Rapid preparation method of titanium copper lamellar electrode composite material

A composite material and layered technology, applied in the direction of electrodes, chemical instruments and methods, lamination, etc., can solve the problems of high thermal cracking tendency, high cost, high thermal stress, etc., and achieve low equipment cost, high yield and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

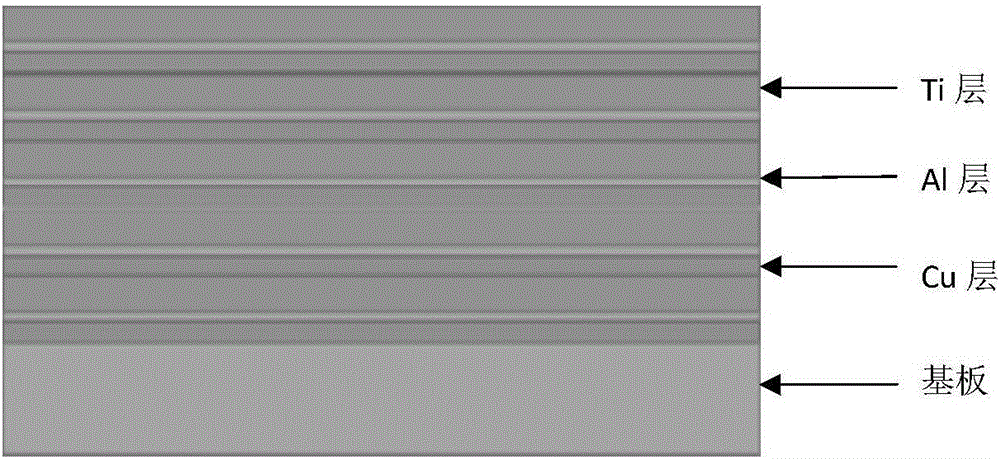

[0030] Take out the 0.2mm Ti foil, 0.1mm Cu foil and 0.015mm aluminum foil, and simply scrub the surface with alcohol to remove the oil on the surface of the material. Taking "Cu foil-Al foil-Ti foil" as a unit, the Ti foil is on the upper layer during consolidation, and a sample containing 5 units is prepared with a thickness of 1.5mm (ignoring the thickness of the aluminum layer), figure 1 for its schematic diagram.

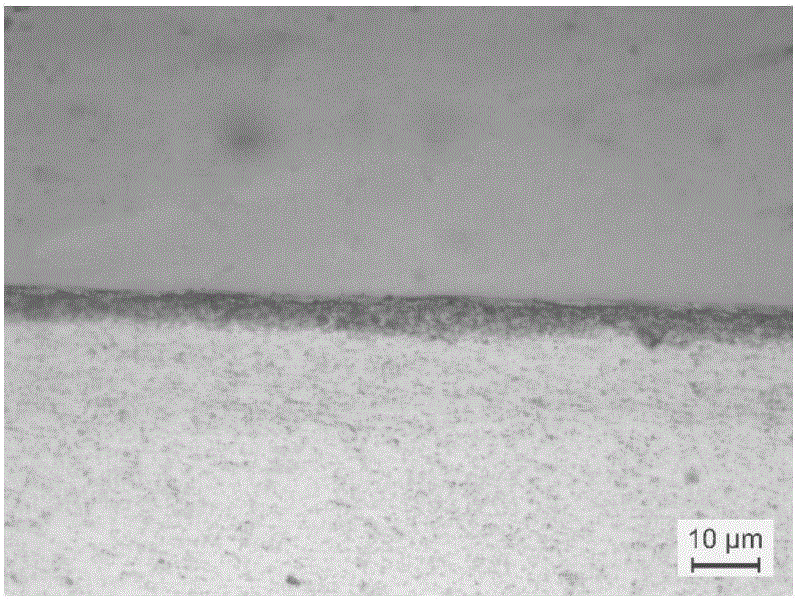

[0031] After pre-treatment, the material is subjected to ultrasonic consolidation processing: at a temperature of 170°C, a consolidation pressure of 2205N, an amplitude of 40μm, and a consolidation speed of 10mm / s are used for consolidation preparation. By adding the aluminum layer, not only the connectivity of copper and titanium is improved, but also the copper layer is buffered to a certain extent to prevent the copper layer from being broken due to excessive pressure.

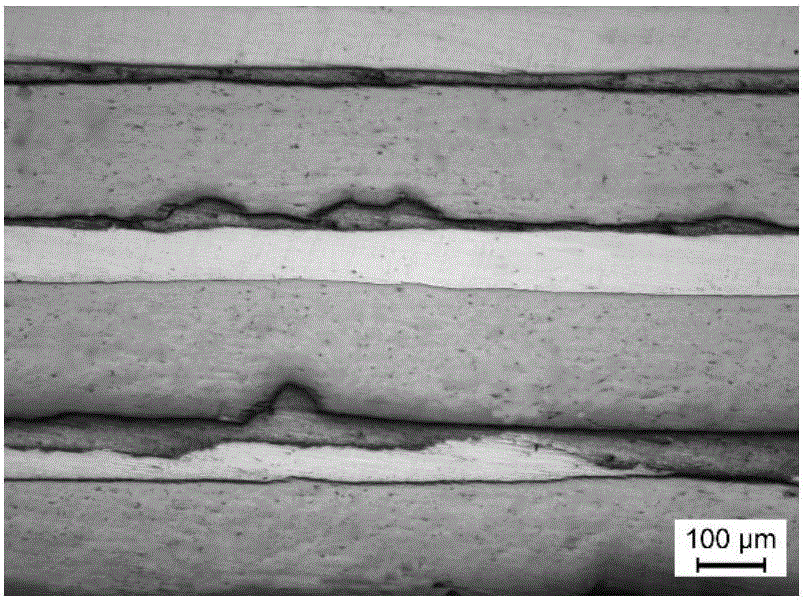

[0032] The metallographic photograph of the titanium-copper layered electrode composite...

Embodiment 2

[0035] The raw materials and processing methods are kept unchanged, and titanium-copper layered electrode composite materials with different layer thickness ratios are prepared. Consolidate a layer of titanium foil first, adopting the following process parameters: the consolidation pressure is 2000N, the amplitude is changed to 35μm, and the consolidation speed is 25mm / s; then six layers of copper foil are consolidated. The intermediate transition layer metal aluminum foil is added between the materials, and the process parameters adopted are: the consolidation pressure is 1764N, the amplitude is changed to 30μm, and the consolidation speed is 25mm / s; finally, a layer of titanium metal foil is consolidated, and the process parameters are the same as the first same layer, image 3 for its schematic diagram.

[0036] The metallographic photograph (copper and self-solidification) of the layered electrode composite material that the present embodiment makes is as follows Figure...

Embodiment 3

[0038] The raw materials and processing principles adopted remain unchanged. The intermediate transition layer was changed to two layers of metal aluminum foil, and the same consolidation parameters as in Example 1 were adopted. The metallographic photograph of the composite material prepared in this embodiment is shown in FIG. 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com