Double-curved-surface skin opening frame forming method

A hyperboloid and skinning technology, which is applied in the field of hyperboloid sawtooth skin frame forming, can solve the problems of high profile precision, high tooling manufacturing cost, and long cycle time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that in this embodiment, the orientation words "up" and "down" are all described according to the drawings, and do not constitute a limitation to the present invention.

[0031] Attached below Figure 1-8 The present invention is described in further detail:

[0032] A method for forming a hyperboloid skin mouth frame, comprising the following steps:

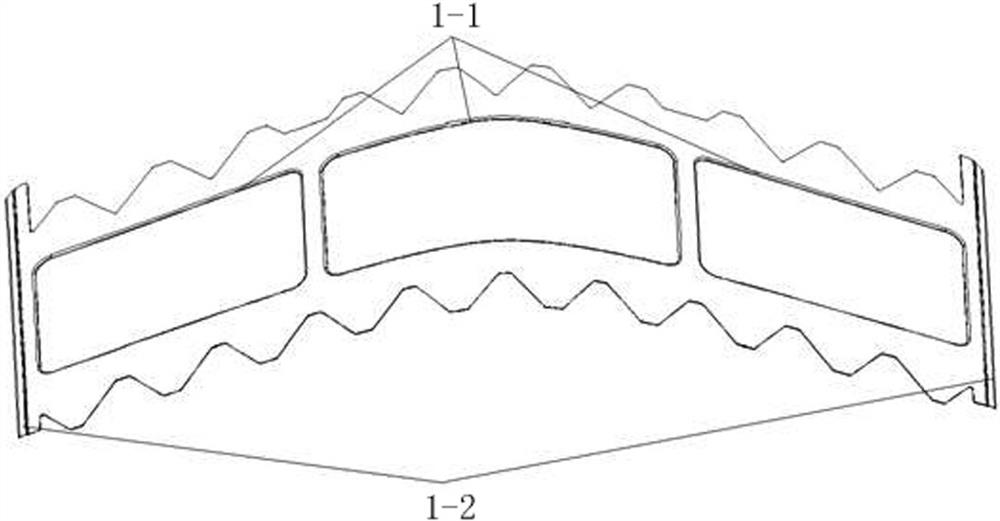

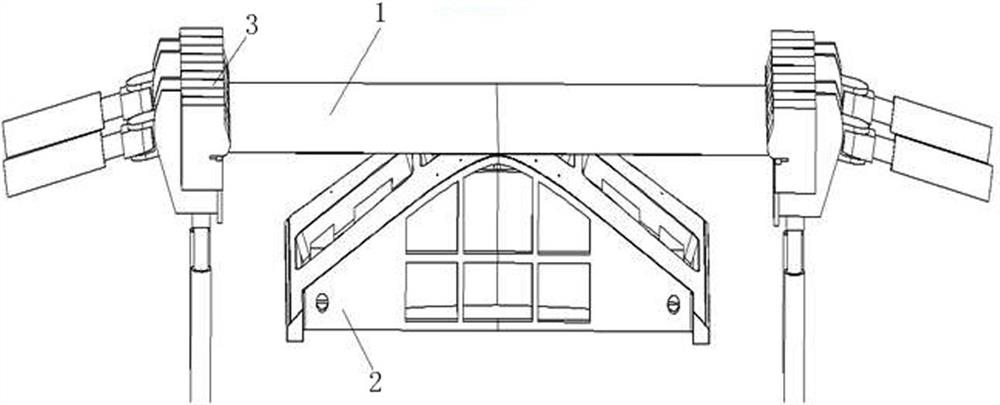

[0033] (1) First put the two ends of the long side of the part blank 1 (usually with the part bending hole 1-1 and the sinking area 1-2) into the jaws of the drawing forming equipment 3, and keep the part blank 1 and the forming mold 2 in phase cut;

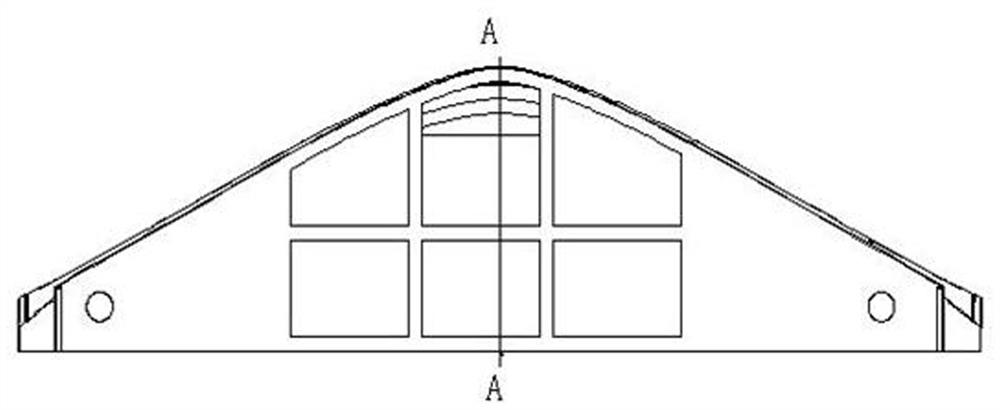

[0034] (2) The hydraulic actuator of the jaws drives the jaws to move, so that the part blank 1 is covered on the upper surface of the forming mold 2, and the part blank 1 and the upper surface of the forming mold 2 are drawn in contact with the hollow area and the profile surface to form the R angle of the mouth frame. 4. Obtain semi-finished parts to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com