Titanium microalloying high-silicon-content aluminum alloy and preparing method thereof

A technology of micro-alloying and aluminum alloy, which is applied in the field of plastic processing and alloy preparation of metal materials, can solve the problems of easy deformation and wear, small alloy stiffness, and reduced elongation, and achieve easy plastic processing, high elastic modulus, The effect of large elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

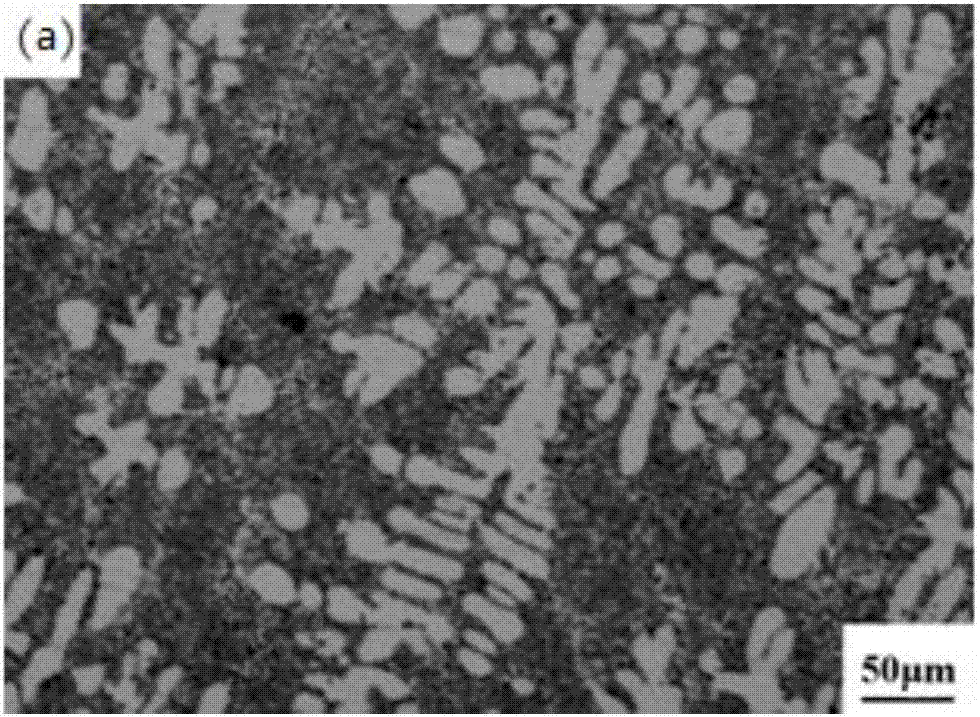

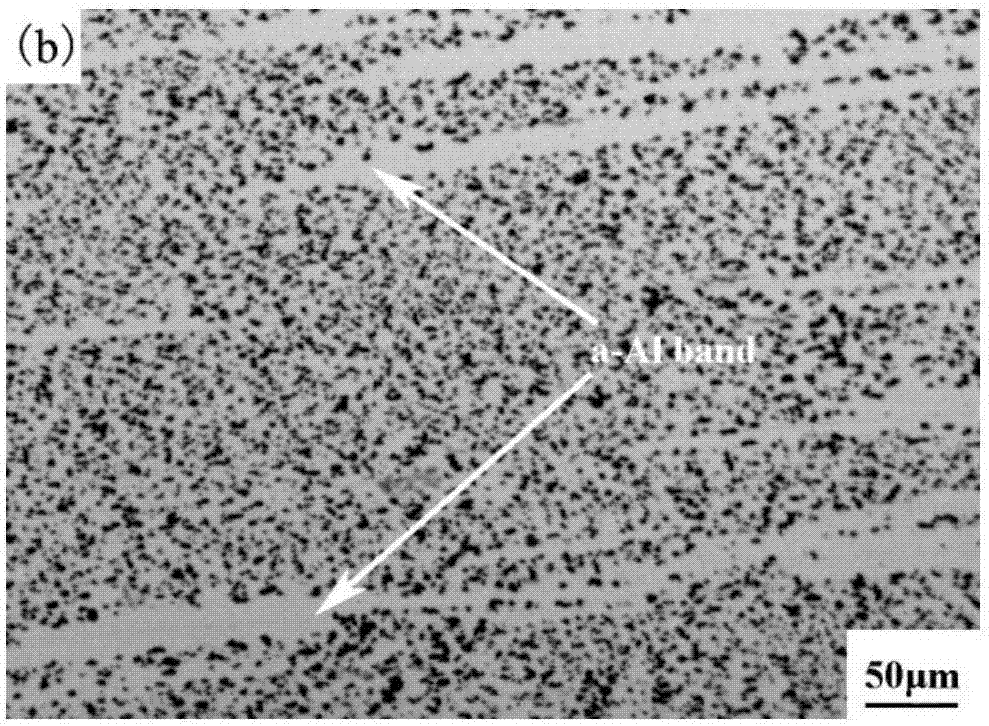

Embodiment 1

[0026] The raw material is an aluminum-silicon master alloy of Al-12.53wt% Si. Add the near-eutectic aluminum-silicon alloy of Al-12.53wt% Si to the graphite crucible, and add an appropriate amount of pure silicon and the master alloy of Al-4wt% Ti, so that the silicon mass percentage of the alloy is 12.3%, and the mass percentage of titanium is Hexachloroethane is added to refine after the temperature of the melt drops to 730°C, and after standing for 10 minutes, pour into the melt Add 0.5wt% pure magnesium ingot, keep it warm for 30 minutes and then drop it to 730°C, then add Al-10wt% Sr and Al-3wt% B master alloy, keep it warm for 30 minutes, wait for the temperature to stabilize at 730°C, and put it under vacuum for 60 minutes Then the obtained melt is cast into a cast iron mold, and naturally cooled to form an ingot; after the ingot is subjected to homogenization annealing at 535° C. for 6 hours, hot extrusion is carried out at 535° C. (extrusion ratio 32), and quenched i...

Embodiment 2

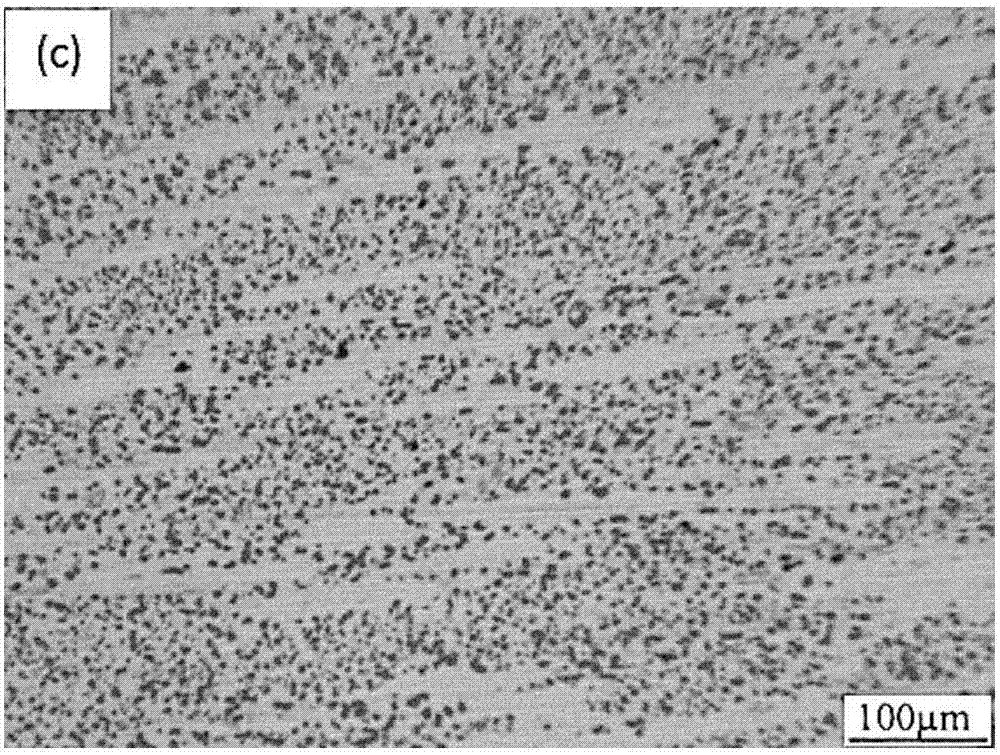

[0029]The raw material is an aluminum-silicon master alloy of Al-12.03wt% Si. Add the near-eutectic aluminum-silicon alloy of Al-12.03wt% Si to the graphite crucible, and add an appropriate amount of pure silicon and the master alloy of Al-4wt% Ti, so that the mass percentage of silicon in the alloy is 12.0%, and the mass percentage of titanium Hexachloroethane is added to refine after the temperature of the melt drops to 730°C, and after standing for 10 minutes, pour into the melt Add 0.7wt% pure magnesium ingot, keep it warm for 30 minutes and then drop it to 730°C, then add Al-10wt% Sr and Al-3wt% B master alloy, keep it warm for 30 minutes, wait for the temperature to stabilize at 730°C, and put it under vacuum for 60 minutes Then the melt obtained is poured into a cast iron mold, and naturally cooled to form an ingot; after the ingot is carried out to 535 ° C * 6h homogenization annealing, hot rolling is carried out at 500 ° C (reduction ratio 67%), Immediately quenched ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com