Method for prolonging service life of semiconductor laser device

A laser and semiconductor technology, applied in the direction of semiconductor lasers, lasers, laser parts, etc., to achieve the effect of simple method, eliminating the state to be oxidized, and preventing the formation of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

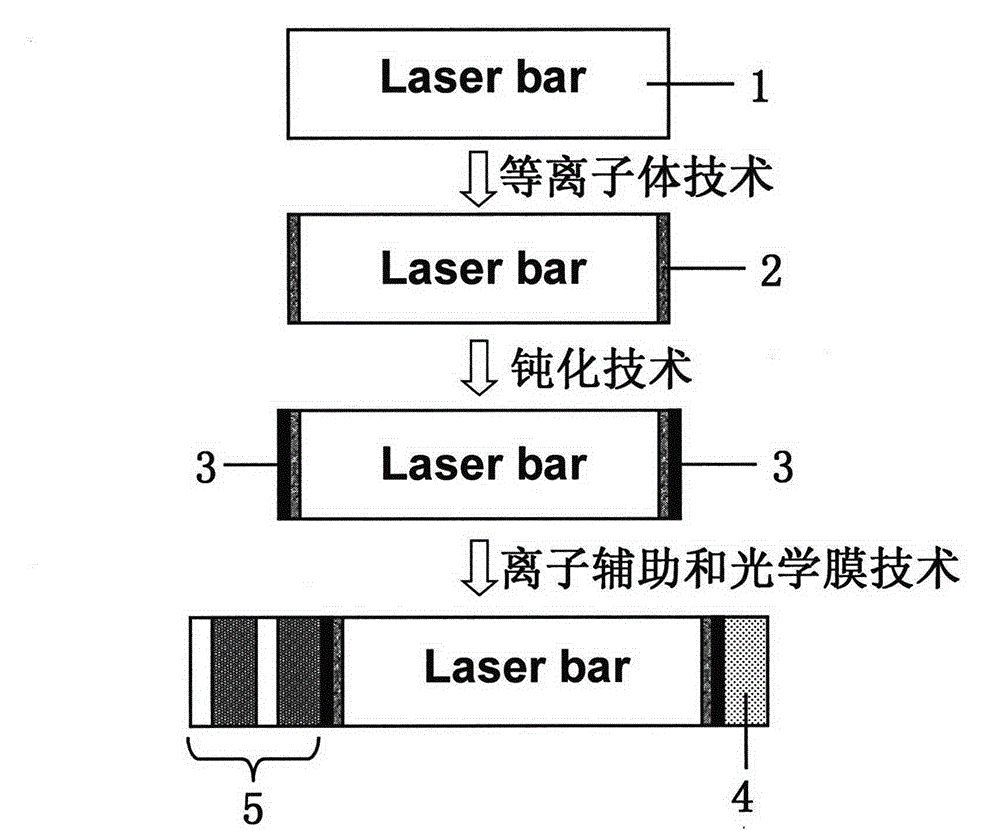

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the embodiments.

[0019] First, cleavage the 808nm semiconductor laser chip into a bar 1 with a cavity length of 1000 μm in the air, neatly stack the cleaved 808nm semiconductor laser bar 1 on a special semiconductor laser bar fixture, and put it into a vacuum coating machine. Draw a vacuum. When the vacuum reaches 1.0×10 -4 At Pa, plasma technology is used to clean the cavity surface with low-energy plasma to form a semiconductor laser bar 2 processed by plasma technology. The purpose of cleaning the cavity surface with low-energy plasma is to remove cavity surface oxides and unstable surface states, and the purpose of selecting low-energy ion sources is to prevent high-energy ions from damaging the cavity surface and forming cavity surface defects.

[0020] After cleaning the cavity surface of the semicondu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com