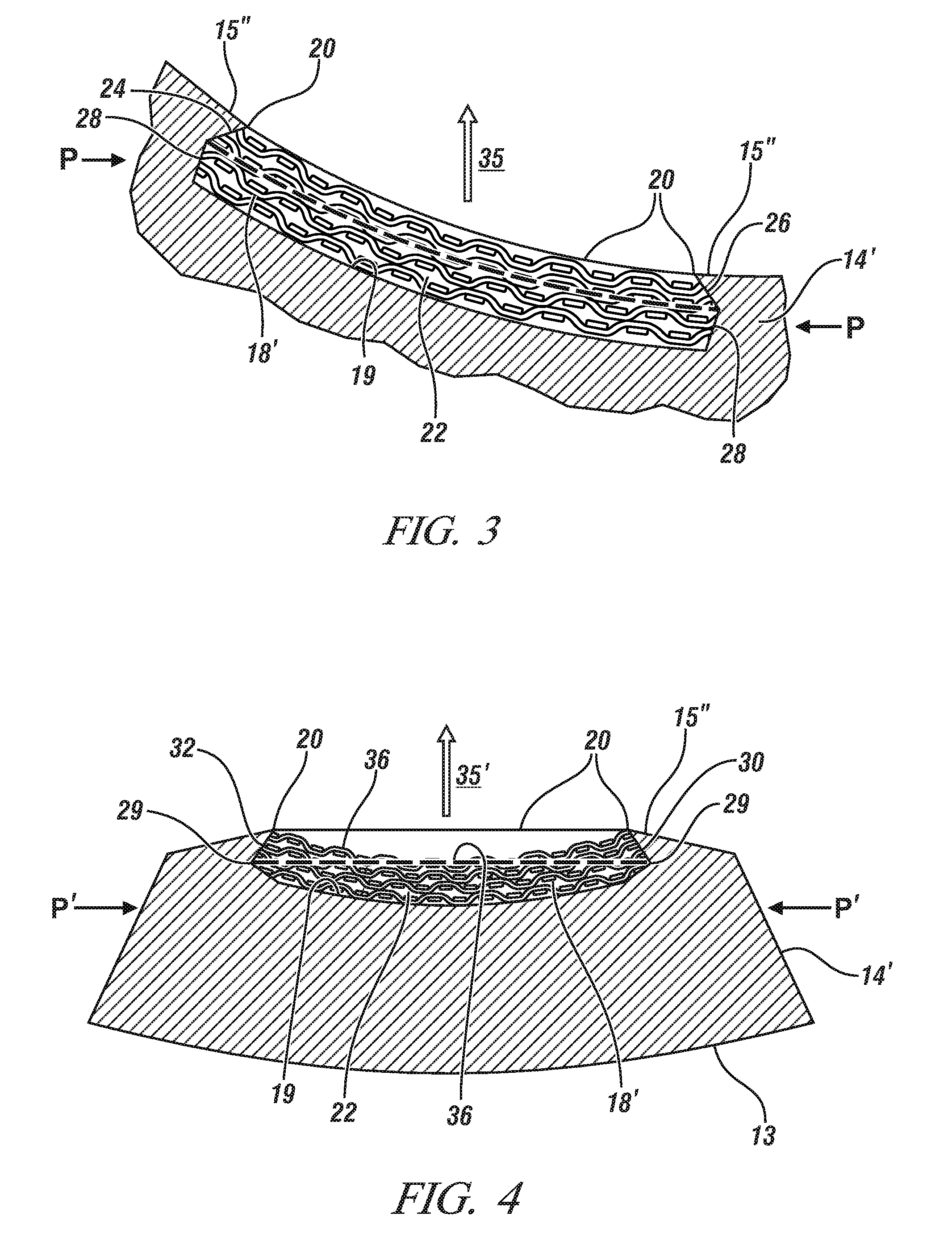

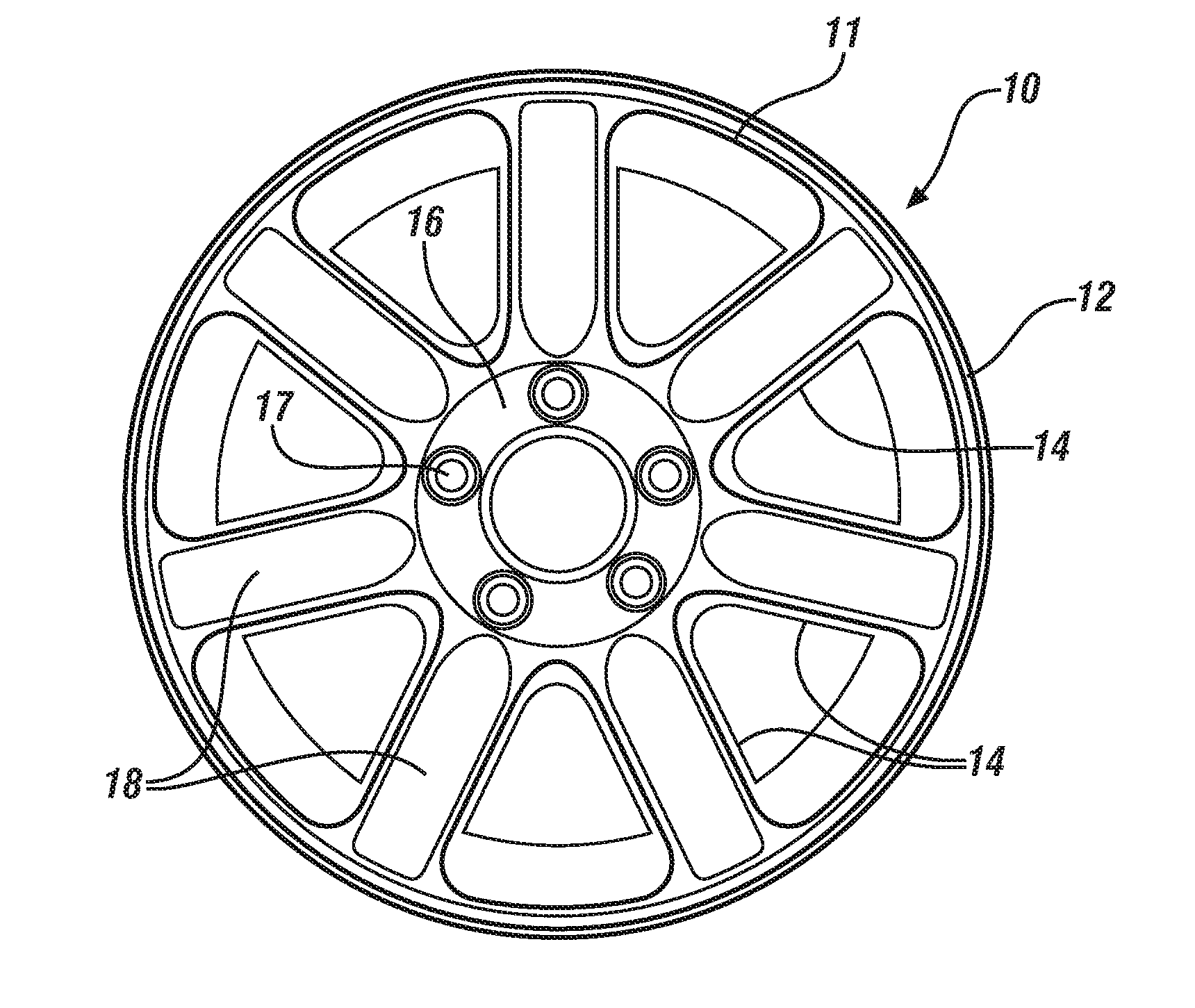

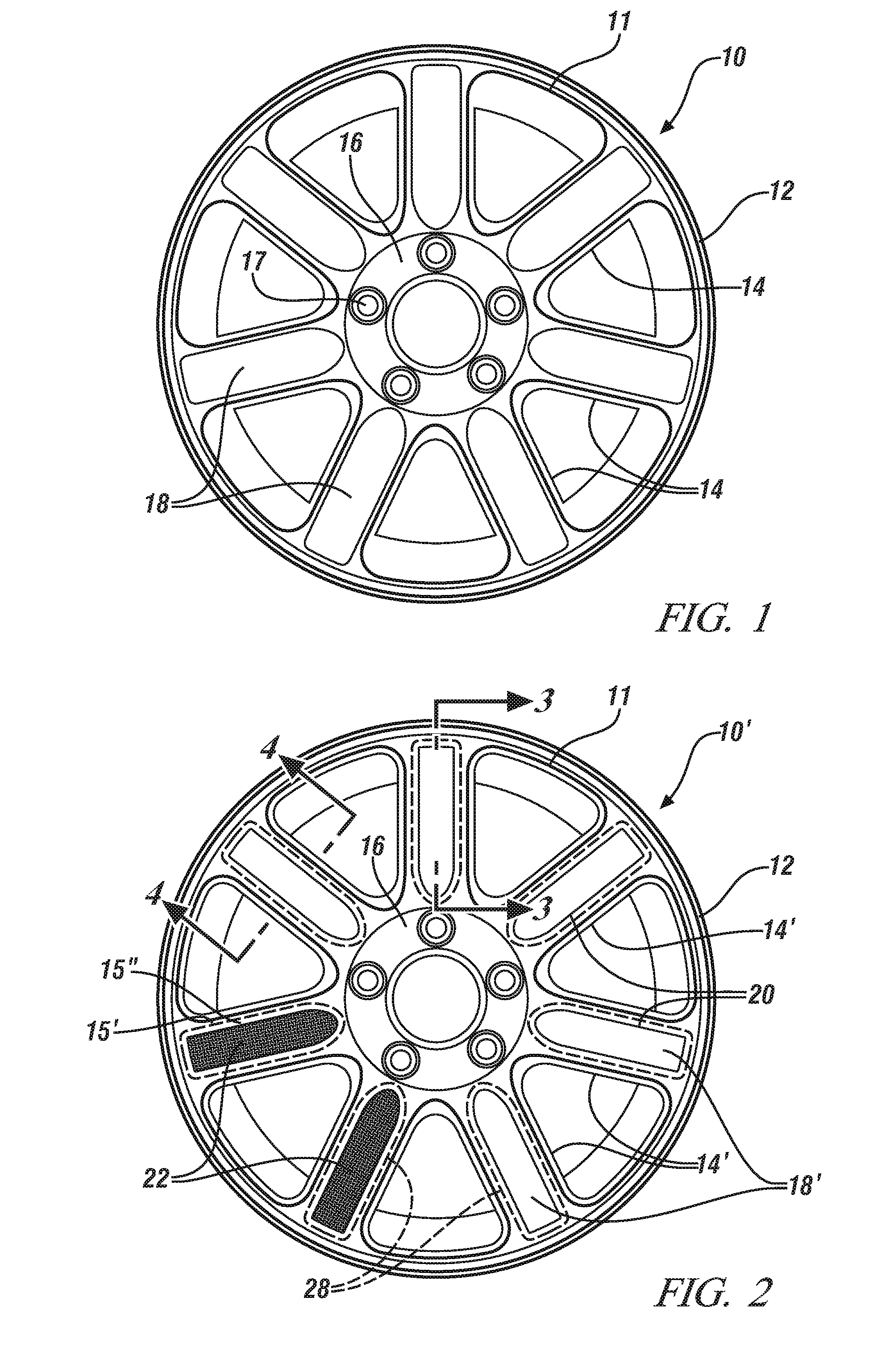

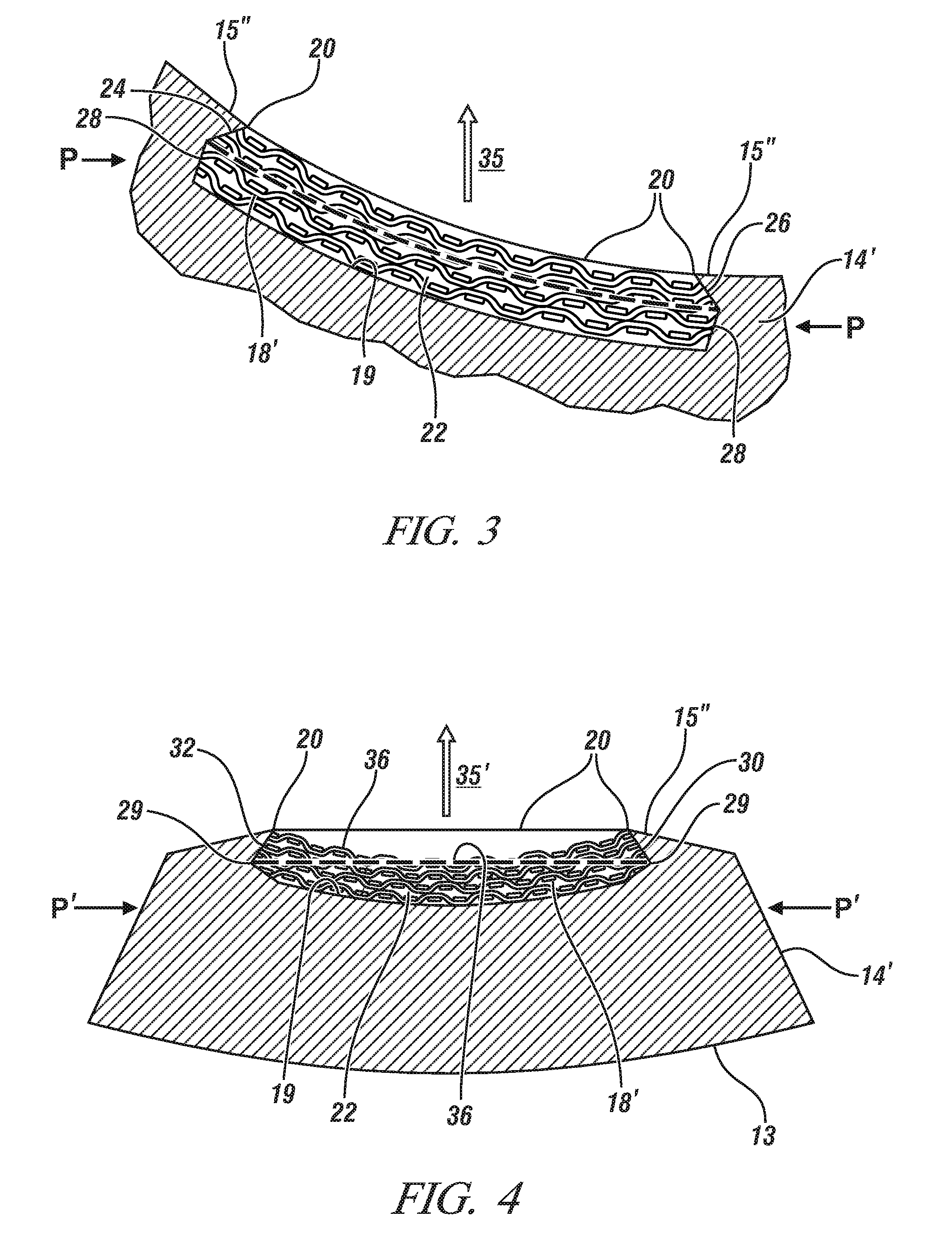

Light-weight vehicle wheels with carbon fiber inserts

ActiveUS20130026816A1Portion is increasedHigh modulusRimsNon-metallic wheel bodyFiberThermal dilatation

Application of carbon fiber reinforced polymer structures to metal vehicle wheels is effective in reducing the mass of the wheel while retaining suitable stiffness in the wheel structure. For maximum effect the reinforced polymer structure and the metal wheel must operate cooperatively. Because of the wide range of operating temperatures experienced by wheels and the large difference in coefficient of thermal expansion between metals and carbon fiber reinforced composites attachment of the polymer structure to the wheel by adhesive alone is problematical. However a wheel with an effective and durable reinforcement may be fabricated by confining, through mechanical interference, the reinforced polymer in a cavity in or on the spoke and by preheating the wheel before curing the polymer.

Owner:GM GLOBAL TECH OPERATIONS LLC

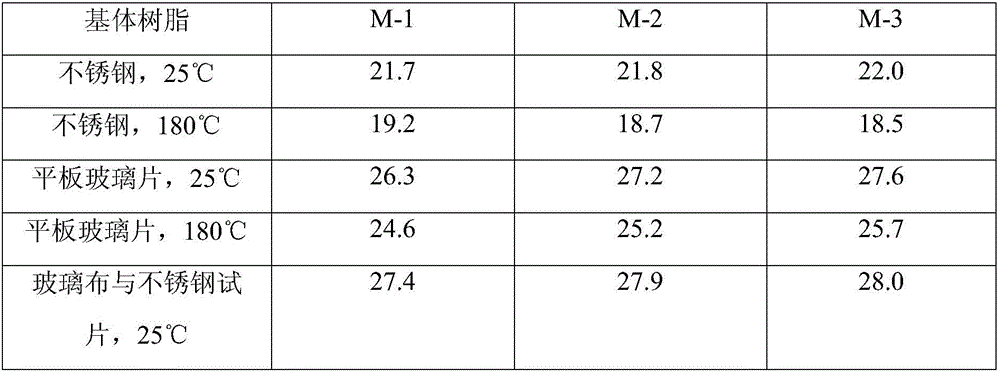

YASI (bis(gamma-aminopropyl) polydimethyl siloxane) siliceous epoxy imide matrix resin and preparation method thereof

The invention relates to a YASI (bis(gamma-aminopropyl) polydimethyl siloxane) siliceous epoxy imide matrix resin and a preparation method thereof. The matrix resin is composed of YASI, an epoxy resin, 3-aminopropyl trialkoxysilane, an imide oligomer and a curing agent. The preparation method comprises the following steps: (1) preparing the imide oligomer; and (2) adding the YASI and epoxy resin into a reaction kettle, stirring and mixing to react, adding the imide oligomer, continuing stirring to react, adding the 3-aminopropyl trialkoxysilane, stirring to react, adding the curing agent, and uniformly stirring and mixing. The resin can be widely used for bonding metals (such as steel, copper, aluminum and the like) and substrates (ceramic, glass, resin-base composite materials and the like), and preparing glass fibers, aramid fibers and carbon-fiber-reinforced polymer composite materials, and thus, has favorable industrialization prospects.

Owner:DONGHUA UNIV +1

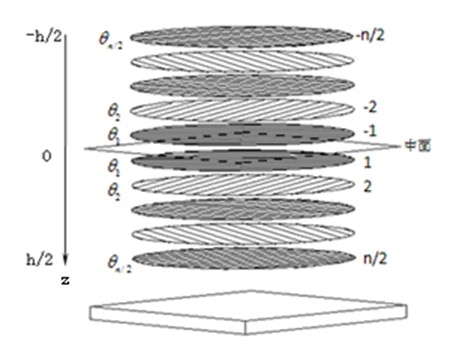

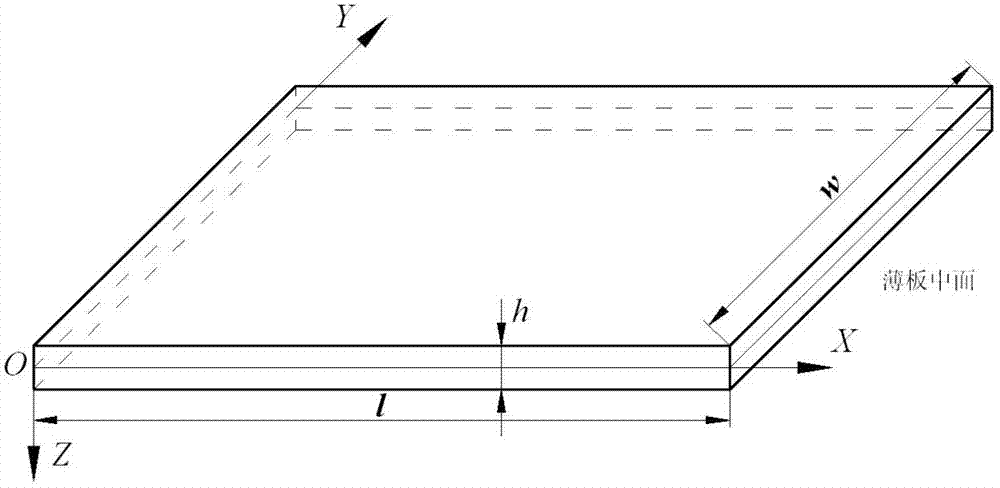

Laminating manufacture method for symmetric laminated plate

InactiveCN102521435AImproved quasi-uniformityImprove uniformitySpecial data processing applicationsIn planeStiffness coefficient

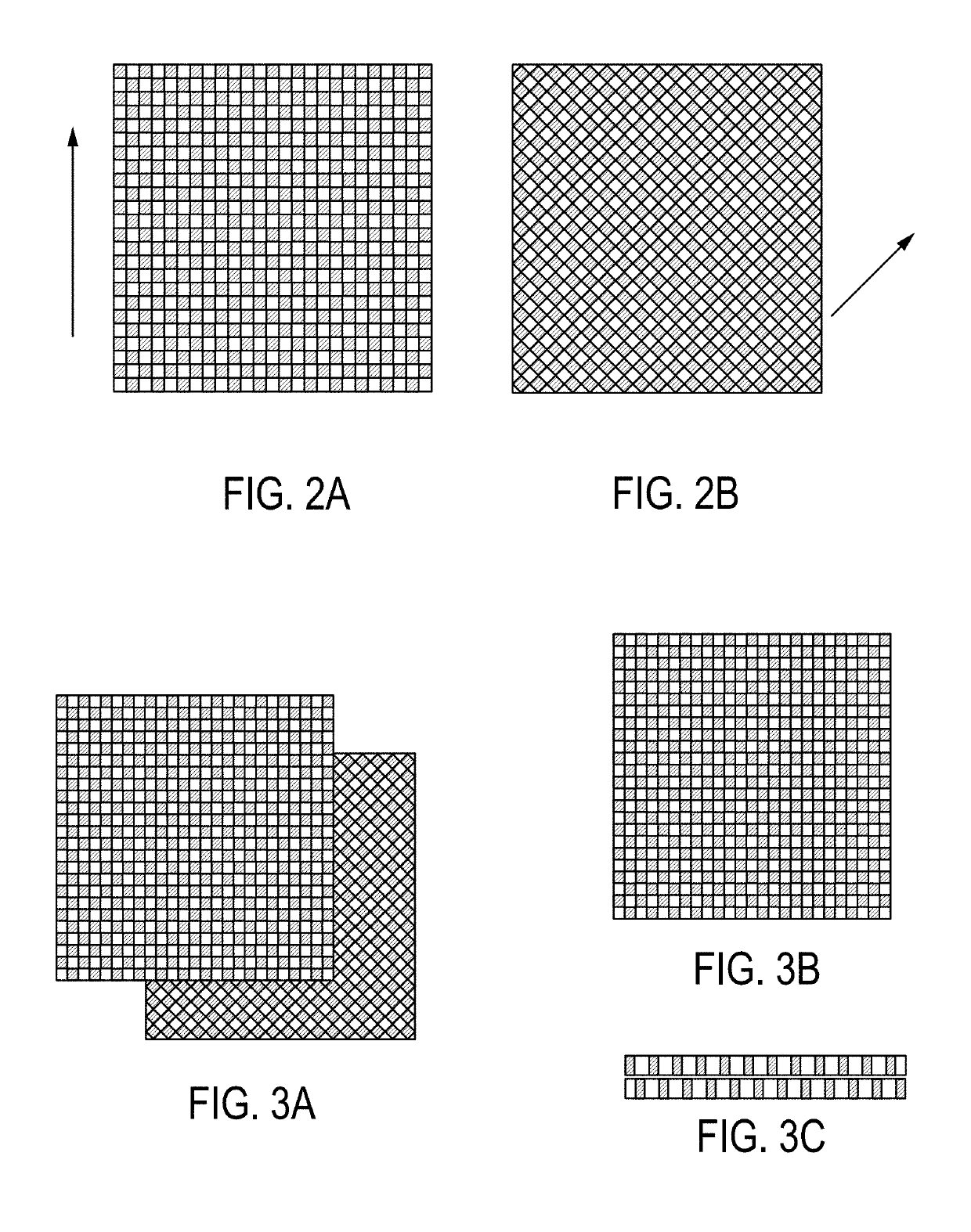

The invention relates to a laminating manufacture method for a symmetric laminated plate. The laminating manufacture method comprises the following steps of: under the condition of quasi-uniform quasi-isotropy, setting up a relational expression between a regularization in-plane stiffness coefficient formula (shown as a drawing) and a flexural stiffness coefficient formula (shown as a drawing) according to the geometric model of the symmetric laminated plate; with appointed number p of directional single layers, adopting a regularization stiffness coefficient method to carry out optimized adjustment on a laminating sequence by taking the quadratic sum of a formula (shown as a drawing) as an evaluation function; and obtaining the symmetric laminated plate with quasi-uniform quasi-isotropy.According to the laminating manufacture method, the theoretical-equation-based regularization stiffness coefficient method is adopted to design and optimize the laminating sequence, and the optimal laminating sequence under a certain number of directional single layers is directly obtained through calculation, so that the obtained symmetric laminated plate has optimal quasi-isotropy for in-plane stiffness, and the quasi-isotropy for the flexural stiffness of the obtained symmetric laminated plate is optimal with the appointed number of directional single layers. A carbon fiber reinforced polymer composite reflecting mirror formed by using the laminating sequence has less asymmetric deformation under active deformation, and thus, the surface shape accuracy of the reflecting mirror after being actively controlled is improved.

Owner:SUZHOU UNIV

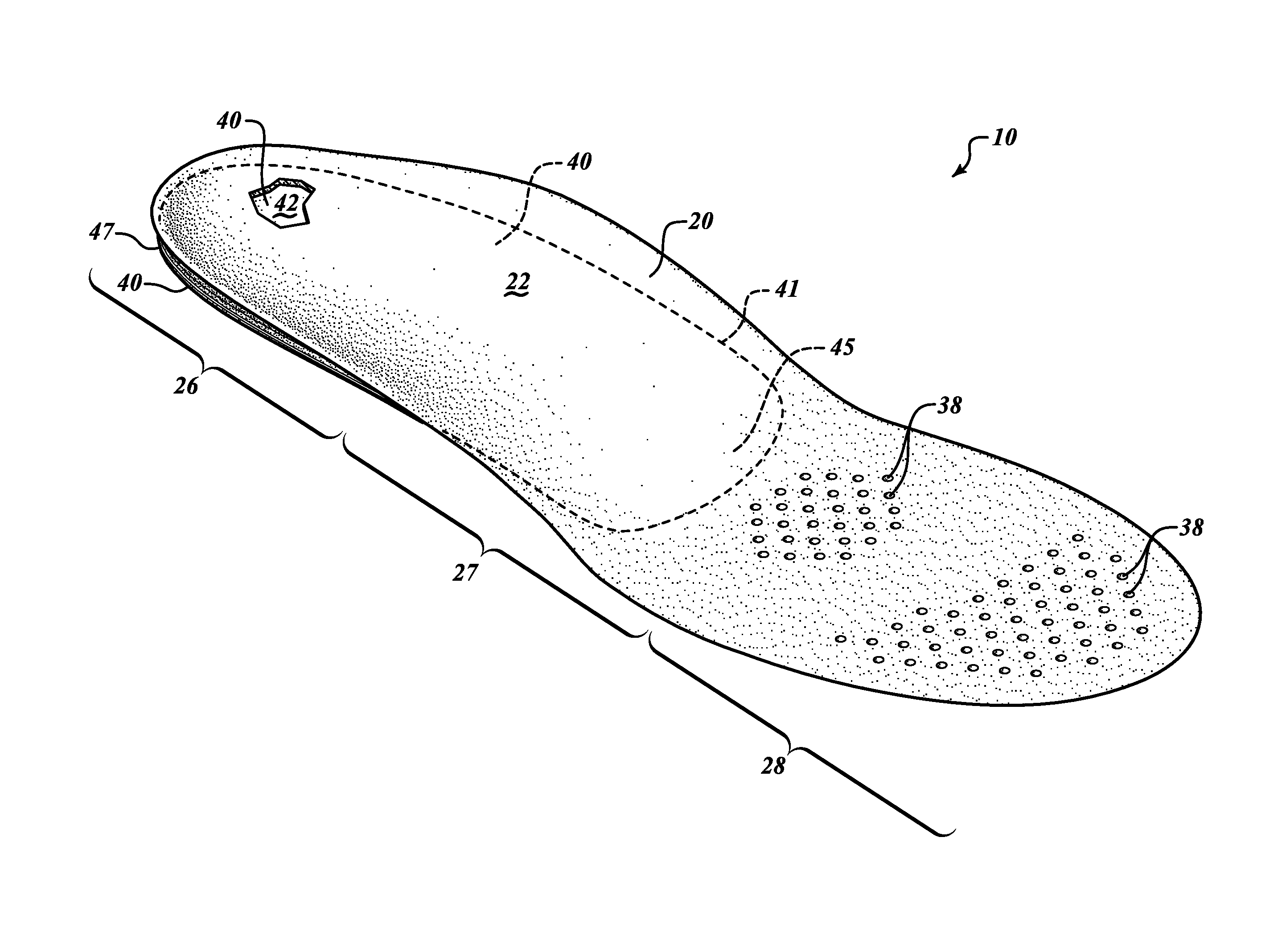

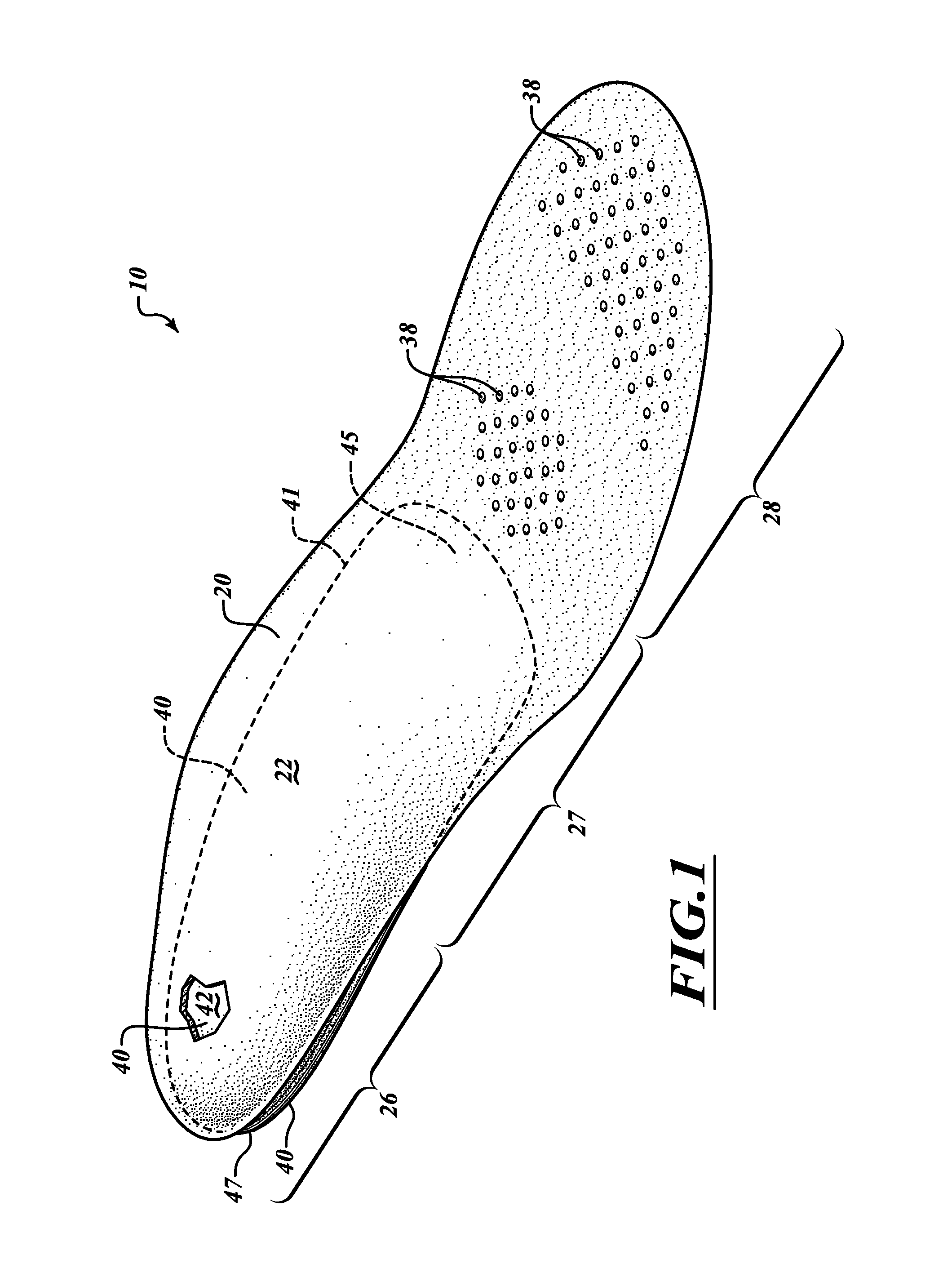

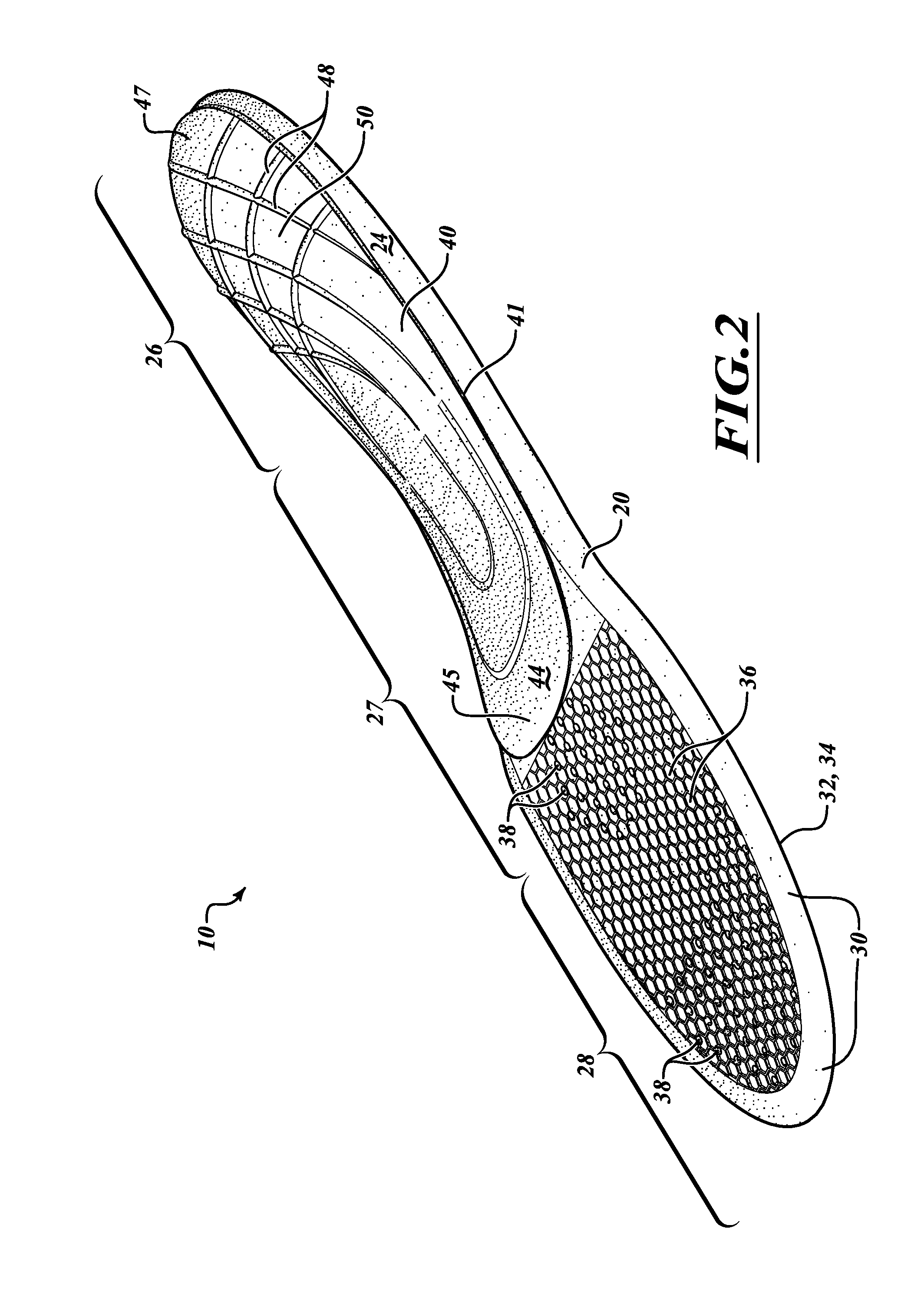

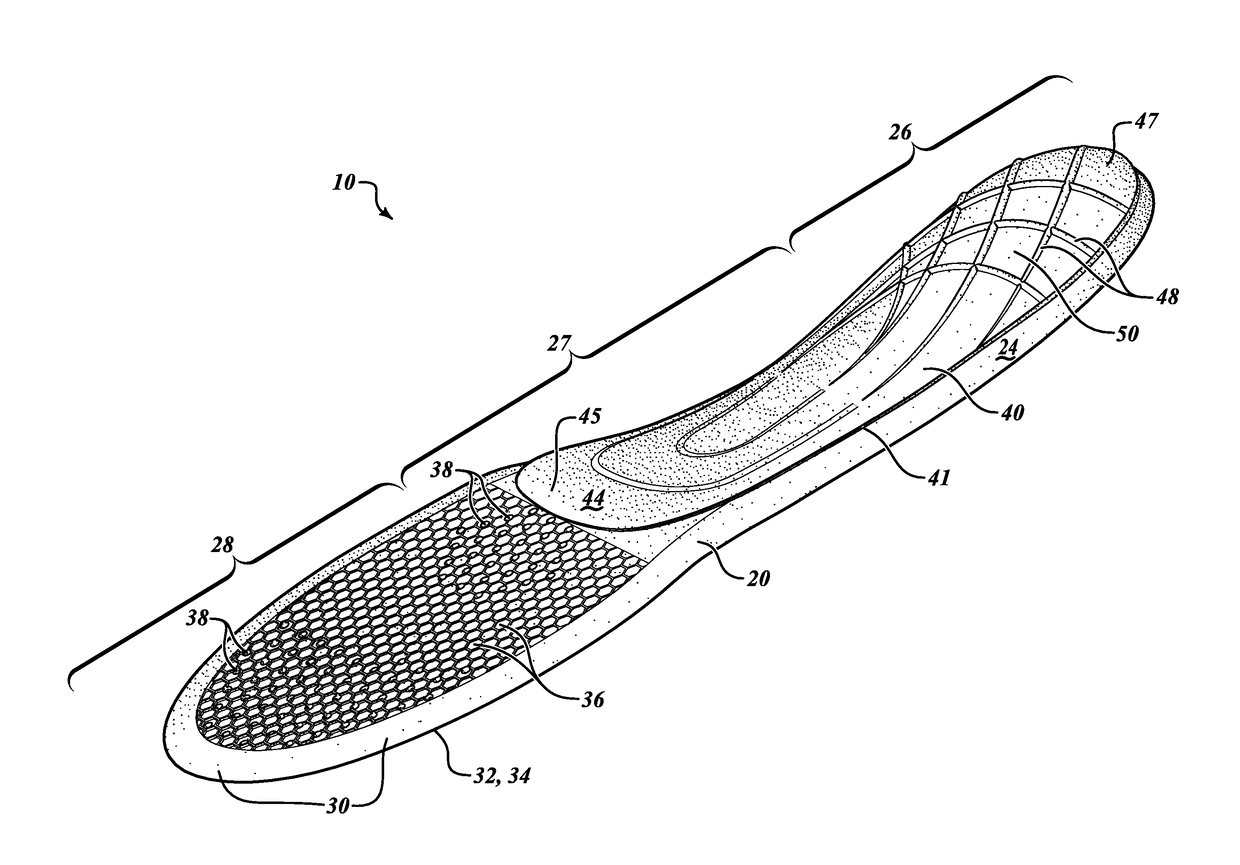

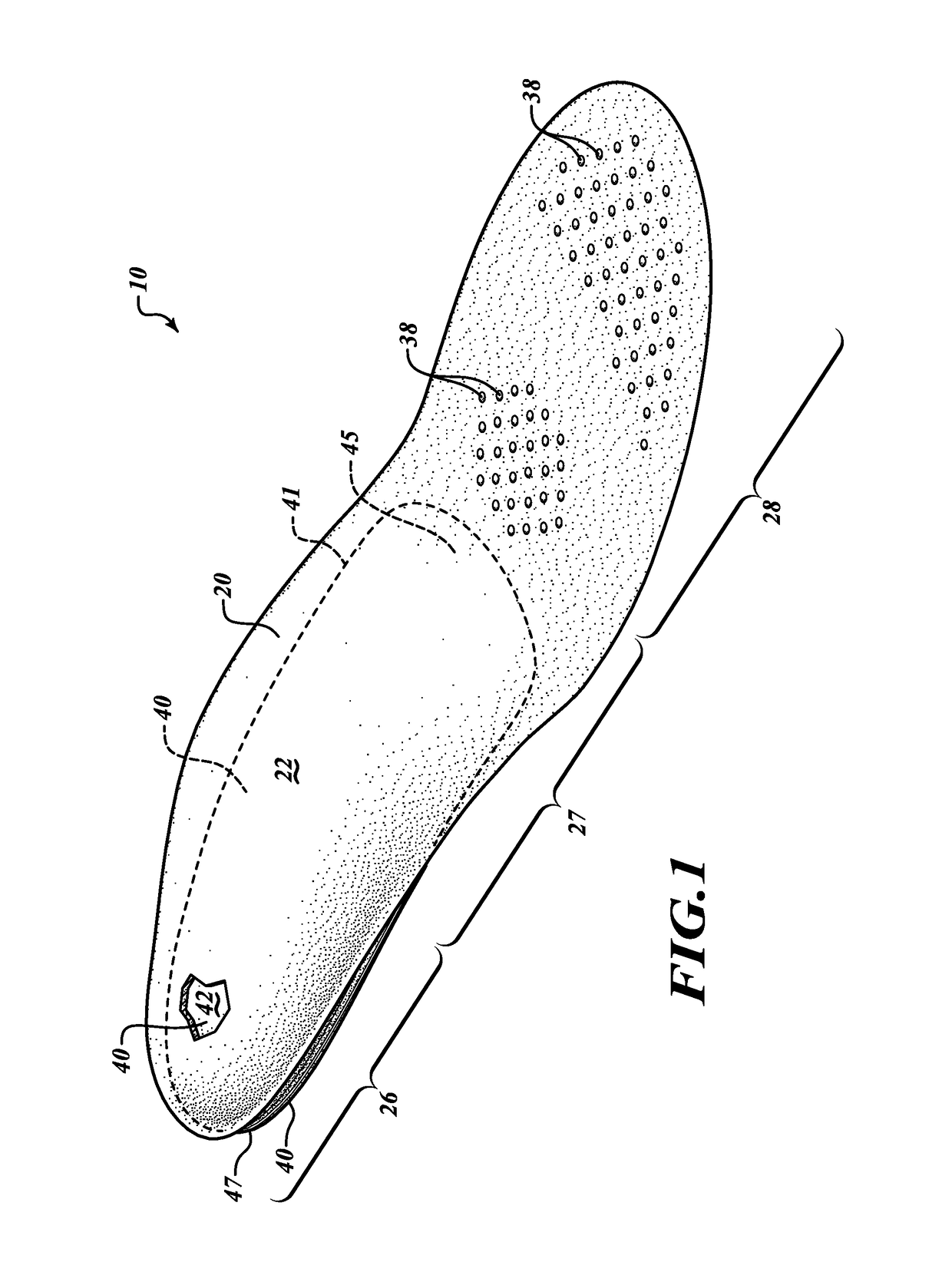

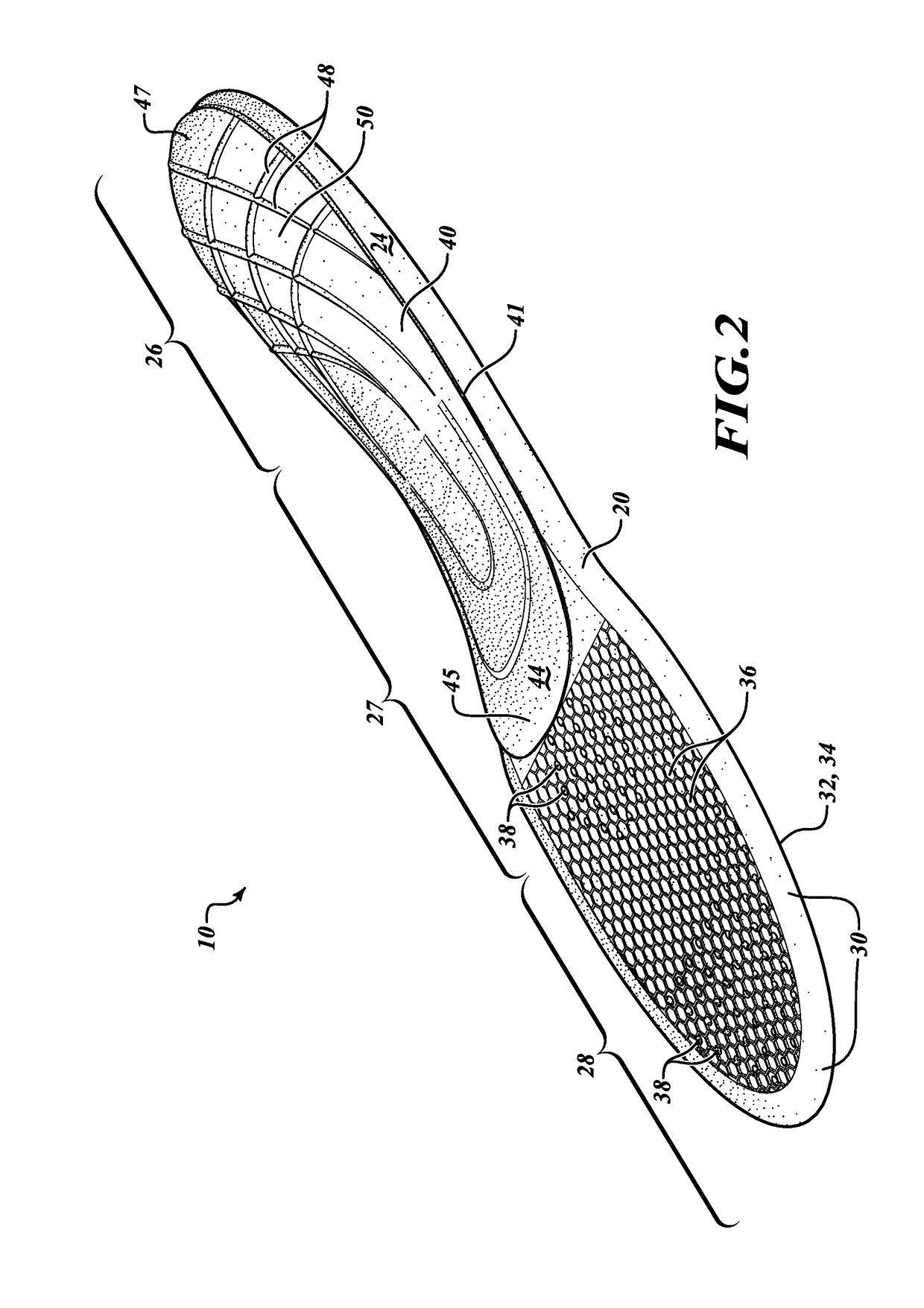

Contoured insoles for footwear

An insole assembly for use in footwear is provided. The insole assembly generally includes a full-length insole base made of a flexible and resilient material (e.g., resiliently compressible foam), and a heel cap made of a generally rigid material (e.g., a carbon fiber reinforced polymer) which is attached to the insole base and mimics the contours thereof to provide proper biomechanical support of the heel and arch areas of a foot in a particularly lightweight and sleek form factor.

Owner:SUPERFEET WORLDWIDE LLC

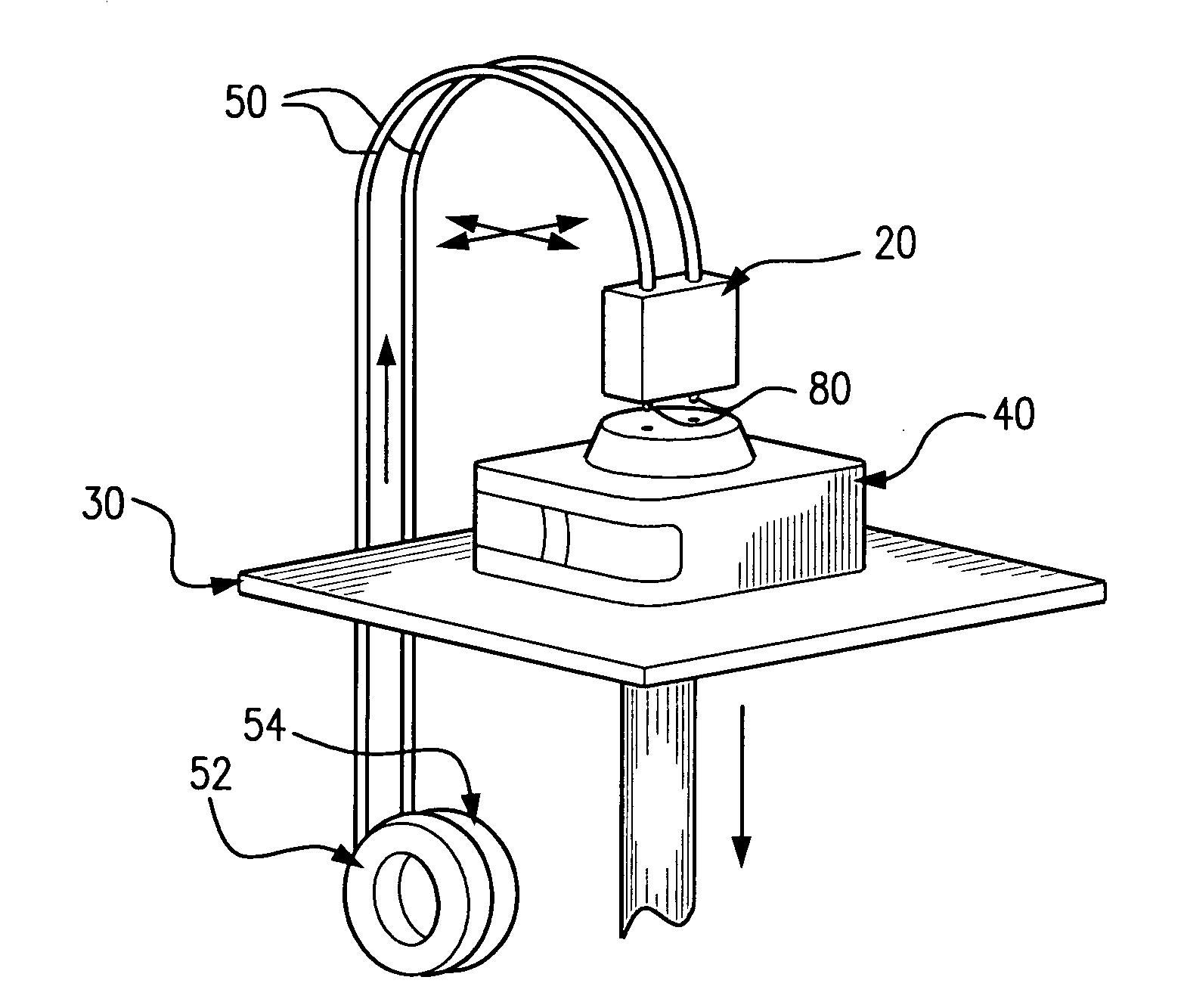

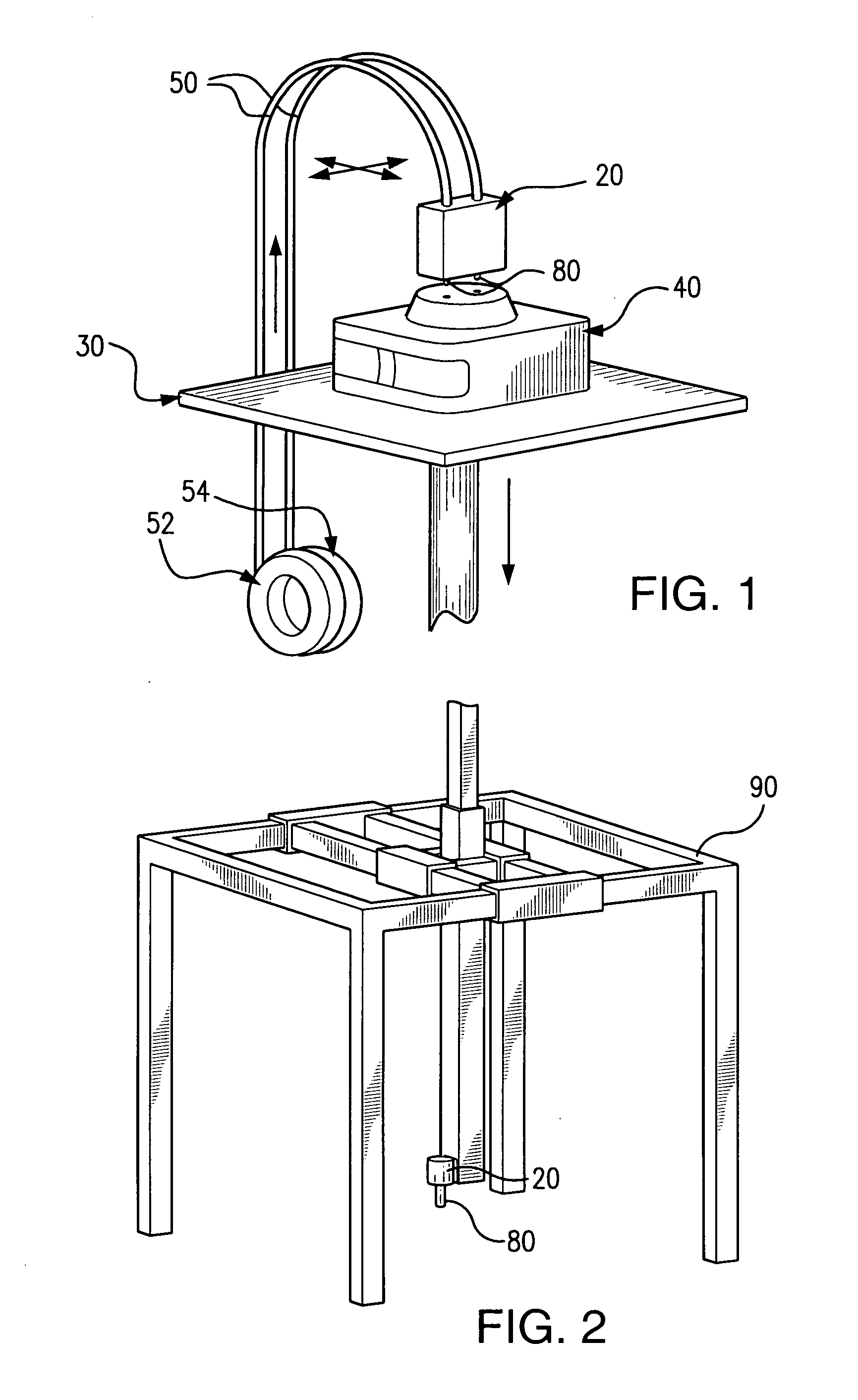

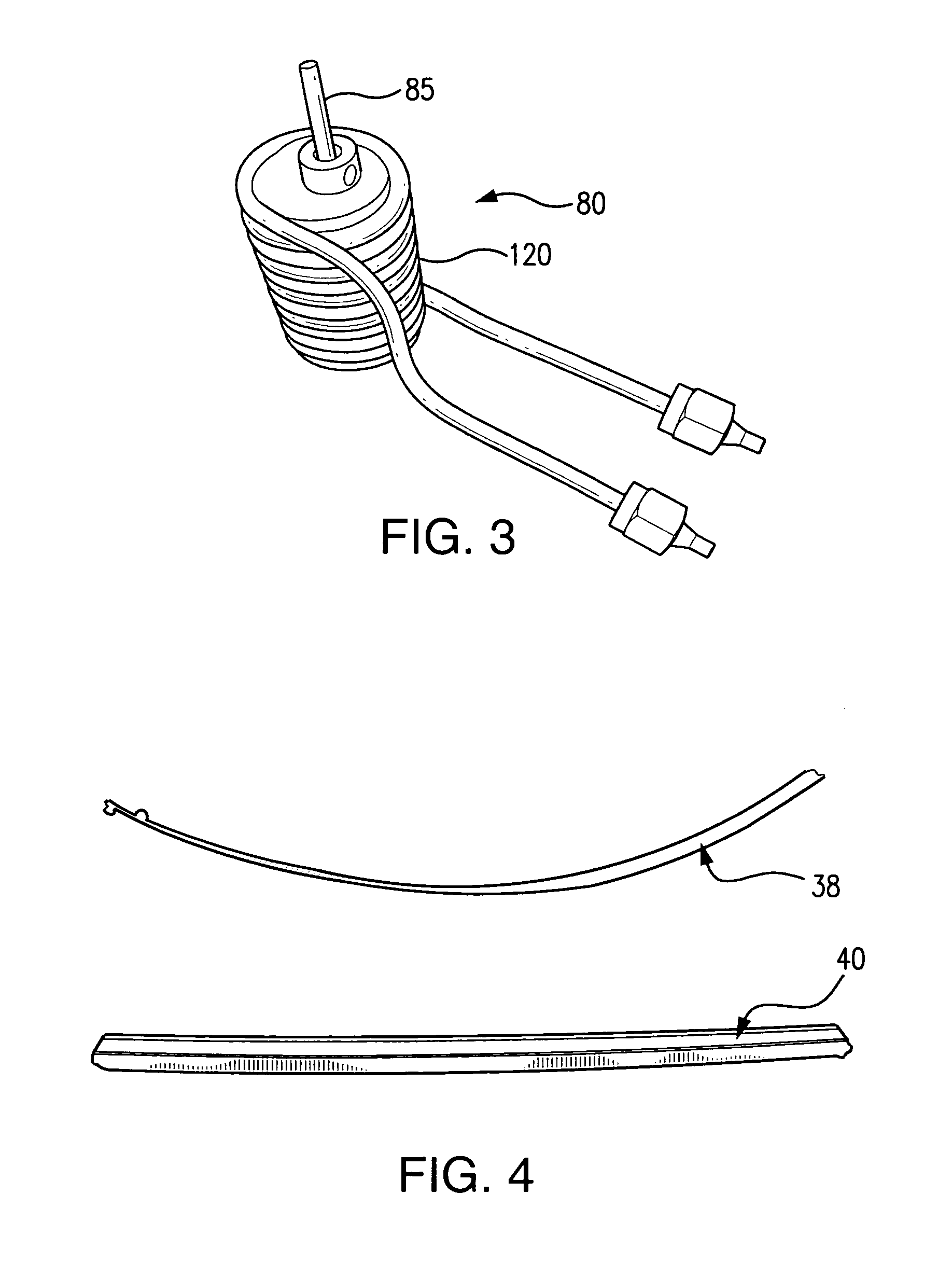

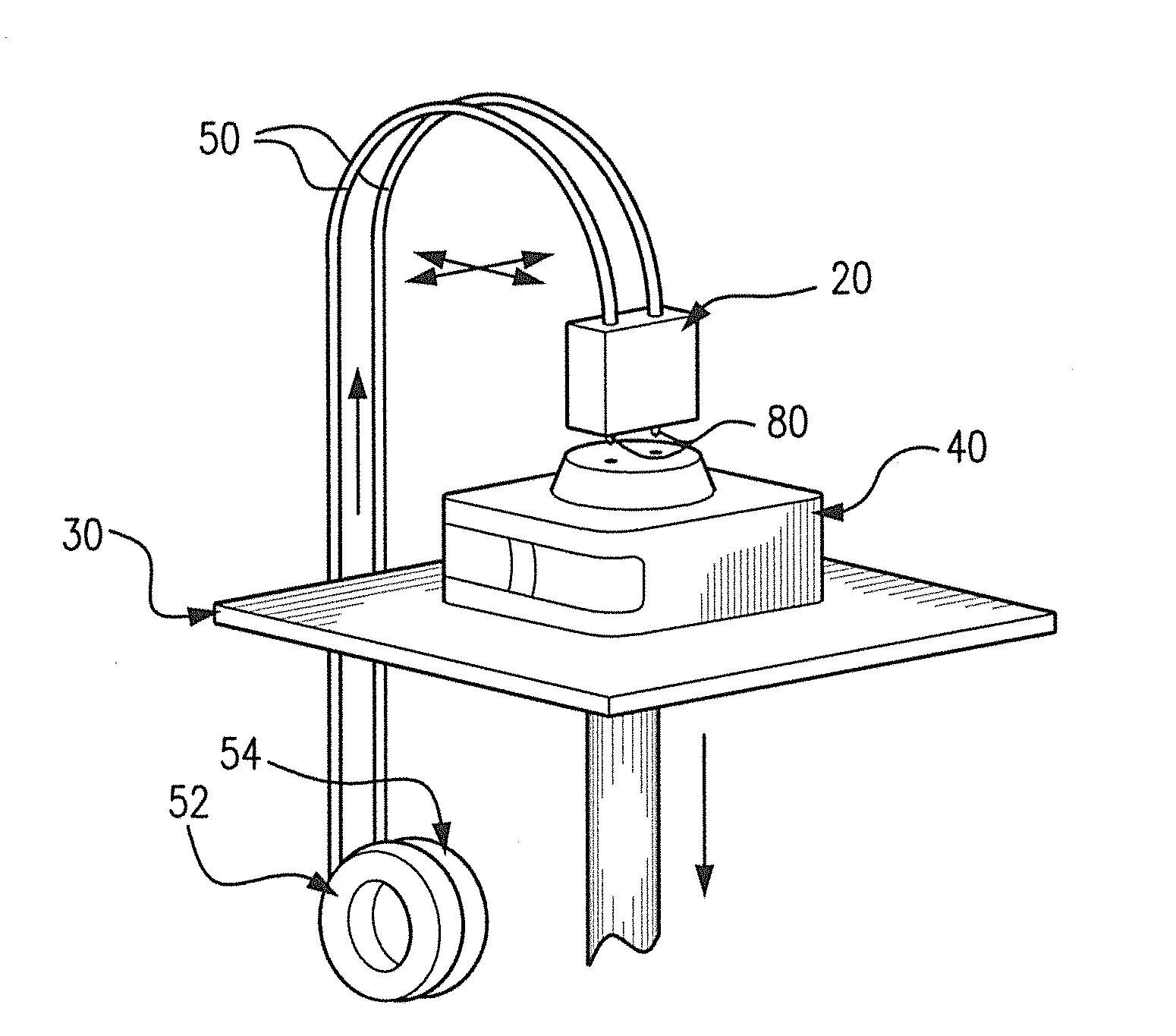

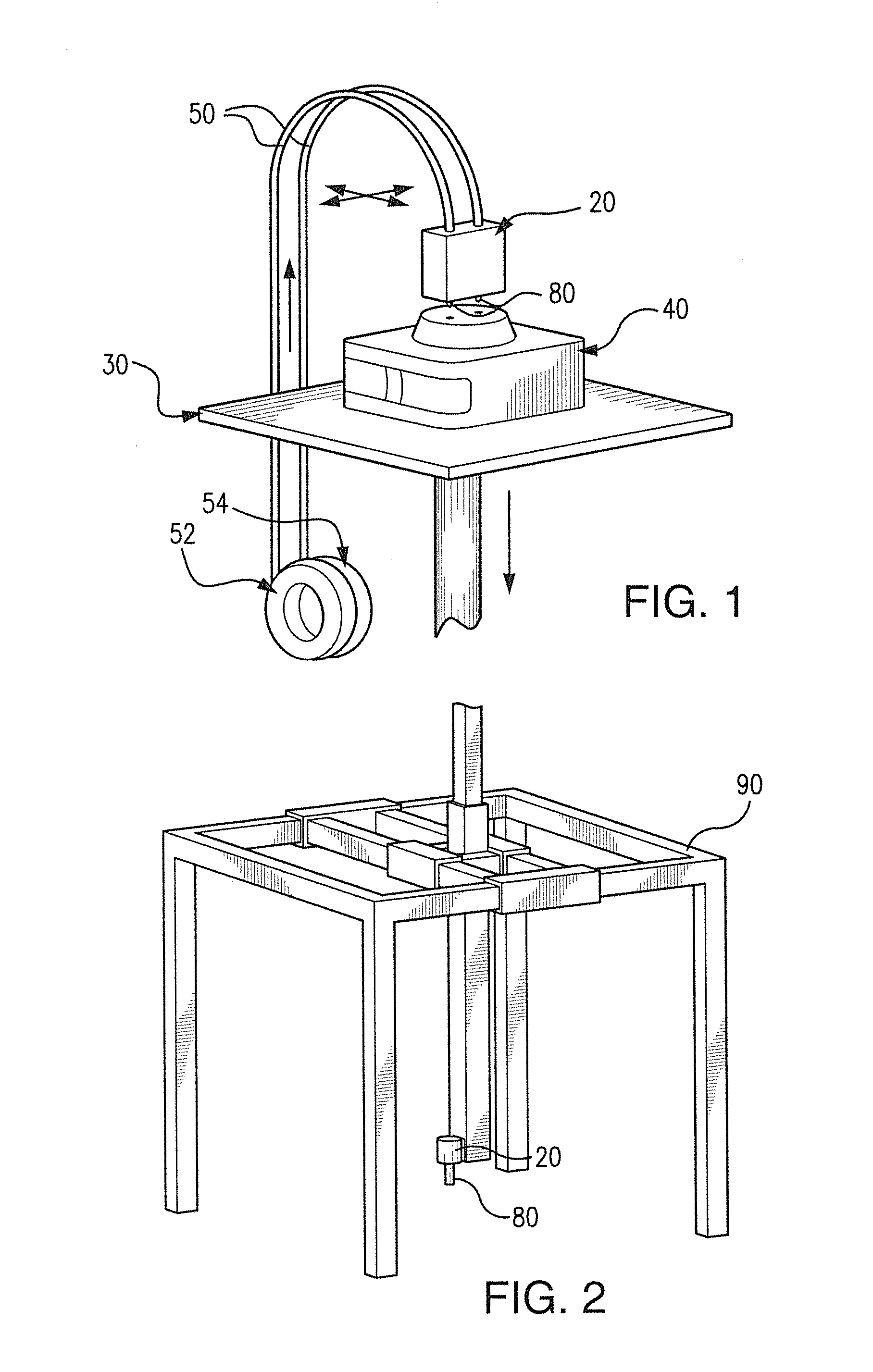

Large scale room temperature polymer advanced manufacturing

InactiveUS20150183159A1Aid in structural stabilityHigh strengthAdditive manufacturing apparatusMouldsAtmospheric temperatureRoom temperature

A manufactured component, method and apparatus for advanced manufacturing that includes a nozzle for extruding a working material, wherein the polymeric working material includes a carbon fiber reinforced polymer. The build of the component takes place on a work surface at atmospheric temperatures.

Owner:UT BATTELLE LLC

Large scale room temperature polymer advanced manufacturing

InactiveUS20170057160A1Removing sizeElimination temperatureAdditive manufacturing apparatusAdditive manufacturing with liquidsAtmospheric temperatureRoom temperature

A manufactured component, method and apparatus for advanced manufacturing that includes a nozzle for extruding a working material, wherein the polymeric working material includes a carbon fiber reinforced polymer. The build of the component takes place on a work surface at atmospheric temperatures.

Owner:UT BATTELLE LLC

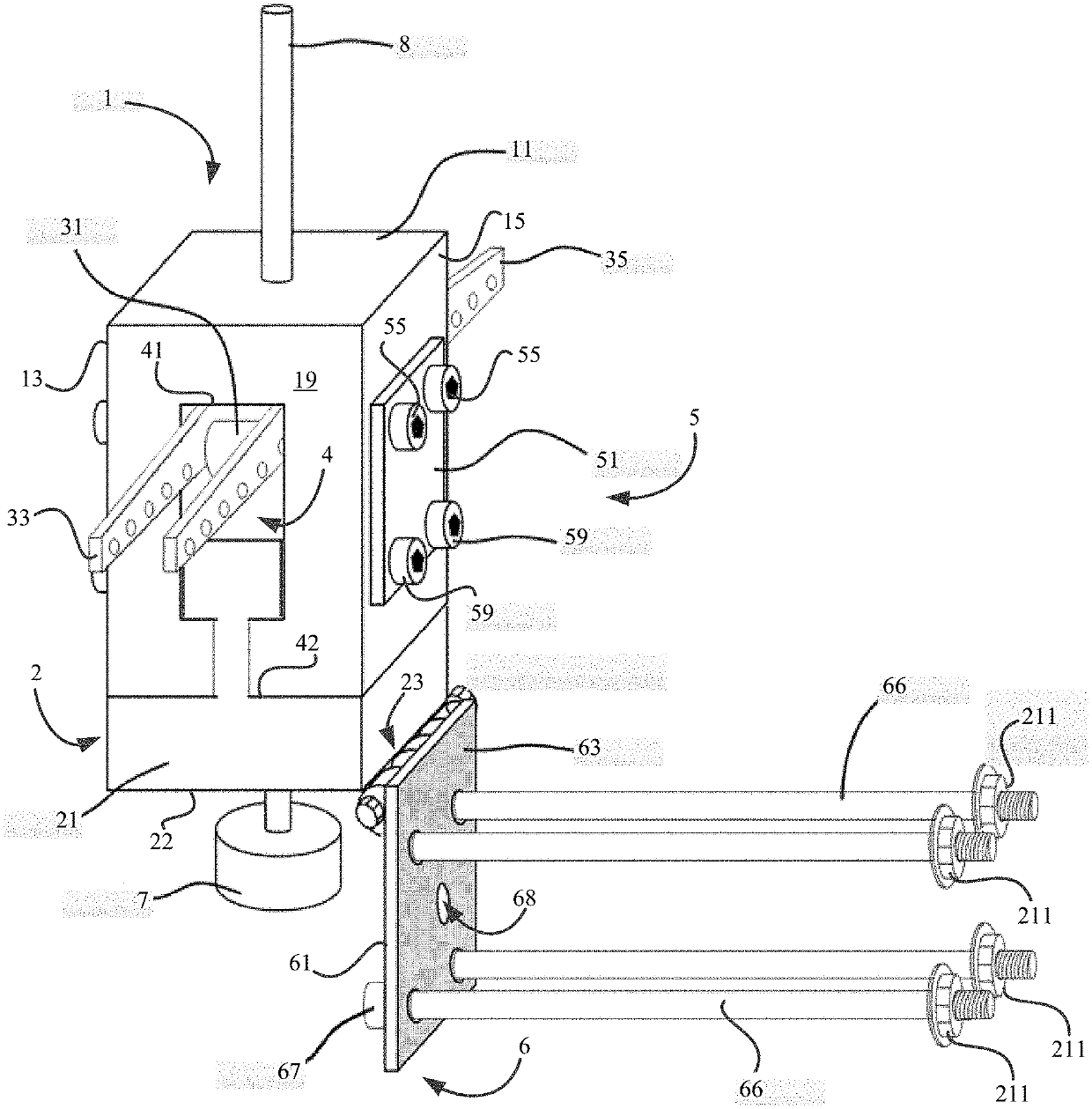

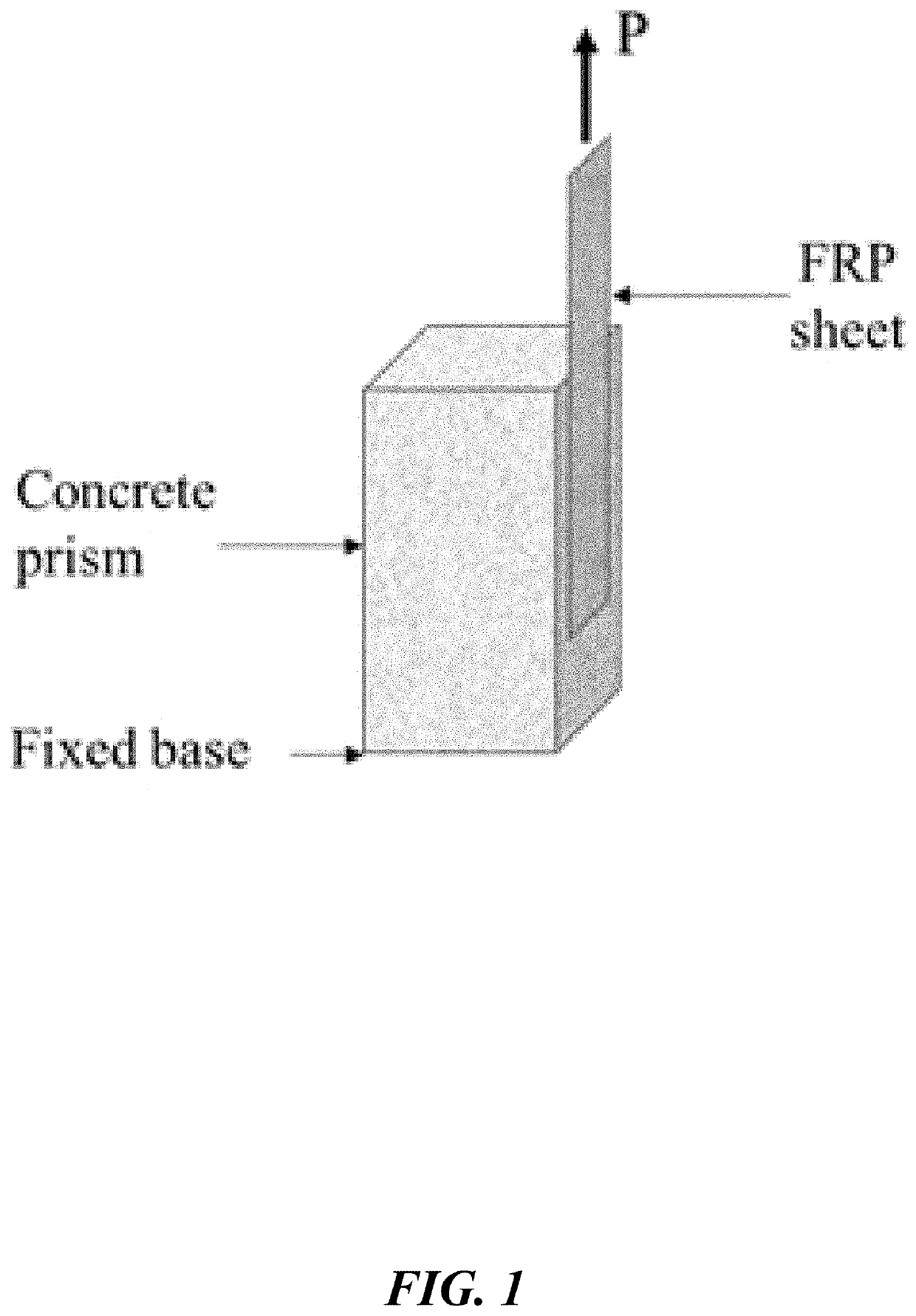

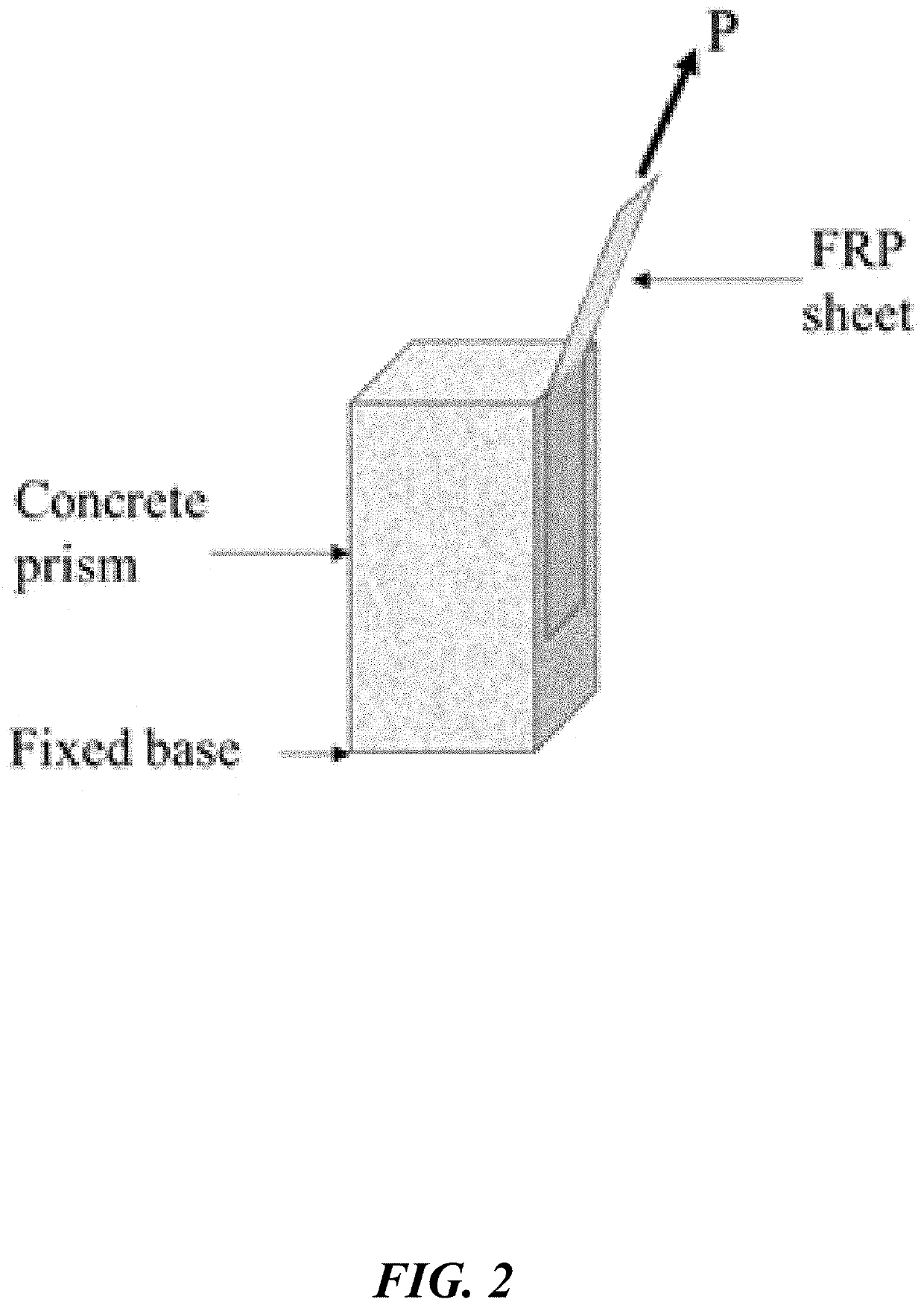

Universal debonding test apparatus for carbon fiber reinforced polymer – concrete system and method for sequential multi-testing

ActiveUS20210033522A1Improve abilitiesMinimize eccentricityEarth material testingUsing mechanical meansMechanical engineeringPolymer

A test apparatus used for simulating debonding between a carbon fiber reinforced polymer (CFRP) and concrete in a CFRP-strengthened structure consists of a primary structural block, a secondary structural block, an adjustable hanger, a receiving slot, an attachment mechanism, a pull-off disk, a connecting plate having a plurality of rods. The adjustable hanger and the secondary structural block are slidably positioned into the receiving slot that traverses into a structural body of the primary structural block. The adjustable hanger is mainly used during double-shearing tests and mixed-mode tests, wherein both shearing and peeling is analyzed in mixed-mode tests. The secondary structural block is used in double-shear tests, mixed-mode tests, single-shear tests, tension pull-off tests, and beam-bend tests. The attachment mechanism, which holds the primary structural block, the secondary structural block, and the adjustable hanger together, is also used during single-shear tests and beam-bend tests.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

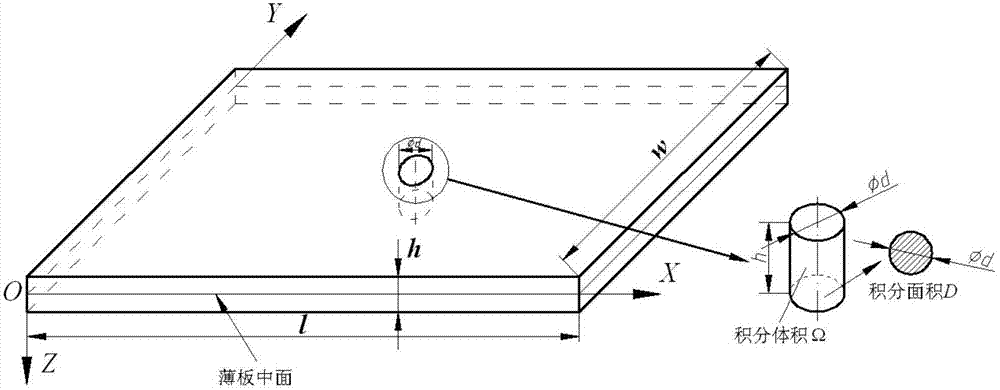

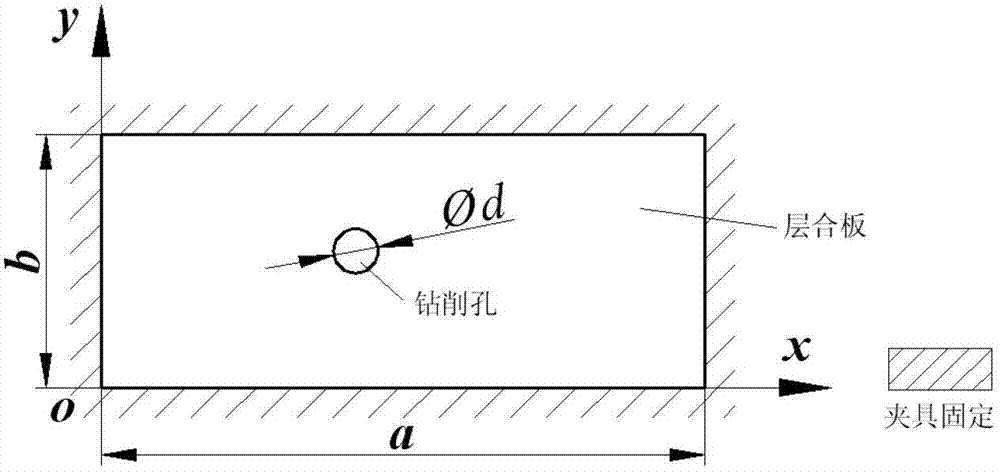

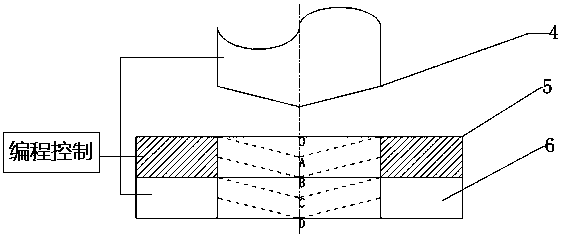

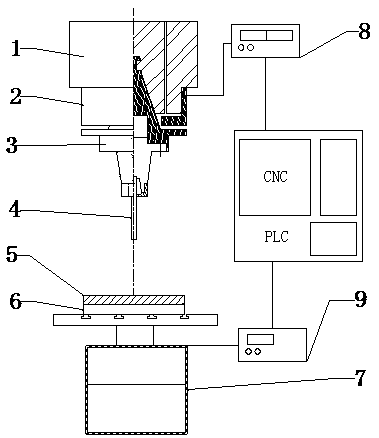

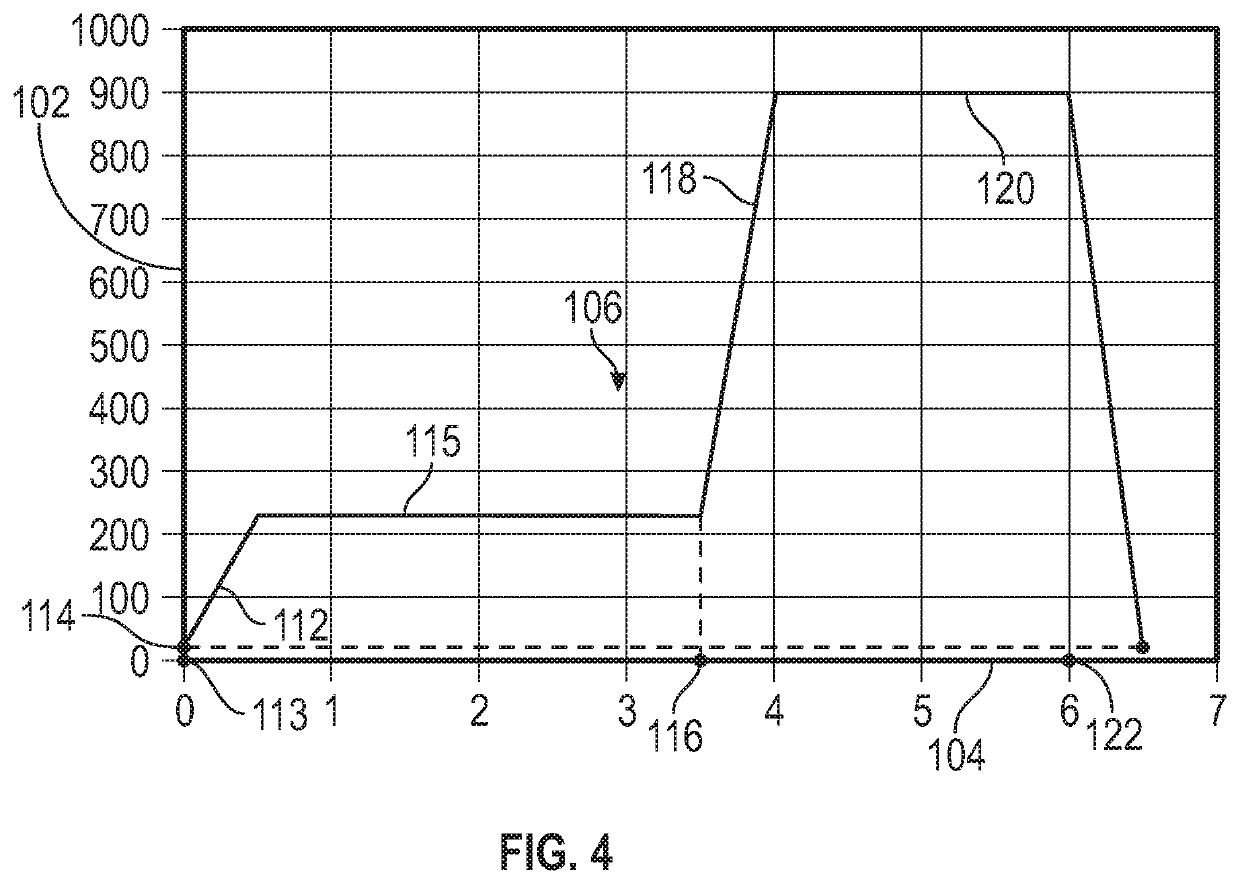

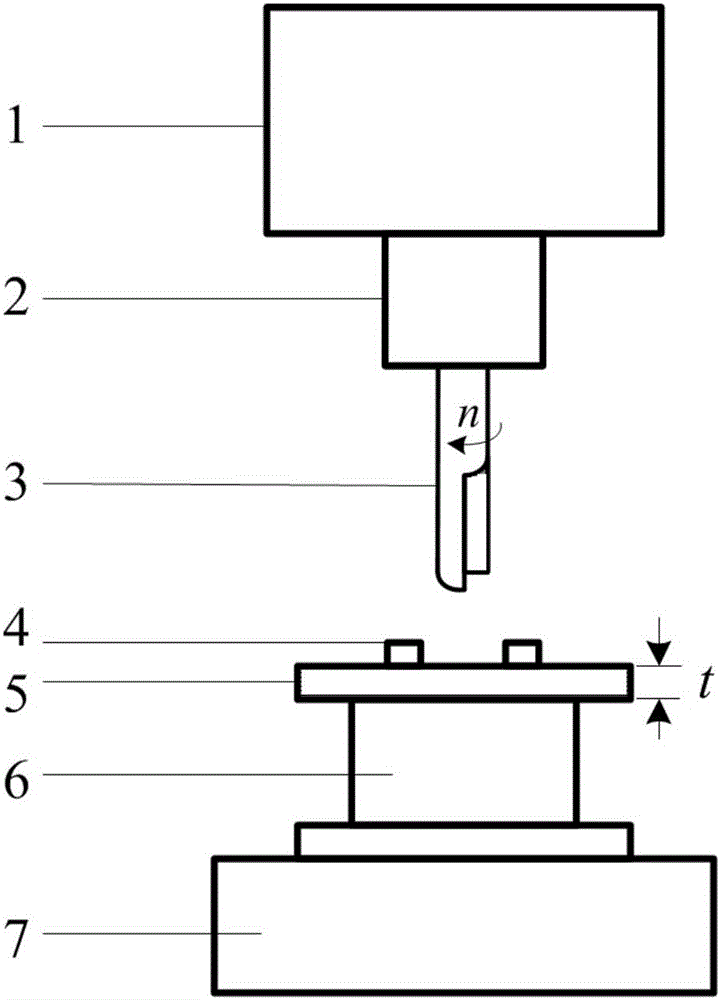

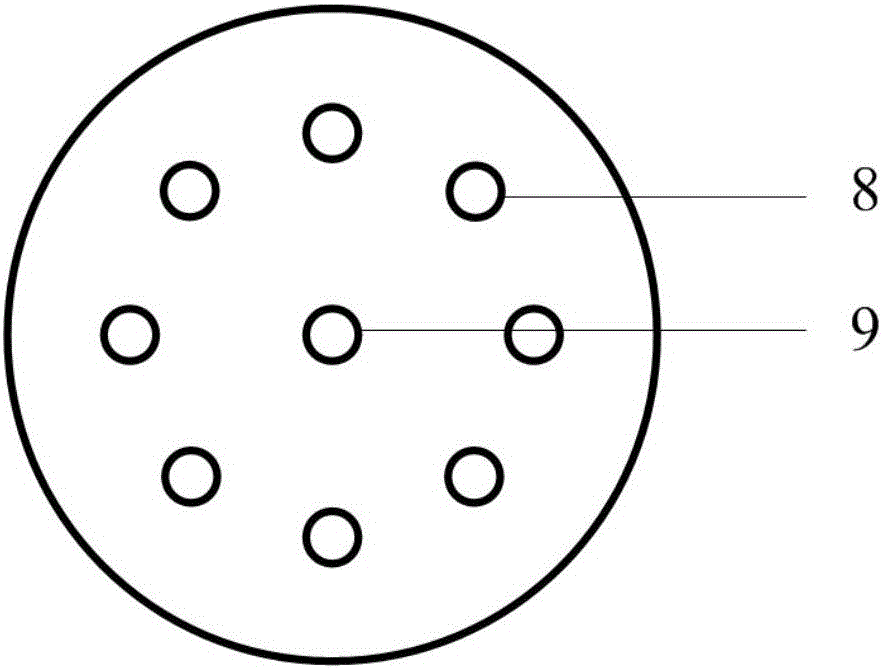

Non-delamination drilling method based on drilling force control for carbon fiber reinforced polymer (CFRP) laminate

InactiveCN102896660ARealize delamination-free drillingAvoid Delamination Damage DefectsMetal working apparatusStable stateAxial force

The invention discloses a non-delamination drilling method based on drilling force control for a carbon fiber reinforced polymer (CFRP) laminate. In the method, in a process of drilling a carbon fiber reinforced polymer (CFRP) laminate with a drill bit, the drilling axial force of the drill bit is controlled to be always smaller than a drilling delamination critical thrust value Fa, wherein Fa is determined by the following steps of: establishing a delamination stable state equation of the CFRP laminate; establishing a polar equation of a small-deflection sheet and a CFRP laminate defection formula of the drill bit during drilling to evaluate the maximum deflection value X of the CFRP laminate; establishing a bending deformation energy formula of the CFRP laminate during drilling, and evaluating the bending deformation energy U of the CFRP laminate during drilling of the drill bit; and determining a drilling delamination critical thrust value Fa according to the evaluated maximum deflection X, the bending deformation energy U and the established delamination stable state equation of the CFRP laminate. Due to the adoption of the method, non-delamination drilling processing of the CFRP laminate is realized, the delamination damage defect of drilling is avoided, the product quality is improved, the cost is lowered, and the efficiency is increased.

Owner:SHANGHAI JIAO TONG UNIV

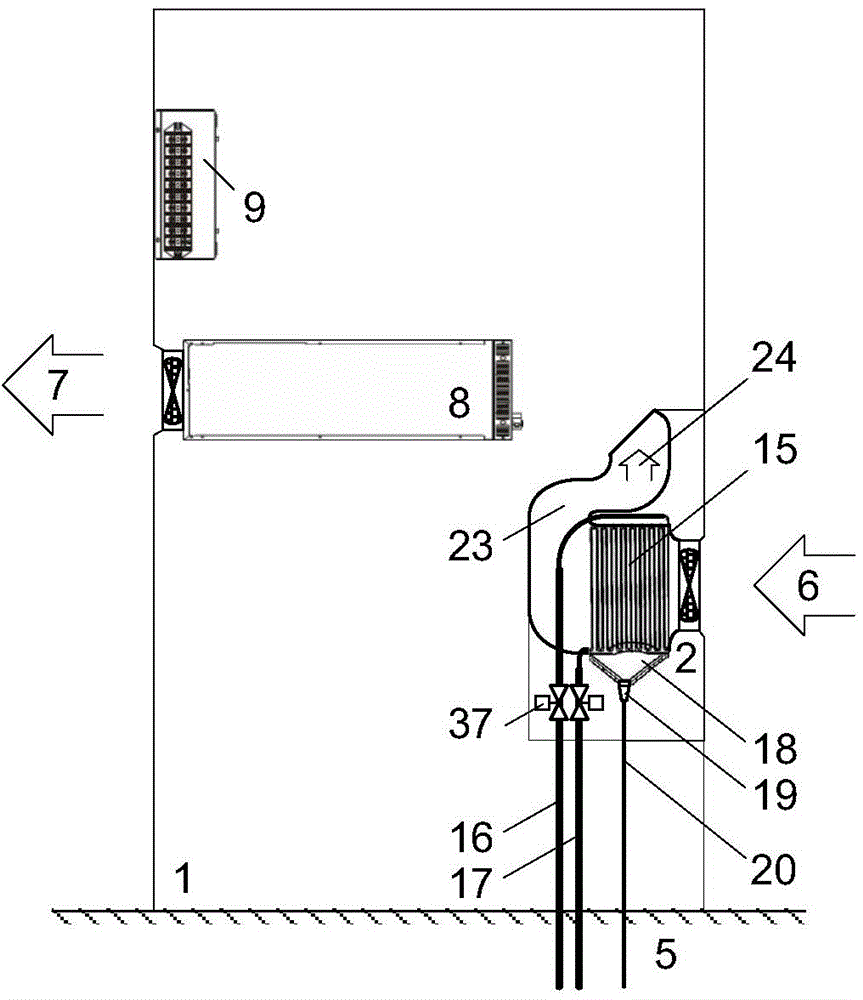

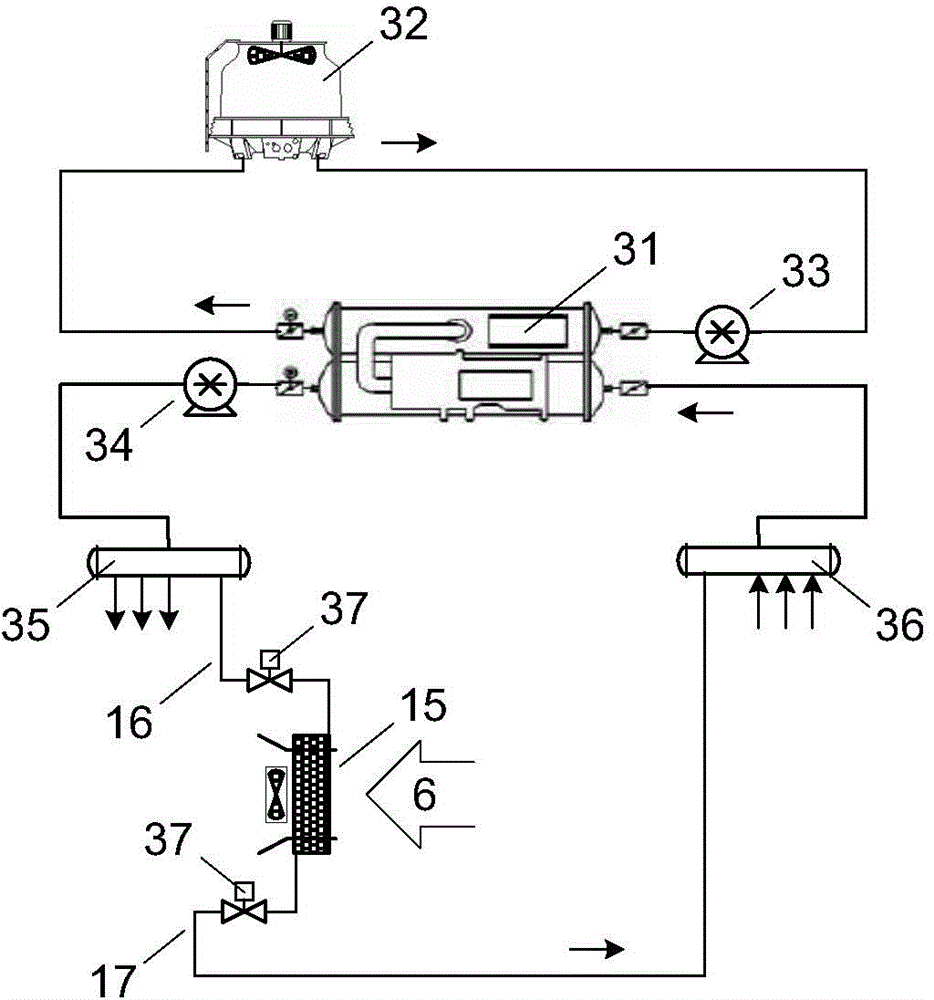

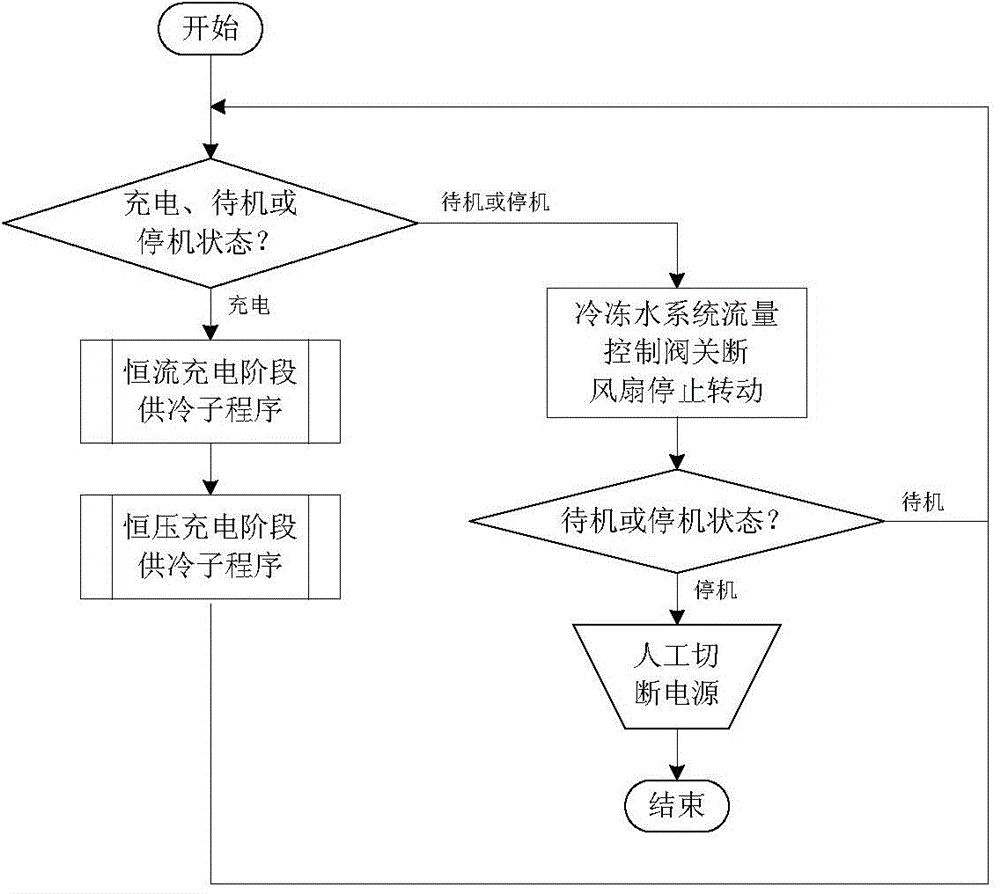

Electric vehicle charger air-cooling system conducting precooling through chilled water and control method thereof

ActiveCN104362700AShorten the timeReduce noiseBatteries circuit arrangementsModifications for power electronicsCooling effectAir cooling system

The invention provides an electric vehicle charger air-cooling system conducting precooling through chilled water and a control method of the electric vehicle charger air-cooling system. The system comprises a cabinet, wherein a lower back plate of the cabinet is provided with an air inlet, and an upper front face plate of the cabinet is provided with an air outlet; an air inlet fan and a refrigerating coil are sequentially arranged at the front end of the air inlet, and a pipeline of the refrigerating coil is vertically arranged at one end of an air inlet of an S-shaped air pipe; an air outlet of the S-shaped air pipe points to the upper front of the cabinet; the refrigerating coil is made of heat conduction continuous carbon fiber reinforced polymer (CFRP) matrix composites; an exhaust fan and a charging module are sequentially arranged at the rear end of the air outlet of the cabinet; a control device is arranged above the charging module. With respect to a high-power indoor charger, the system avoids the situation that the cooling effect is poor because hot air accumulates in a charging room; with respect to an outdoor charger, the system solves the contradiction between cabinet shell protection and power device heat dissipation and enables a high-power charger to become the outdoor charger and be installed, put into operation and used outdoors.

Owner:STATE GRID CORP OF CHINA +1

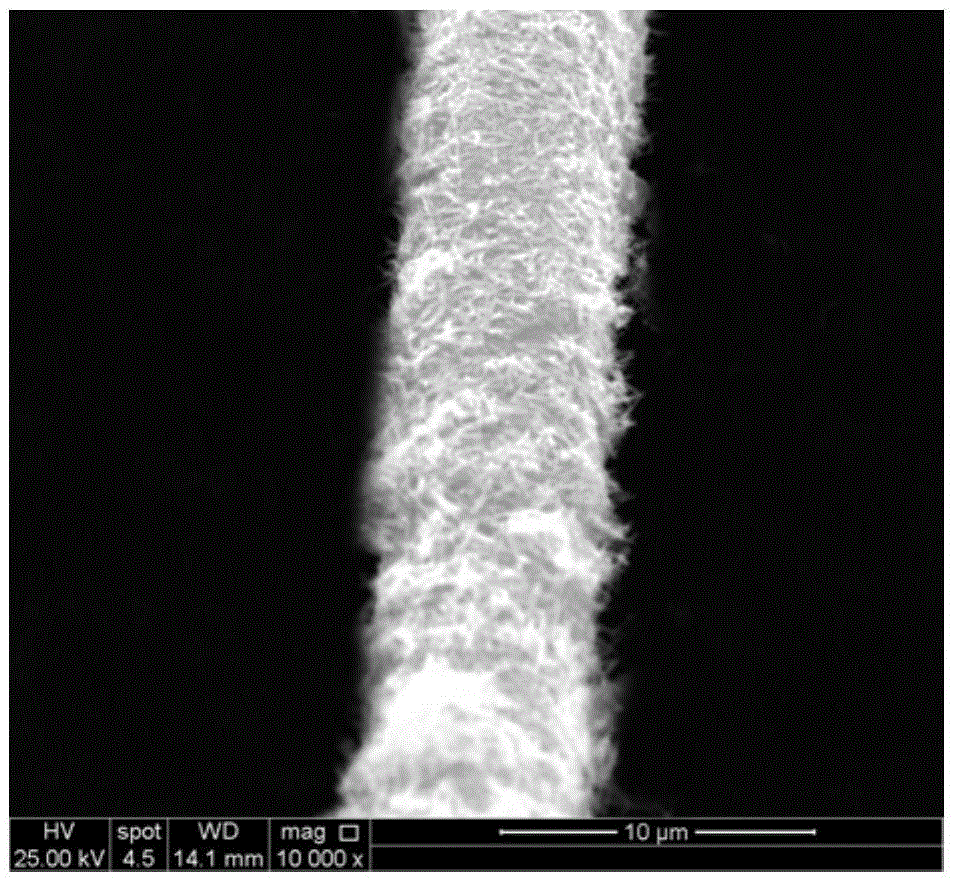

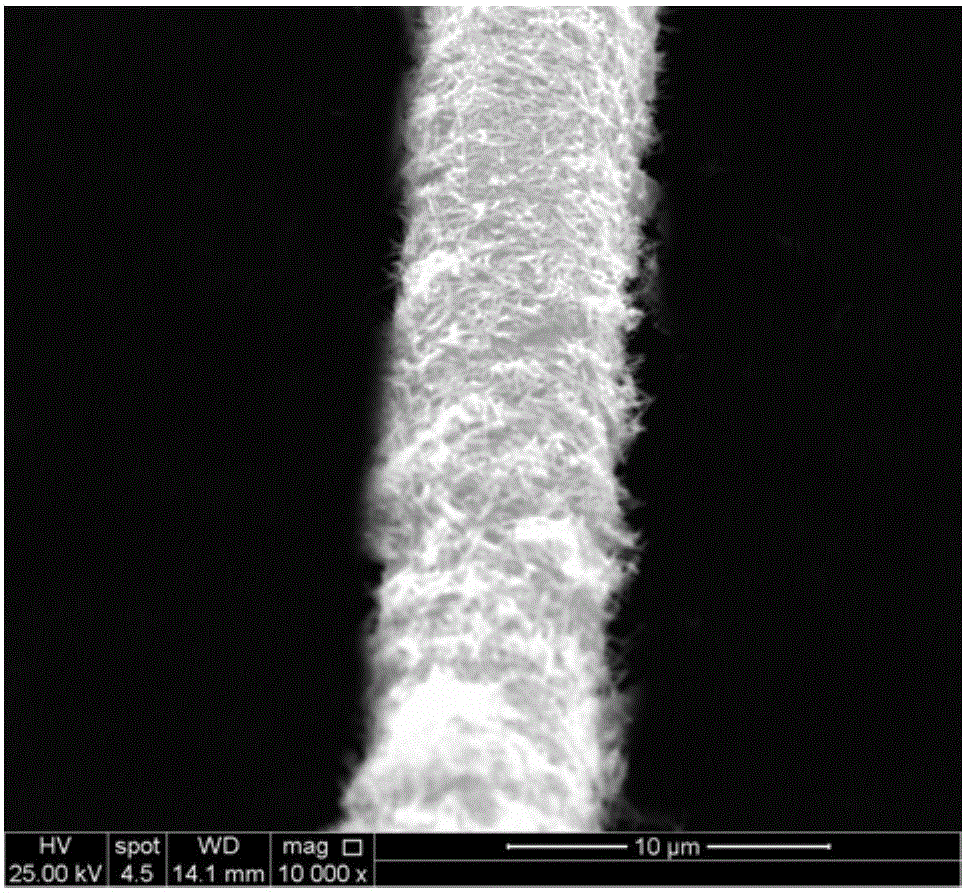

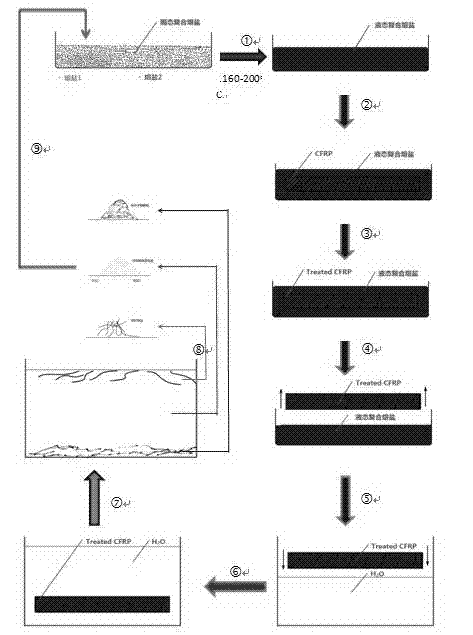

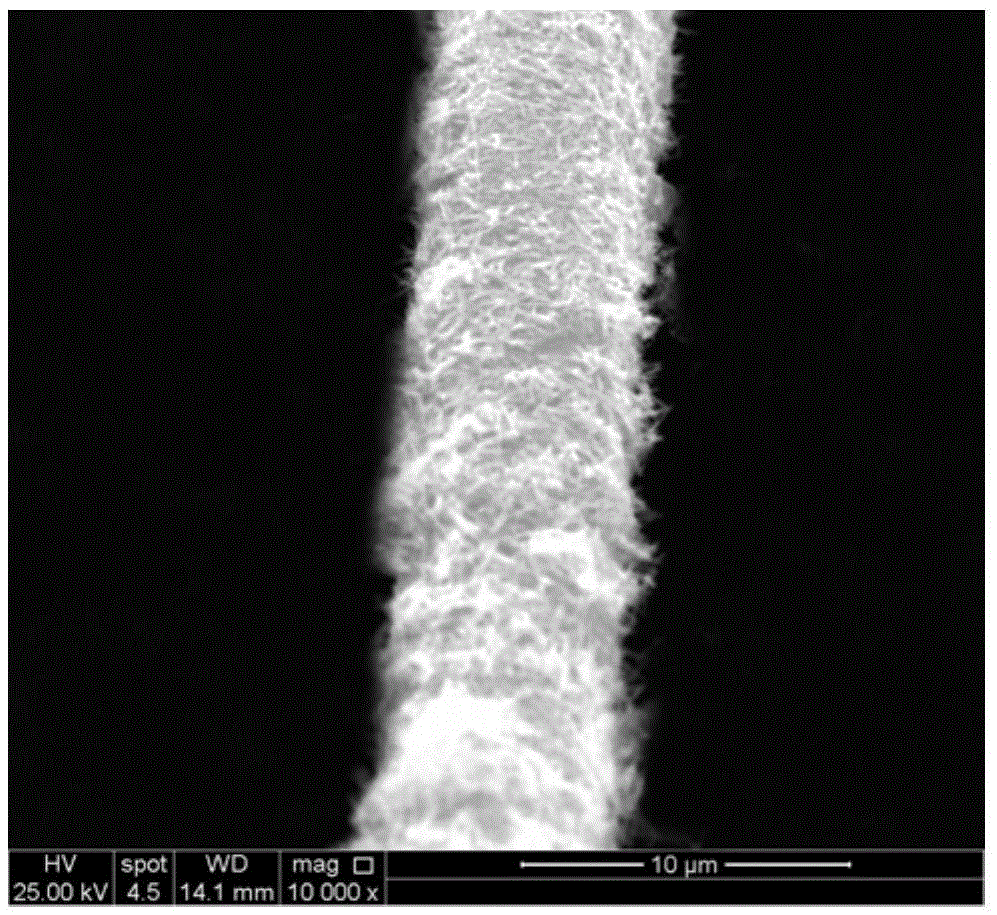

Preparation method and application of carbon fiber reinforced polymer-based composite material

ActiveCN105600770AShort preparation cycleThe process is simple and easy to controlHybrid capacitor electrodesCell electrodesFiberInorganic compound

The invention discloses a preparation method and application of a carbon fiber reinforced polymer-based composite material. The preparation method comprises the following steps: putting a salt solution for an inorganic compound into a reaction kettle, and putting a base material for inducing an alternating magnetic field into the reaction kettle; sealing the reaction kettle and putting in hydrothermal induction heating equipment; cooling the reaction kettle to room temperature; taking out the base material loaded with the inorganic compound, and cleaning and drying; and finally, performing hot-press moulding to obtain the carbon fiber reinforced polymer-based composite material. In the invention, the hydrothermal induction heating technology is applied to the surface grafting of carbon fiber, and the shortcoming of difficult combination with other components caused by the surface inertia of carbon fiber is overcome. Moreover, under the effect of alternating magnetic field, the high temperature of carbon fiber promotes the growth of multiple nano materials on the surface thereof, more meshing sites are provided for the combination of carbon fiber and resin, and the interface bonding between the carbon fiber and resin as well as the mechanical properties of the composite material are improved.

Owner:SHAANXI UNIV OF SCI & TECH

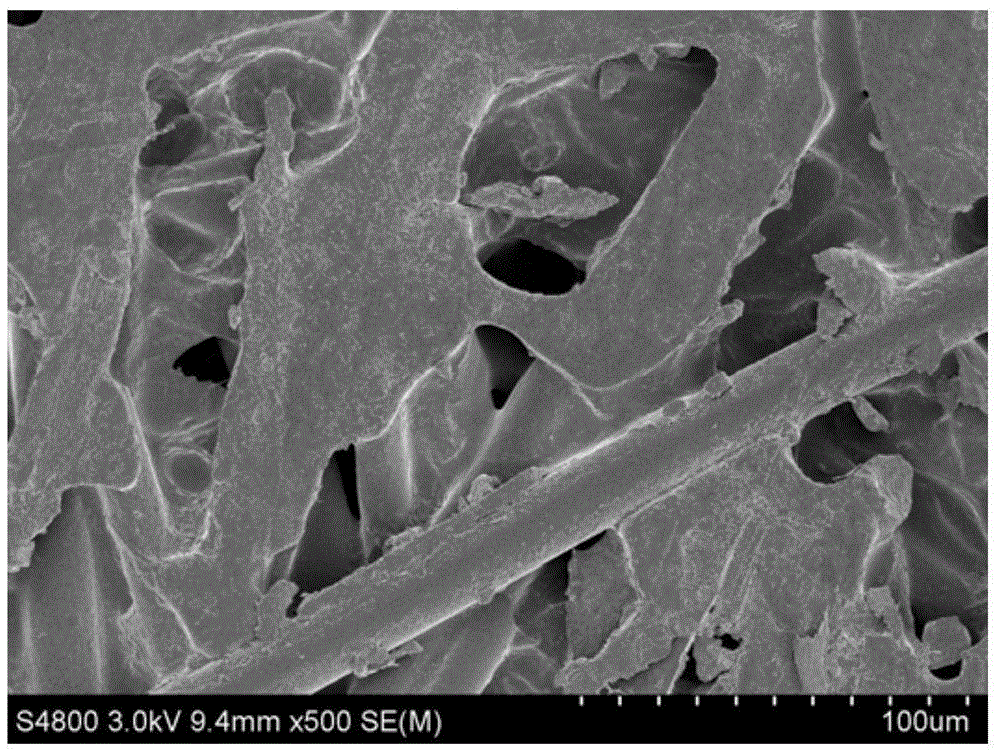

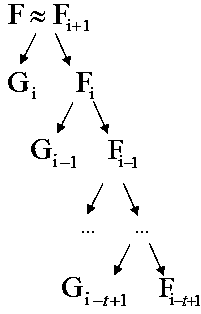

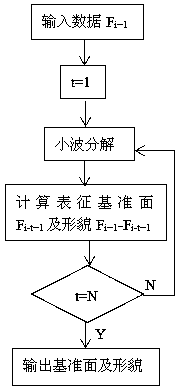

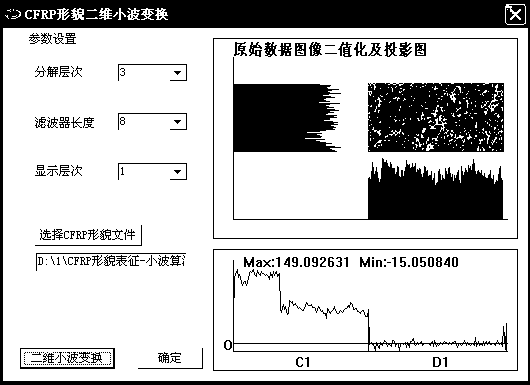

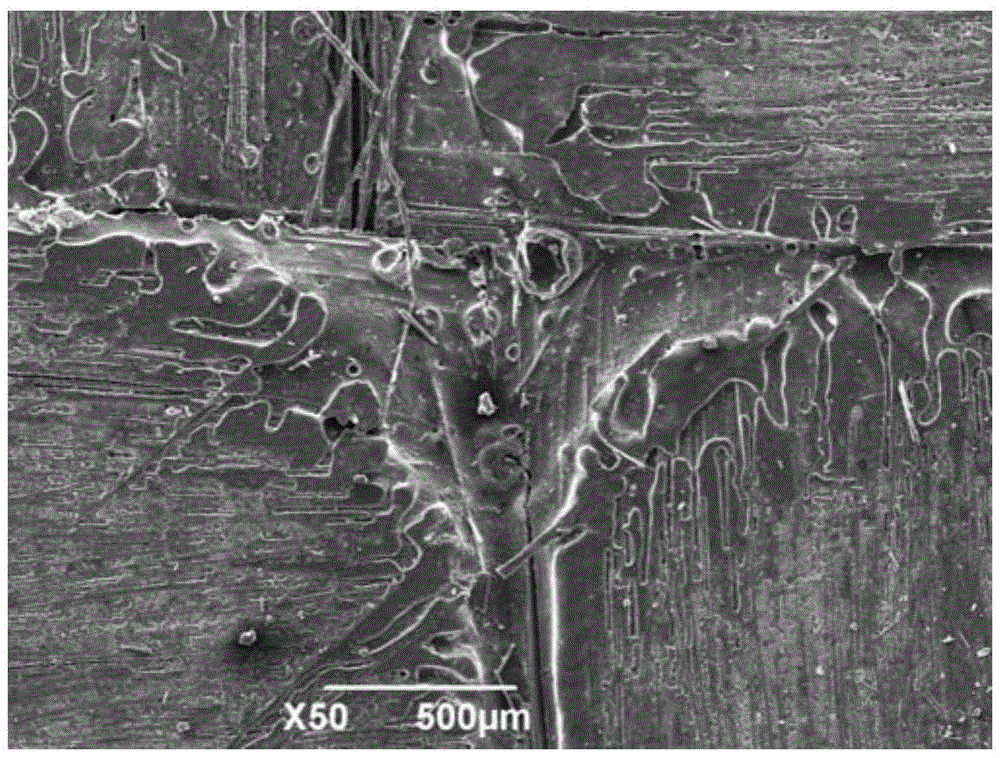

Carbon fiber reinforced polymer (CFRP) machined surface appearance representation method

The invention provides a carbon fiber reinforced polymer (CFRP) machined surface appearance representation method. The method includes the steps that a to-be-represented workpiece is a continuous curve block on a bounded domain, and a surface appearance characteristic function F(x,y) is measured; wavelet component division is carried out on the appearance characteristic function F(x,y) of the three-dimensional surface of the bounded domain, and representation of the surface appearance is further carried out. The method is based on a wavelet assessment reference, machined surface appearance of the CFRP is truly reflected, and meanwhile the machined surface appearance which is precisely represented is obtained by calculating representation parameters. According to a wavelet theory, a multi-fractal spectrum of the machined surface of the CFRP is calculated by means of a wavelet transform method, and multi-fractal parameters are identified to represent characteristics of the machined surface appearance of the CFRP. An appearance representation model is built on the basis of multi-fractal characteristic analysis of the machined surface of the CFRP, the characteristics of the whole machined surface can be described, and local appearance characteristics can be described.

Owner:陈慧群

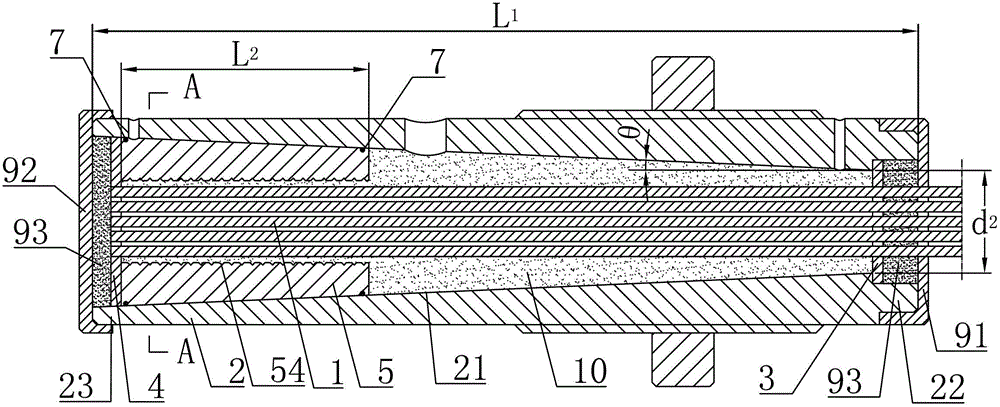

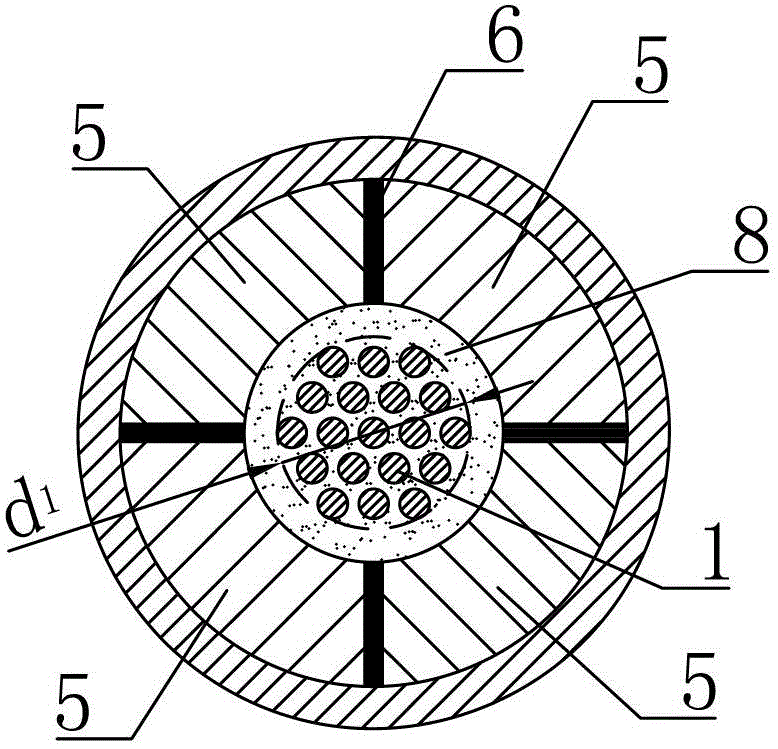

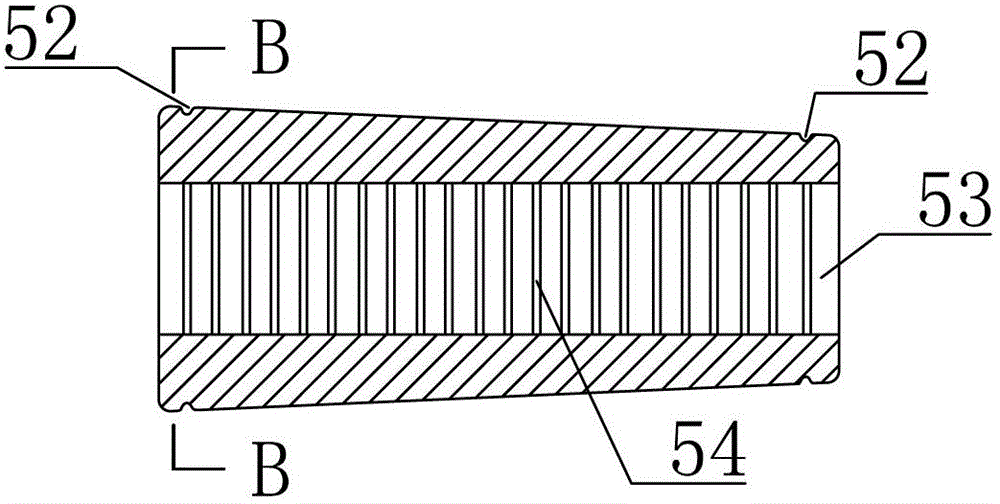

Carbon fiber reinforced polymer rope anchor

ActiveCN102747811AImprove performanceSmall volumeBuilding reinforcementsStress concentrationEngineering

The invention discloses a carbon fiber reinforced polymer (CFRP) rope anchor, which comprises an anchor cylinder for anchoring a CFRP rope, a first plugging board, a second plugging board and an adhesive medium, wherein a conical through hole is coaxially formed in the anchor cylinder. The carbon fiber reinforced polymer rope anchor is characterized in that a clamping piece component surrounding the CFRP rope is arranged in the conical through hole in the free end of the anchor cylinder; and the anchor cylinder is filled with an anti-corrosion material. The carbon fiber reinforced polymer rope anchor has the advantages that compressive stress of the surface of the CFRP rope corresponding to the clamping piece component is far higher than that of the surface of the CFRP rope at other regions, so that the phenomenon of damage of the surface of the CFRP rope at a loading end due to stress concentration is avoided, the distribution form of the compressive stress in an anchoring region is substantially optimized, the internal stress is more rational, the size of the anchor is greatly reduced, and further, the anchoring performance is greatly improved, so that the anchoring efficiency coefficient of the anchor reaches 100 percent, and the anchor has good durability.

Owner:宁海睿翔建设有限公司

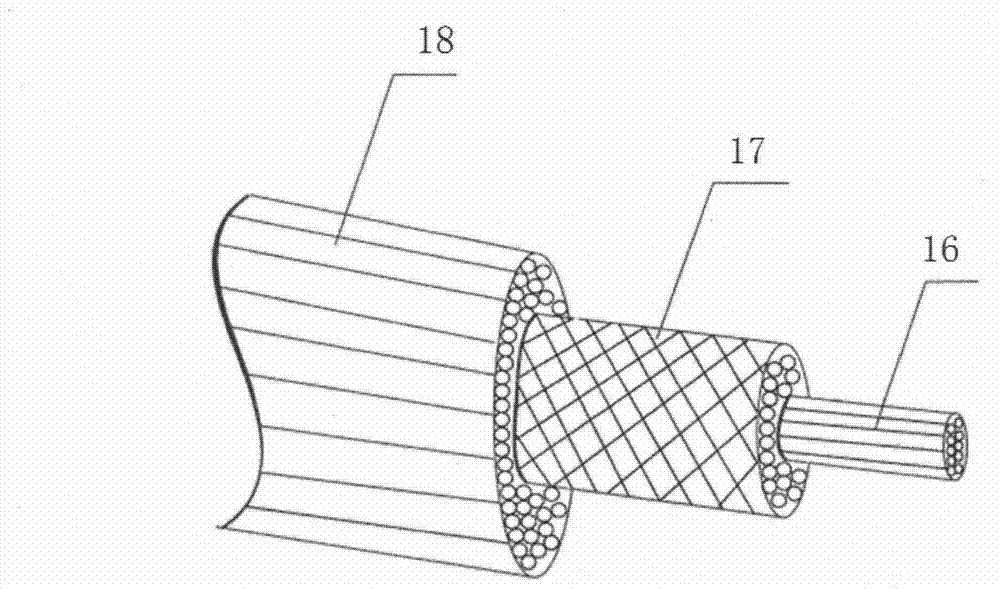

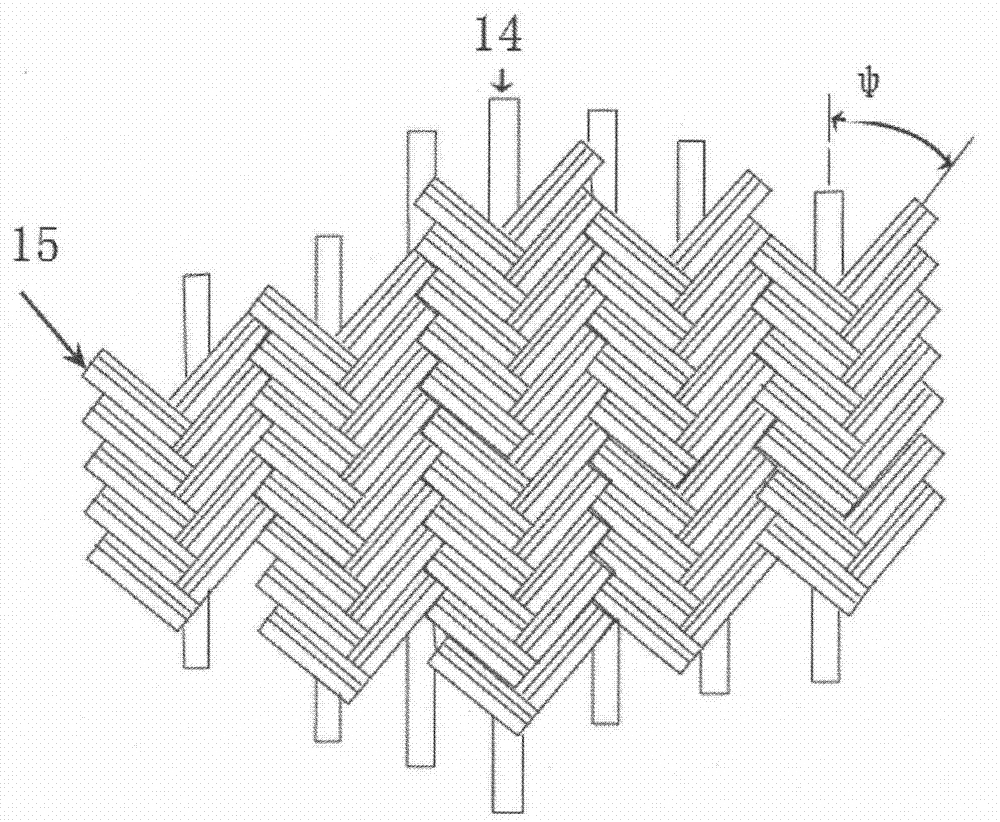

Carbon fiber reinforced polymer cable core with high elongation and production method thereof

The invention discloses a carbon fiber reinforced polymer cable core with high elongation and a production method thereof. The carbon fiber reinforced polymer cable core structure is characterized by comprising a glass fiber insulating layer which is internally provided with a 2D (2-dimension) woven carbon fiber layer. The 2D woven carbon fiber layer is in a rope structure which comprises axial yarns and textile yarns. The axial yarns are made of aramid fibers, and the textile yarns are made of carbon fibers. The inner side of the 2D woven carbon fiber layer is provided with a high-strength glass fiber layer or an aramid fiber layer. The carbon fiber reinforced polymer cable core keeps the advantages of high carrying capacity, high working temperature, resistance to corrosion, light weight, high strength, low relaxation degrees and low loss of existing ACCC (aluminum conductor composite core) cable cores. However the elongation is increased and toughness of the cable core is improved, so that production and application of the cables are facilitated.

Owner:DONGHUA UNIV +1

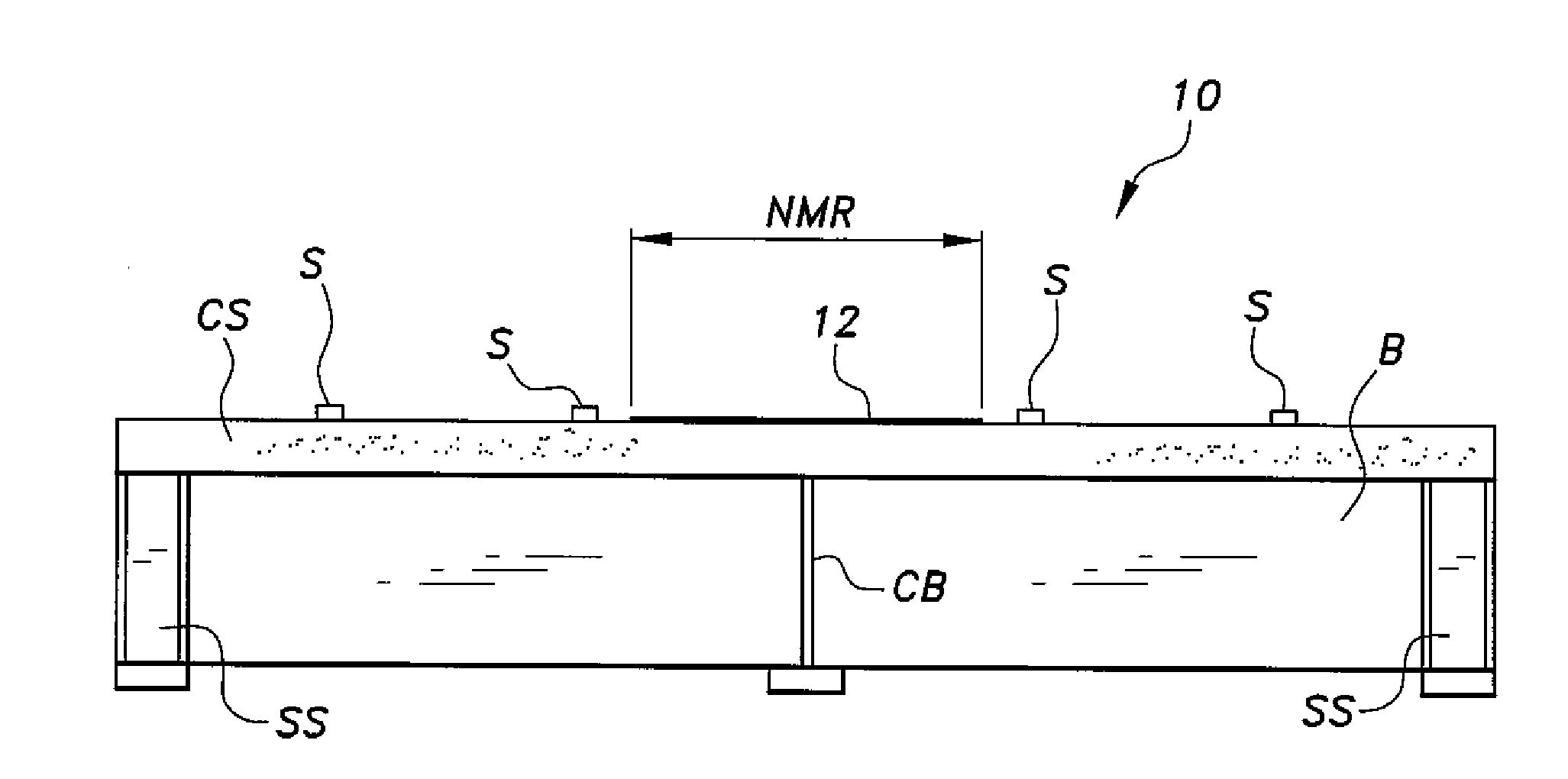

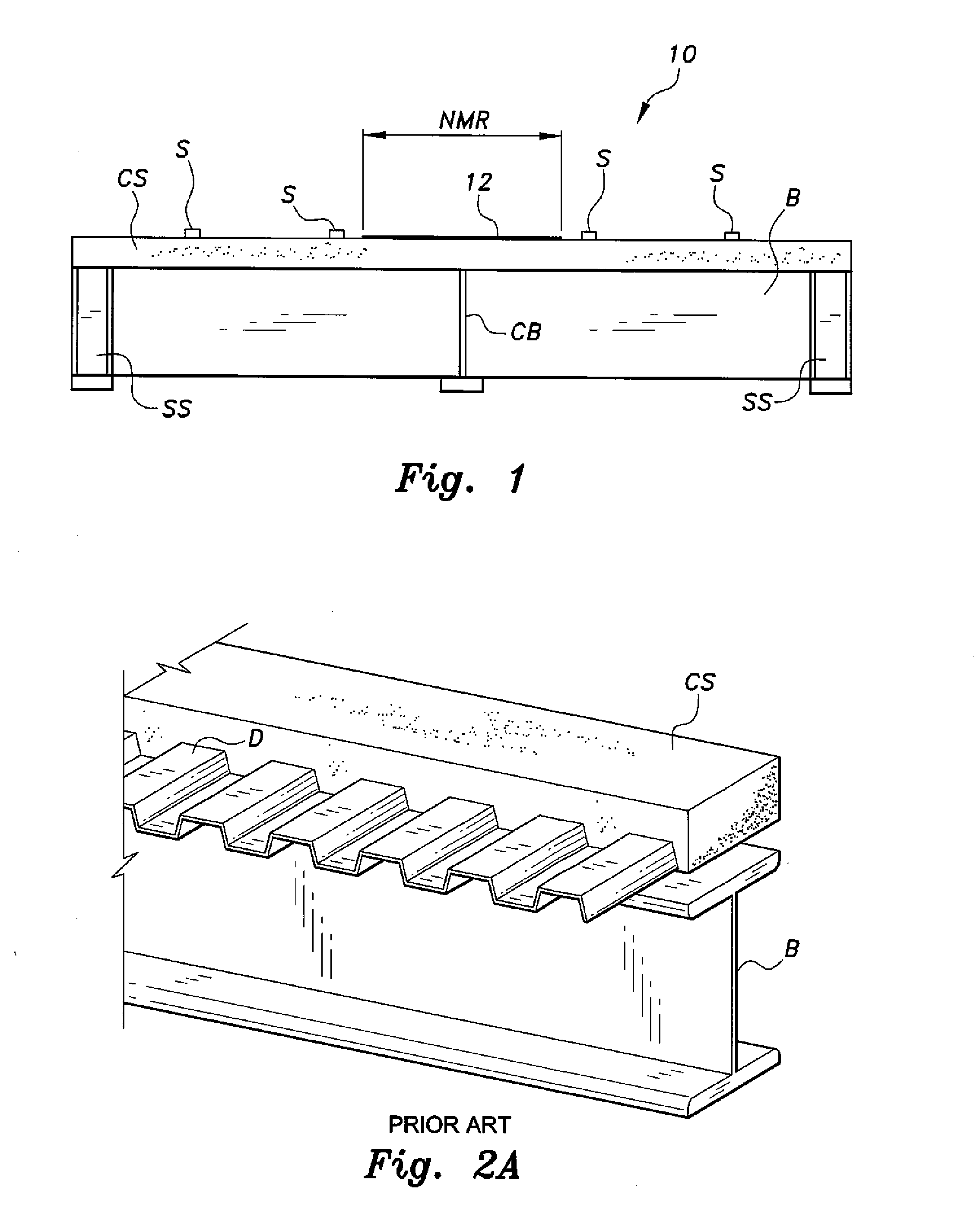

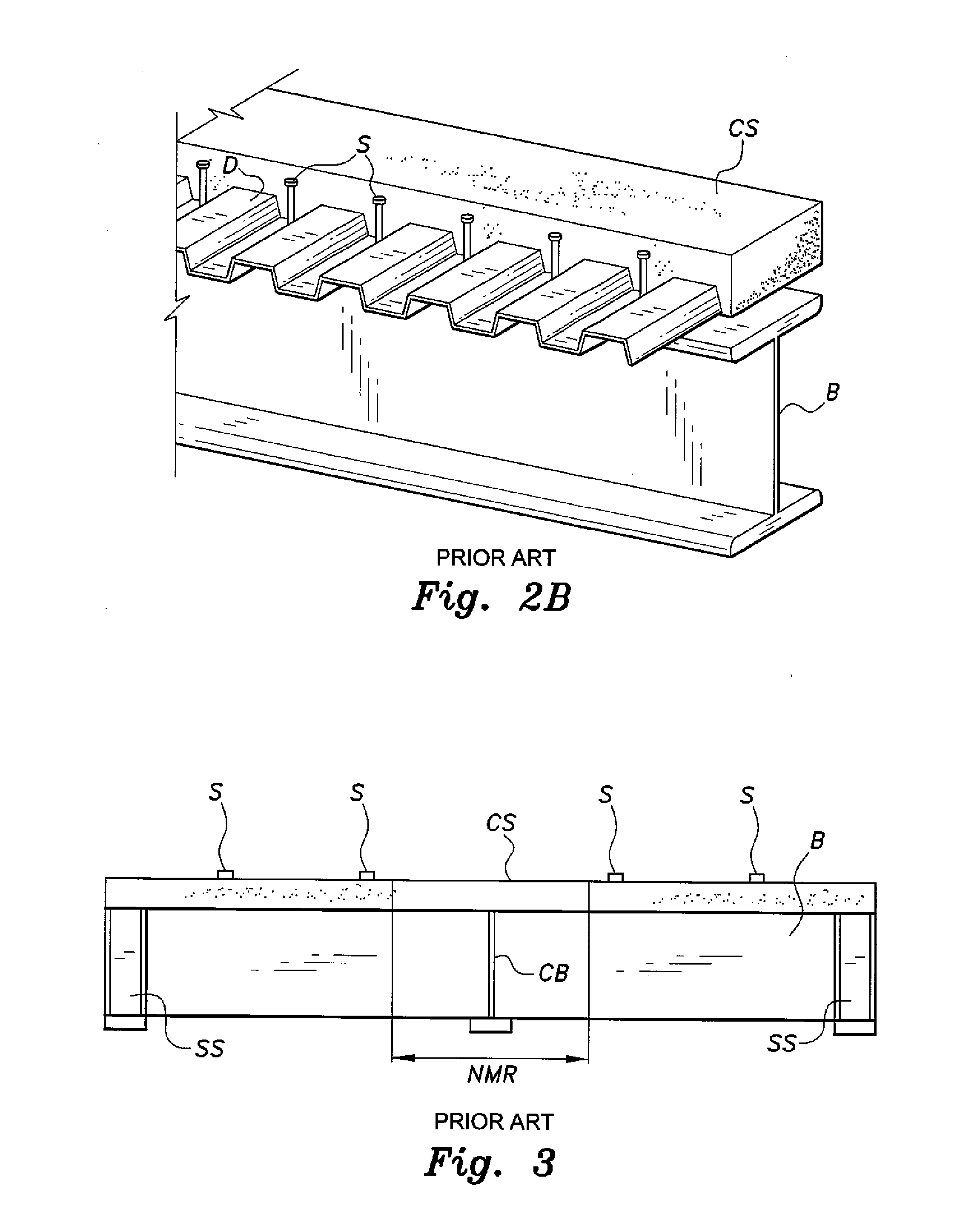

Composite girder partially reinforced with carbon fiber reinforced polymer

The composite girder partially reinforced with carbon fiber reinforced polymer is a composite steel-concrete beam partially reinforced with a sheet of carbon fiber reinforced polymer bonded to a concrete slab secured to a flange of the steel beam by shear studs, the sheet of CFRP extending across the length and width of the negative moment region of the beam. The negative moment region may be centered about a point of interior support of the composite steel-concrete beam. The carbon fiber reinforced polymer may have a thickness of about 0.25 mm.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Preparation method and application of carbon fiber-reinforced polymer-based composite material

ActiveCN105713234AShort preparation cycleThe process is simple and easy to controlFriction liningFiberInorganic compound

The invention discloses a preparation method and application of a carbon fiber-reinforced polymer-based composite material.The preparation method comprises the steps that firstly, a saline solution needed by an inorganic compound is put into a reaction kettle, a basis material used for inducing an alternating magnetic field is put into the reaction kettle, and the reaction kettle is sealed and then put into hydrothermal induction heating equipment; secondly, the temperature of the reaction kettle is lowered to the room temperature, and the basis material loaded with the inorganic compound is taken out, cleaned and dried; lastly, hot press molding is performed on the basis material, and then the carbon fiber-reinforced polymer-based composite material is obtained.According to the preparation method and application of the carbon fiber-reinforced polymer-based composite material, a hydrothermal induction heating technique is applied to carbon fiber surface grafting, and therefore the defect, brought by the surface inertia of carbon fibers, that the carbon fibers are not prone to be combined with other components is overcome; in addition, under the action of the alternating magnetic field, the high temperature of the carbon fibers promotes growth of multiple nanometer materials on the surfaces of the carbon fibers, more meshing sites are supplied to combination of the carbon fibers and resin, and interface bonding of the carbon fibers and the resin and the mechanical property of the composite material are improved.

Owner:SHAANXI UNIV OF SCI & TECH

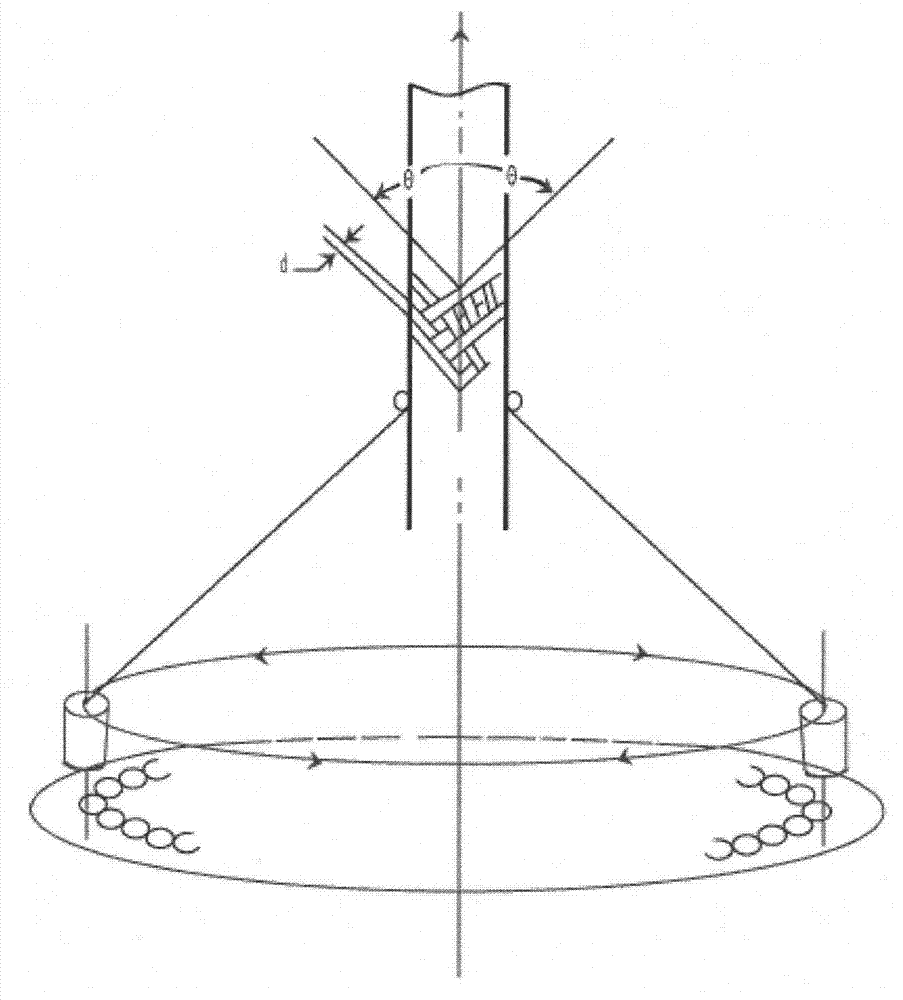

Light-weight vehicle wheels with carbon fiber inserts

Application of carbon fiber reinforced polymer structures to metal vehicle wheels is effective in reducing the mass of the wheel while retaining suitable stiffness in the wheel structure. For maximum effect the reinforced polymer structure and the metal wheel must operate cooperatively. Because of the wide range of operating temperatures experienced by wheels and the large difference in coefficient of thermal expansion between metals and carbon fiber reinforced composites attachment of the polymer structure to the wheel by adhesive alone is problematical. However a wheel with an effective and durable reinforcement may be fabricated by confining, through mechanical interference, the reinforced polymer in a cavity in or on the spoke and by preheating the wheel before curing the polymer.

Owner:GM GLOBAL TECH OPERATIONS LLC

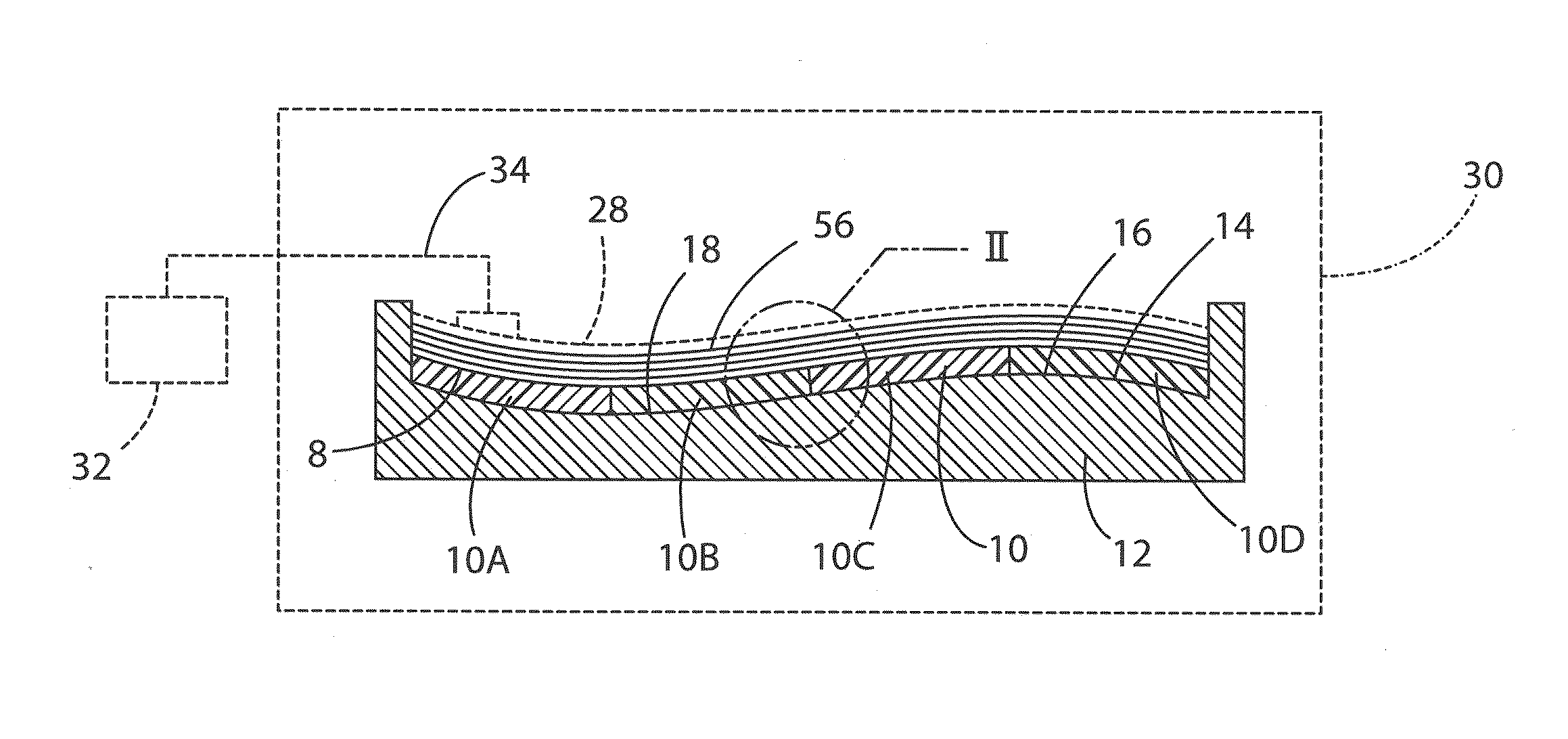

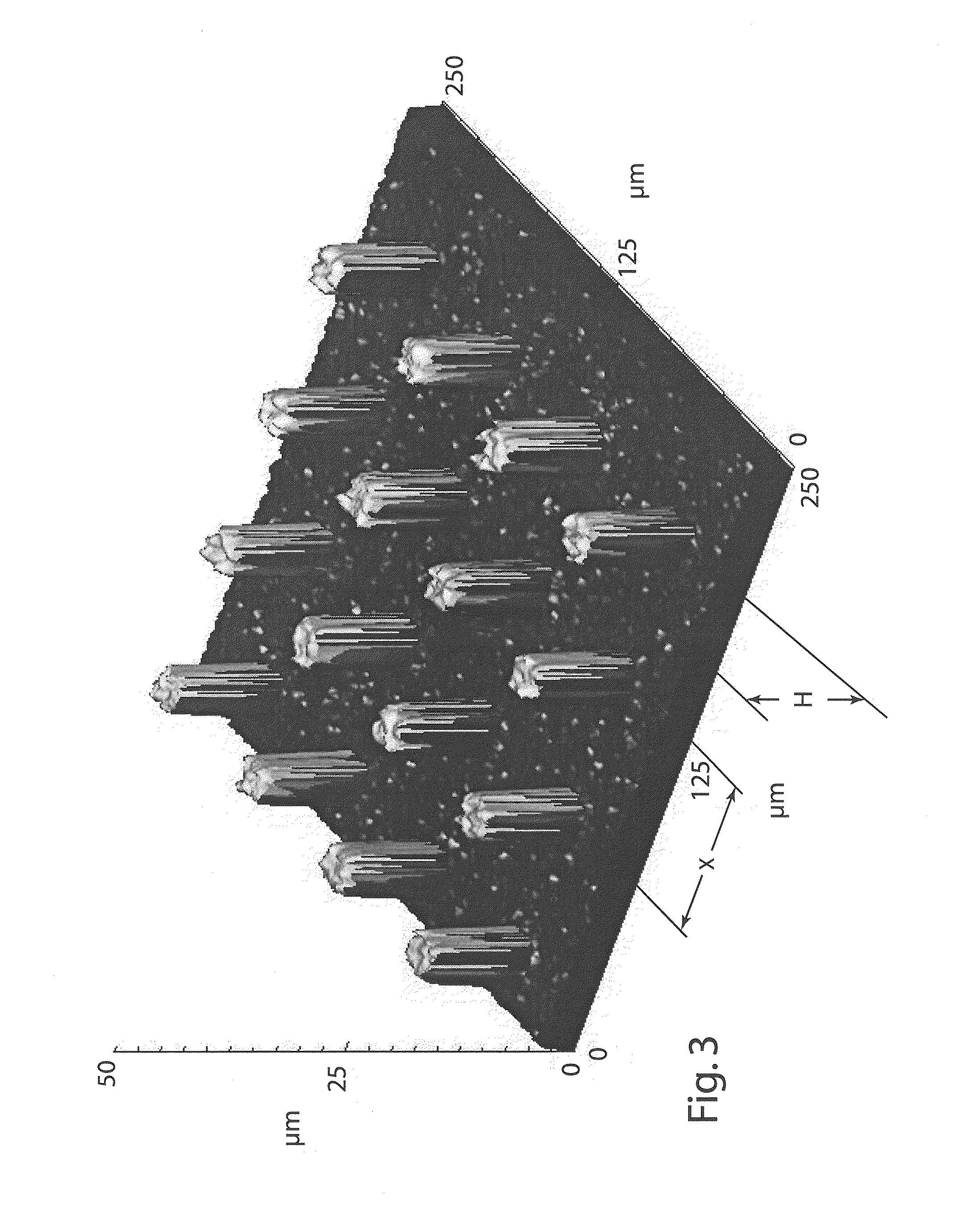

High Pressure Soft Lithography for Micro-Topographical Patterning of Molded Polymers and Composites

A soft lithography template or stamp is made by casting a polydimethysiloxane (PDMS) or other suitable elastomeric precursor onto a master pattern. The master pattern may be formed utilizing known micro-fabrication techniques. The PDMS template includes an inverse copy of the micro-structures on the master pattern, and can be placed into a mold used to prepare a carbon-fiber reinforced polymer composite part or other polymer molding systems where a matrix material passes through a fluid state during the cure process. The liquid resin material flows into the structures on the surface of the PDMS template and hardens during the curing cycle. After the part is released from the mold, the PDMS template can be peeled from the surface of the part to reveal the free standing micro structures which are a replica of the master pattern.

Owner:NAT INST AEROSPACE ASSOC +1

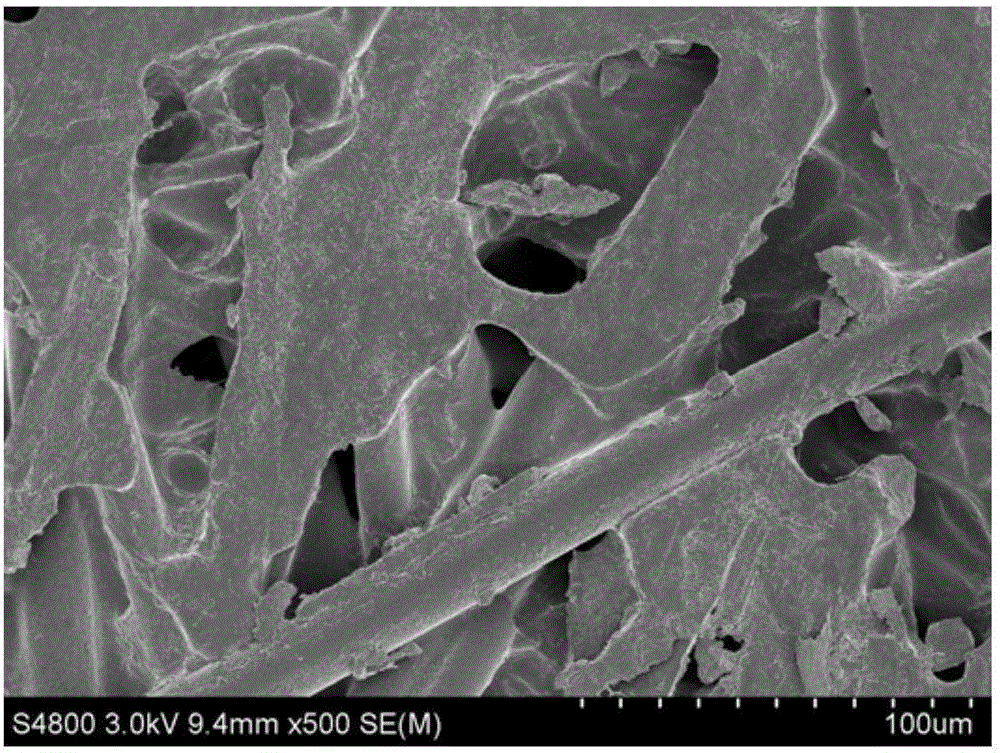

Method for recovery of carbon fiber by use of low temperature molten salt

Owner:EAST CHINA UNIV OF SCI & TECH

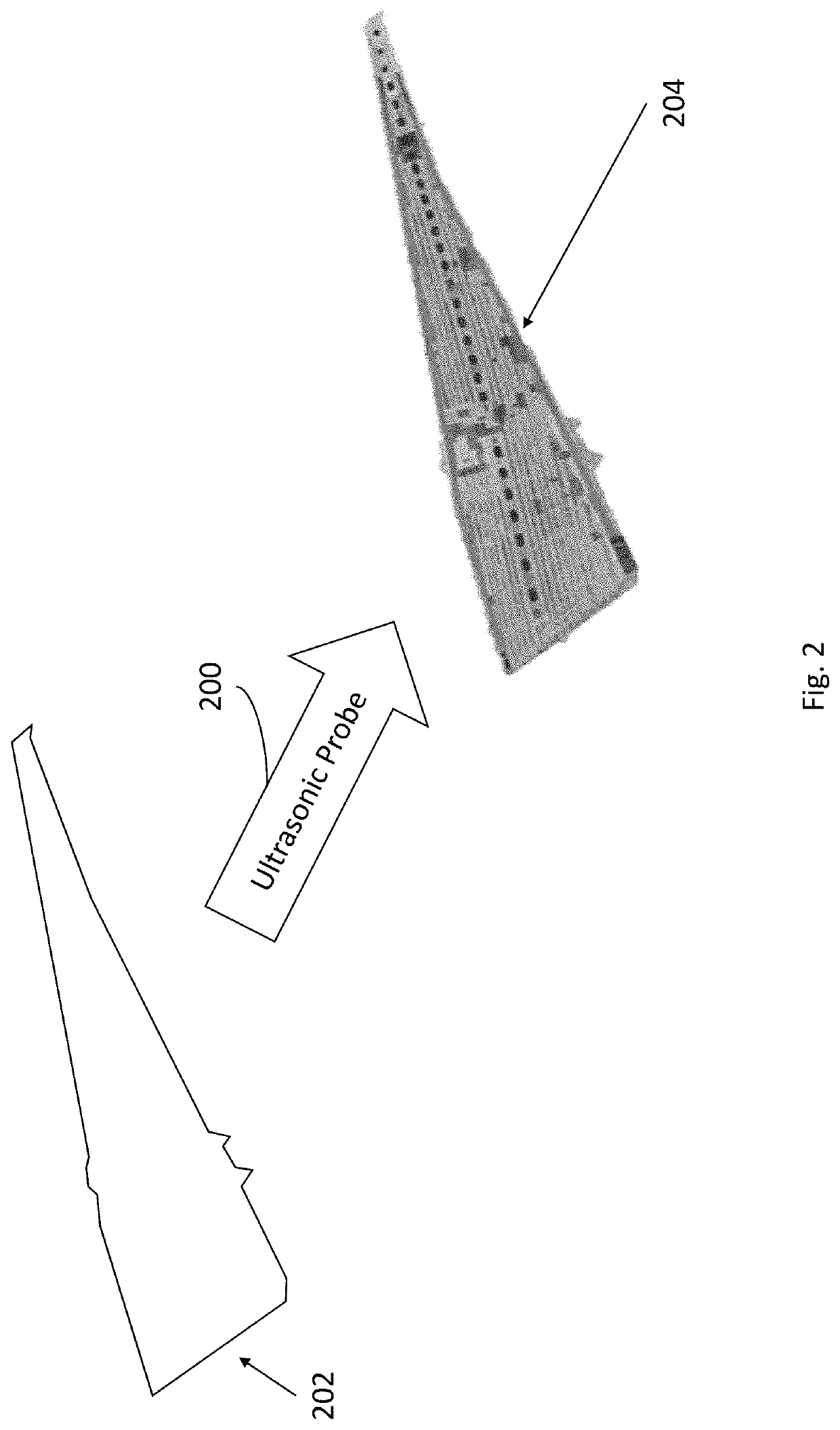

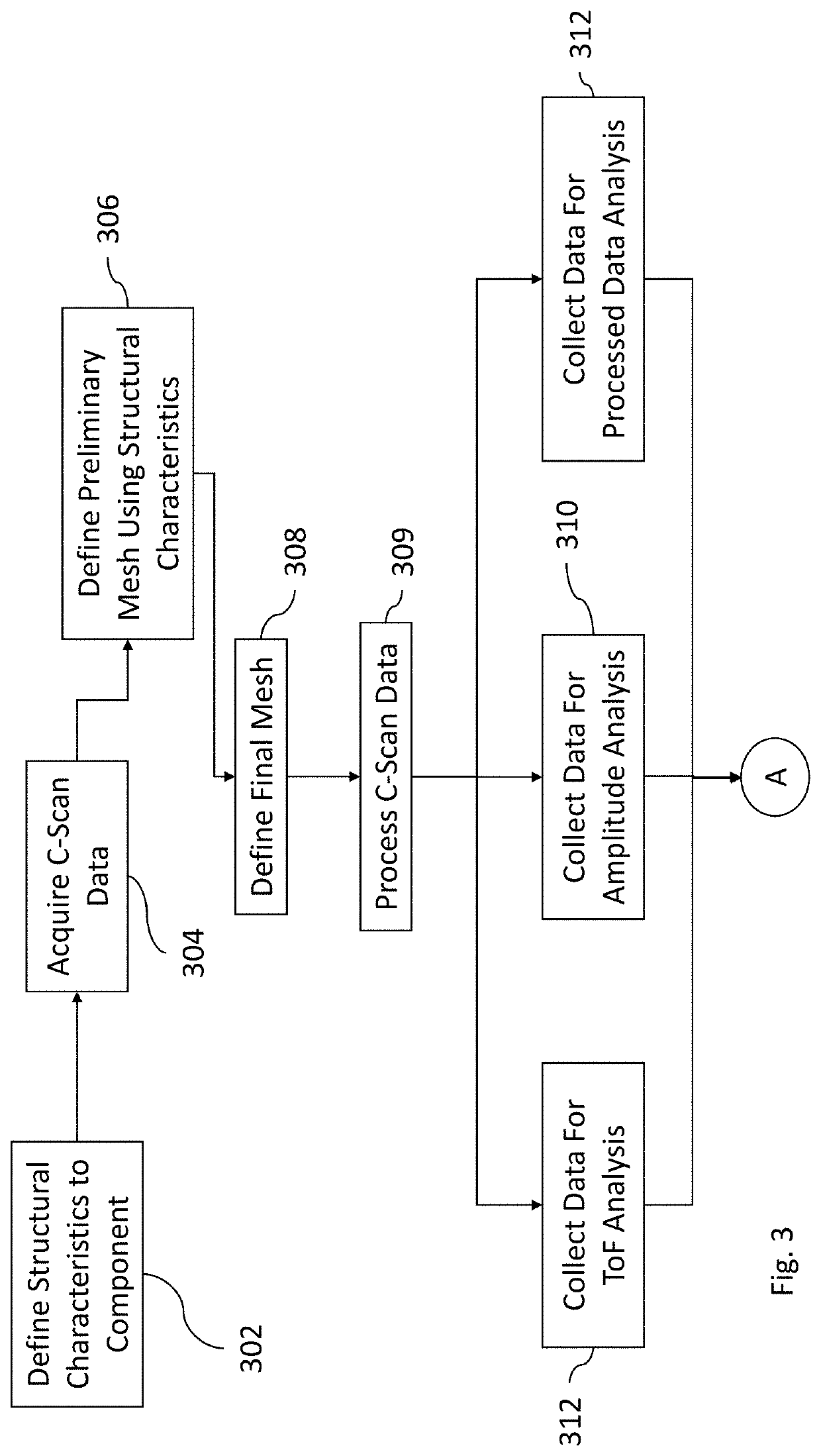

Systems and methods of ultrasonic data evaluation of composite aircraft components

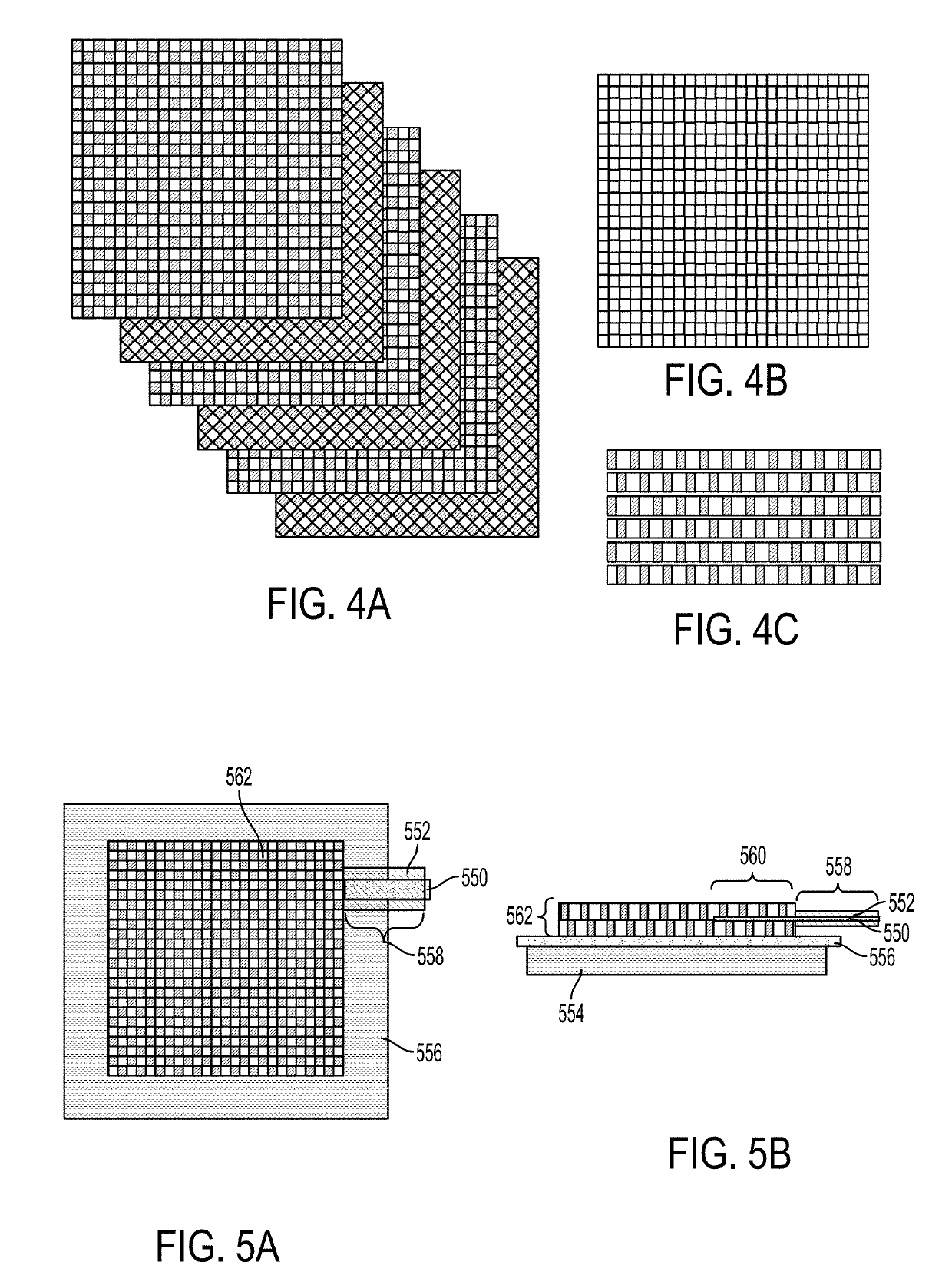

A computer system is provided for processing ultrasonic data of an ultrasonic probe applied to an area of an aircraft component that includes carbon fiber reinforced polymer. C-scan data is obtained and a preliminary mesh is defined over the C-scan data by taking into account the underlying structural or mechanical characteristics of the analyzed component. The mesh is further refined and data gathered for each mesh cell. A heat map is generated based on the mesh.

Owner:AIRBUS SAS +1

Structural lithium-ion batteries with carbon fiber electrodes

ActiveUS20190305292A1Reduce weightImprove battery lifeSecondary cellsBatteriesCarbon fiber reinforced polymersPolymer electrode

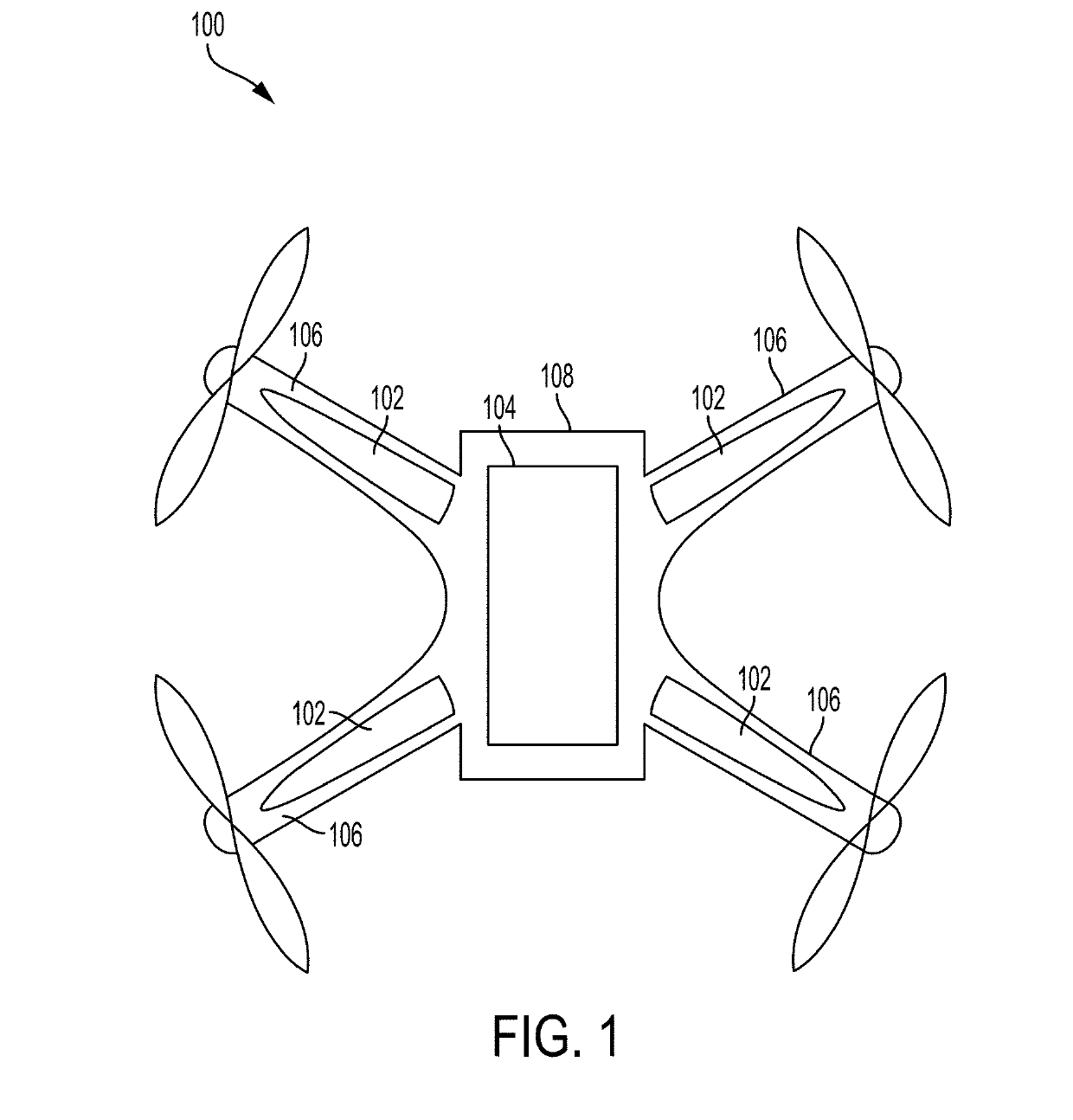

Described are structural electrode and structural batteries having high energy storage and high strength characteristics and methods of making the structural electrodes and structural batteries. The structural batteries provided can include a liquid electrolyte and carbon fiber-reinforced polymer electrodes comprising metallic tabs. The structural electrodes and structural batteries provided can be molded into a shape of a function component of a device such as ground vehicle or an aerial vehicle.

Owner:MITRE SPORTS INT LTD

Composite vibration drilling method suitable for CFRP/titanium (aluminum) alloy laminated material

ActiveCN109108317AAutomate operationReduce Delamination DefectsWorkpiecesTurning toolsAlloyUltrasonic vibration

The invention provides a composite vibration drilling method suitable for a CFRP / titanium (aluminum) alloy laminated material. The method applies ultrasonic vibration and / or low frequency vibration toa tool and / or workpiece during drilling of the laminated material, and according to different drilled objects in a drilling process, different vibration modes are added to suppress processing defectsof all layers so as to obtain optimal drilling effect of the materials of all layers. The method controls a vibration device through a numerical control system so as to realize automatic operation ofthe high and low frequency composite vibration drilling process of the laminated material. The method can select the ultrasonic vibration and / or low frequency vibration processing according to processed objects so as to avoid the defect that a single vibration mode cannot take into account both in processing the carbon fiber reinforced polymer (CFRP) and titanium (aluminum) alloy laminated material.

Owner:HENAN POLYTECHNIC UNIV

Preparation method and application of carbon fiber reinforced polymer-based composite material

ActiveCN105599321AShort preparation cycleThe process is simple and easy to controlFiberInorganic compound

The invention discloses a preparation method and application of a carbon fiber reinforced polymer-based composite material. The preparation method comprises the following steps: putting a salt solution for an inorganic compound into a reaction kettle, and putting a base material for inducing an alternating magnetic field into the reaction kettle; sealing the reaction kettle and putting in hydrothermal induction heating equipment; cooling the reaction kettle to room temperature; taking out the base material loaded with the inorganic compound, and cleaning and drying; and finally, performing hot-press moulding to obtain the carbon fiber reinforced polymer-based composite material. In the preparation method, the hydrothermal induction heating technology is applied to the surface grafting of carbon fiber, and the shortcoming of difficult combination with other components caused by the surface inertia of carbon fiber is overcome. Moreover, under the effect of alternating magnetic field, the high temperature of carbon fiber promotes the growth of multiple nano materials on the surface thereof, more meshing sites are provided for the combination of carbon fiber and resin, and the interface bonding between the carbon fiber and resin as well as the mechanical properties of the composite material are improved.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing a carbon/carbon composite

InactiveUS7871592B2Comparable mechanical propertyAcceptable tribological performanceMaterial nanotechnologyAlkali metal halidesCarbon compositesAtmosphere

A method for preparing a carbon / carbon (C / C) composite comprising carbonizing a carbon fiber-reinforced polymer matrix composite precursor by heating the precursor in an inert atmosphere with a heating rate greater than 20° C. / min up to 1500° C. / min.

Owner:NAT CHENG KUNG UNIV

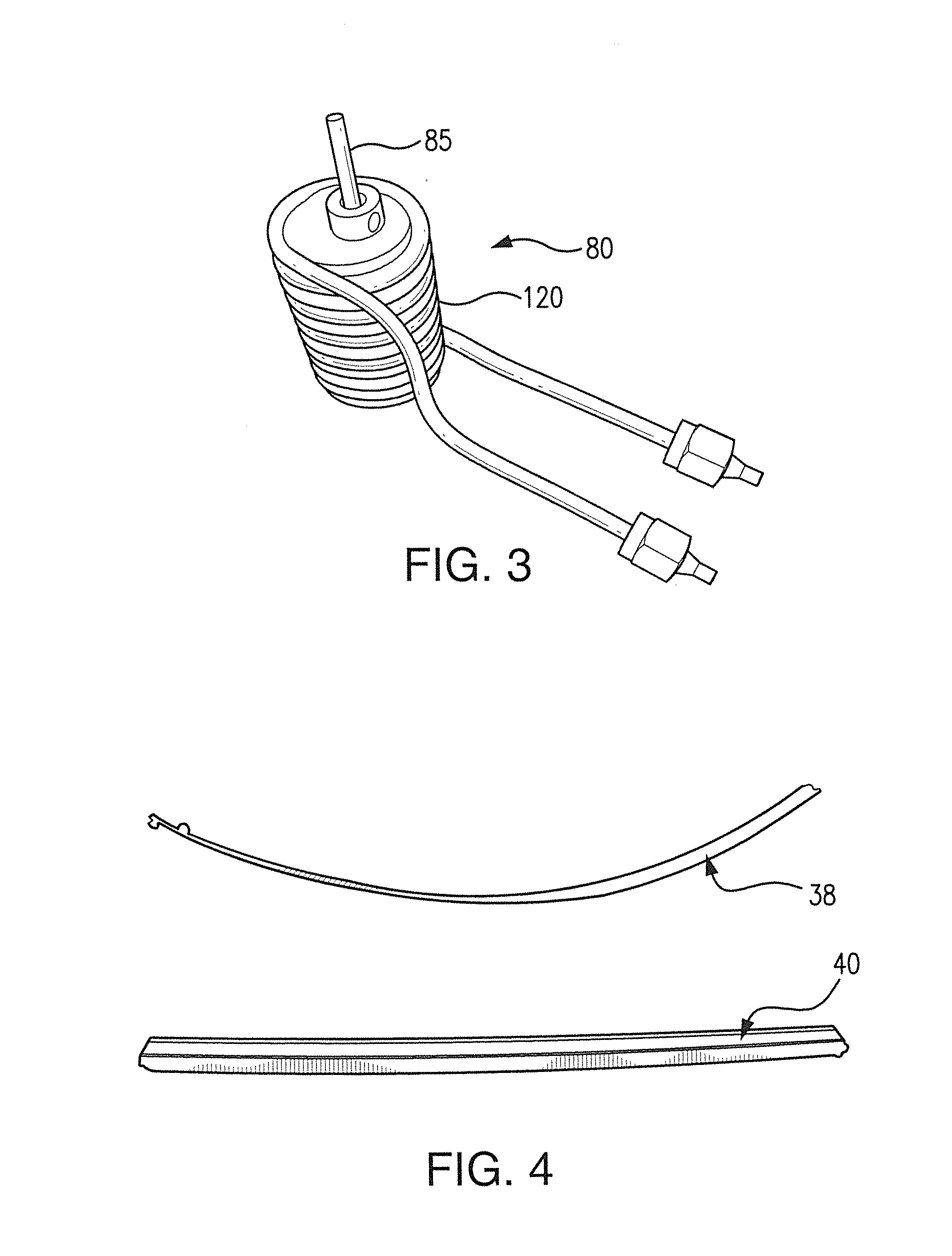

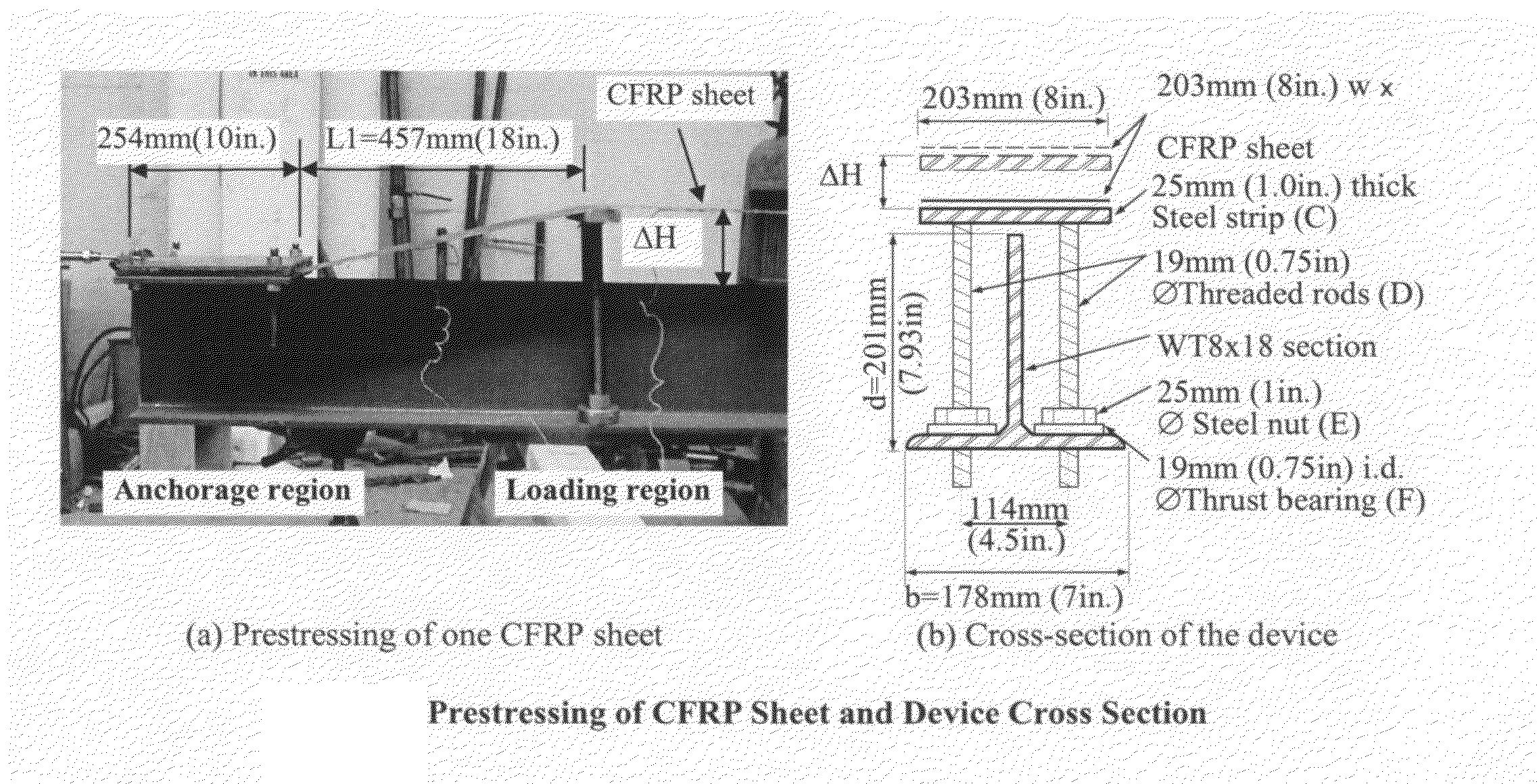

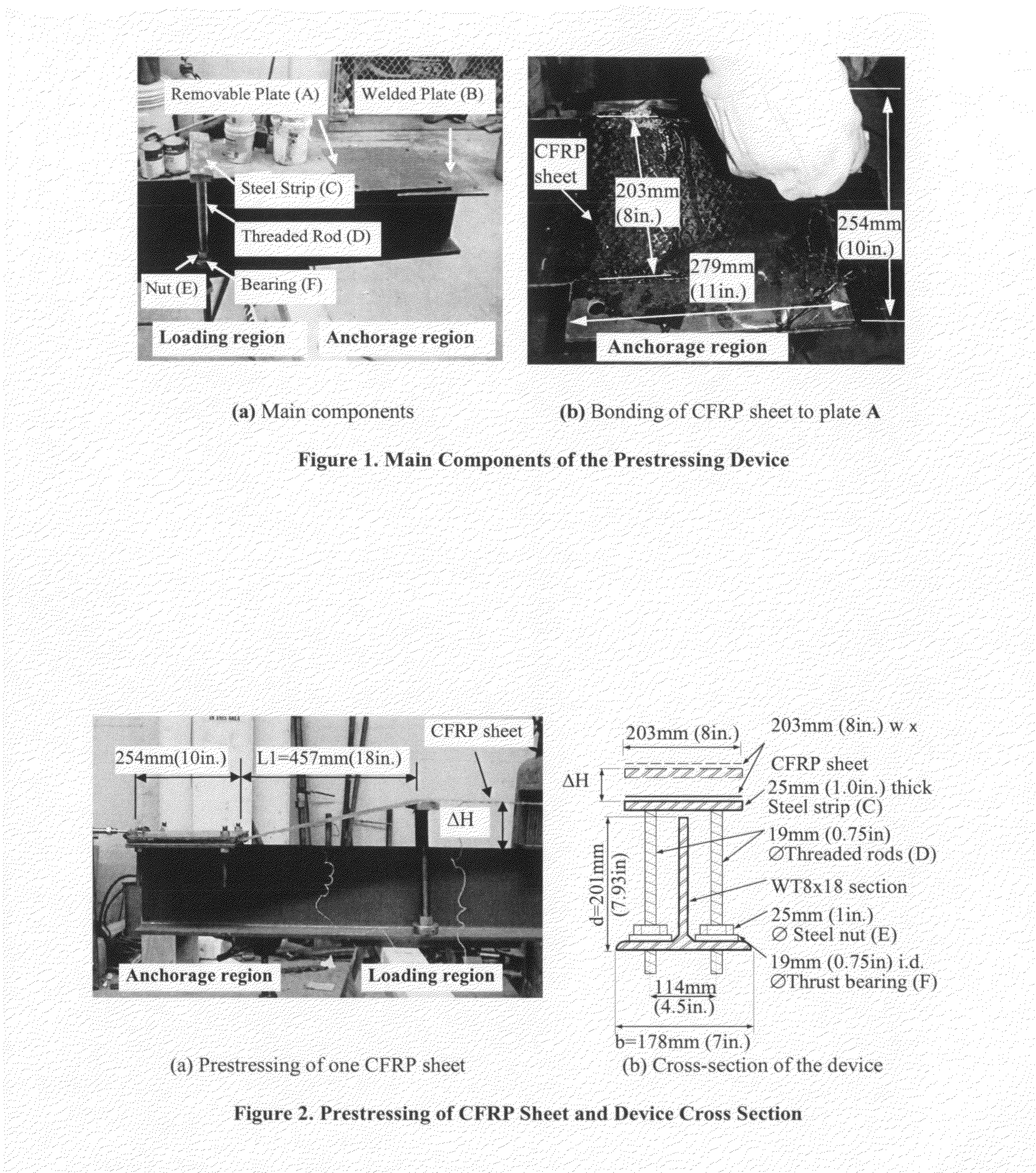

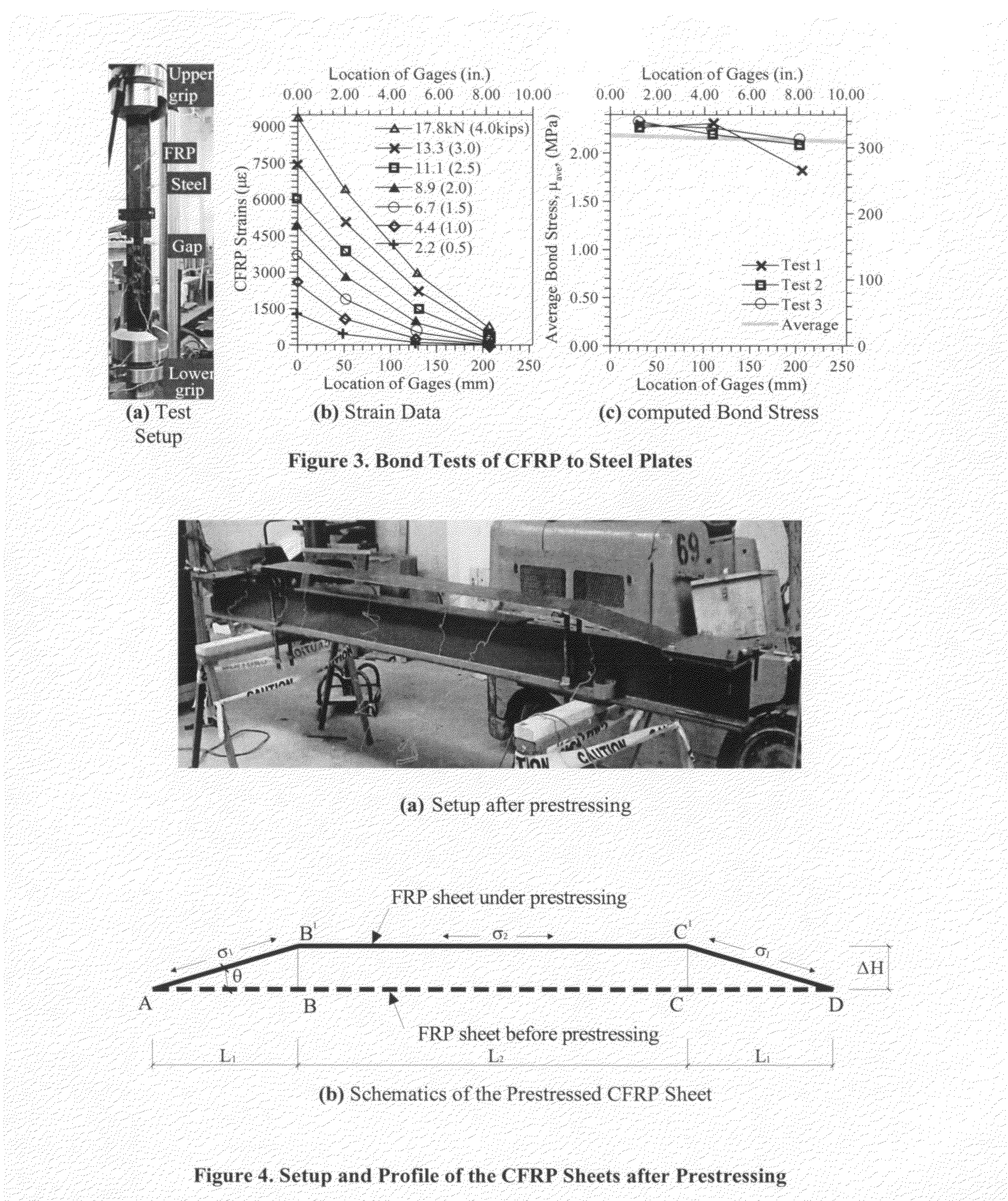

Mechanical device for prestressing of carbon fiber reinforced polymer (CFRP) sheets

InactiveUS20100319171A1Overcome disadvantagesCeramic shaping apparatusBuilding reinforcementsPre stressStrain rate

A mechanical device was invented for prestressing of carbon fiber reinforced polymer (CFRP) sheets. Significant features of this device are that the CFRP sheets are directly anchored to the mechanical device itself, the prestressing forces are applied with a manual torque wrench without the need for power operated hydraulic jacks and the prestressing transfer is accomplished under slow strain rates. Experimental investigation clearly indicates that the device was efficient in applying prestressing to the CFRP sheets and prestress losses during stressing were maintained at a minimum.

Owner:YU PIYONG +1

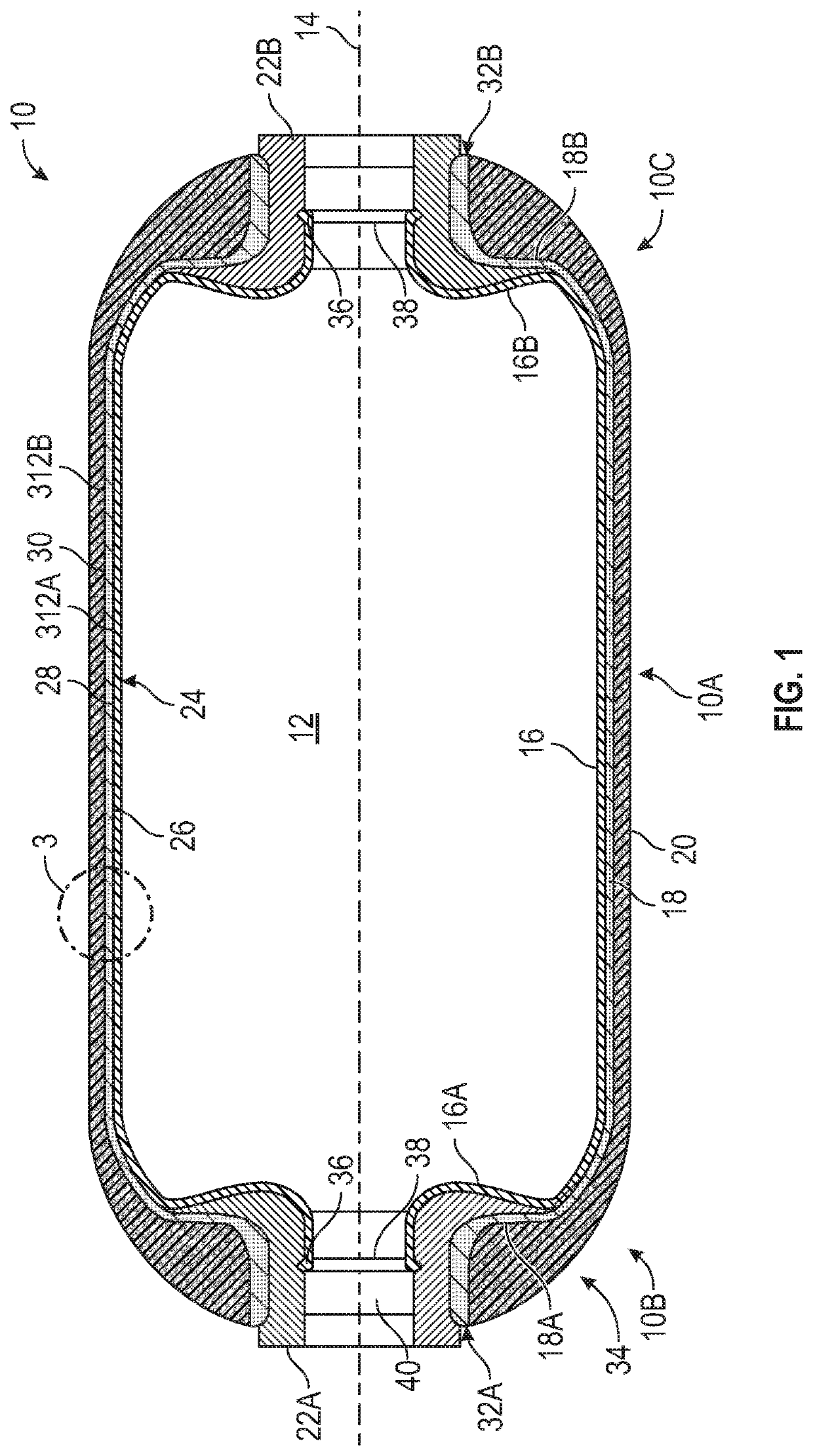

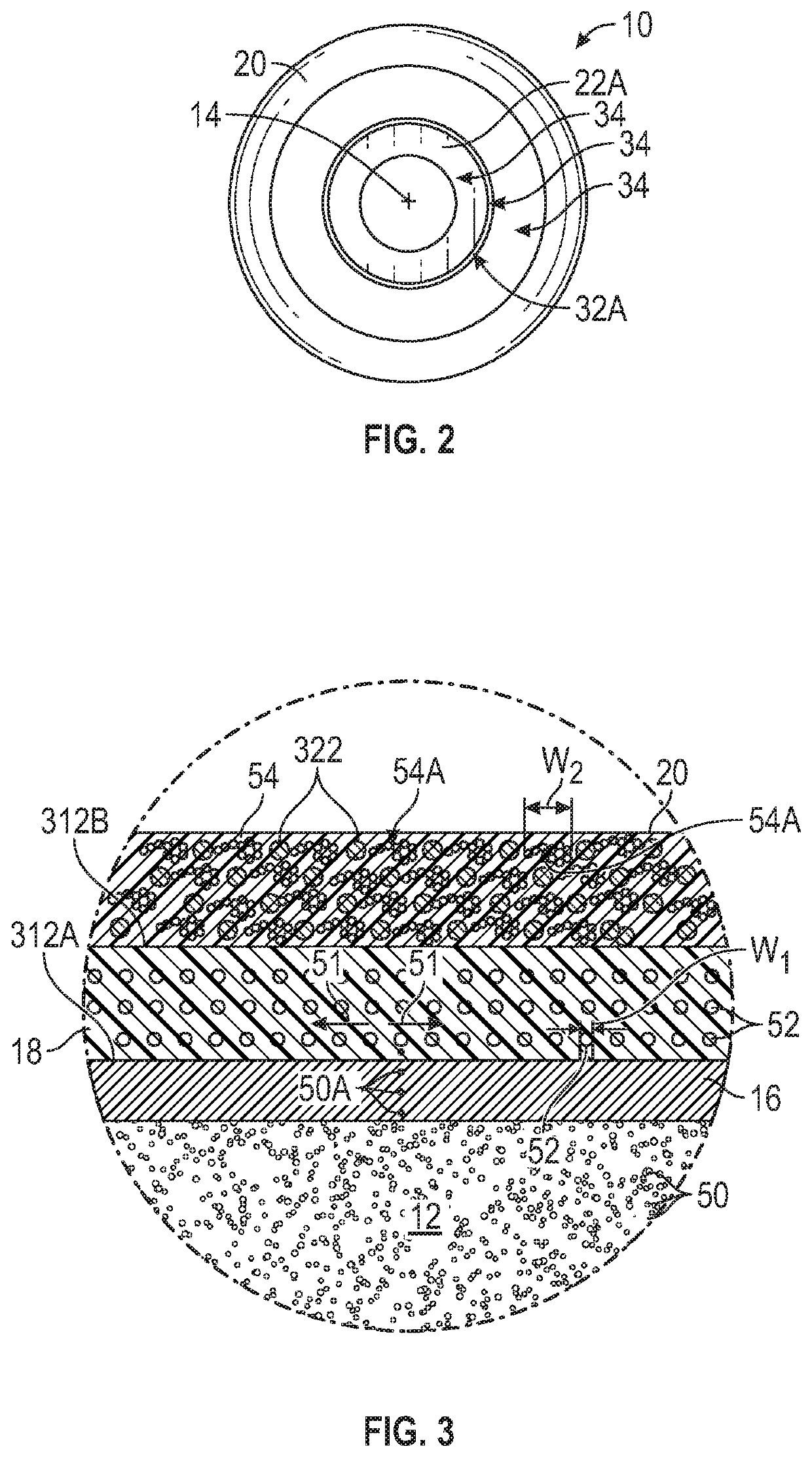

Storage tank for pressurized gas and method of manufacturing same

ActiveUS20210010640A1Easy to disassembleReduce gas permeationVessel mounting detailsVessel manufacturingPolymer sciencePorous carbon

A storage tank for pressurized gas includes a liner defining an interior cavity for storing the pressurized gas. The storage tank further includes a nanoporous carbon shell formed from at least one pyrolyzed polymer. The liner is disposed at an inner side of the nanoporous carbon shell. The storage tank further includes a carbon fiber reinforced polymer layer disposed on an outer side of the nanoporous carbon shell opposite from the liner. The nanoporous carbon shell has an exposed surface at an exterior of the storage tank and is configured to permit gas permeated through the liner from the interior cavity to diffuse through the nanoporous carbon shell to the exposed surface.

Owner:GM GLOBAL TECH OPERATIONS LLC

Contoured insoles for footwear

An insole assembly for use in footwear is provided. The insole assembly generally includes a full-length insole base made of a flexible and resilient material (e.g., resiliently compressible foam), and a heel cap made of a generally rigid material (e.g., a carbon fiber reinforced polymer) which is attached to the insole base and mimics the contours thereof to provide proper biomechanical support of the heel and arch areas of a foot in a particularly lightweight and sleek form factor.

Owner:SUPERFEET WORLDWIDE LLC

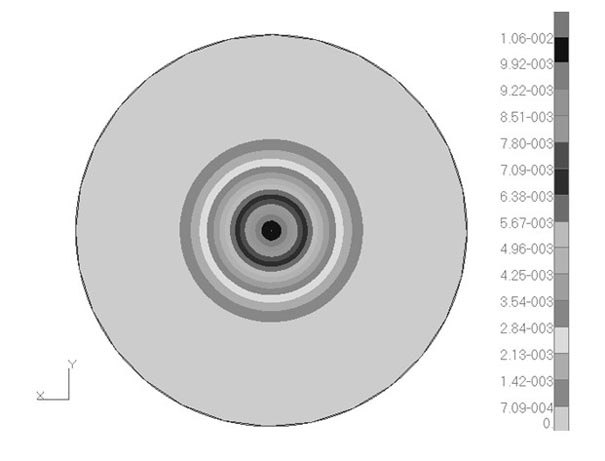

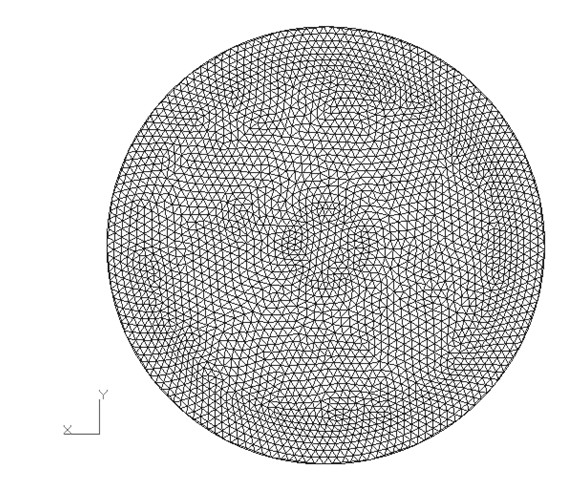

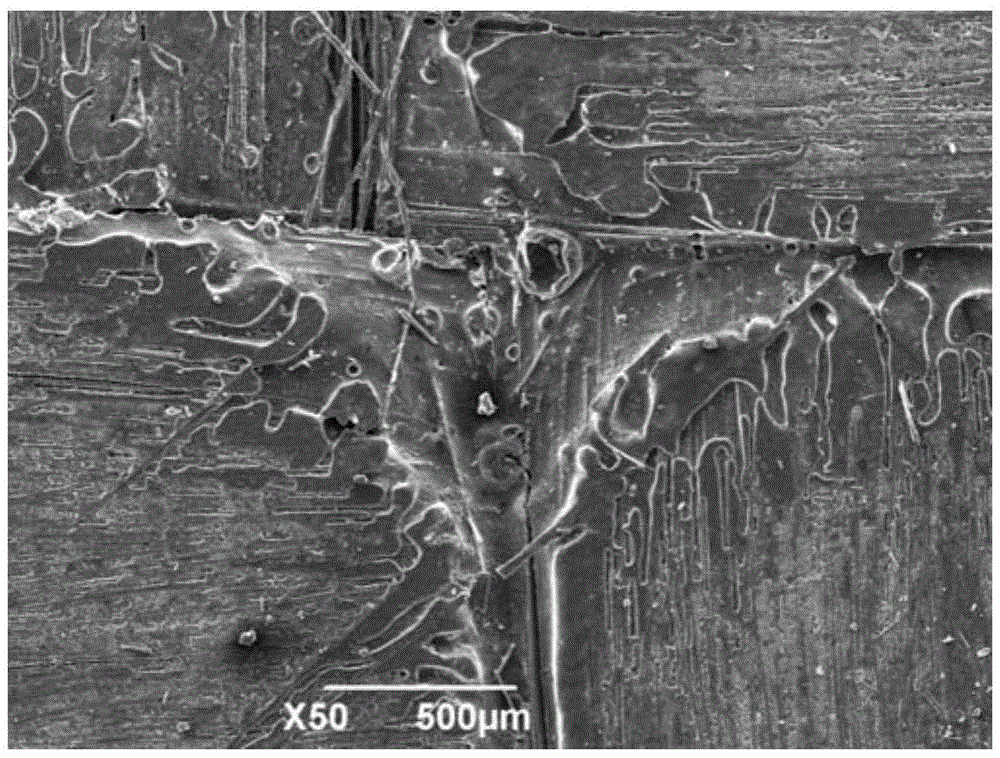

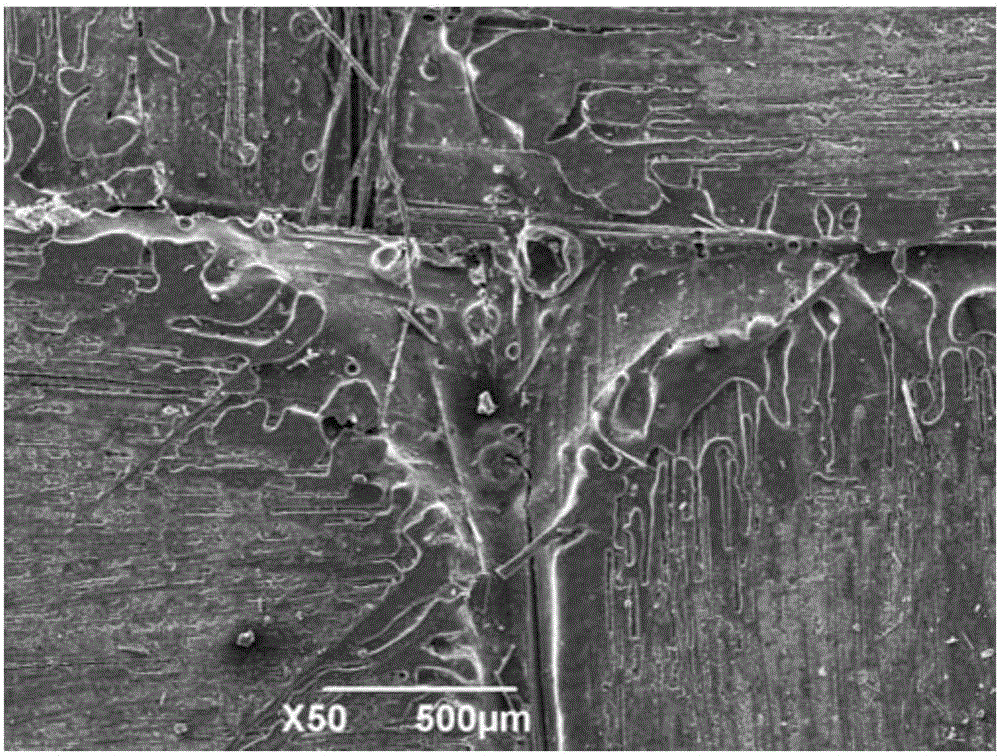

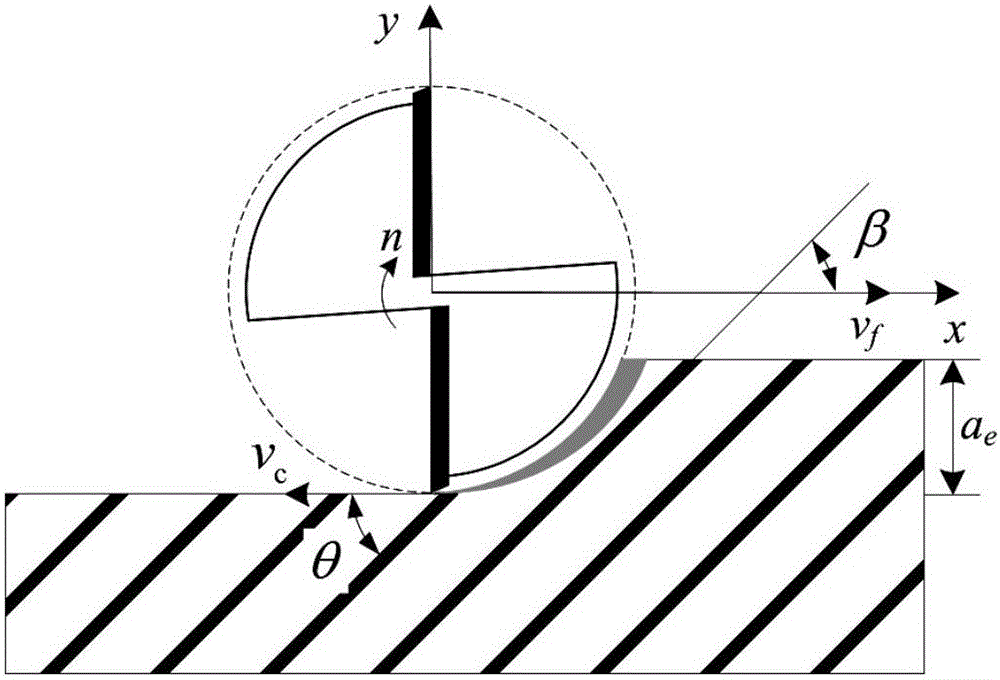

Quality evaluation method of CFRP cut and machined surface at full-range fiber orientation angle

The invention relates to a quality evaluation method of a CFRP (Carbon Fiber Reinforced Polymer) cut and machined surface at a full-range fiber orientation angle. The method comprises the following steps: acquiring the CFRP cut and machined surface at the full-range fiber orientation angle by performing annular milling on a CFRP disc workpiece, and performing quality evaluation on the CFRP cut and machined surface at different fiber orientation angles; during milling machining, acquiring the cut and machined surface and measuring the surface roughness of the cut and machined surface, wherein the tool path is a circular trace taking the center of the disc workpiece as the circle center; taking optical microscope pictures to be spliced to form an image of the cut and machined surface at the full-range fiber orientation angle of 0-180 degrees; measuring the burr height of the cut and machined surface at different fiber orientation angles; finally acquiring burr height factors of the surface at the full-range fiber orientation angle and evaluating the quality of the CFRP cut and machined surface according to the burr height factors. According to the quality evaluation method of the CFRP cut and machined surface at the full-range fiber orientation angle, only by a one-step milling and machining test, the CFRP cut and machined surface at the full-range fiber orientation angle of 0-180 degrees can be obtained, and quality evaluation can be performed on the CFRP cut and machined surface.

Owner:SHANGHAI JIAO TONG UNIV

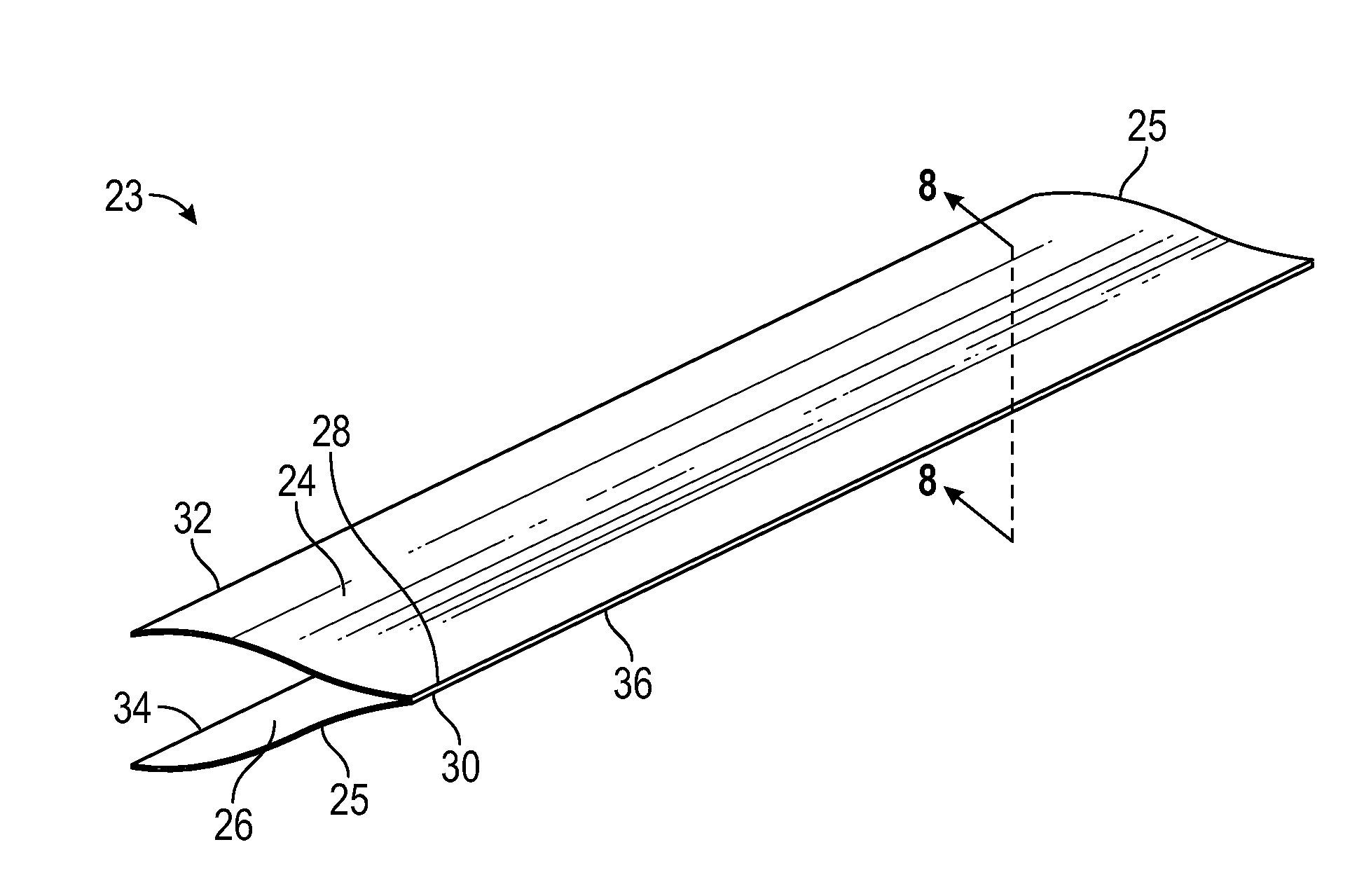

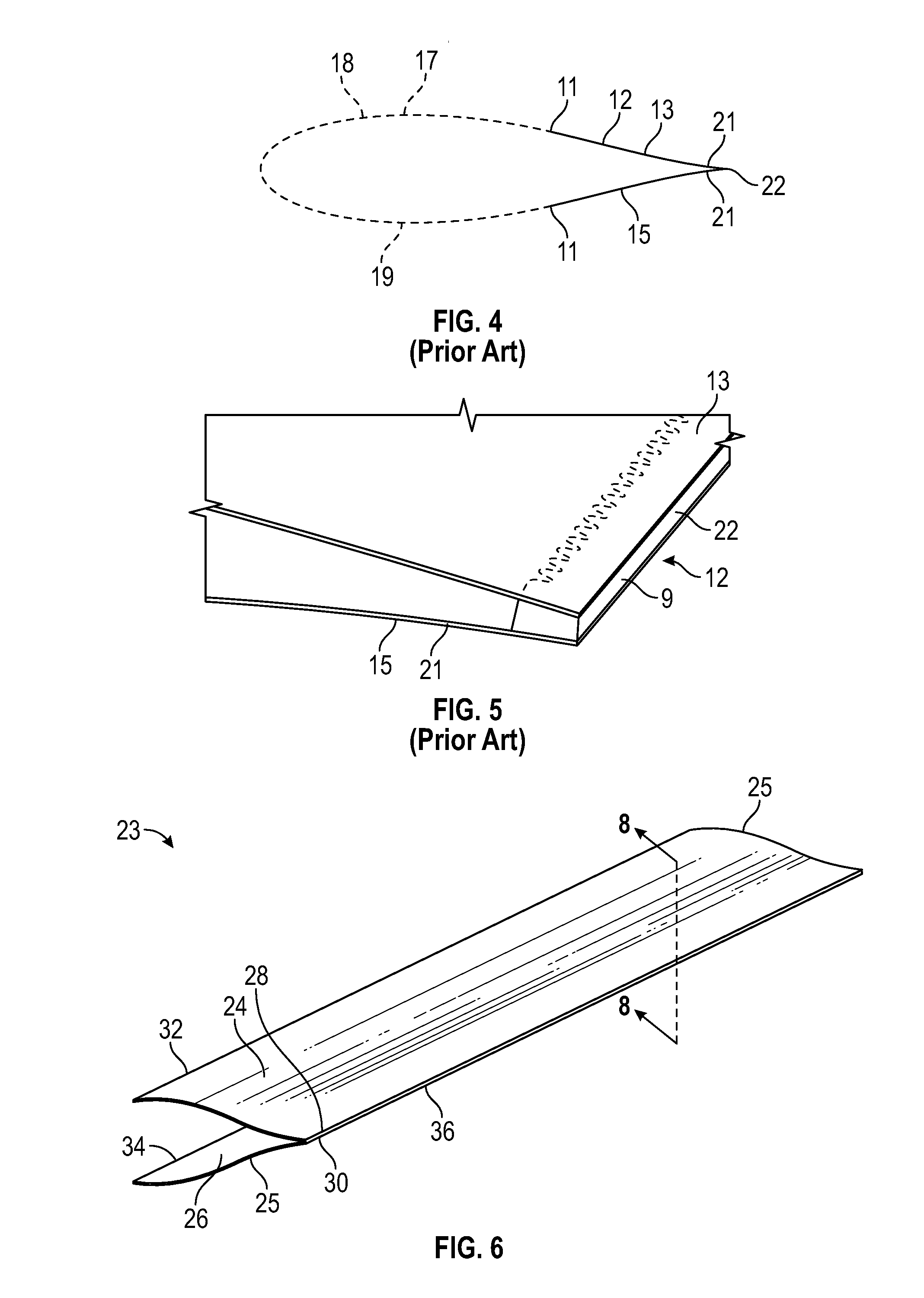

Trailing edge components, aircraft structures including trailing edge components and methods for manufacturing trailing edge components

InactiveUS20170043859A1Influencers by generating vorticesLayered productsTrailing edgeCarbon fiber reinforced polymers

Trailing edge components of aircraft structures, aircraft structures comprising such trialing edge components, and methods of manufacturing such trailing edge components are provided. In an exemplary embodiment, a trailing edge component includes a first skin comprising a first plurality of plies of carbon fiber reinforced polymer material and having a first mating region. The first plurality of plies includes a first ply with a first drop-off edge in the first mating region. A second skin includes a second plurality of plies of carbon fiber reinforced polymer material and having a second mating region affixed to the first mating region.

Owner:GULFSTREAM AEROSPACE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com