Magneto-rheological composite soft mold and plate forming method based on same

A magnetorheological and magnetorheological elastic technology, applied in the field of sheet metal forming, can solve the problems of different, incapable of forming and processing of sheet metal parts, and inability to realize local differential pressure distribution, so as to promote full filling and solve local differential pressure distribution , the effect of avoiding forming defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

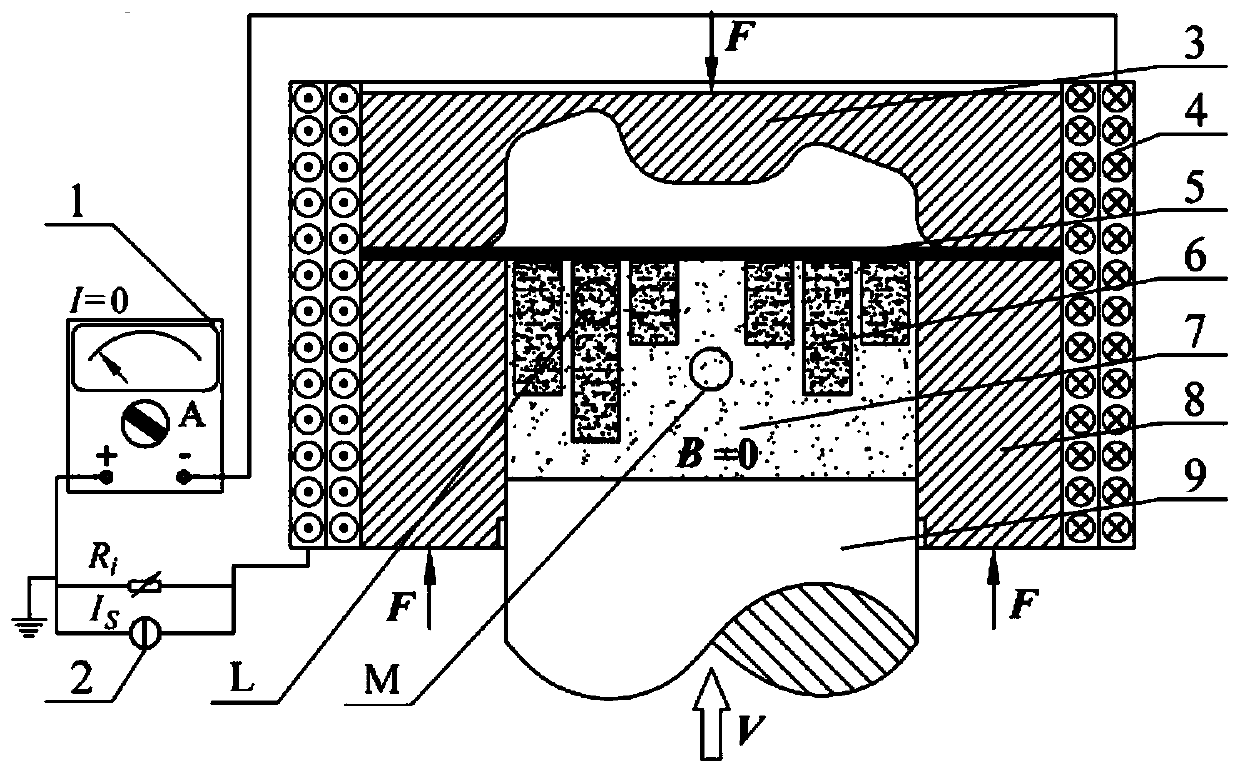

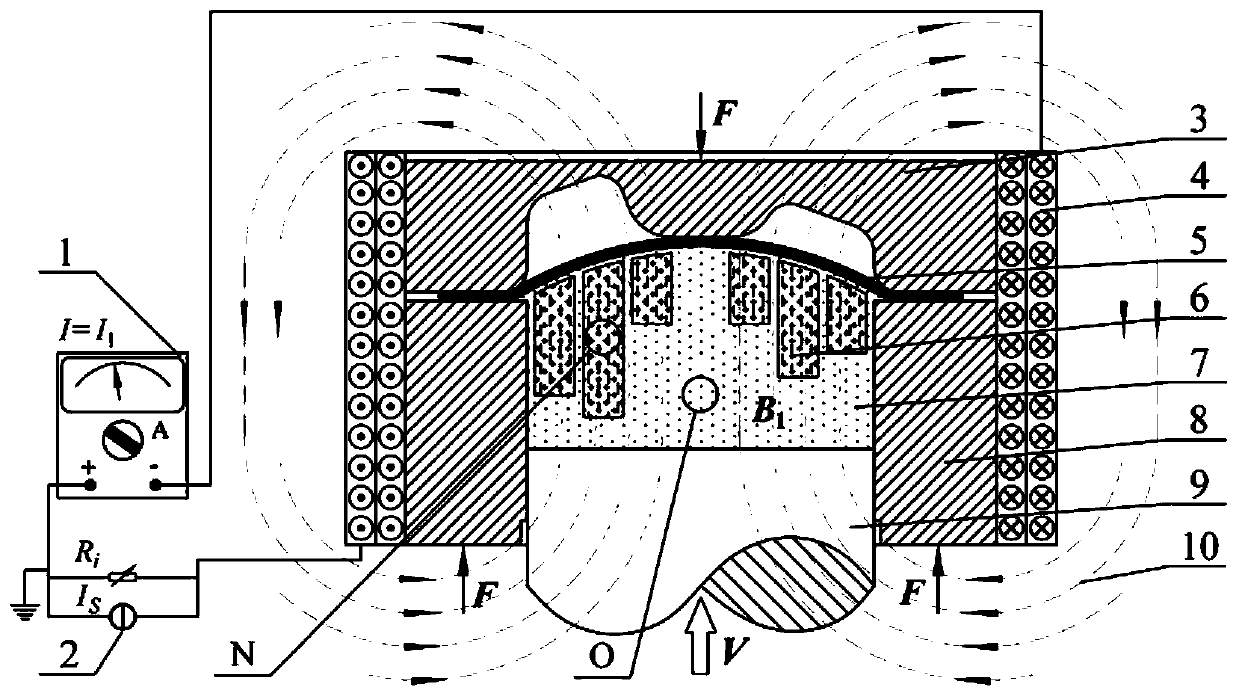

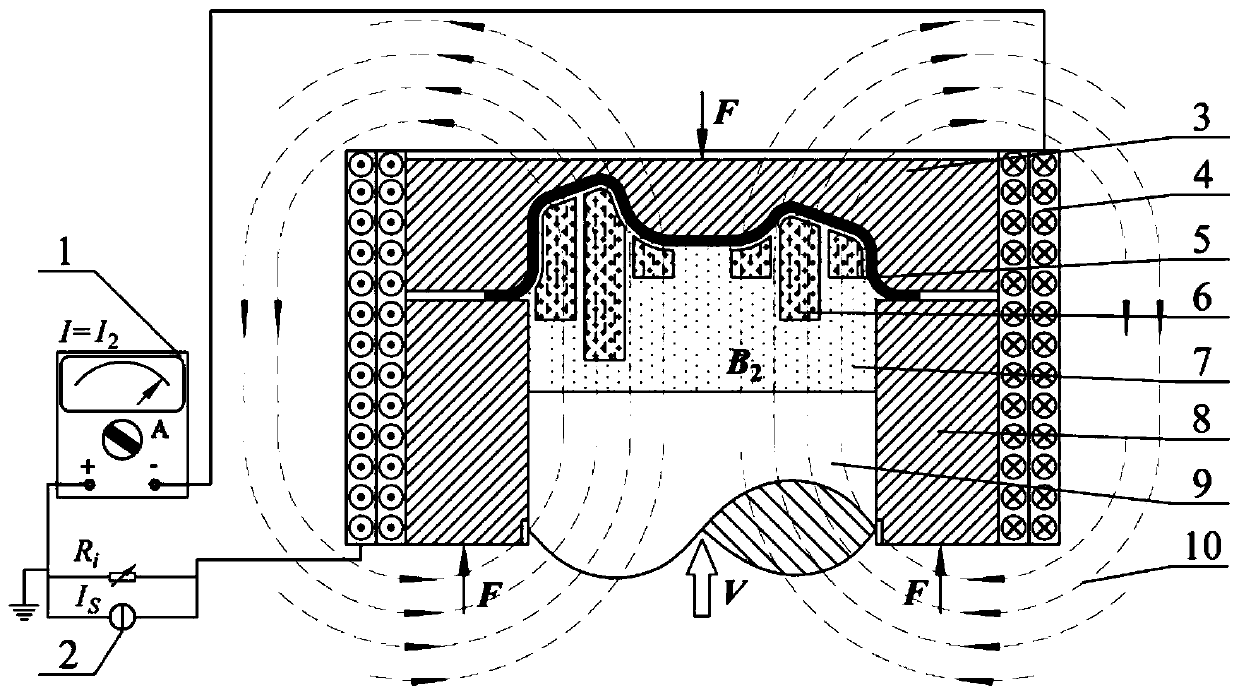

[0033] Embodiment of magnetorheological composite soft mold:

[0034] This embodiment provides a magnetorheological composite soft mold, such as figure 1 As shown, the magnetorheological composite soft mold includes a soft mold base composed of solid type I magnetorheological elastic material 7, and a semi-solid magnetorheological viscoplastic material 6 is encapsulated at a predetermined position inside the soft mold base. Six cylindrical magnetorheological viscoplastic units are formed to form a cylindrical magnetorheological elasticity-viscoplastic composite soft mold (abbreviated as a magnetorheological composite soft mold).

[0035] Wherein, the magnetorheological viscoplastic material 6 is magnetorheological fluid, magnetorheologica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com