A high-efficiency selective emitter solar cell laser doping method

A solar cell and laser doping technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of low peripheral energy density, reduced absorption, uneven distribution of beam energy density, etc., to reduce uneven deformation of the battery, reduce The probability of local breakdown and the effect of reducing beam energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A laser doping method for a highly efficient selective emitter solar cell, comprising the following steps:

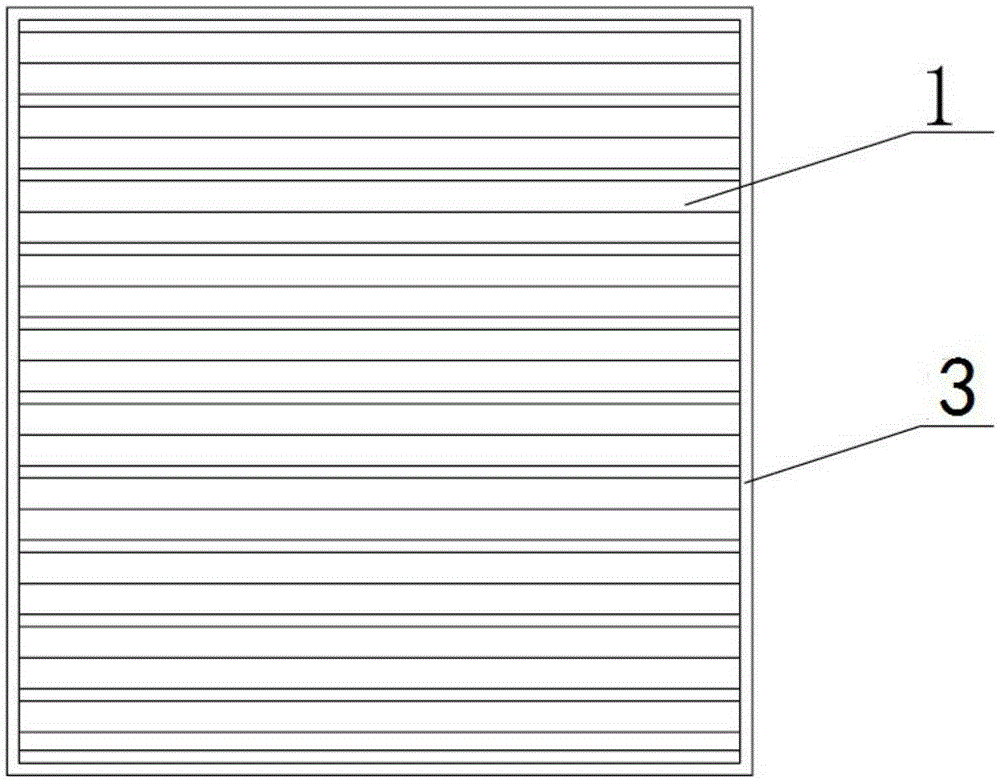

[0030] (1) Use a P-type polycrystalline silicon wafer with a size of 156mm×156mm, clean and texture it, clean and texture the crystalline silicon wafer, use the thermal diffusion process to perform preliminary impurity diffusion on the silicon wafer, and control the concentration of impurity sources and diffusion time Make the crystalline silicon square resistance value reach the required size (such as 70-90Ω), so that a pre-coating layer is formed on the surface of the crystalline silicon wafer;

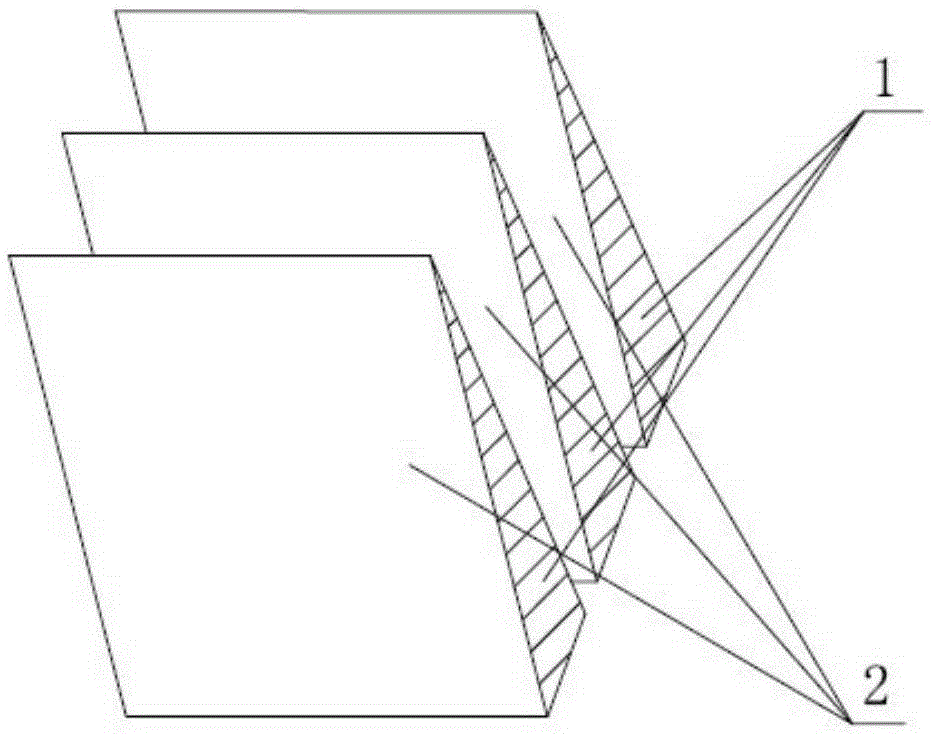

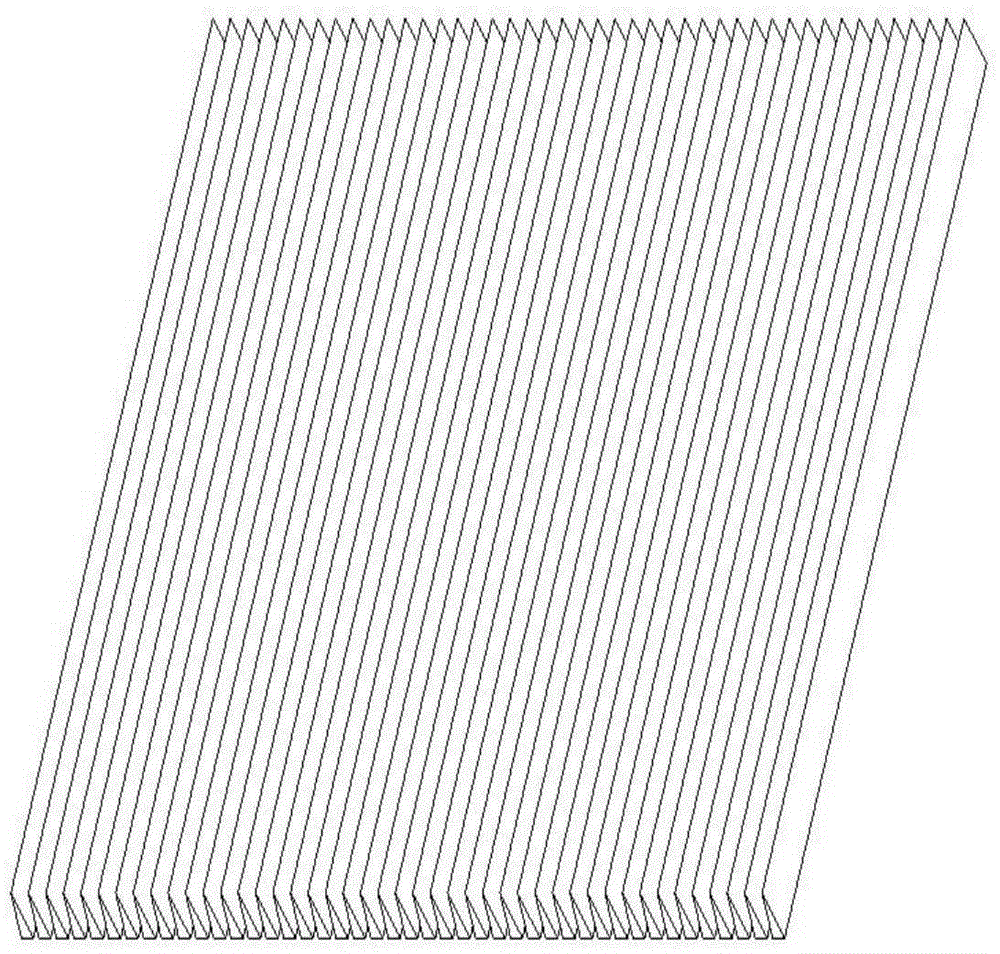

[0031] (2) Send the P-type polysilicon wafer directly under the mask plate, so that the geometric center of the P-type polysilicon wafer coincides with the geometric center of the mask plate, and the light leakage gap of the mask plate coincides with the fine grid of the cell on the P-type polysilicon wafer , the mask plate is closely attached to the P-type polysilicon...

Embodiment 2

[0037] A laser doping method for a highly efficient selective emitter solar cell, comprising the following steps:

[0038] (1) Use a P-type polycrystalline silicon wafer with a size of 156mm×156mm, clean and texture it, clean and texture the crystalline silicon wafer, use the thermal diffusion process to perform preliminary impurity diffusion on the silicon wafer, and control the concentration of impurity sources and diffusion time Make the square resistance of crystalline silicon at 70-90Ω, so that a pre-coating layer is formed on the surface of crystalline silicon wafer;

[0039] (2) Send the P-type polysilicon wafer directly under the mask plate, so that the geometric center of the P-type polysilicon wafer coincides with the geometric center of the mask plate, and the light leakage gap of the mask plate coincides with the fine grid of the cell on the P-type polysilicon wafer , the mask plate is closely attached to the P-type polysilicon wafer;

[0040] The mask plate inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com