Roll forming method for stainless steel thick-wall ring forged piece

A technology of stainless steel and stainless steel bar, applied in the field of rolling and forming of stainless steel thick-walled ring forgings, can solve the problems of reducing the strength of the ring, wasting materials, destroying the metal flow line of the end face of the forging, etc., and achieves the effect of meeting the deformation requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0030] The main chemical element content (percentage by weight) of the alloy is: 0.10% to 0.16% of C, 10.50% to 12.00% of Cr, 1.40% to 1.80% of Ni, 1.50% to 2.00% of W, The Mo content is 0.35%-0.50%, the V content is 0.18%-0.30%, the Mn content is ≤0.60%, the Si content is ≤0.60%, the S content is ≤0.025%, the P content is ≤0.030%, and the balance is Fe.

[0031] The steps of this method are as follows:

[0032] Step 1: Prepare the intermediate blank

[0033] The 1Cr11Ni2W2MoV alloy rods cut according to the specifications are heated to the deformation temperature of 1140 ° C ~ 1180 ° C in the forging heating furnace, upsetting, punching, and pre-rolled into a rectangular ring billet.

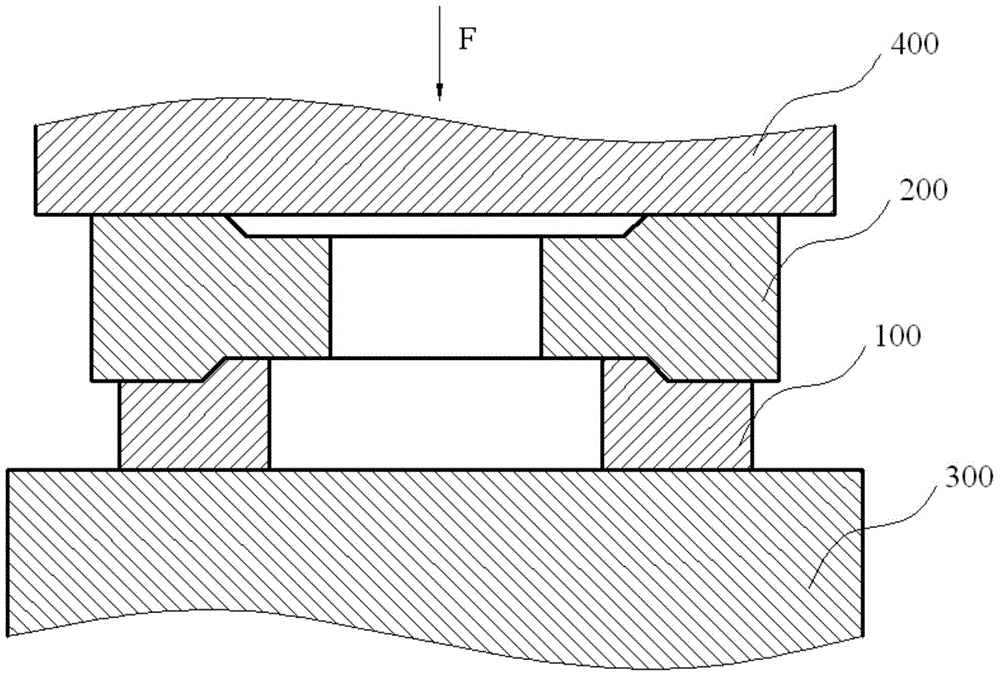

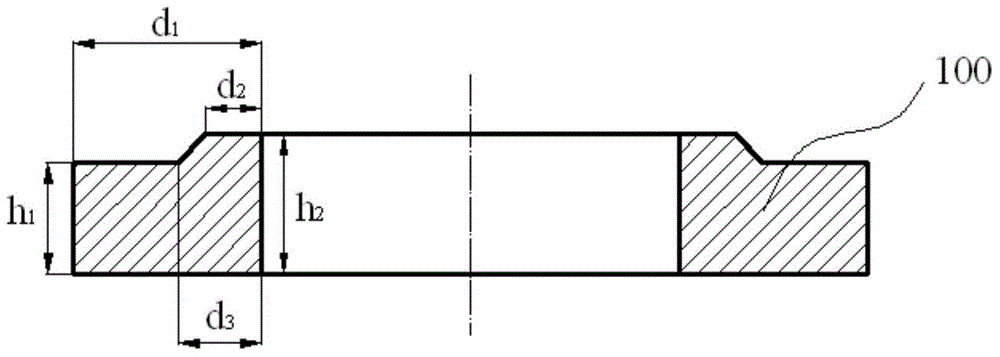

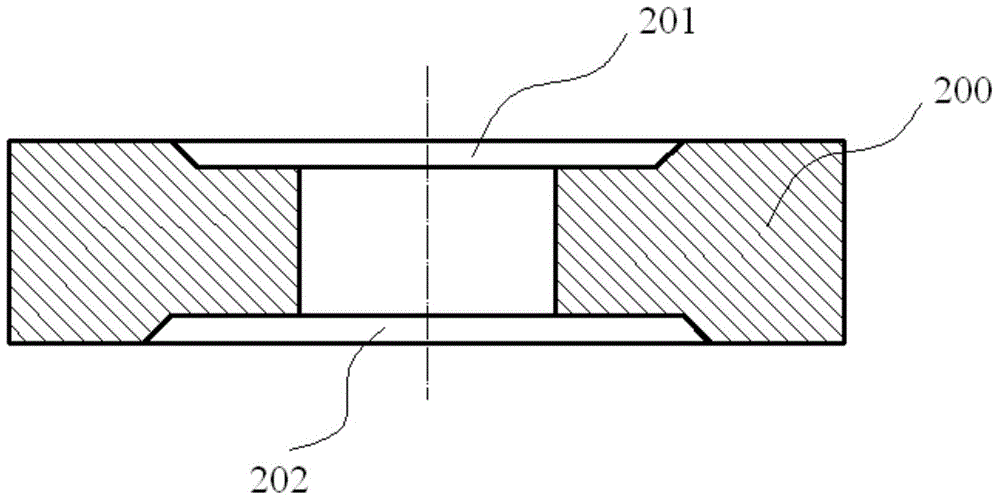

[0034] Put the rectangular ring blank on the cutting board 300 of the press, and then place the special mold 200 evenly on the rectangular ring blank, as figure 1 As shown, the pressing hammer 400 is driven downward with a downward force of F=400KN-3800KN, and the rectangular ring blank is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com