Embossing machine transferring pattern on wet flocked fabric

a technology of embossed fabric and pattern, which is applied in the direction of textile shaping, non-woven fabrics, textiles and papermaking, etc., can solve the problems of colour and pattern deterioration, end-product lack of permanence and fine general appearance, and colour troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

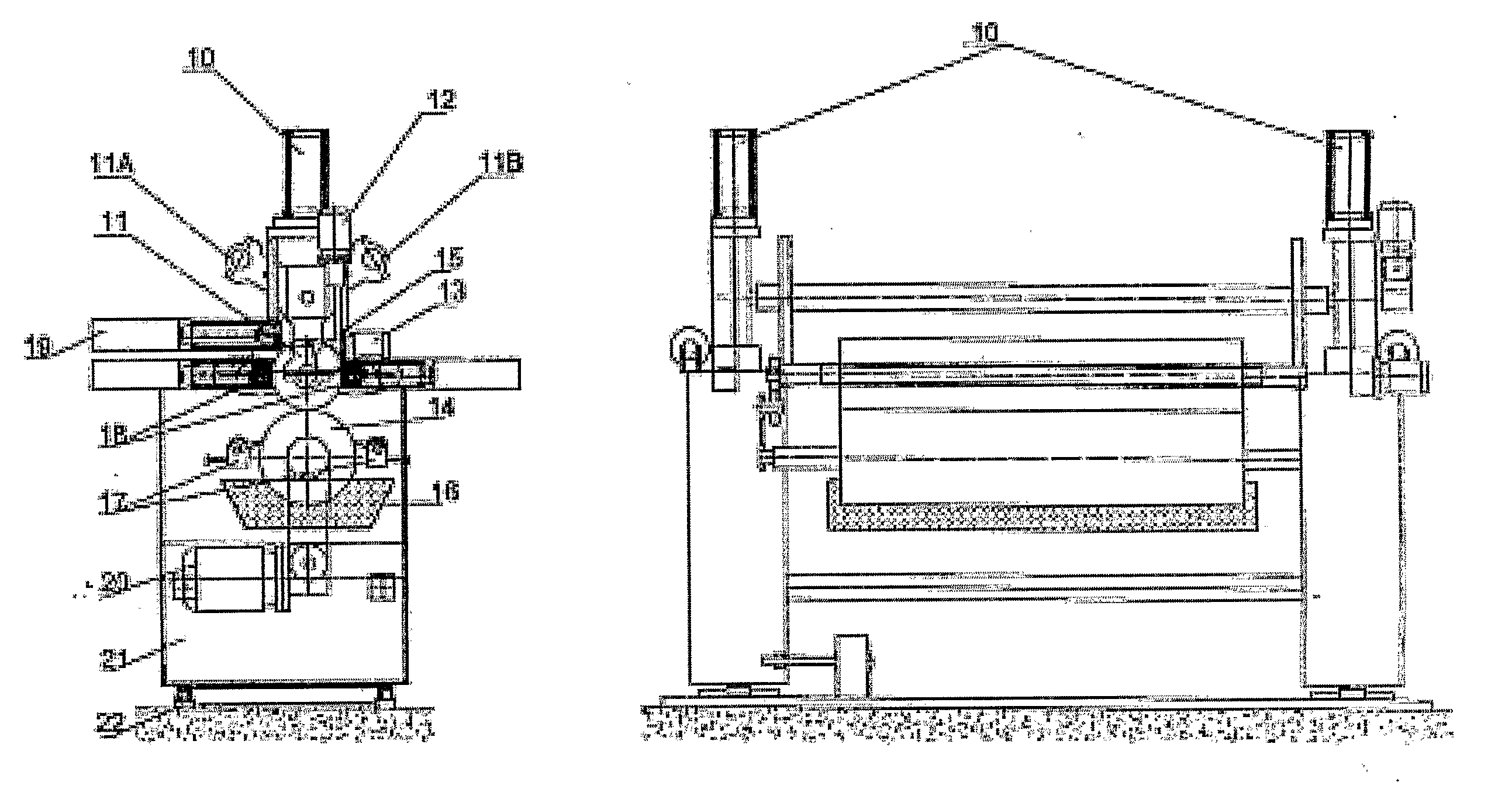

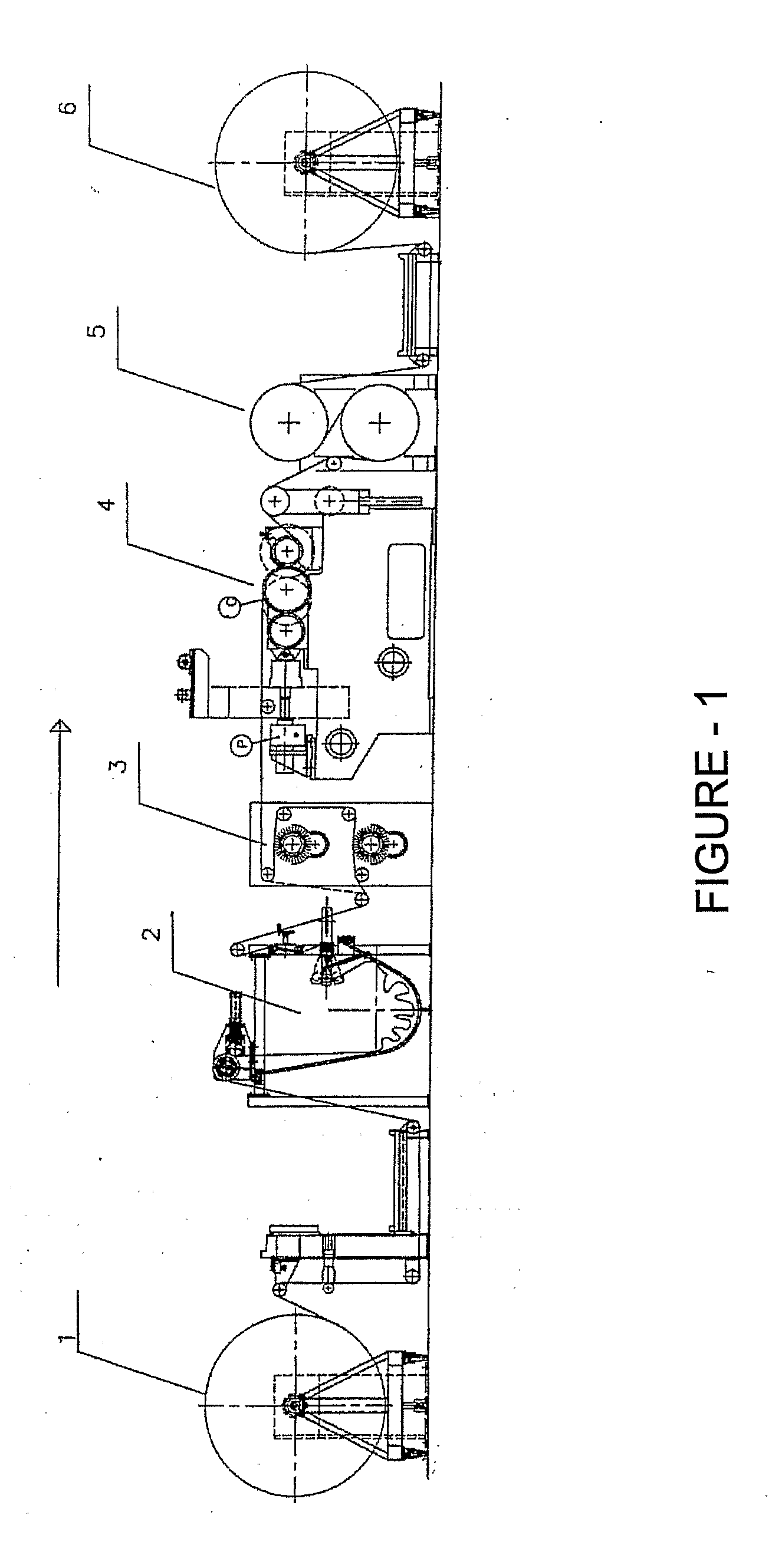

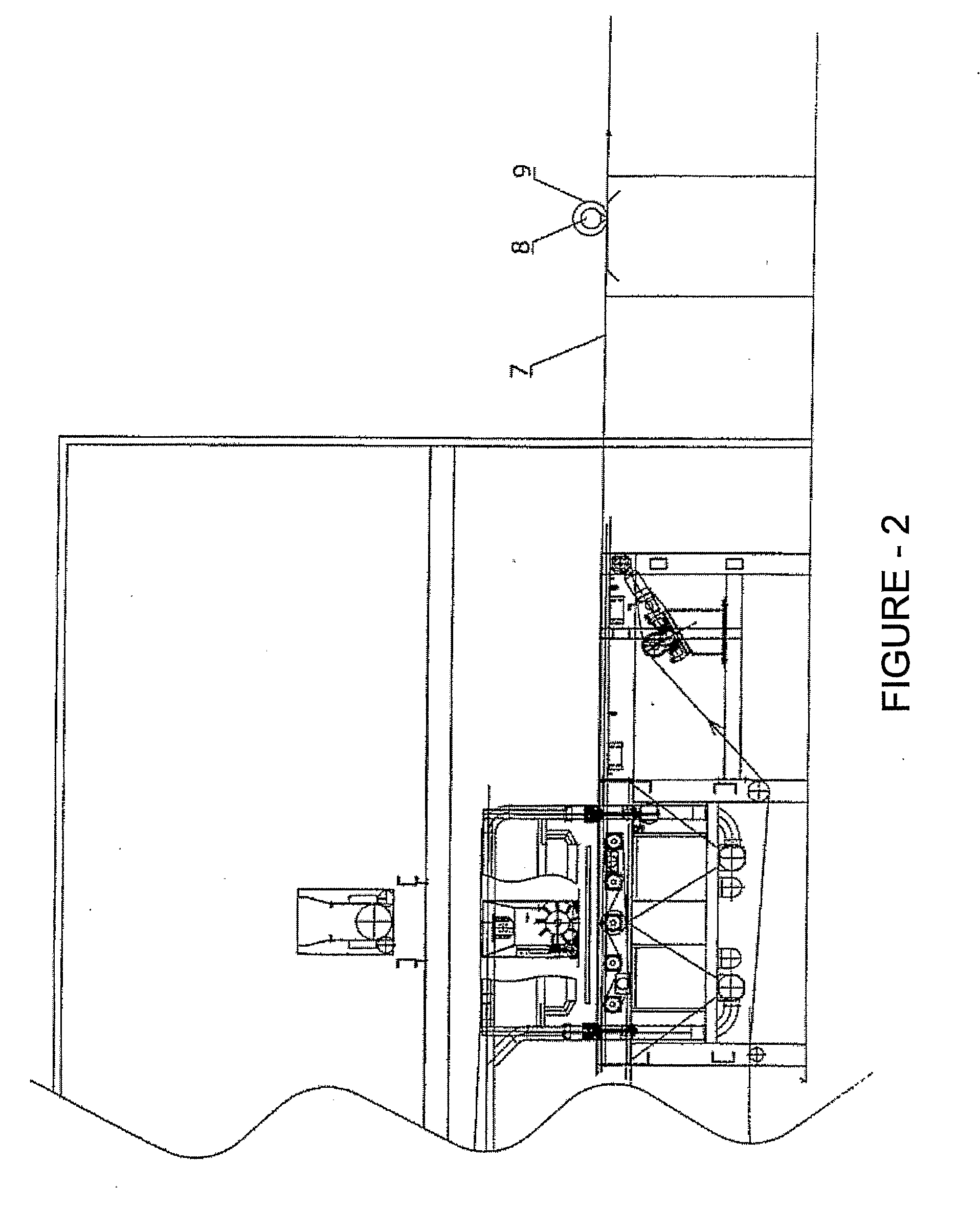

[0097]Main process steps of embossing machine according to the invention, which transfers pattern on flocked wet fabric, and processes applied by the said machine are as follows:[0098]1. Enabling pattern transfer by directly passing colour or natural flocked wet fabric from flocking unit between patterned steel cylinder (15) and lower steel cylinder (unpatterned cylinder) (14),[0099]2. Drying embossed and flocked wet fabric with courtesy of cold cylinder (29),[0100]3. Dying embossed and colour or natural flocked fabric in single or multiple-colour(s).

[0101]Colour or natural-colour flocked, wet fabric (but undyed) from flocking unit is directly transferred pattern by embossing machine according to the invention and if natural flock is used, various dying methods are used and the aforementioned processes are sequentially performed.

[0102]Emboss machine according to the invention, which transfers pattern on wet fabric, comprises following elements.[0103]Patterned steel cylinder (pattern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com