Super-high-performance cement base repairing material and preparing method thereof

A repair material and ultra-high performance technology, applied in the field of building materials, can solve the problems of low shrinkage performance, high strength, high bonding performance, low shrinkage, high elastic modulus, etc., to improve interface bonding performance and matrix strength , Increase the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

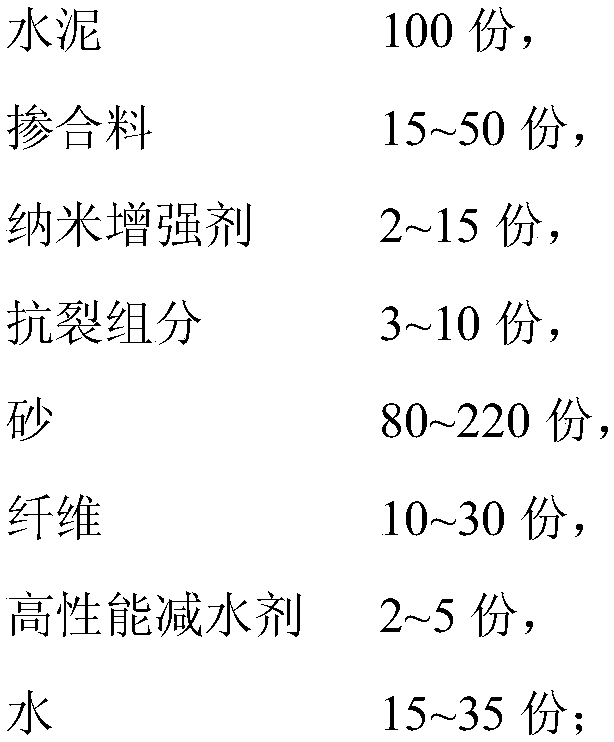

Method used

Image

Examples

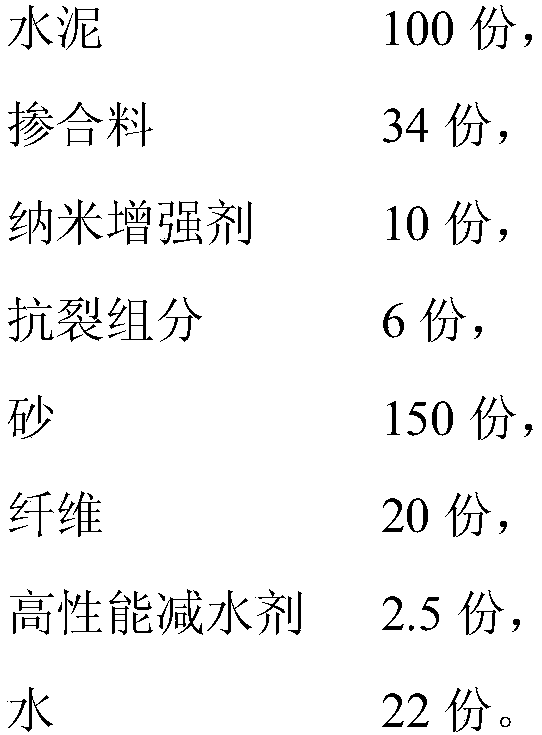

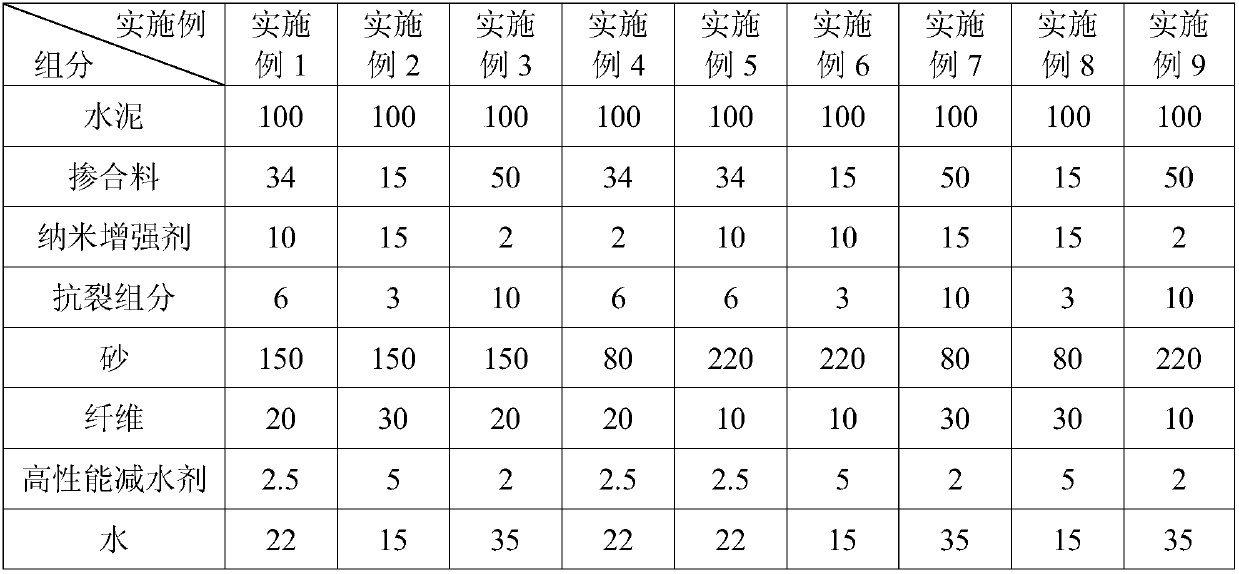

Embodiment 1

[0033] The anti-cracking component in Example 1 is starch-based hydration heat control material, calcium oxide expansion agent, magnesium oxide expansion agent and polyether shrinkage reducer mixed in a mass ratio of 5:48:32:15; the fiber is 3 mm in length, The diameter is 0.15mm; the sand is a mixture of quartz sand and silicon carbide in a mass ratio of 60:40, and the maximum particle size of the sand is 0.6mm.

Embodiment 2

[0034] In Example 2, the anti-cracking component is a mixture of starch-based hydration heat regulating material and calcium oxide expansion agent in a mass ratio of 10:90; the fiber is steel fiber, 12 mm long and 0.2 mm in diameter; the sand is quartz sand and corundum sand according to The mass is mixed in a ratio of 40:60, and the maximum particle size of the sand is 5.0mm.

Embodiment 3

[0035] In Example 3, the anti-cracking component is calcium sulfoaluminate expansion agent; the fiber is steel fiber with a length of 12 mm and a diameter of 0.2 mm; the sand is a mixture of quartz sand and corundum in a mass ratio of 60:40, and the maximum particle size of the sand is 2.5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com