Patents

Literature

91results about How to "Avoid forming defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

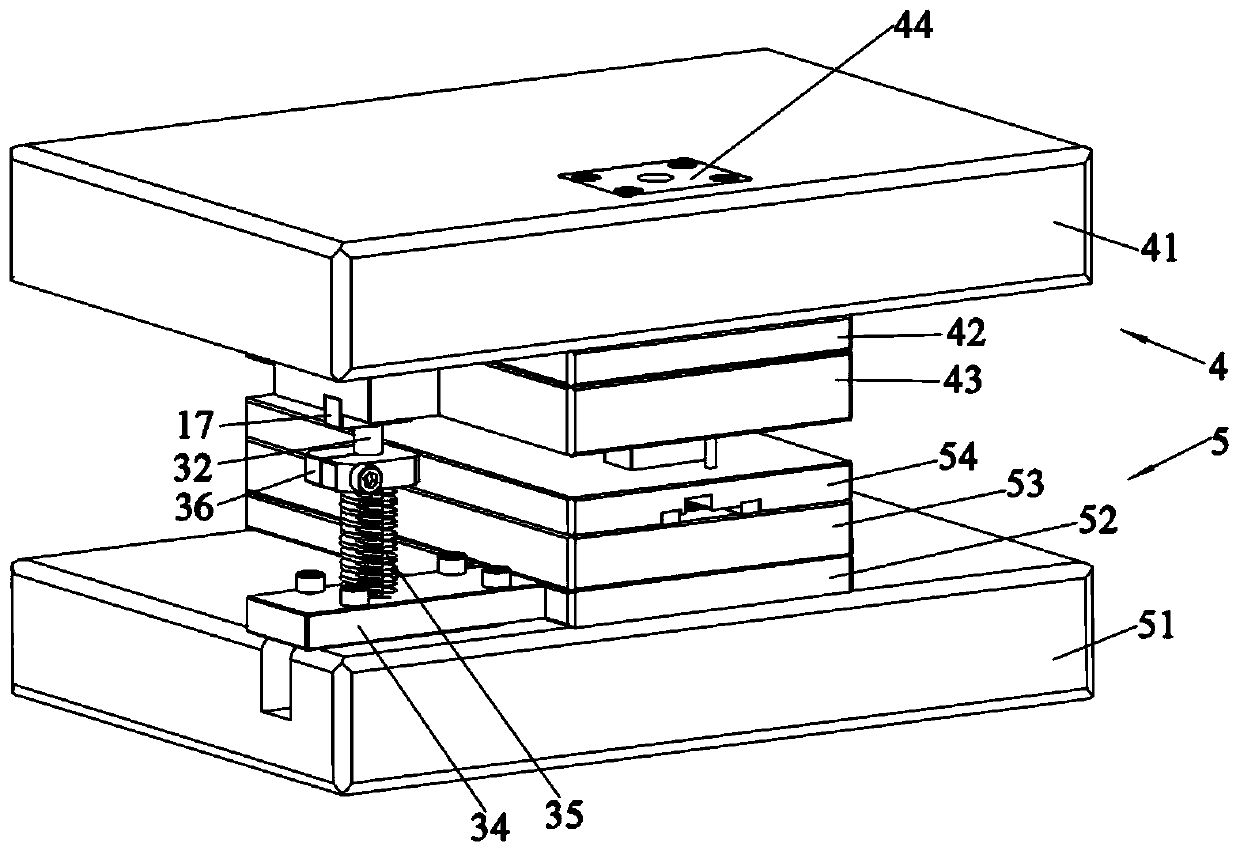

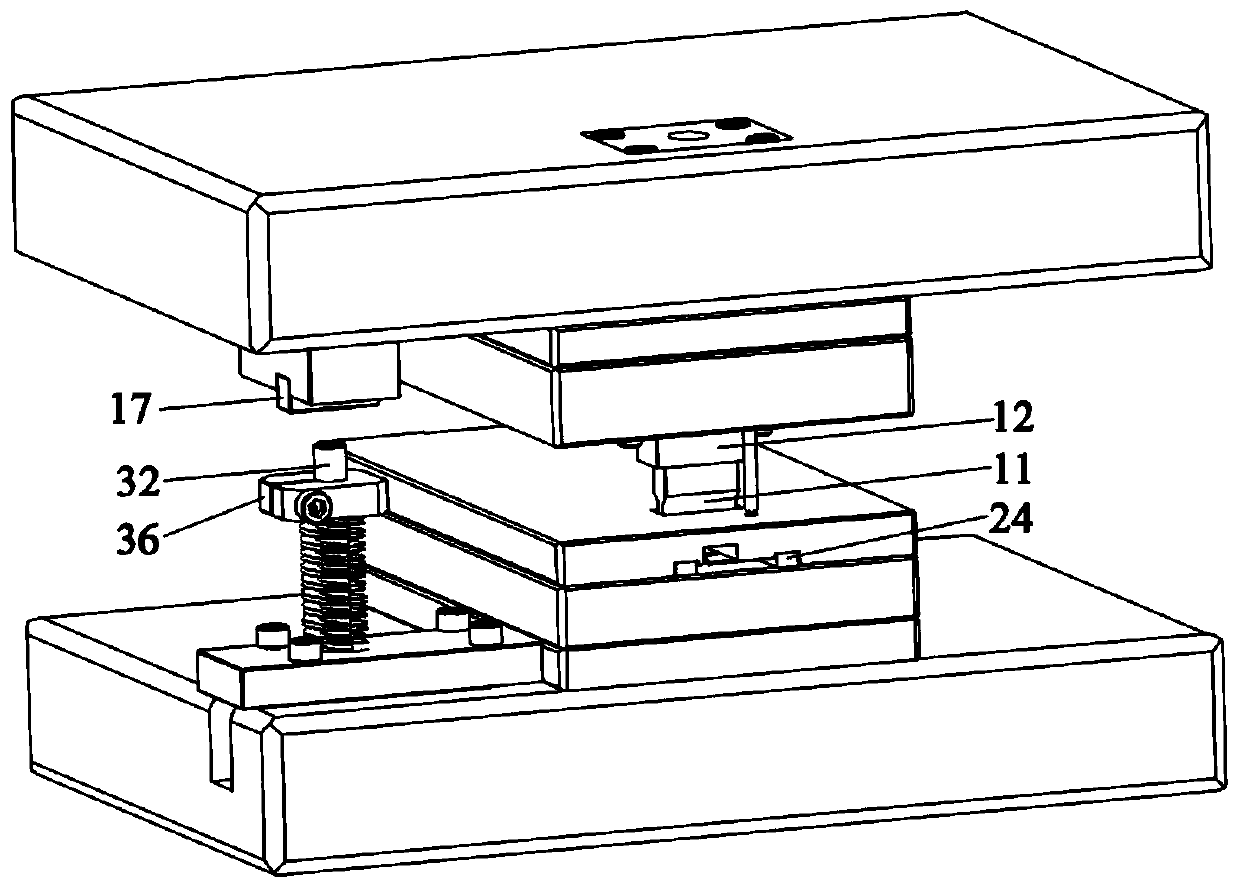

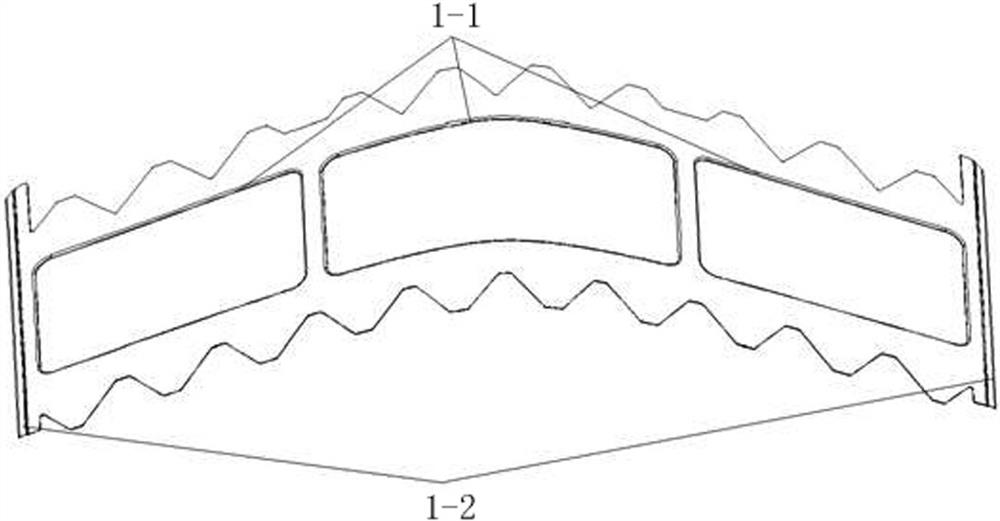

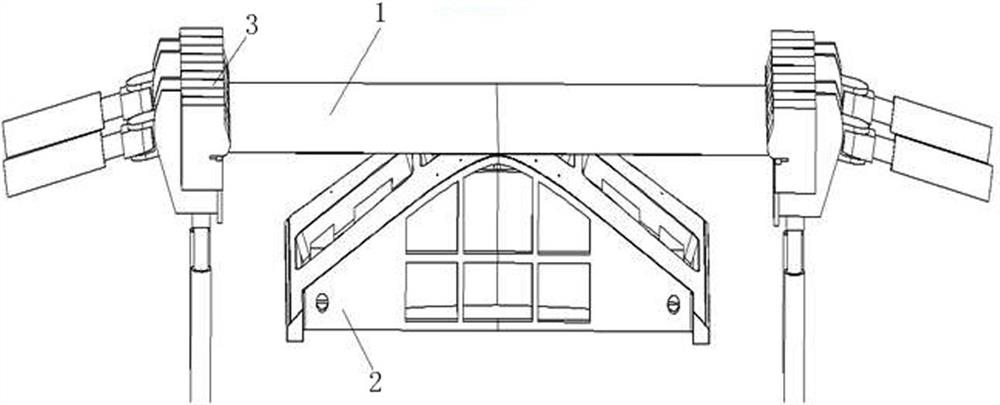

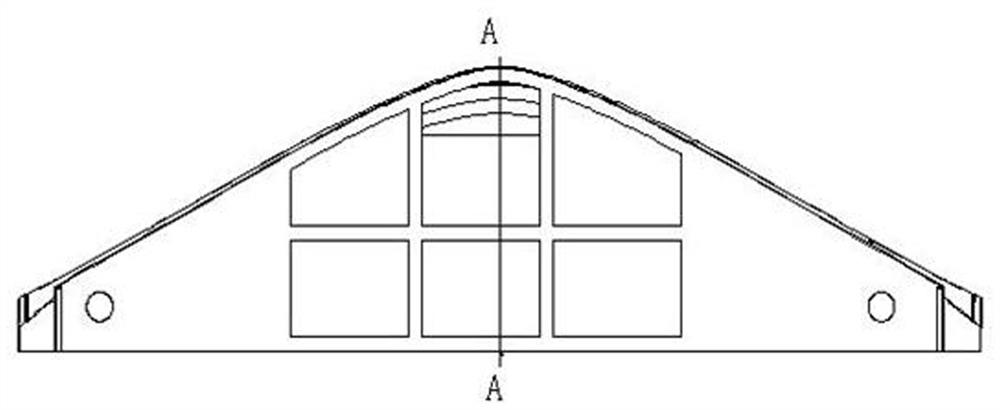

Three-dimensional curved surface stretch forming method based on surface-changing discrete mould

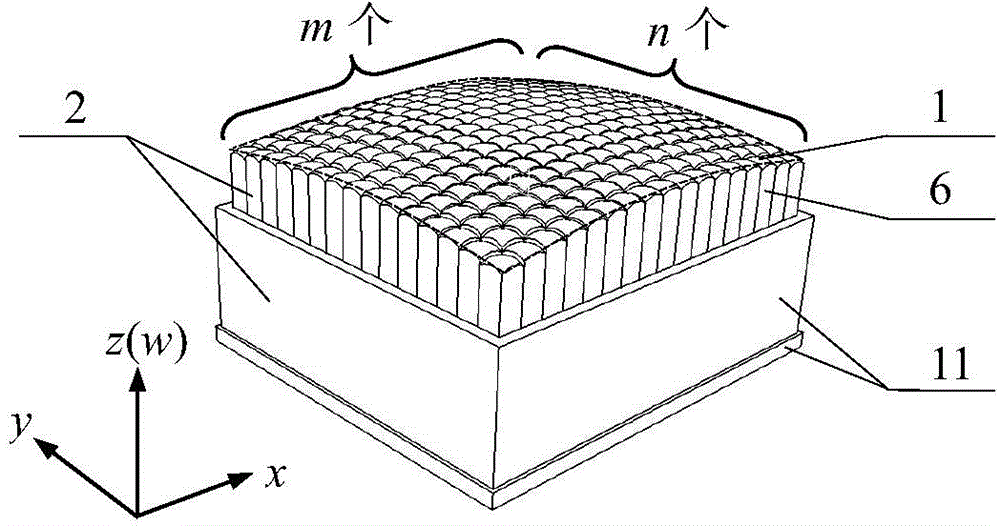

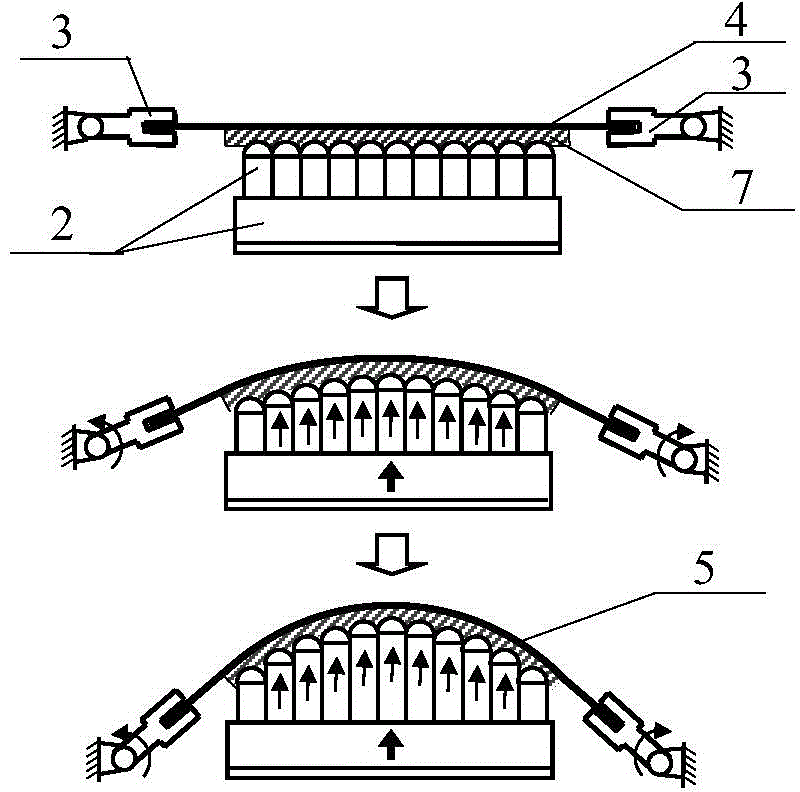

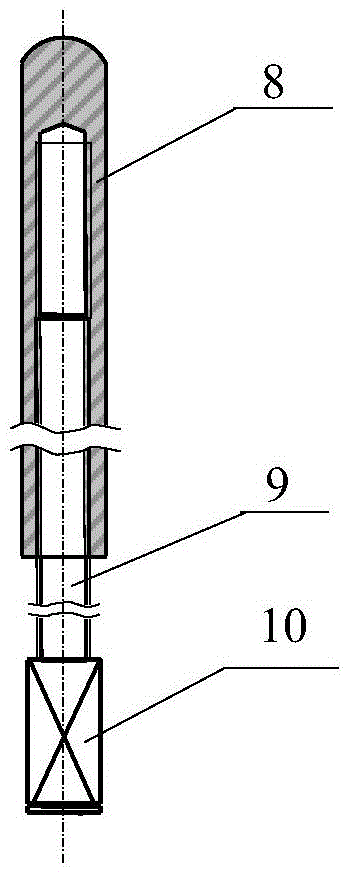

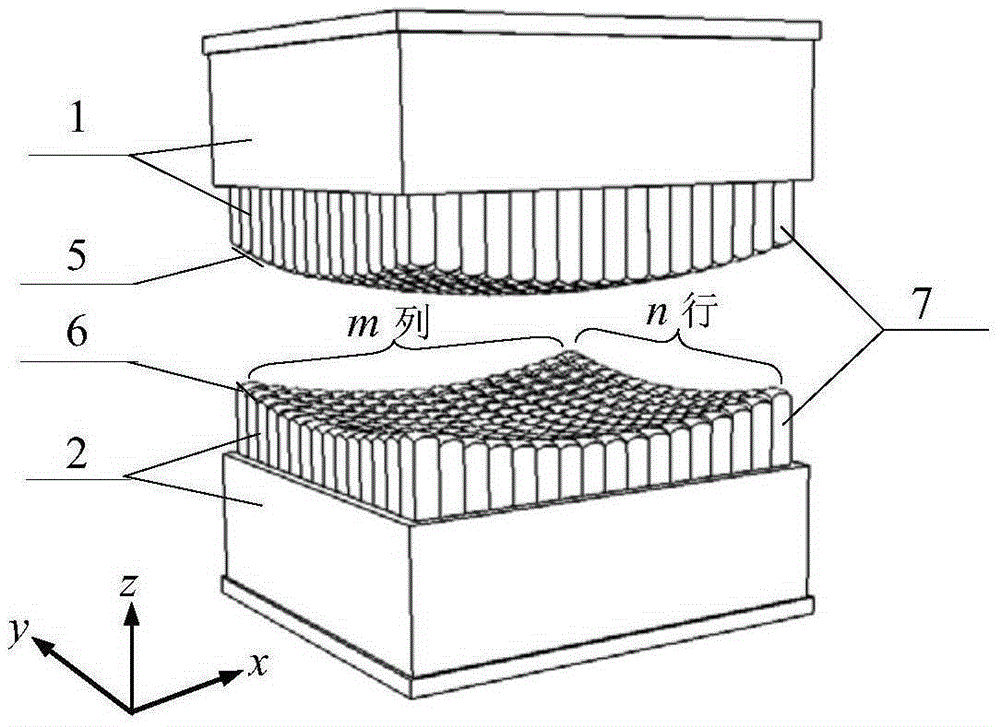

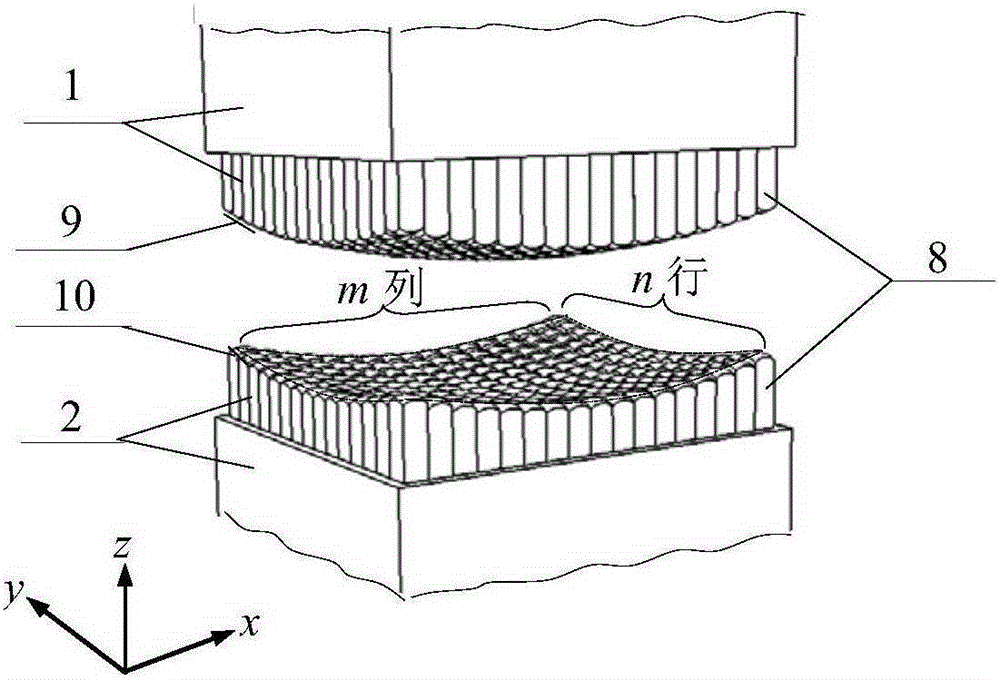

The invention provides a three-dimensional curved surface stretch forming method based on a surface-changing discrete mould, and belongs to the field of metal plastic machining. Nonuniform deformation of a plate in the stretch forming process is the main cause of kinds of defects. According to the method, based on the discrete mould, the forming process of a curved surface is controlled through the change of the mould surface. In the forming process, the plate is kept completely attached to the mould surface all the time, the continuous and uniform change of the mould surface makes the deformation of the plate more and more uniform, the forming defects are avoided, and a high-quality curved-surface part can be obtained through stretch forming. The discrete mould is composed of regularly-arrayed basic body units, and real-time control over the geometrical shape of the surface of the stretch forming mould is achieved by changing the height of the basic body units. Besides, in the stretch forming process, the plate is clamped by a clamp to rotate along with the change of the mould surface, the clamp does not need to move in the horizontal direction or height direction, and therefore a loading structure of stretch forming equipment can be simplified through the forming method.

Owner:JILIN UNIV

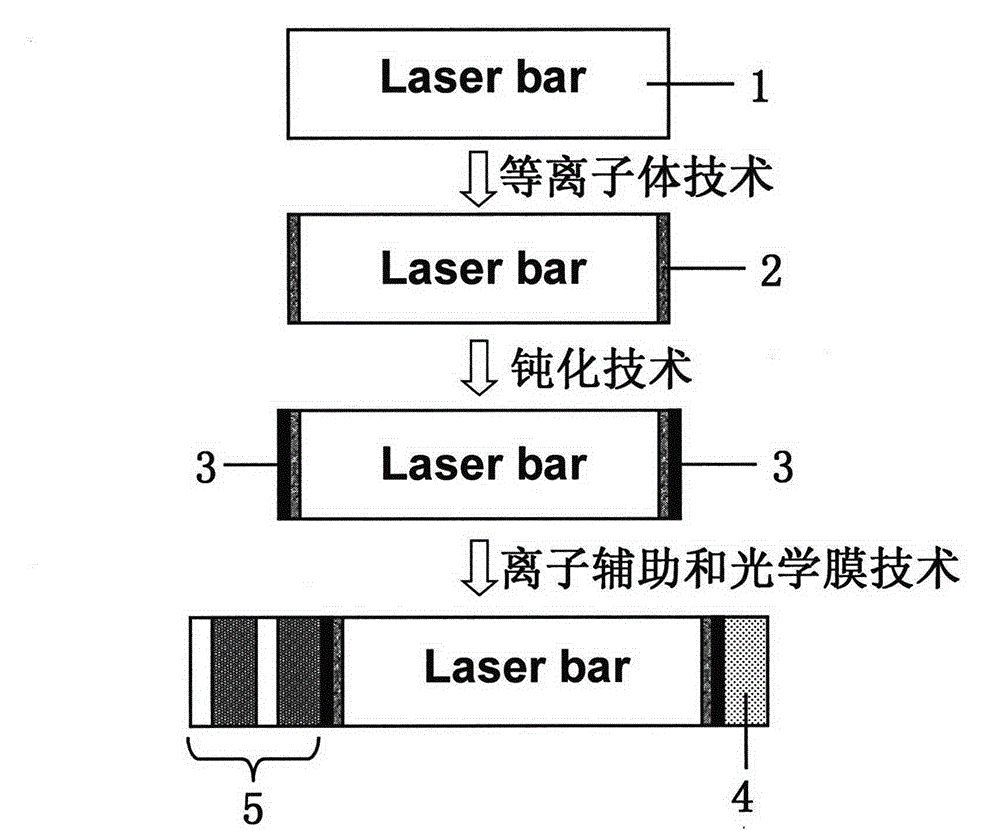

Method for prolonging service life of semiconductor laser device

InactiveCN102882120AExtend your lifeEfficient removalLaser detailsSemiconductor lasersPlasma technologyLaser damage

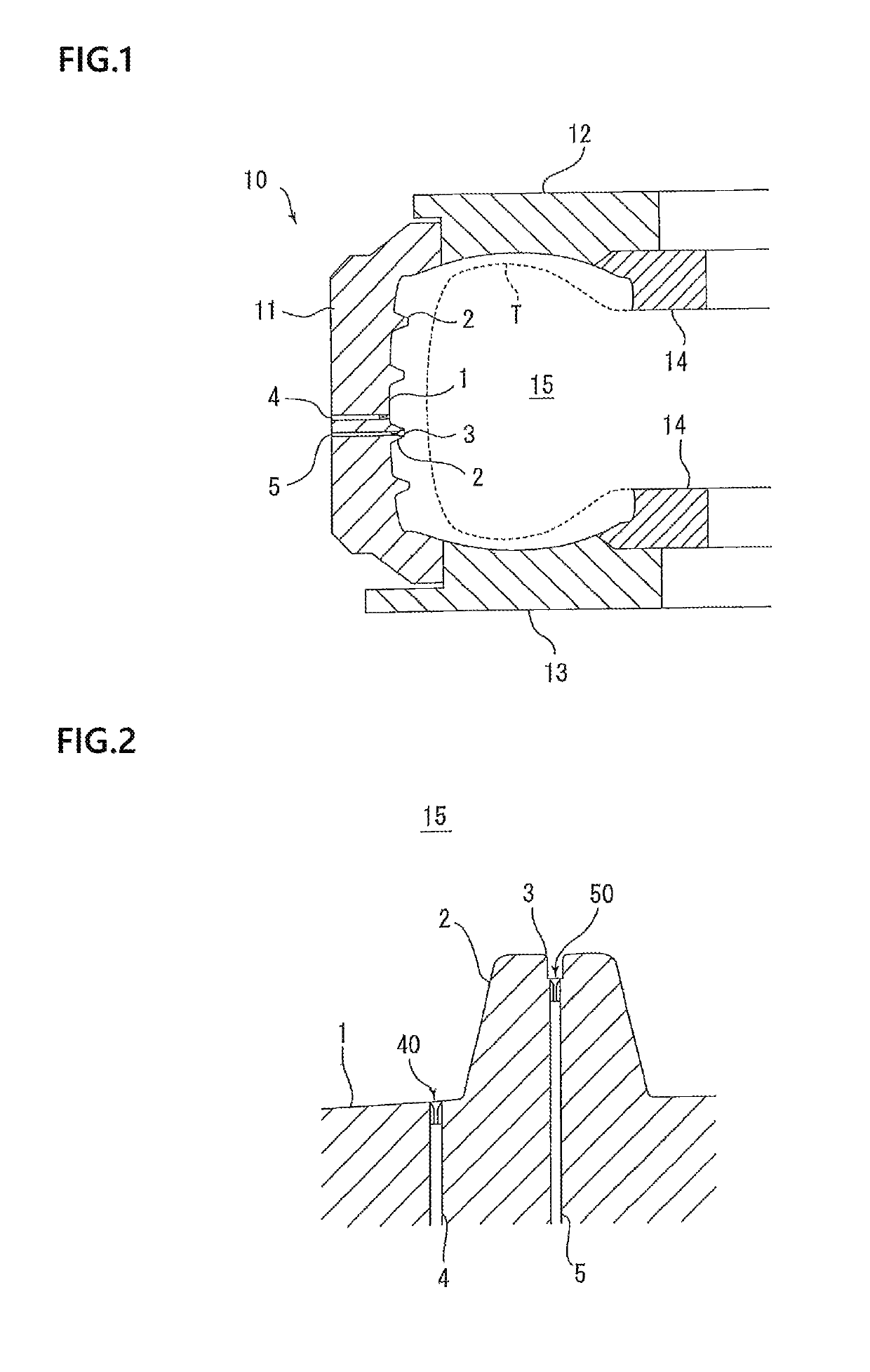

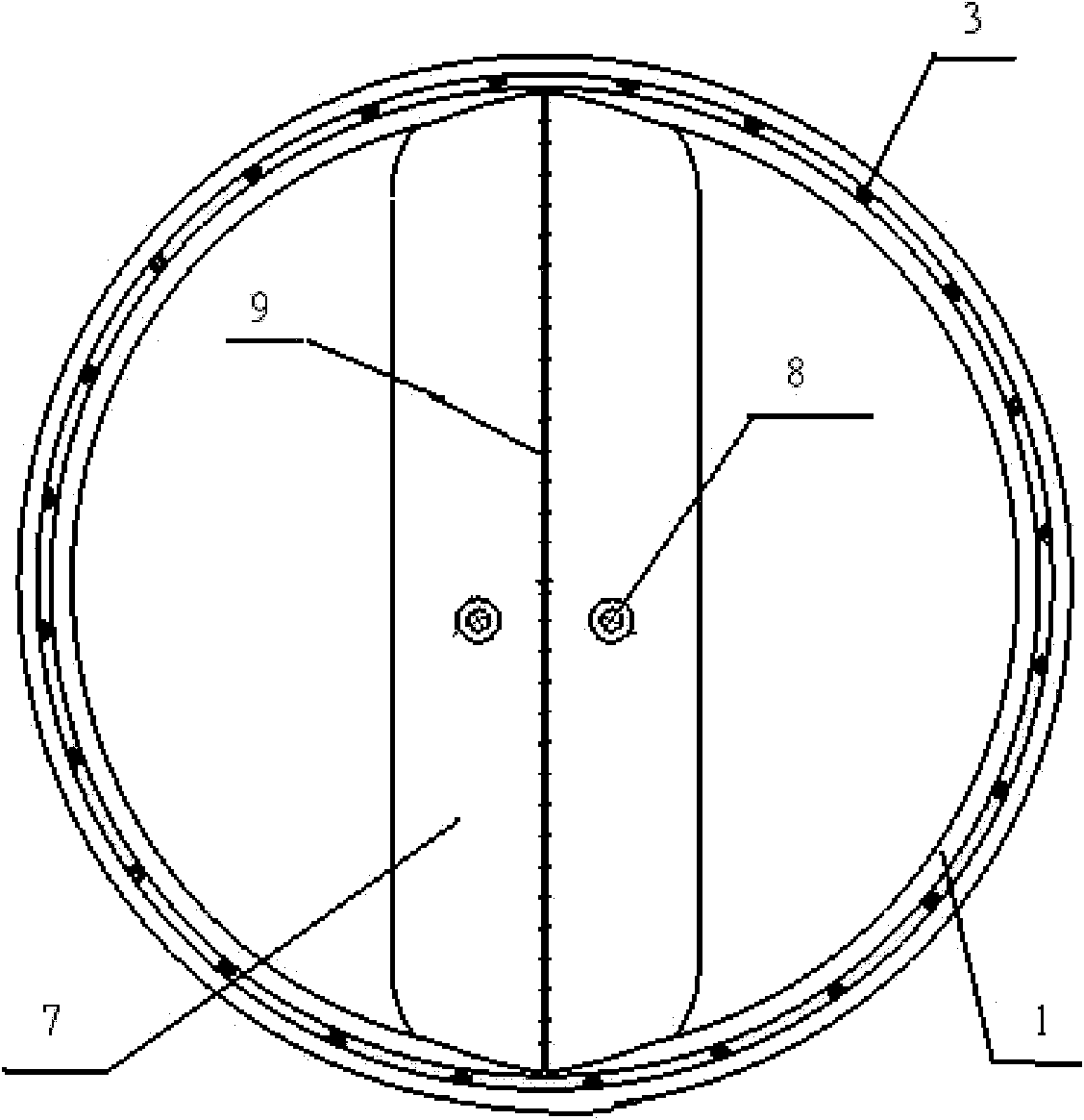

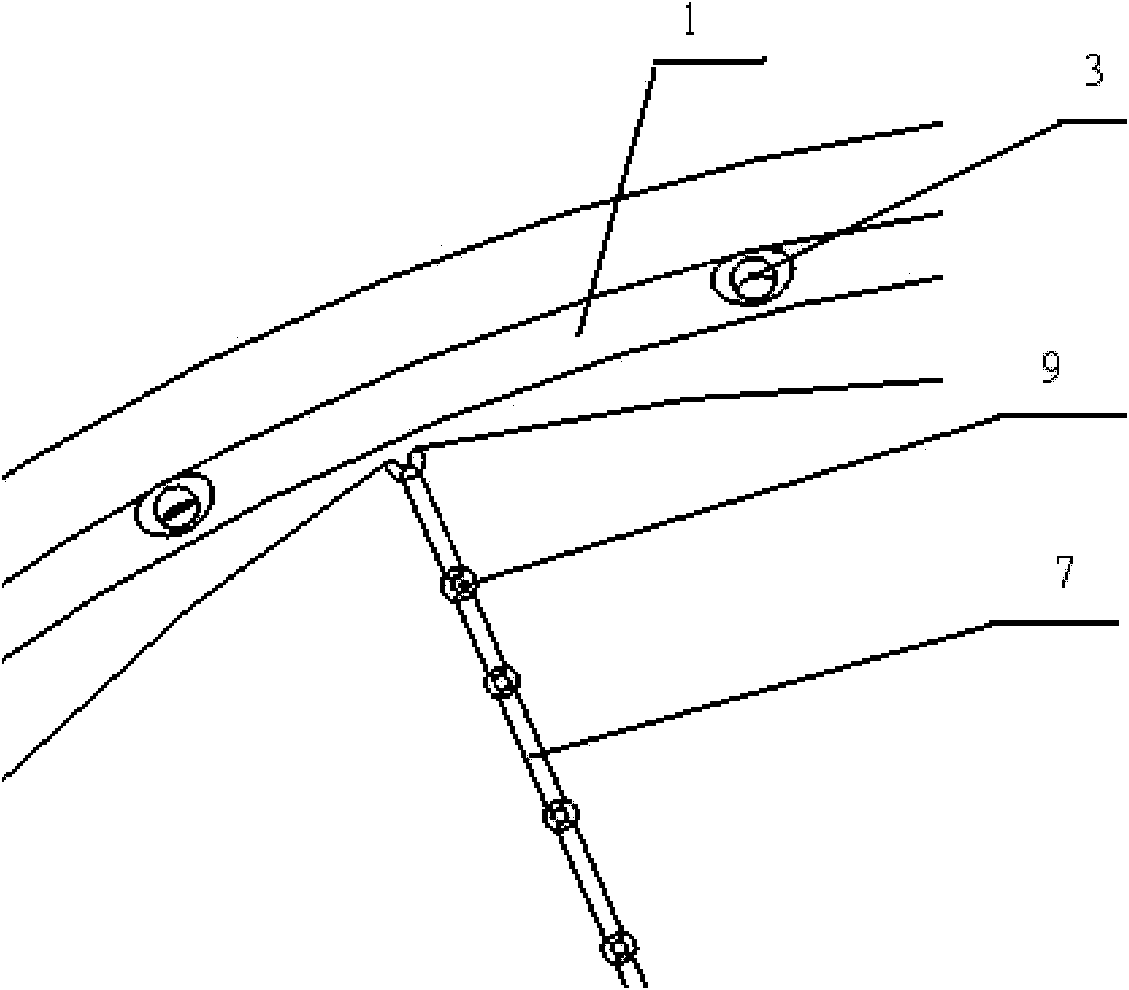

The invention belongs to the technical field of an optoelectronics technology of a semiconductor and relates to a method for prolonging the service life of a semiconductor laser device, namely an integrated technology of plasma technology, passivation technology, ion auxiliary technology and optical film technology. The method comprises a semiconductor laser device bar 1, a semiconductor laser device bar 2 processed by the plasma technology, a passivation film 3, a front cavity surface film 4 and a rear cavity surface film 5. The method comprises the following steps of: orderly stacking the sorted semiconductor laser device bar 1 on a special bar clamp; putting into a vacuum coating machine; and extracting vacuum. When a pre-set vacuum degree is realized, the plasma technology is firstly adopted to carry out cavity surface washing to wash cavity surface oxides and an unstable surface state to form the semiconductor laser device bar 2 processed by the plasma technology; then the passivation technology is adopted to deposit one layer of the passivation film 3 on the cavity surface to inhibit the cavity surface from being oxidized; and finally, the ion auxiliary technology and the optical film technology are adopted to prepare the front cavity surface film 4 and the rear cavity surface film 5, which have high-laser damage threshold values, so as to improve a cavity surface damage threshold value of the semiconductor laser device. With the adoption of the method disclosed by the invention, the service life of the semiconductor laser device can be effectively prolonged.

Owner:CHANGCHUN UNIV OF SCI & TECH

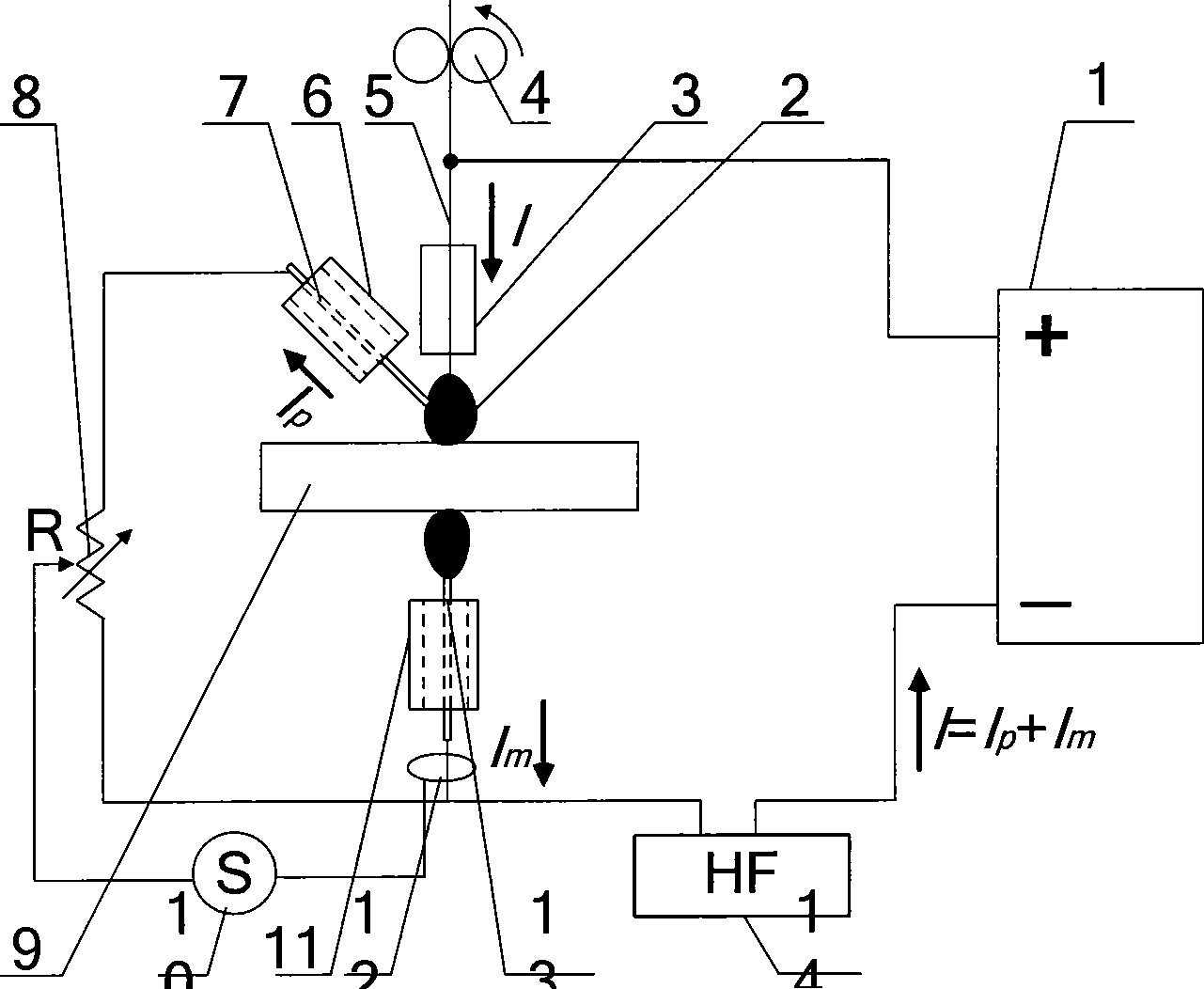

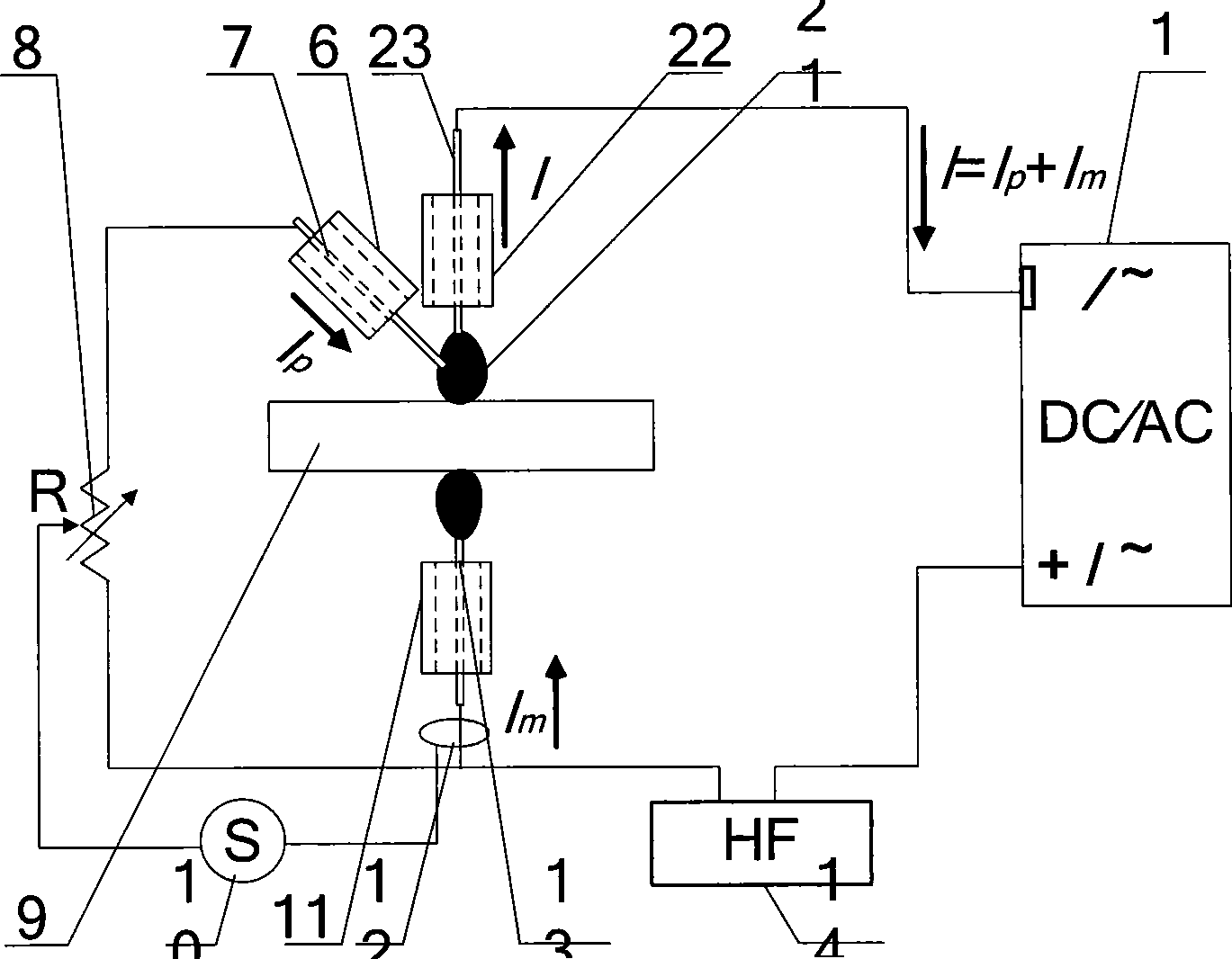

Bypass shunt double-sided arc welding device and welding method

InactiveCN101530943AImprove carrying capacityAchieve high deposition rateArc welding apparatusElectrode erosionWelding power supply

The invention relates to a bypass shunt double-sided arc welding device and a welding method, which is characterized in that the device comprises a welding source, a main welding gun, an auxiliary welding gun, a bypass welding gun, an arc striker, a current sensor, a bypass resistor and a control system, etc. the main welding gun and the auxiliary welding gun are symmetrically arranged at both sides of a workpiece and are connected with two poles of the welding source; the bypass welding gun is argon tungsten-arc welding gun and is applied to one side of the main welding gun as a bypass to shunt partial welding current flowing through mother plates; therefore, the main welding gun can be connected with big current, reduce heat input acting on the mother plates while realizing high deposition efficiency and improve welding quality, while the auxiliary welding gun on the back of a molten pool is only connected with partial current, which is conductive to reducing electrode erosion and improving bearing capacity of the molten pool. As tungsten electrode electronic work function of the bypass welding gun is far lower than that of a metal workpiece, by the method, limit of welding wire shunt can be overcome and bypass current can be conveniently adjusted so as to ensure heat and force acting on the arc and molten pool are at ideal levels, therefore, the welding method is efficient and controllable.

Owner:HARBIN ENG UNIV

Modification method of phosphogypsum for PVC material production

InactiveCN105482503AImprove processing rheologyHigh strengthPigment treatment with non-polymer organic compoundsFilling materialsParaffin oils

The invention relates to the technical field of PVC production filling materials and especially relates to a modification method of phosphogypsum for PVC material production. The method comprises mixing fresh phosphogypsum and quicklime until pH is in a range of 6-8 so that phosphogypsum free water content is reduced, carrying out heating treatment through a stirring heater, controlling the temperature in a range of 150-180 DEG C so that the fresh phosphogypsum is transformed into semi-hydrated phosphogypsum, adding paraffin into the semi-hydrated phosphogypsum so that phosphogypsum plasticity and rheological properties are improved and the dry phosphogypsum adsorbs water to form crystal water with an unstable structure, carrying out dry grinding and screening so that crystal water in the phosphogypsum is exposed, related content of phosphogypsum impurities in unit volume is reduced and phosphogypsum whiteness is improved, and carrying out stir-frying at a temperature of 180-200 DEG C so that a part of crystal water in phosphogypsum is lost. The prepared phosphogypsum is a mixture of semi-hydrated gypsum, III-type anhydrite and II-type anhydrite, has high rheological properties and plasticity and improves PVC quality.

Owner:GUIZHOU KAILIN GRP CO LTD

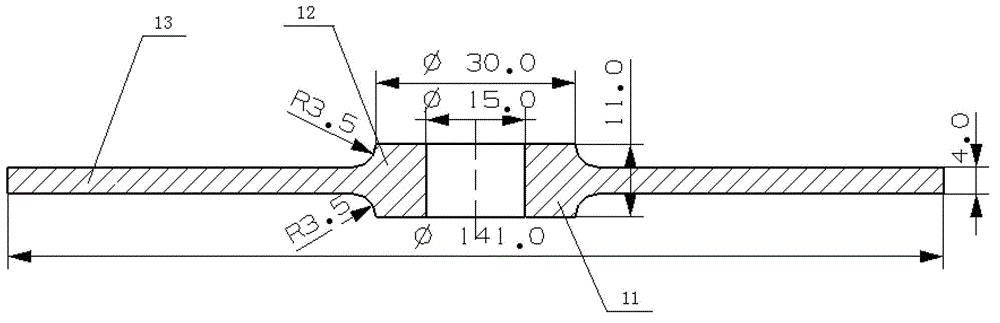

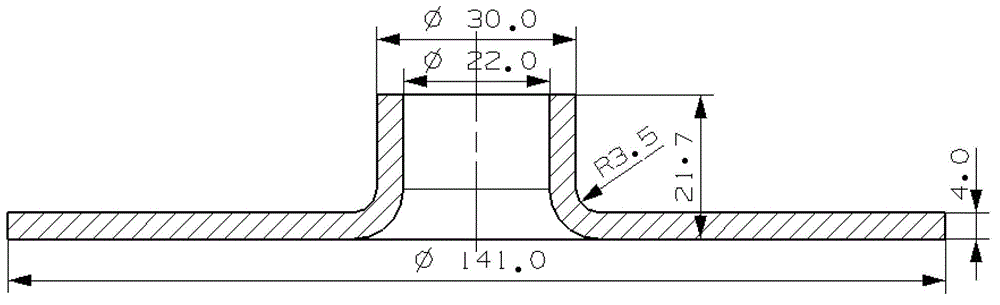

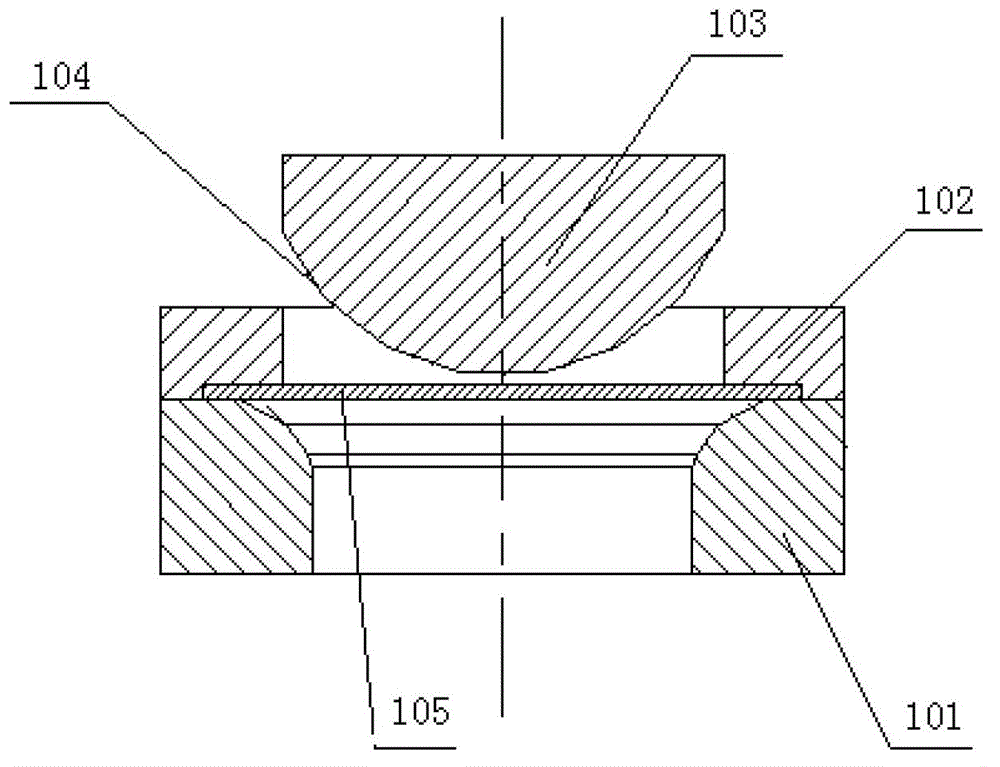

Forming technique of hub with bidirectional cylindrical boss

The invention provides a forming technique of a hub with a bidirectional cylindrical boss. The forming technique forms and manufactures the hub with the bidirectional cylindrical boss by adopting an impact forging composite formation process, and comprises the steps as follows: firstly, a blank is stretched to form a conical part with a protruding edge via two times of stretch; secondly, two times of shrinkage edge turning and shaping of the punched conical part are performed, and a blank central cylinder wall is formed; lastly, the bidirectional cylindrical boss is formed step by step via four times of upsetting. Therefore, the formation defects of a hub with the bidirectional cylindrical boss, formed by adopting ways of monoblock cast, welding and processing with a forging machine, are overcome. The hub with the bidirectional cylindrical boss, formed via the forming technique is high in utilization ratio of material, formation efficiency and formation precision, and is better in overall mechanical property.

Owner:NANTONG FULEDA AUTOMOBILE FITTINGS

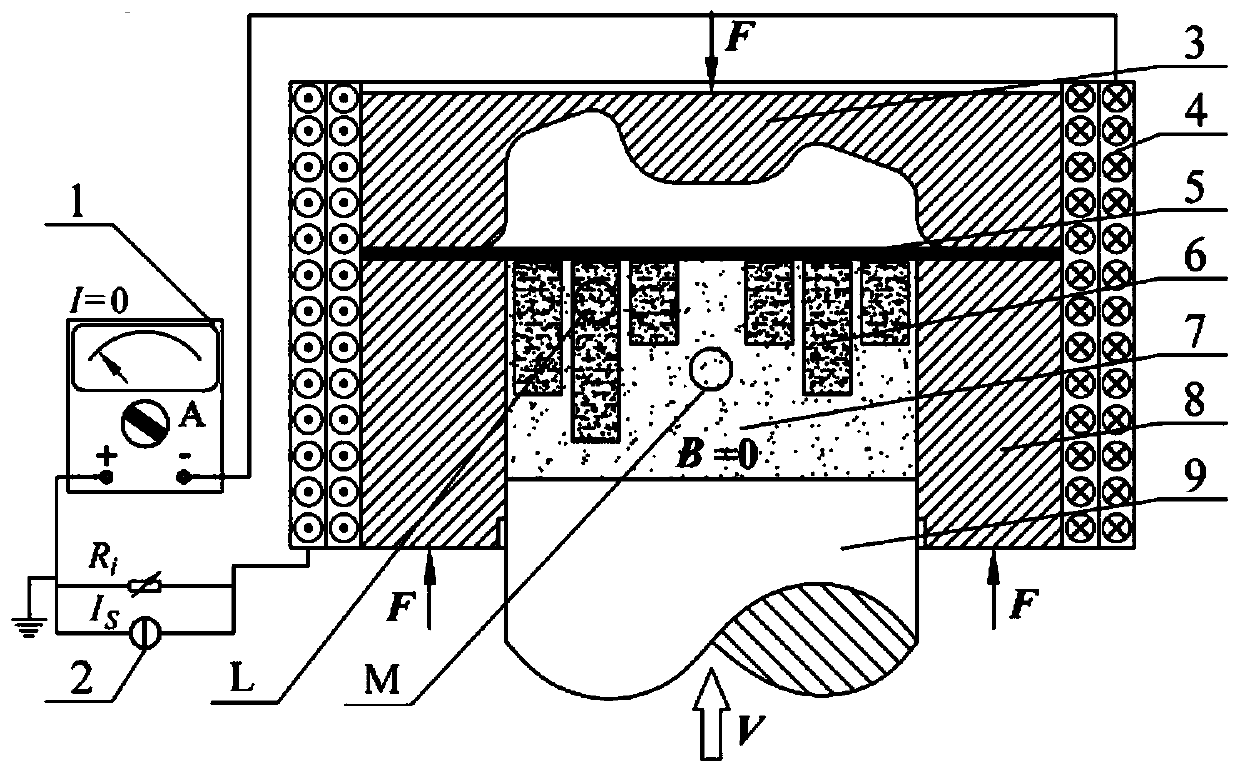

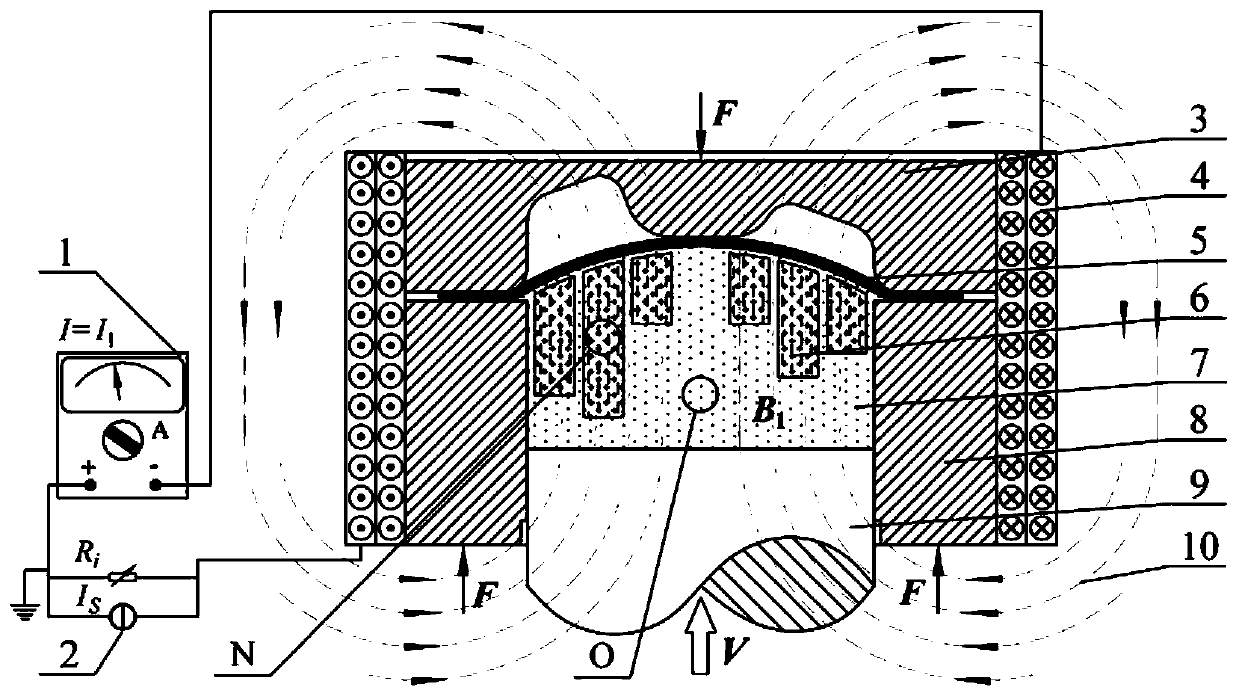

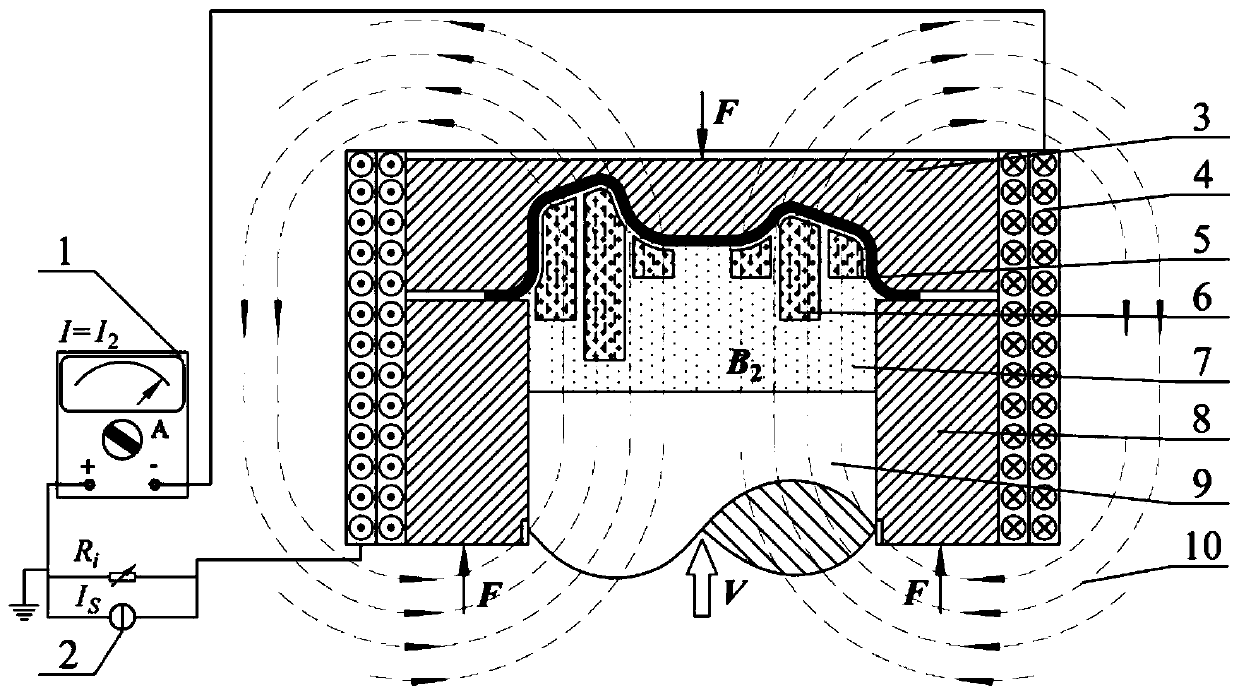

Magneto-rheological composite soft mold and plate forming method based on same

The invention relates to a magneto-rheological composite soft mold and a plate forming method based on the same. The magneto-rheological composite soft mold comprises a soft mold matrix constituted byI-type magneto-rheological elastic materials, and one or more II-type magneto-rheological elastic units or one or more magneto-rheological visco-plastic units are packaged at the predetermined position in the soft mold matrix; the II-type magneto-rheological elastic units are constituted by II-type magneto-rheological elastic materials; the magneto-rheological visco-plastic units are constitutedby magneto-rheological visco-plastic materials; and in an applied magnetic field, the pressure response characteristics of the I-type magneto-rheological elastic materials, the II-type magneto-rheological elastic materials and the magneto-rheological visco-plastic materials are different. The magneto-rheological composite soft mold is used as a plate forming force-transmitting medium, full fillingof plate local complex structural characteristics can be promoted, the forming defects are avoided, and the problem that an existing magneto-rheological elastomer soft mold cannot achieve local differential pressure distribution is effectively solved.

Owner:HENAN UNIV OF SCI & TECH

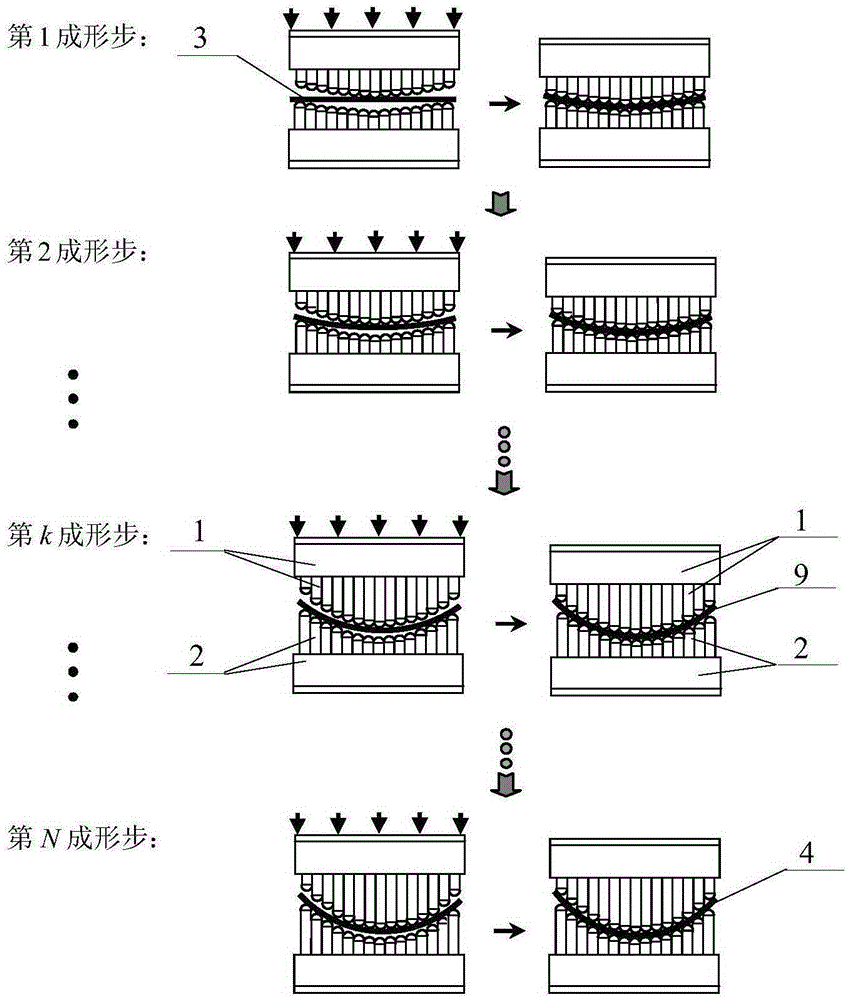

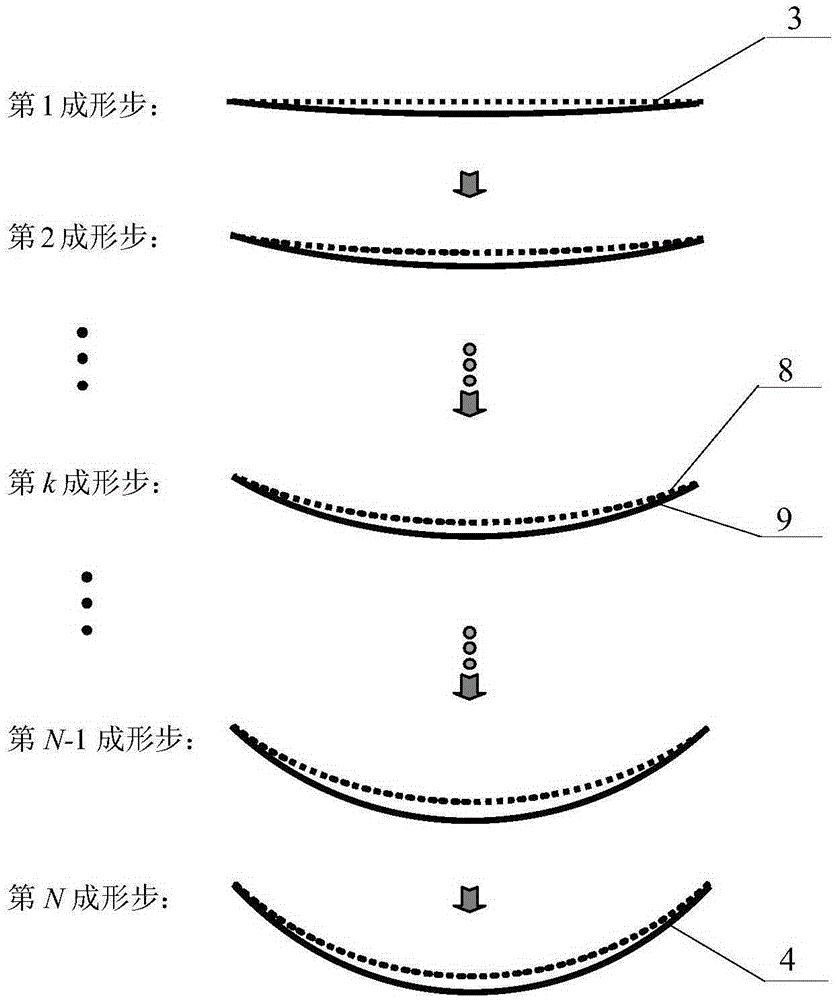

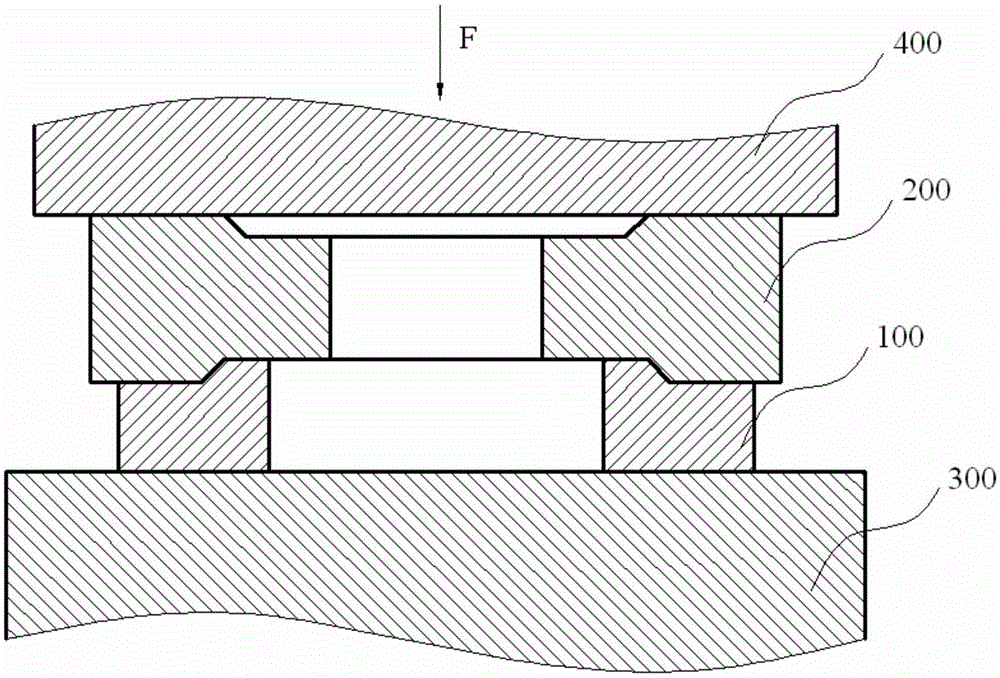

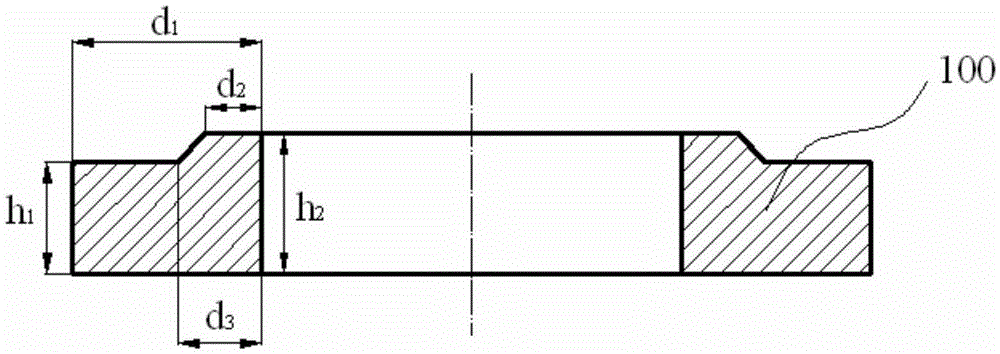

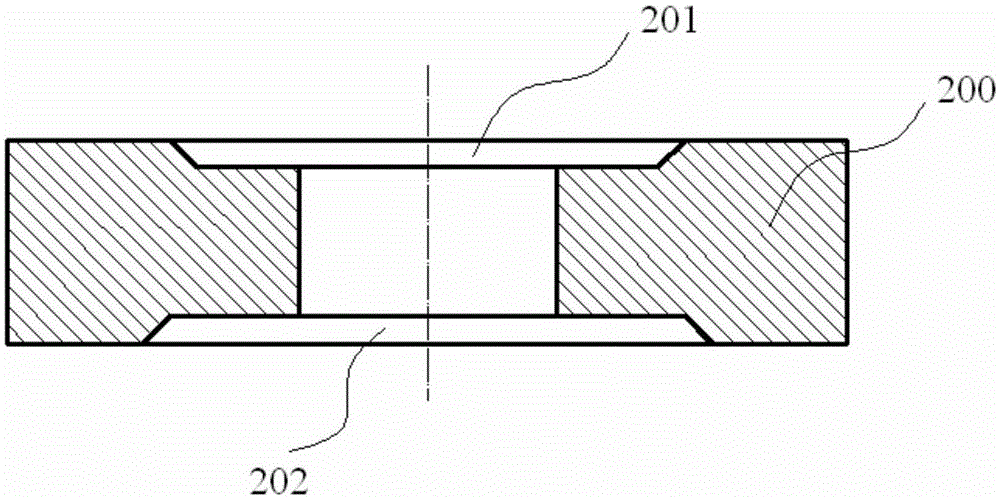

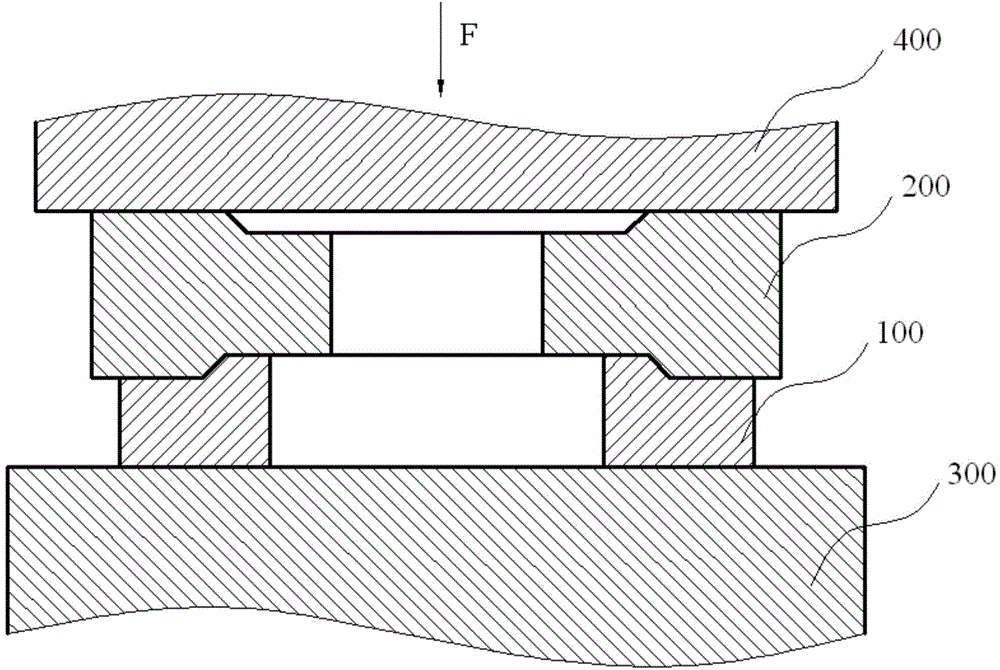

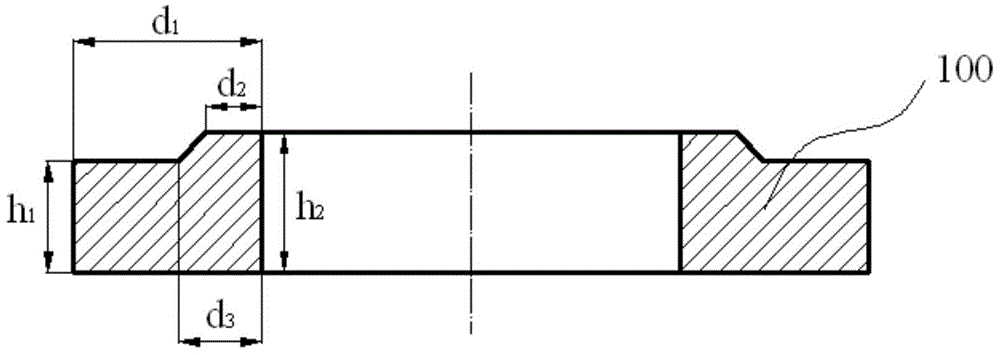

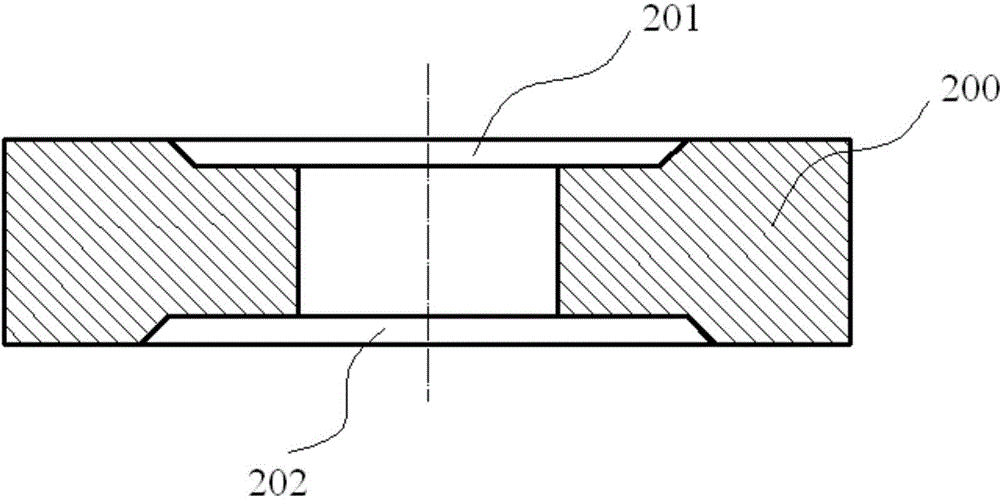

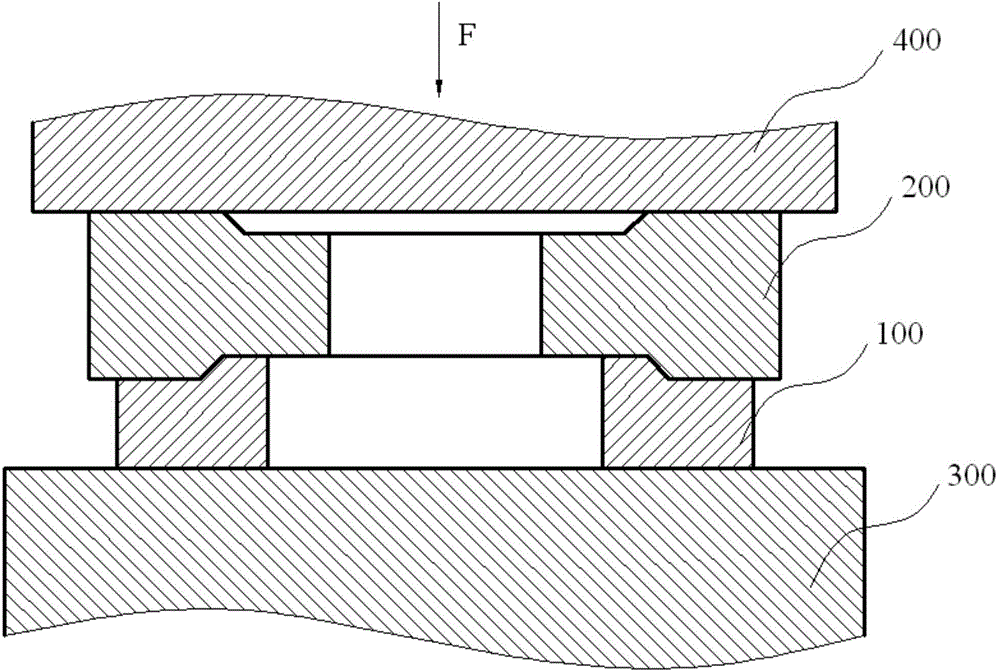

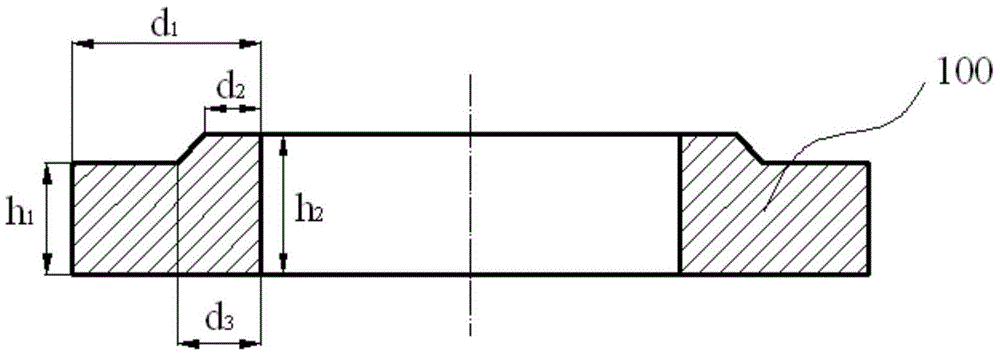

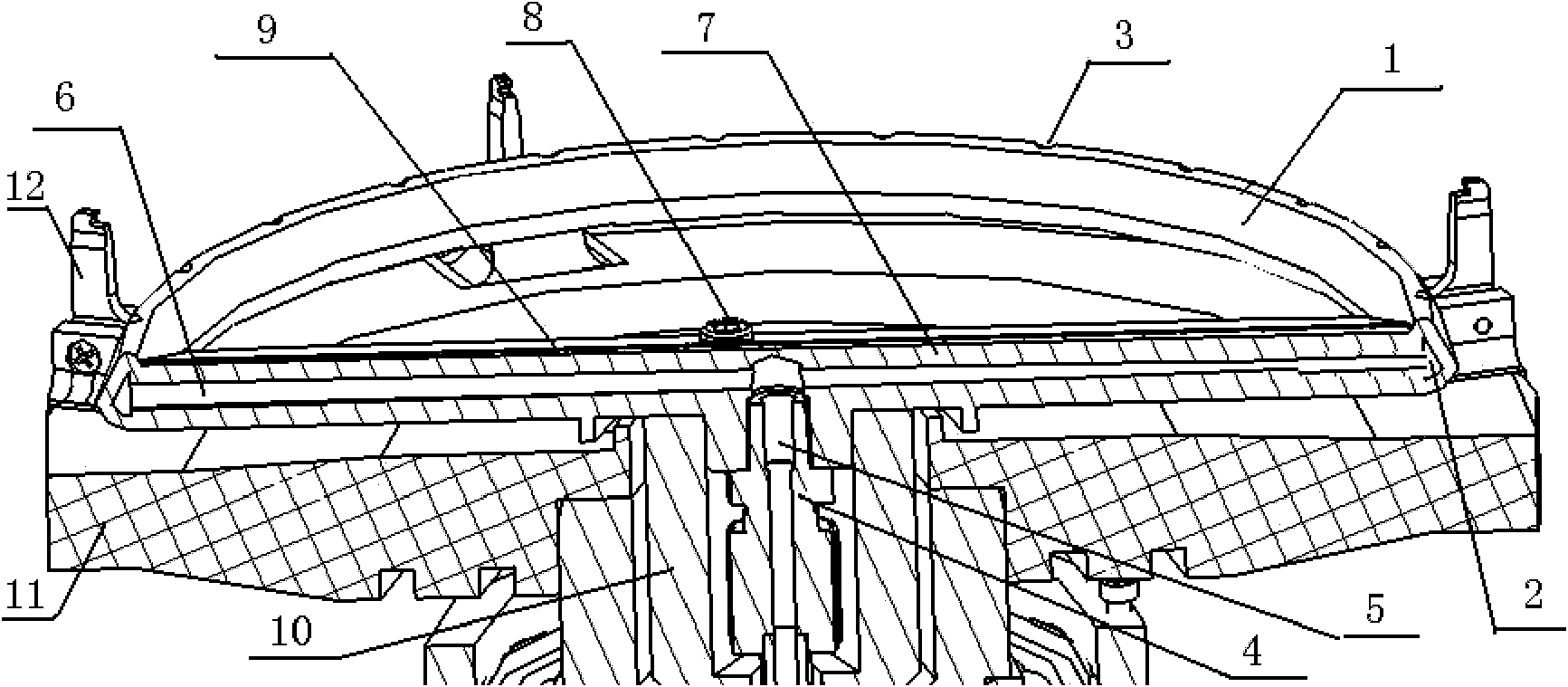

Large-curvature three-dimensional hook face multi-step forming method based on gradually-changed mold molded face

The invention provides a large-curvature three-dimensional hook face multi-step forming method based on a gradually-changed mold molded face, and belongs to the field of metal plastic working. Large-curvature three-dimensional hook face parts are difficult to form, and various forming defects, in particular to the corrugation defect, are extremely prone to occurrence in the forming process; and in a traditional drawing forming method, even though large-curvature hook faces can be machined, complex blank pressing molds are needed, and the method is suitable for thin-plate forming and cannot be used for forming medium and thick plate hook face parts. The method is based on a mold with the adjustable dispersed type molded face, the mold molded surface is adjusted step by step to conduct multi-step forming, and the shapes of the hook face formed in all forming steps are gradually changed, so that the deformation amount of plates in all forming steps is smaller, and the corrugation defect is avoided; and after multi-step oppositely-pressed forming is carried out on the plates, the large-curvature three-dimensional hook face parts are obtained. The method is suitable for forming the medium and thick plate hook face parts and also suitable for forming the thin-plate hook face parts.

Owner:JILIN UNIV

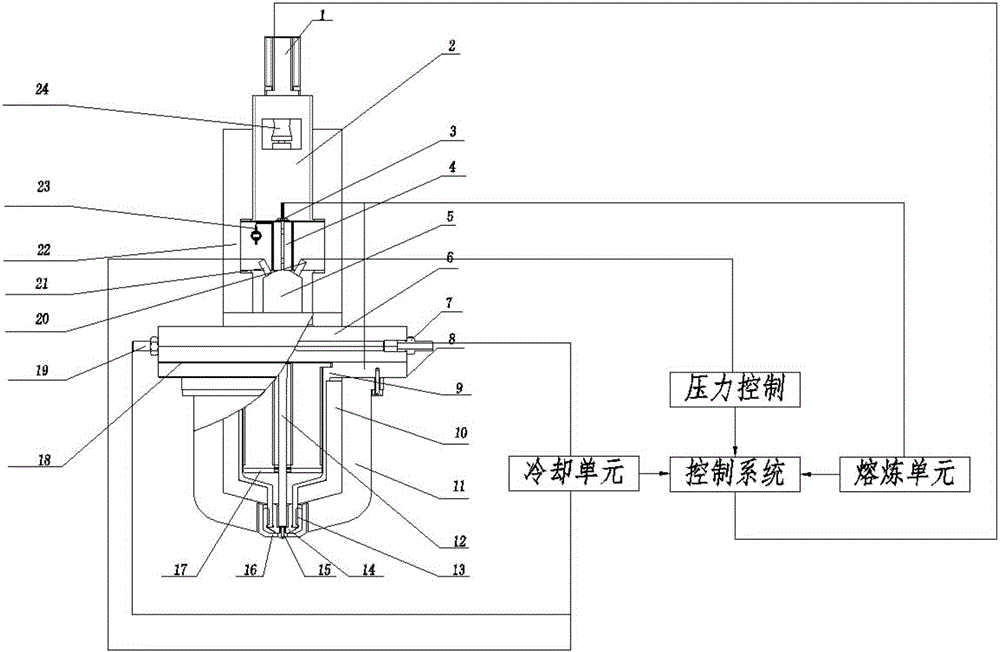

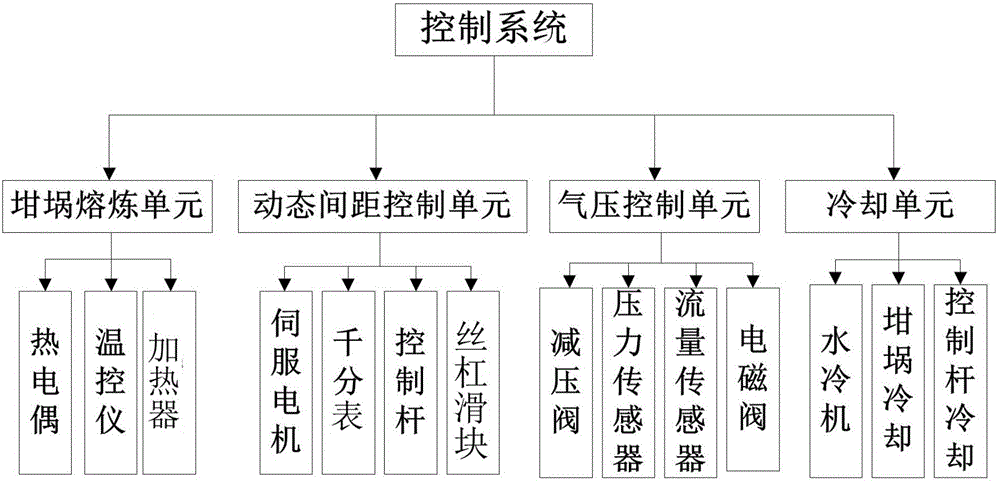

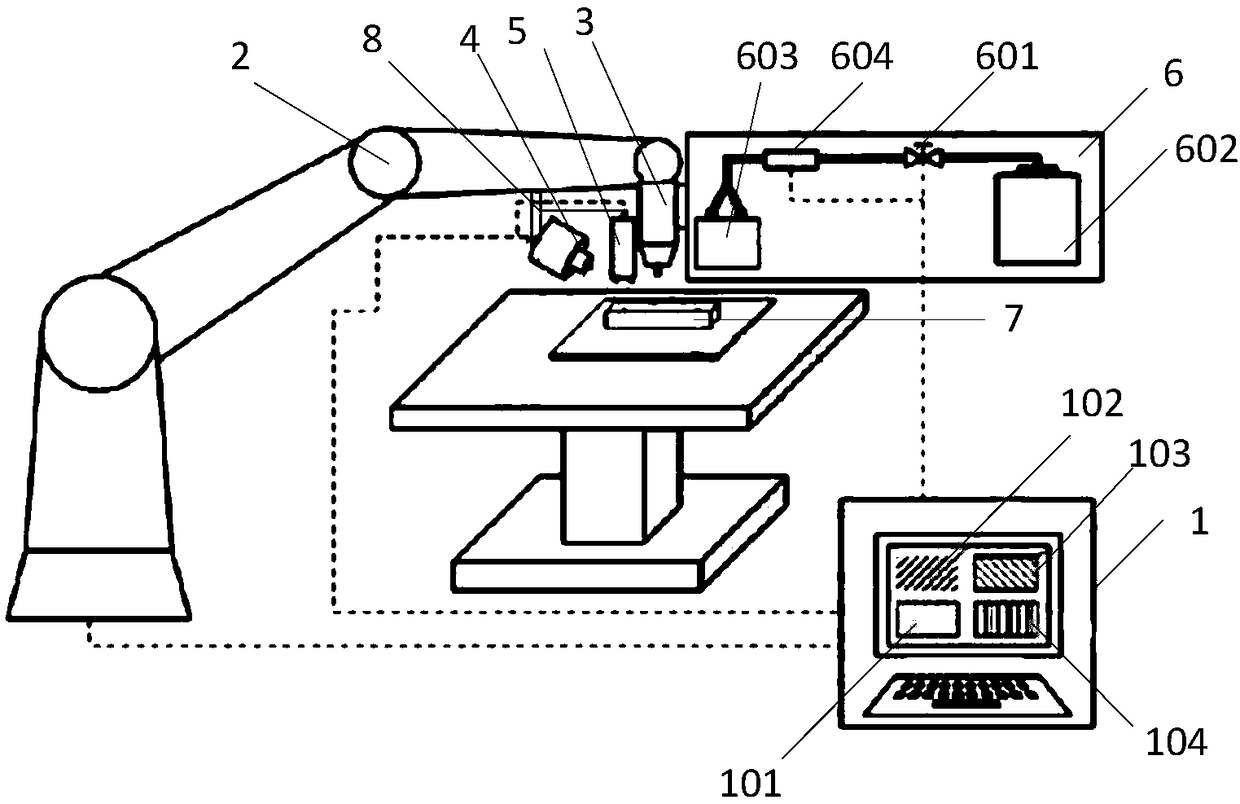

Melt flow control method and device for melt coating additive manufacturing

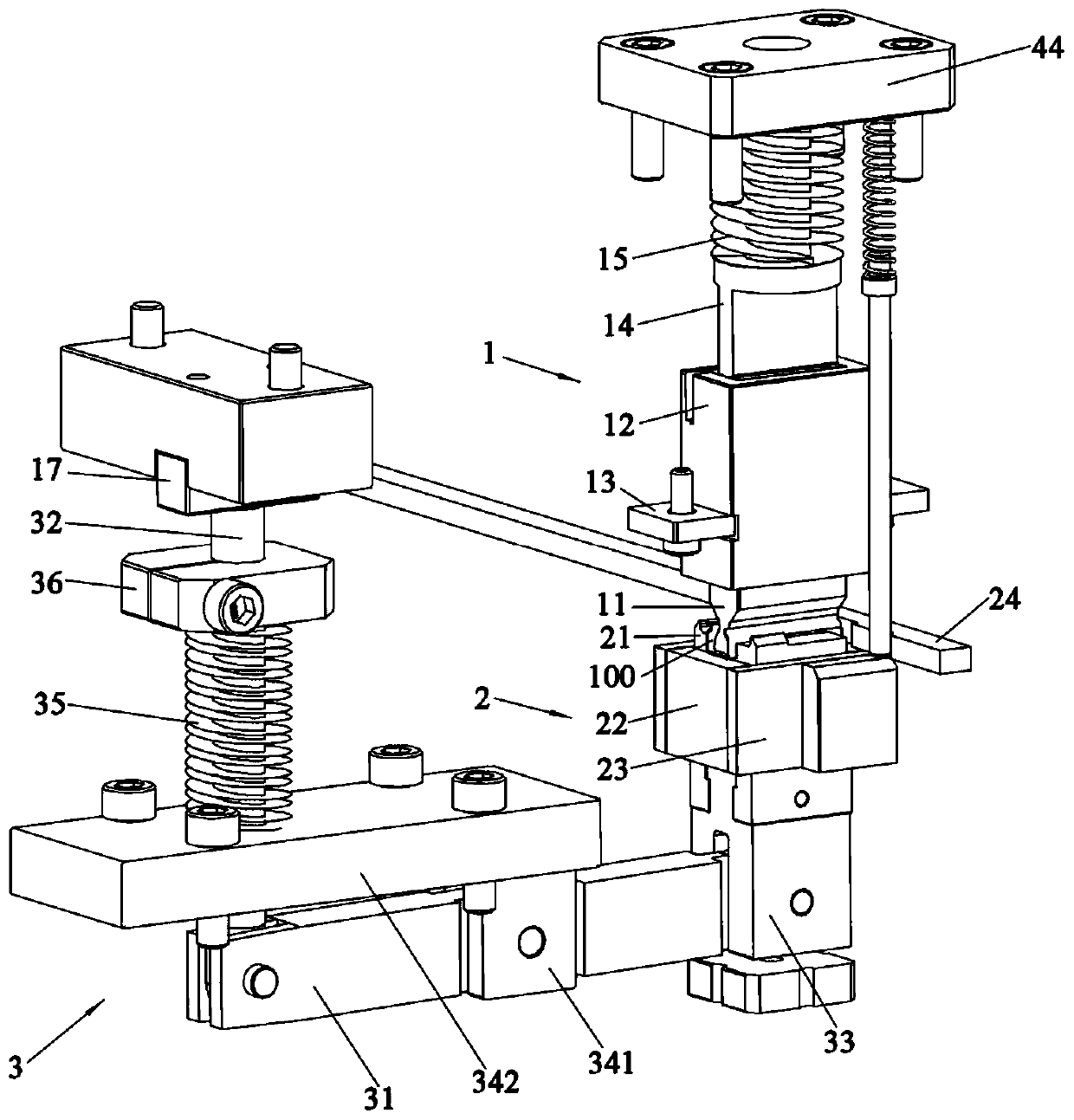

InactiveCN106001576AImplement flow controlManufacturing and Forming RealizationAdditive manufacturing apparatusControl systemMetallic materials

The invention discloses a melt flow control device for melt coating additive manufacturing. The melt flow control device comprises a crucible smelting unit, a dynamic gap control unit, a pneumatic control unit and a control system, wherein the dynamic gap control unit is connected with the crucible smelting unit through a control rod; the pneumatic control unit is hermitically connected with the crucible smelting unit through a pipeline; and the control system realizes data feedback and control for the crucible smelting unit, the dynamic gap control unit and the pneumatic control unit. The melt flow control device can control the magnitude of the flow in the whole melt coating forming process of a metal member, to fulfill the aim of additive manufacturing of an efficient, high-quality and low-cost metal material part.

Owner:XI AN JIAOTONG UNIV

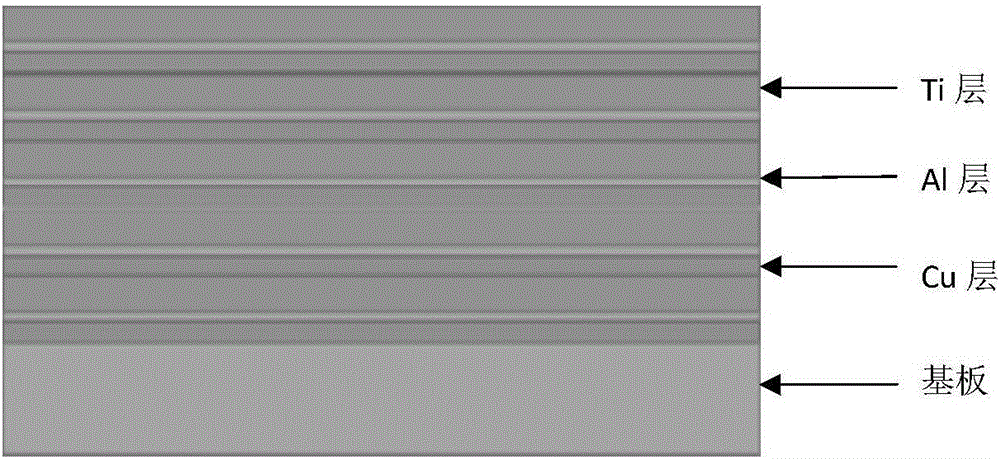

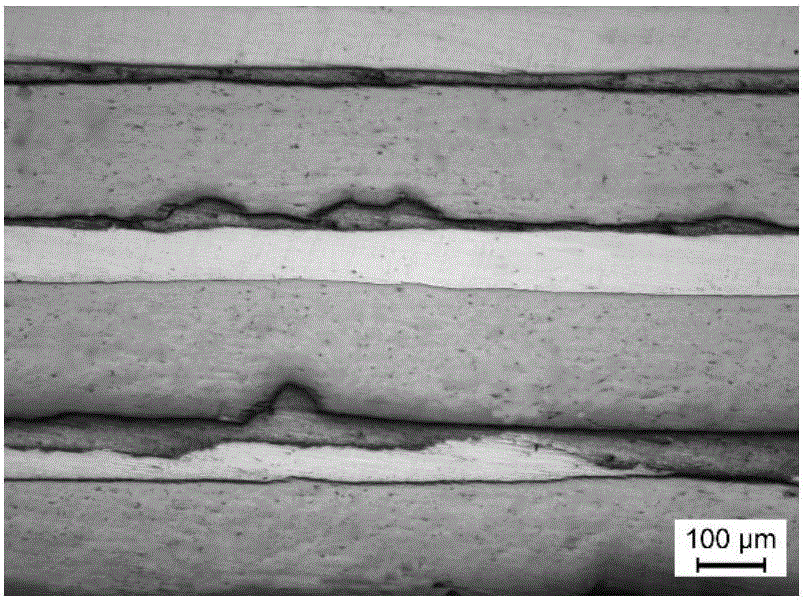

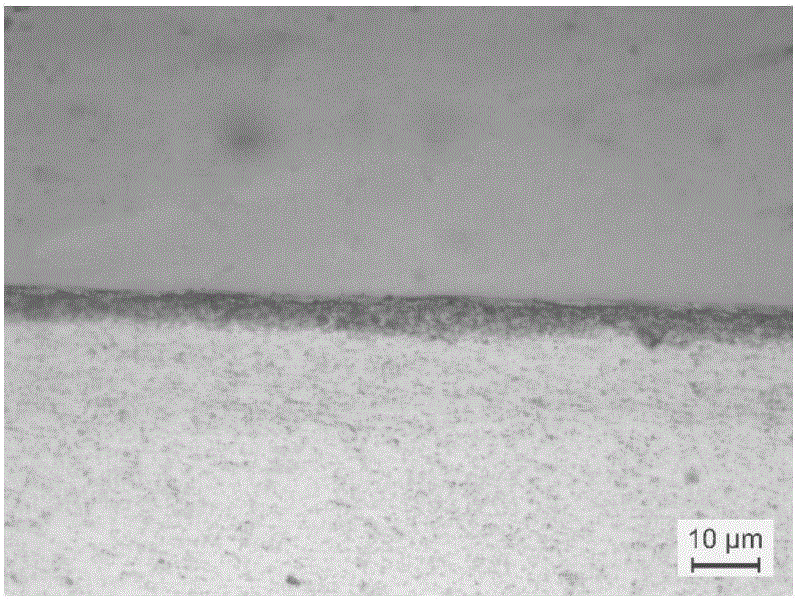

Rapid preparation method of titanium copper lamellar electrode composite material

ActiveCN106476395ALow costEasy to purchase materialsLamination ancillary operationsLaminationMetal foilCopper foil

The present invention provides a rapid preparation method of a titanium copper lamellar electrode composite material, which comprises the steps that: (1) copper foils, aluminum foils and titanium foils are superposed to form unit bodies, and one unit body is put on an ultrasonic quick-consolidating moulding work table; (2) an ultrasonic quick-consolidating moulding work table substrate is pre-heated to a temperature between 50 DEG C and 200 DEG C, and consolidating preparation is started and a metal foil material is formed; (3) the next unit body is put on the metal foil material, and the consolidating preparation is carried out by using the same parameters with the step (2) and the metal foil material is formed; and (4) the step (3) is repeated and after a predetermined thickness is reached, corner waste materials are milled and removed and the titanium copper lamellar electrode composite material is obtained. The titanium copper lamellar electrode composite material is prepared in the low temperature and is energy saving and environment-friendly. The cost of the raw materials is low. The titanium copper lamellar electrode composite material is prepared through solid-state physical metallurgical bonding. Diffusion layers are thin and by-products are few. The equipment cost is low because no vacuum devices or gas protection devices are used. The production period is short and the production efficiency is substantially improved. The precision and the yield are high.

Owner:HARBIN ENG UNIV

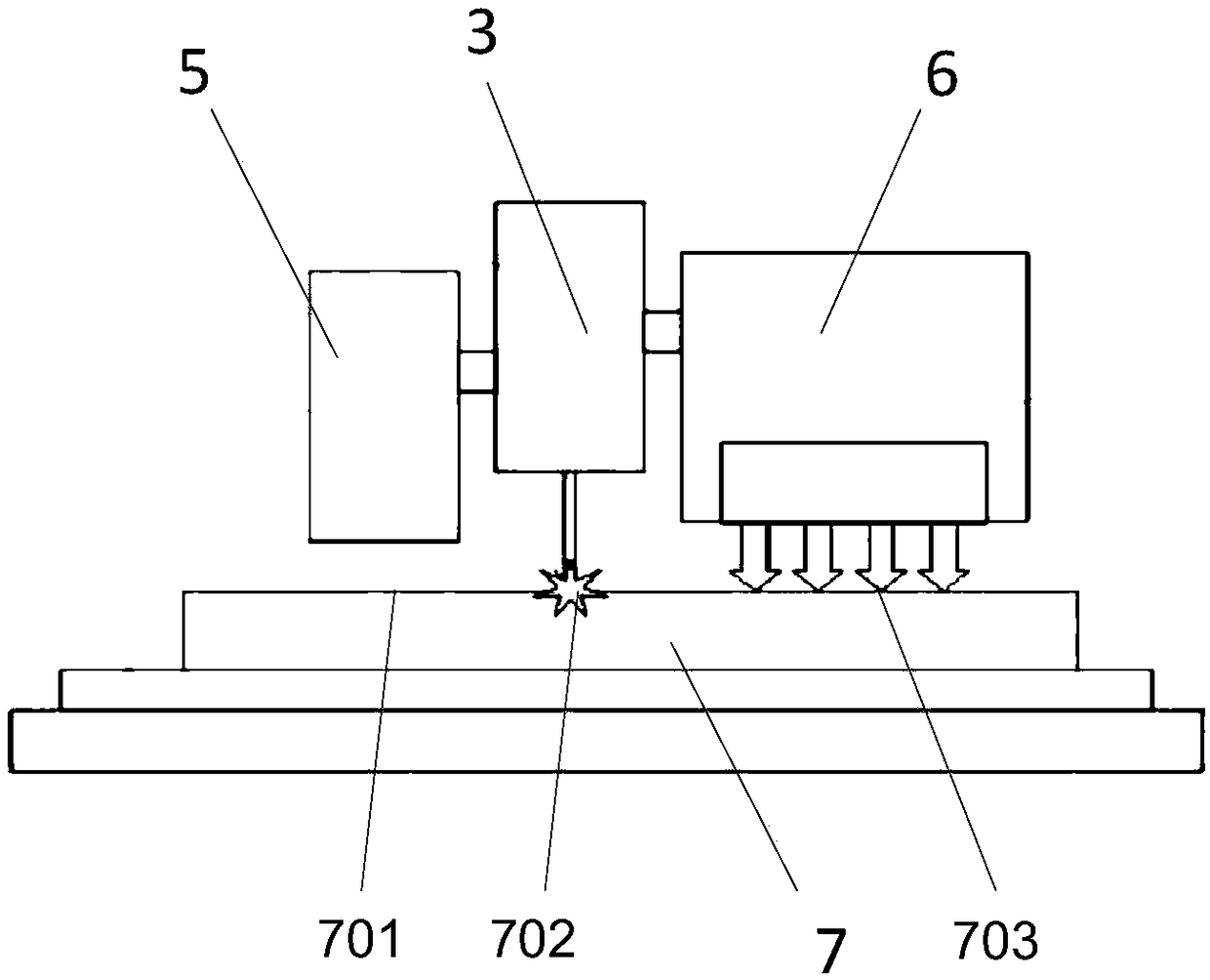

Temperature control device and method for additive manufacturing

PendingCN108907188AAccurate responsePrecise Response InflowAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankTemperature control

The invention discloses a temperature control device and method for additive manufacturing. According to the temperature control device, a front preheating part is arranged at the front end of a printing head, and a rear cooling part is arranged at the rear end of the printing head. Before a formed part enters a printing position, the difference between the surface temperature of the formed part and the temperature of a printing portion can be reduced, and the frequency of the phenomenon that due to the large temperature difference, the organizations of the formed part are not uniform can be reduced. Due to the fact that the rear cooling part is arranged behind the printing head, the formed part can be rapidly cooled by the cooling gas after printing is accomplished, the situation that dueto the fact that the temperature is too high, the formed part is oxidized by the surrounding air is avoided, and the surface quality of the formed part is improved. According to the temperature control system and method for additive manufacturing, on the basis of control over the temperature of a molten pool in the additive manufacturing deposition process and the cooling speed in the solidification process, the front preheating device and the rear cooling device are added, and therefore zone control of the temperature field of the formed part is achieved, the forming defect is avoided, the distribution of the temperature field in the additive manufacturing process is improved, and the internal property of the formed part can be improved.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

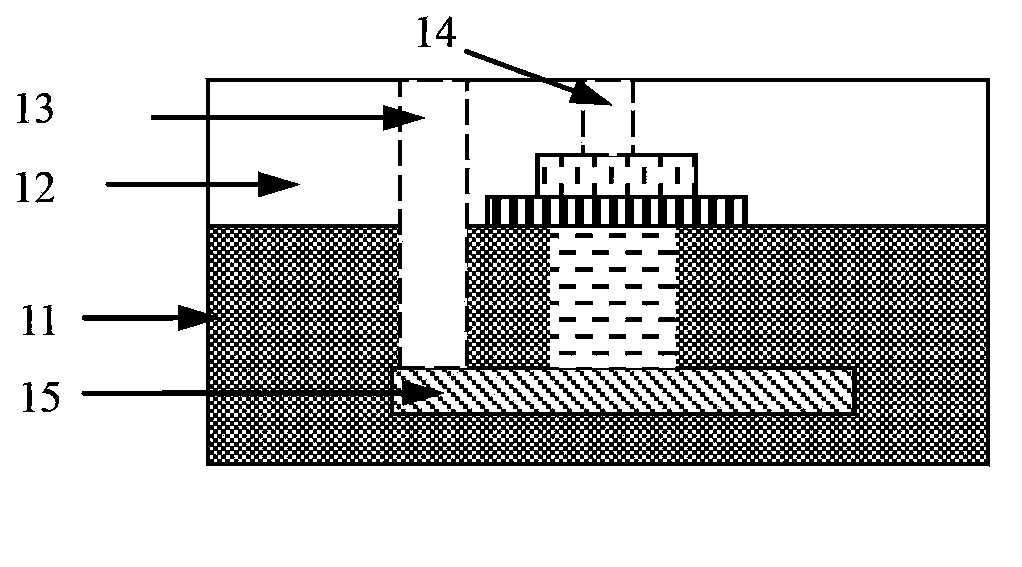

Deep trench filling method

ActiveCN103579073AImprove liquidityIncreasing the thicknessSemiconductor/solid-state device manufacturingRefluxEtching

The invention discloses a deep trench filling method which comprises the steps of forming a deep trench in a substrate, carrying out surface pretreatment on the surface of the substrate, heating the substrate, spouting pure water on the surface of the substrate to carry out pre-infiltration, forming a first photoresist layer on the surface of the substrate and carrying out heat reflux on the first photoresist layer. The process of photoresist heat reflux is added after the surface of the substrate is gelatinized and before the photoresist is softly baked. As the photoresist has much solvent during heat reflux, the photoresist has good liquidity. The photoresist is enabled to generate reflux through heating, thereby increasing the thickness of the photoresist in the top corner of the deep trench and strengthening the protection of the top corner of the trench. The deep trench can be protected in the process of etching trenches of different depths through two times of photo etching, defects can be prevented from being formed in the top of the deep trench, and the electric property of devices can be improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

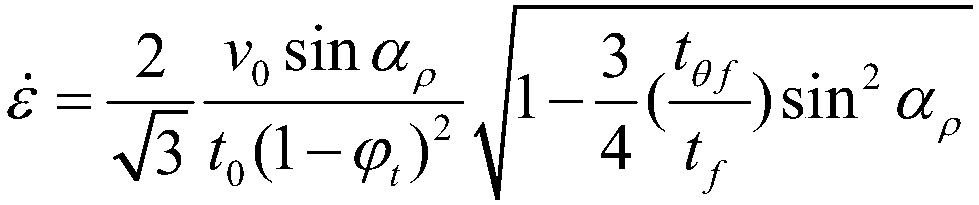

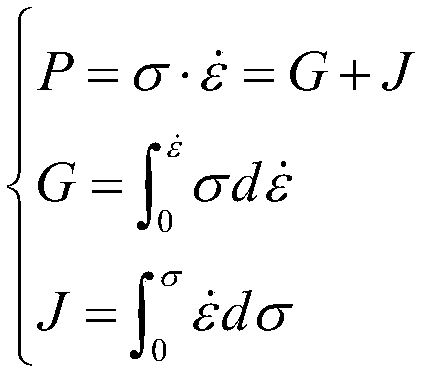

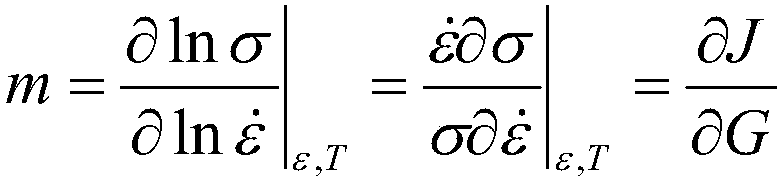

Hot working diagram-based cylindrical part hot power spinning precision/property integrated control method

InactiveCN107121992ARealize shape/performance integrated controlHigh dimensional accuracyShaping toolsAuxillary controllers with auxillary heating devicesThermoplasticMetallic materials

The present invention discloses a hot working diagram-based cylindrical part hot power spinning precision / property integrated control method. In the thermoplastic forming process of difficult-to-deform metal, a metal material high-temperature mechanical property test is performed in the temperature range and strain rate range of dynamic recrystallization; on the basis of power dissipation and rheological instability judgment criteria in the thermoplastic forming process, power dissipation diagrams and rheological instability diagrams under different strains are constructed according to a rheological stress and strain relation obtained in the high-temperature mechanical property test; the power dissipation diagrams and rheological instability diagrams are combined, a material hot working diagram is obtained; forming conditions under a potential dangerous forming condition which satisfies the rheological instability judgment criteria and a safe forming condition are obtained through analysis according to the distribution of power dissipation factors eta and the rheological instability judgment criteria, wherein the forming conditions have large power dissipation factors eta and can benefit thermoplastic forming; and cylindrical part hot power spinning forming is performed according to a material obtained according to the hot working diagram and temperature and a strain rate which benefit thermoplastic forming.

Owner:SOUTH CHINA UNIV OF TECH

Application of chlorinated polyvinyl chloride to water treatment of hollow fiber membrane and preparation method of hollow fiber membrane

ActiveCN104147944AAvoid decompositionGood chemical resistanceSemi-permeable membranesFiberProcedure Agents

The invention discloses an application of chlorinated polyvinyl chloride to water treatment of a hollow fiber membrane and a preparation method of the hollow fiber membrane and provides a hollow fiber membrane which takes chlorinated polyvinyl chloride as a main material. The hollow fiber membrane comprises the following active ingredients in percentage by mass: 15-35% of CPVC (Chlorinated Polyvinyl Chloride), 40-60% of a solvent, 5-15% of a pore-foaming agent and 4-15% of processing aid. The preparation method of the hollow fiber membrane comprises the following steps: uniformly mixing CPVC, the pore-forming agent and the processing aid and adding into a reaction kettle which is filled with the solvent, heating to 50-90 DEG C, and uniformly dissolving by stirring to prepare a polymer homogeneous solution; and standing and defoaming, then pumping vacuum and detecting the defoaming effect, and spinning and forming after defoaming is ended. The prepared hollow fiber membrane is good in chemical resistance, relatively applicable to the filtration industry of tap water with hypochlorous acid and capable of facilitating chemical washing of membrane filaments in the sewage industry with serious pollution and prolonging the service lives of the membrane filaments; and moreover, the production cost of the hollow fiber membrane can be greatly reduced, so that the wide popularization of the environmental protection water treatment process can be facilitated.

Owner:康泽源(天津)科技发展有限公司

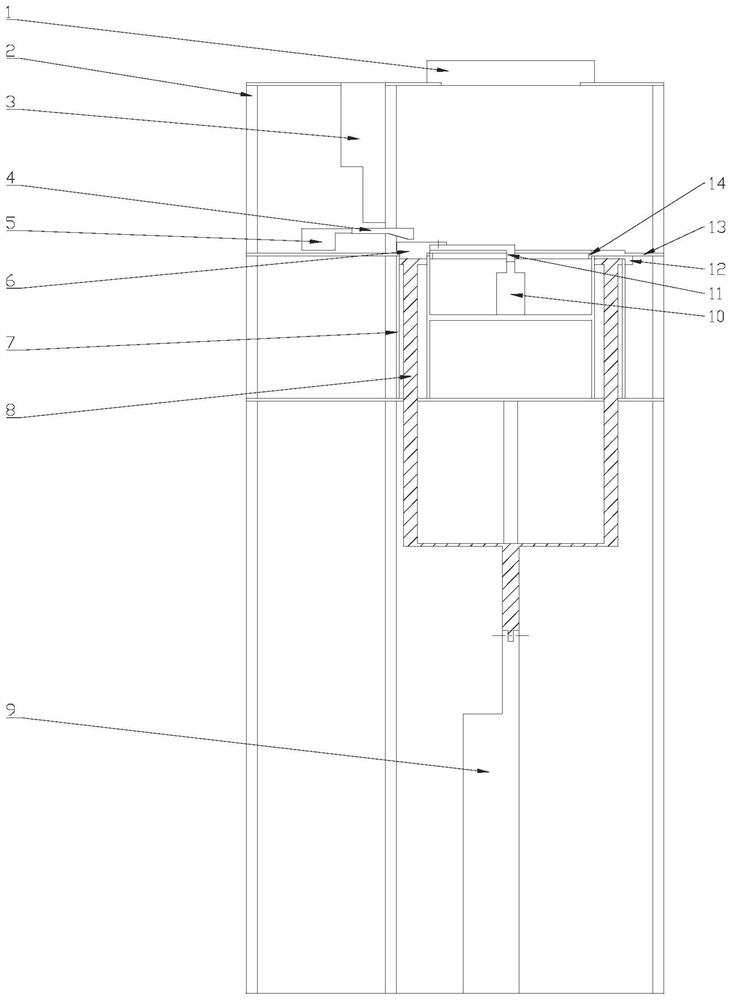

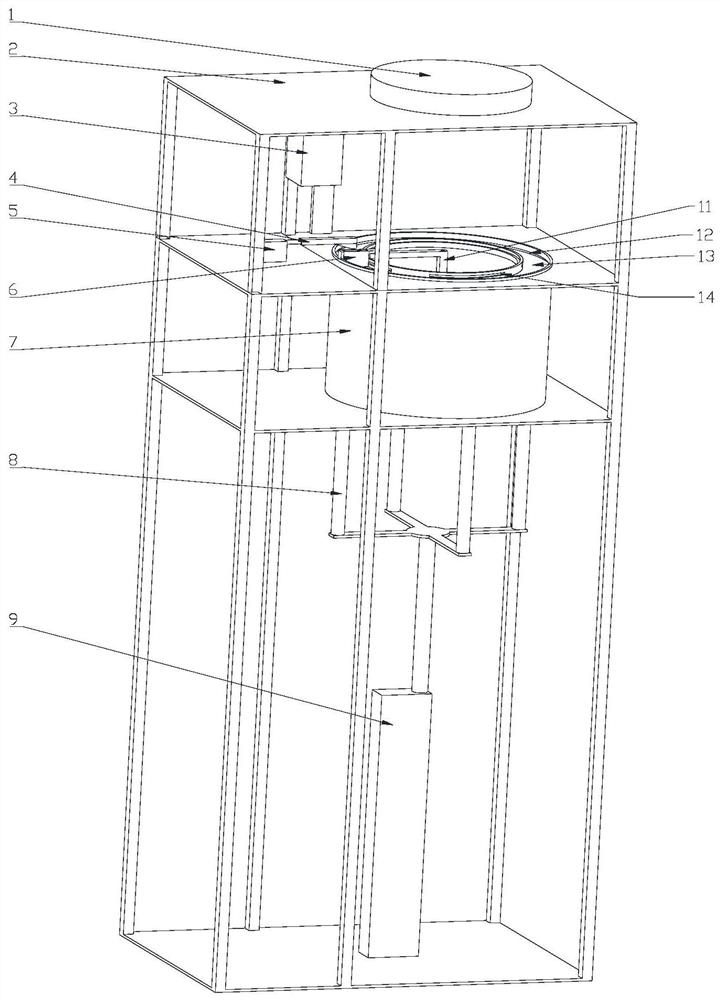

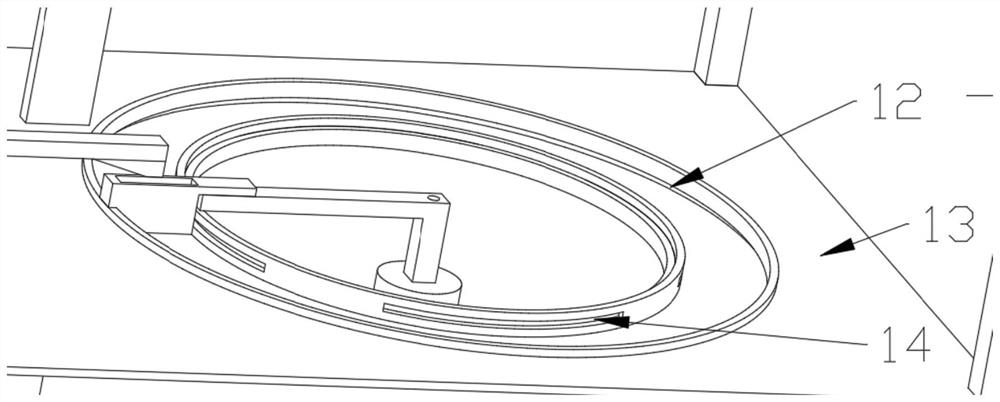

Annular powder-spreading selective laser melting forming device

InactiveCN112108648AReduce dosageReduce pollutionAdditive manufacturing apparatusSelective laser meltingForming face

The invention discloses an annular powder-spreading selective laser melting forming device. An annular structure that an annular forming bin is formed by the inner wall and the outer wall is adopted,an annular piston is arranged in an annular forming bin of an annular forming cylinder; the annular piston is connected to a piston rod of a piston electric cylinder which is fixed to the lower end ofthe annular forming cylinder; and the annular forming cylinder is provided with a powder feeder and a scraper which can annularly slide in the annular forming bin. The scraper is driven by a scraperdriving device to achieve powder spreading and forming in the annular forming bin; when the annular forming cylinder structure is matched with a powder-spreading structure, powder is simply spread inan annular printing face without powder spreading in the central area of the forming face; the powder consumption is greatly reduced; and powder pollution is reduced. In the annular powder spreading process, an optical circuit system can scan the area in which the powder has been spread; printing is conducted while powder spreading; the inefficient movement that a layer of powder is spread beforeprinting in a traditional powder spreading way is avoided; and the printing efficiency is greatly improved.

Owner:XI AN JIAOTONG UNIV

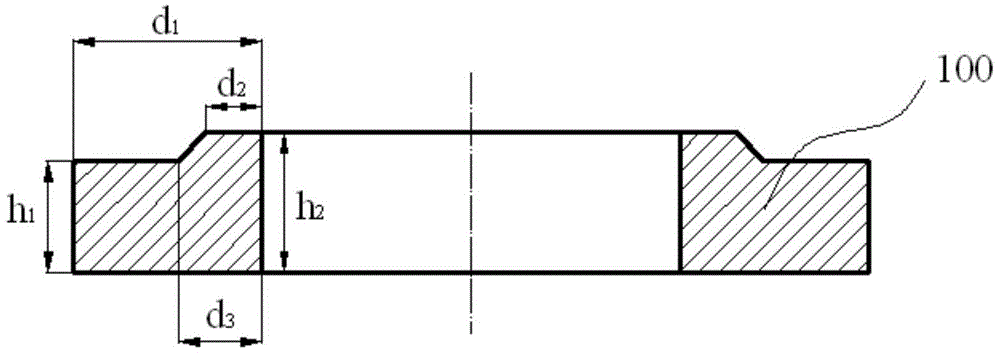

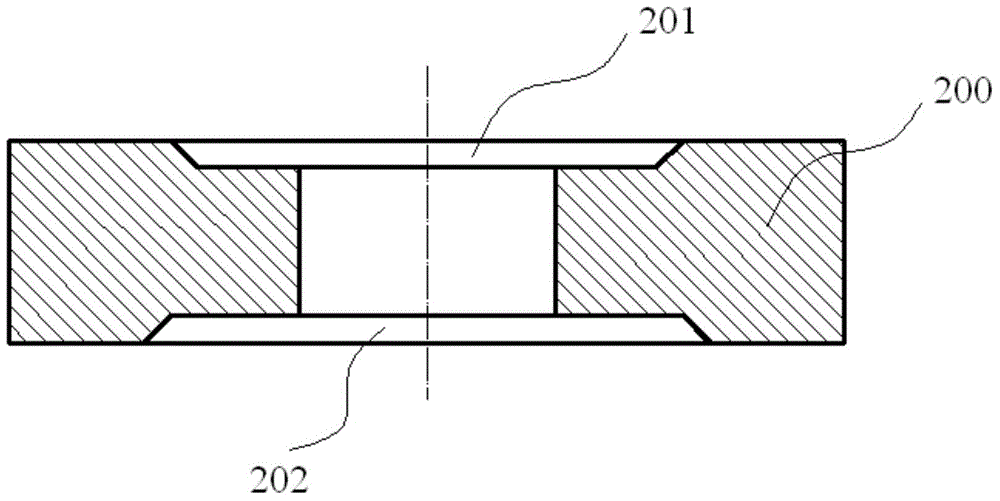

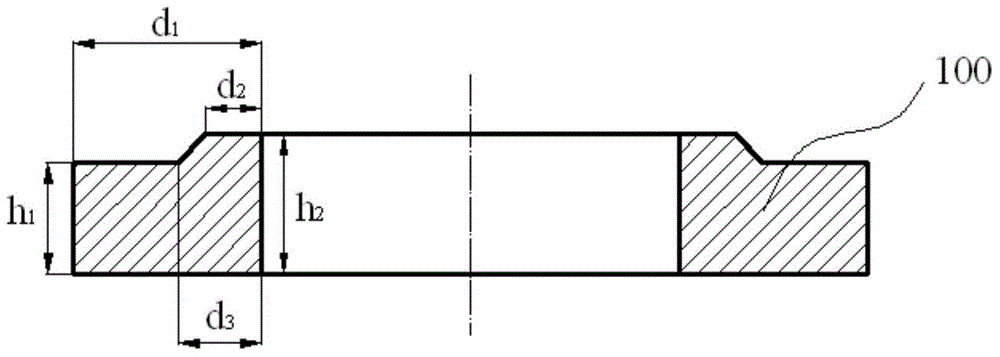

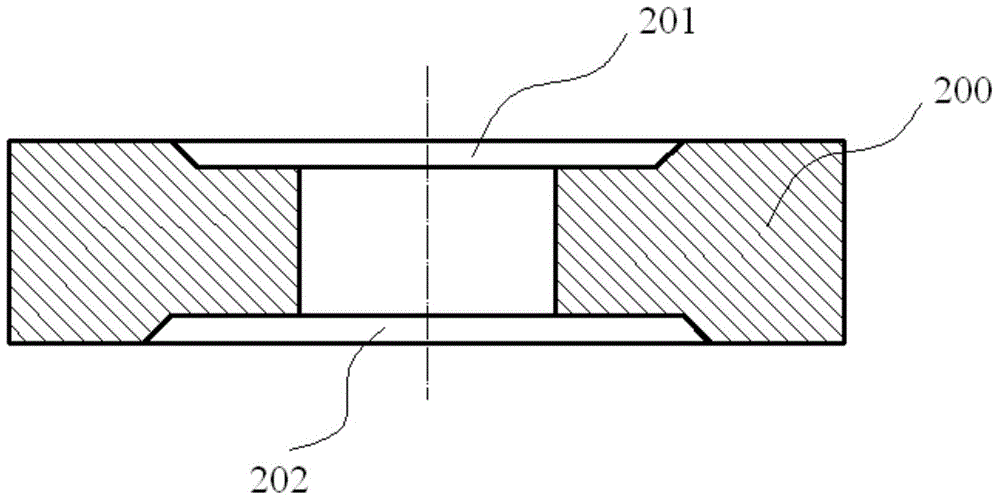

Roll forming method for cobalt-based superalloy thick-wall ring forgings

InactiveCN104550584AIncrease inner diameterIncrease the outer diameterMetal rollingThick wallRoll forming

The invention discloses a roll forming method for cobalt-based superalloy thick-wall ring forgings. The roll forming method comprises the following steps: designing an intermediate billet into specially-shaped ring billets each of which is provided with a lug boss close to the inner wall; calculating the size of each specially-shaped billet according to an isovolumetric principle; designing a special die according to the shape and size of each specially-shaped ring billet; heating a cobalt-based superalloy rod to a deformation temperature, carrying out upsetting, punching and pre-rolling, and then manufacturing the cobalt-based superalloy rod into specially-shaped ring billets under the action of the special dies; heating the specially-shaped ring billets to the deformation temperature again, and rolling the specially-shaped ring billets into the thick-wall ring forgings by matching with appropriate rolling parameters. According to the method disclosed by the invention, the defects of grooves, folding and the like occurring in the thick-wall ring forging rolling process can be effectively overcome, and the rolling quality of the thick-wall ring forgings can be improved. The roll forming method can be used for roll forming of the thick-wall ring forgings.

Owner:GUIZHOU ANDA AVIATION FORGING

Bending pressing convex die

PendingCN110090894AReduce development costsSimplify the process stepsShaping toolsMechanical engineering

The invention relates to the technical field of dies, and discloses a bending pressing convex die. The bending pressing convex die comprises an upper die assembly, a lower die assembly and a lever assembly, the upper die assembly comprises a bending convex die, and a pressing convex groove is formed in the bending convex die; the lower die assembly comprises two first die cores and a second die core, the two first die cores are symmetrically arranged on the two sides of the second die core respectively, the first die cores and the second die core can be spliced to form the bending convex die,and a pressing convex protrusion matched with the pressing convex groove is arranged on the second die core; and the lever assembly comprises a lever, one end of the lever is capable of being connected with the upper die assembly, and the other end of the lever is connected with the two first die cores. According to the bending pressing convex die, on the one hand, the bending and pressing convexprocedures can be completed by using one set of dies and one-time molding process, the procedure step is simplified, and the cost is reduced; and on the other hand, the two first die cores are drivento move upwards simultaneously through the lever assembly, and a metal plate can be bent simultaneously from the two sides, so that the deformation of the metal plate is more uniform.

Owner:昆山市兴凯胜智能科技有限公司

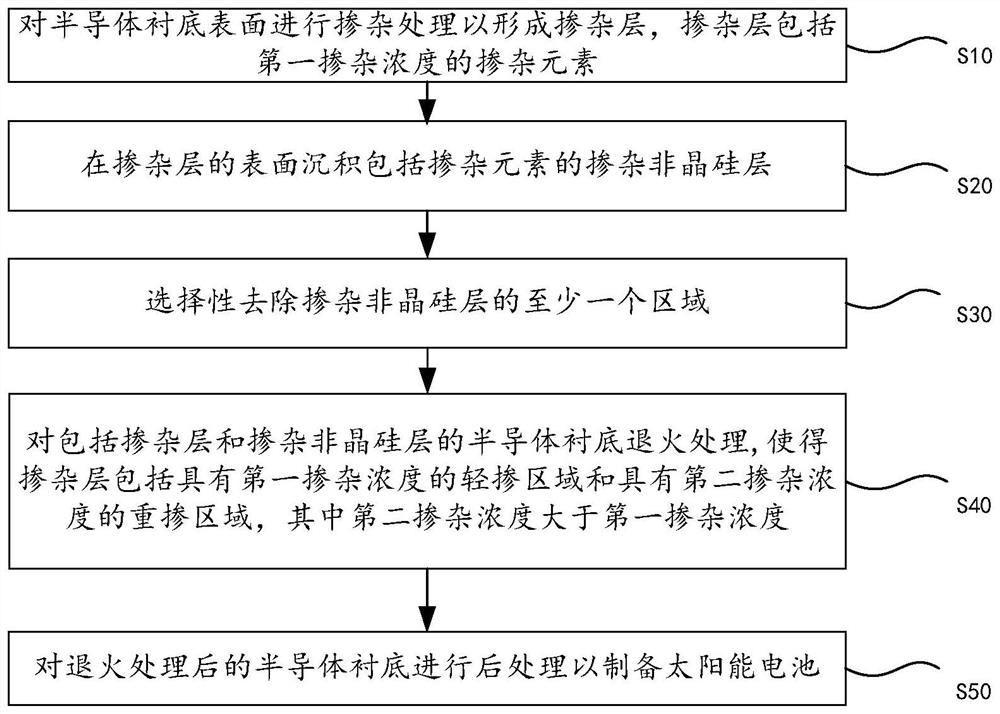

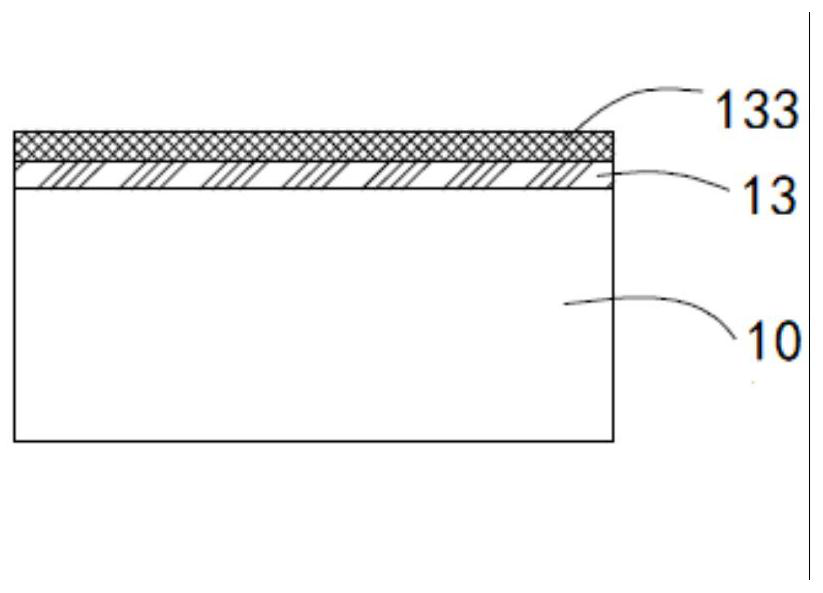

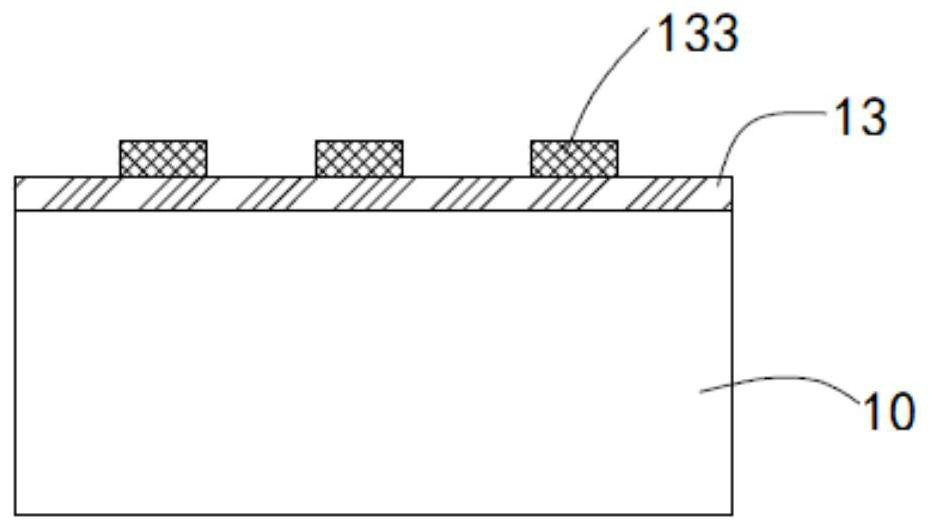

Solar cell and preparation method thereof

PendingCN111952417ATo achieve local heavy dopingLower crystallization temperatureFinal product manufacturePhotovoltaic energy generationPhysical chemistryAmorphous silicon

The invention relates to the photovoltaic field, and provides a solar cell and a preparation method therefor, and the method comprises the following steps: carrying out the doping processing of the surface of a semiconductor substrate, so as to form a doping layer which comprises a doping element with a first doping concentration; depositing a doped amorphous silicon layer comprising doped elements on the surface of the doped layer; selectively removing at least one region of the doped amorphous silicon layer; annealing the semiconductor substrate including the doped layer and the doped amorphous silicon layer so that the doped layer includes a lightly doped region having a first doping concentration and a heavily doped region having a second doping concentration, wherein the second dopingconcentration is greater than the first doping concentration; and performing post-processing on the annealed semiconductor substrate to prepare the solar cell. According to the solar cell and the preparation method thereof, the preparation process of the solar cell is simplified, and the cell conversion efficiency is improved.

Owner:JINKO GREEN ENERGY SHANGHAI MANAGEMENT CO LTD +1

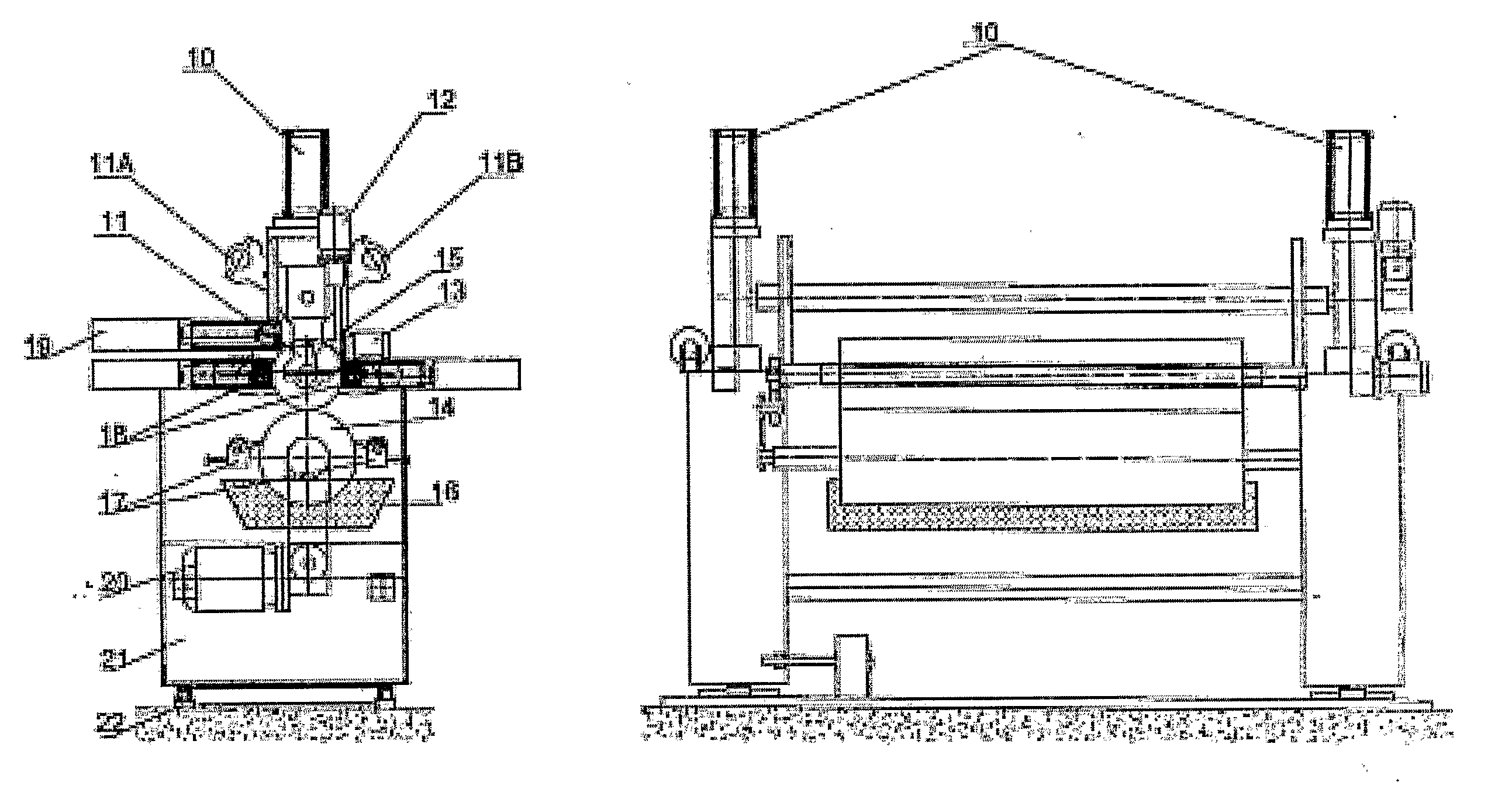

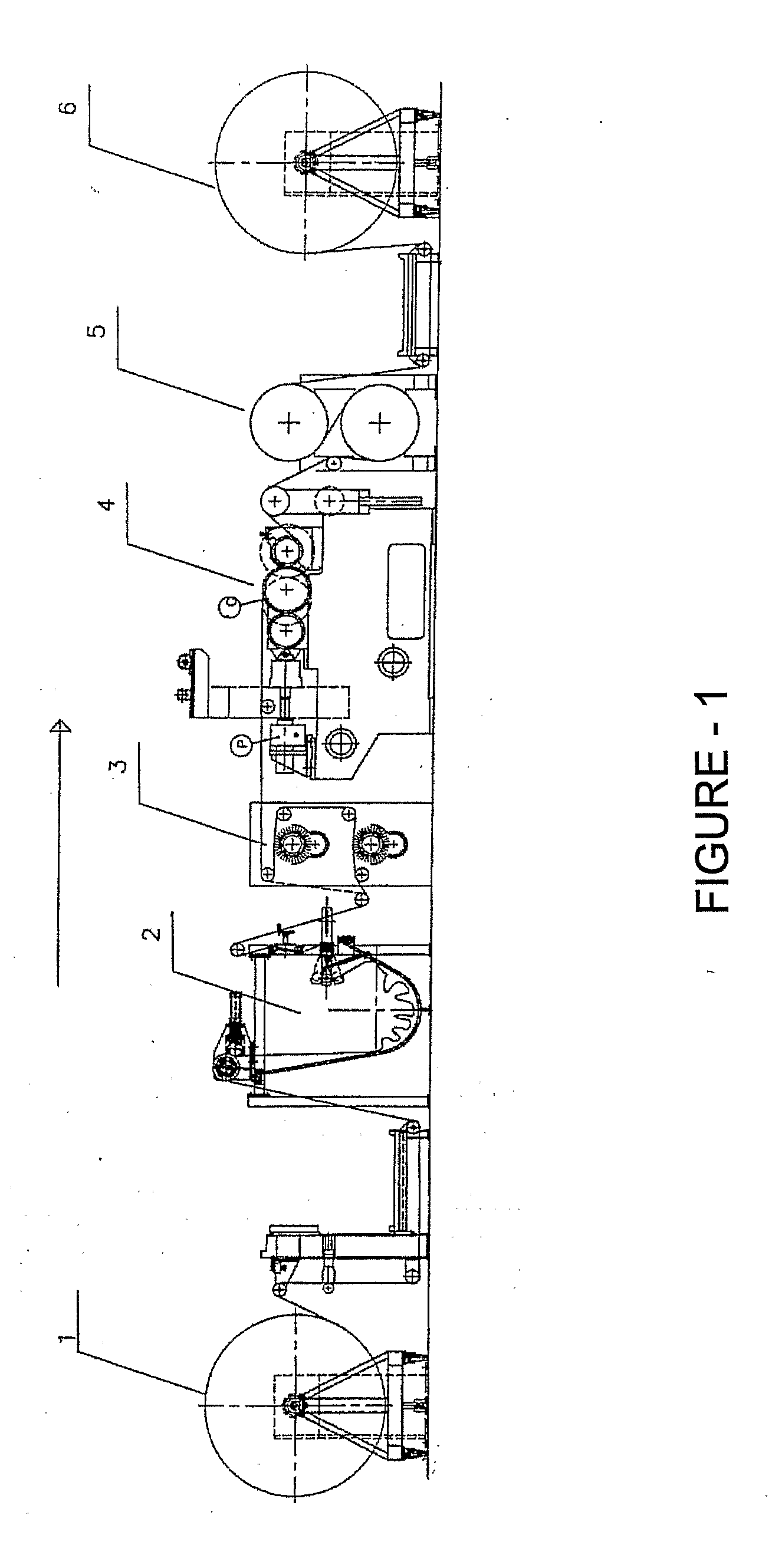

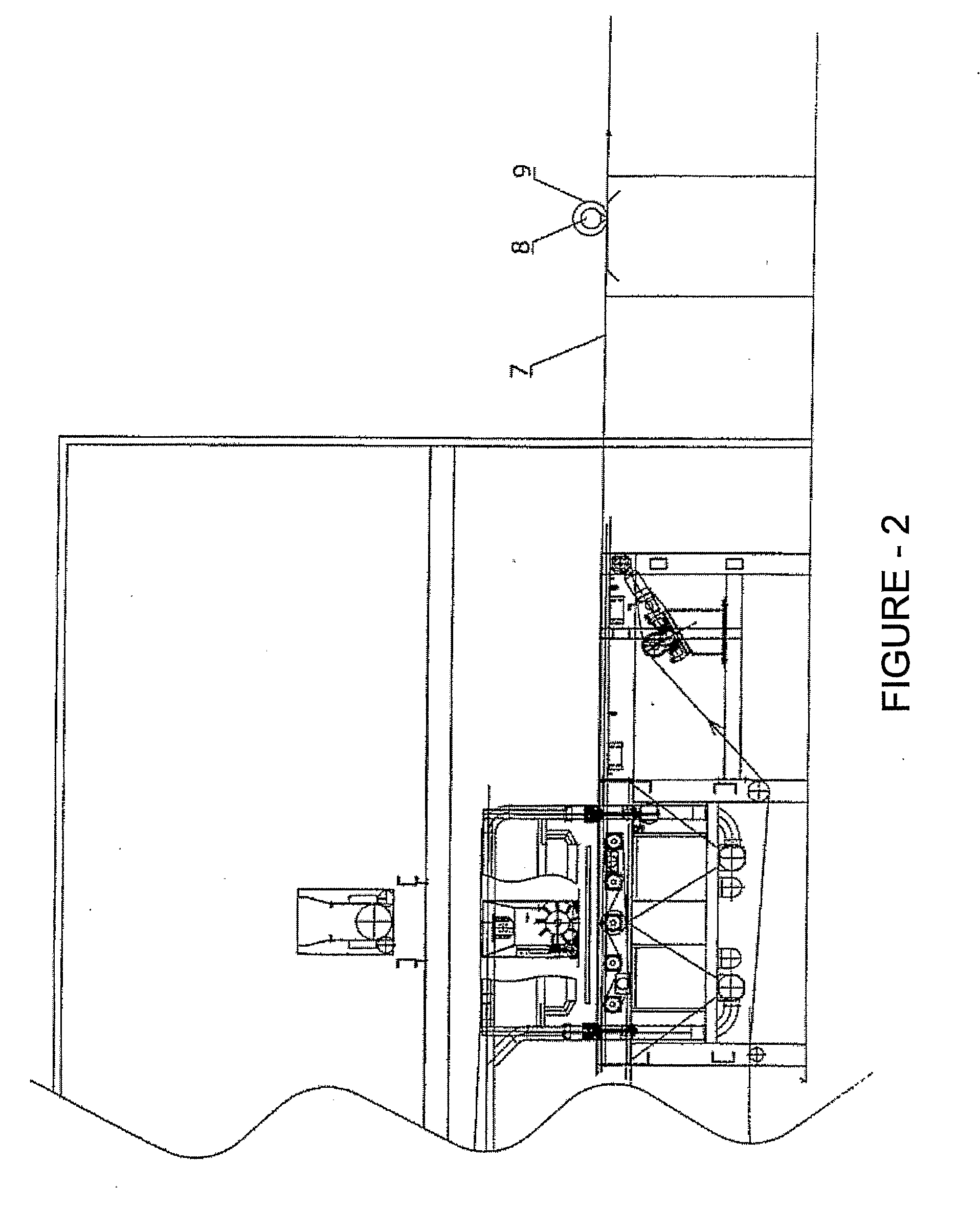

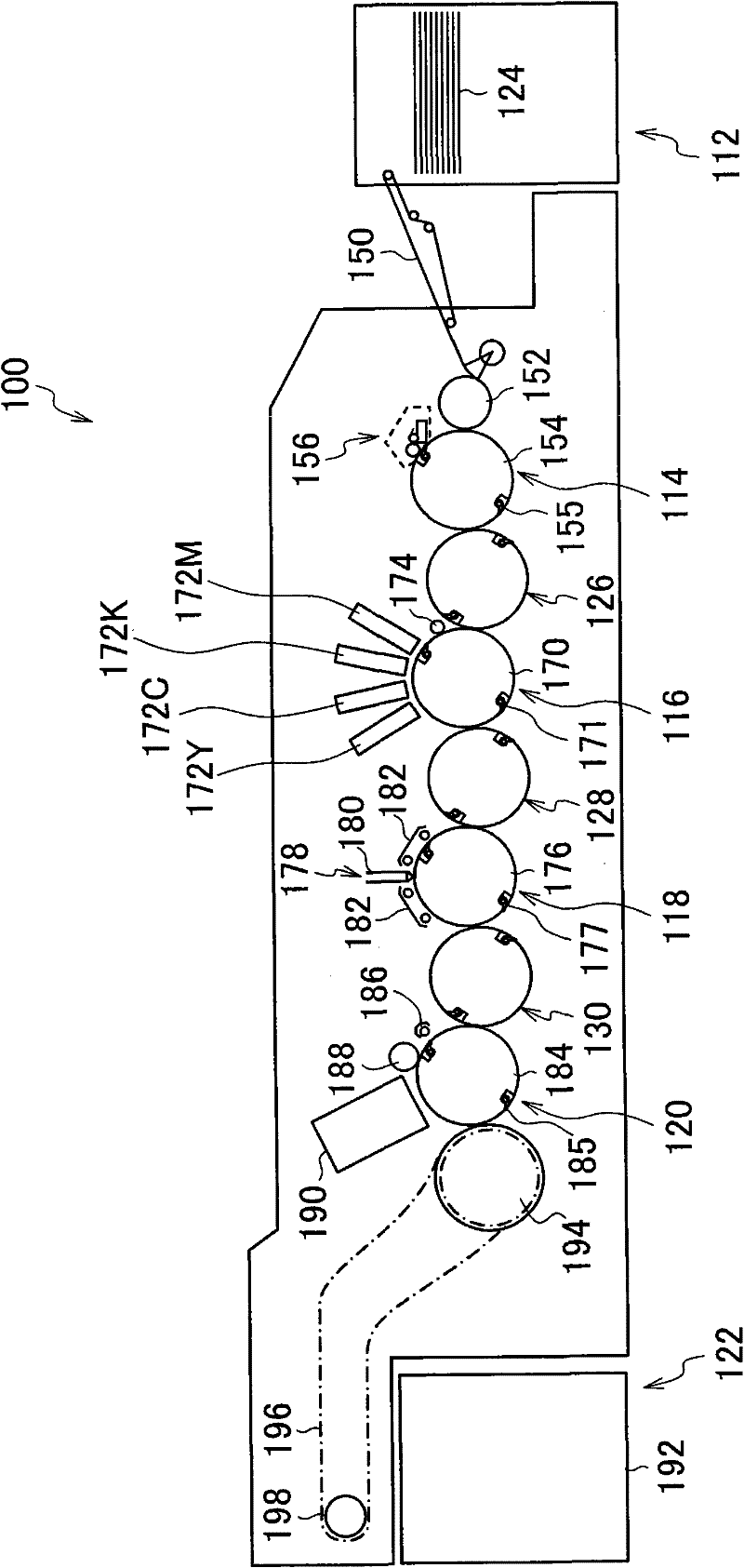

Embossing machine transferring pattern on wet flocked fabric

InactiveUS20100192338A1Avoid forming defectsPattern makingNon-woven fabricsProduction lineAcid corrosion

Present invention relates to a machine which directly transfers pattern on wet, colour or natural-colour flocked fabric base before drying fabric flocked in colour or natural-colour flocked fabric production line, which is used in various sectors, and a process involving the said machine. The invention is characterized with followings as main components: acid-corrosion, patterned cylinder (15) which directly transfers pattern on fabric, an unpatterned cylinder (14), which turns on within water, a system (13) which adjust distance between cylinders, scrapping blade (17), vacuum brushes (18), high-pressure blowing apparatus and air system (19), a sensor system (23) which monitors edge of fabric, a system and motor (20) which moves body of machine to left or right side.

Owner:FLOKSER TEKSTIL SANAYI & TICARET ANONIM SIRKETI

Roll forming method for stainless steel thick-wall ring forged piece

InactiveCN104607578AIncrease inner diameterIncrease the outer diameterMetal rollingRoll formingThick wall

The invention discloses a roll forming method for a stainless steel thick-wall ring forged piece. The roll forming method comprises the steps that a middle blank is firstly designed into a special-shaped ring blank with a boss nearby the inner wall; all dimensions of the special-shaped ring blank are calculated based on the equivolumetric principle; a dedicated mold is designed according to the shape and dimensions of the special-shaped ring blank; after a stainless steel rod is heated to deformation temperature, upsetting, punching and pre-rolling are carried out, the special-shaped ring blank is manufactured under the action of the dedicated mold; the special-shaped ring blank is reheated to the deformation temperature, and is rolled into the thick-wall ring forged piece in cooperation with proper rolling parameters. According to the method, the defects of grooves, folding and the like occurring in the rolling process of the thick-wall ring forged piece can be effectively overcome, and the rolling quality of the thick-wall ring forged piece can be improved. The method is used for roll forming of the thick-wall ring forged piece.

Owner:GUIZHOU ANDA AVIATION FORGING

Double-curved-surface skin opening frame forming method

ActiveCN112588956AAvoid forming defectsReduce correctionShaping toolsMetal-working feeding devicesGlass fiberAviation

The invention relates to a double-curved-surface sawtooth skin opening frame forming method, and belongs to the technical field of aeronautical manufacturing metal plate forming. The double-curved-surface skin opening frame forming method comprises the following steps that (1) the two ends of the long edge of a skin plate are put in a jaw of drawing forming equipment, and the skin plate is kept tangent to a forming mold; (2) a hydraulic actuator cylinder of the jaw drives the jaw to move, the skin plate is in contact with a hollow area and a molded surface of the surface of the forming mold and is drawn to generate an opening frame R angle, and a semi-finished product of a to-be-formed part is obtained; (3) a square hole is formed in the drawn semi-finished product of the part to be formedon the forming mold, and meanwhile, edge bending operation is carried out on the square hole by an edge bending hole cover plate; and (4) the outer surface of the semi-finished product of the part tobe formed is covered with a glass fiber reinforced plastic scribing template for scribing, excess materials are removed along a line, and correcting is carried out on the trimmed semi-finished product on a mold until a product is completely formed. The double-curved-surface sawtooth skin opening frame forming method has the following advantages that 1, the forming defect of a typical fuselage hyperboloid skin opening frame structural part can be overcome; and 2, the production efficiency is obviously improved.

Owner:JIANGXI HONGDU AVIATION IND GRP

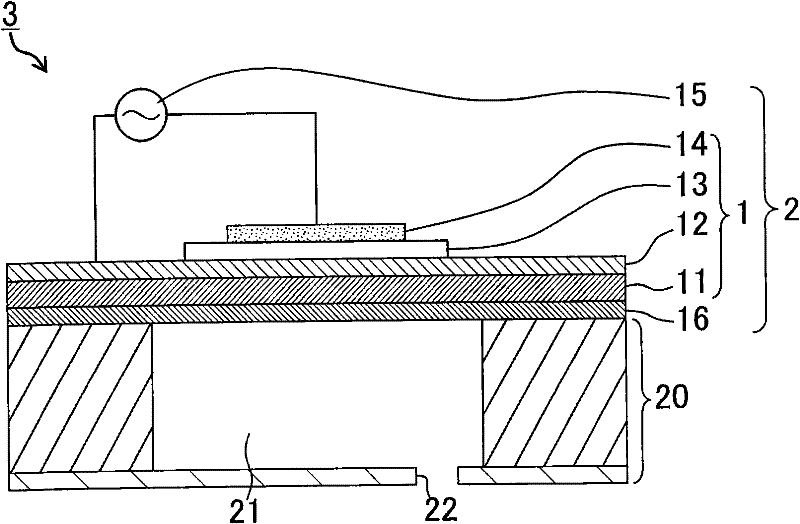

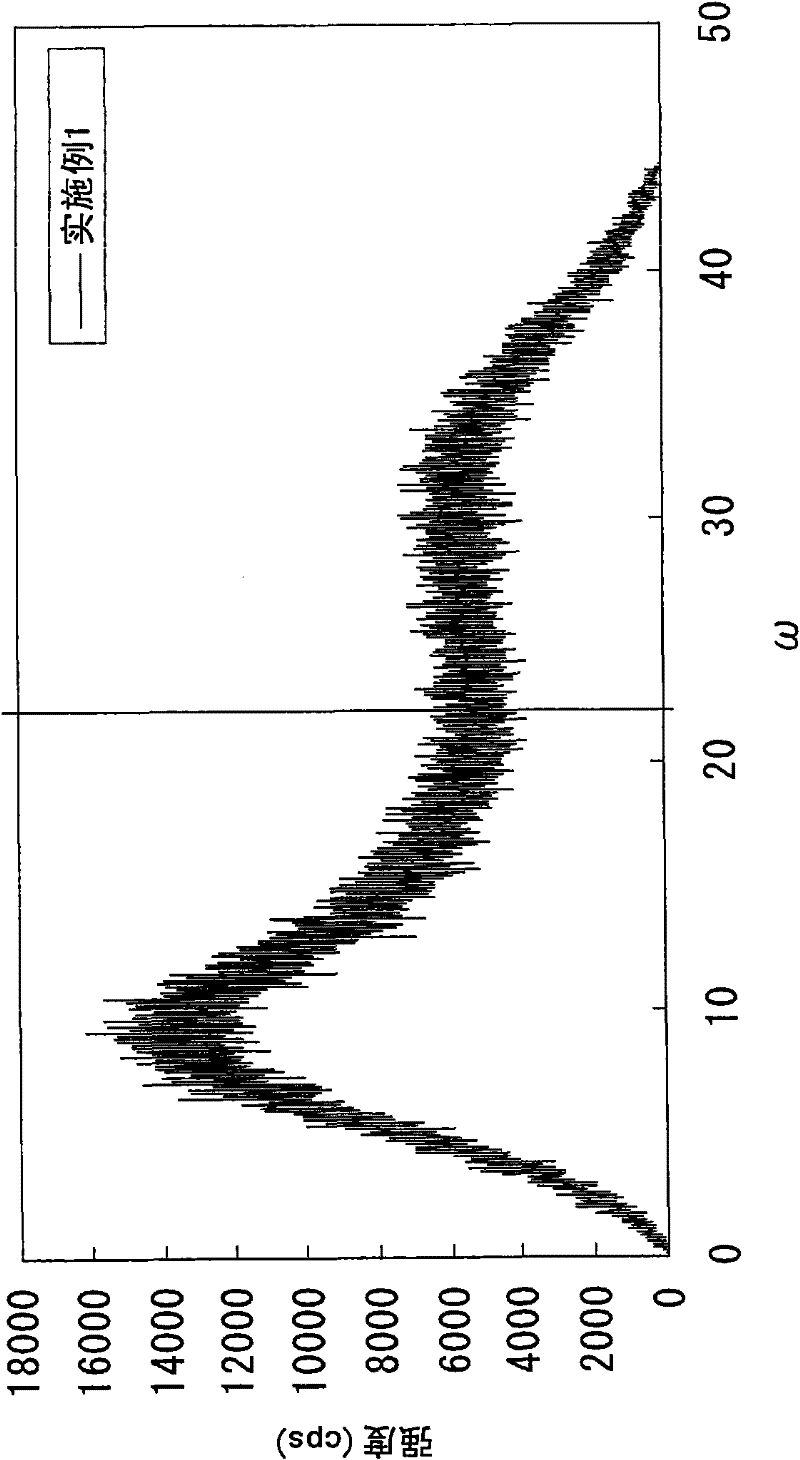

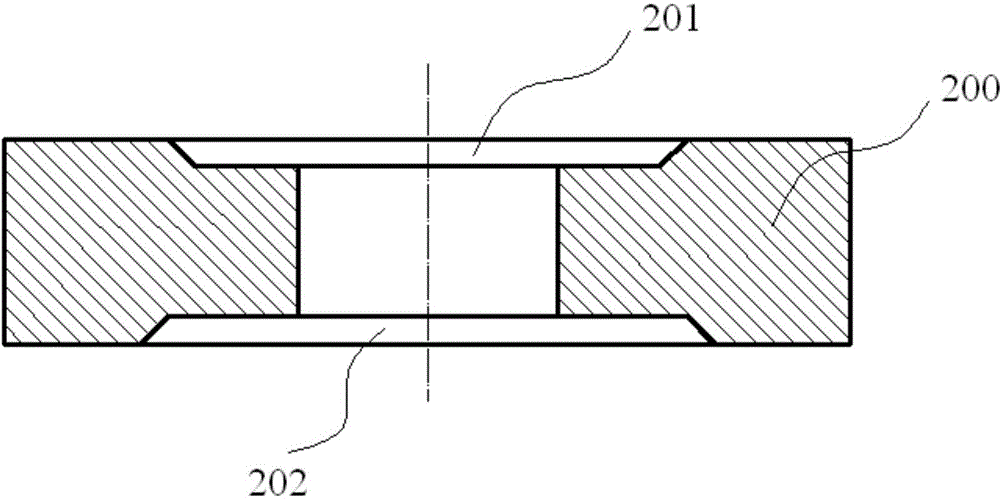

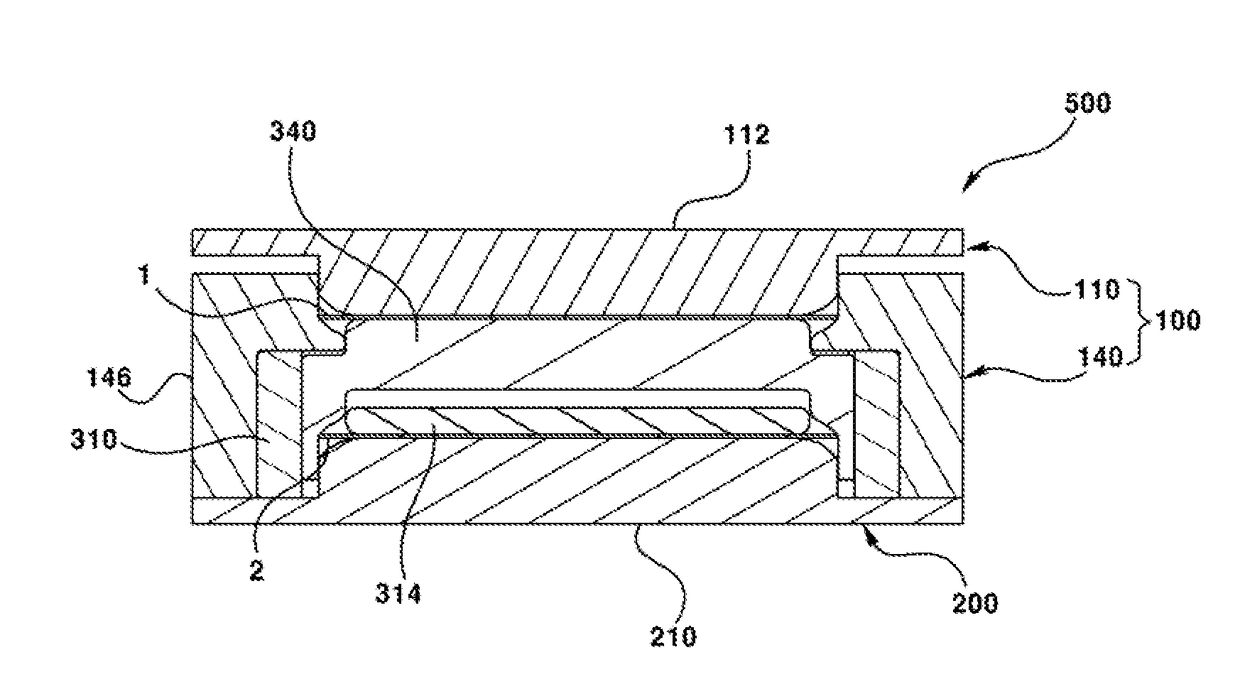

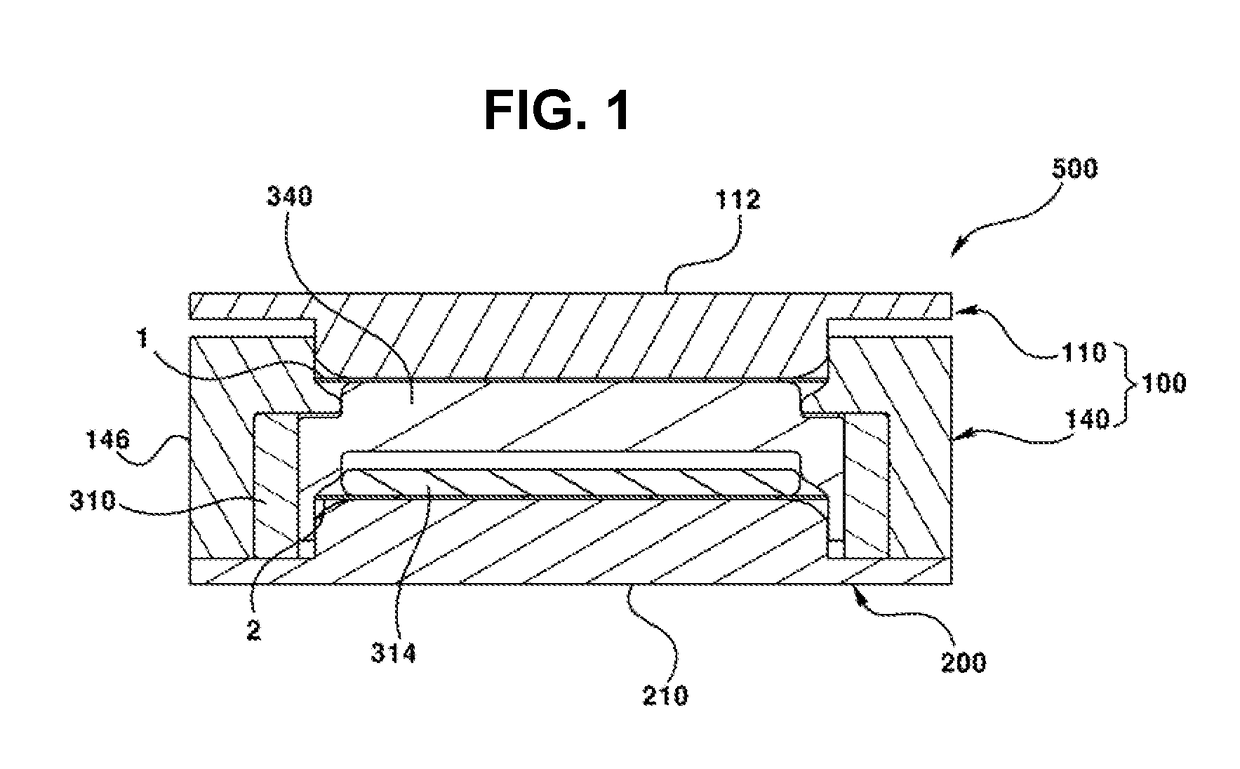

Piezoelectric film, piezoelectric device, liquid ejection apparatus, and method of producing piezoelectric film

ActiveCN102194670AInhibition of compositional changesImprove performanceVacuum evaporation coatingSemiconductor/solid-state device manufacturingEngineeringDeposition process

The invention relates to a piezoelectric film, a piezoelectric device, a liquid ejection apparatus, and a method of producing piezoelectric film. The piezoelectric film is formed on a surface of a substrate by a vapor deposition process without generating grain boundaries which are substantially parallel to the surface of the substrate and are caused by lamination. A normal of a (100) plane of each of crystals constituting the piezoelectric film is inclined from a normal of the surface of the substrate by an angle of not smaller than 6 DEG and not larger than 36 DEG .

Owner:FUJIFILM CORP

Roll forming method for alpha-beta two-phase titanium alloy thick-wall ring forged piece

InactiveCN105382155AIncrease inner diameterIncrease the outer diameterMetal rollingRoll formingThick wall

The invention discloses a roll forming method for an alpha-beta two-phase titanium alloy thick-wall ring forged piece. The roll forming method includes the steps that an intermediate billet is designed to be a special-shaped ring billet with a boss arranged close to the inner wall; all dimensions of the special-shaped ring billet are worked out according to the equivolumetric principle; a special die is designed according to the shape and the dimensions of the special-shaped ring billet; after an alpha-beta two-phase titanium alloy bar is heated to a deformation temperature, the special-shaped ring billet is manufactured through upsetting, punching and pre-rolling under the effect of the special die; and the special-shaped ring billet is heated again to the deformation temperature, and then the special-shaped ring billet is rolled to obtain the thick-wall ring forged piece according to proper rolling parameters matched with the deformation temperature. By means of the method, the defects of grooves, folding and the like generated in the thick-wall ring forged piece rolling process can be effectively overcome, and the rolling quality of the thick-wall ring forged piece is improved. The method is used for roll forming of the thick-wall ring forged piece.

Owner:GUIZHOU ANDA AVIATION FORGING

Method for rolling and forming alpha-phase titanium alloy thick-wall ring forging

InactiveCN104550583AIncrease inner diameterIncrease the outer diameterMetal rollingThick wallAbnormal shaped

The invention discloses a method for rolling and forming alpha-phase titanium alloy thick-wall ring forging. The method for rolling and forming alpha-phase titanium alloy thick-wall ring forging comprises the following steps of: designing an intermediate blank to be a special ring blank provided with a lug boss close to an inner wall; calculating respective dimensions of the special ring blank according to an equivolumetric principle; designing a specific mould according to shape and dimensions of the special ring blank; preparing the special ring blank from an alpha-phase titanium alloy rod by using a specific mould after the alpha-phase titanium alloy rod is heated until the alpha-phase titanium alloy rod is heated at a temperature which can cause a deformation and is subject to upsetting, punching and pre-rolling; and reheating the special ring blank until reheating the special ring blank at the temperature which can cause a deformation, and rolling the special ring blank into the thick-wall ring forging matched with appropriate rolling parameters. According to the method for rolling and forming the alpha-phase titanium alloy thick-wall ring forging provided by the invention, defects such as recesses and folds arisen during the rolling of the thick-wall ring forging can be overcome efficiently, and rolling quality of the thick-wall ring forging can be improved. The method is used for rolling and forming the thick-wall ring forging.

Owner:GUIZHOU ANDA AVIATION FORGING

Rolling forming method of structural steel thick-wall ring forging

The invention discloses a rolling forming method of a structural steel thick-wall ring forging. The method comprises the following steps: firstly designing an intermediate billet as a specially-shaped ring billet with a lug boss adjacent to the inner wall; calculating each size of the specially-shaped ring billet according to an equivolumetric principle; designing a special mold according to the shape and size of the specially-shaped ring billet; heating a structural steel bar to reach a deformation temperature, upsetting, perforating and pre-rolling the structural steel bar, and preparing the structural steel bar into a specially-shaped ring billet under the effect of the special mold; reheating the specially-shaped ring billet to reach the deformation temperature, and rolling the specially-shaped ring billet to form a thick-wall ring forging by matching with an appropriate rolling parameter. According to the method, the defects such as grooves, folding and the like in the rolling process of the thick-wall ring forging can be effectively solved, and the rolling quality of the thick-wall ring forging can be improved. The method is used for rolling and forming the thick-wall ring forging.

Owner:GUIZHOU ANDA AVIATION FORGING

Tire cure mold and method of manufacturing tire

InactiveUS10456952B2Improve appearance qualityAvoid forming defectsTyresTyre tread bands/patternsMechanical engineeringTread

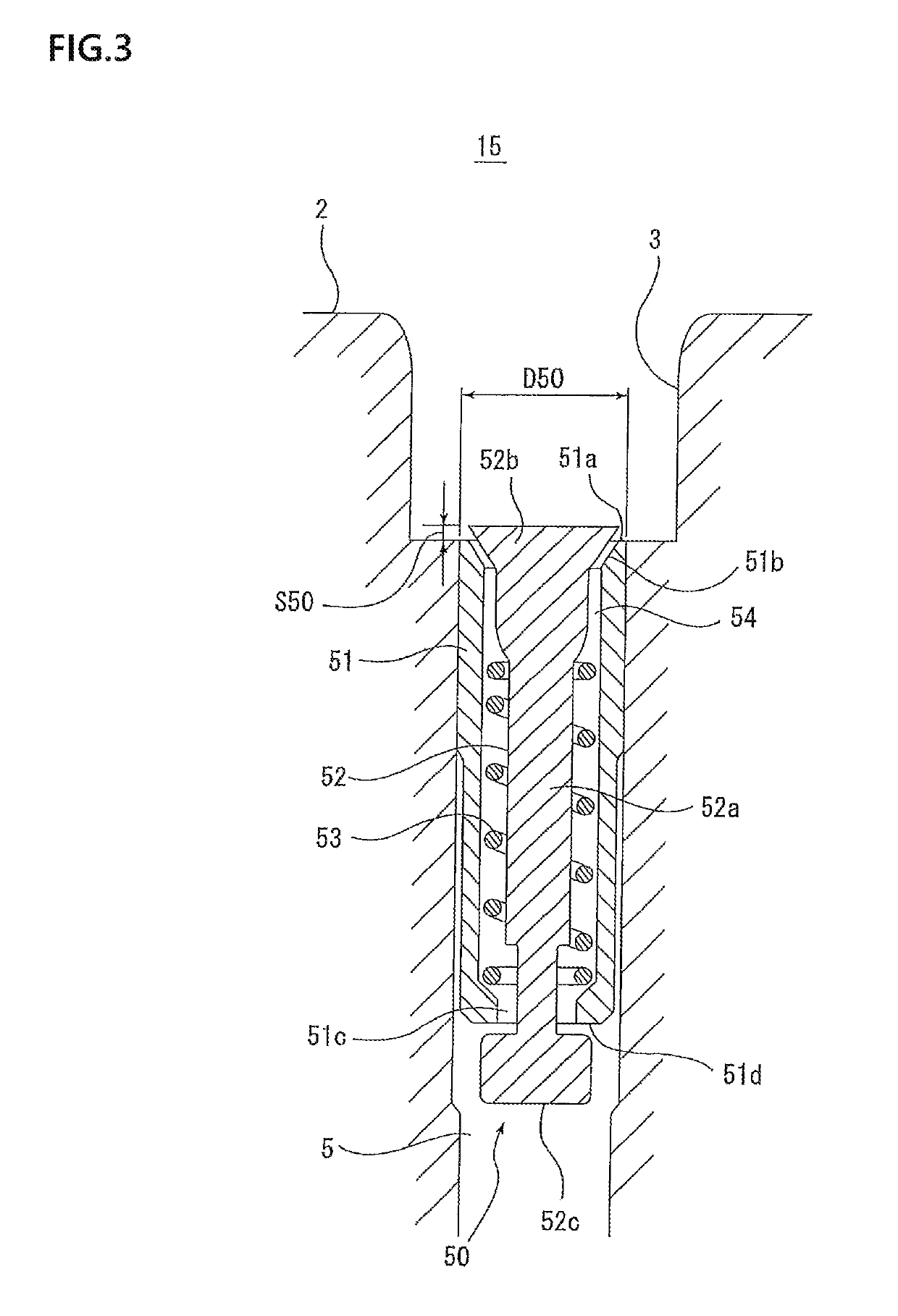

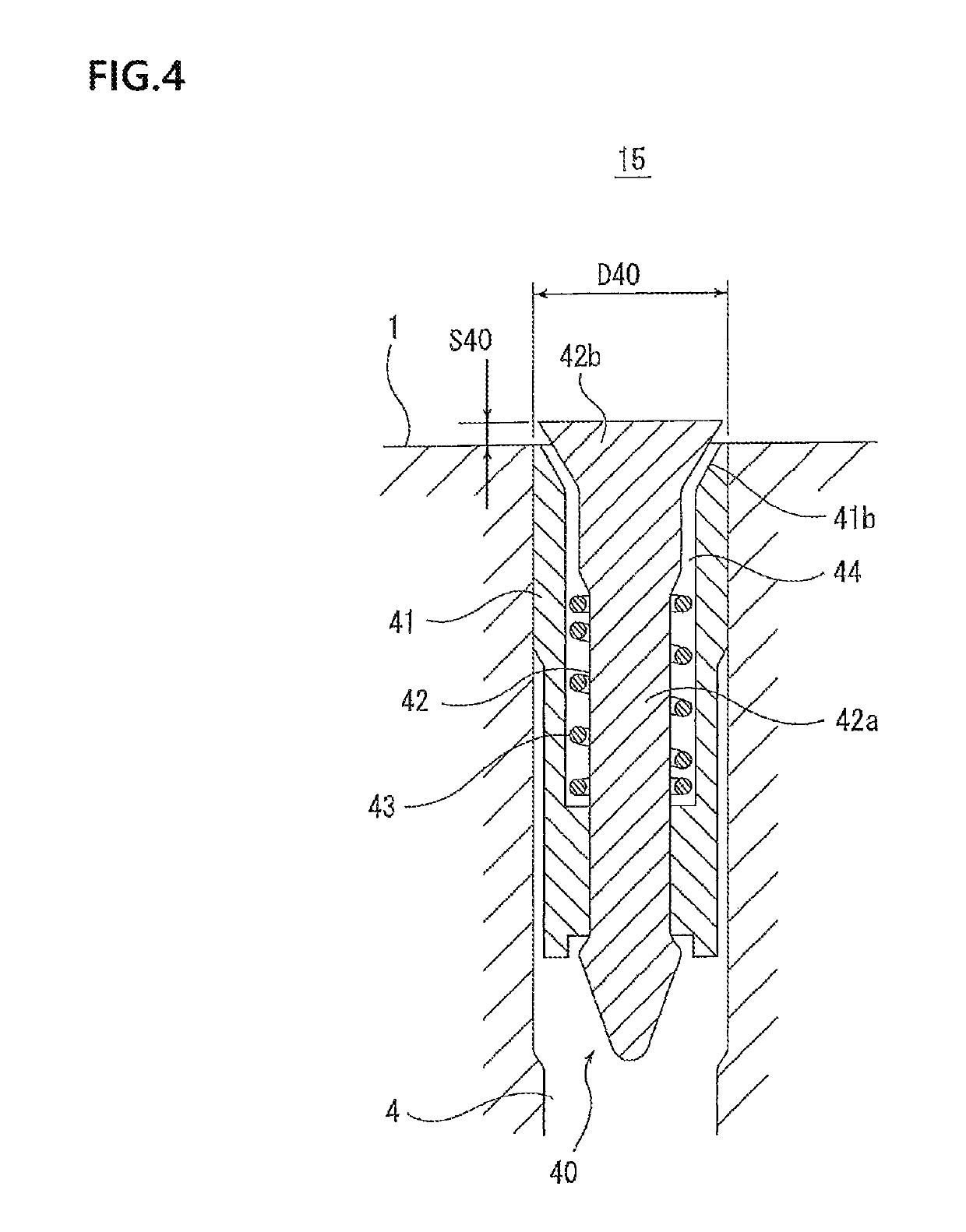

A tire cure mold has a tread molding face that comes in contact with a tread face of a tire set in a cavity, a protruding portion for forming a groove portion and protruding inward in a tire diametrical direction from the tread molding face, a depression for forming a groove bottom projection and formed by recessing a top face of the protruding portion, a first vent hole open in the tread molding face, a second vent hole open in a bottom face of the depression, and a spring vent mounted in the second vent hole.

Owner:TOYO TIRE & RUBBER CO LTD

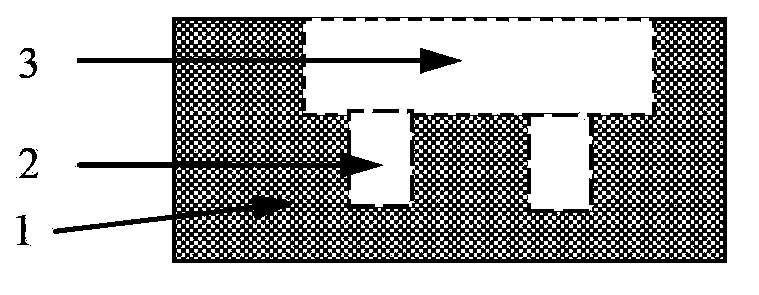

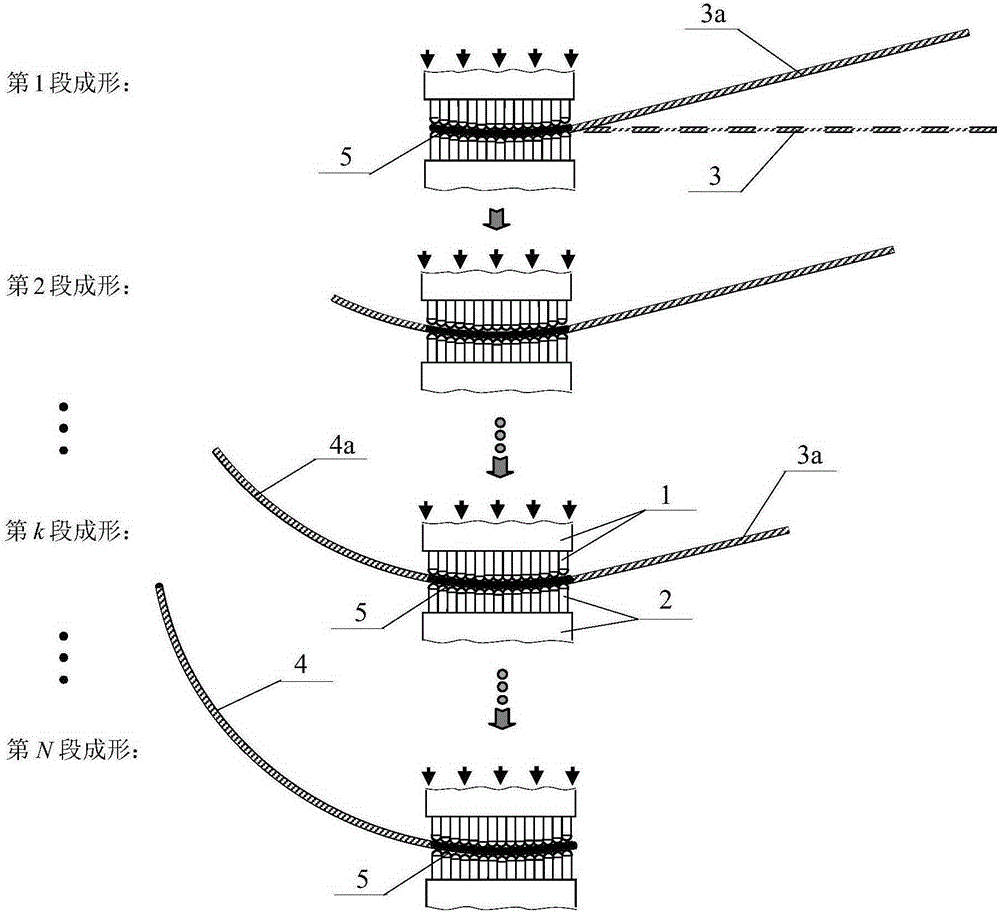

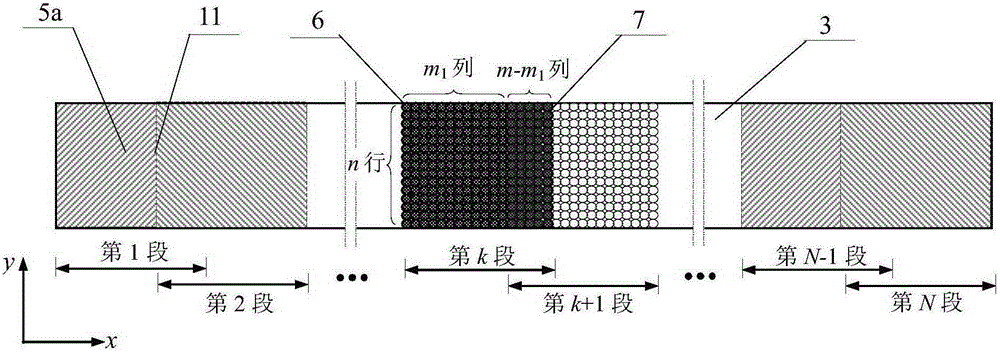

Segment-by-segment forming method for large curved surface adopting discrete die

InactiveCN105344782AReduce manufacturing costsReduce manufacturing costShaping toolsEngineeringLarge size

The invention provides a segment-by-segment forming method for a large curved surface adopting a discrete die. A large 3D curved-surface part is difficult in forming, and in a conventional integral stamping forming method, a large die is needed, large or extra-large table facet machining equipment is required, and therefore, the production cost of large 3D curved-surface parts is extremely high. According to the invention, a set of discrete profile adjustable die is adopted, a to-be-formed large curved surface is sequentially divided into a plurality of segments with size equal to that of the forming area of the die; during forming of each segment, the discrete die is divided into an effective forming area and a forming transition area; and by reasonably designing the profile shape of the die of the forming transition area, deformation of joint part of adjacent forming segments are in uniform transition, so as to avoid production of forming defects, and the large curved-surface part is finally obtained after segment-by-segment forming. The method disclosed by the invention only needs one set of discrete die, and with small equipment, large-size parts can be formed, and quick machining of large curved-surface parts with low cost can be achieved.

Owner:JILIN UNIV

Pollution prevention device

ActiveCN102357477AAvoid enteringAvoid forming defectsSemiconductor/solid-state device manufacturingCleaning using liquidsEngineeringProduct gas

The invention discloses a pollution prevention device, relating to the technical field of semiconductor wafer processes. The device comprises a purging unit, a gas supply line and a gas supply unit, wherein a vent pipe is arranged in the purging unit; a plurality of first pores are arranged at the upper end of the purging unit and are respectively communicated with the vent pipe; one end of the gas supply line is communicated with the vent pipe; and the other end of the gas supply line is communicated with the gas supply unit. The device has the following beneficial effects: by arranging the purging unit, the cleaning fluid and cleaning products are prevented from entering into the back of the wafer from the edges of the wafer, thus preventing defects from being formed on the back and edges of the wafer.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Preparation method of PIPD (poly[2,6-diimidazo-(4,5-b:4'5'-e)pyridinylene-1,4-(2,5-dihydroxy)phenylene]) fiber

ActiveCN105350108AStretch smoothlyStretch stopArtificial filament washing/dryingDry-cleaning apparatus for textilesFiberPolyphthalamide

The invention relates to a preparation method of PIPD (poly[2,6-diimidazo-(4,5-b:4'5'-e)pyridinylene-1,4-(2,5-dihydroxy)phenylene]) fiber and belongs to the technical field of preparation of high-performance fiber. The PIPD fiber is obtained through air gap stretching, cooling in a quenching chamber, phosphoric solution curing, washing, multi-level gradual drying, heat treatment and coiling of a PIPD / PPA (polyphthalamide) liquid crystal solution. According to the method, the drawing rate of as-spun fiber can be stably controlled; meanwhile, most of PPA in the as-spun fiber can be rapidly and effectively removed; moisture in the as-spun fiber of PIPD can be slowly removed, and high-performance PIPD fiber with a good structure is obtained.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Rolling and forming method for iron-based high-temperature alloy thick-walled ring forging

InactiveCN104550586AIncrease inner diameterIncrease the outer diameterMetal rollingAlloyAbnormal shaped

The invention discloses a rolling and forming method for an iron-based high-temperature alloy thick-walled ring forging. The rolling and forming method comprises the following steps: designing an intermediate blank into a special-shaped ring blank, wherein a boss is formed at the position, close to the inner wall, of the special-shaped ring blank; calculating each size of the special-shaped ring blank according to an equivolumetric principle; designing a special mould according to the shapes and the sizes of the special-shaped ring blank; heating an iron-based high-temperature alloy rod to a deforming temperature, performing upsetting, punching and pre-rolling, and preparing the special-shaped ring blank under the action of the special mould; reheating the special-shaped ring blank to the deforming temperature, and preparing the special-shaped ring blank into a thick-walled ring forging by matching suitable rolling parameters. According to the method, the defects of grooving and folding caused during a rolling process of the thick-walled ring forging can be effectively overcome; the rolling quality of the thick-walled ring forging can be improved. The method is used for the rolling and forming of the thick-walled ring forging.

Owner:GUIZHOU ANDA AVIATION FORGING

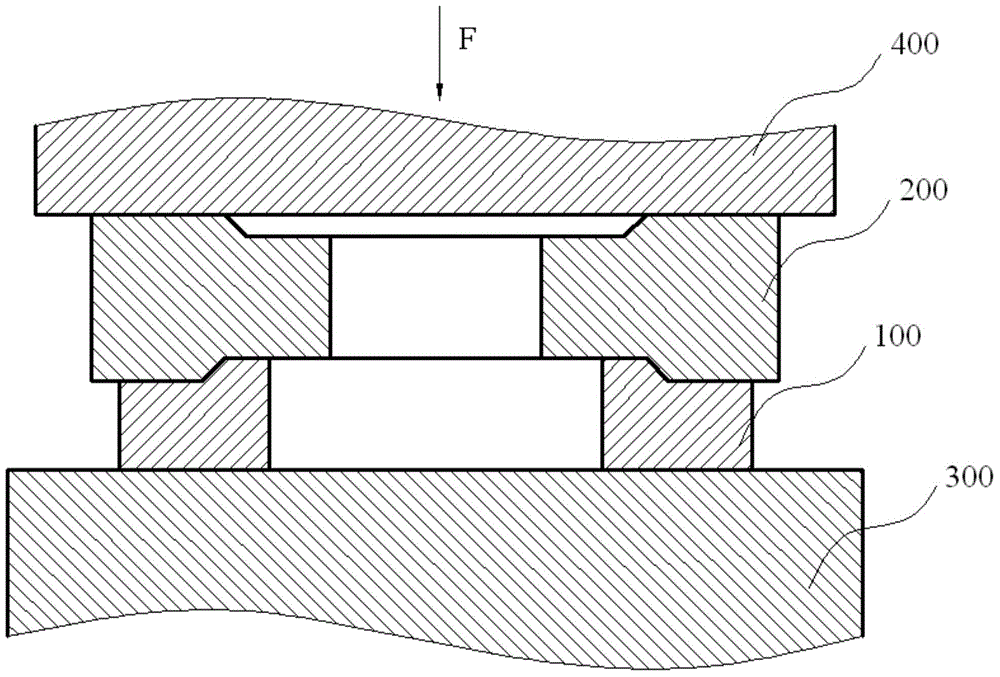

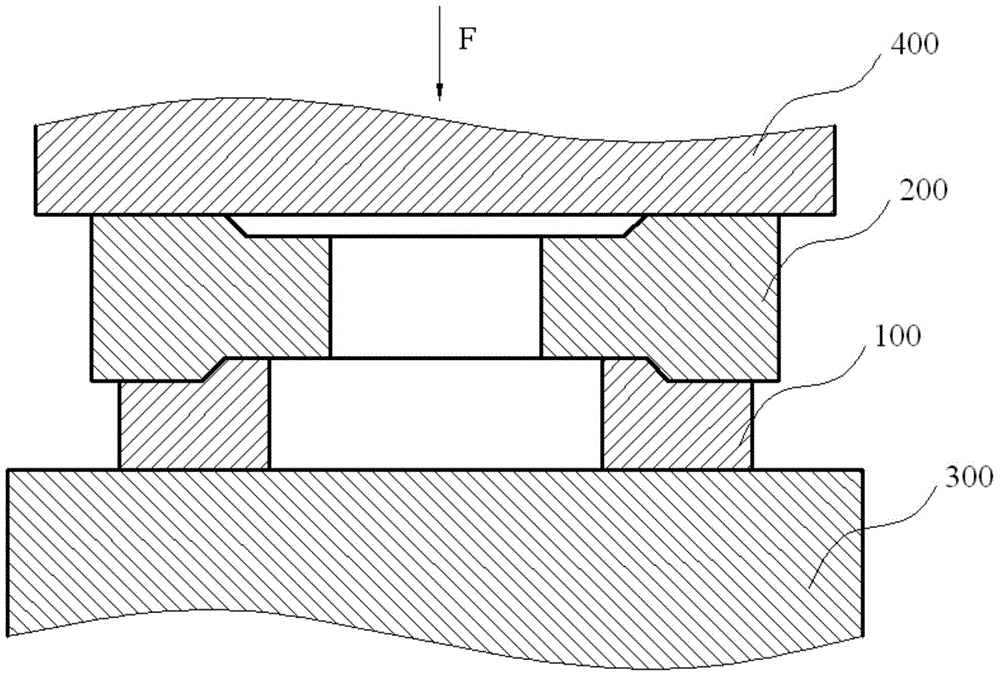

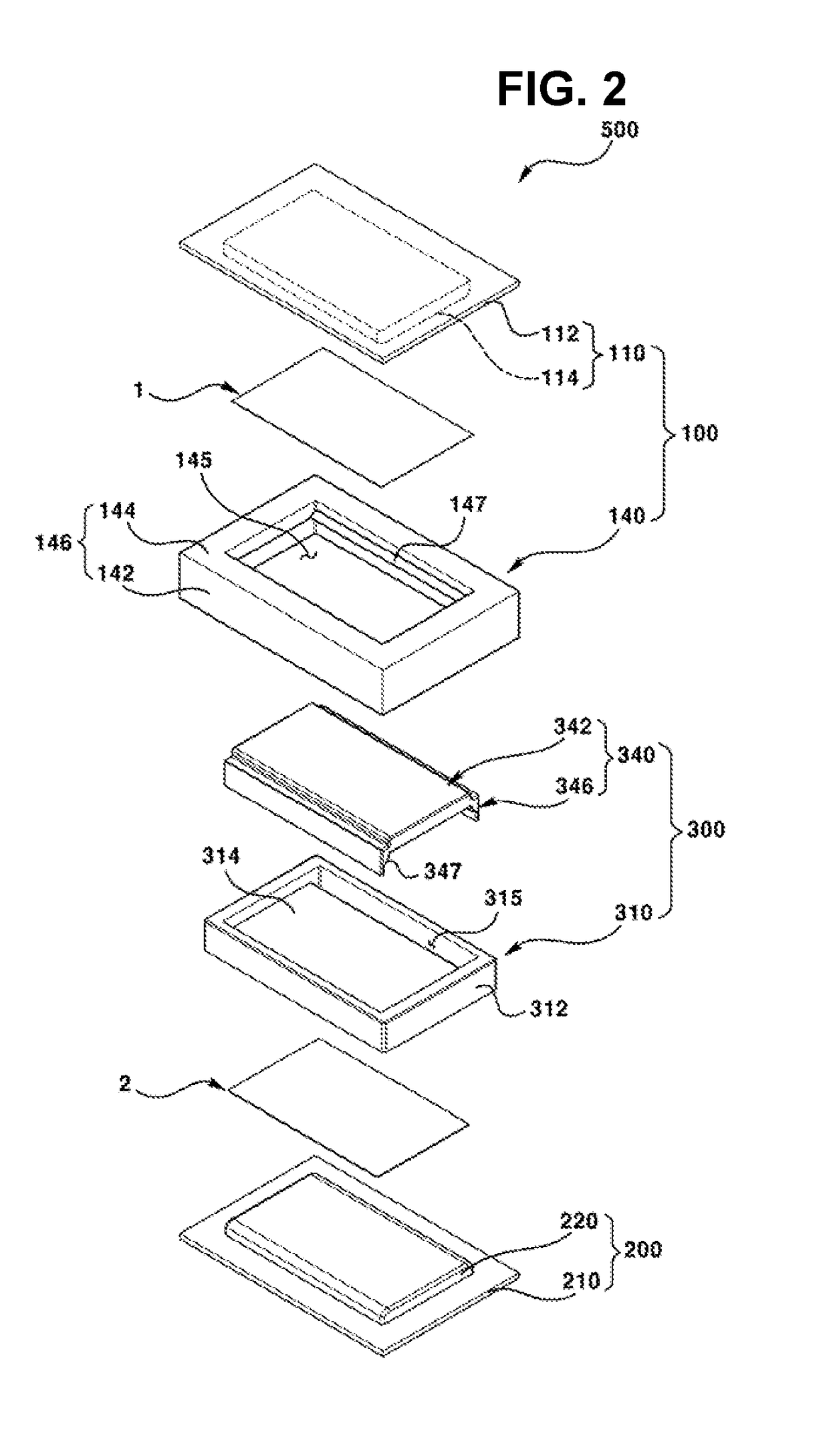

Apparatus for fabricating materials

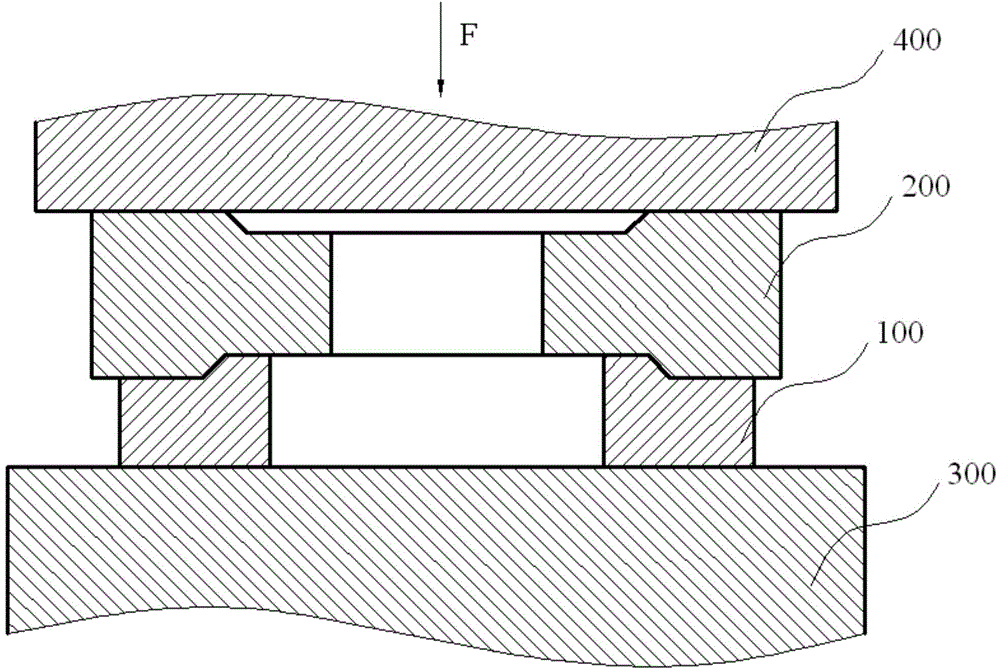

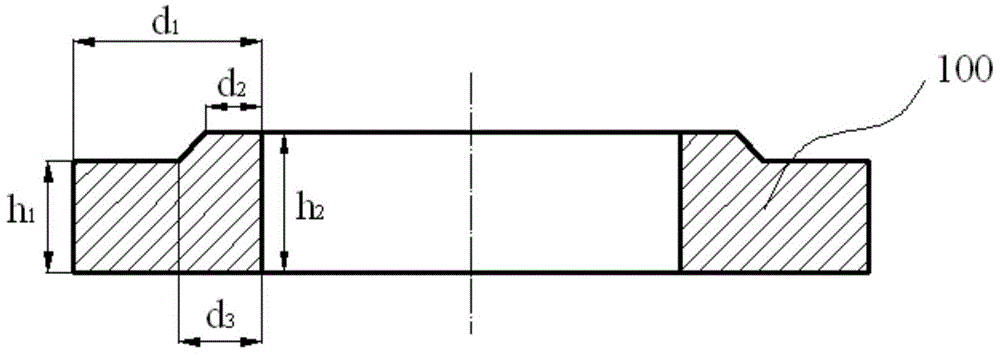

ActiveUS20180016178A1Avoid forming defectsShorten molding timeGlass reforming apparatusGlass press-moulding apparatusMaterials science

Provided is apparatus for fabricating materials, including: a first mold including a first forming unit pressing a first material, and a second forming mold arranged at a bottom surface of the first forming unit to have an opening exposing the first material and to form at least a part of the first material by being meshed at a part with the first forming unit; a second mold arranged at a bottom surface of the first mold to support a second material; and an interlocking mold including a fixing unit interposed between the first and second molds to fix the second material arranged at the second mold by pressing the second material, and an interlocking unit ascendably and descendibly coupled to the fixing unit to form the second material by pressing the second material in association with the forming of the first material.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com