Preparation method of Ti2AlNb/TA15 bi-metal titanium alloy composite hollow structure

A hollow structure, titanium alloy technology, applied in the field of titanium alloy processing, can solve the problems of low design freedom, narrow process window, and high forming temperature, and achieve the effects of low equipment requirements, large design freedom, and low forming temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The material used in this embodiment is Ti 2 AlNb alloy 5 and TA15 alloy 6.

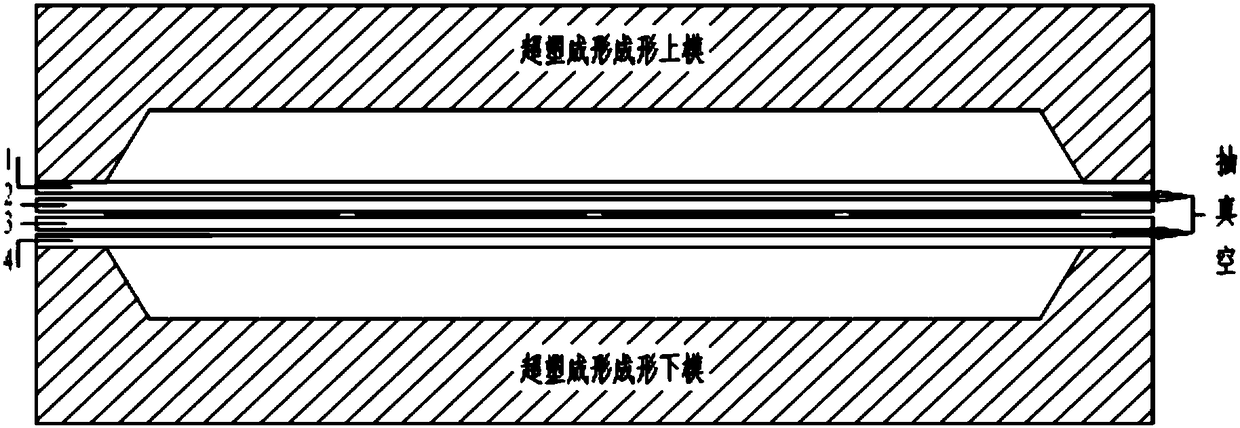

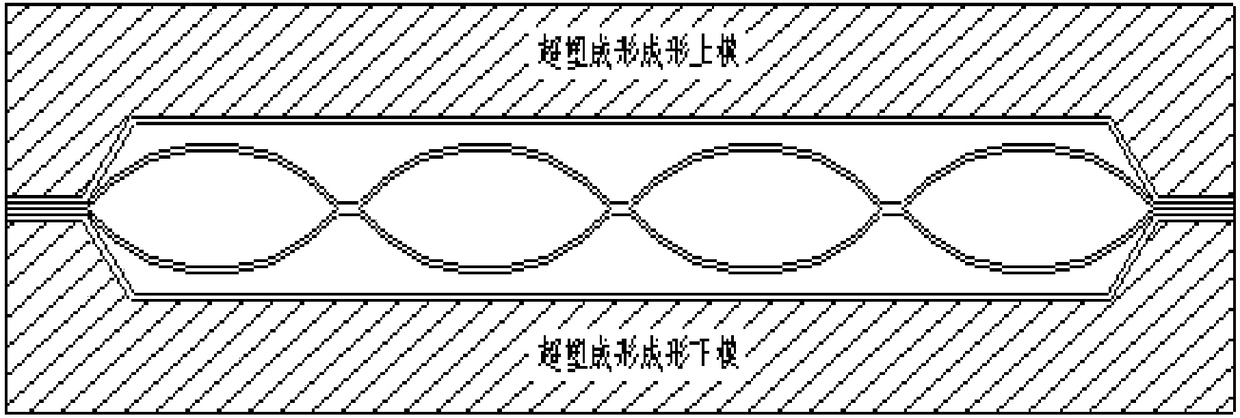

[0039] The present invention as Figure 5 shown in the following steps:

[0040] 1. Preparation of blank

[0041] (1) Prepare the upper core board 2, the lower core board 3, the outer board 1 and the lower outer board 4 by means of wire cutting or laser cutting.

[0042] 2. Blank line drawing, surface treatment

[0043] (1) Draw lines on the upper or lower core boards 2, 3.

[0044] (2) The four-layer blank is subjected to surface treatment, and the surface treatment can be carried out by pickling or mechanical grinding to remove scale.

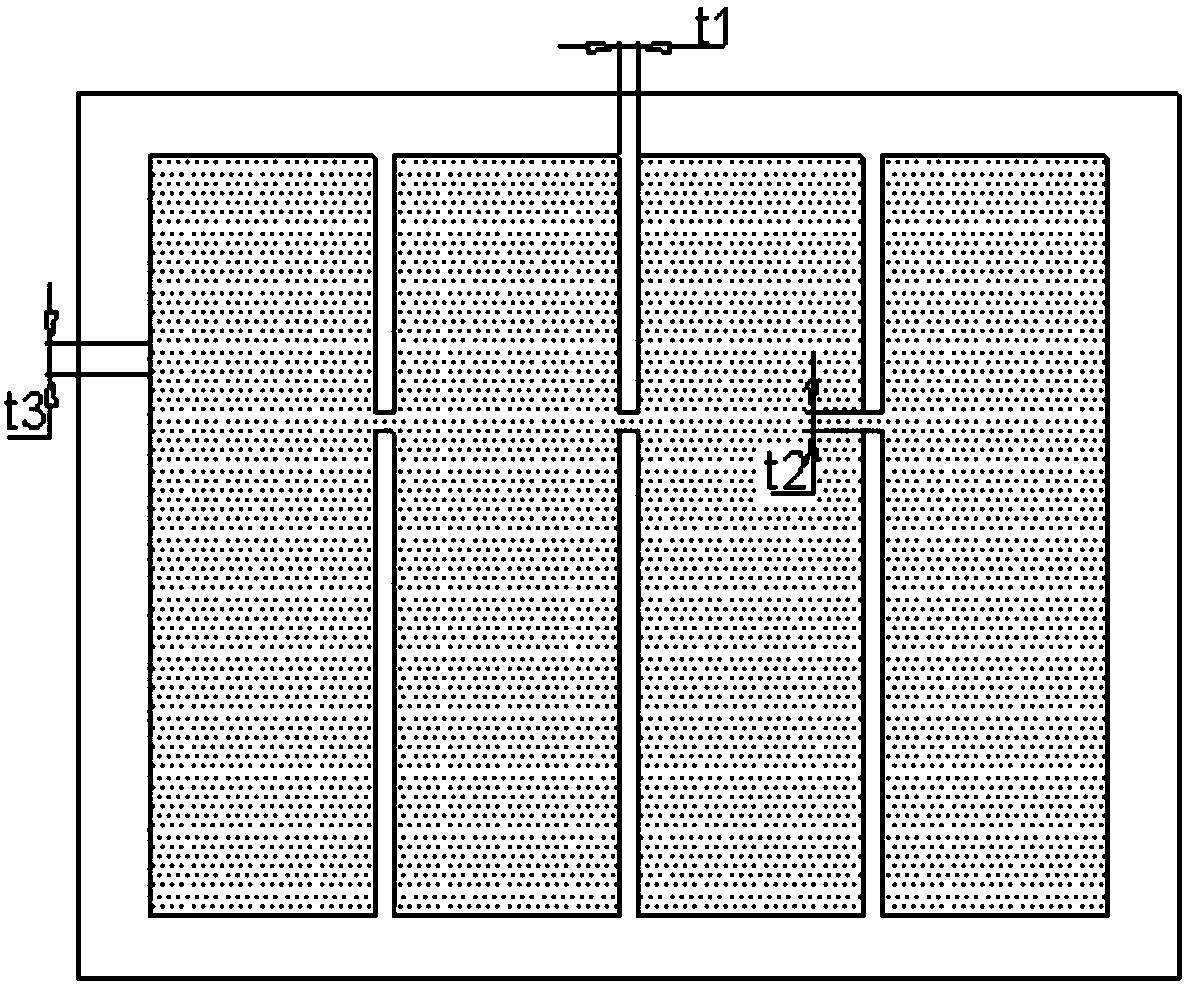

[0045] (3) Coat solder stop flux on the lined core board, and reserve the airflow channel t2, the width of the airflow channel t2 is about 3mm.

[0046] 3. Seal welding

[0047] (1) Assembling the surface-treated outer layer plates 1, 4 and the surface-treated core plate preform;

[0048] (2) After the four-layer slab is fixed, it is sealed by argon arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com