Patents

Literature

52 results about "Carbon fiber reinforced polymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon fiber reinforced polymer (American English), Carbon fibre reinforced polymer (Commonwealth English), or carbon fiber reinforced plastic, or carbon fiber reinforced thermoplastic (CFRP, CRP, CFRTP, or often simply carbon fiber, carbon composite, or even carbon), is an extremely strong and light fiber-reinforced plastic which contains carbon fibers. The spelling 'fibre' is usual outside the USA. CFRPs can be expensive to produce but are commonly used wherever high strength-to-weight ratio and stiffness (rigidity) are required, such as aerospace, superstructure of ships, automotive, civil engineering, sports equipment, and an increasing number of consumer and technical applications.

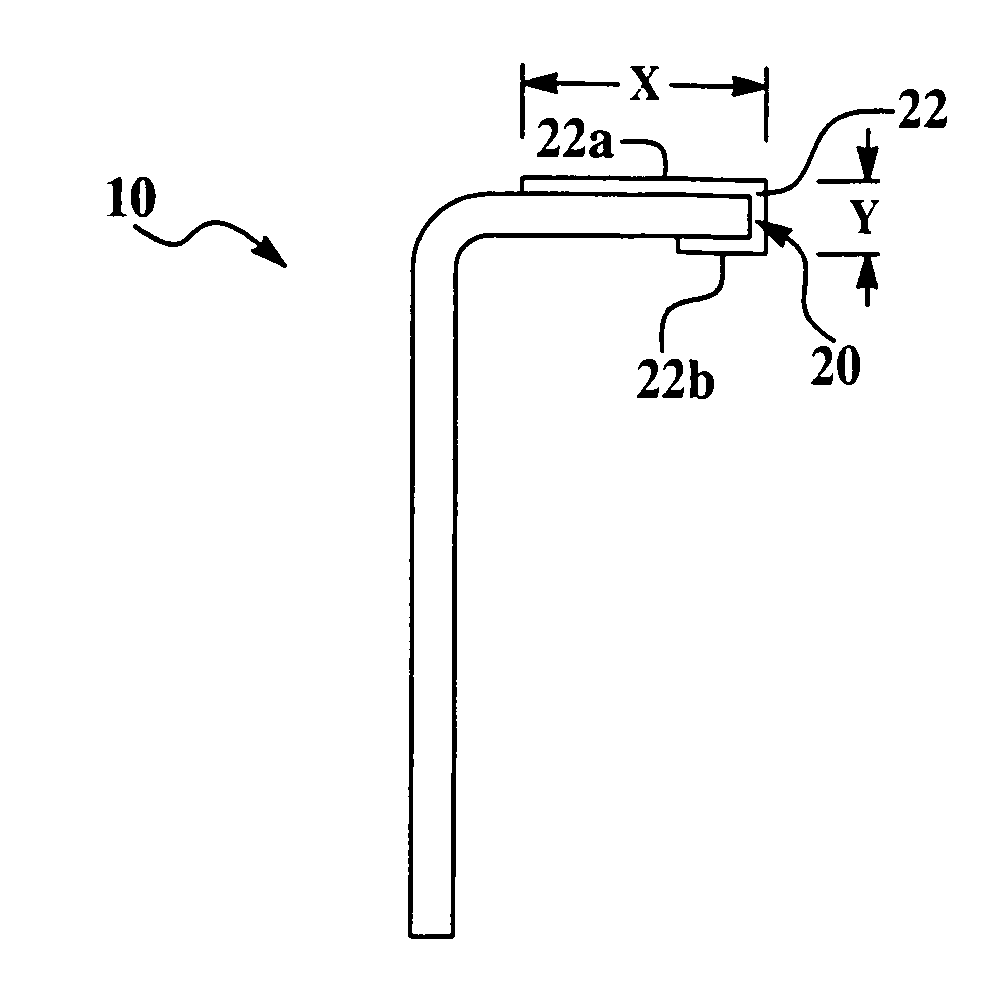

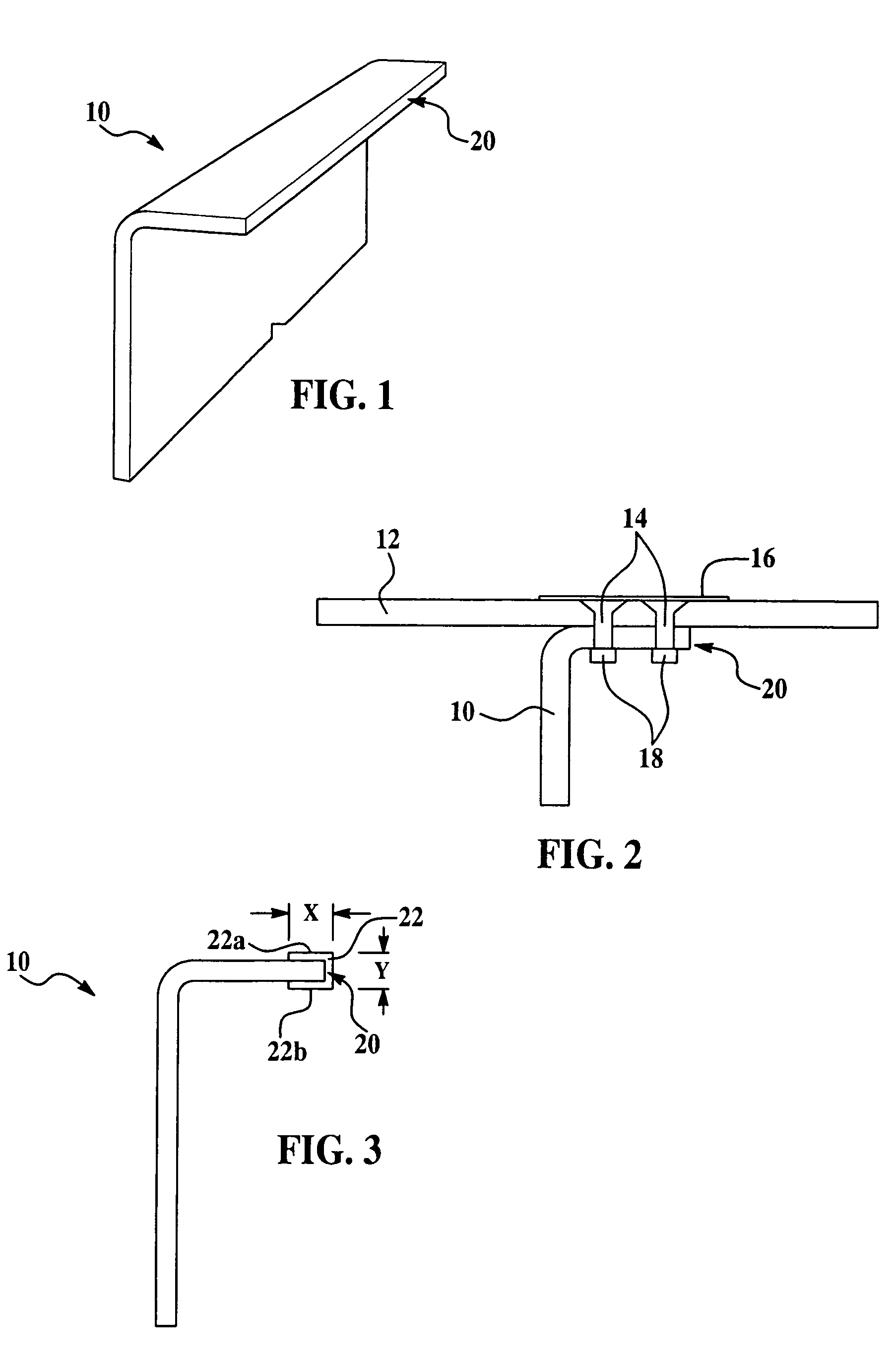

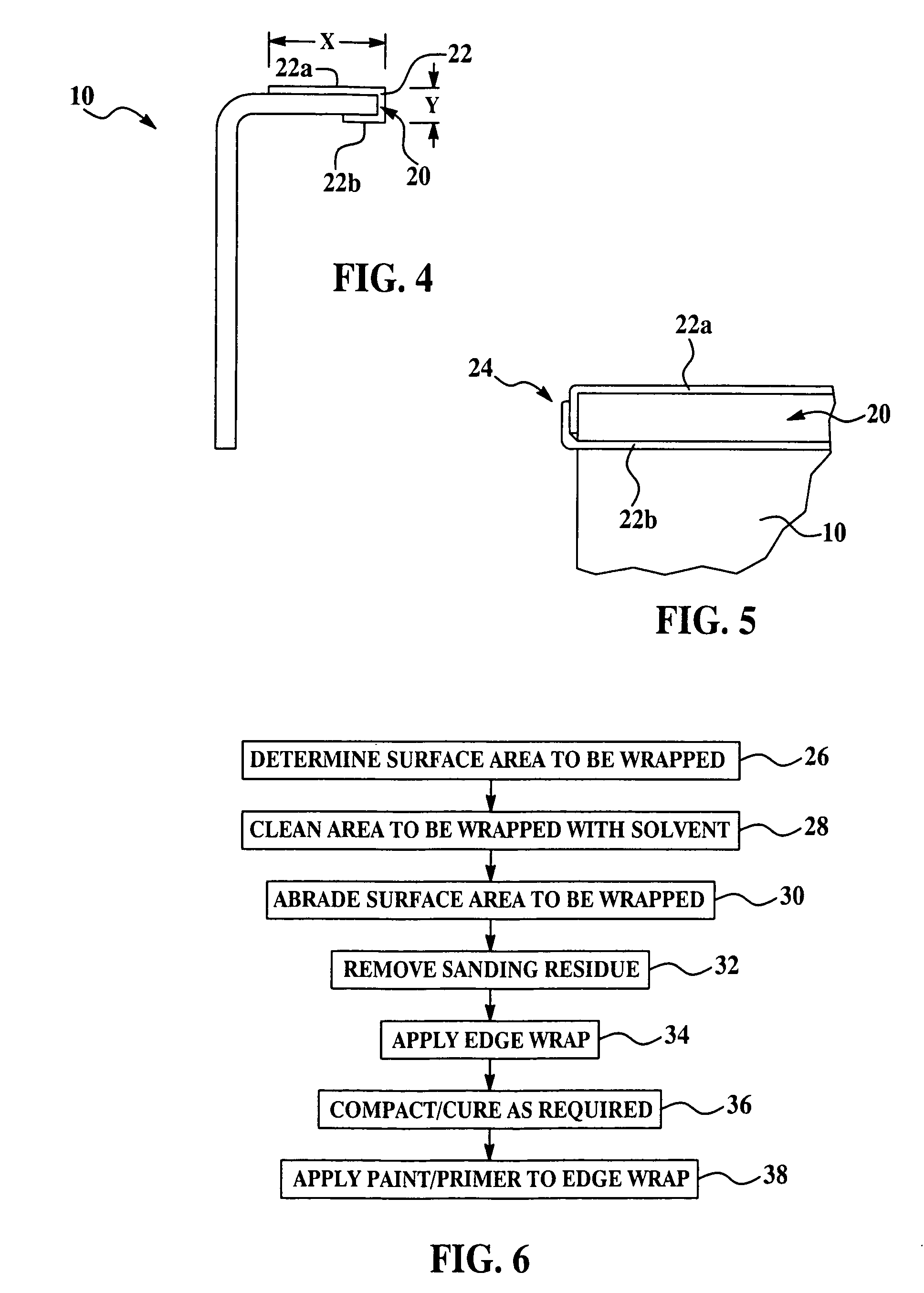

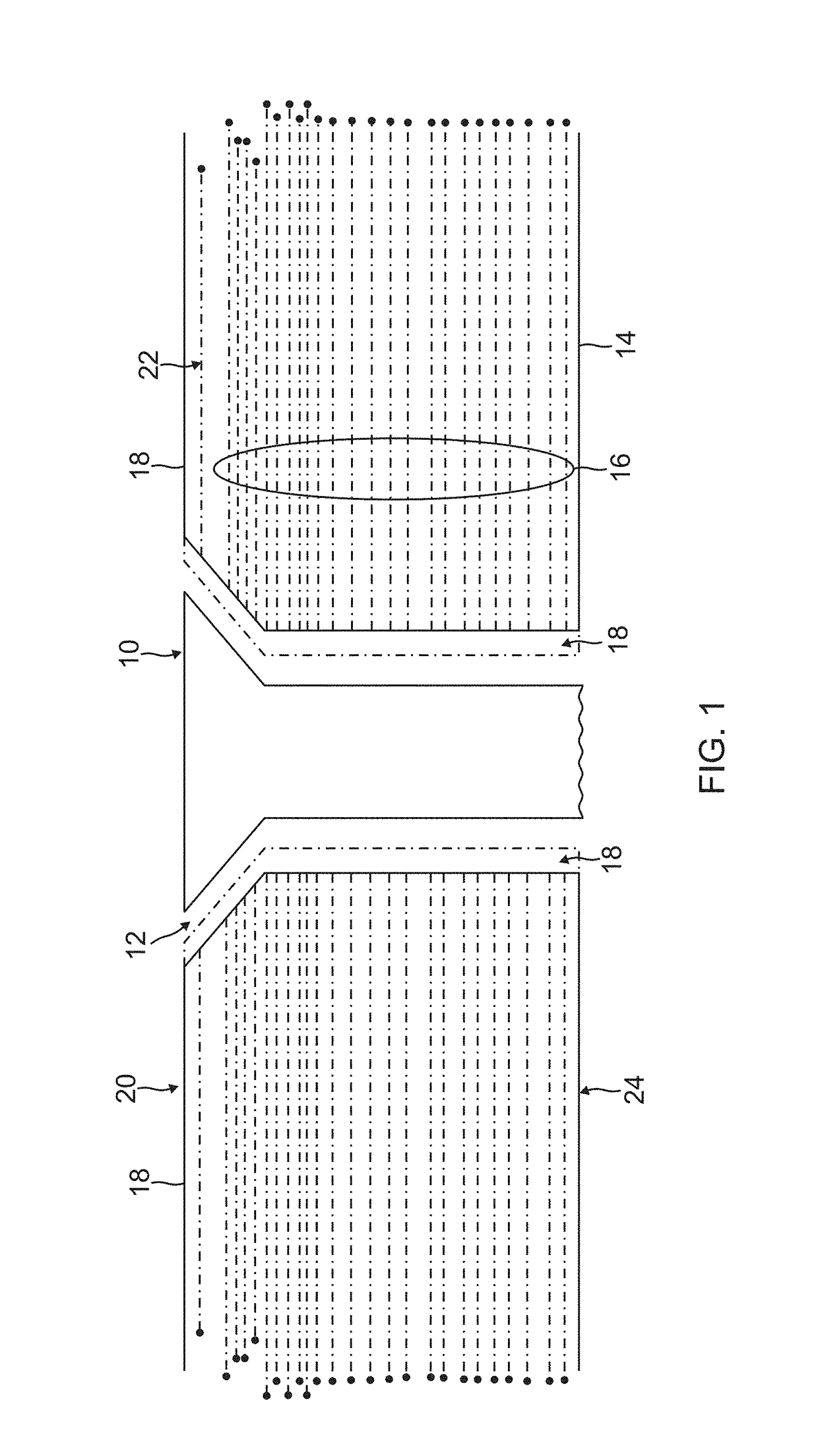

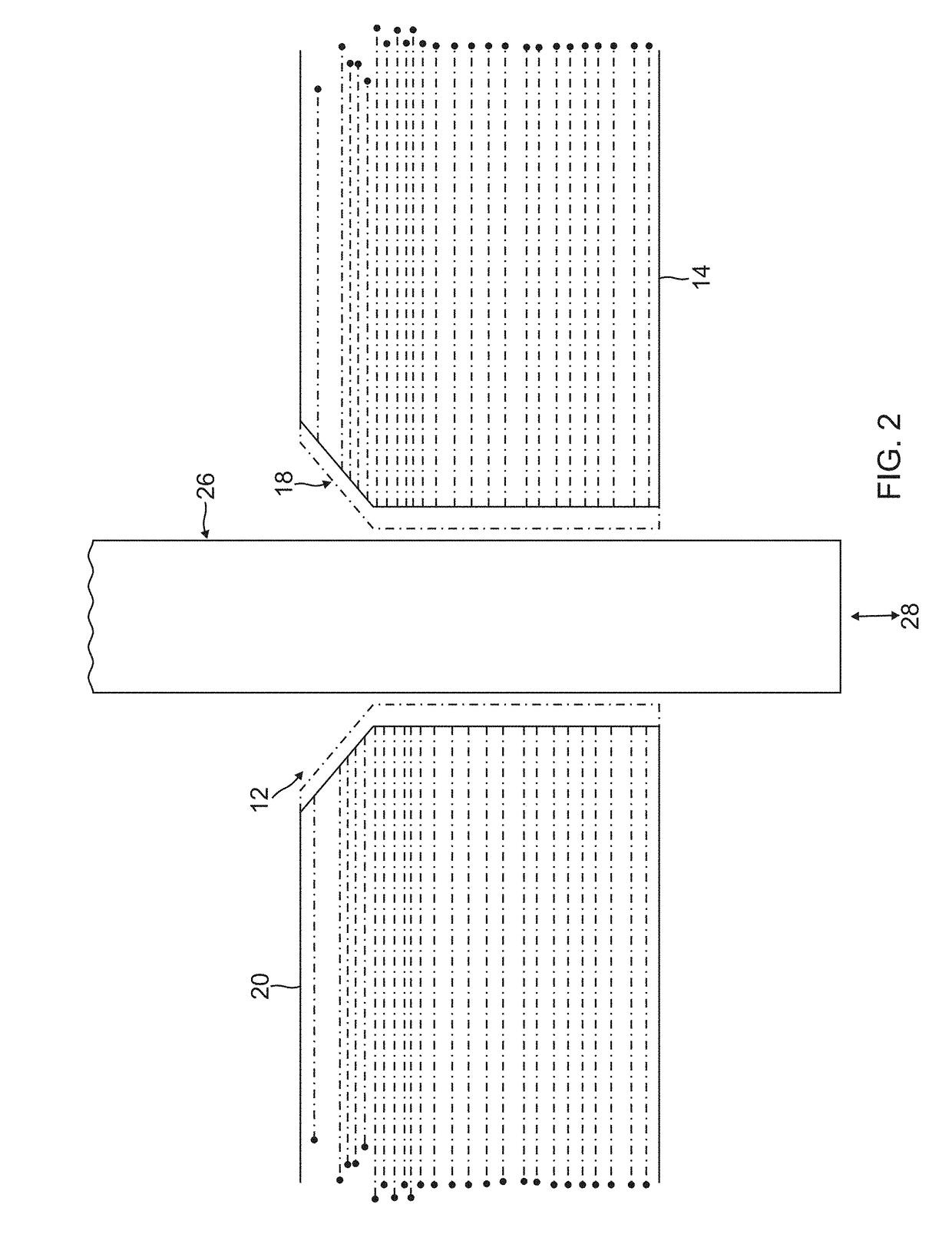

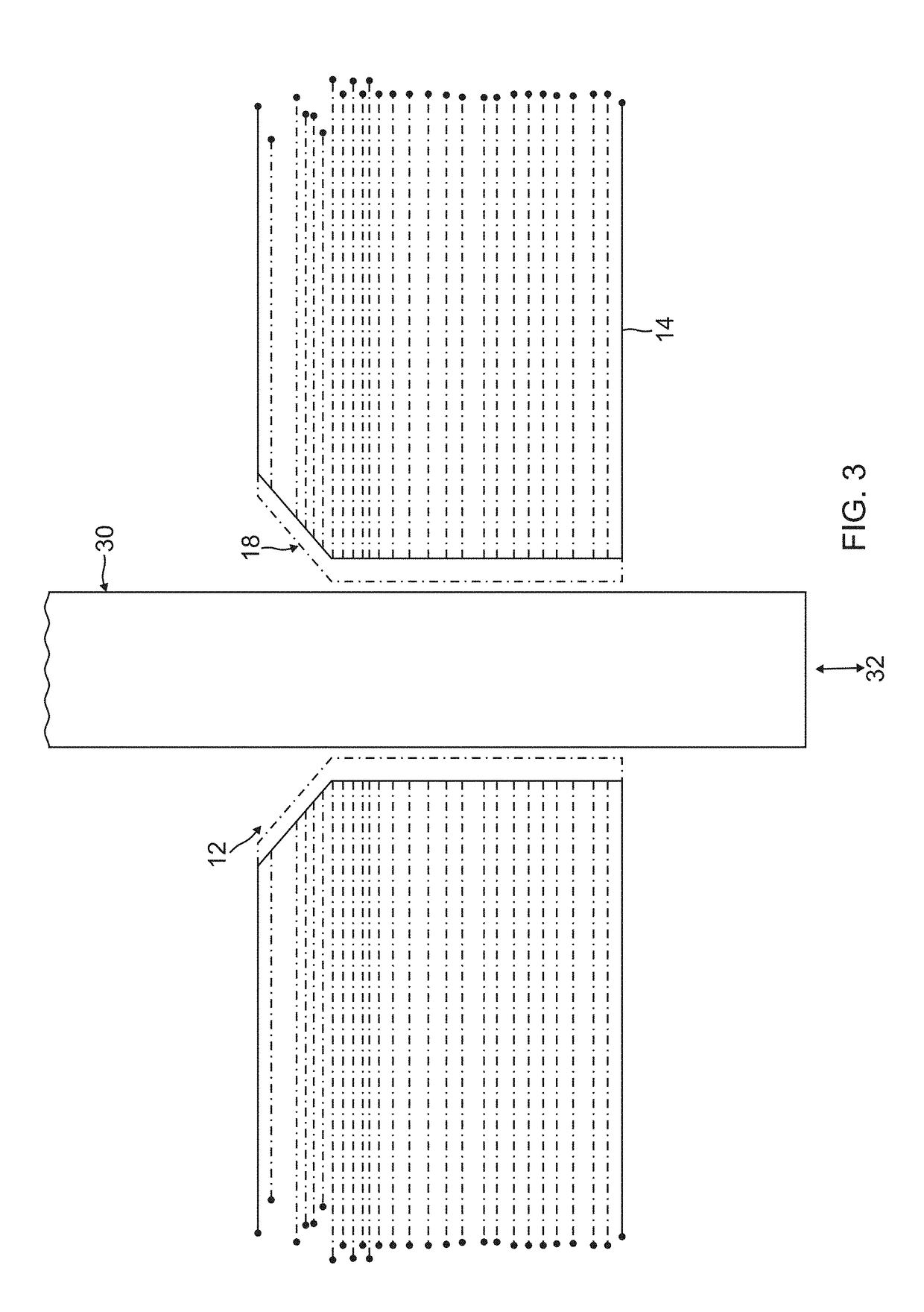

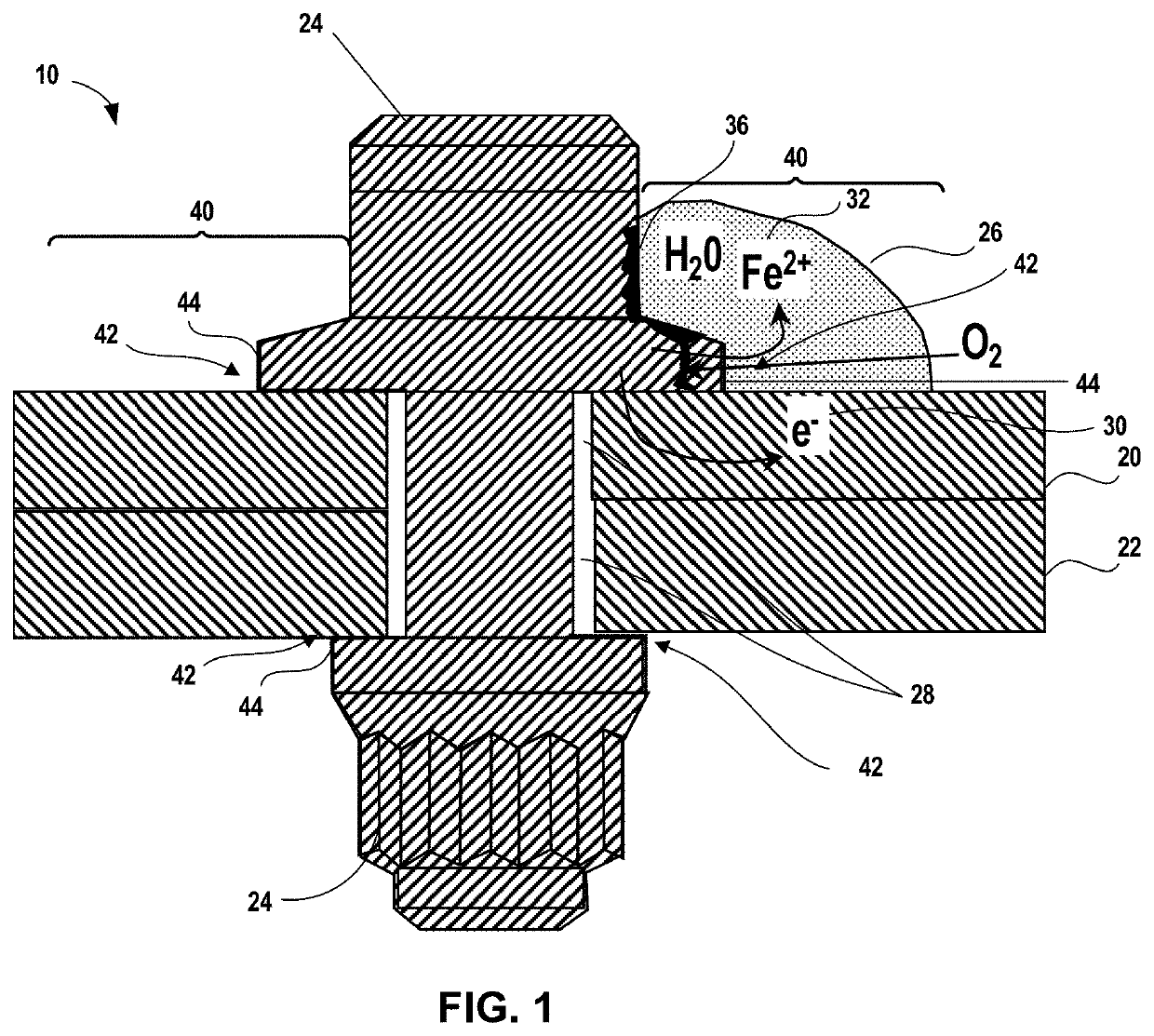

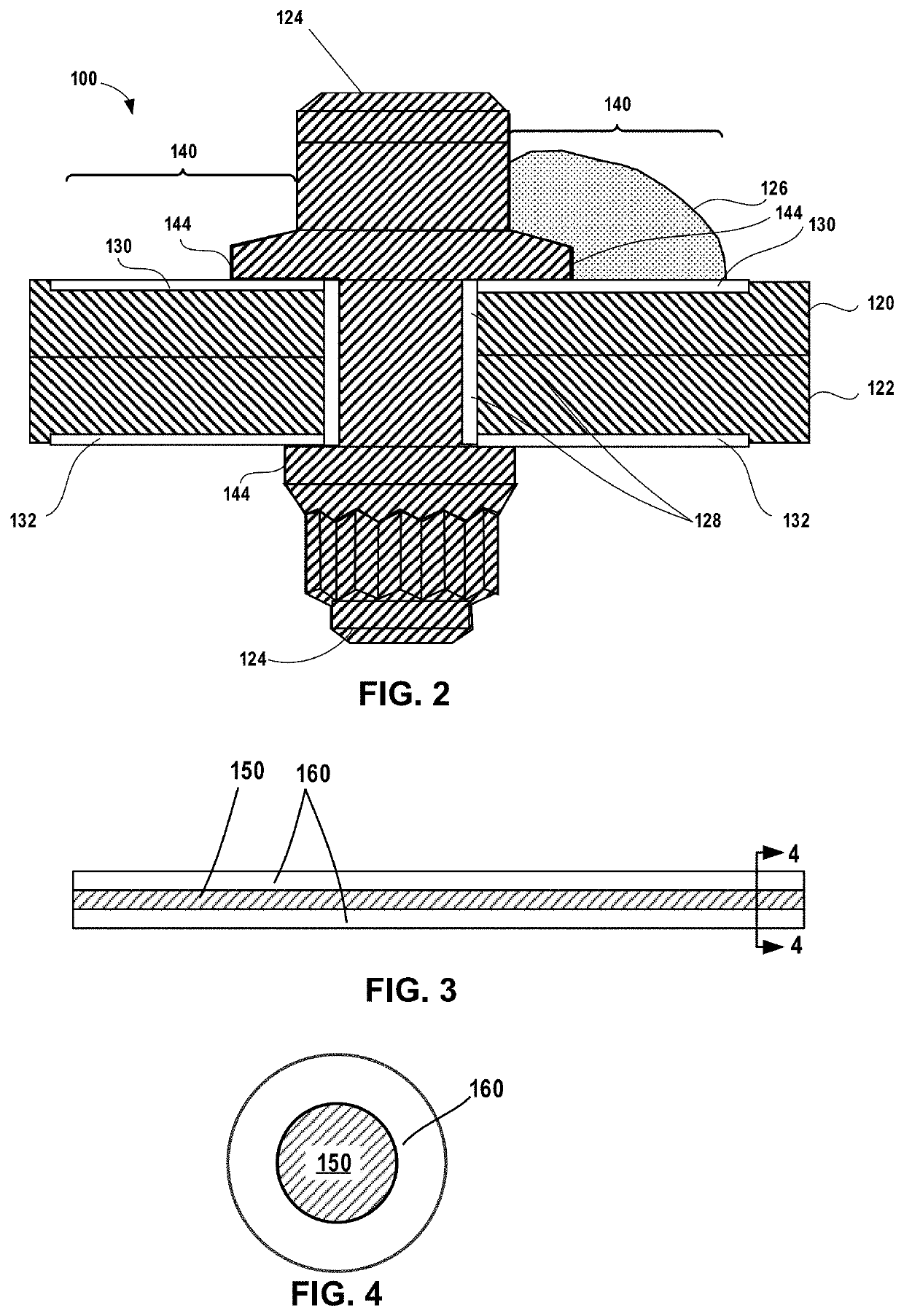

Edge seals for composite structure fuel tanks

ActiveUS20080128430A1Avoid contactPower plant fuel tanksFuel tank safety measuresFuel tankEngineering

The cut laminate edges of aircraft fuel tanks formed of carbon fiber reinforced polymers are sealed to prevent the exposure of carbon fibers to combustible fuel. The edge seal is produced from a prepreg form using a thermosetting resin matched to the characteristics of the resin used in the laminate. The prepreg form can be applied to the cut laminate edges either before or after the laminate is cured. The edge seal acts a dielectric layer that both electrically insulates the cut laminate edges from the fuel and mechanically contains energetic particles produced at the edges due to lighting strikes or other sources of electrical charges.

Owner:THE BOEING CO

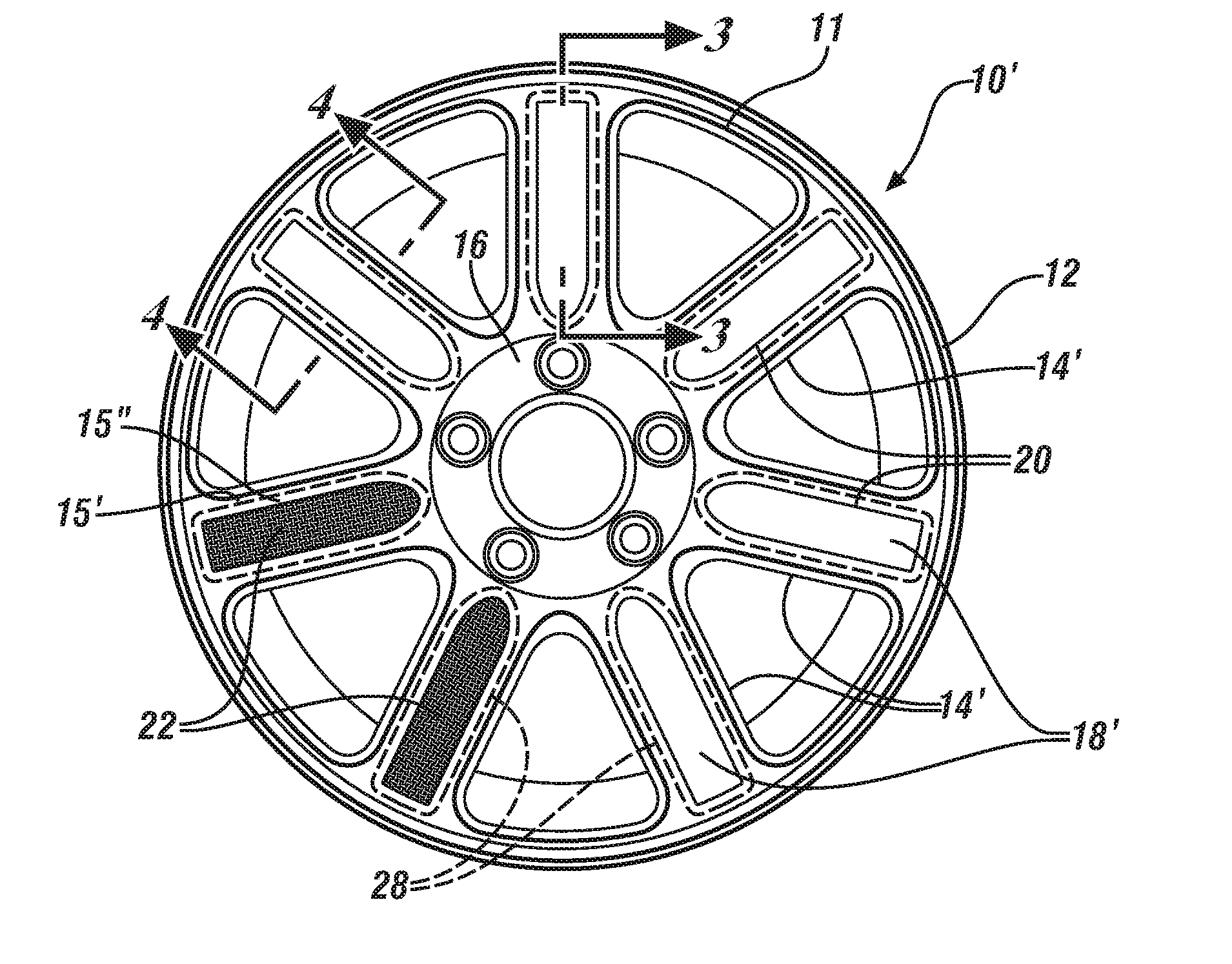

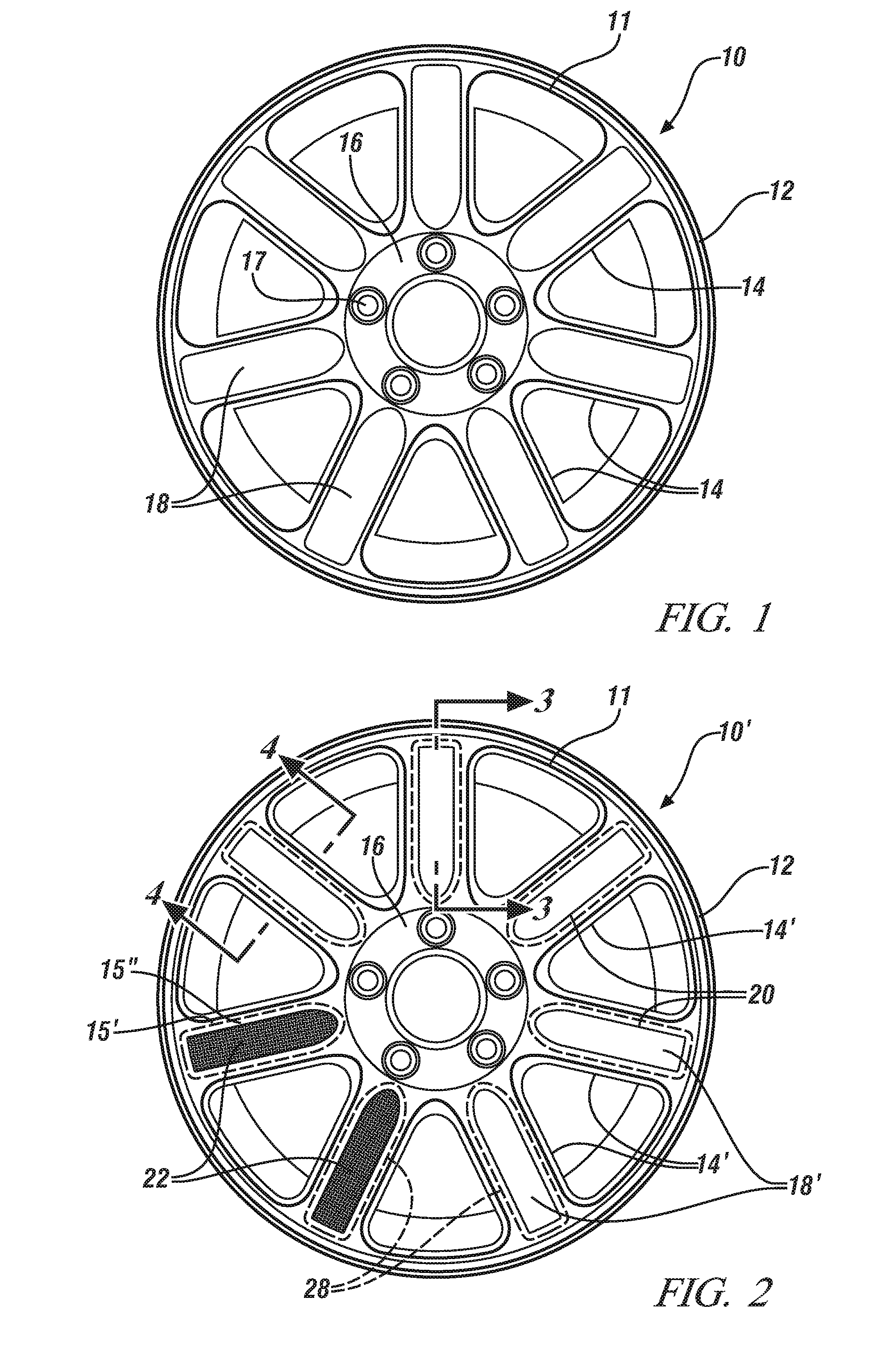

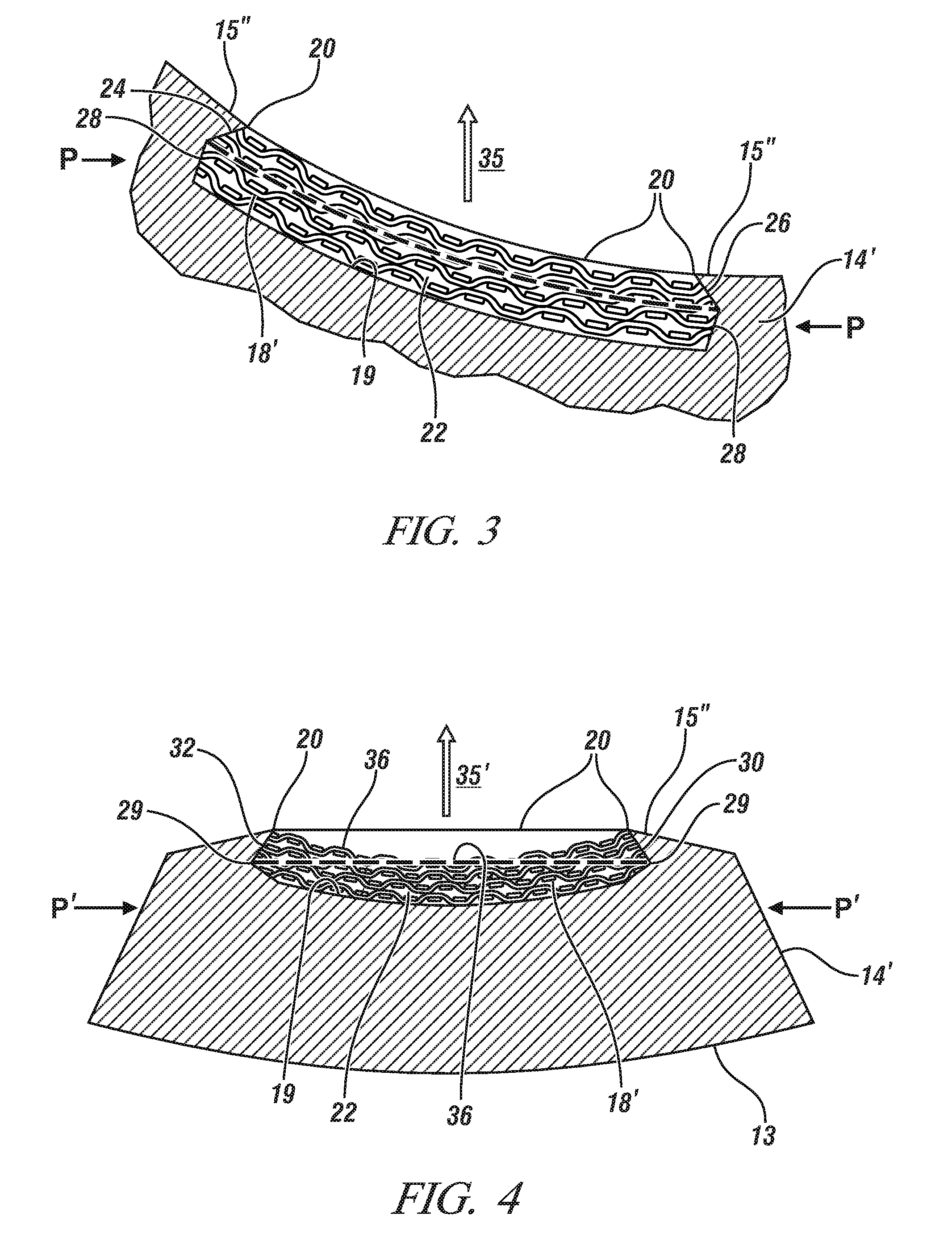

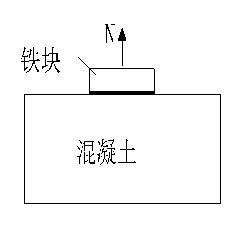

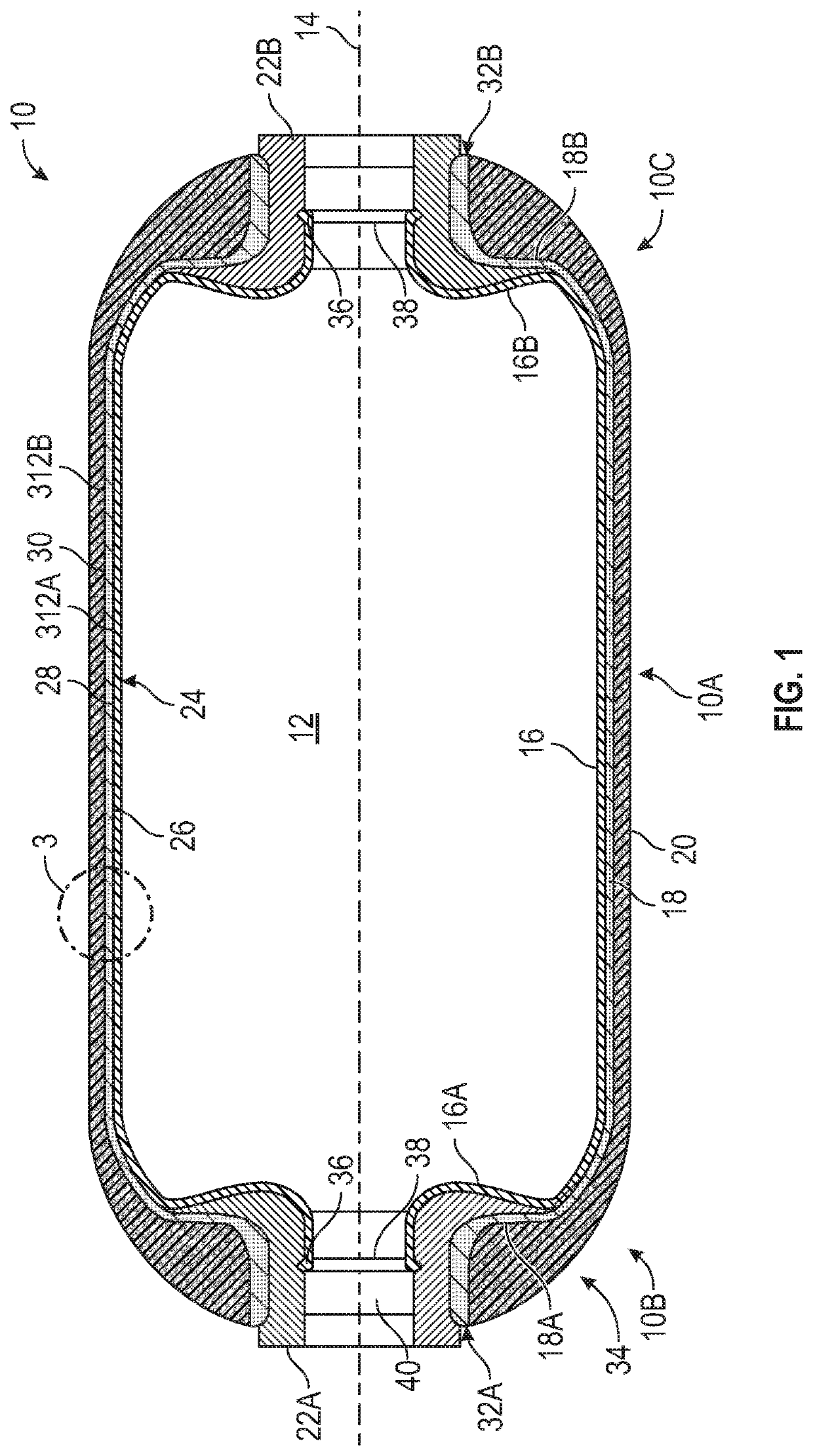

Light-weight vehicle wheels with carbon fiber inserts

ActiveUS20130026816A1Portion is increasedHigh modulusRimsNon-metallic wheel bodyFiberThermal dilatation

Application of carbon fiber reinforced polymer structures to metal vehicle wheels is effective in reducing the mass of the wheel while retaining suitable stiffness in the wheel structure. For maximum effect the reinforced polymer structure and the metal wheel must operate cooperatively. Because of the wide range of operating temperatures experienced by wheels and the large difference in coefficient of thermal expansion between metals and carbon fiber reinforced composites attachment of the polymer structure to the wheel by adhesive alone is problematical. However a wheel with an effective and durable reinforcement may be fabricated by confining, through mechanical interference, the reinforced polymer in a cavity in or on the spoke and by preheating the wheel before curing the polymer.

Owner:GM GLOBAL TECH OPERATIONS LLC

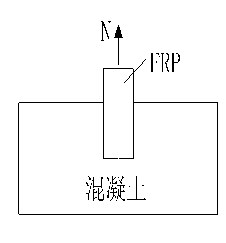

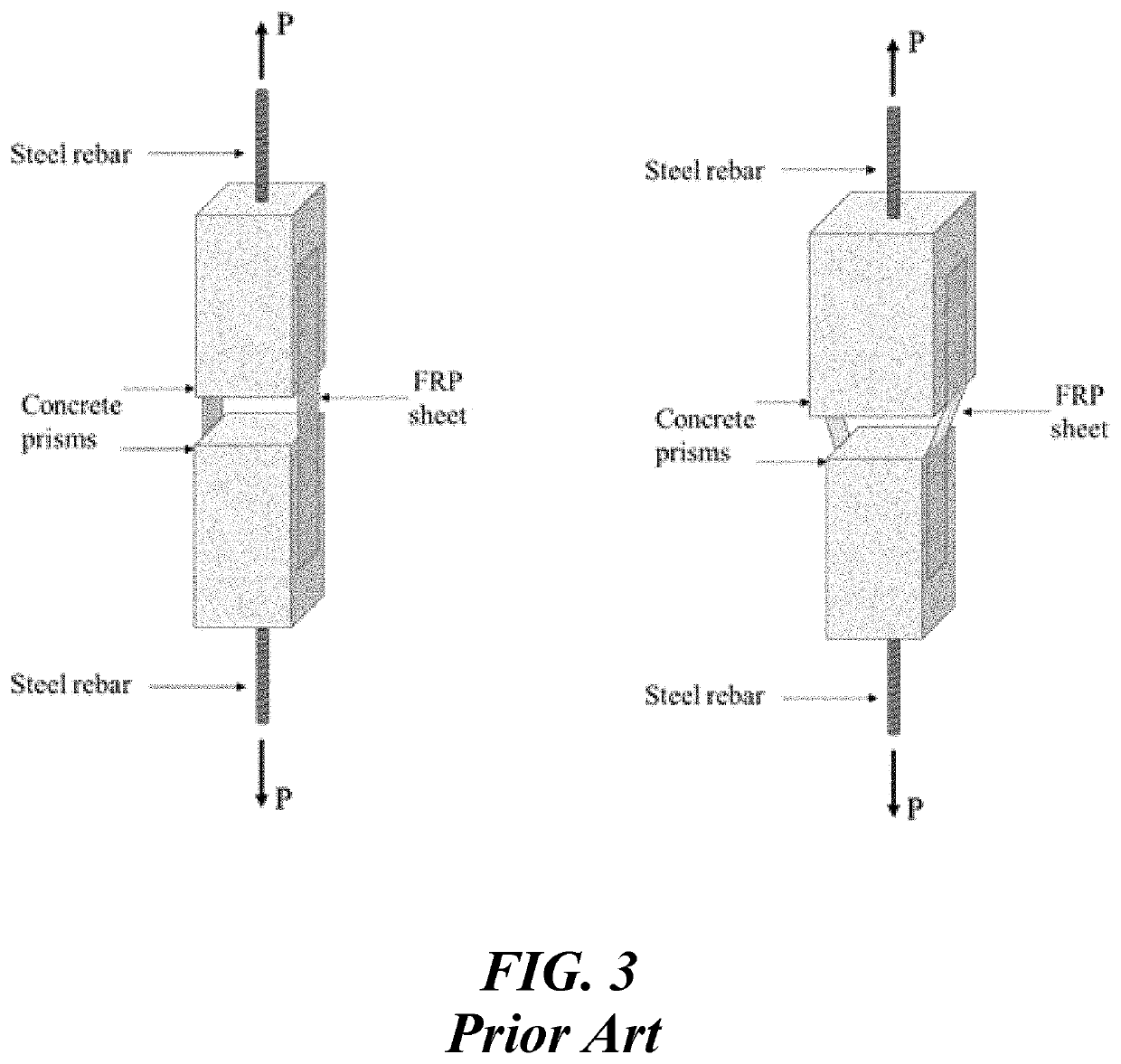

Method for testing interface bond behavior of CFRP (carbon fiber reinforced polymer) cloth-concrete based on beam specimen

InactiveCN103344560ATruly reflect the state of stressEasy to operateUsing mechanical meansMaterial analysisInverted-T shapeEngineering

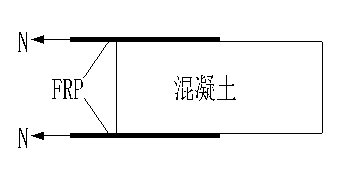

The invention discloses a method for testing interface bond behavior of CFRP (carbon fiber reinforced polymer) cloth-concrete based on a beam specimen. The method comprises three steps of preparing a test specimen, arranging a test point and loading a test. The test specimen manufactured in the first step is the beam specimen and comprise two concrete test blocks, which are arranged at left and right and symmetric in shape; the two concrete test blocks are inverted T-shaped concrete test blocks; the upper parts in the middle of the two concrete test blocks are connected by a steel hinge; the steel hinge is divided into left and right halves; and the left and right halves are respectively adhered to the concrete test block at the corresponding side, and have the rotation ability. Compared with the traditional double shear test method for testing the interface bond behavior of the CFRP cloth-concrete, the effect of asymmetric loading on the data reliability is avoided; the method has a unique advantage of high accuracy of the test result; and the accuracy and the creditability of the detection result are improved.

Owner:ZHENGZHOU UNIV

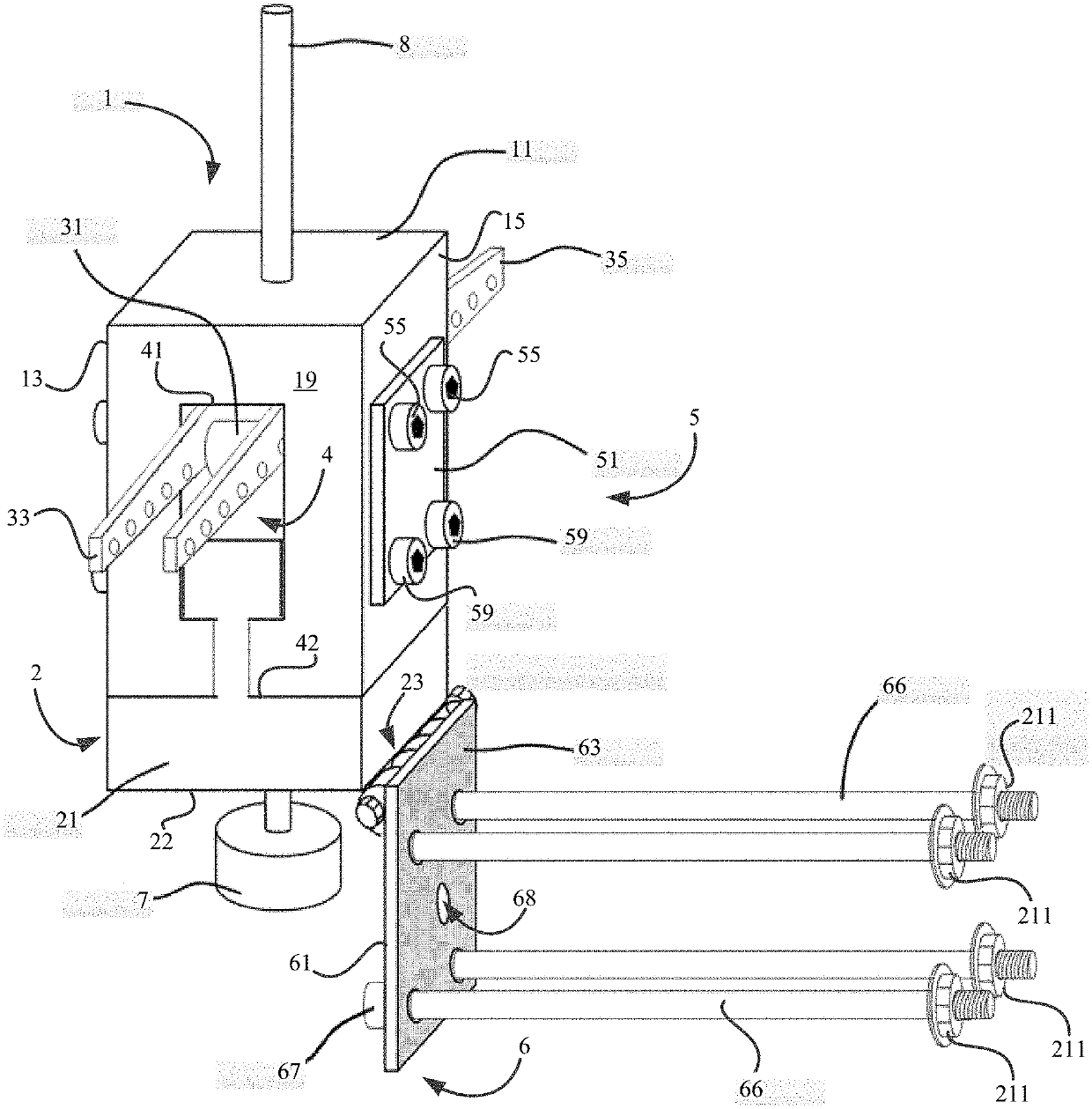

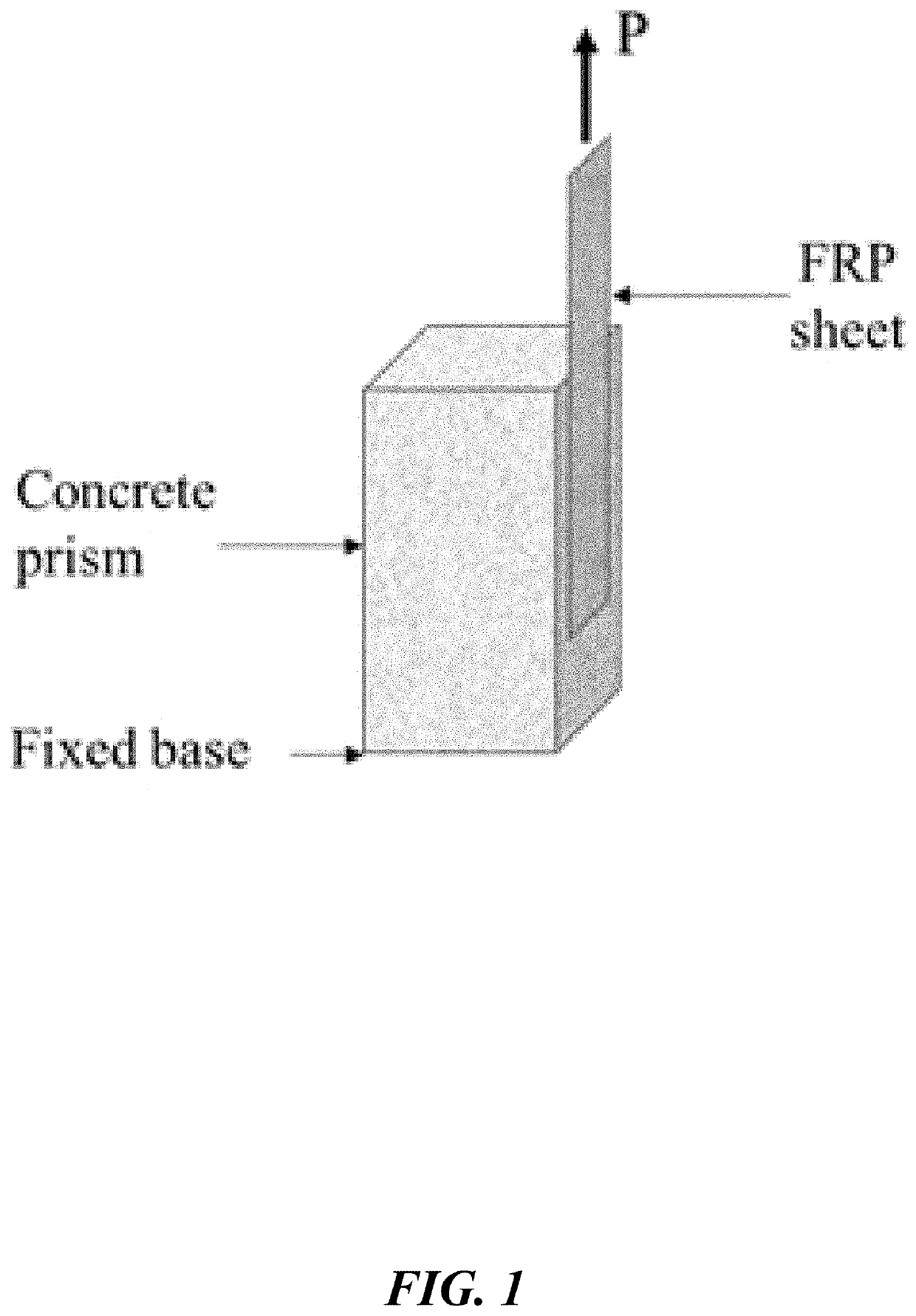

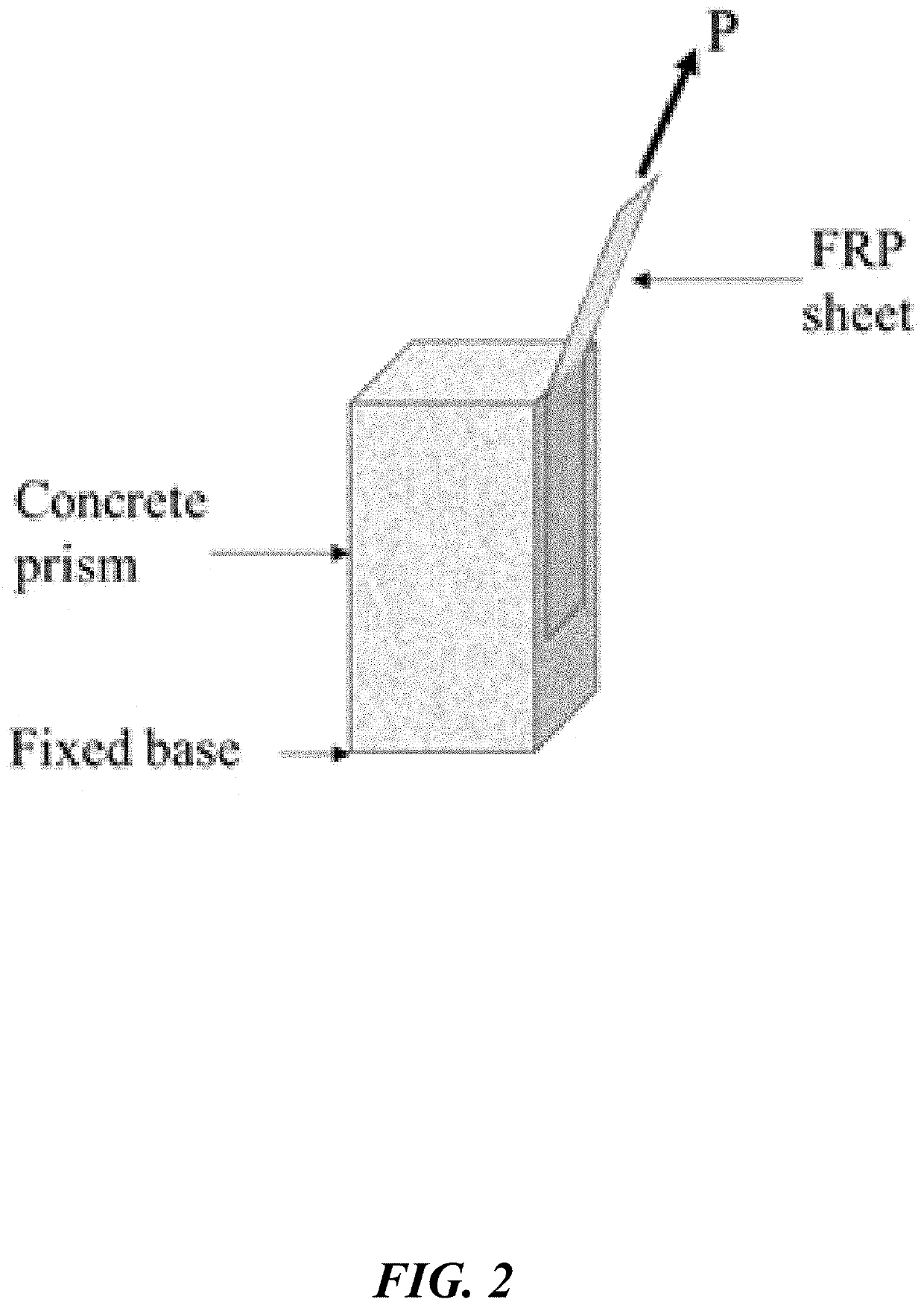

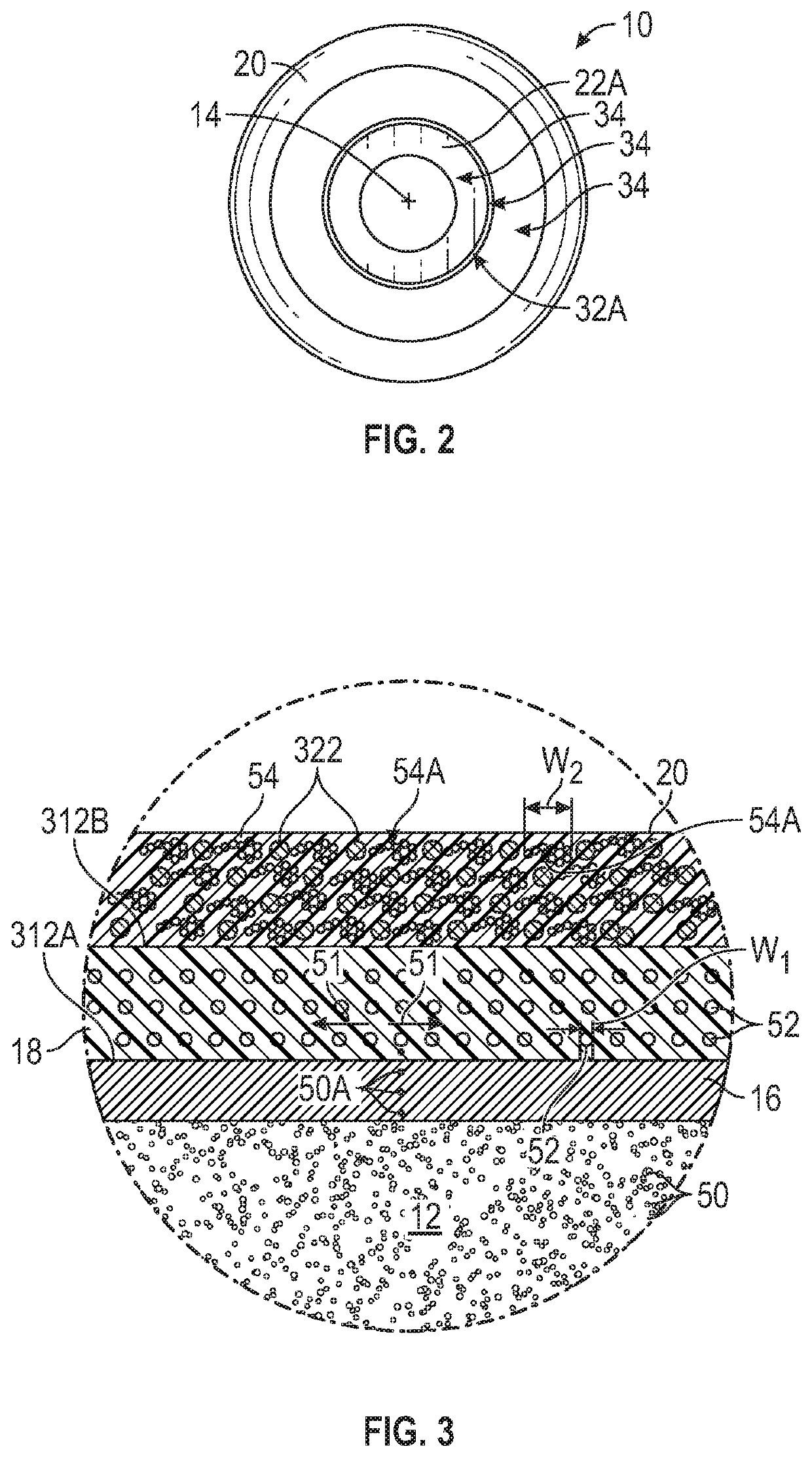

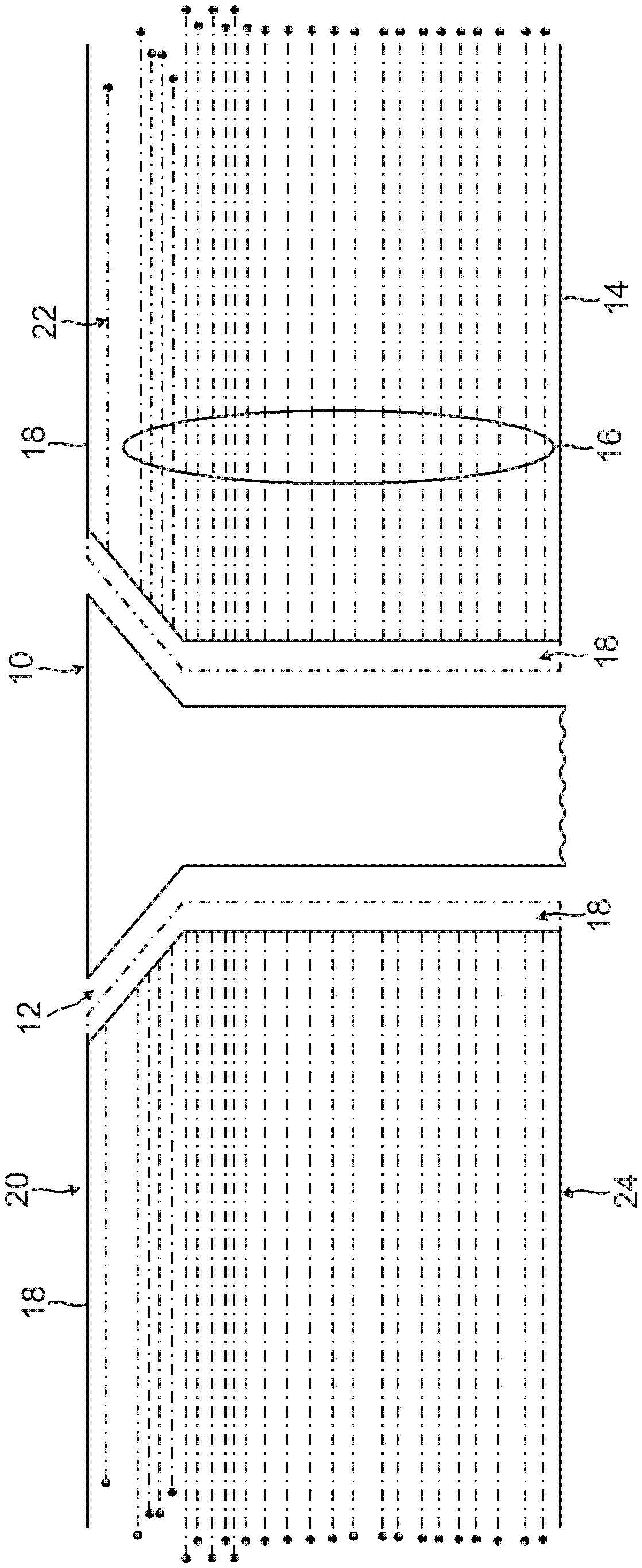

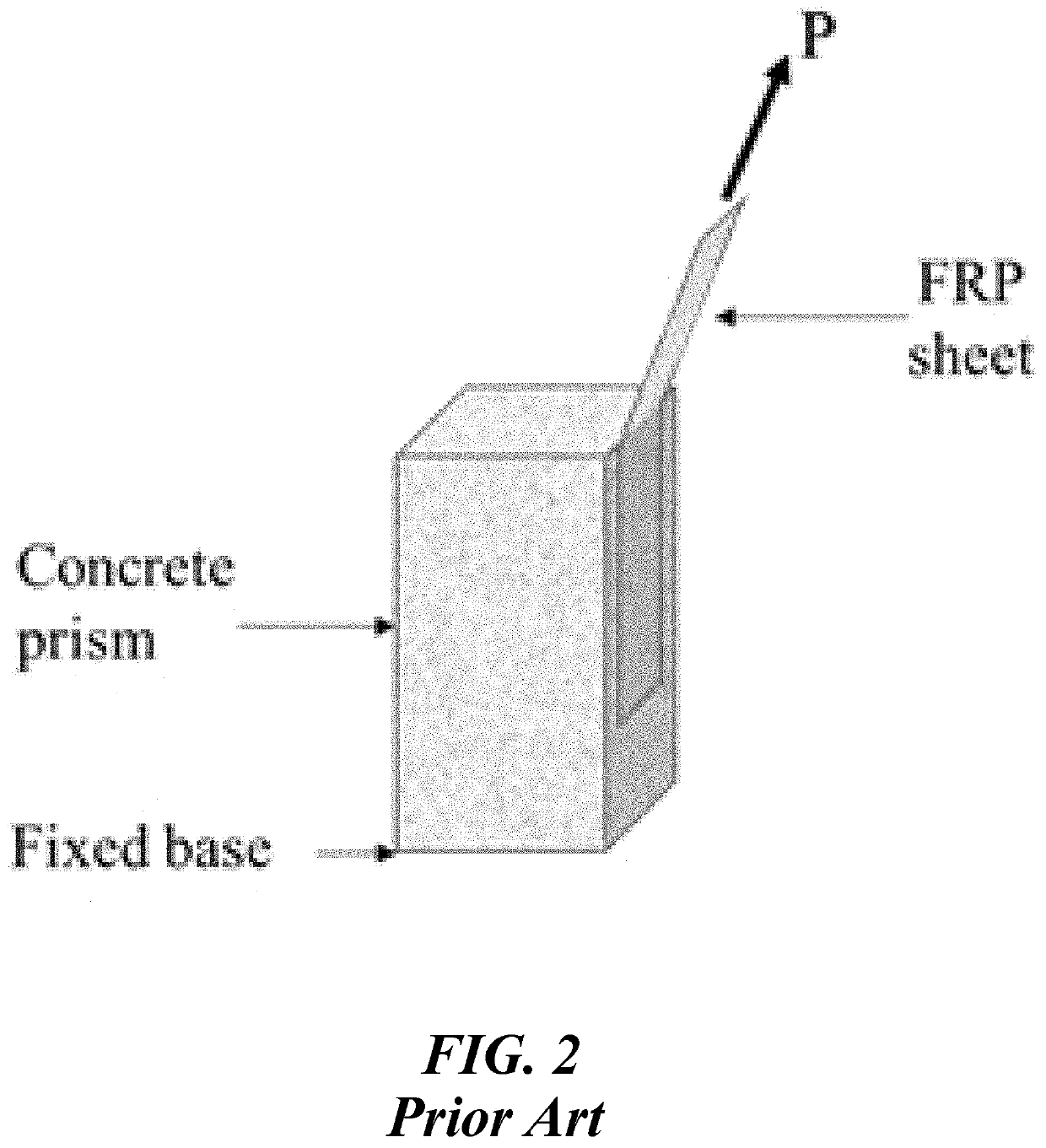

Universal debonding test apparatus for carbon fiber reinforced polymer – concrete system and method for sequential multi-testing

ActiveUS20210033522A1Improve abilitiesMinimize eccentricityEarth material testingUsing mechanical meansMechanical engineeringPolymer

A test apparatus used for simulating debonding between a carbon fiber reinforced polymer (CFRP) and concrete in a CFRP-strengthened structure consists of a primary structural block, a secondary structural block, an adjustable hanger, a receiving slot, an attachment mechanism, a pull-off disk, a connecting plate having a plurality of rods. The adjustable hanger and the secondary structural block are slidably positioned into the receiving slot that traverses into a structural body of the primary structural block. The adjustable hanger is mainly used during double-shearing tests and mixed-mode tests, wherein both shearing and peeling is analyzed in mixed-mode tests. The secondary structural block is used in double-shear tests, mixed-mode tests, single-shear tests, tension pull-off tests, and beam-bend tests. The attachment mechanism, which holds the primary structural block, the secondary structural block, and the adjustable hanger together, is also used during single-shear tests and beam-bend tests.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Method for preparing high thermal conductivity chopped carbon fiber reinforced polymer-based resistance welding unit

InactiveCN102672867AImprove thermal conductivityImprove mechanical propertiesFiberElectrical resistance and conductance

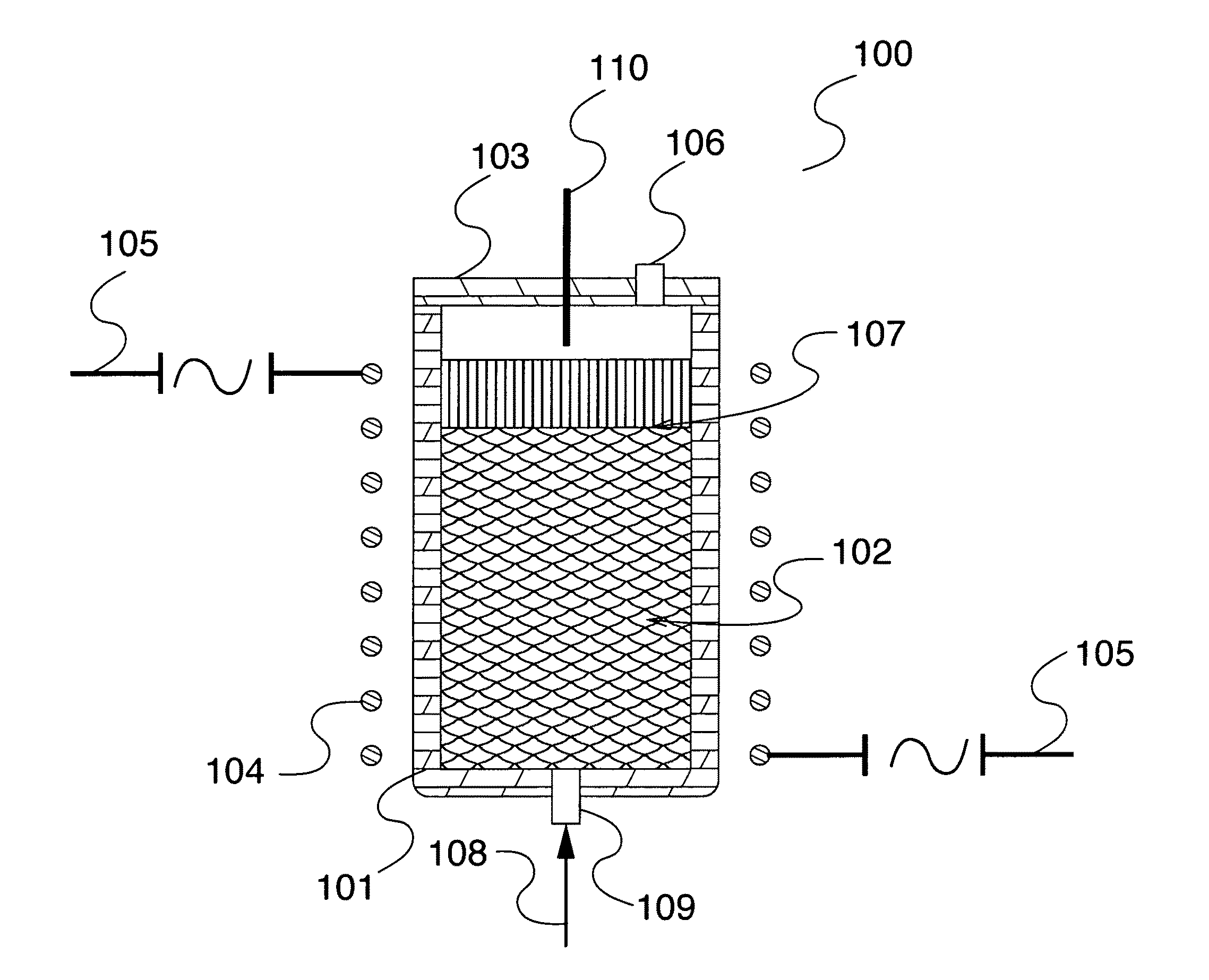

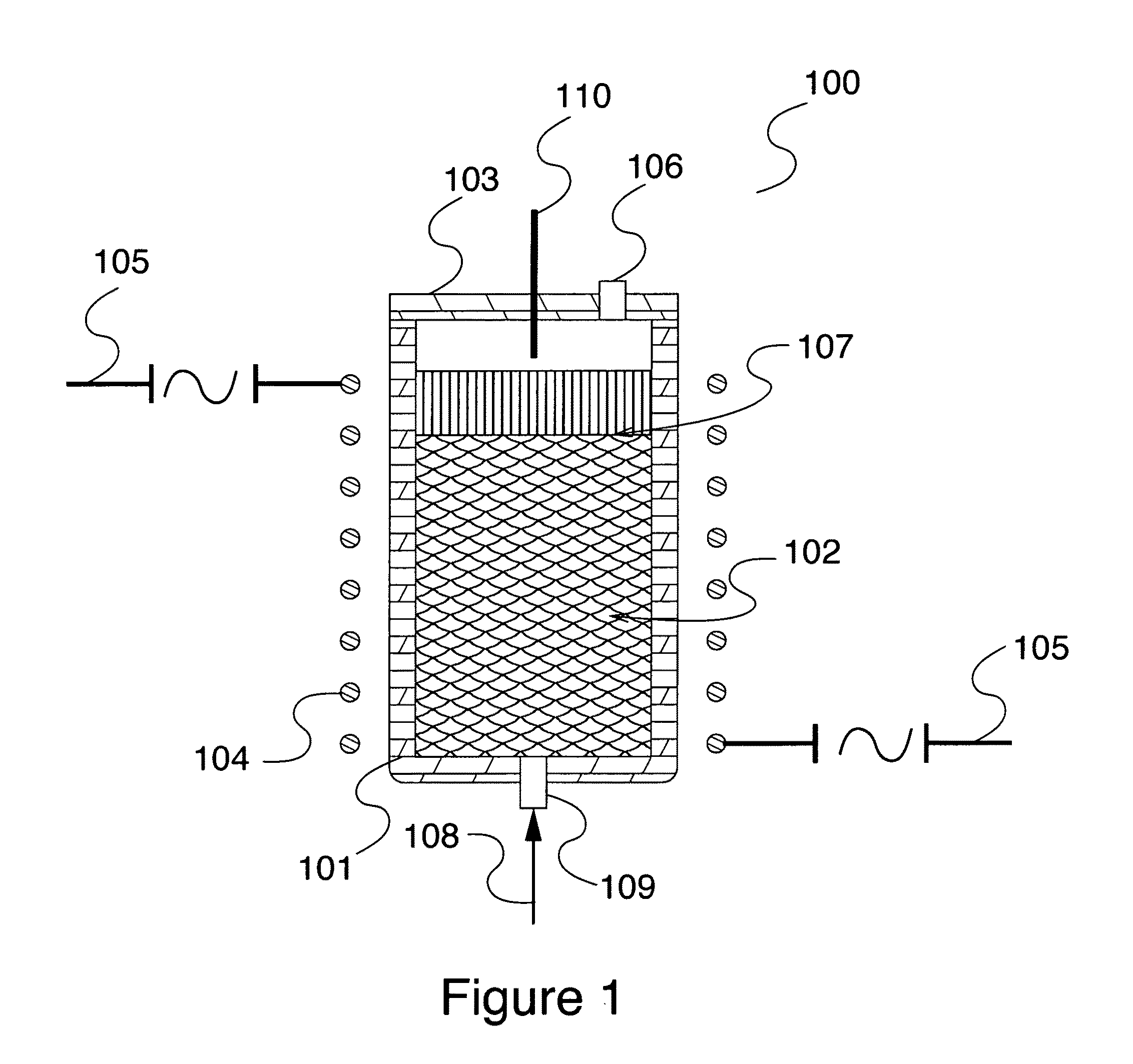

The invention discloses a method for preparing a high thermal conductivity chopped carbon fiber reinforced polymer-based resistance welding unit. The method comprises the following steps of: mixing graphene micro tablets and chopped carbon fiber in water with ultrasonic dispersion and adding a surfactant for uniformly mixing after drying; placing the mixture and thermoplastic resin to an internal mixer for mixing and pressing into a sheet in a die; and placing the sheet in a die the length of which is larger than that of the sheet, respectively adding a conducting material in clearances of both ends of the sheet and the end of the die, performing hot pressing, and grinding both ends of the sheet after demoulding so that the conducting material is exposed outside to be used as an energized electrode of the welding unit. The method is simple in preparation process, high thermal conductivity graphene micro tablets are adopted, phenomena of overburning and overshooting existing in resistance welding are avoided so that a weld is uniformly heated, the mechanical property and the conductive property of the welding unit are improved due to that the carbon fiber is added, and the resistance value of a weld assembly is at 102-101 orders of magnitude.

Owner:ZHEJIANG UNIV

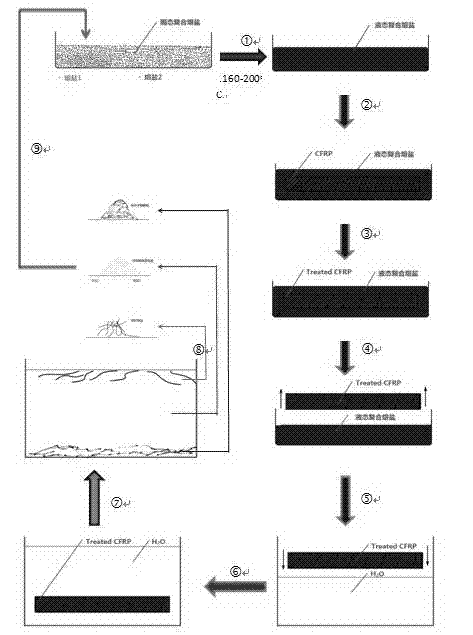

Method for recovery of carbon fiber by use of low temperature molten salt

Owner:EAST CHINA UNIV OF SCI & TECH

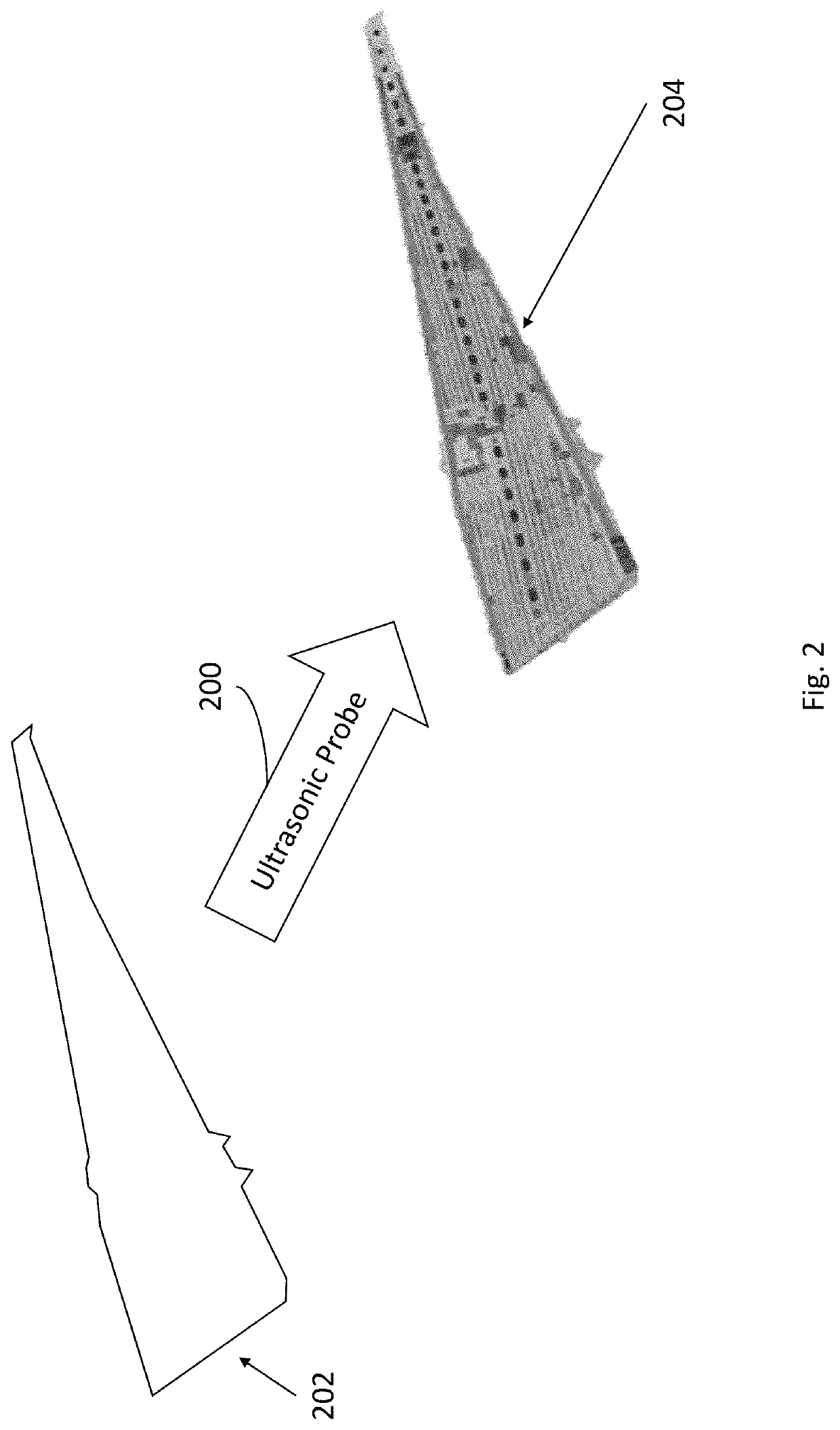

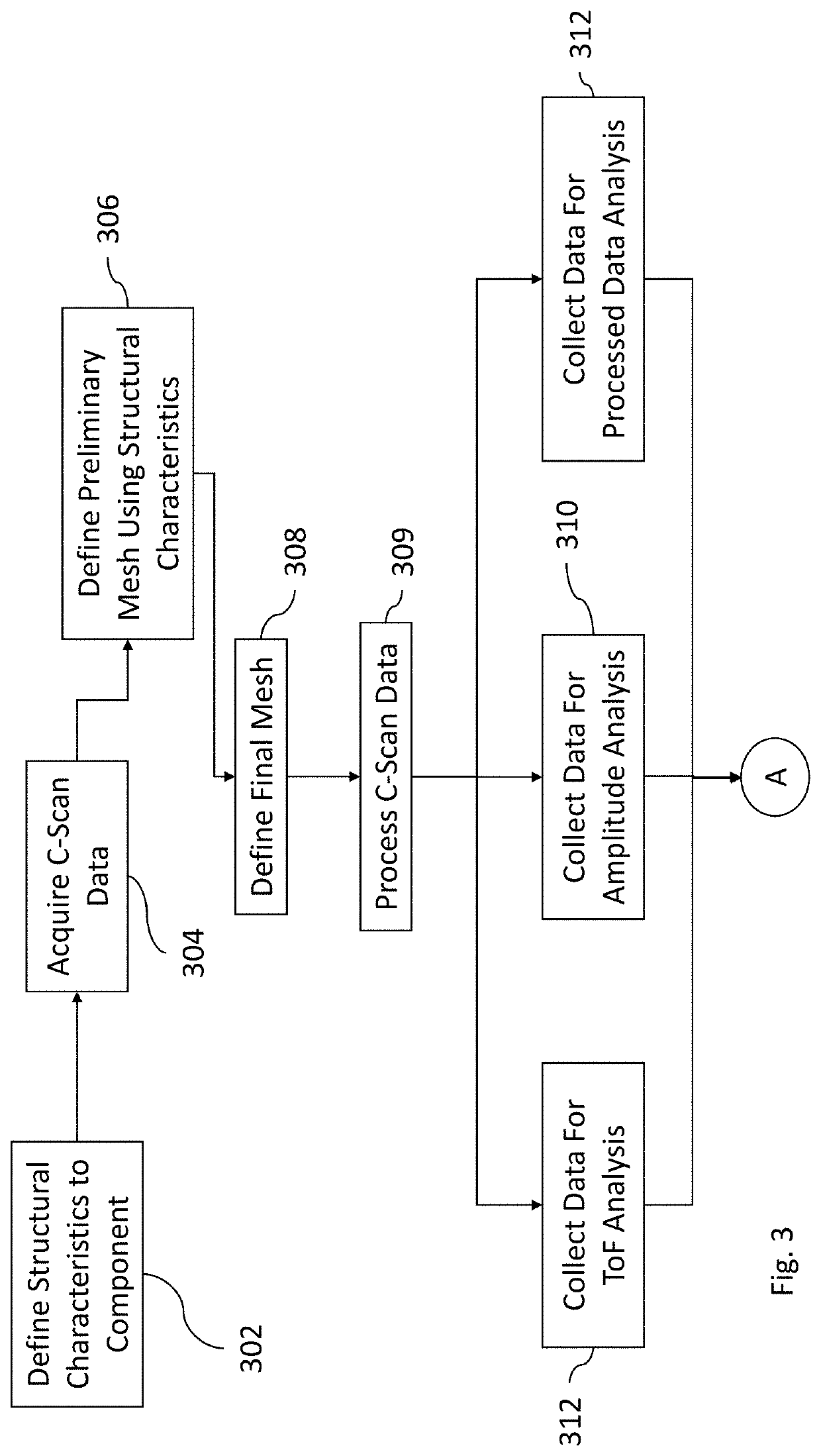

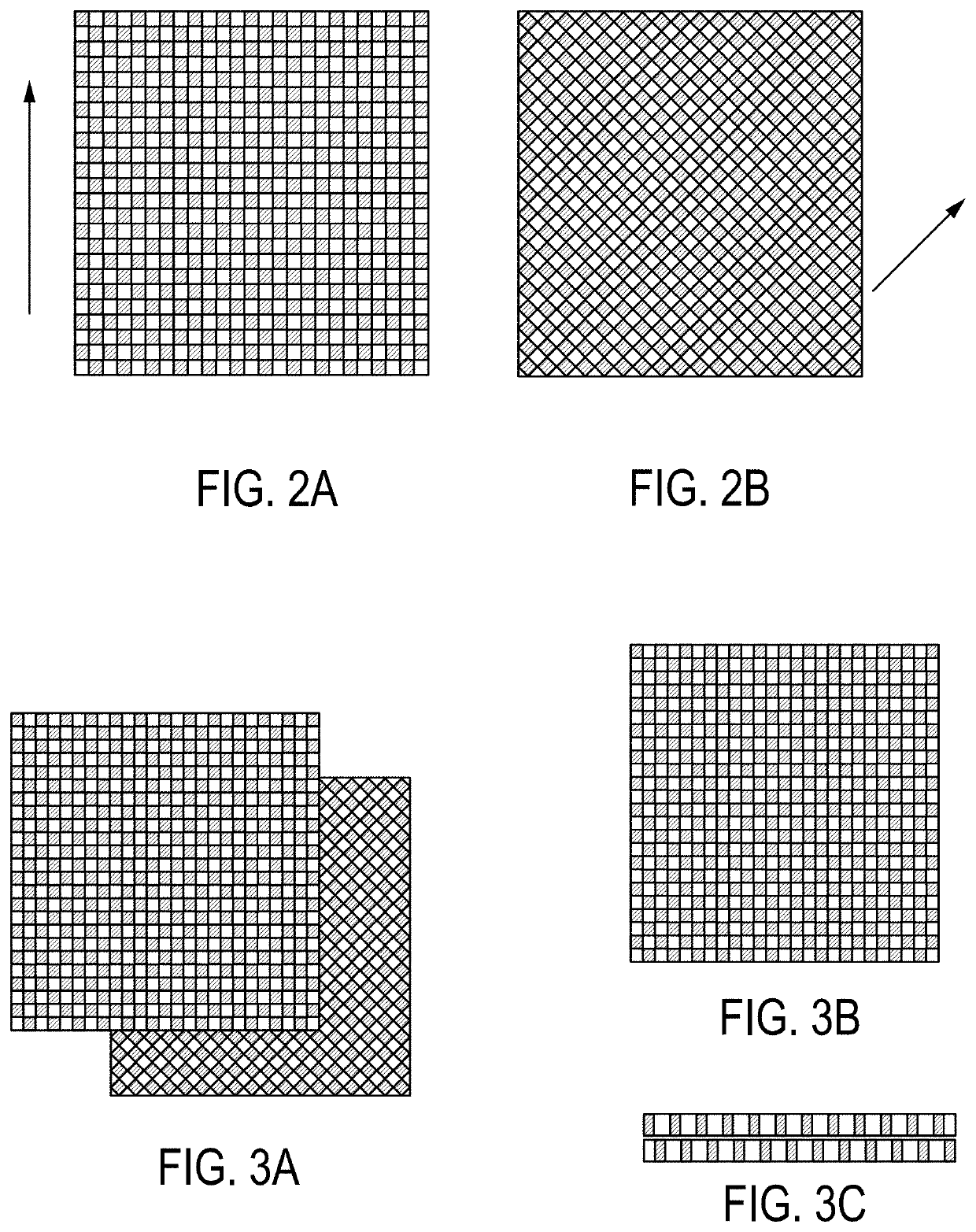

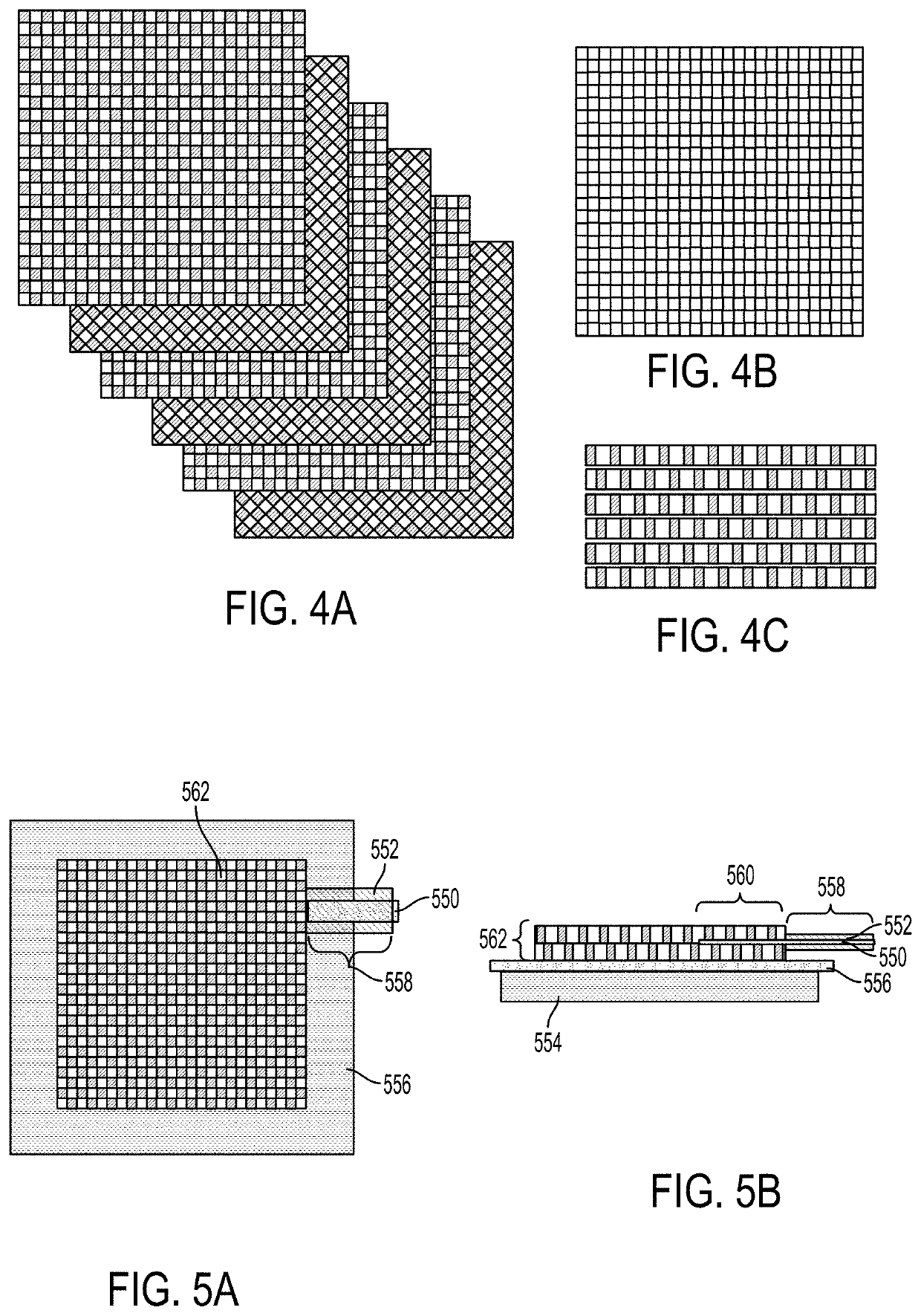

Systems and methods of ultrasonic data evaluation of composite aircraft components

A computer system is provided for processing ultrasonic data of an ultrasonic probe applied to an area of an aircraft component that includes carbon fiber reinforced polymer. C-scan data is obtained and a preliminary mesh is defined over the C-scan data by taking into account the underlying structural or mechanical characteristics of the analyzed component. The mesh is further refined and data gathered for each mesh cell. A heat map is generated based on the mesh.

Owner:AIRBUS SAS +1

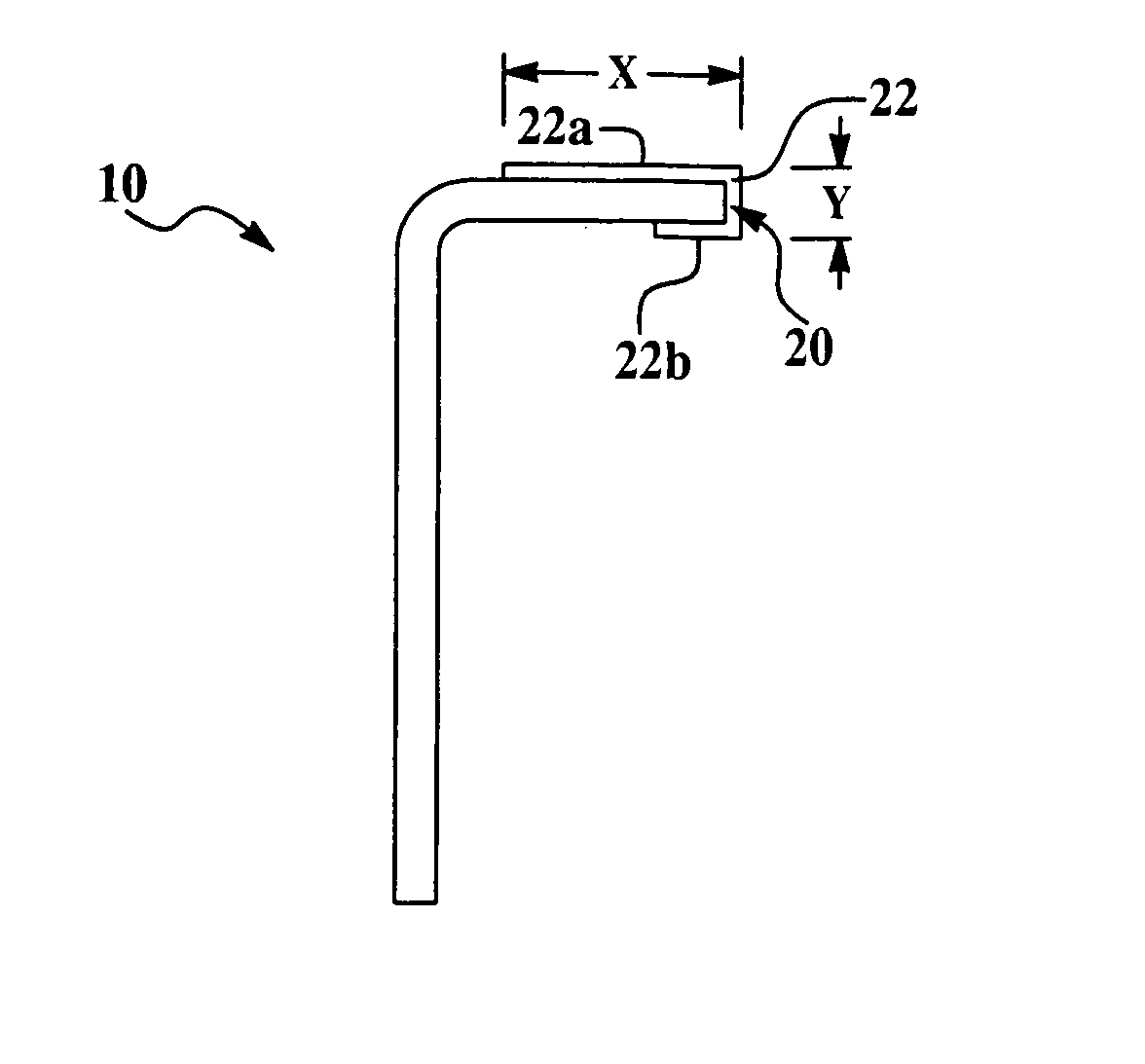

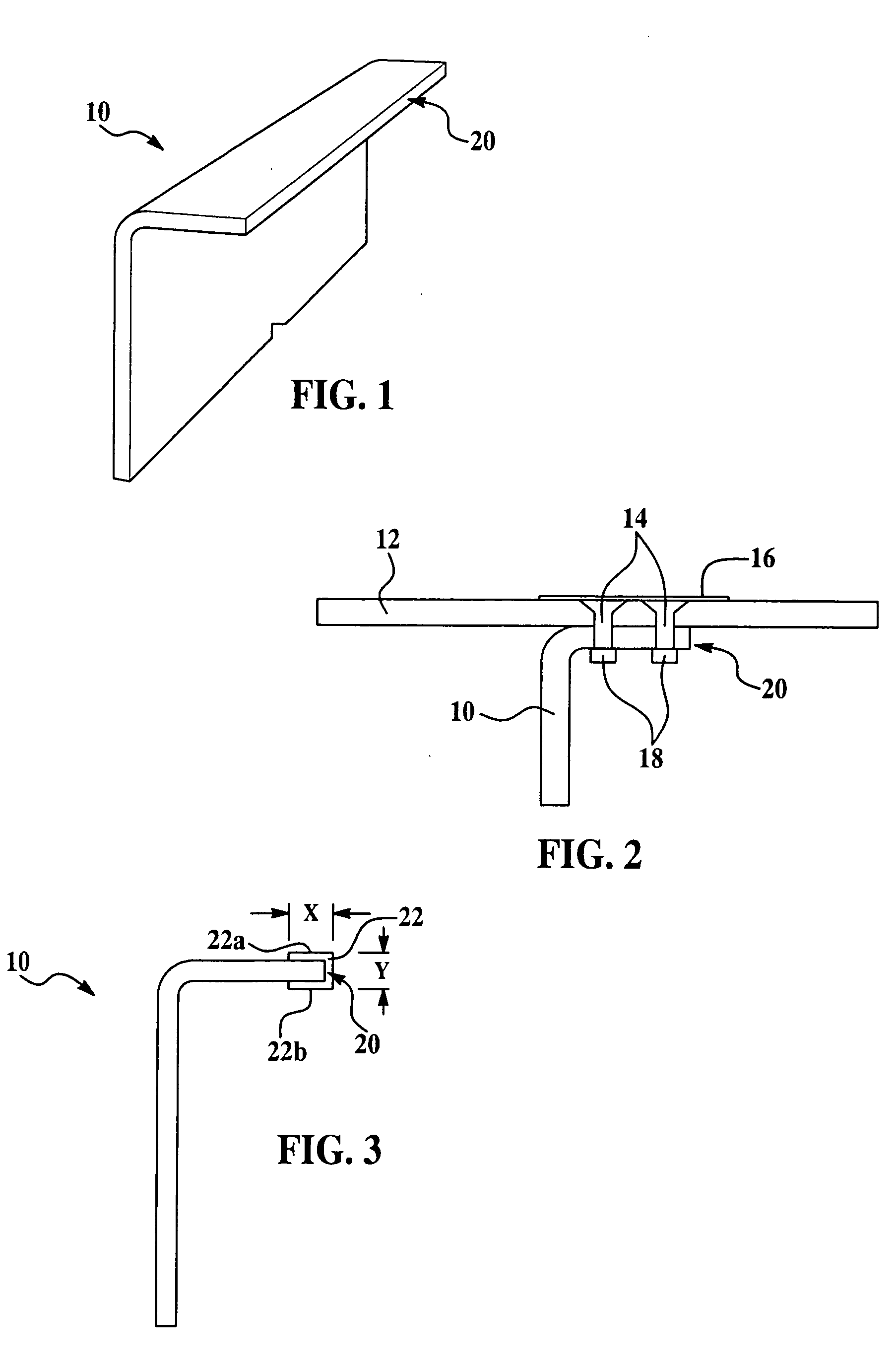

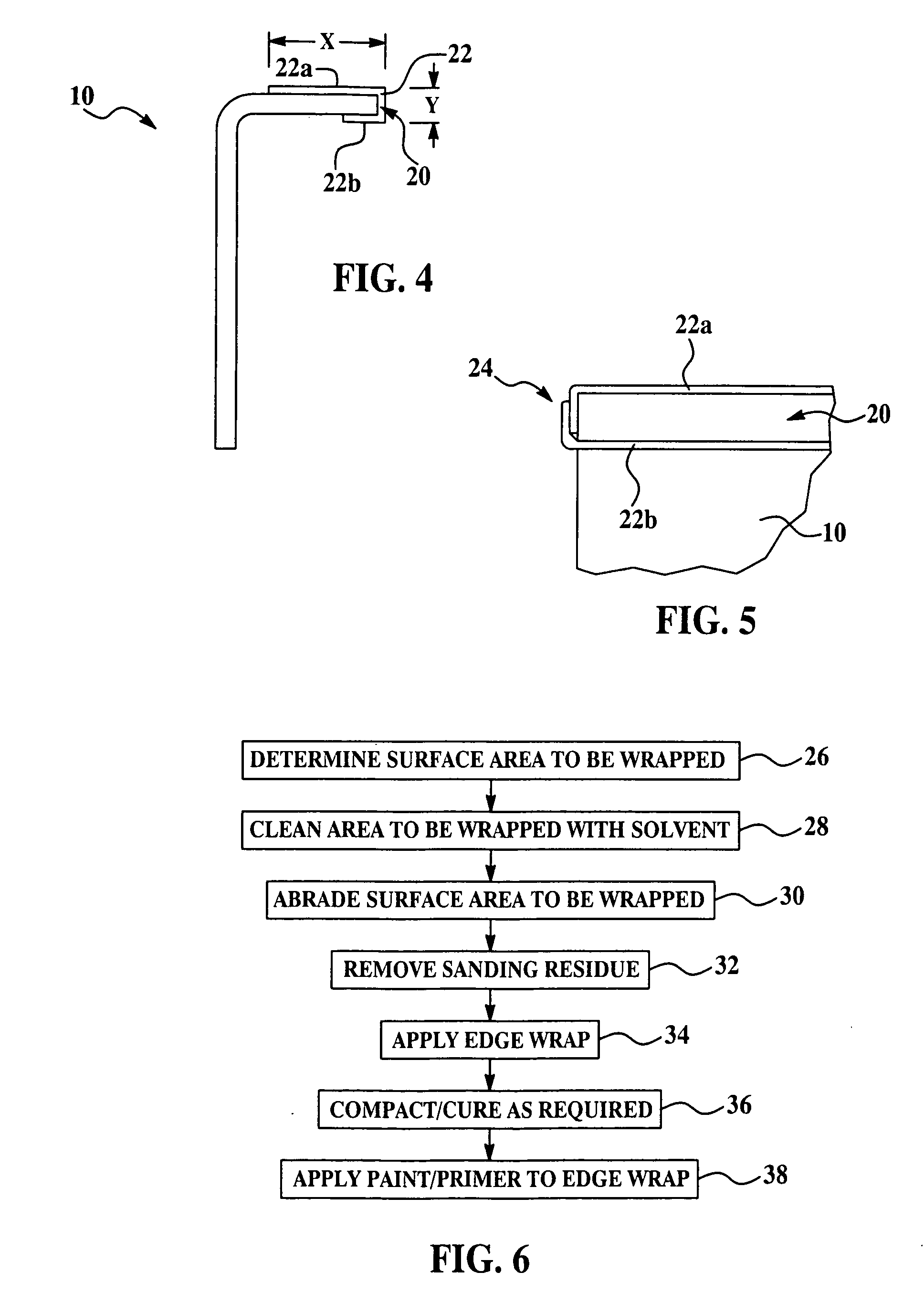

Edge seals for composite structure fuel tanks

ActiveUS8900496B2Avoid contactPower plant fuel tanksFuel tank safety measuresLightning strikeFuel tank

The cut laminate edges of aircraft fuel tanks formed of carbon fiber reinforced polymers are sealed to prevent the exposure of carbon fibers to combustible fuel. The edge seal is produced from a prepreg form using a thermosetting resin matched to the characteristics of the resin used in the laminate. The prepreg form can be applied to the cut laminate edges either before or after the laminate is cured. The edge seal acts as a dielectric layer that both electrically insulates the cut laminate edges from the fuel and mechanically contains energetic particles produced at the edges due to lightning strikes or other sources of electrical charges.

Owner:THE BOEING CO

Storage tank for pressurized gas and method of manufacturing same

ActiveUS20210010640A1Easy to disassembleReduce gas permeationVessel mounting detailsVessel manufacturingPolymer sciencePorous carbon

A storage tank for pressurized gas includes a liner defining an interior cavity for storing the pressurized gas. The storage tank further includes a nanoporous carbon shell formed from at least one pyrolyzed polymer. The liner is disposed at an inner side of the nanoporous carbon shell. The storage tank further includes a carbon fiber reinforced polymer layer disposed on an outer side of the nanoporous carbon shell opposite from the liner. The nanoporous carbon shell has an exposed surface at an exterior of the storage tank and is configured to permit gas permeated through the liner from the interior cavity to diffuse through the nanoporous carbon shell to the exposed surface.

Owner:GM GLOBAL TECH OPERATIONS LLC

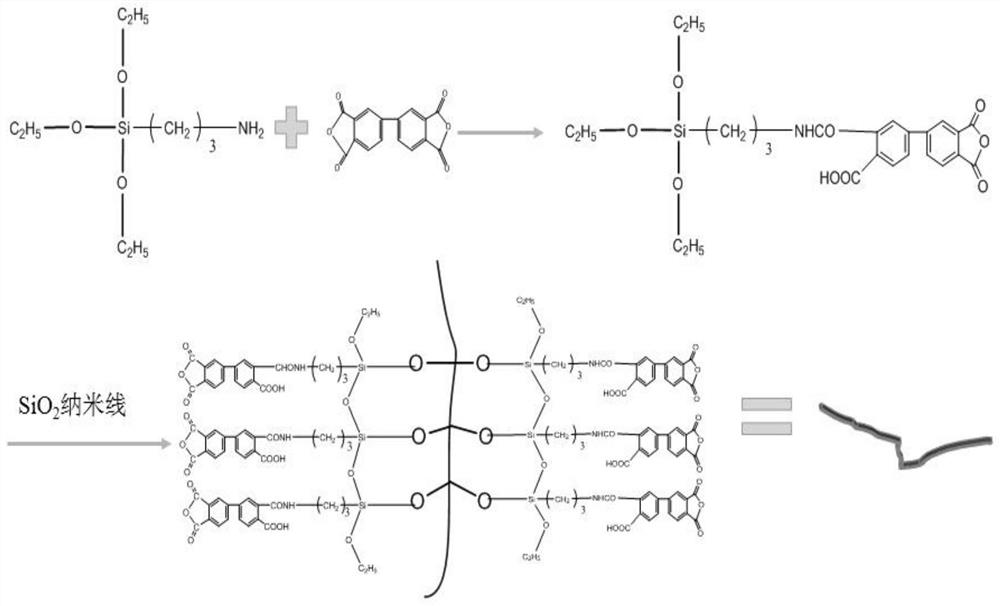

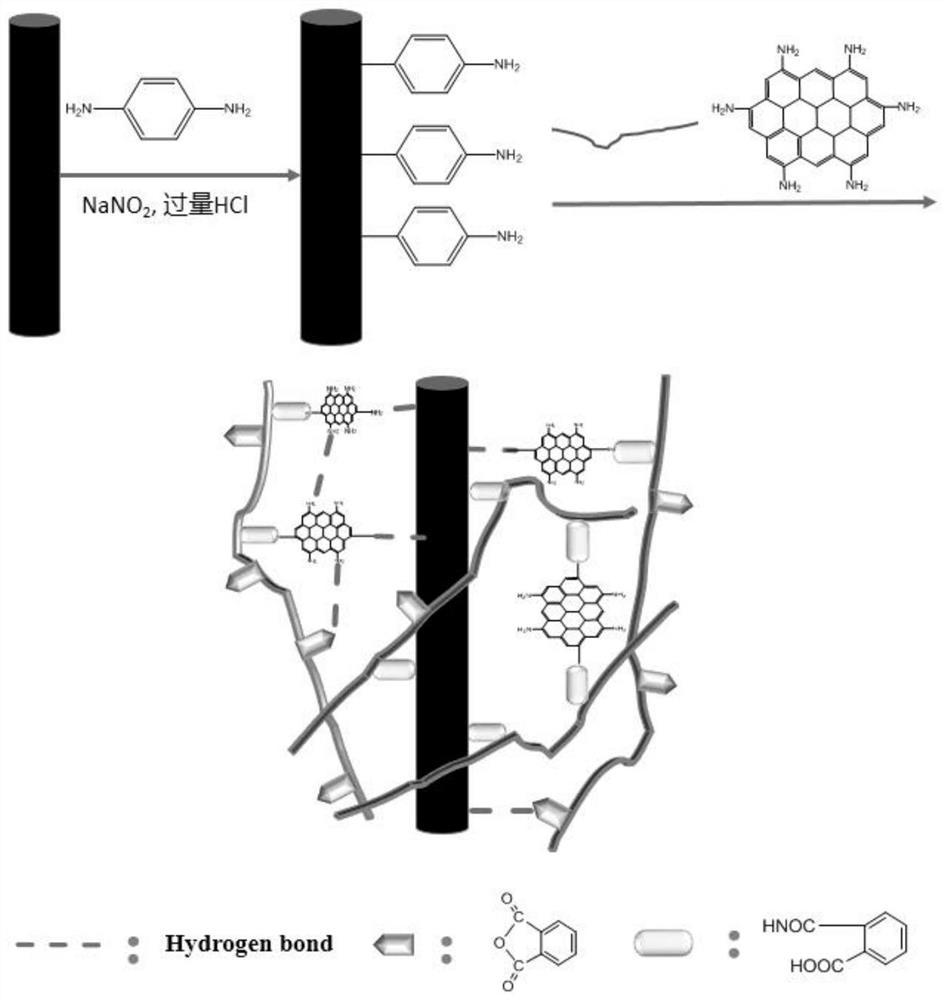

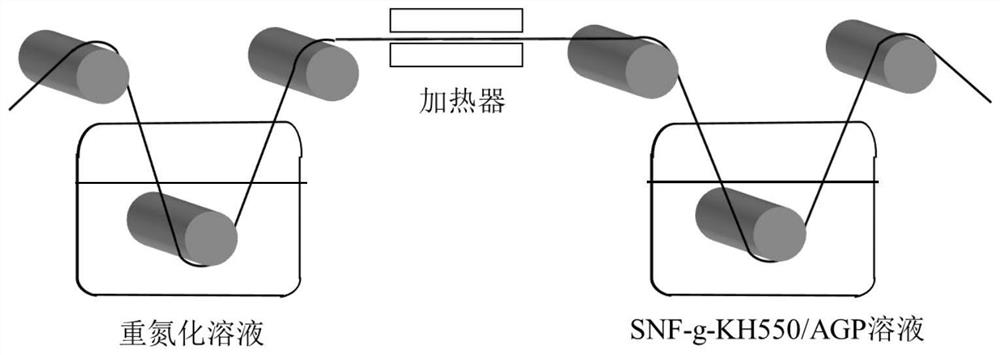

Carbon fiber surface grafted two-dimensional network structure reinforced polyether-ether-ketone composite material and preparation method thereof

ActiveCN112457629AImprove heat resistanceAvoid forming defectsPolymer sciencePoly ether ether ketone

The invention provides a carbon fiber surface grafted two-dimensional network structure reinforced polyether-ether-ketone composite material and a preparation method thereof, and belongs to the technical field of carbon fiber reinforced polymer matrix composite materials. The carbon fiber surface is functionalized (grafted with amino) by diazotization reaction, and active functional groups are introduced into the surface of the carbon fiber on the premise of not damaging the strength and integrity of the carbon fiber, so that the polarity and activity of the carbon fiber surface are improved;and then silicon dioxide nanowires and aminated graphene are grafted on the surface of the carbon fiber through covalent bond action to form the carbon fiber containing a two-dimensional interpenetrating network structure, so that the surface polarity and roughness of the carbon fiber are improved, the interface strength of the CF / PEEK composite material can be improved, and the problem of infirmcombination of the nano particles and the surface of the fiber is solved.

Owner:JILIN UNIV

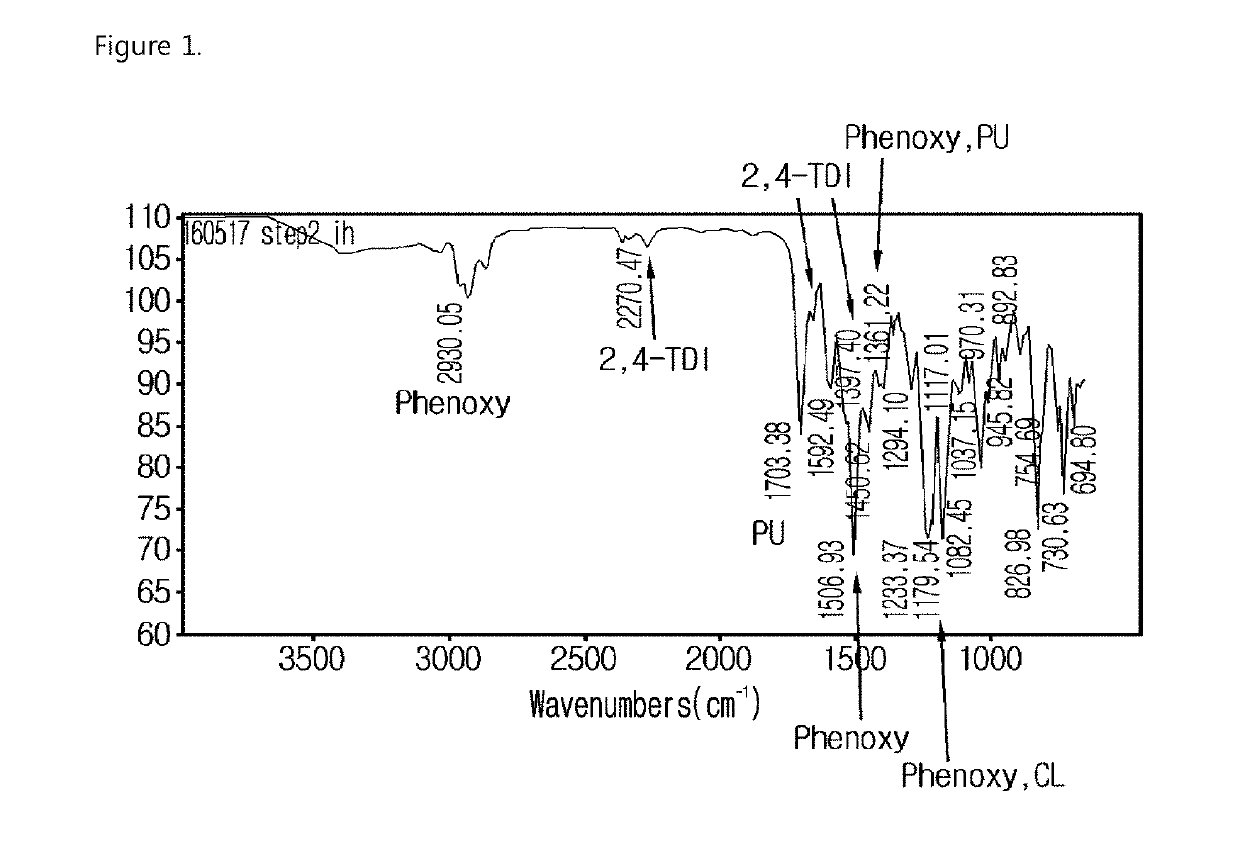

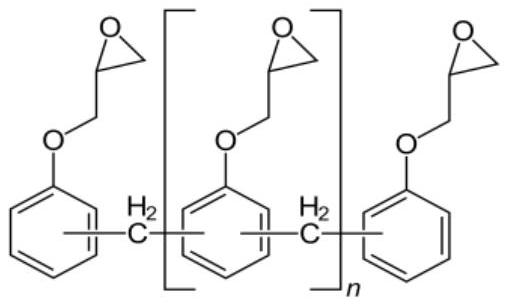

Sizing agent for carbon fiber, carbon fiber with improved interfacial adhesion, polymerization reaction type carbon fiber-reinforced polymer composite material using same, and production method therefor

ActiveUS20190284751A1Improve interface adhesionHigh strengthOrganic chemistryCarbon fibresFiberInterfacial adhesion

The present invention relates to a sizing agent for carbon fibers, a carbon fiber with improved interfacial adhesion, a polymerization reaction type carbon fiber-reinforced polymer composite material using the same, and a production method therefor and, more specifically, to a sizing agent for carbon fibers, comprising a phenoxy resin and a block isocyanate compound prepared through a reaction of ε-caprolactam with one of two isocyanate groups of a diisocyanate compound, and the production of a carbon fiber with improved interfacial adhesion using the same, a polymerization reaction type carbon fiber-reinforced polymer composite material using the carbon fiber with improved interfacial adhesion, and a production method therefor.

Owner:KOREA INST OF MATERIALS SCI

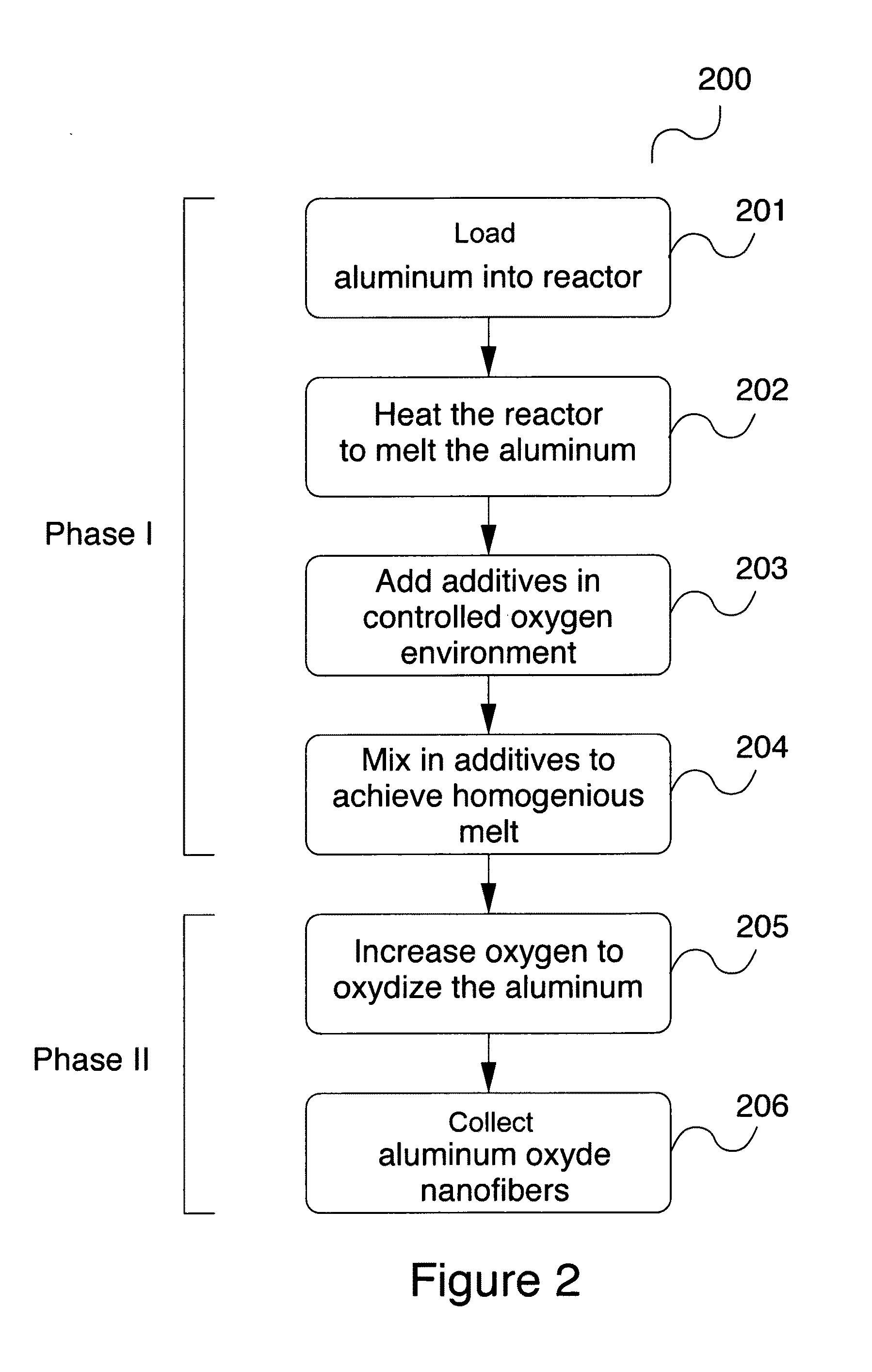

Method and apparatus for producing a carbon-fiber-reinforced polymers additiuonally reinforced by alumina nanofibers

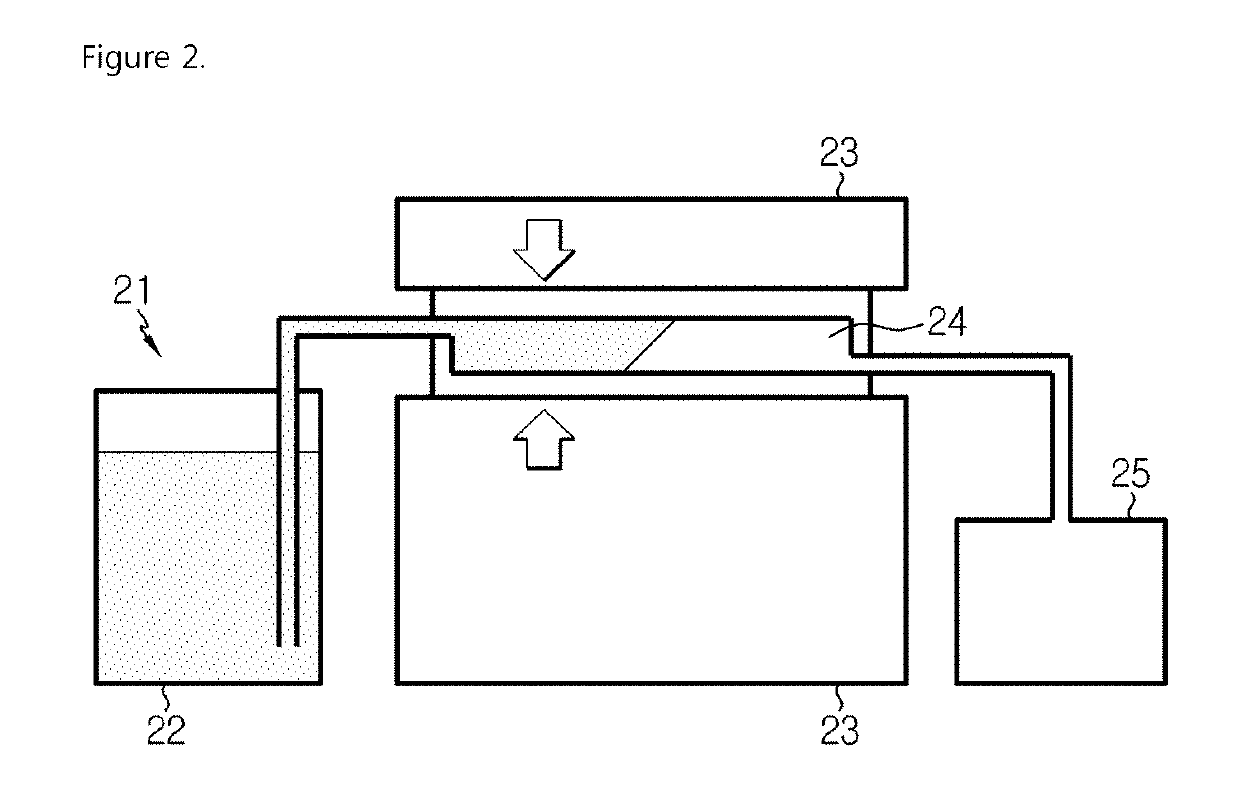

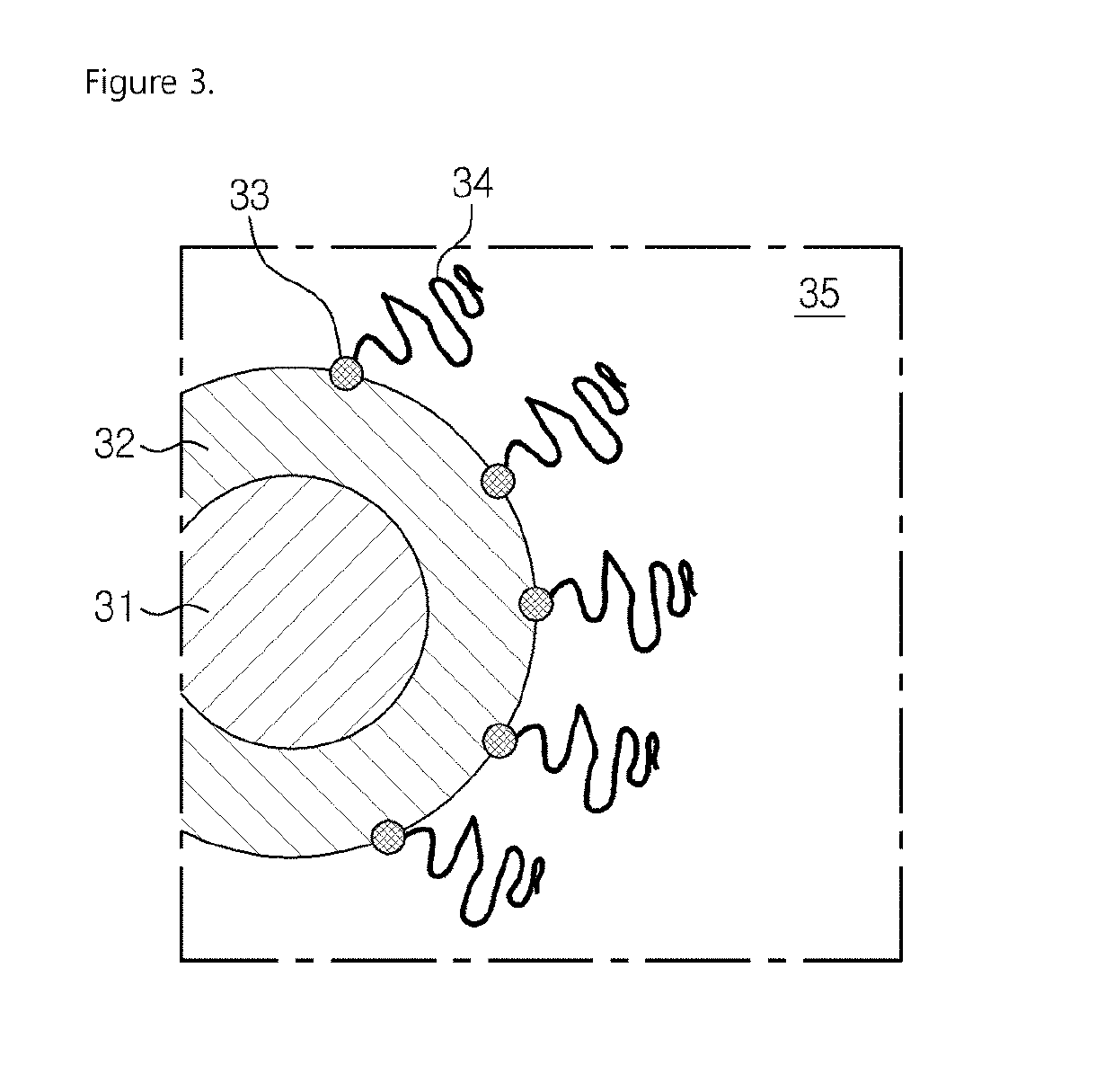

Carbon-fiber-reinforced polymers are composite materials. In this case the composite consists of two parts; a matrix and a reinforcement. In CFRP the reinforcement is carbon fiber, which provides the strength. The matrix is usually a polymer resin, such as epoxy, to bind the reinforcements together. Because CFRP consists of two distinct elements, the material properties depend on these two elements. In accordance with one aspect of the invention, there is provided a method and apparatus for producing carbon-fiber-reinforced polymers, wherein the polymer resin used in their manufacture is additionally reinforced by unidirectionally oriented pre-dispersed alumina nanofibers. The aforesaid process is well suited for industrial-scale production of the carbon-fiber-reinforced polymers. In one or more embodiments, the production process involves dispersing alumina nanofibers in the polymer resin, such as epoxy, and using the resulting alumina nanofiber-reinforced polymer resin in the production of the carbon-fiber-reinforced polymers.

Owner:GRODNENSKY ILYA

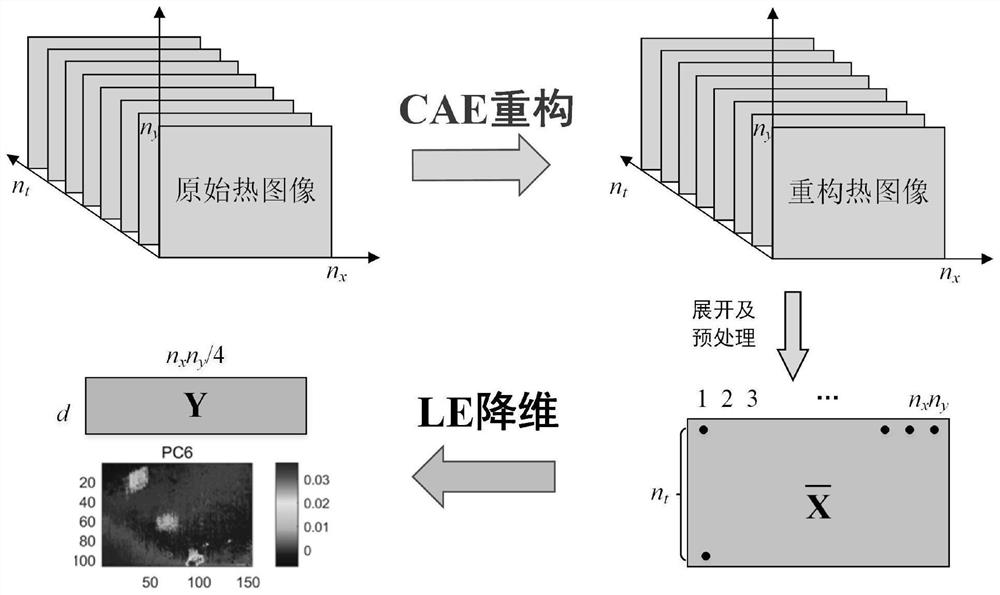

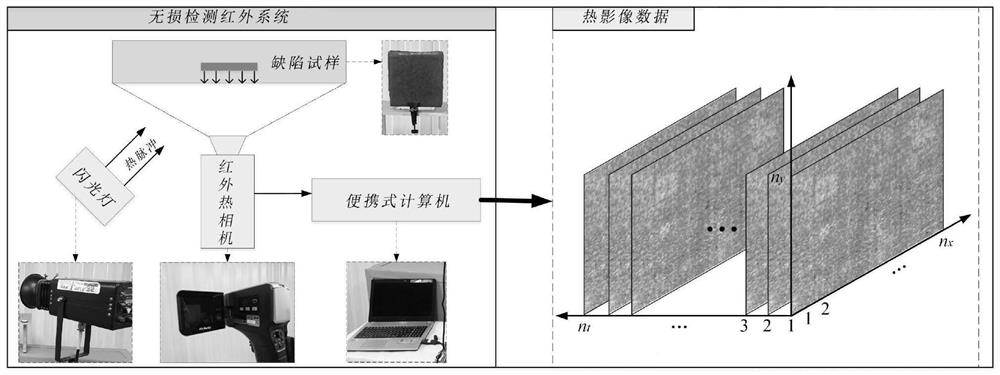

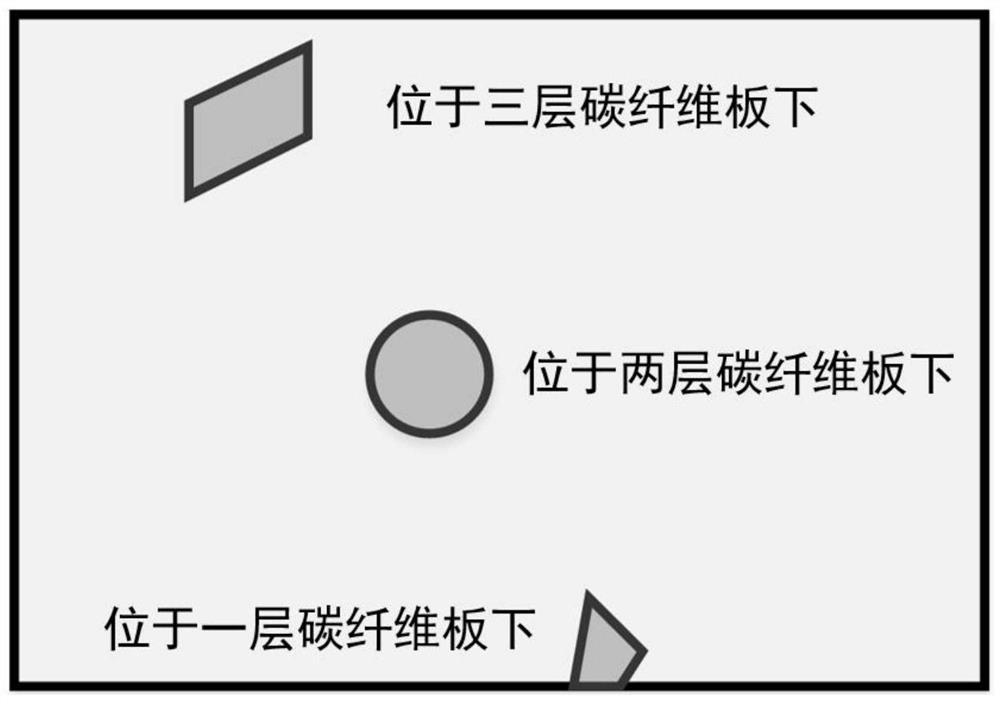

Thermal imaging defect detection method based on convolution auto-encoder image amplification

PendingCN112837294ALess uneven backgroundQuality improvementImage enhancementImage analysisRadiologyFeature mapping

The invention discloses a thermal imaging defect detection method based on convolution auto-encoder image amplification. The method comprises the following steps: 1, obtaining a thermal image and thermal image data of a carbon fiber reinforced polymer composite material; 2, selecting and processing the thermal image; 3, establishing a convolutional auto-encoder image enhancement model, and carrying out noise reduction on the thermal image; 4, preprocessing the thermal image data; 5, establishing a Laplau feature mapping thermal imaging model based on the experimental thermal image and the convolutional auto-encoder reconstructed thermal image, extracting defect information in the thermal image and visualizing the defect information to realize qualitative monitoring of the defect; and 6, evaluating the established model by adopting a separation degree index, and verifying the effect of the image enhancement strategy in defect detection modeling.

Owner:ZHEJIANG UNIV OF TECH

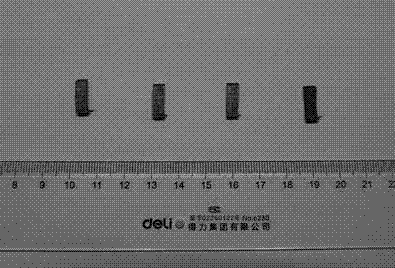

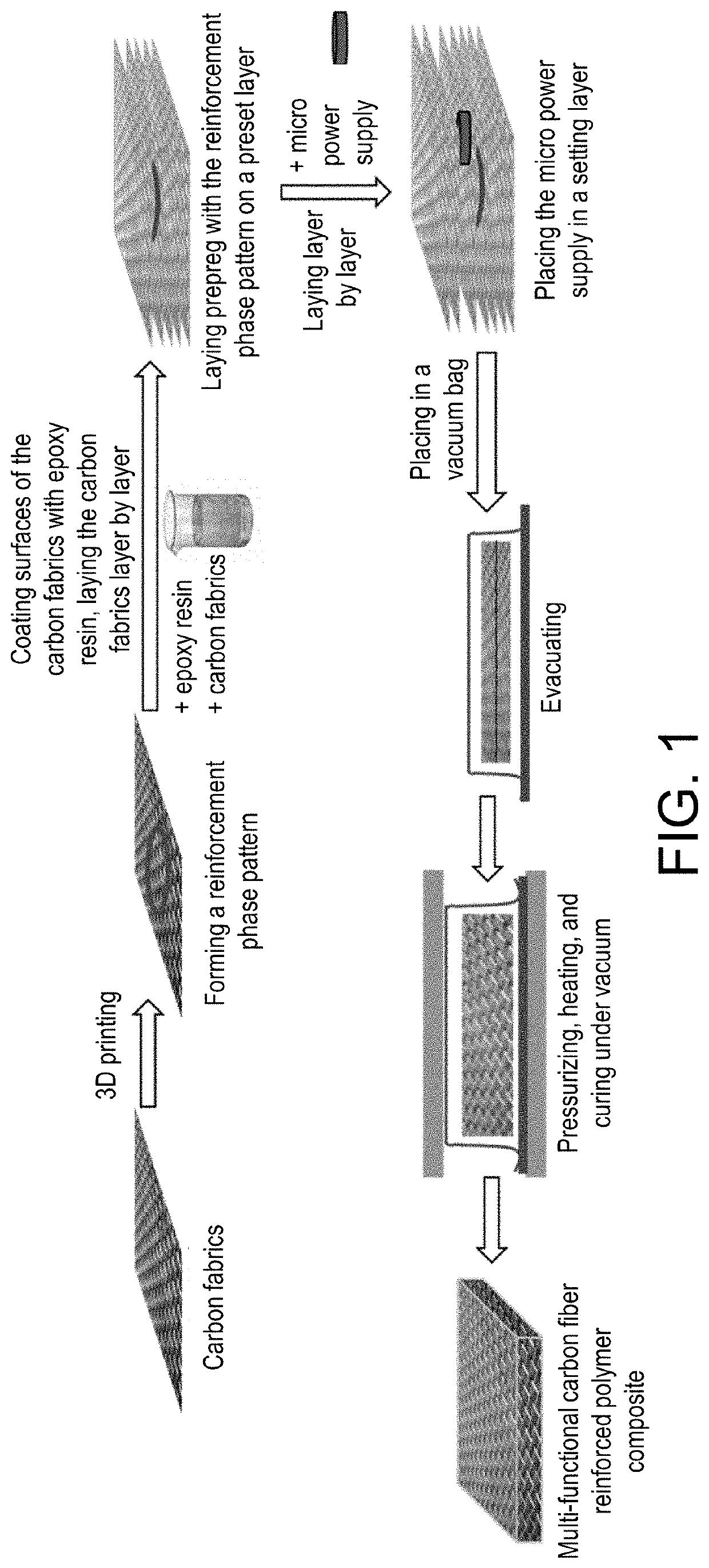

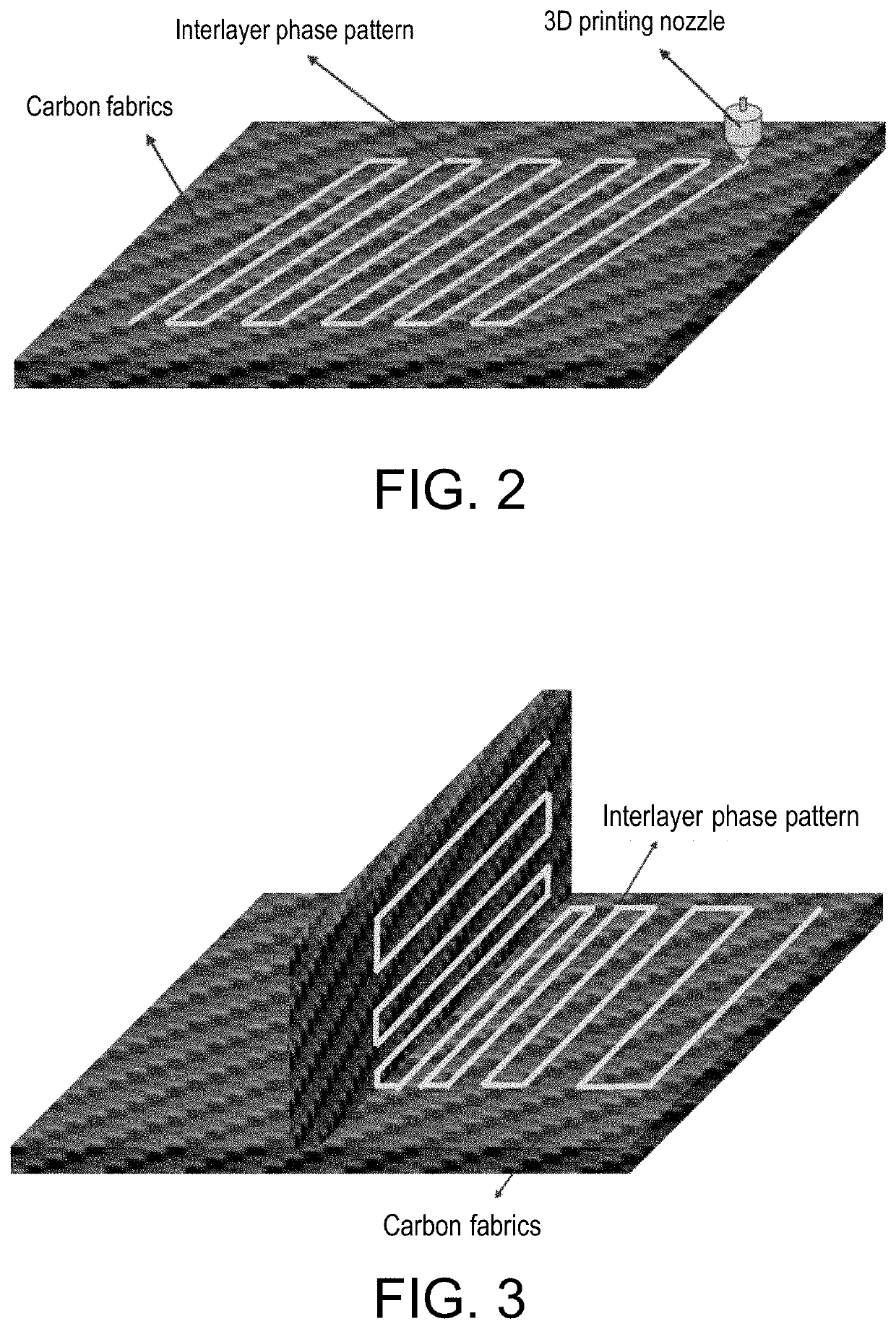

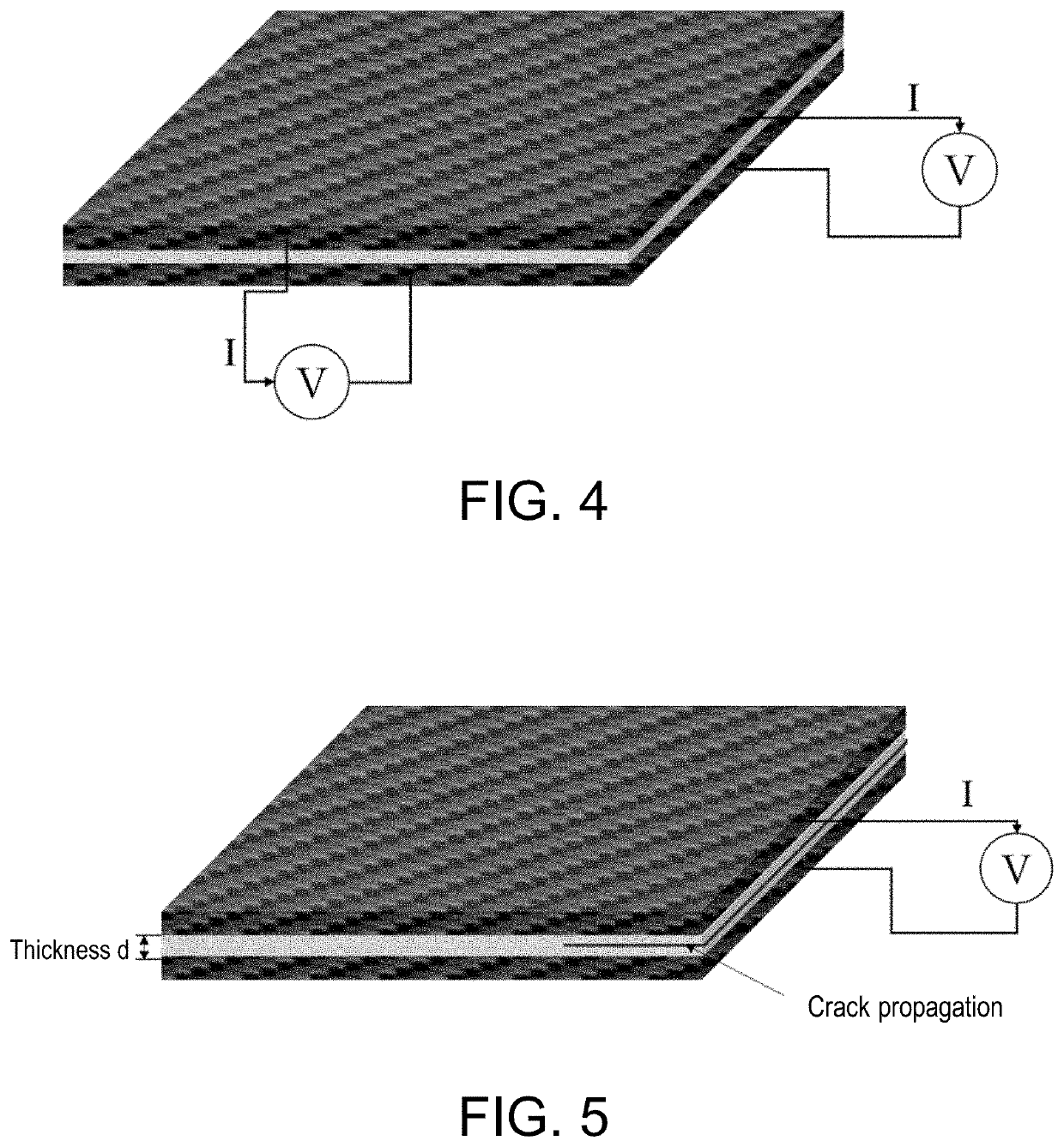

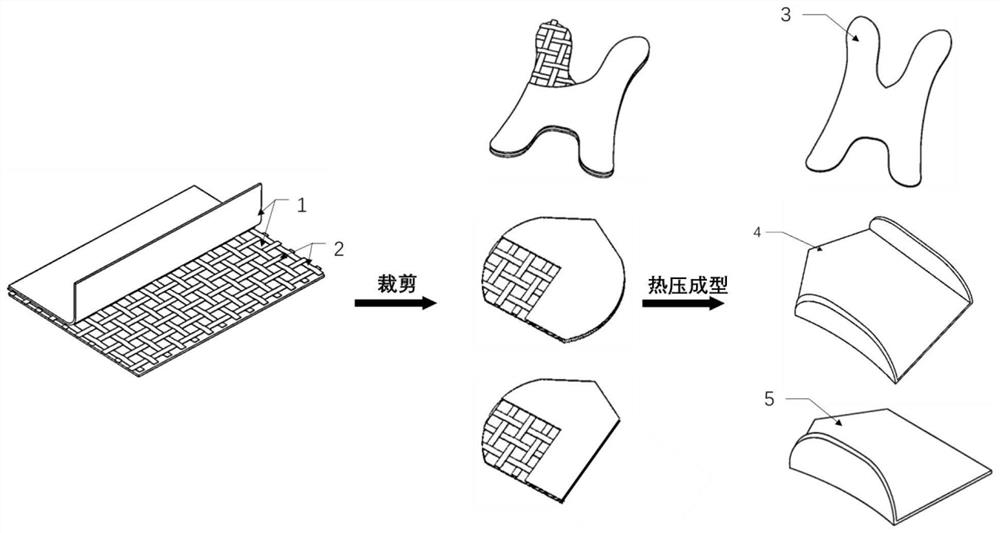

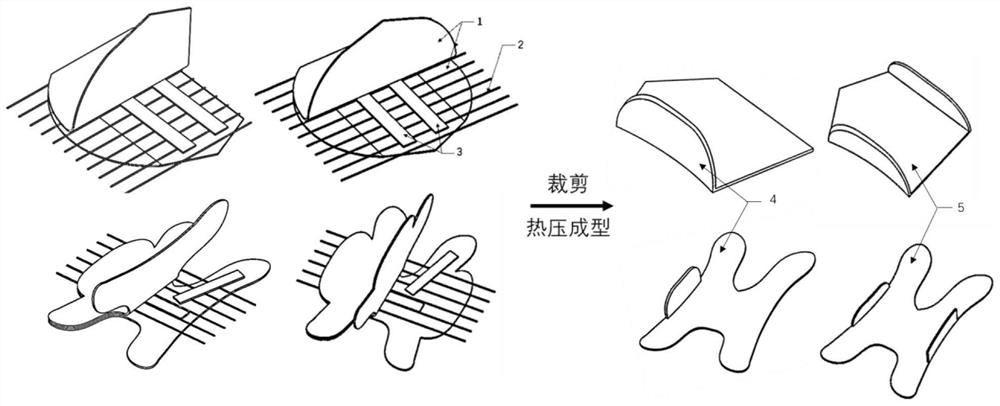

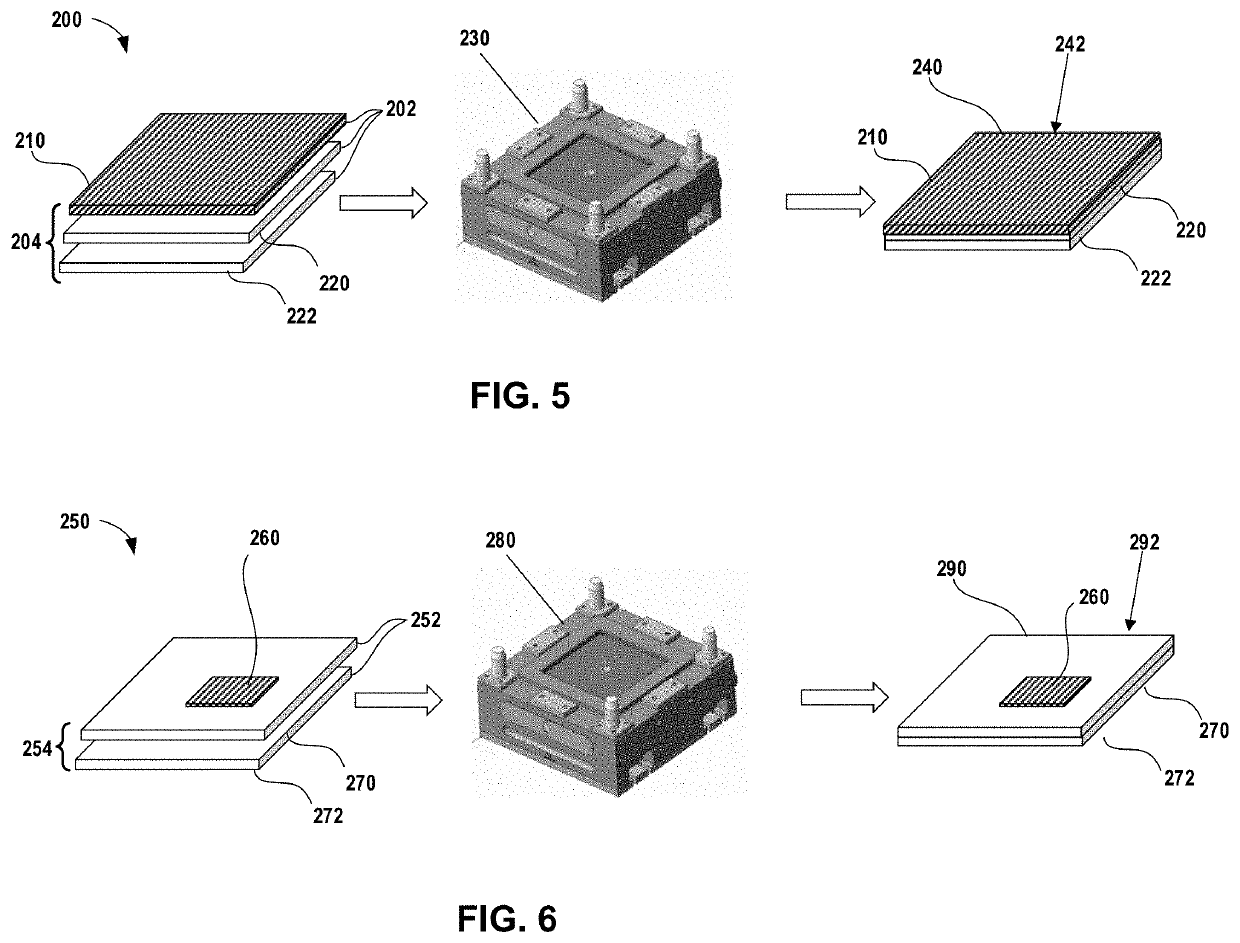

Preparation method and product of carbon fiber reinforced polymer composite with designable characteristic structure

PendingUS20210332203A1Easily and quickly detect locationAccelerate thecuring of the resinAdditive manufacturing apparatusCoatingsResin matrixPolymer

The disclosure discloses a preparation method and product of carbon fiber reinforced polymer composites with a designable characteristic structure. The method includes: (a) choosing carbon fabrics as raw material, where a predetermined number of the fabrics are selected to deposit the reinforcement phase; (b) coating all carbon fabrics with resin matrix, placing the fabrics layer by layer, where the carbon fabrics with the reinforcement phases are placed in a predetermined layer, meanwhile a micro power supply is placed in a setting layer during the stacking process, then a prefabricated product is obtained; (c) placing the prefabricated product in a vacuum bag then evacuating and sealing, hot pressing the sealed prefabricated product, finally the carbon fiber reinforced polymer composite product in the vacuum bag after hot pressing is successfully manufactured.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for promoting electrical conduction between metallic components and composite materials

ActiveUS20180079172A1Fuel tank safety measuresSynthetic resin layered productsElectrical connectionConductive materials

A method for promoting electrical conduction between metallic components and composite materials. A composite body is coated with an adhering layer comprising a conductive material, and a metallic component is electrically connected to the conductive material of the adhering layer, when the metallic component is coupled to the composite body. The adhering layer is deposited inside a hole in the composite body, and / or along an edge of the hole, and / or on at least a portion of a surface of the composite body. The composite body is a structure of an aircraft or other vehicle comprised of composite materials formed from carbon fiber-reinforced polymers (CFRPs), the metallic component is a fastener or is positioned at an interface between the fastener and the composite body, and the electrical connection is made as part of a lightning protection system, an electromagnetic effects (EME) management system, or grounding system.

Owner:THE BOEING CO

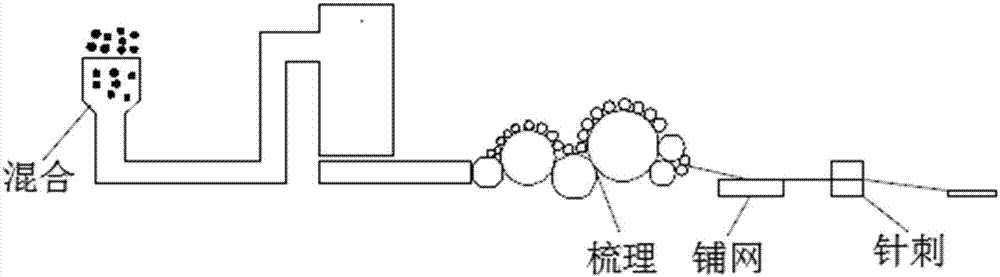

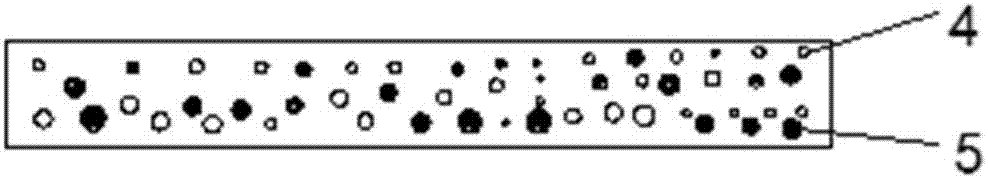

Carbon fiber reinforced polymer matrix composite board and preparing method thereof

PendingCN107351469ALow costMeet production requirementsSynthetic resin layered productsLaminationPolymer sciencePolymer thin films

The invention provides a carbon fiber reinforced polymer matrix reinforced board and a preparing method thereof and belongs to the technical field of automobile internal decorating materials. The board is formed in the mode that short-cut carbon fiber is mixed with polymer, and methods of felt making of fiber mixing, lamination of carbon fiber cloth and polymer film and lamination of carbon fiber felt and polymer film are adopted to prepare preforming parts respectively. Then, through a compound forging forming technology, the preforming parts are subjected to pressing forming, and a carbon fiber reinforced composite material of high performance is prepared. The carbon fiber reinforced polymer matrix reinforced board meets requirements of mass and assembly line production, lowers cost, improves production efficiency, and promotes large-scale industrialization application of the carbon fiber composite material.

Owner:JILIN UNIV

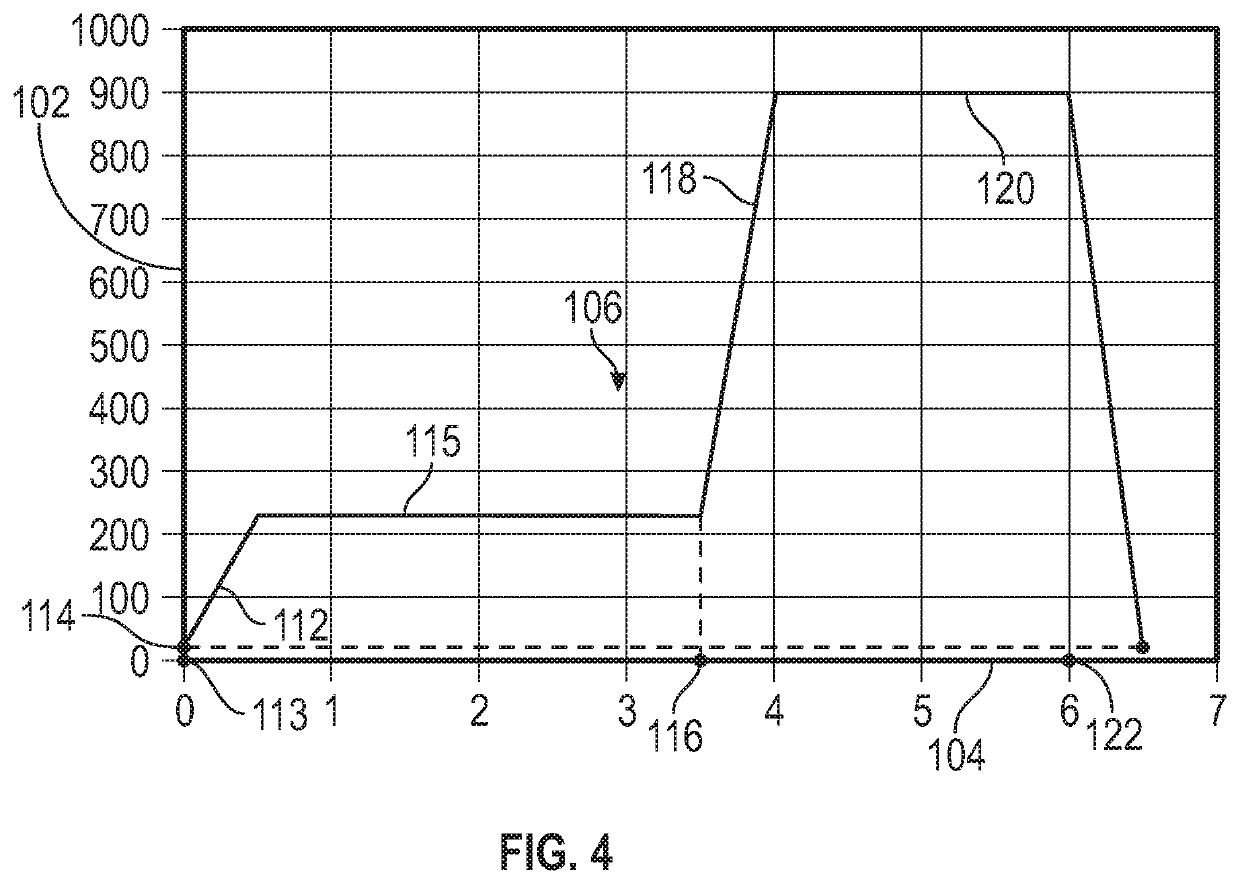

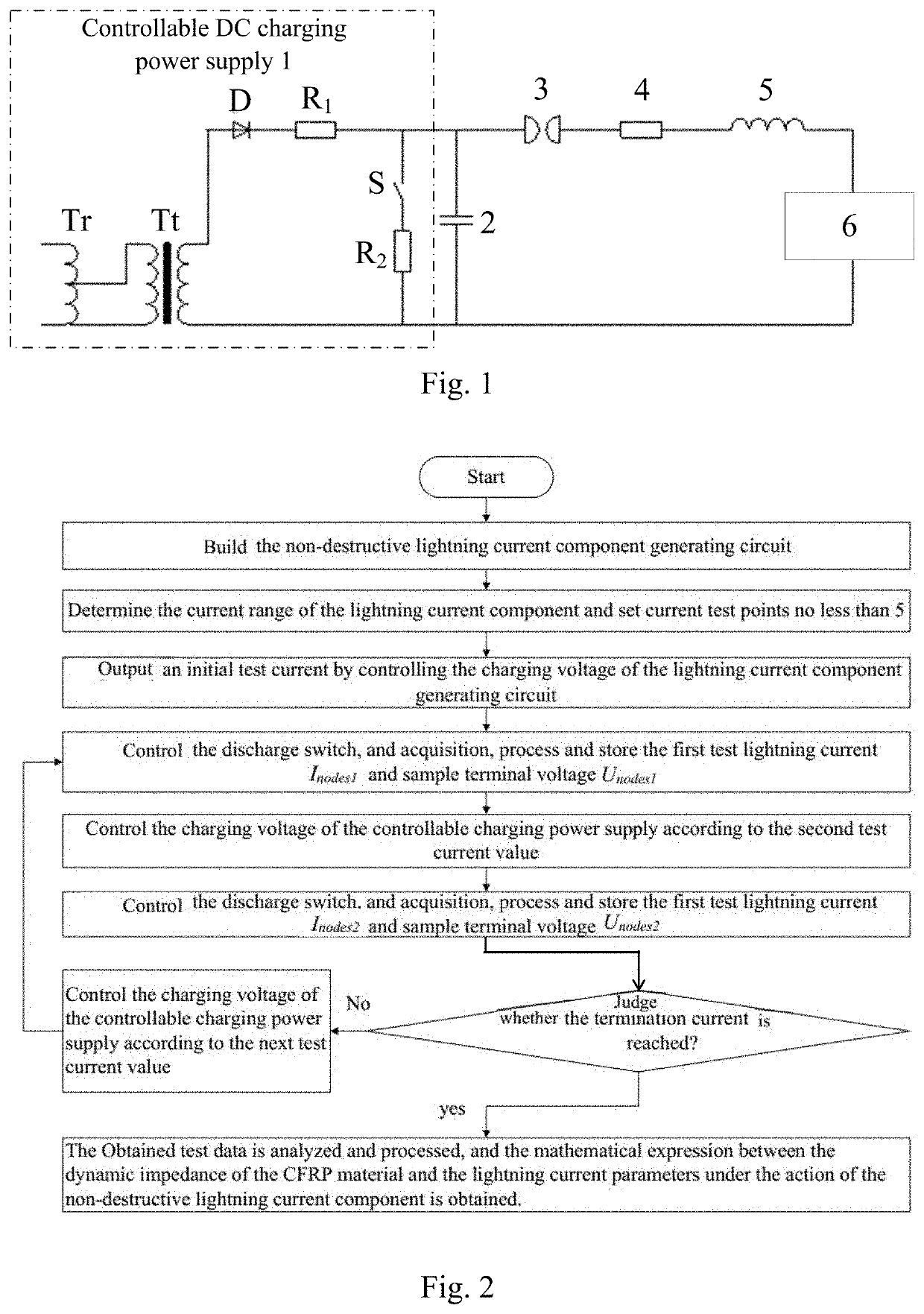

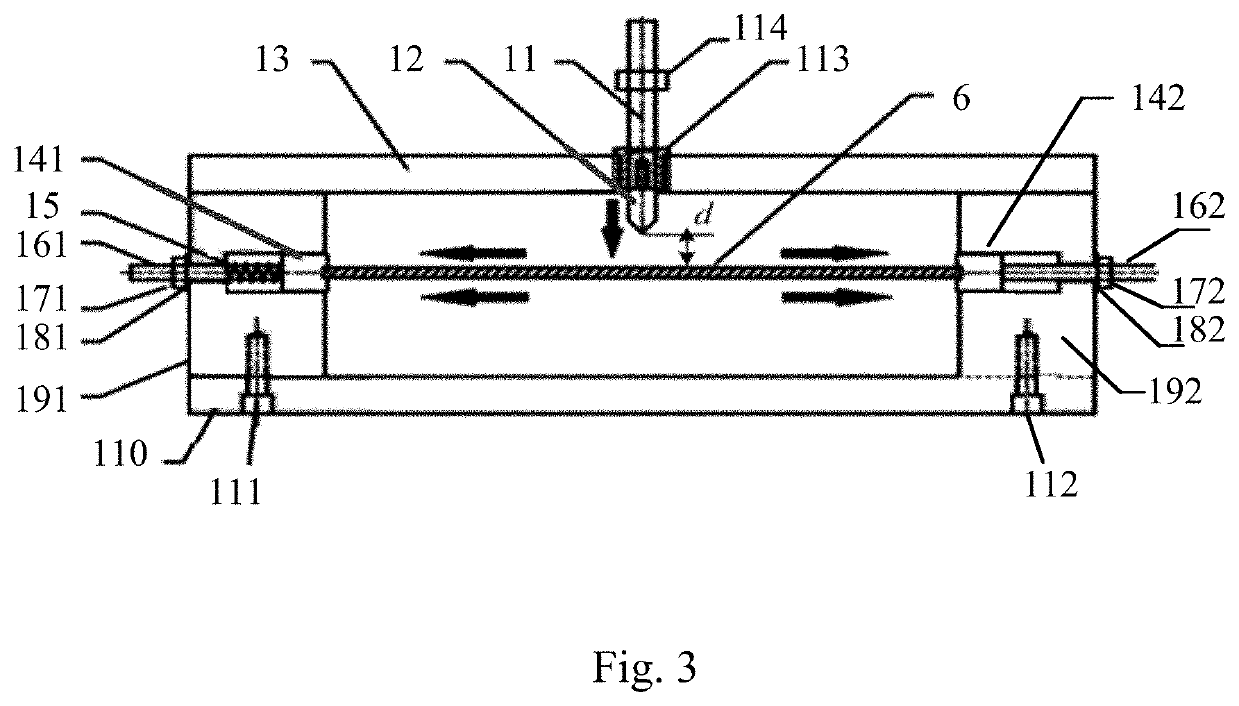

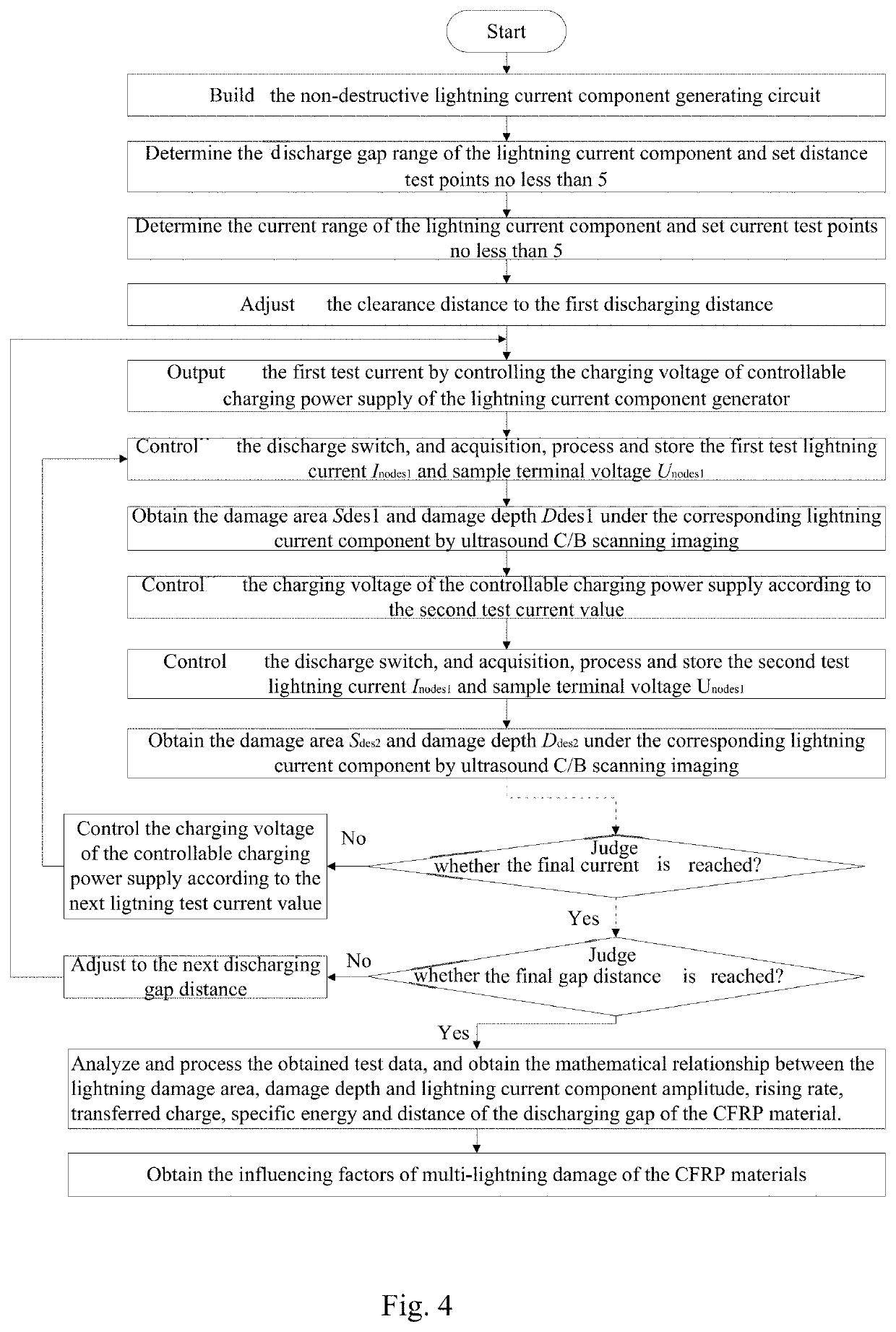

Lightning damage assessment method for carbon fiber reinforced polymer material considering non-linear impedance characteristic

PendingUS20210215629A1Improve performanceAircraft lighting protectorsImpedence measurementsStructural engineeringLightning injuries

A lightning damage assessment method for the carbon fiber reinforced polymer (CFRP) material considering non-linear impedance characteristic includes steps of: studying various influencing factors of the lightning damage of the CFRP material under the action of the single lightning current component; obtaining the law between the lightning damage of the CFRP material, including the lightning damage area and depth, and various influencing factors, including the peak value, the rising rate, the charge transfer amount, the specific energy of the single lightning current component, and the non-linear impedance characteristic of the CFRP; on the basis of the law, building the multi-factor assessment model of the lightning damage of CFRP material under the action of the single lightning current component; and obtaining mathematical expressions between the lightning damage of the CFRP material and the influencing factors.

Owner:XI AN JIAOTONG UNIV

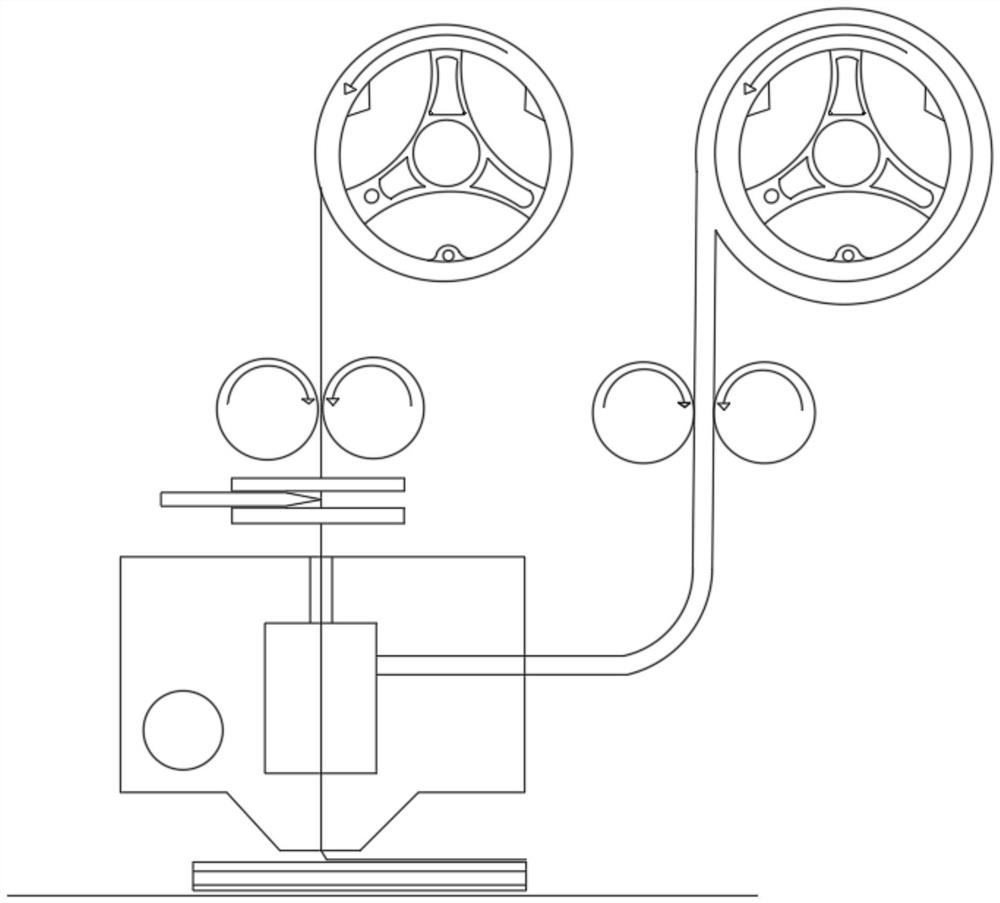

Continuous carbon fiber FDM 3D printing forming method

PendingCN112757626AImprove high temperature resistanceGood chemical resistanceAdditive manufacturing apparatus3D object support structures3d printThermoplastic

The invention discloses a continuous carbon fiber FDM 3D printing forming method which comprises the following steps that rotatable wire coils are wound with a continuous carbon fiber filament reinforcing material and a thermoplastic plastic filament base material respectively; the two wire coils are placed in a common air blast drying box for drying; a forming chamber and a printing platform of an FDM printing system and a melting cavity and a nozzle of an extruder are heated; and the continuous carbon fiber filament reinforcing material and the thermoplastic plastic filament base material are sent to the printing system according to program settings for printing forming. By using the continuous carbon fiber FDM 3D printing forming method, a complex-shaped part printed by combining with a continuous carbon fiber reinforced polymer composite has excellent high temperature resistance and chemical resistance, so that a light high-strength 3D printing carbon fiber composite part can be manufactured, and a set of process technology with reference significance is provided for the forming process aspect of high-performance complex structural parts in China.

Owner:华融普瑞(北京)科技有限公司

Structural lithium-ion batteries with carbon fiber electrodes

Owner:MITRE SPORTS INT LTD

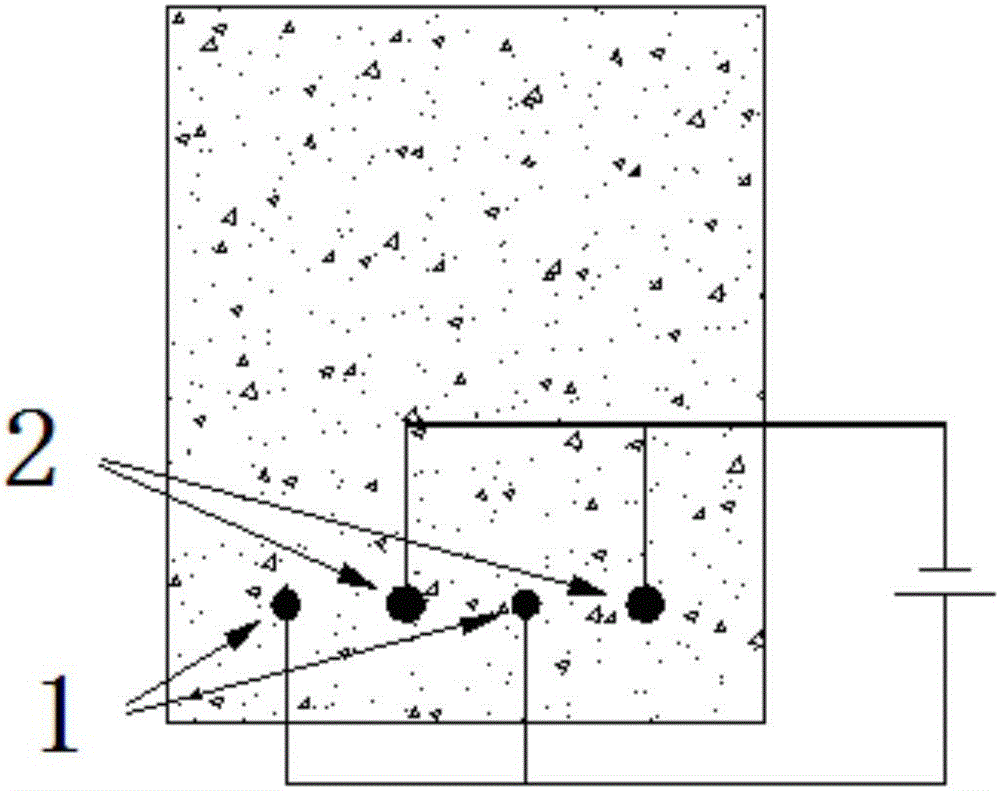

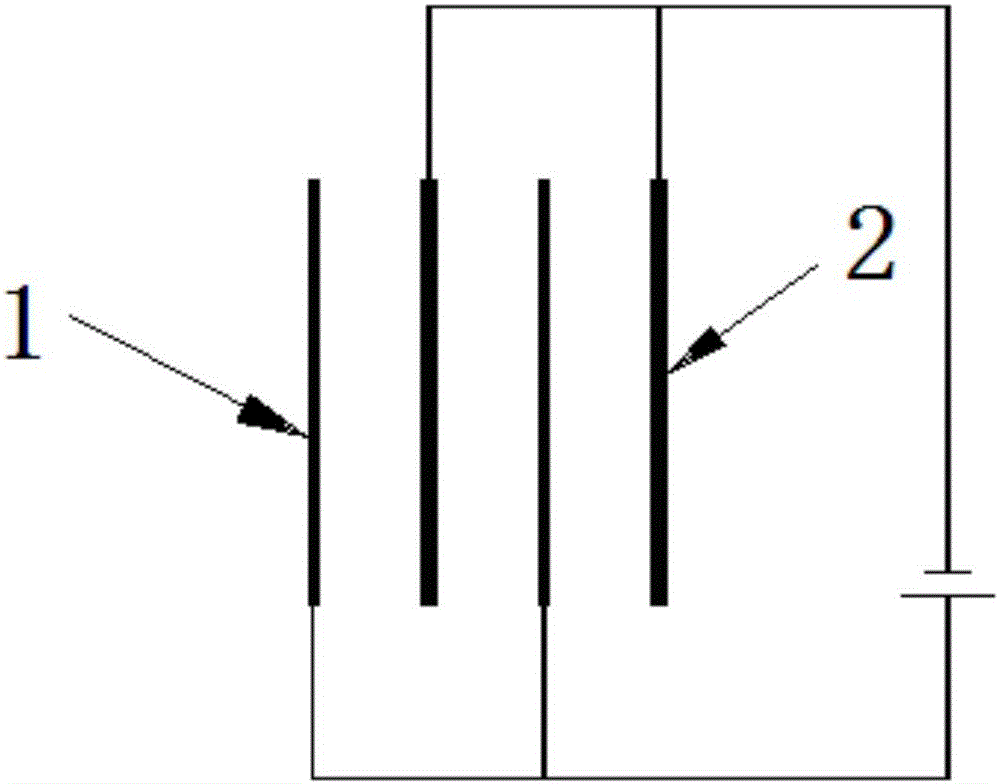

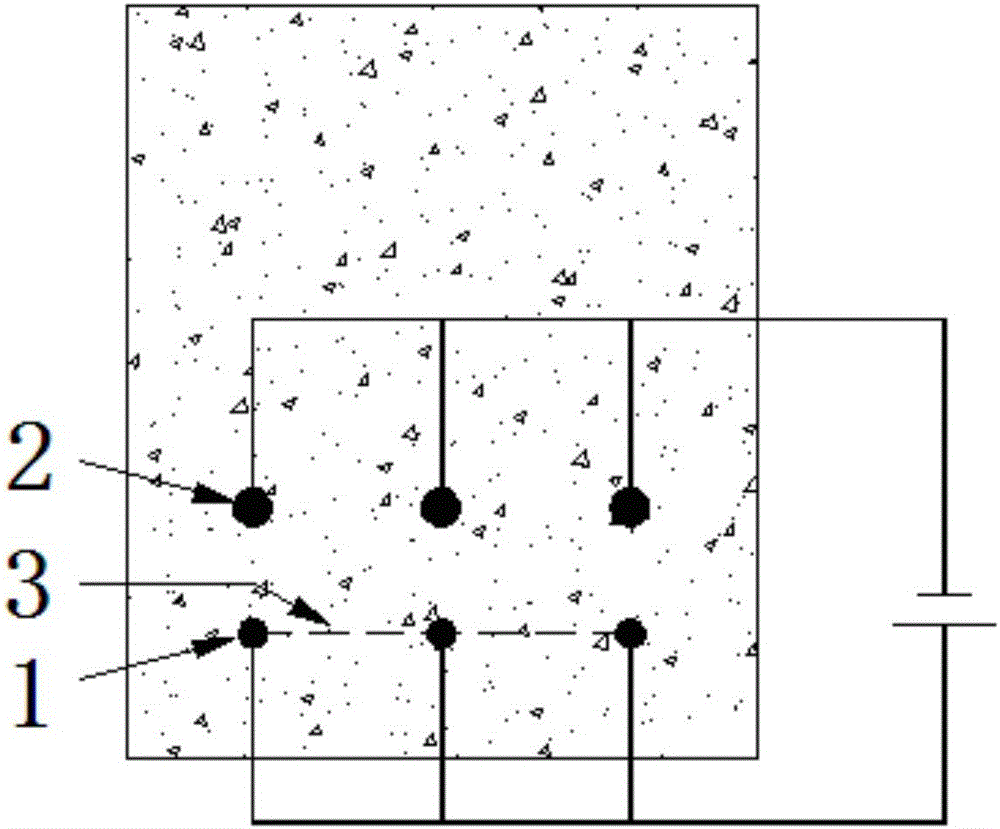

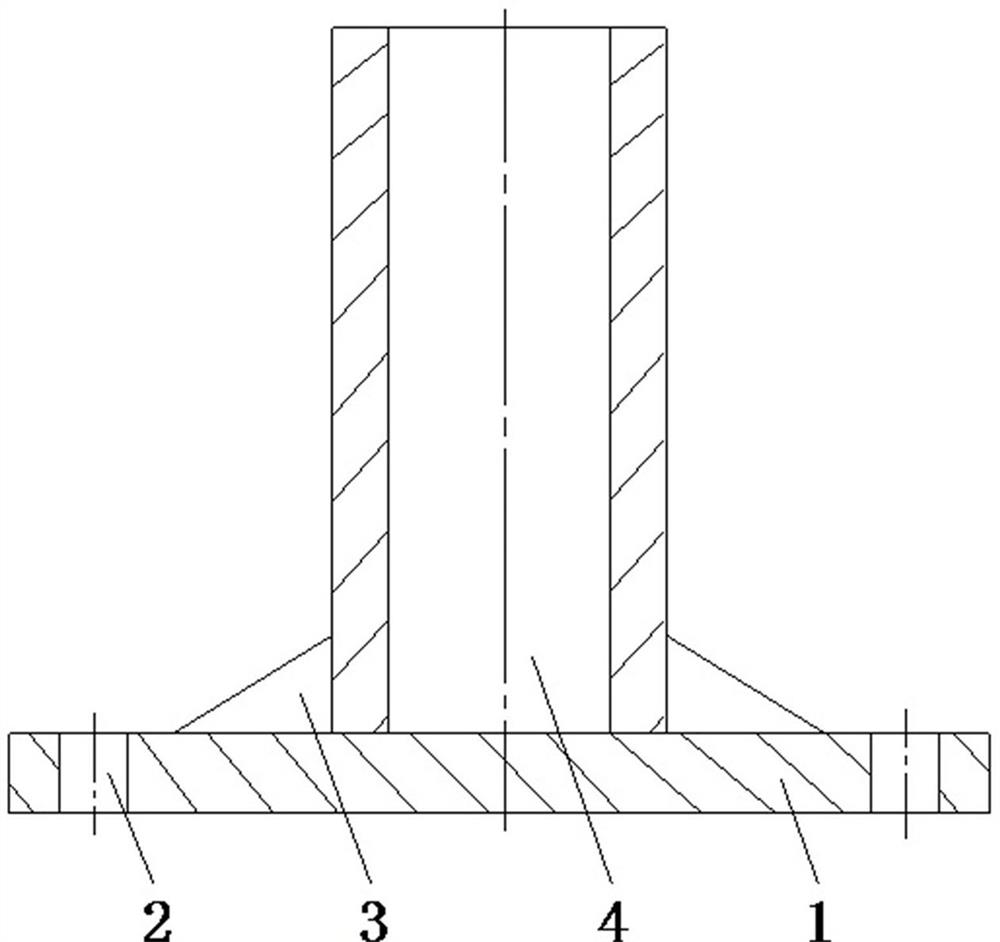

CFRP-embedded-anode reinforcing-steel-bar-concrete cathode protection method and device

The invention discloses a CFRP-embedded-anode reinforcing-steel-bar-concrete cathode protection method and device. The reinforcing-steel-bar-concrete cathode protection device comprises concrete, plural reinforcing steel bars, a direct-current power source and a CFRP anode; the CFRP anode comprises plural carbon fiber reinforced polymer bars (CFRP), and the CFRP bars and reinforcing steel bars are parallelly embedded into the concrete; the plural CFRP bars are connected with the anode of the direct-current power source in parallel, and the reinforcing steel bars are parallel and connected with the cathode of the direct-current power source. The CFRP-embedded-anode reinforcing-steel-bar-concrete cathode protection method and device are convenient to construct, the bonding strength between an anode material and concrete is high, the resistance between the cathode and the anode is small, and the engineering cost and the cost for protecting a circuit to be normally used are reduced.

Owner:SHENZHEN UNIV

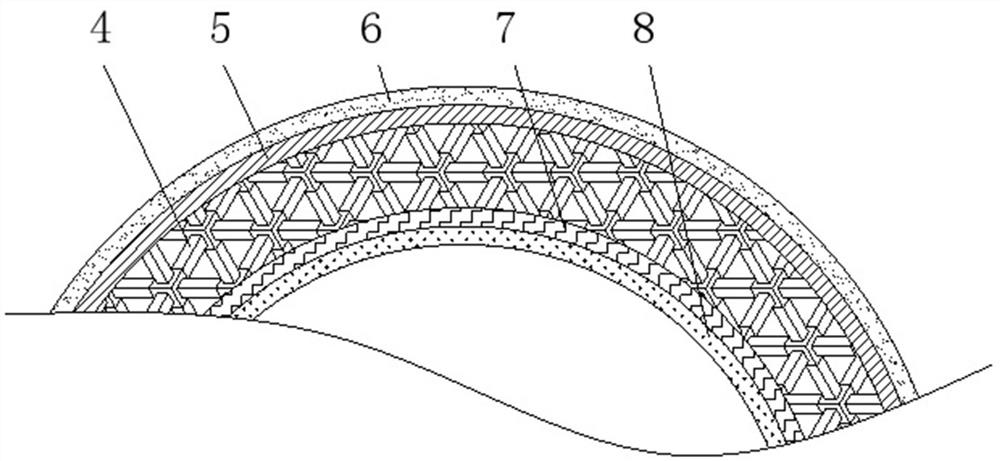

Concrete filled steel tube inner support

PendingCN112502358AImprove support strengthExtended service lifeArched girdersPortal framesIron oxidePhenolic aldehyde

The invention discloses a concrete filled steel tube inner support. The concrete filled steel tube inner support comprises a supporting plate, a supporting pipe is fixedly connected to the middle endof the top of the supporting plate, and the inner side of the supporting pipe is coated with JS waterproof paint. Meanwhile, the inner side of the JS waterproof paint is coated with an epoxy coal pitch coating, the outer side of the supporting pipe and the outer side of the supporting plate are both coated with iron oxide red phenolic aldehyde antirust coatings, and the outer sides of the iron oxide red phenolic aldehyde antirust coatings are coated with carbon fiber reinforced polymers CFRP. The supporting pipe is arranged, and people can pour concrete into the supporting pipe, so that the overall supporting strength of the supporting piece is effectively improved; the carbon fiber reinforced polymers CFRP are arranged, the overall strength of the supporting pipe and the supporting platecan be improved, and the overall rust resistance of the supporting pipe and the supporting plate can be improved through the iron red phenolic aldehyde antirust coatings; the epoxy coal tar pitch coating is arranged, and the corrosion resistance of the inner side of the supporting pipe can be improved; and the JS waterproof coating is arranged, the waterproofness of the inner side of the supporting pipe is improved, and therefore the service life of the whole supporting piece is prolonged.

Owner:CHINA THIRD METALLURGICAL GRP

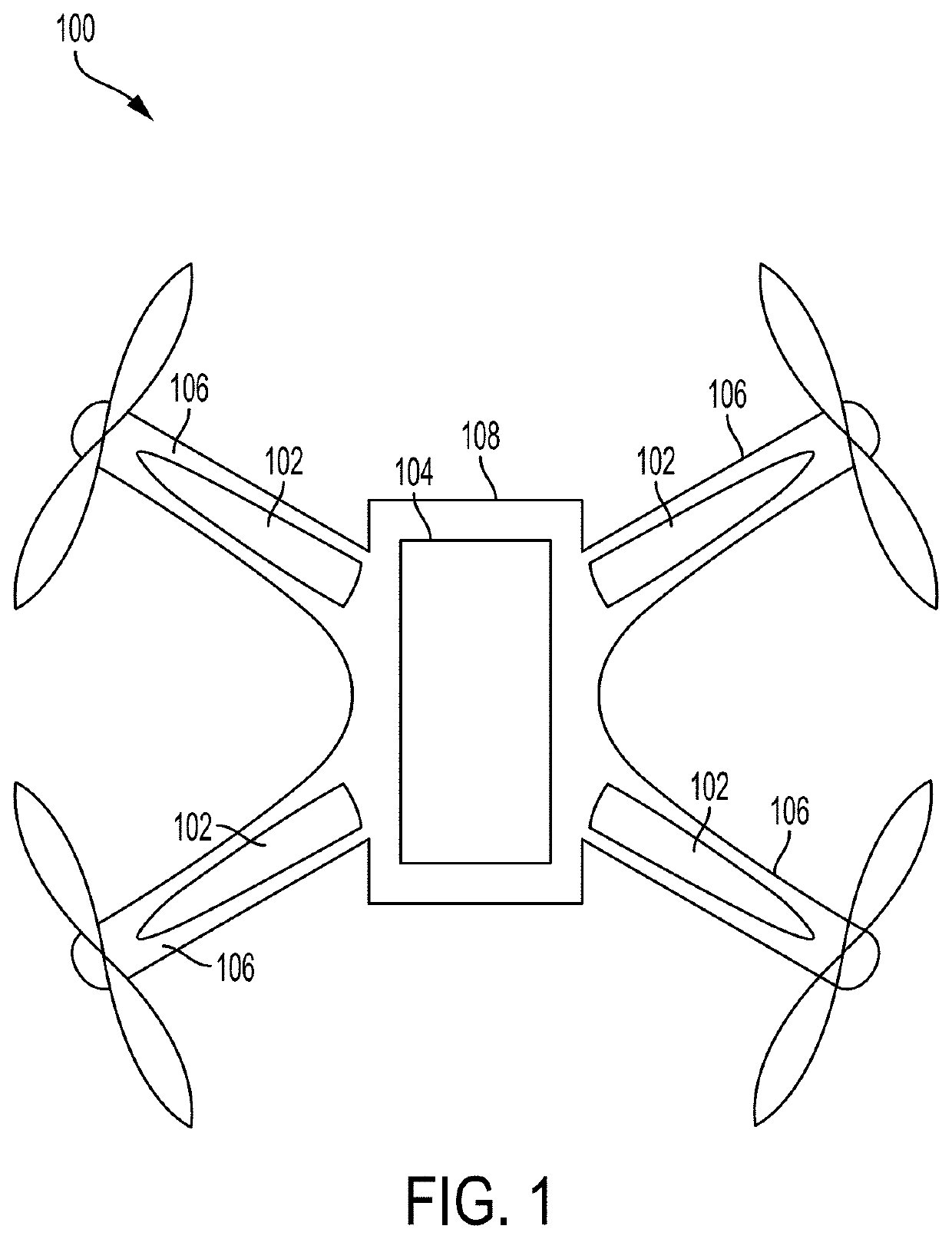

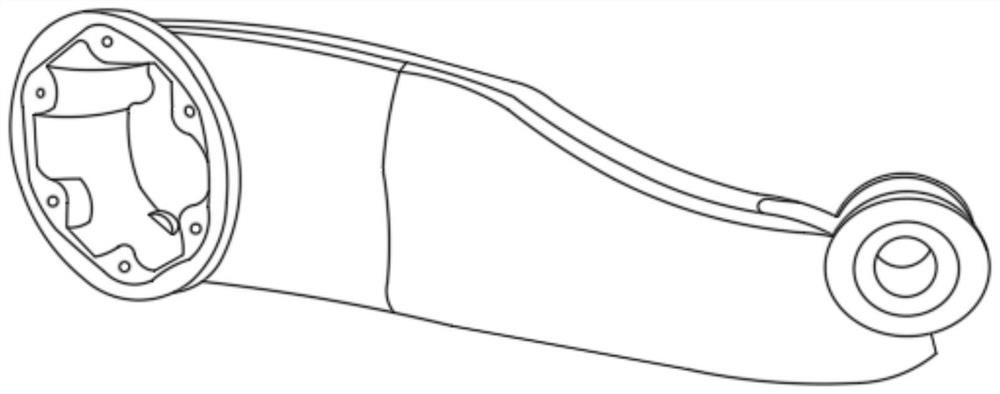

Continuous carbon fiber FDM 3D printing method for thighs of quadruped robot

PendingCN112757624AImprove high temperature resistanceGood chemical resistanceAdditive manufacturing apparatus3D object support structures3d printFiber

The invention discloses a continuous carbon fiber FDM 3D printing method for thighs of a quadruped robot. The 3D printing method comprises the following steps of: carrying out split structure optimization and redesign optimization on a design of the thighs of the quadruped robot according to the characteristics of a 3D printing technology, and respectively obtaining a model A and a model B. In the continuous carbon fiber FDM 3D printing method for the thighs of the quadruped robot, a complex-shaped part printed by investing the continuous carbon fiber FDM 3D printing method for the thighs of the quadruped robot and combining with a continuous carbon fiber reinforced polymer composite has the characteristics of light weight and high strength and has excellent high temperature resistance and chemical resistance; and by adopting the 3D printing technology, continuous carbon fiber 3D printing forming manufacturing of legs and feet of the quadruped robot is firstly achieved, continuous carbon fiber 3D printing forming manufacturing of a quadruped robot body and overall components thereof is gradually achieved, and the method has an important significance of development of light weight and high bearing ratio of the quadruped robot.

Owner:华融普瑞(北京)科技有限公司

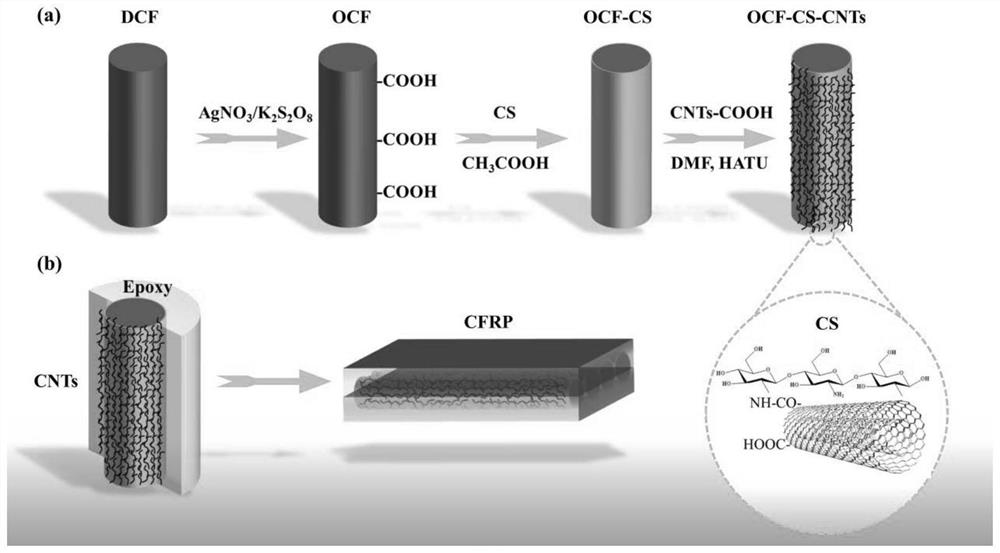

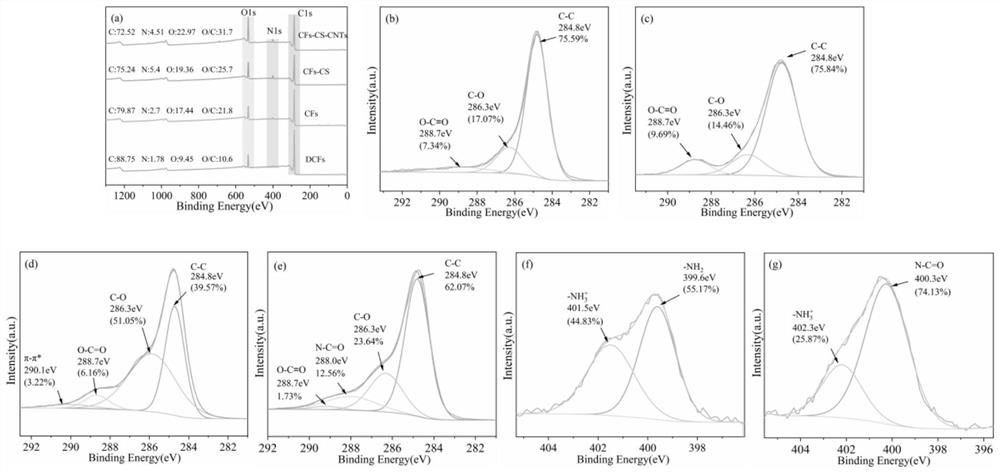

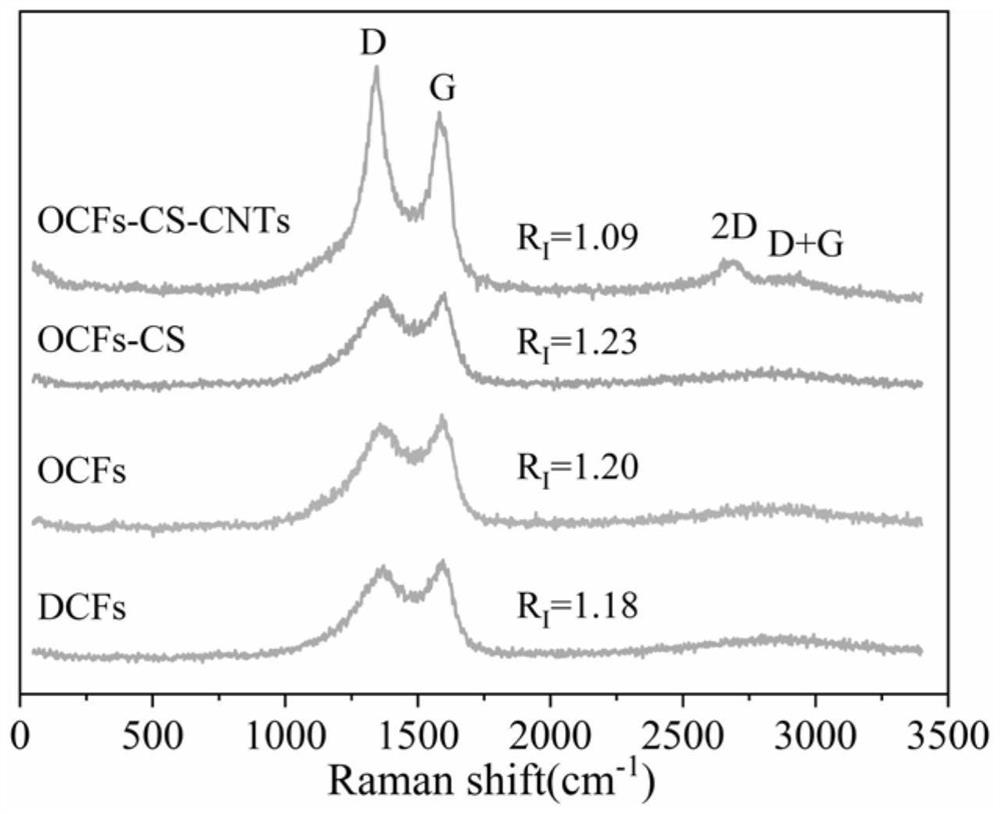

Modified carbon fiber reinforced polymer matrix composite material

ActiveCN114262497ALower contact angleIncreased monofilament tensile strengthInterlaminar shearResin matrix

The invention provides a modified carbon fiber reinforced polymer-based composite material, and belongs to the field of composite materials. According to the invention, the oxidized carbon fiber is encapsulated by using the biomass polymer to obtain the modified carbon fiber OCFs-CS, and the interlaminar shear strength of the carbon fiber composite material prepared by compounding the OCFs-CS as the reinforcing fiber and the resin matrix is greatly improved, and the carbon fiber composite material has excellent mechanical strength. According to the preparation method disclosed by the invention, carbon nanotubes are further grafted on OCFs-CS to obtain modified carbon fibers OCFs-CS-CNTs, and the mechanical strength of the carbon fiber composite material prepared by compounding the OCFs-CS-CNTs serving as reinforced fibers and a resin matrix is further improved. The modified carbon fiber reinforced polymer-based composite material disclosed by the invention has excellent interface performance and mechanical strength, and has a wide application prospect in the fields of aerospace, transportation tools, energy equipment and the like.

Owner:SICHUAN UNIV

Method for promoting electrical conduction between metallic components and composite materials

PendingCN107826259AAircraft lighting protectorsSynthetic resin layered productsElectricityGround system

A method for promoting electrical conduction between metallic components and composite materials. A composite body is coated with an adhering layer comprising a conductive material, and a metallic component is electrically connected to the conductive material of the adhering layer, when the metallic component is coupled to the composite body. The adhering layer is deposited inside a hole in the composite body, and / or along an edge of the hole, and / or on at least a portion of a surface of the composite body. The composite body is a structure of an aircraft or other vehicle comprised of composite materials formed from carbon fiber-reinforced polymers (CFRPs), the metallic component is a fastener or is positioned at an interface between the fastener and the composite body, and the electricalconnection is made as part of a lightning protection system, an electromagnetic effects (EME) management system, or grounding system.

Owner:THE BOEING CO

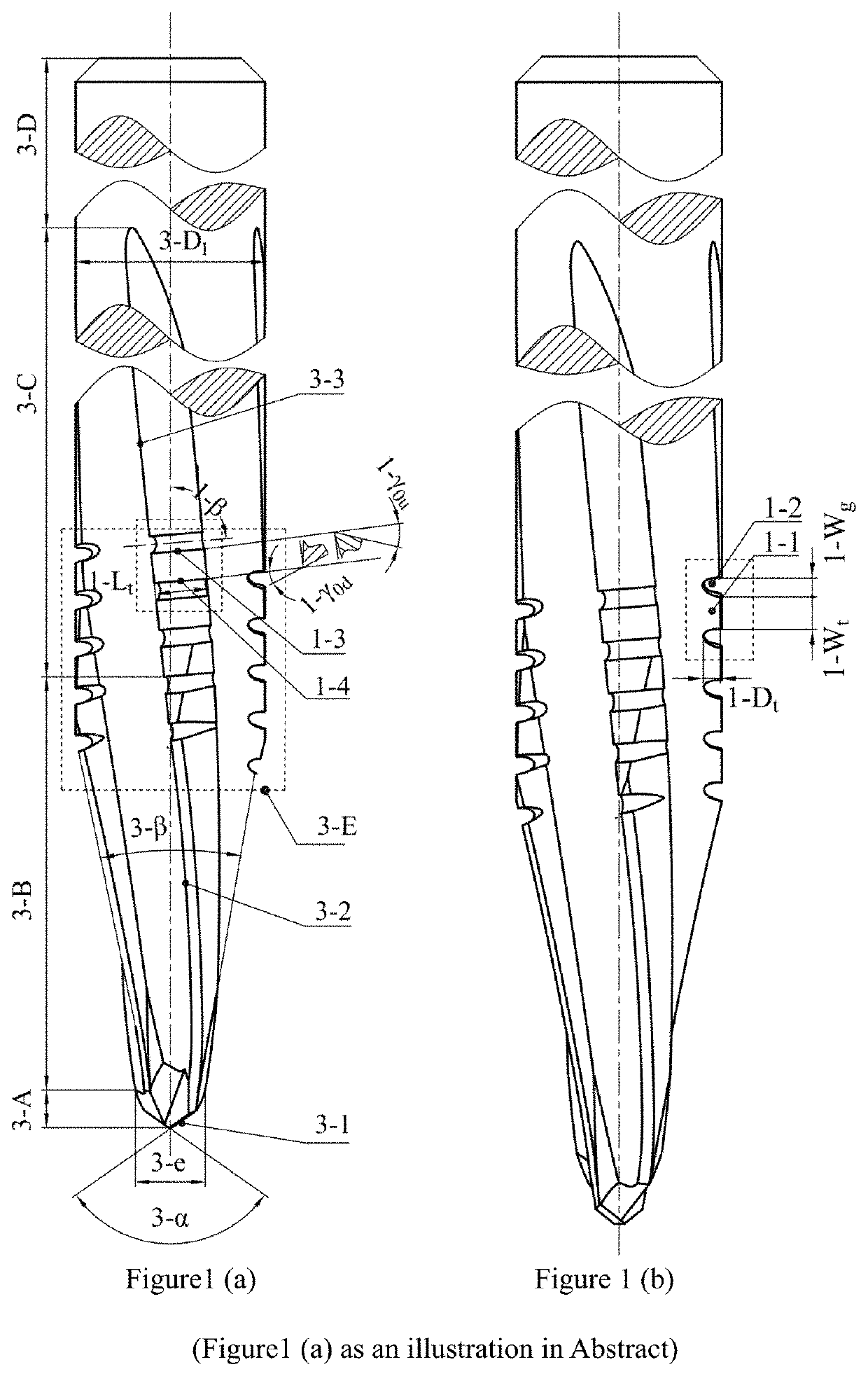

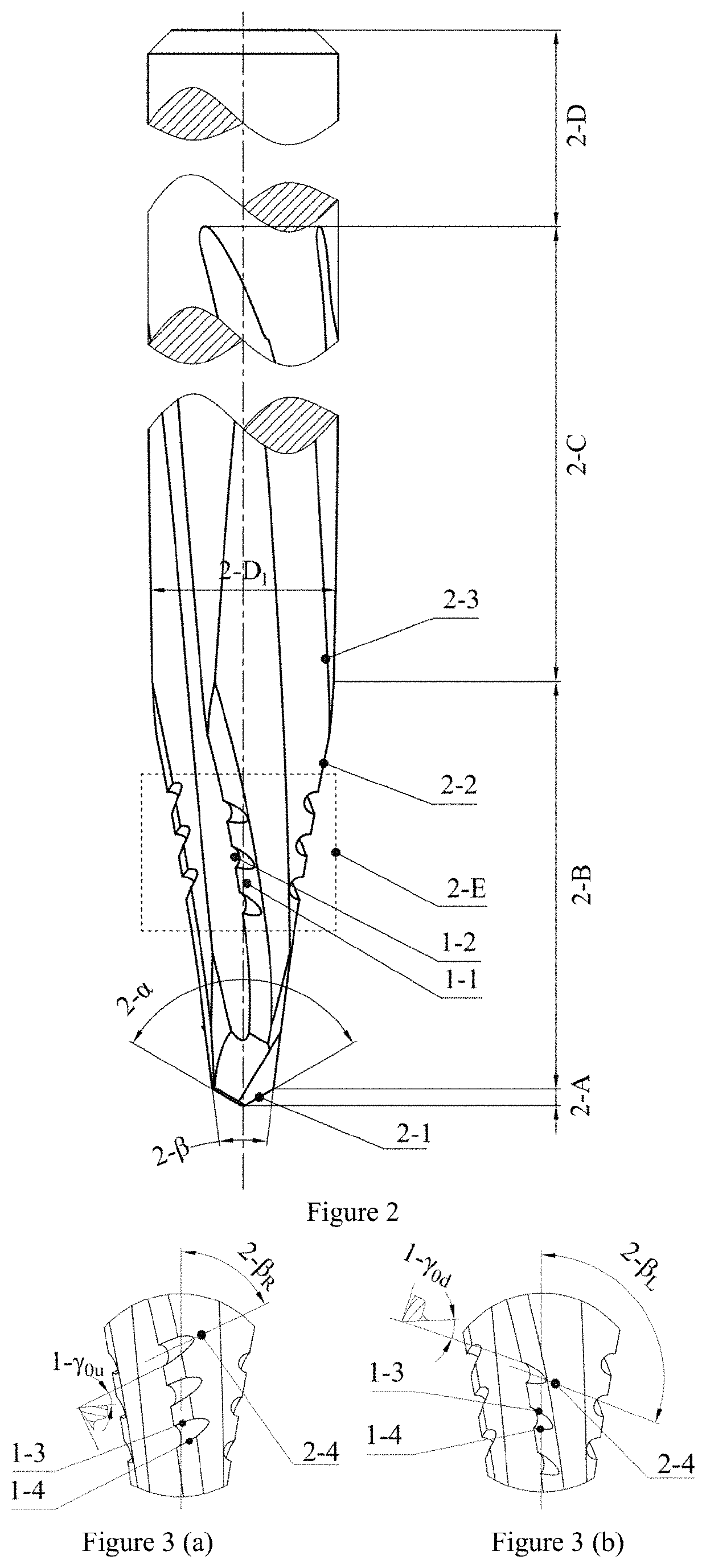

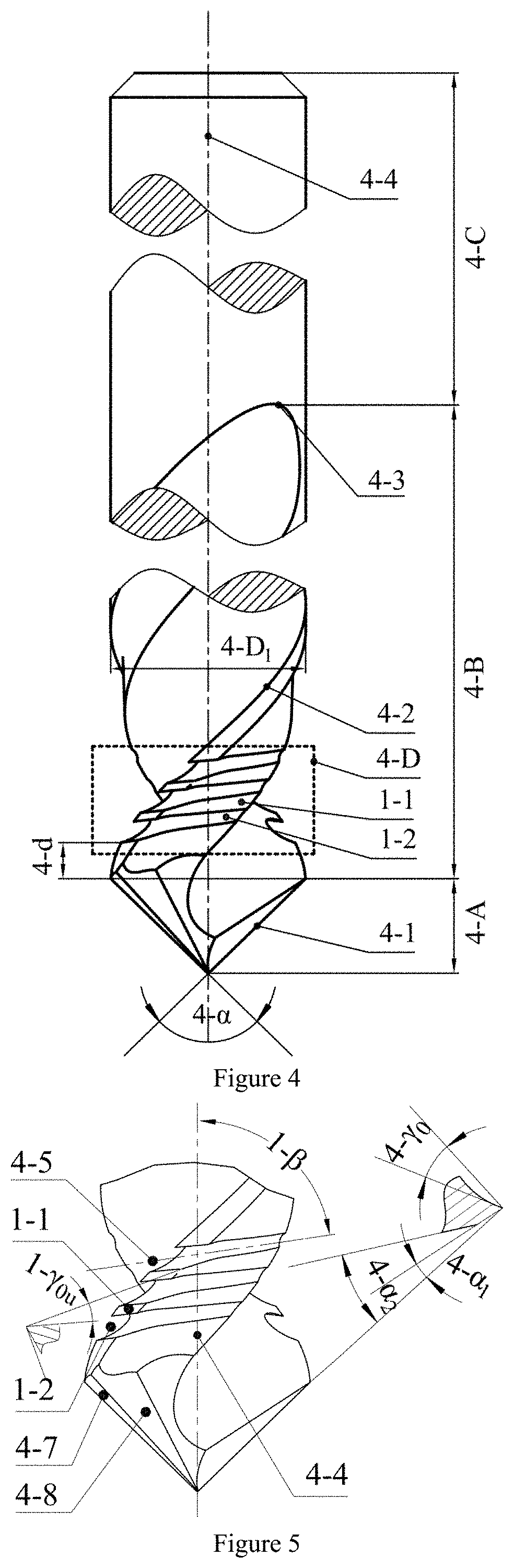

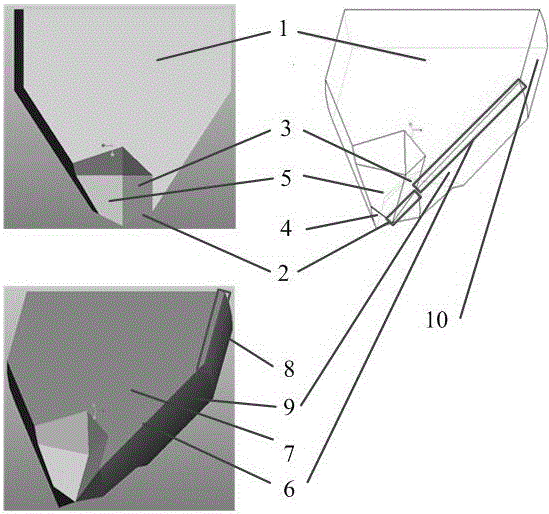

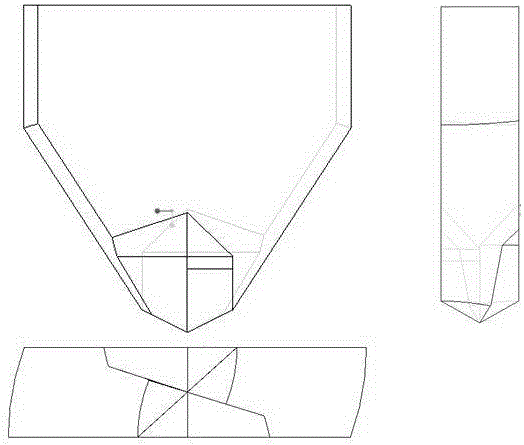

Sawtooth structure with reversed cutting function and its drill series

ActiveUS10857601B2Promote generationImprove cutting effectTransportation and packagingWorkpiecesClassical mechanicsEngineering

A kind of sawtooth structure with reversed cutting function and its drill series are presented in this invention. This invention is suitable for drilling low-damage holes on carbon fiber reinforced polymers (CFRP). The sawtooth structure is comprised of sawteeth and grooves located on the cutting edges of drill. And the sawtooth structure is helically arranged with a specific helix angle around the axis of the drill. It can be classified as the left-hand helix sawtooth structure and the right-hand helix sawtooth structure based on the helix angle value. The bottom edges of the left-hand helix sawtooth structure are the cutting edges, and the rake angles are positive; while the top edges of the right-hand helix sawtooth are the cutting edge with the positive rake angles. The sawtooth structure can be applied to various drilling tools, which proves to be universal. And it can effectively reduce delamination at both hole entrance and hole exit as well as burrs defects. The series of drilling tools include the double point angle drill, the twist drill and the stepped drill all of which have the sawtooth structure on the cutting edges. These series of drilling tools can achieve the CFRP holes with minimum drilling defects. The drilling performance of the tools is improved to a great extent, the tool life is extended and the costs are reduced.

Owner:BLUEDRILL TECH SHENZHEN CO LTD

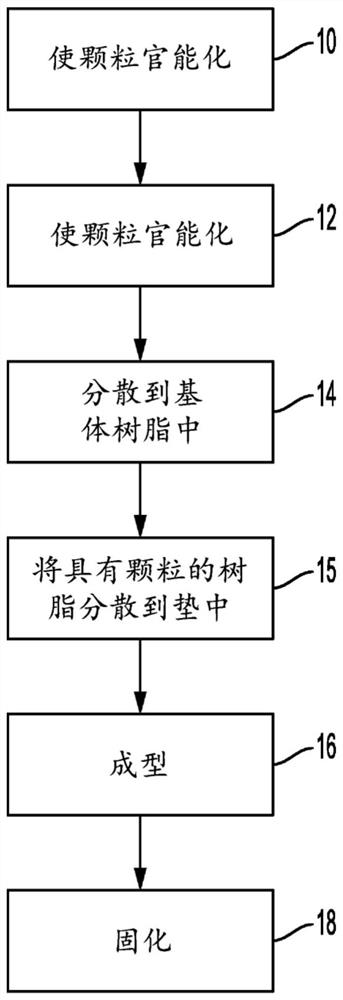

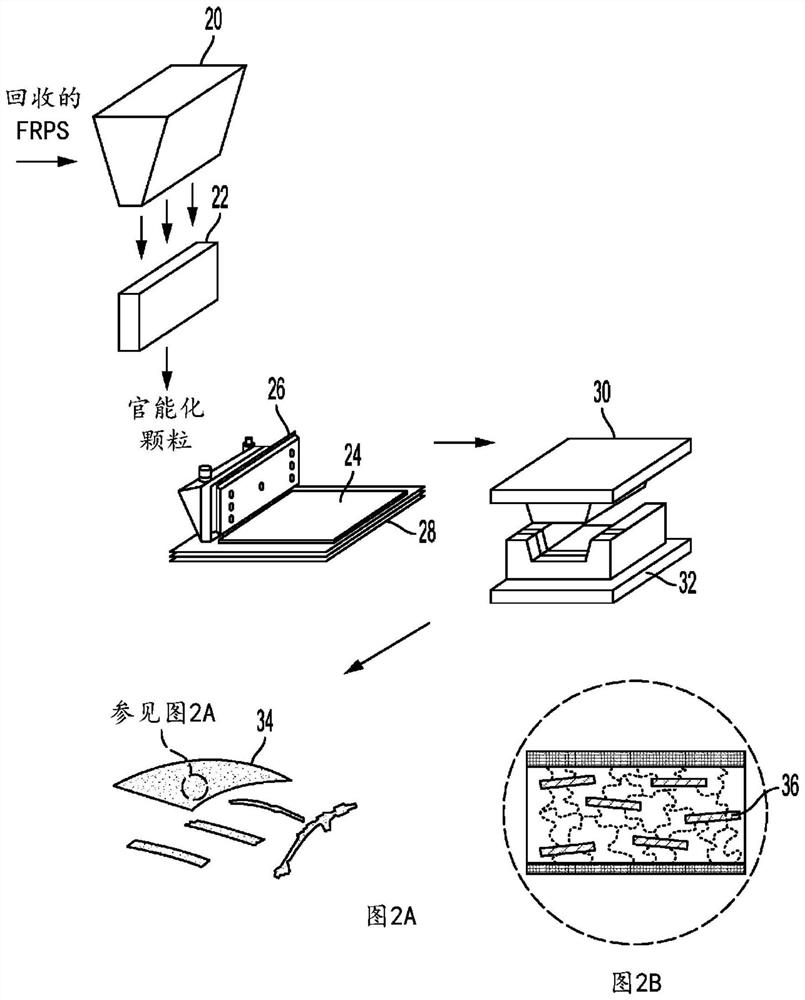

Recyclable enhanced performance carbon fiber reinforced polymers

PendingCN113292817AWaste processingSolid waste disposalGlass fiber reinforced polymerPolymer science

A method of recycling fiber reinforced polymers includes grinding used fiber reinforced polymers material to produce ground particles, functionalizing the ground particles to produce functionalized particles, dispersing the functionalized particles into a base resin, dispensing the resin with functionalized particles into one or more layers of continuous fiber mats, molding the resin with functionalized particles and the continuous fiber mats into a form of a desired part, and curing the form to produce the part. The used fiber reinforced polymer materials may be carbon fiber reinforced polymers or glass fiber reinforced polymer materials.

Owner:PALO ALTO RES CENT INC

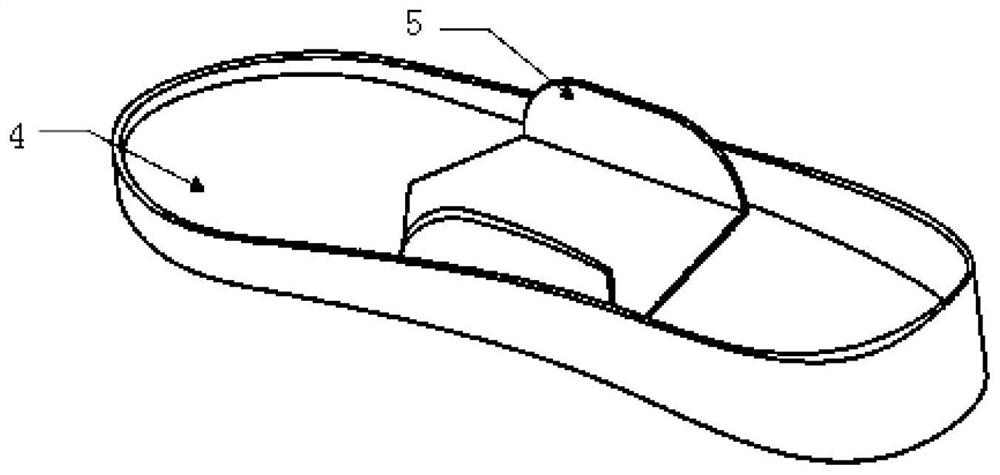

Anti-torsion bearing disc in badminton shoes and production method thereof

ActiveCN113619211AReduce stress concentrationExtended service lifeSolesLamination ancillary operationsPolymer sciencePolymer chemistry

The invention discloses an anti-torsion bearing disc in badminton shoes and a production method thereof. The excellent properties of an amorphous alloy material including high strength, high elasticity and high toughness are ingeniously applied, the amorphous alloy material is prepared into sheets, belts or threads for improving the performance of the anti-torsion bearing disc in badminton shoes, and meanwhile, an optimized surface treatment process is adopted, so that a novel amorphous alloy / carbon fiber reinforced polymer-based composite material with comprehensively improved toughness is prepared, and the defects that a carbon fiber anti-torsion bearing disc is easy to twist and deform, easy to bend and fracture, poor in interlayer fracture toughness and insufficient in elasticity are overcome.

Owner:SHENZHEN UNIV

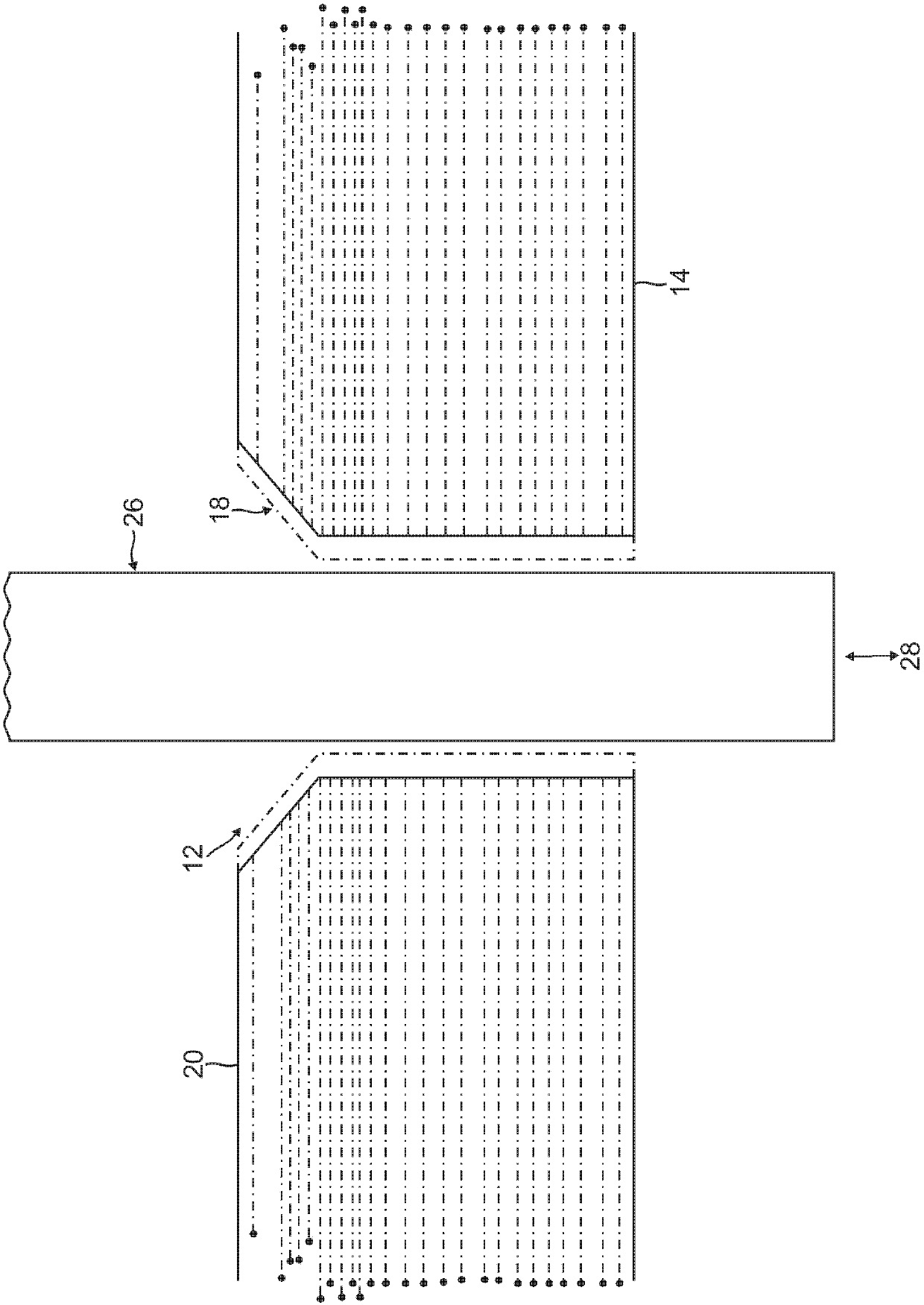

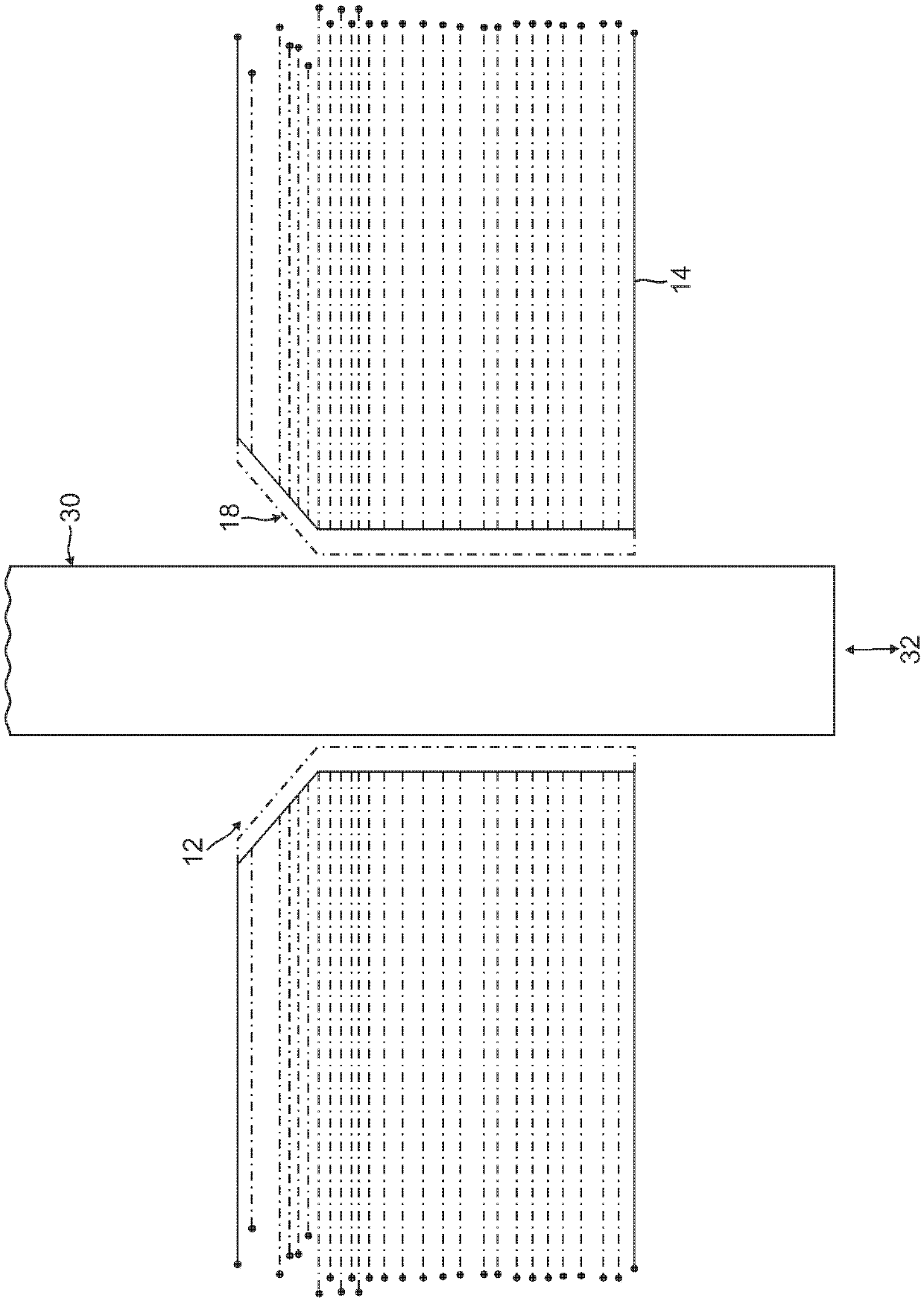

Debonding test apparatus for measuring bond strength to concrete

ActiveUS20210364418A1Minimize eccentricityMinimized in sizeEarth material testingUsing mechanical meansStructural engineeringUltimate tensile strength

A test apparatus used for simulating debonding between a carbon fiber reinforced polymer (CFRP) and concrete in a CFRP-strengthened structure consists of a primary structural block, a secondary structural block, an adjustable hanger, a receiving slot, an attachment mechanism, a pull-off disk, a connecting plate having a plurality of rods. The adjustable hanger and the secondary structural block are slidably positioned into the receiving slot that traverses into a structural body of the primary structural block. The adjustable hanger is mainly used during double-shearing tests and mixed-mode tests, wherein both shearing and peeling is analyzed in mixed-mode tests. The secondary structural block is used in double-shear tests, mixed-mode tests, single-shear tests, tension pull-off tests, and beam-bend tests. The attachment mechanism, which holds the primary structural block, the secondary structural block, and the adjustable hanger together, is also used during single-shear tests and beam-bend tests.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Welded type blade used for CFRP drilling machining

InactiveCN105921794AInhibition defectQuality improvementTransportation and packagingTrepanning drillsResin-Based CompositeAxial force

Due to the fact that a carbon fiber reinforced polymer composite (CFRP) has the beneficial effects of being high in specific strength, high in specific modulus, light, durable and the like, the carbon fiber reinforced polymer composite (CFRP) becomes an ideal use material in the field of aerospace. Machining defects such as layering, burrs, fiber tearing and hole wall scratching are quite likely to be generated in the CFRP hole making process and seriously influence the strength and the fatigue life of CFRP connection structures. Layering is mainly caused by the fact that the axial force of holes is larger than the interlayer bonding force of CFRP plates during hole machining. The burrs and tearing are mainly caused by obtuse cutting edges of blades. The hole scratching is mainly caused by the interaction between rear cutter faces of tools, cuttings and hole walls. Thus, a welded type blade used for CFRP drilling machining is designed and used for reducing the defects in the CFRP machining process. The blade mainly comprises a blade body 1, a main cutting edge 2, a main front cutter face 3, a first main rear cutter face 4, a second main rear cutter face 5, a first auxiliary cutting edge 6, an auxiliary front cutter face 7, a second auxiliary cutting edge 8, a first auxiliary rear cutter face 9 and a second auxiliary rear cutter face 10.

Owner:HARBIN UNIV OF SCI & TECH

Coated carbon fiber reinforced polymeric composites for corrosion protection

InactiveUS20210130963A1Minimizing and preventing galvanic corrosionMinimizes driving forceSynthetic resin layered productsSuperstructure subunitsFiberPolymer

An assembly for a vehicle having reduced galvanic corrosion includes a first component defining at least one interface region that includes a carbon-fiber reinforced polymeric composite (CFRP) and a first material present in the at least one interface region and having a first electrochemical potential. A second component has a second material and is in contact with the at least one interface region of the first component. The second material has a second electrochemical potential different than the first electrochemical potential. In this manner, in the presence of an electrolyte the first material may be either less noble than the second material and serve as a sacrificial material or alternatively more noble to the second material reducing a driving force for corrosion. Methods of reducing galvanic corrosion in an assembly (e.g., for a vehicle) are also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com