Carbon fiber reinforced polymer (CFRP) machined surface appearance representation method

A technology of surface morphology and composite materials, which can be used in measurement devices, instruments, etc., and can solve problems such as errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

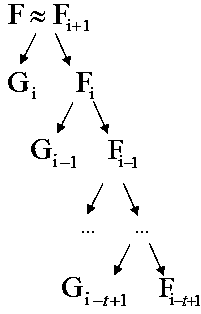

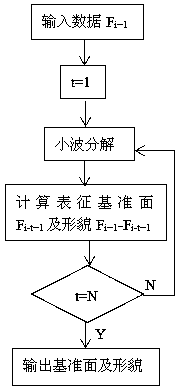

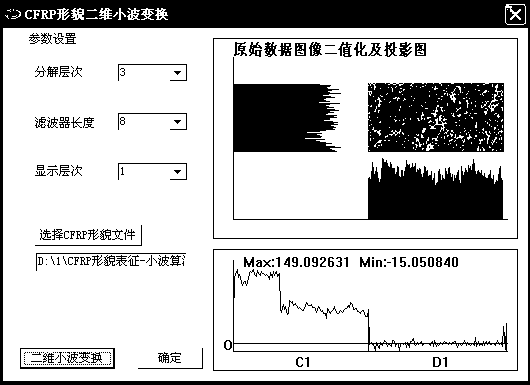

[0044] see Figure 1 to Figure 6 , The invention provides a carbon fiber composite material machining surface morphology characterization method, the carbon fiber composite material processing surface morphology characterization. On the basis of the parameters characterizing the surface roughness of the workpiece, the present invention studies the application of wavelet theory in the shape extraction of CFRP (Carbon Fiber Reinforced Polymer) material cutting surface, and establishes the wavelet analysis method to extract the three-dimensional surface shape mathematical model , provide a CFRP machining surface morphology characterization method based on wavelet evaluation criteria, design an evaluation system that can truly reflect the CFRP cutting surface morphology, and at the same time obtain a method for accurately characterizing the cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com