Bypass shunt double-sided arc welding device and welding method

An arc welding, double-sided technology, applied in the direction of arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems that the welding process is not easy to control, affect the bypass shunt effect, increase the disturbance of the molten pool, etc., to improve the welding quality, Avoid weld formation defects, arc current density and the effect of electromagnetic force distribution concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

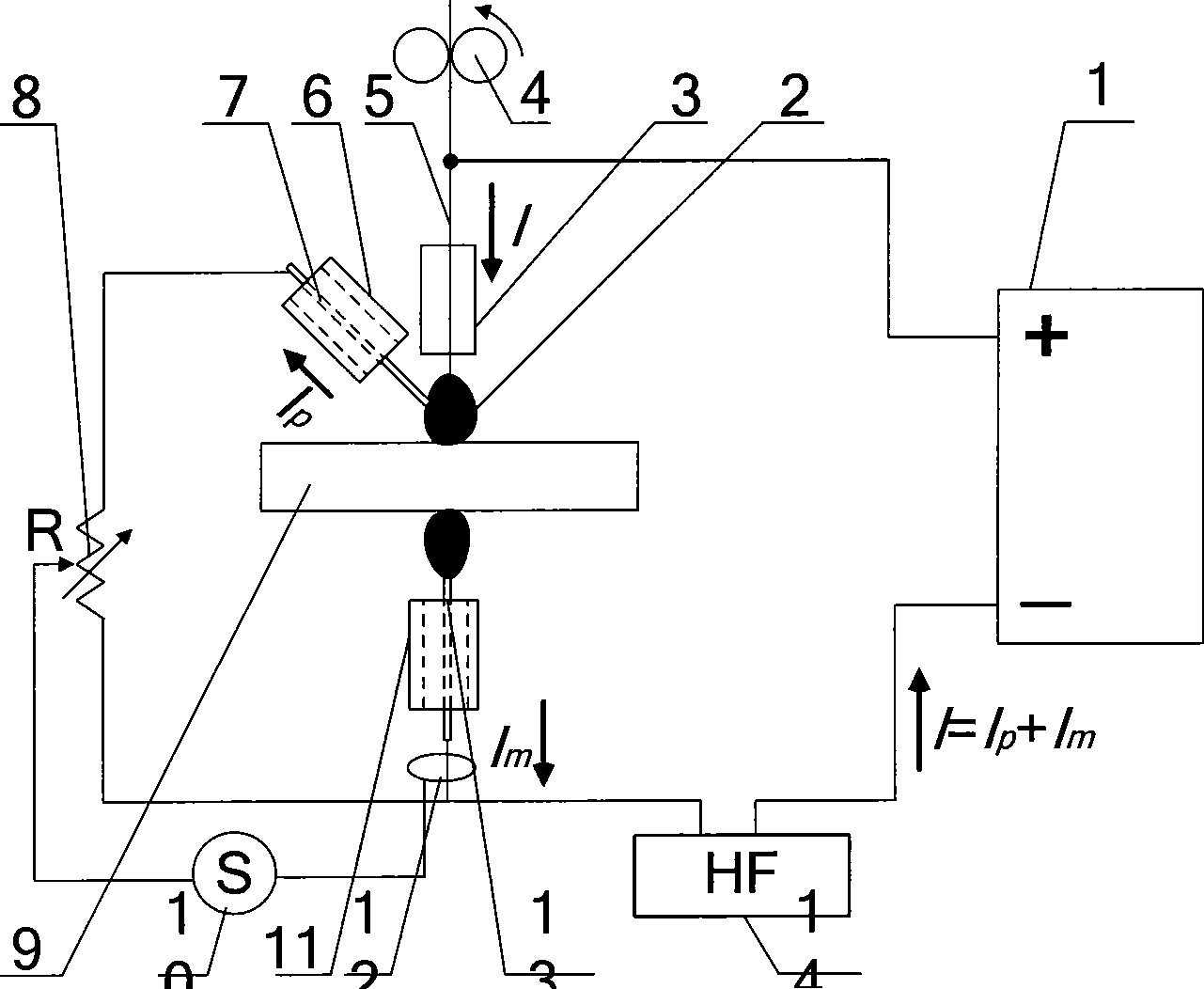

[0026] combine figure 1 , it is a bypass shunt melting electrode-non-melting electrode double-sided arc welding implementation mode, this embodiment consists of welding power source 1, melting electrode main welding torch 3, non-melting electrode auxiliary welding torch 11, bypass tungsten argon arc welding torch 6. Composed of current sensor 12, arc starter 14, bypass resistor 8 and its control system 10, etc. The workpiece 9 is not connected to the welding power supply 1, and the main welding torch 3 and the auxiliary welding torch 11 are symmetrically placed on both sides of the workpiece, and are respectively connected to the positive and negative poles of the welding power supply 1, and a tungsten argon arc welding torch is applied to the main welding torch 3 side of the melting electrode. 6 as a bypass to shunt a part of the welding current through the workpiece 9. Turn on the welding power supply 1, start the arc starter 14, ignite the welding arc, detect the magnitude...

specific Embodiment approach 2

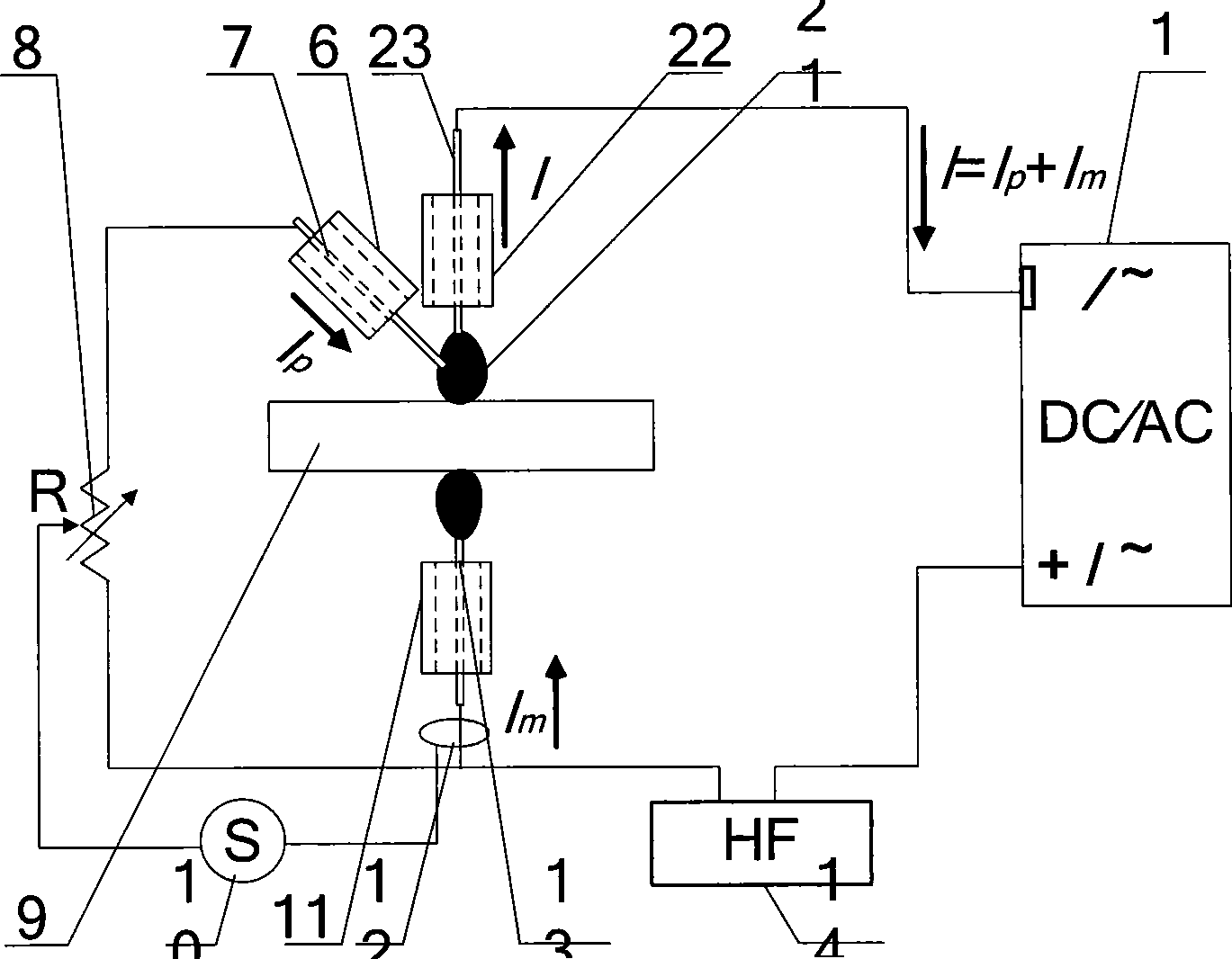

[0034] combine figure 2, it is a non-melting pole-non-melting pole double-sided arc welding implementation mode with bypass shunting. Arc welding torch 6, current sensor 12, arc starter 14, bypass resistor 8 and its control system 10 and so on. The workpiece 9 is not connected to the welding power supply 1, and the main welding torch 22 and the auxiliary welding torch 11 are symmetrically placed on both sides of the workpiece, respectively connected to the two poles of the welding power supply 1, and the argon tungsten arc welding torch 6 is applied on the side of the main welding torch 22 as a bypass. Part of the welding current passing through the workpiece 9 is shunted. Turn on the welding power supply 1, start the arc starter 14, ignite the welding arc, detect the welding current flowing through the workpiece 9 through the current sensor 12, and change the bypass resistor 8 through the control system 10 to adjust the bypass current I p , and then adjust the welding curr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com