Three-dimensional curved surface stretch forming method based on surface-changing discrete mould

A discrete mold and stretch forming technology, which is applied in the field of sheet metal forming and stretch forming of large three-dimensional curved surface parts, can solve problems such as uneven deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

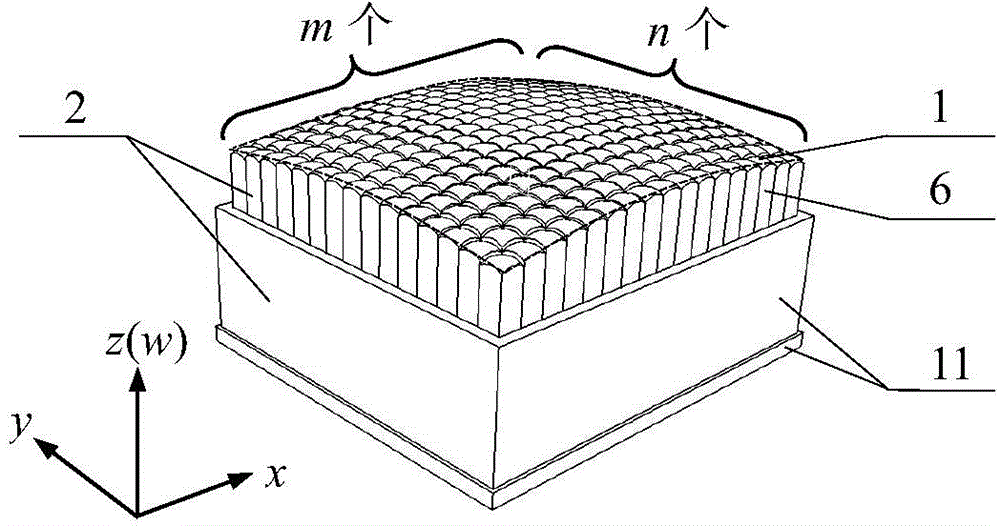

[0055] like figure 1 and figure 2 As shown, the discrete mold 2 for stretch forming is composed of basic unit units 6 arranged in m rows and n columns. During the stretch forming process of the sheet material 4, the change of the mold surface 1 is controlled by the relative height change of each basic body, and the movement of the discrete mold 2 includes the overall lifting of the discrete mold 2 and the movement of each basic body in the discrete mold 2. Relative movement between body units 6.

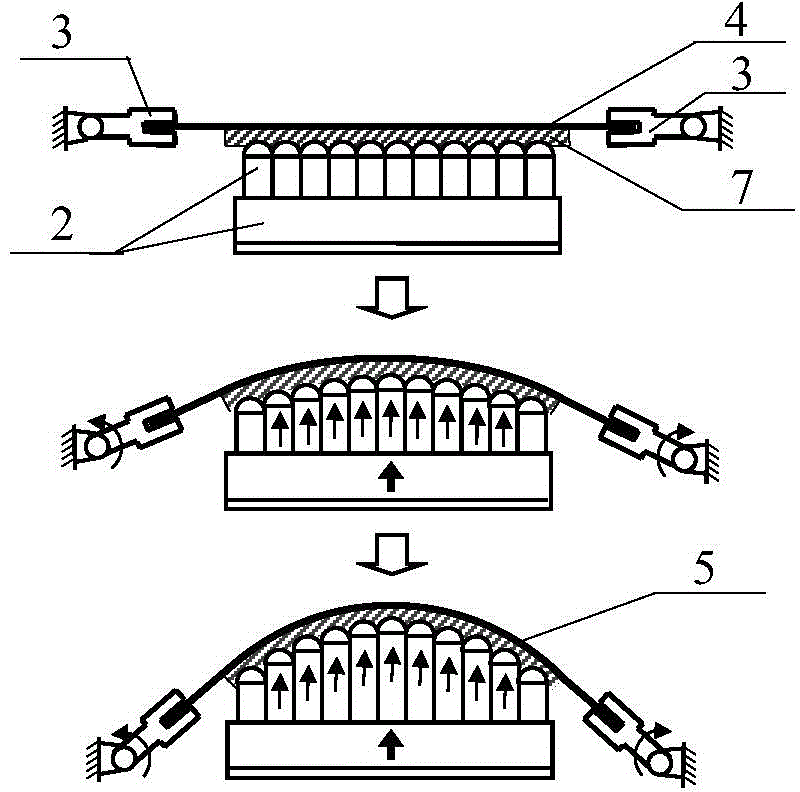

[0056] like figure 2 and Figure 4 As shown, the clamp 3 clamps the sheet 4, and during the stretch forming process, it rotates with the tangential change of the edge of the mold surface 1, but does not move in the horizontal and height directions.

[0057] like figure 2 and Figure 4 As shown in Fig. 1, through the movement of the discrete mold 2 and the rotation of the clamp 3, it is ensured that the sheet 4 is always fully attached to the mold surface 1 during the forming...

specific Embodiment

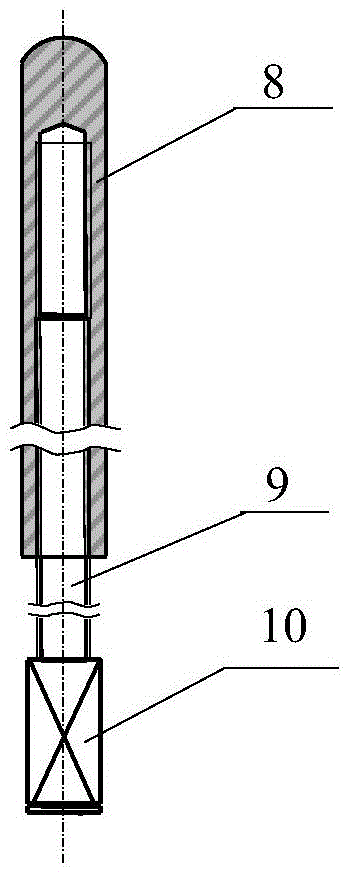

[0080] The sheet material 4 is 400mm×240mm, the thickness h=1mm; the target curved surface of the three-dimensional curved surface part 5 is a spherical surface with a radius of 360mm, and the forming area of the discrete mold 2 is 250mm×250mm; the discrete mold 2 consists of 10×10 basic body units 6 Composition, the size of the basic body is 25mm×25mm, the radius of the spherical head of the basic body unit 6 is r=15mm; the distance from the edge of the discrete mold 2 to the clamp 3 is l=45mm, and the elastic pad 7 is a polyurethane plate with a thickness H=30mm.

[0081] The specific steps of controlling the forming process of the three-dimensional curved surface stretch forming method based on the discrete mold of the deformed surface are as follows:

[0082] The first step: adjust the initial surface of the discrete mold 2 to a plane, and the clamp 3 clamps the sheet 4 to fit the initial plane of the mold;

[0083] The second step: determine the coordinate x of the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com