Melt flow control method and device for melt coating additive manufacturing

A flow control device and additive manufacturing technology, applied in the field of materials, can solve problems such as large time lag of melt, achieve fast and effective stabilization and control, fast and effective flow, and avoid forming defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail below in conjunction with accompanying drawing:

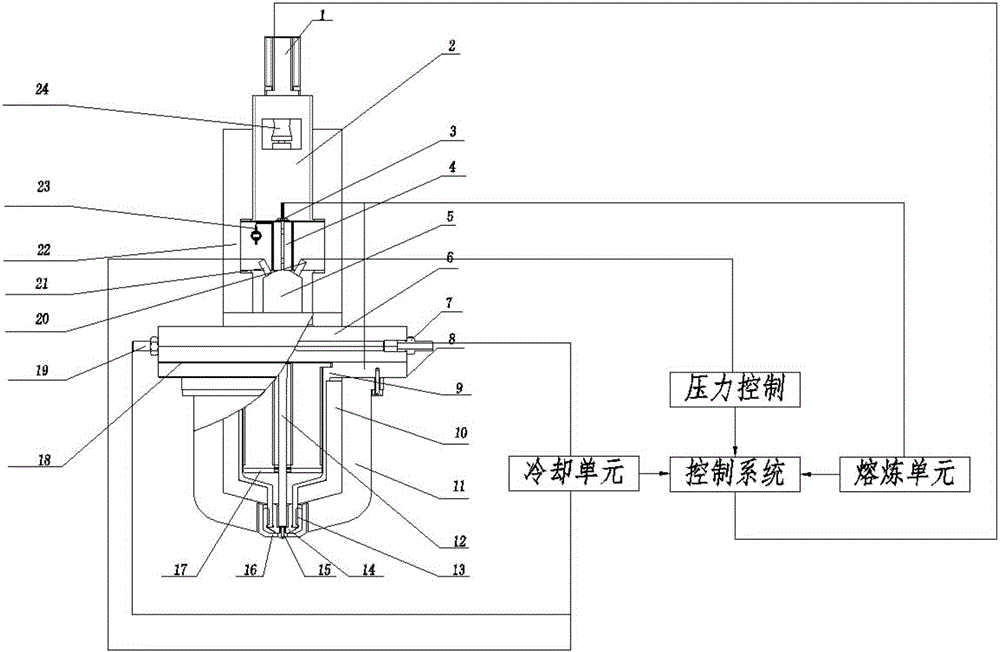

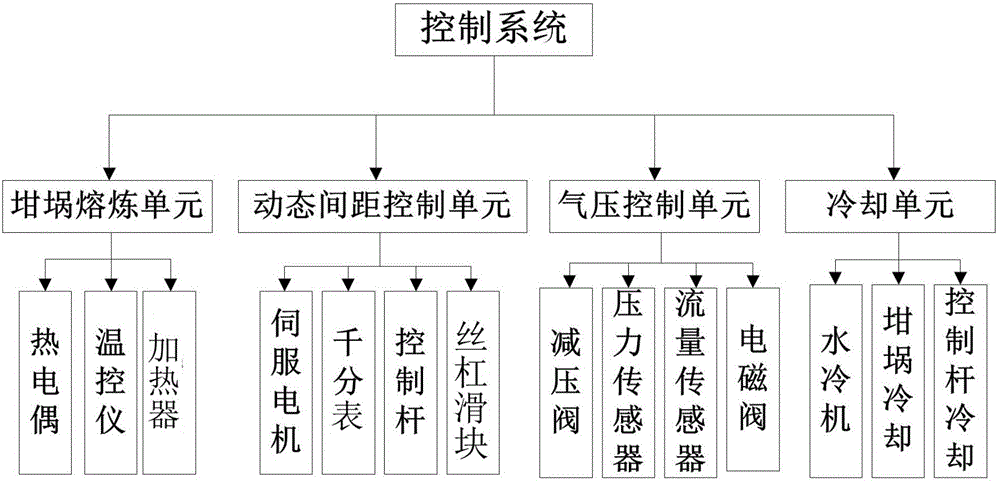

[0027] Such as figure 1 , figure 2 As shown: the present invention discloses a melt flow control device for fusion coating and additive manufacturing, including a crucible melting unit, a dynamic distance control unit, an air pressure control unit and a control system; the dynamic distance control unit communicates with the crucible through its control rod 12 The smelting unit is connected; the air pressure control unit is sealed and connected with the crucible smelting unit through the pipeline; the control system performs data feedback and control with the crucible smelting unit, the dynamic distance control unit and the air pressure control unit.

[0028] The crucible smelting unit comprises a crucible 9, a first temperature sensor and a filter 17 are arranged inside the crucible 9; a heater 10 and a thermal insulation cover 11 are arranged outside the crucible 9;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com