Spiral tungsten filament for superfine semiconductor slices

A semiconductor and tungsten wire technology, which is applied in the field of spiral tungsten wire for ultra-fine semiconductor slicing, can solve the problems of unsuitable deformation and inability to use filaments in batches, and achieve the effect of strong deformation resistance, better retention ability and better cutting ability.

Pending Publication Date: 2021-05-04

ZHENJIANG NAISI ADVANCE MATERIALS

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the thin wire materials used in semiconductor slicing are all steel properties, and their diameters are generally 0.09-0.175 microns. However, due to the influence of steel smelting, there are inevitably impurities in steel, and the carbon content is generally 0.08%-0.92%. Steel wire applied to multi-wire mortar cutting, the thinnest is 0.09 microns; and semiconductor materials such as gallium arsenide and germanium are very expensive and relatively soft, suitable for cutting with thin wires to reduce material waste, while steel wires are limited by their materials. It is impossible to mass-use filaments with a diameter below 0.09 microns; on the other hand, its variation is composed of two sets of waves, the second set of waves is vertically pressed on the first set, and the existing wavelength structure is not suitable for finer diameter filaments. Up deformation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

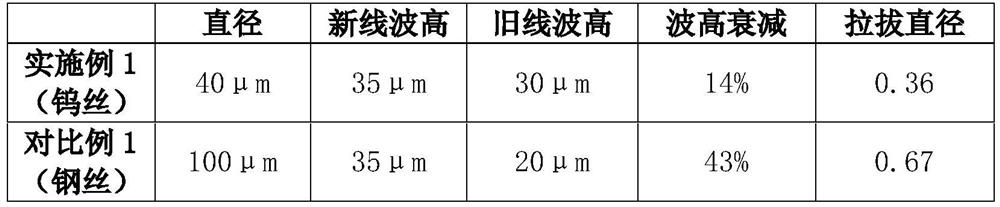

[0016] A spiral tungsten wire for ultra-fine semiconductor slicing, made of tungsten wire; the original diameter of the tungsten wire is 40 μm;

[0017] The helical shape of the tungsten wire is formed by compounding two sets of waveforms; wherein the first waveform is a 0-degree waveform, and the second waveform is a 90-degree waveform. The wave height of the first waveform is 35 μm. The wave height of the second waveform is 27 μm.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a spiral tungsten filament for superfine semiconductor slices. The spiral tungsten filament is made of tungsten filaments. The original diameter of the tungsten filament is 40 microns; the spiral shape of the tungsten filament is formed by compounding at least two waveforms; the first waveform is a 0-degree waveform, and the second waveform is a 90-degree waveform; the tungsten filament replaces the original steel wire to obtain greater limit compression rate; the new waveform design is denser, rolling of silicon carbide sand grains on the surface of a cutting wire is effectively organized, and the better cutting capacity is achieved; and in addition, the deformation resistance of the waveforms of the tungsten filament is higher, and in the cutting process, the front and rear waveforms are better in holding capacity.

Description

technical field [0001] The invention relates to the field of preparation methods of steel cords, in particular to a spiral tungsten wire for ultrafine semiconductor slices. Background technique [0002] At present, the thin wire materials used in semiconductor slicing are all steel properties, and their diameters are generally 0.09-0.175 microns. However, due to the influence of steel smelting, there are inevitably impurities in steel, and the carbon content is generally 0.08%-0.92%. Steel wire applied to multi-wire mortar cutting, the thinnest is 0.09 microns; and semiconductor materials such as gallium arsenide and germanium are very expensive and relatively soft, suitable for cutting with thin wires to reduce material waste, while steel wires are limited by their materials. It is impossible to mass-use filaments with a diameter below 0.09 microns; on the other hand, its variation is composed of two sets of waves, the second set of waves is vertically pressed on the first ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B28D5/04B24B27/06

CPCB28D5/045B24B27/0633

Inventor 张释伟李晓军盛荣生蔡磊

Owner ZHENJIANG NAISI ADVANCE MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com