Solar cell and preparation method thereof

A solar cell, amorphous silicon layer technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as unfavorable cell conversion efficiency and complex preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

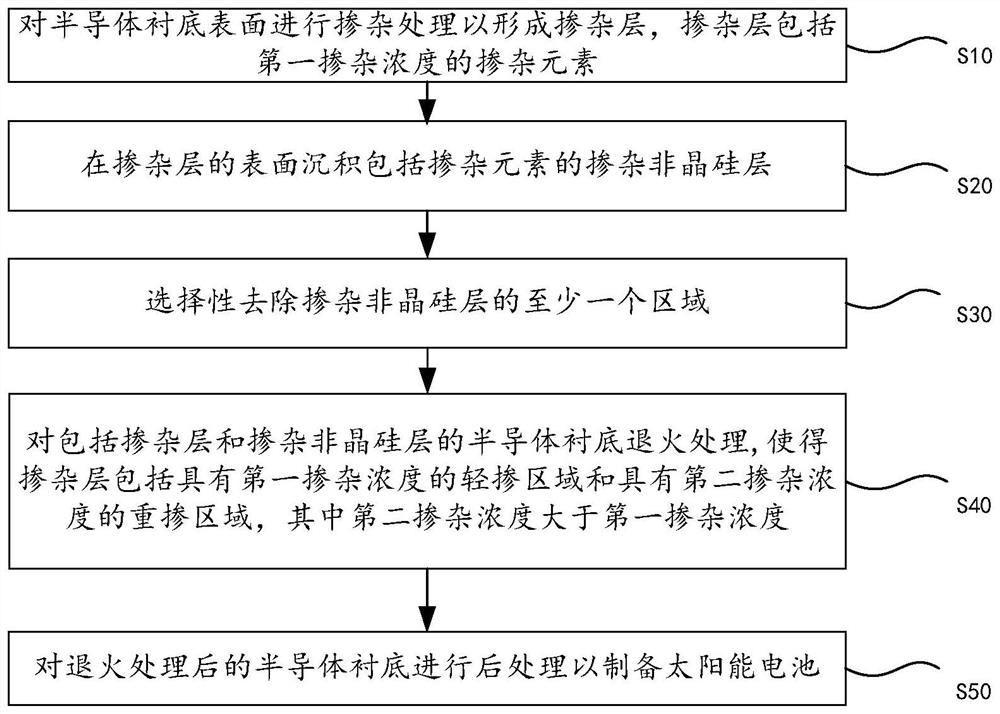

[0052] See figure 1 , figure 1 A flowchart of a method for preparing a solar cell provided in an embodiment of the present invention specifically includes the following steps:

[0053] Step S10 , performing doping treatment on the surface of the semiconductor substrate to form a doped layer, where the doped layer includes a doping element of a first doping concentration. Wherein, the formed doped layer may form a PN junction structure with the semiconductor substrate.

[0054] Specifically, an N-type or P-type doped layer may be formed on the surface of the semiconductor substrate by using any one or more methods of high temperature diffusion, slurry doping or ion implantation.

[0055] Exemplarily, taking the Topcon cell as an example, boron diffusion doping is performed on the front side (the surface facing the sun) of the N-type semiconductor substrate to form a P-type doped layer (P+ layer). Then deposit a boron-doped amorphous silicon layer on the surface of the P-type...

Embodiment approach

[0067] One-step deposition method: forming an amorphous silicon layer on the surface of the doped layer and simultaneously performing in-situ doping treatment to form the doped amorphous silicon layer; or,

[0068] Two-step deposition method: an amorphous silicon layer is deposited on the surface of the doped layer, and then the amorphous silicon layer is doped to form a doped amorphous silicon layer.

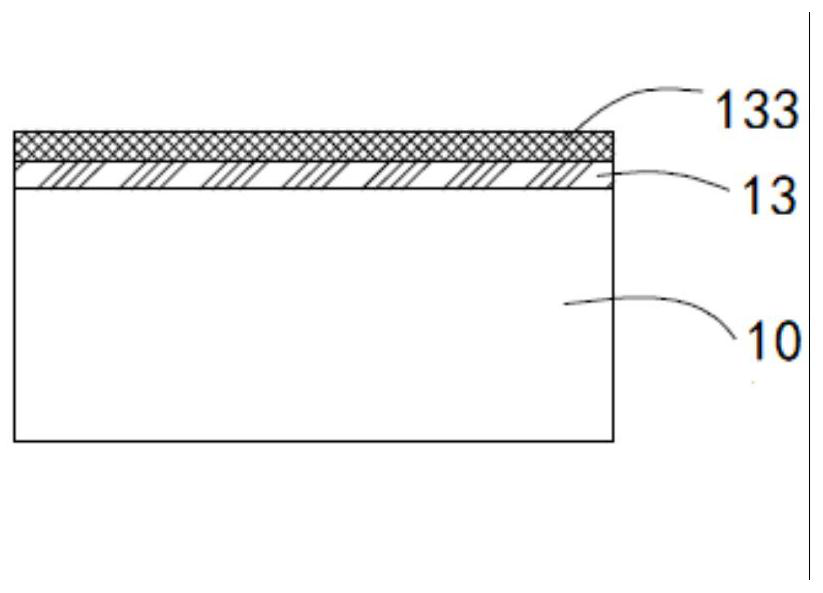

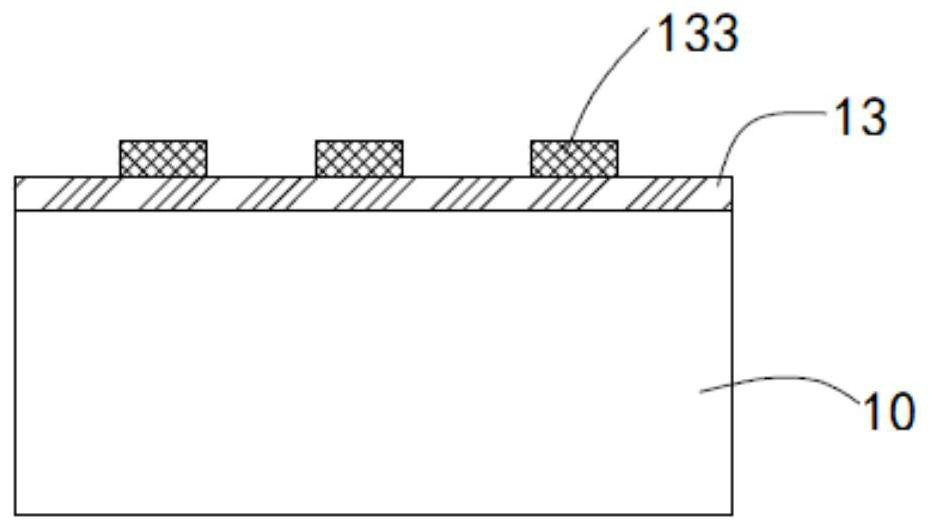

[0069] It should be noted that, if Figure 2a-2c As shown, the in-situ doped amorphous silicon is deposited on the surface of the doped layer 13, that is, the doped amorphous silicon layer 133 is formed by PEVCD or PVD, and the amorphous silicon layer is doped while depositing.

[0070] The doping process may also adopt any one or more methods of high temperature diffusion, slurry doping or ion implantation. The doped amorphous silicon layer 133 can be a P-type amorphous silicon layer, and its doping element can be three main group elements such as boron, gallium or indium; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com