Patents

Literature

49results about How to "Reduce uneven deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

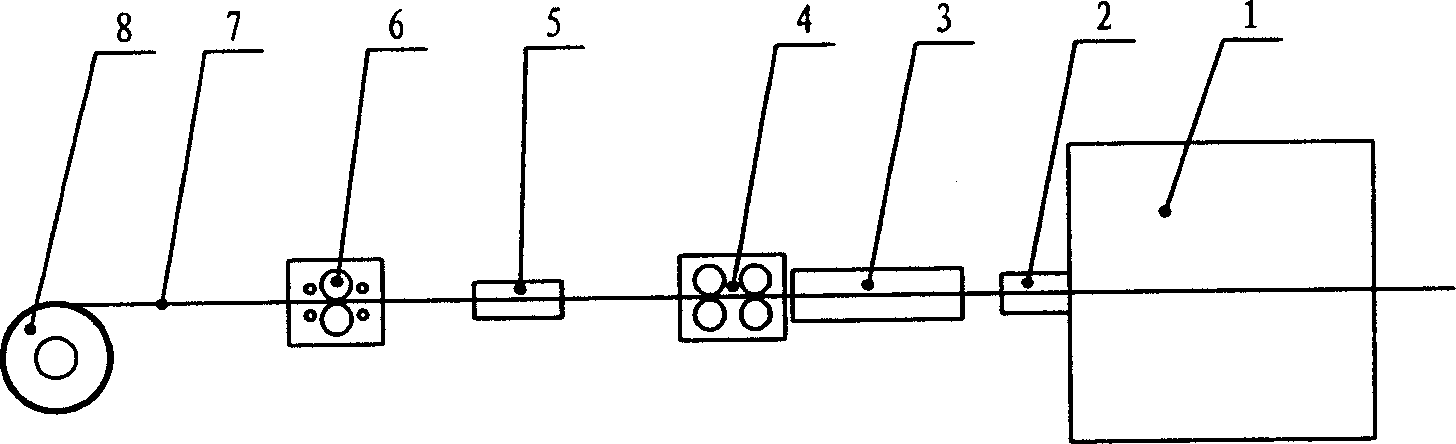

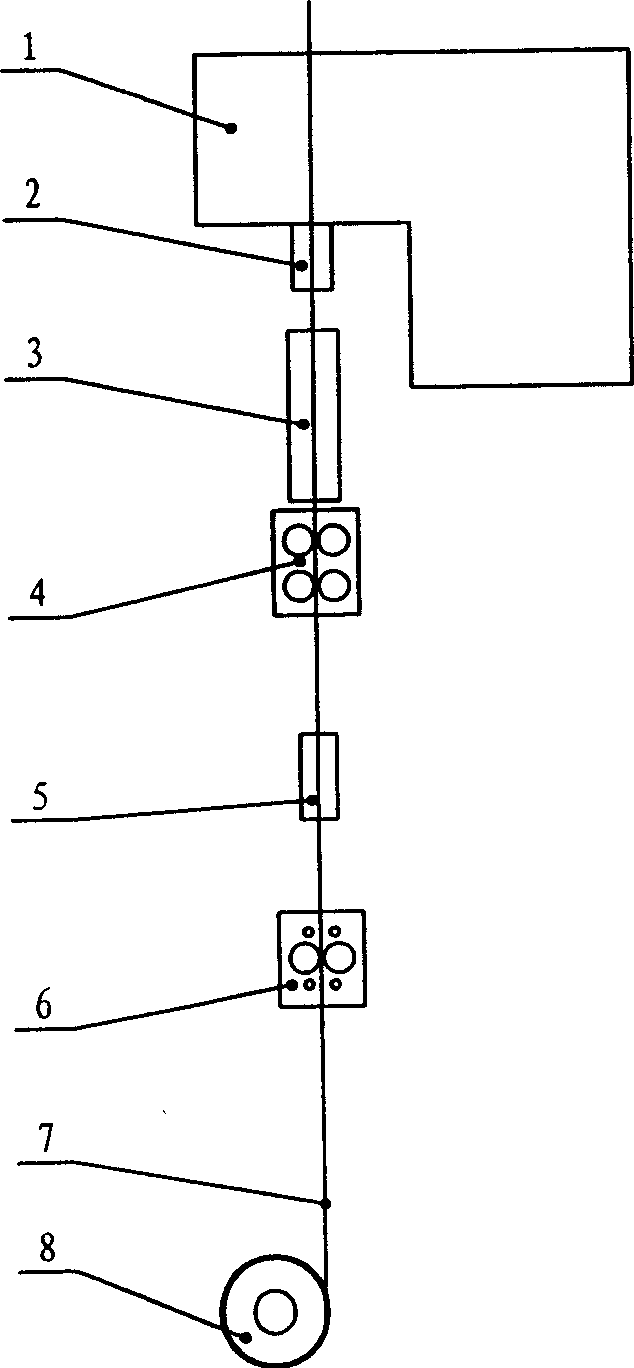

Casting-milling process method for manufacturing copper and copper alloy band

InactiveCN1730181AIncrease the elongation factorReduce energy consumptionWork treatment devicesMetal rolling arrangementsNitrogen gasDynamic recrystallization

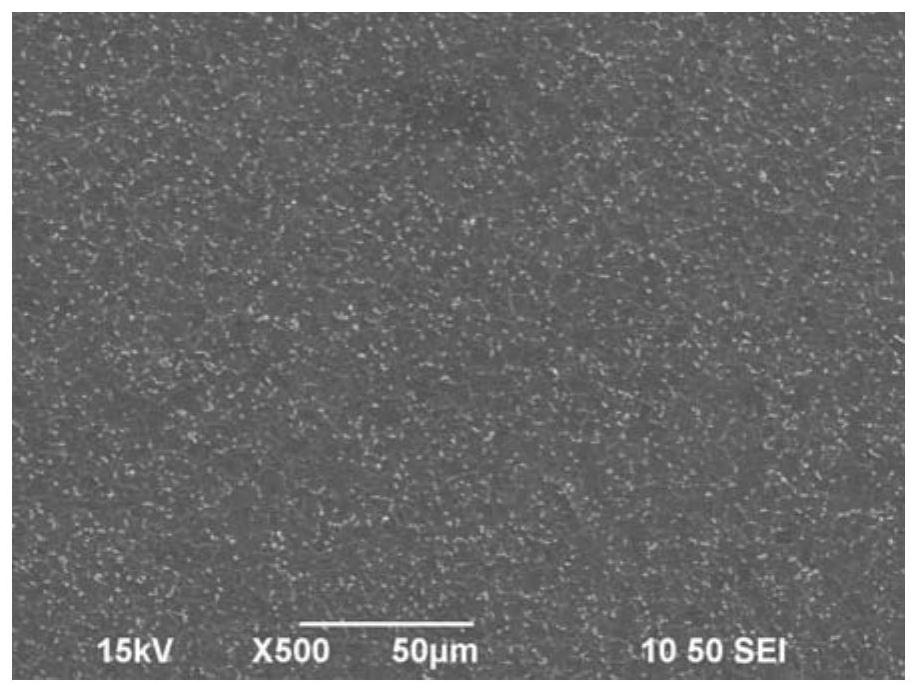

The invention relates to a processing method for copper and copper alloy strip, which pertains to sheet metal strip casting, heat-rolling and machining technology. Specifically, the invention adopts continuous casting, hot rolling, thermomechanical treatment and machining principle and subjects band of horizontal continuous casting and downward continuous casting to heat preservation and samming, rapidly cooling after directly hot-rolling, on-line surface milling and rolling to built-up coil. Rolling is operated under the condition of exceeding recrystallization temperature and nitrogen protection. In the rolling, dynamic recrystallization of band structure takes place. The invention provides photo-quality and high-accuracy blank for cold rolling of end product.

Owner:JIANGSU XINGRONG HI TECH

Control method of local loading and shaping equiaxial alpha content of titanium alloy

InactiveCN101603163AAvoid abnormal growthReduce uneven deformationHeat treatment process controlLoad stepTitanium alloy

The invention discloses a control method of local loading and shaping equiaxial alpha content of titanium alloy. After a blank is changed to forge and is pre-shaped, a shaped forging piece is obtained by isothermal local loading and shaping, finishing and heat treating. Local loading is finished by two passes, and each pass is finished by two loading steps. A mould is divided into two to three modules, and the relative position of different modules can be adjusted. In each loading step in the same pass, different modules are used for carrying out deforming on the blank; after all loading steps in the pass are finished, the next step is started, the loading method in the last step is repeated to finish the forging piece deformation; the equiaxial alpha phase volume fraction effectively controlling the local loading and shaping of the forging piece is obtained, and is controlled within 10-20%; the equiaxial alpha phase volume fraction of different positions on the forging piece differs within 5%; equiaxial alpha crystal and beta crystal are both even and small, have no phenomena of coarsing, unevenness and extraordinary growth, and have favourable mechanical property.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

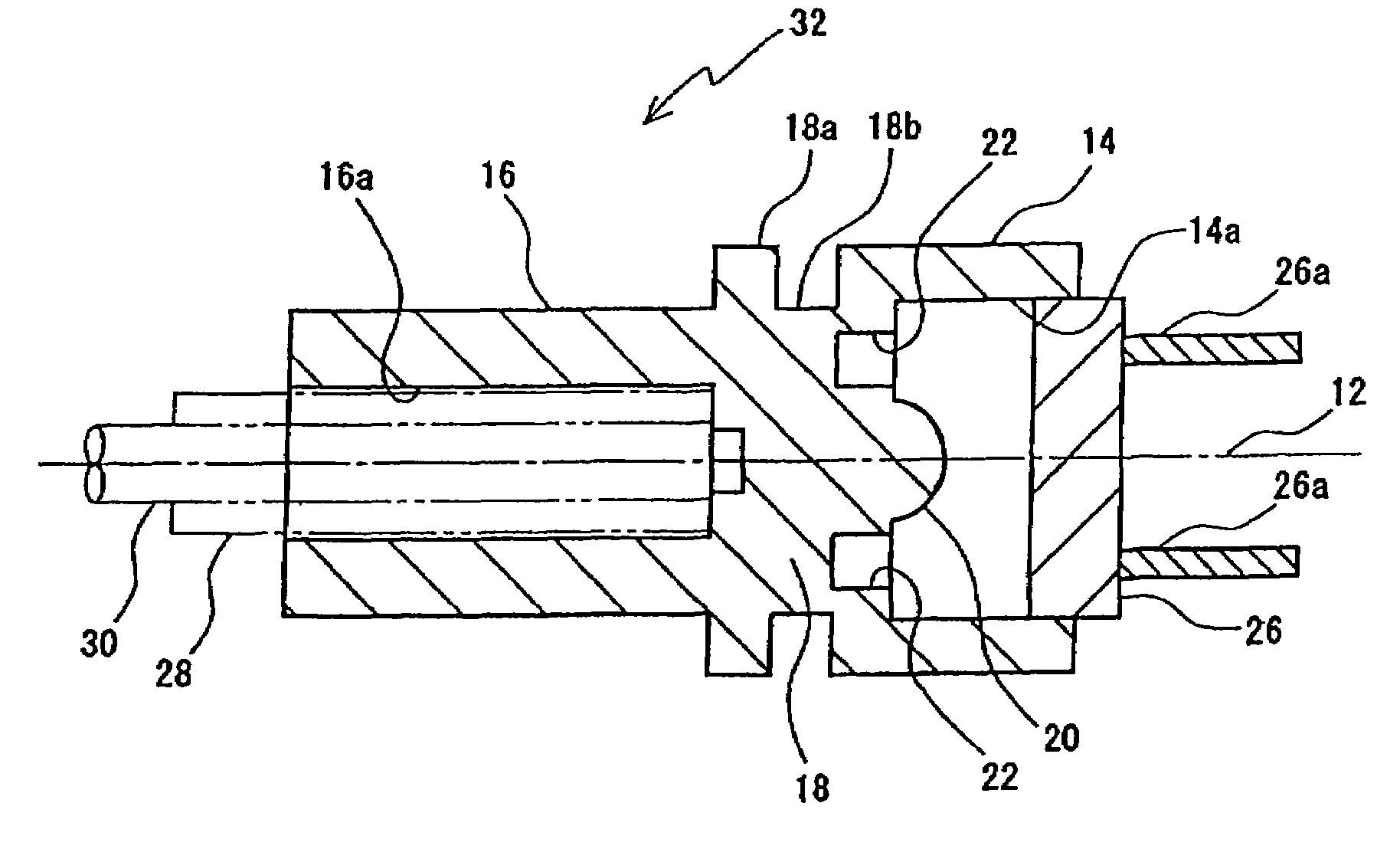

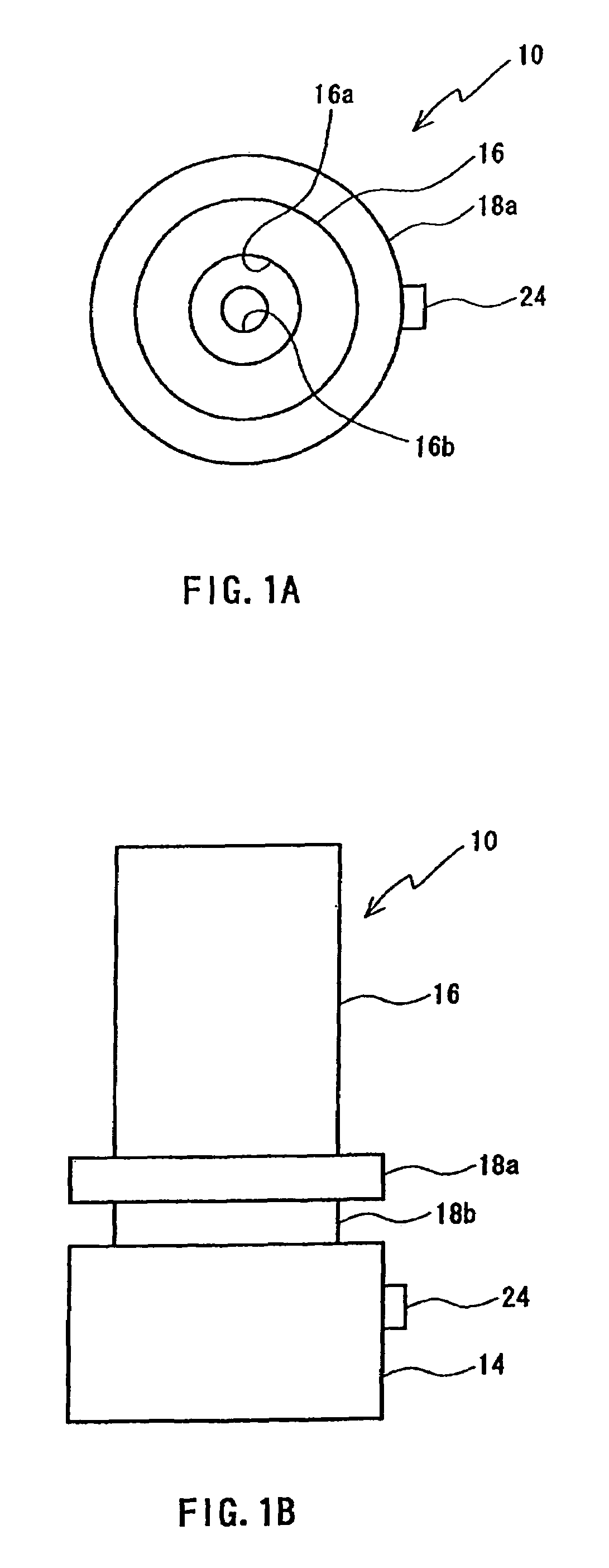

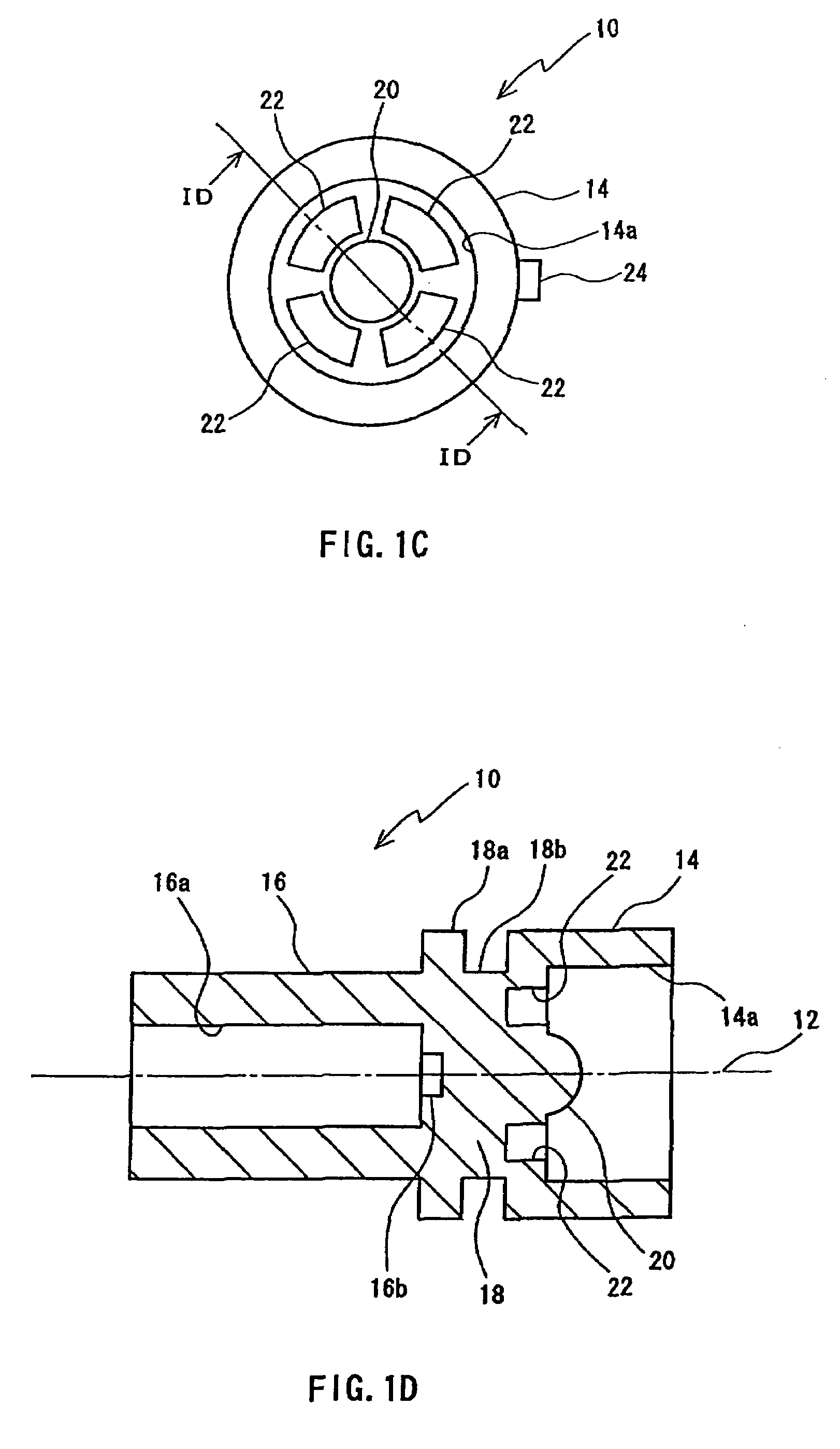

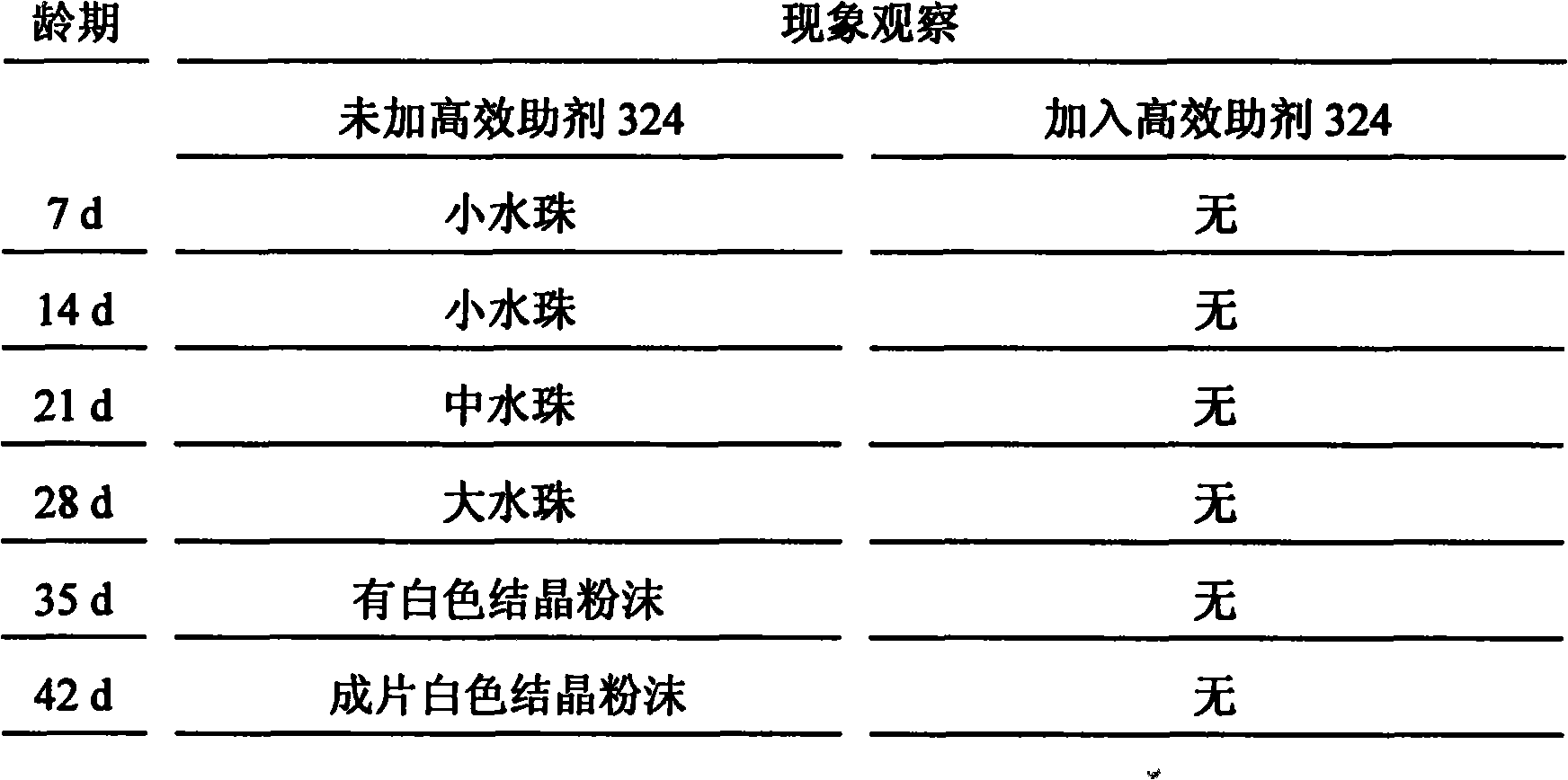

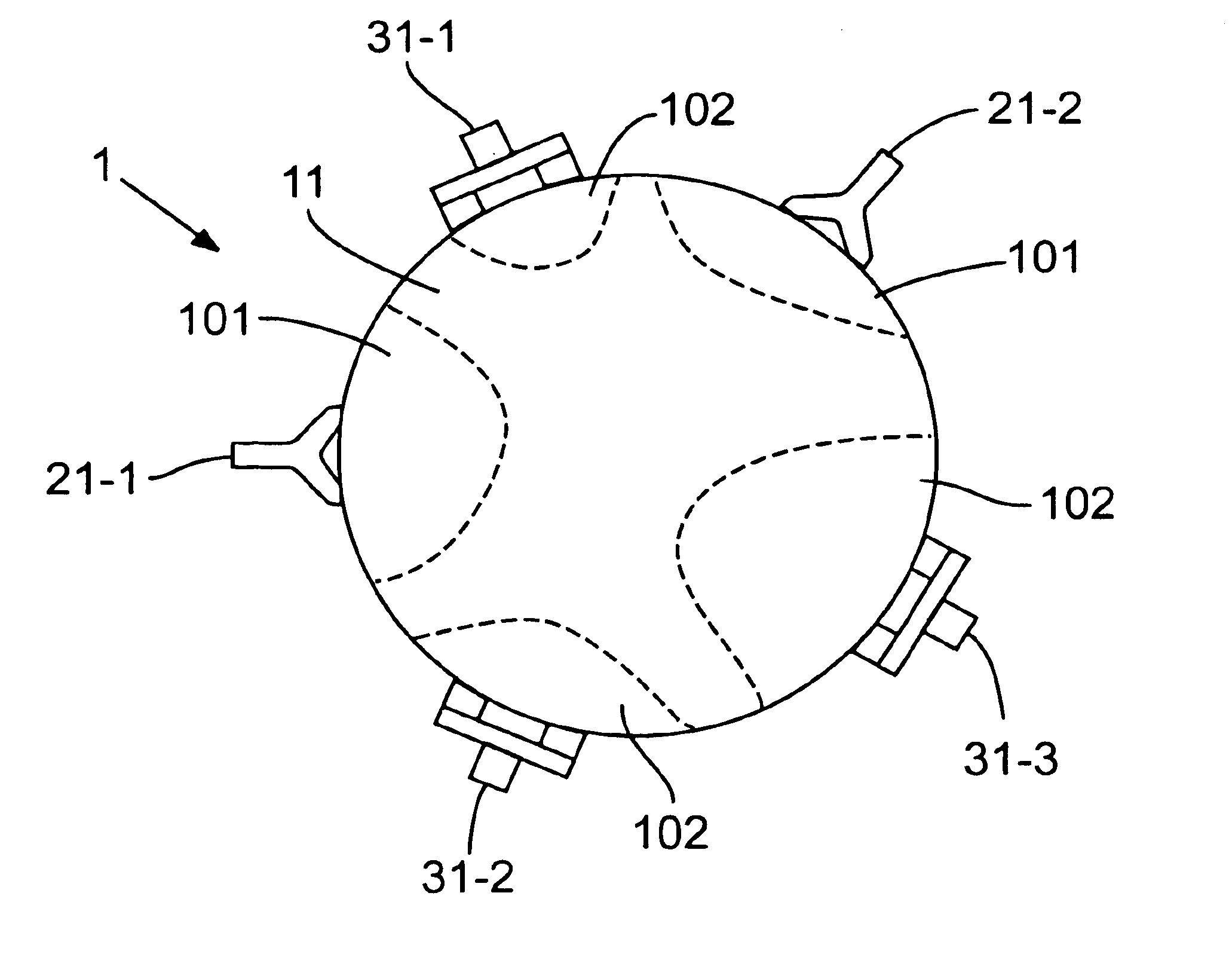

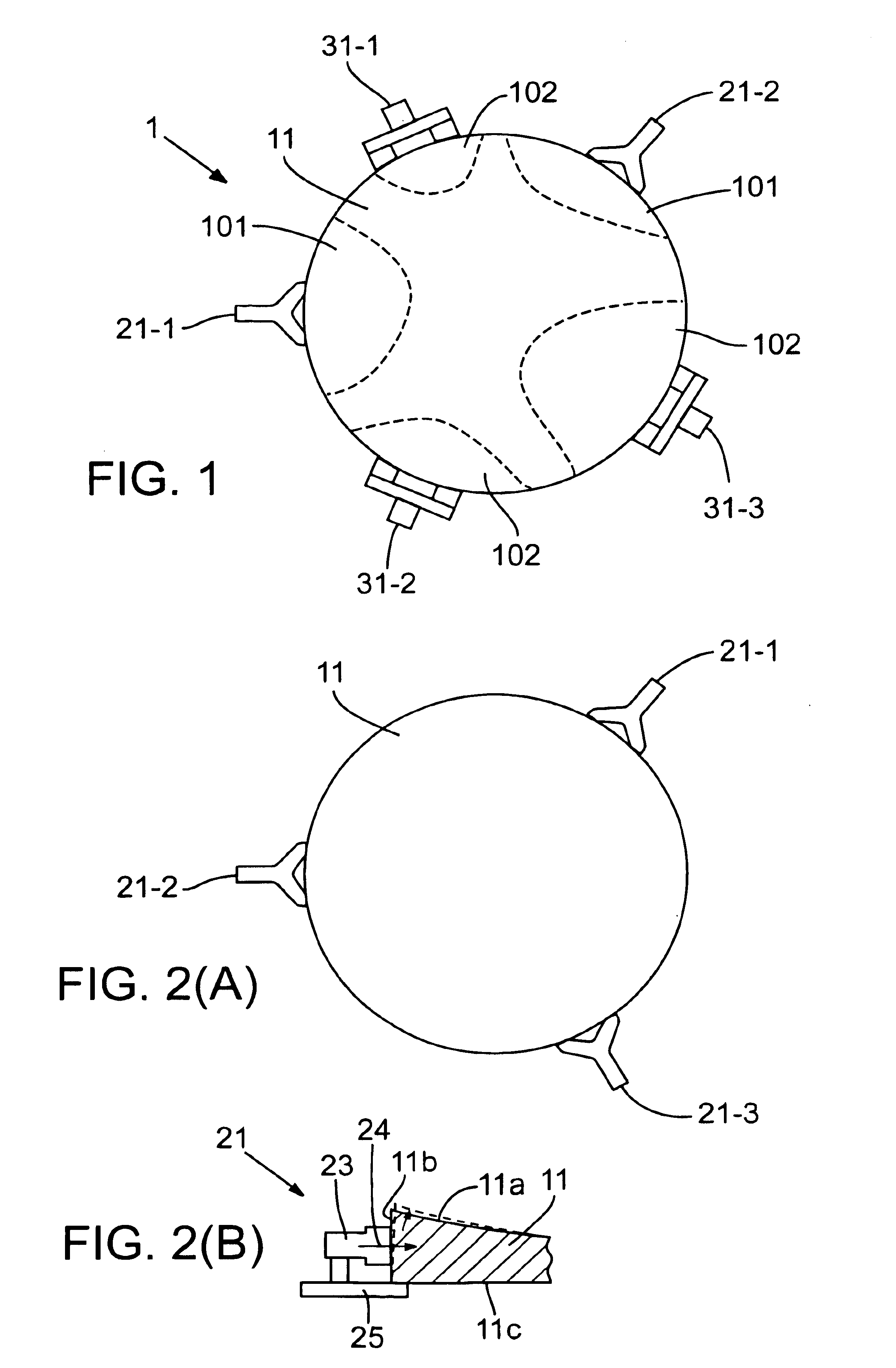

Holder for optical modules, optical module and optical connector

InactiveUS7348540B2Reduce uneven deformationRadiation pyrometryMaterial analysis by optical meansOptical ModuleEngineering

An optical module holder in which an optical transmission line attaching section for attaching an end section of a light transmission line, a photoelectric element attaching section for attaching a photoelectric element including at least one of a light-emitting element or a light-receiving element, and a wall section connecting the optical transmission line attaching section and the photoelectric element attaching section are formed integrally, and a lens for optically joining the photoelectric element and the optical transmission line is formed integrally with the wall section, so that the convex surface of the lens is on the photoelectric element side, facing the photoelectric element attached to the photoelectric attaching section, wherein one or a plurality of concave sections are formed as grooved sections on the wall section so as to surround the lens.

Owner:ENPLAS CORP

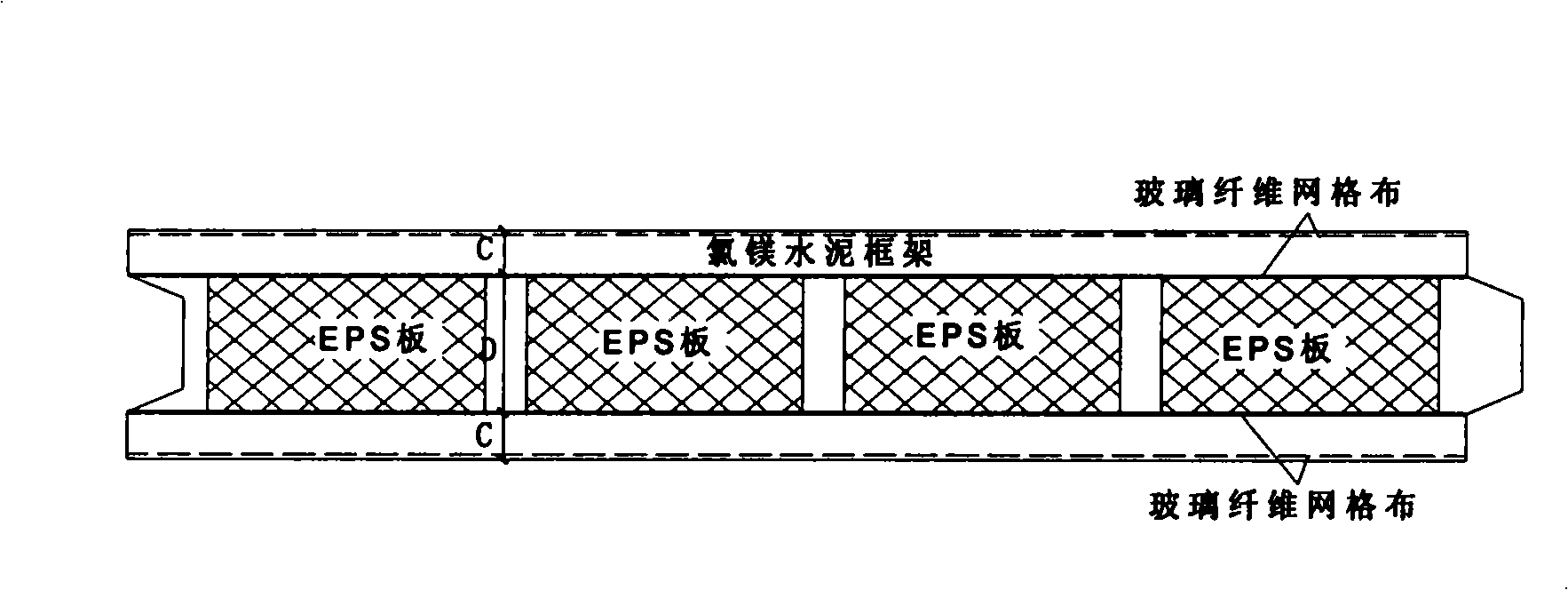

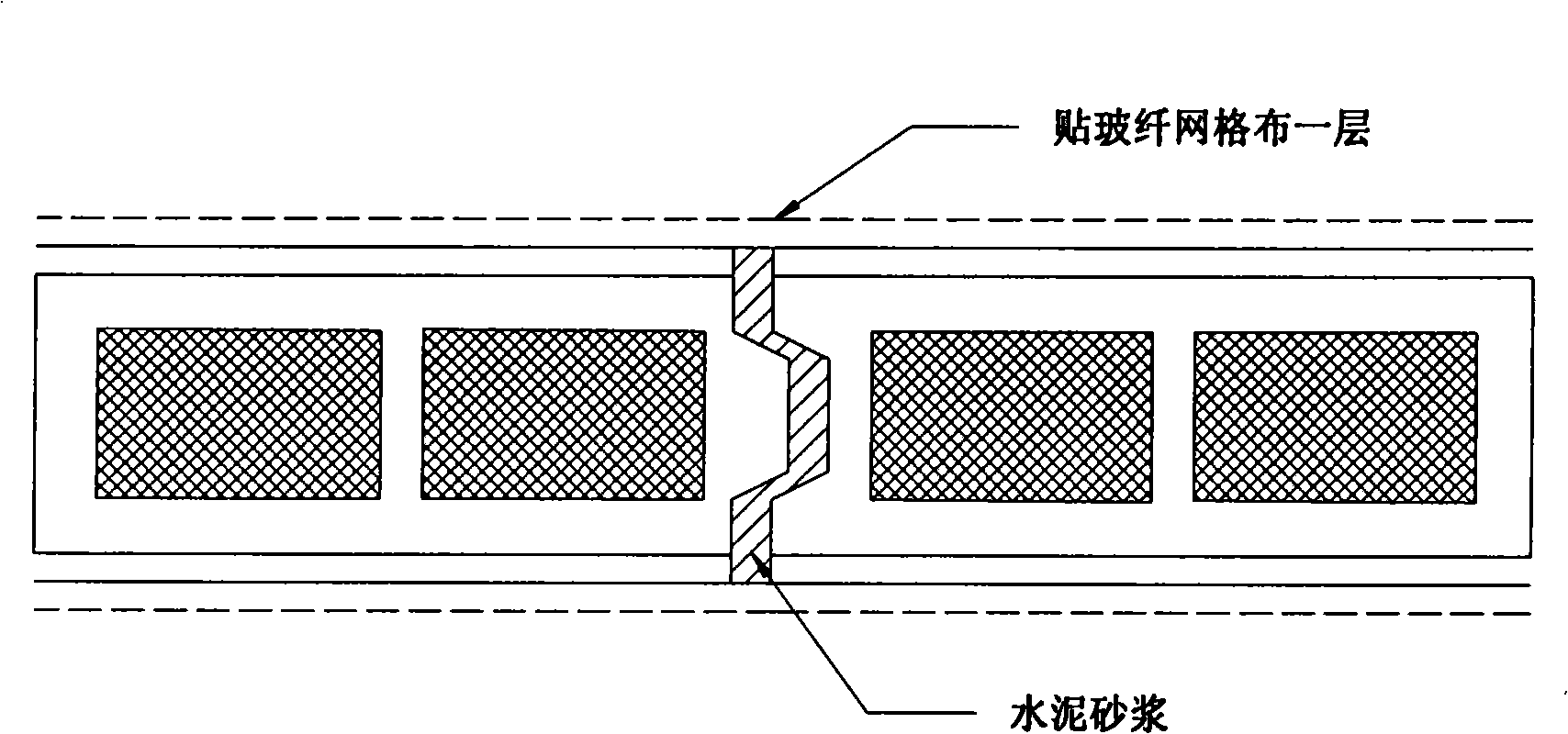

Light composite internal partition plate

InactiveCN101293748AAvoid destructionAvoid being destroyedSolid waste managementWallsReinforced concreteFire protection

The invention belongs to the building material field; in particular to the field of wall body board. A light composite inner partition board of the invention adopts light burning magnesia and magnesium chloride as main gelled materials, wherein, the magnesia accounts for 50 percent of the total weight of the board, and the purity of the magnesia is 83 to 86 percent; the magnesium chloride accounts for 15 percent of the total weight of the board, or the Baume proportion of magnesium chloride solution is modulated at 23 to 24 degrees; the filler of the invention comprises fly ash and sawdust, wherein, the fly ash accounts for 25 to 30 percent of the total weight of the board and the sawdust accounts for 5 to 10 percent of the total weight of the board. The light composite inner partition board of the invention can be used as a partition wall, a baffle, etc. of a light steel frame structure and a reinforced concrete frame structure. The light composite inner partition board has the advantages of low density, sound and heat insulation, fire protection and good installation and processing performance such as sawability, nailability, etc.

Owner:天津航达建材有限公司

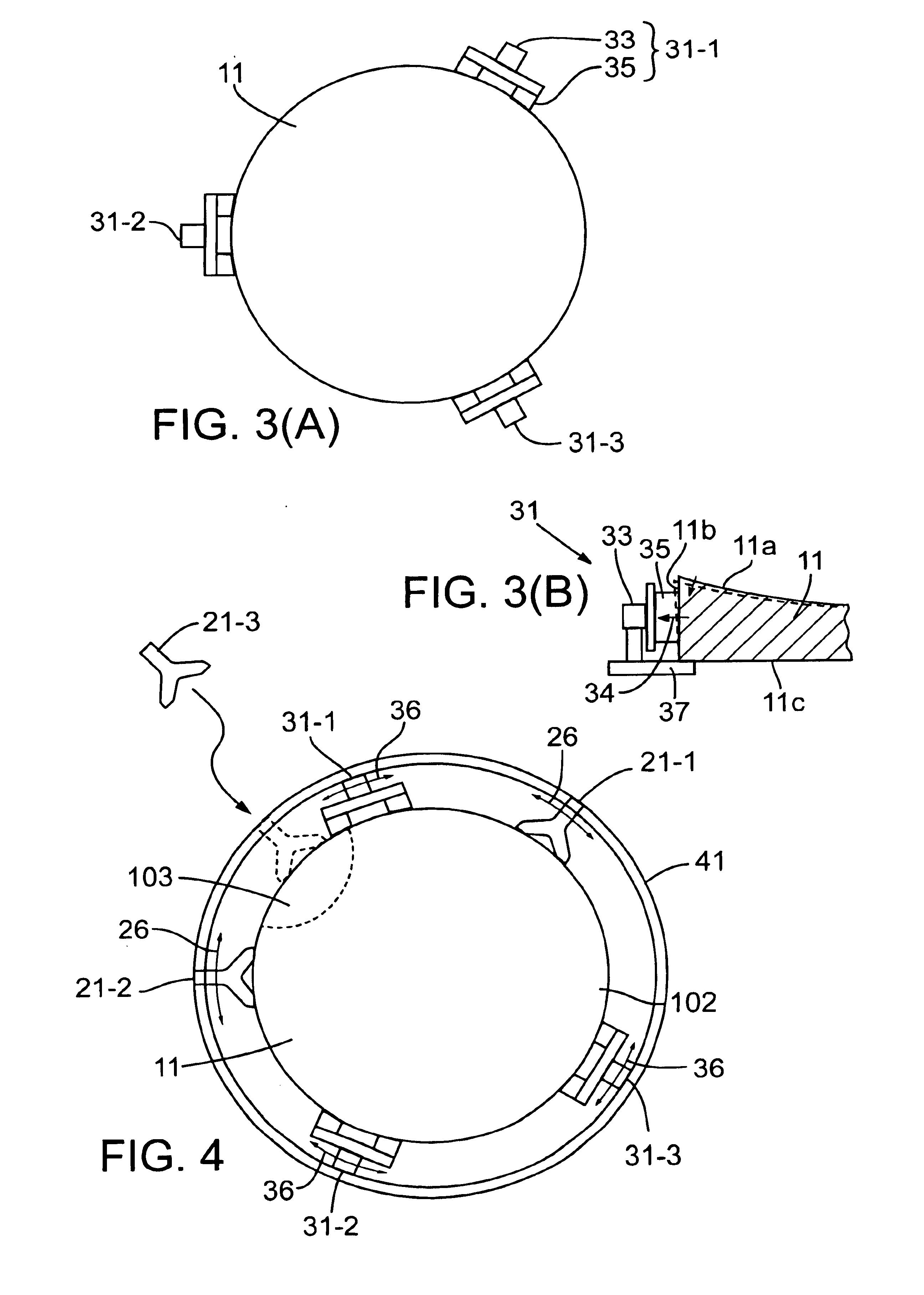

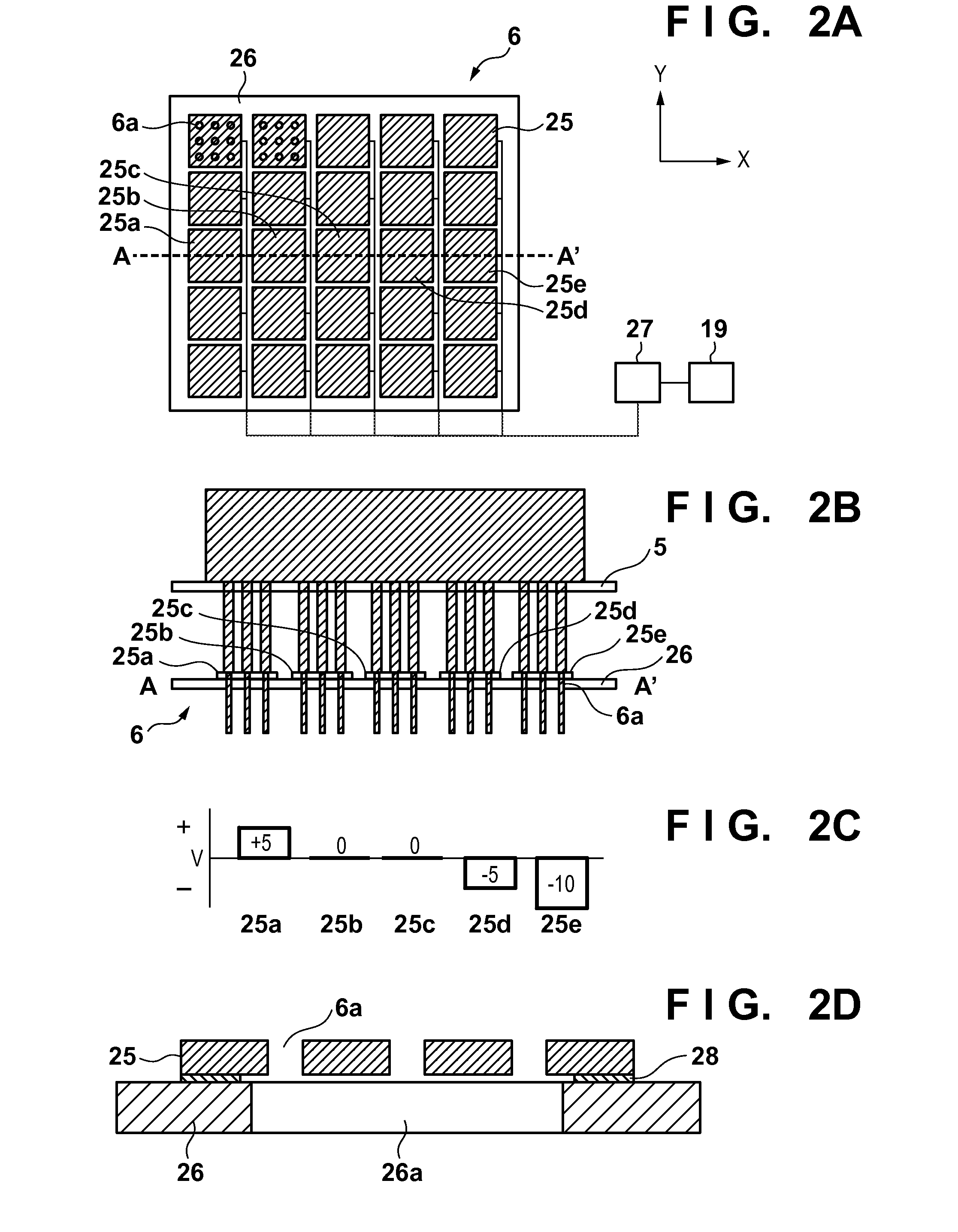

Form-error-cancelling mirror-support devices and related methods, and microlithography systems comprising same

InactiveUS6843572B2Reduce form errorReduce uneven deformationMirrorsSemiconductor/solid-state device manufacturingForm errorAcoustics

Methods and apparatus are disclosed for peripherally supporting X-ray-reflective mirrors such as used in X-ray microlithography systems and other X-ray optical systems. The methods provide effective physical support while reducing certain deformations in the reflective surface of the mirror. An embodiment of the method or mirror-support apparatus utilizes multiple “pushing” and “pushing” devices that apply a compressive stress and tensile stress, respectively, to respective locations on the peripheral-side surface of the mirror. One or more pushing devices and one or more pulling devices can be used as required. For example, at time of mirror fabrication, respective pushing devices can be placed adjacent concave-deviation regions and respective pulling devices can be placed adjacent convex-deviation regions on the reflective surface of the mirror. (Each pushing device produces an offsetting convexity in the adjacent mirror material, and each pulling device produces a corresponding concavity in the adjacent mirror material.) Thus, form errors arising at fabrication time are offset while simultaneously supporting the mirror.

Owner:NIKON CORP

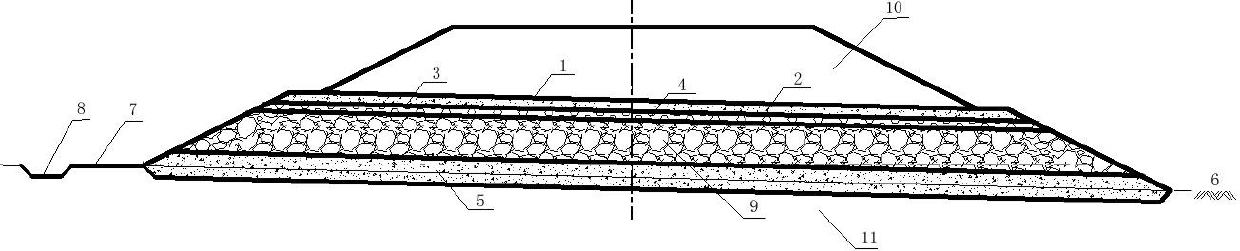

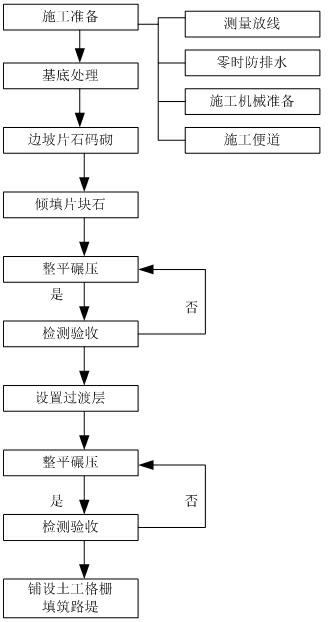

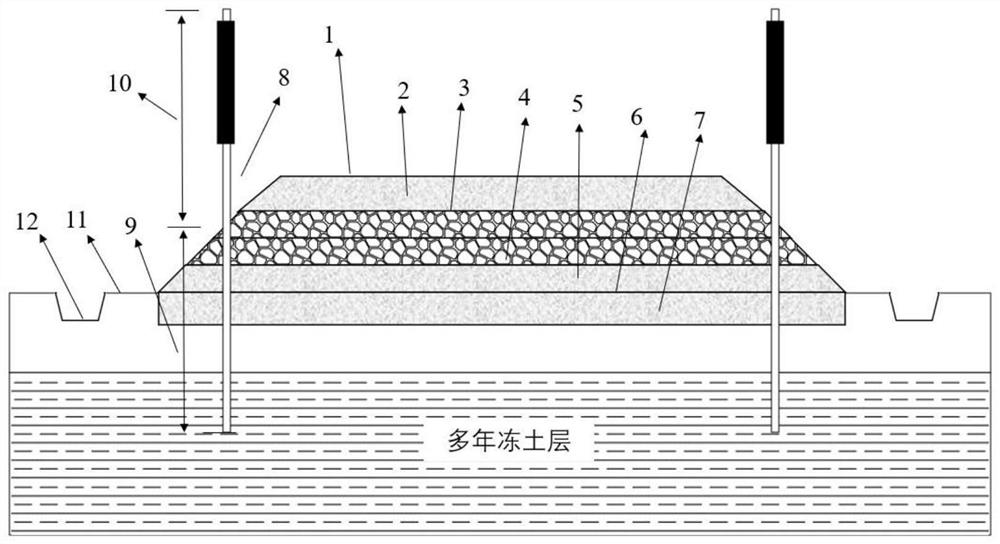

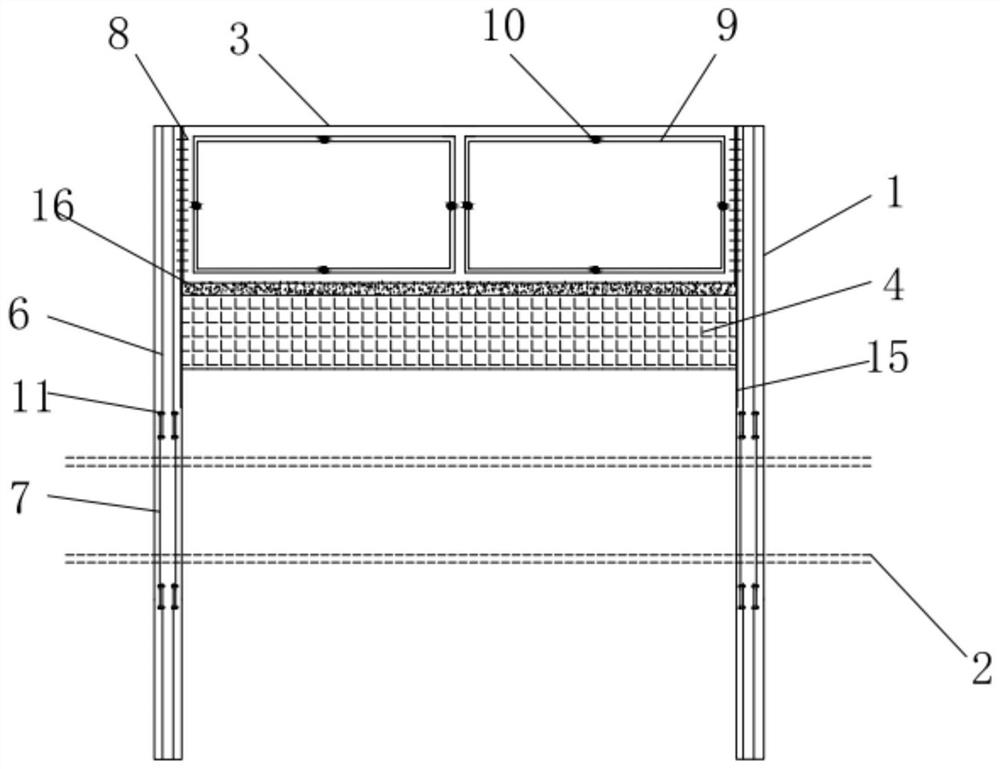

Permafrost region expressway flaky and blocky stone ventilation roadbed and construction method thereof

The invention relates to a permafrost region expressway flaky and blocky stone ventilation roadbed and a construction method thereof. The construction safety and the service life are severely influenced caused by the lengthways cracking of the roadbed, the roadbed size effect under the asphaltpavement and the like because of the hot melting and the sinking of the permafrost roadbed. The construction method comprises the following steps of: impacting, laminating and filling 30cm of lower gravel cushion layer at a soil arching base; impacting and laminating the lower gravel cushion layer under the ground line; building a flaky and blocky stone layer with the thickness of 0.9m-1.5m on the lower gravel cushion layer; flattening the upper part of the flaky and blocky stone layer by a macadam transition layer with the thickness of 20cm; filling an upper gravel cushion layer with the thickness of 30cm; paving a water-permeable geotextile between the upper gravel cushion layer and the macadam transition layer; distributing a geogrid which is made from the plastic steel at the upper part of the upper gravel cushion layer; and compacting by a heavy type vibratory roller layer by layer. Therefore, the melting of the permafrost roadbed and the uneven deforming of the permafrost roadbed can be reduced, the influence of the climate warming and the human engineering activity to the permafrost roadbed characteristic can be reduced, and the safety and the flaky and blocky stone stability of the roadbed structure can be improved.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

High-latitude forest island-shaped frozen soil roadbed structure and construction method

PendingCN113250025AReduce deformation damageImprove carrying capacityRoadwaysClimate change adaptationSoil scienceDrainage ditch

The invention discloses a high-latitude forest region island-shaped frozen soil roadbed structure and a construction method, and the construction method comprises the following steps: impacting and rolling filled sheet and block stones with the thickness of 1m below a horizon, filling a sheet and block stone layer with the thickness of 50cm above the sheet and block stones, then paving two pieces of cloth and one film, then filling a gravel lower cushion layer with the thickness of 50cm, filling a gravel upper cushion layer with the thickness of 1 m is filled after inverted filter geotechnical cloth is laid on the top layer of the roadbed, setting a row of hot bar structures on each of the two sides of the roadbed, and setting a slope protection channel and a drainage ditch. The water-heat exchange balance condition in the frozen soil roadbed in the high-latitude forest region can be adjusted and maintained, the frozen soil melting amplitude and uneven deformation of the frozen soil roadbed are reduced, the stability of the roadbed structure is improved, the service life of the road is prolonged, and the later maintenance cost of the road is reduced.

Owner:BEIJING MUNICIPAL ROAD & BRIDGE

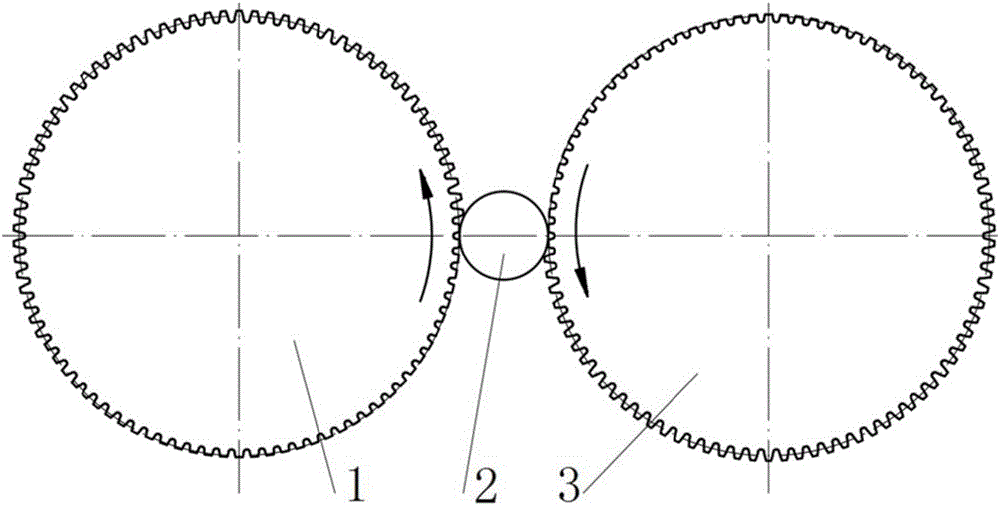

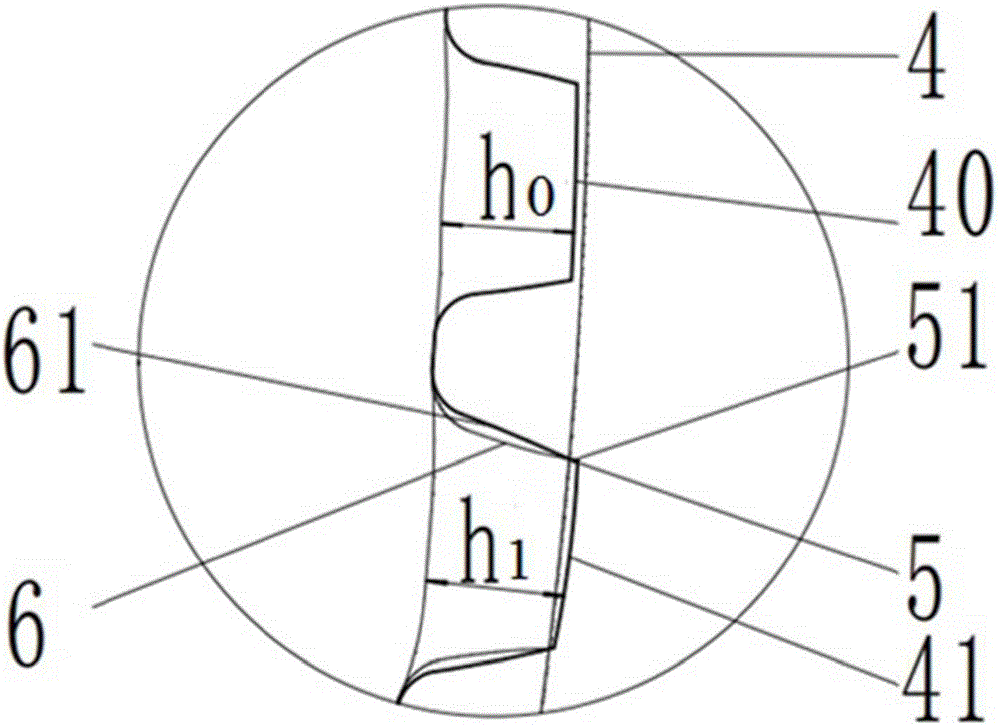

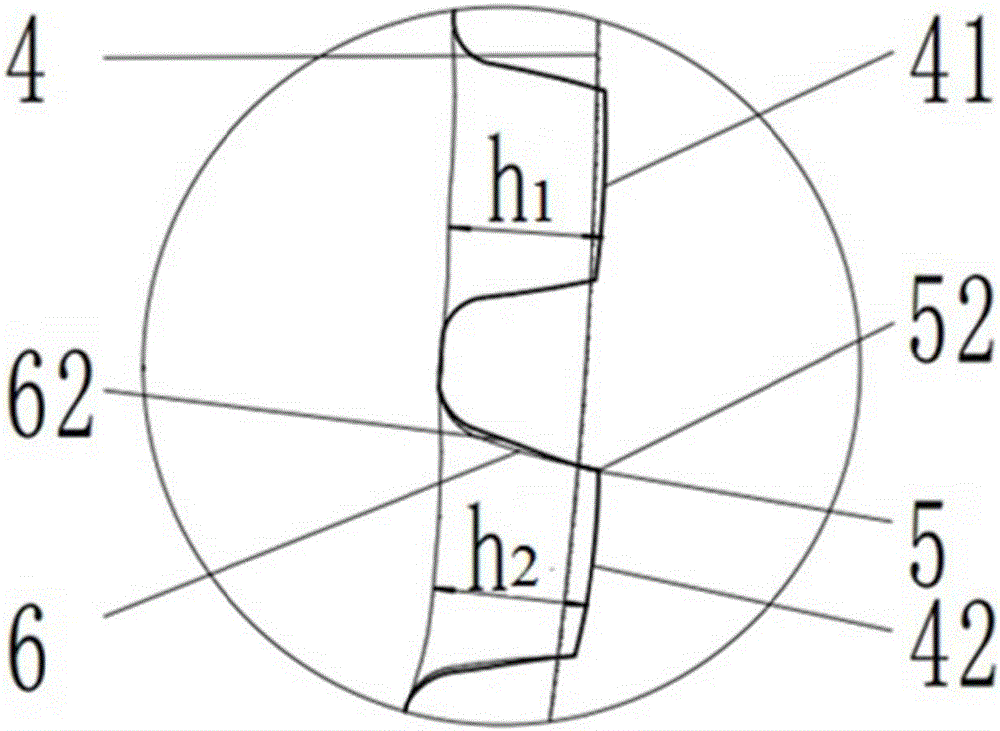

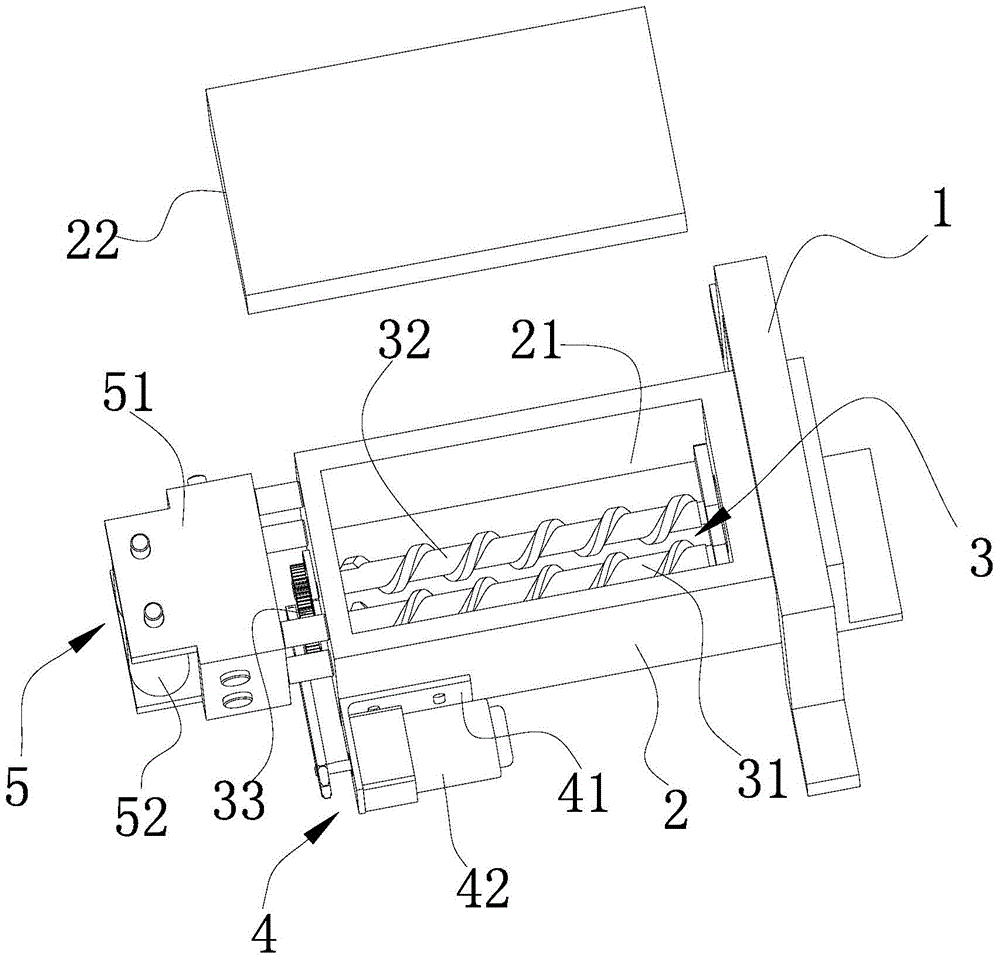

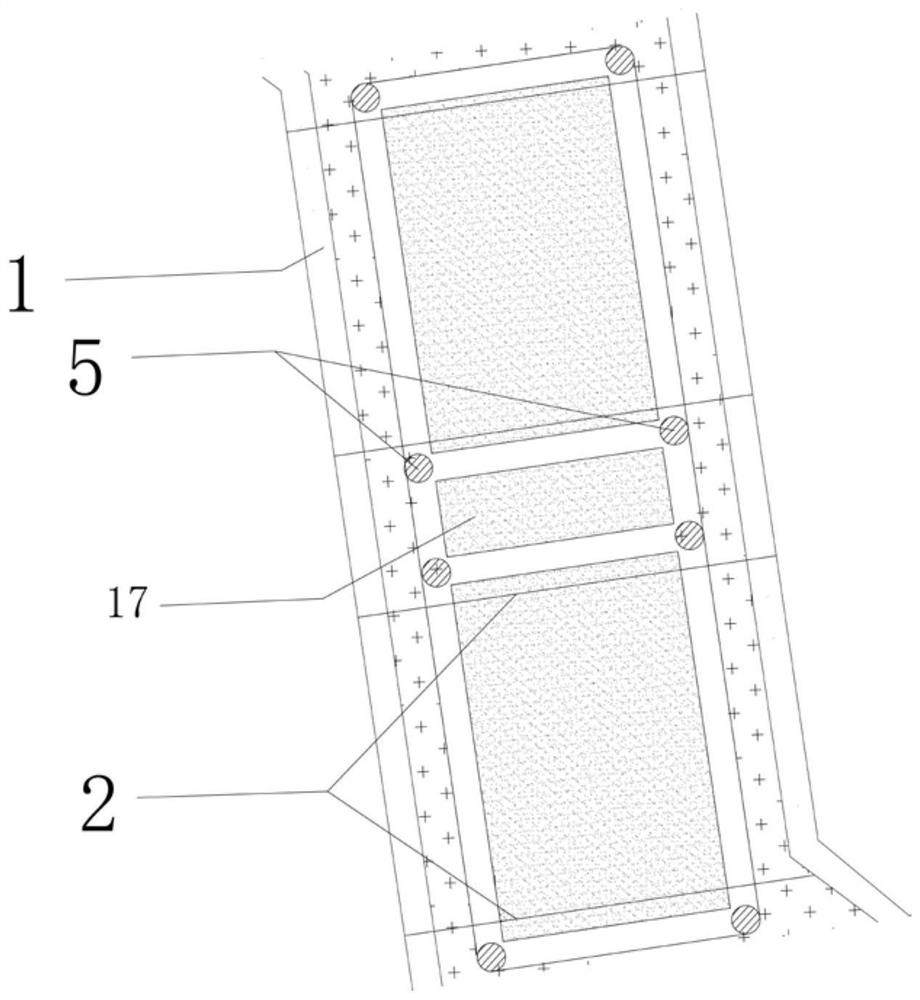

Involute-gear rolling mold and forming technology

The invention discloses an involute-gear rolling mold and forming technology. The rolling mold comprises a first rolling mold body and a second rolling mold body which are parallelly arranged at intervals, and the tooth number and the mold number of the two molds are same; a zero-pass tooth area, a first-pass tooth area, a second-pass tooth area and the like, a N-pass tooth area are sequentially arranged on the first rolling mold body; the tooth type in all the pass tooth areas is same; the first rolling mold body and the second rolling mold body are same in structure, and tooth types are formed in an involute mode; the areas from the zero-pass tooth area to the N-pass tooth area are clockwise arranged on the first rolling mold body, and are clockwise arranged on the second rolling mold body. According to the involute-gear rolling mold and forming technology, blanks are rolled in a fixed-point mode, the center distances between the rolling mold bodies are fixed, the rolling mold does not need to be fed in a radial-direction mode in the forming process, blanks are balanced in stress, accurate in positioning and small in uneven deformation; the speed forced synchronization rolling mode is adopted, dynamic graduation of the tooth type in the forming process is achieved, and the tooth-distance accumulative errors caused by free-graduated rolling are eliminated.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

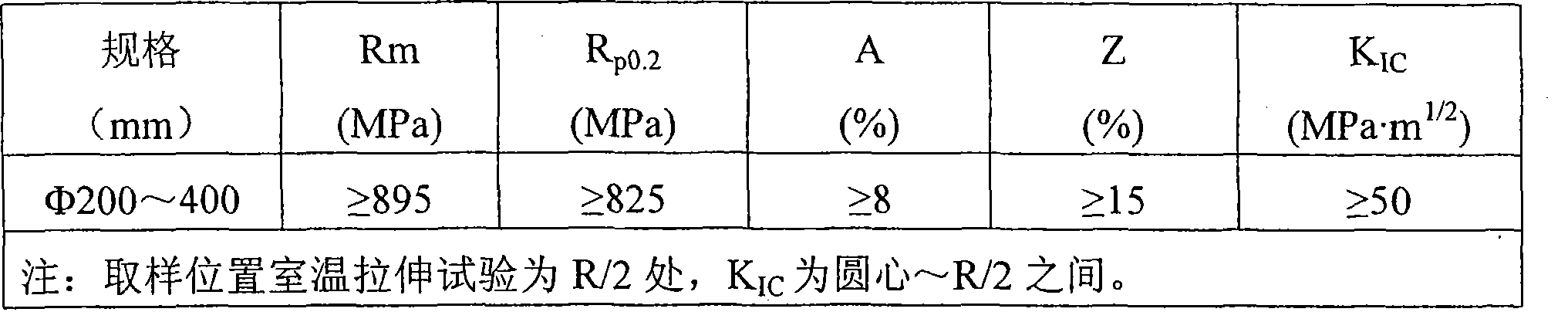

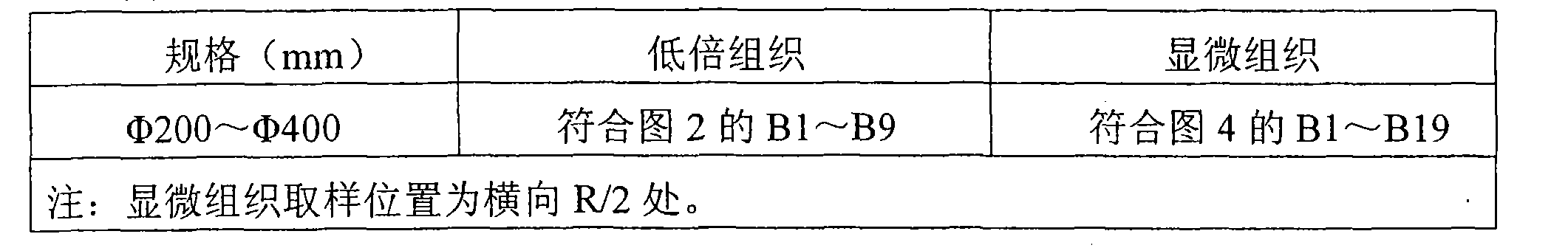

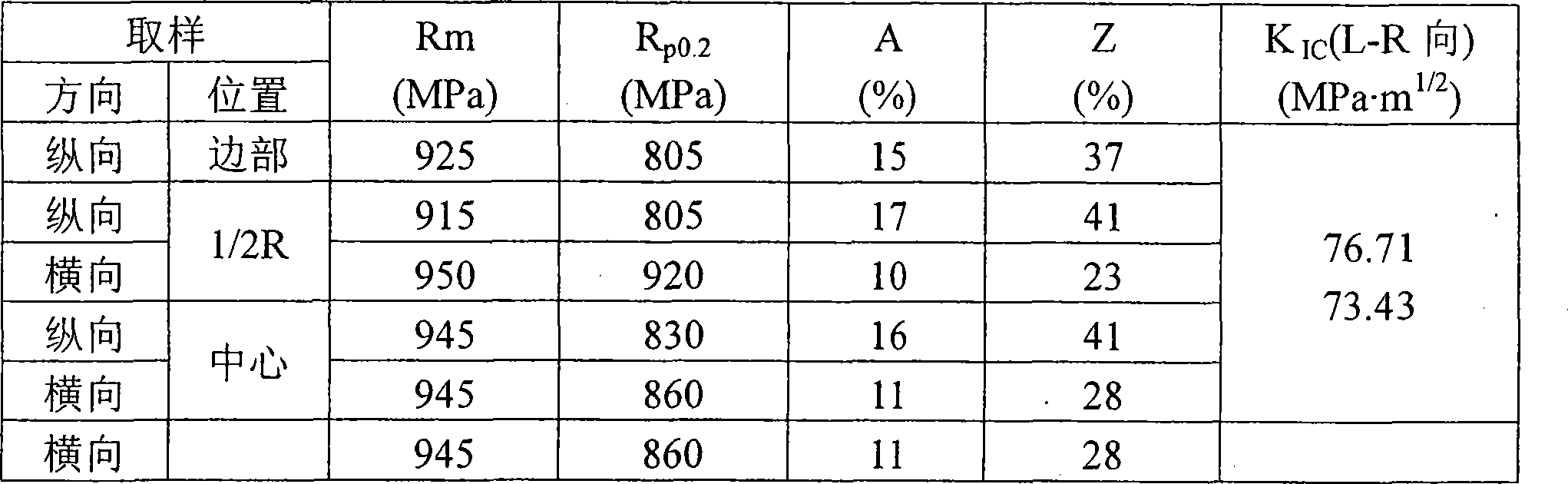

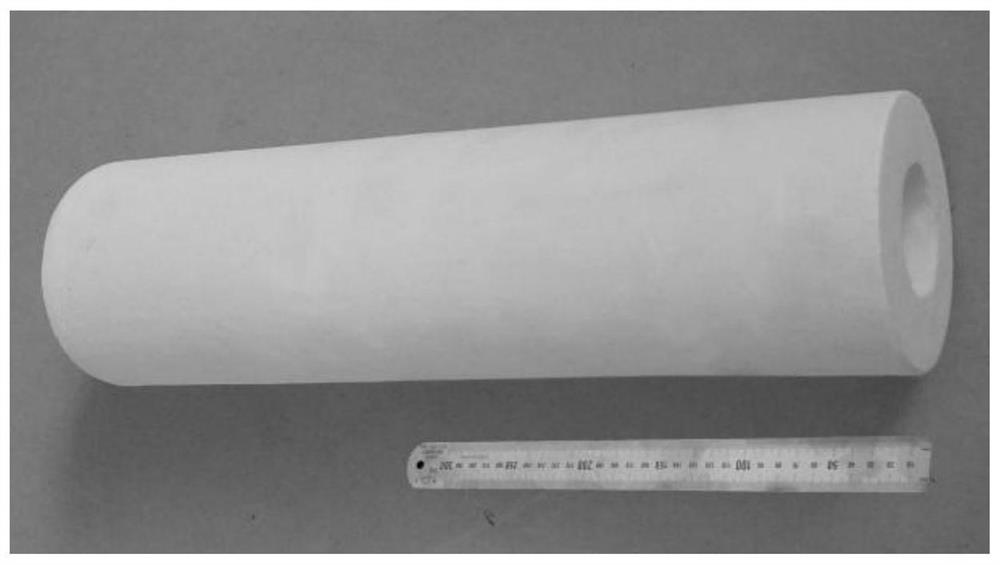

Method for processing Ti-6Al-4V titanium alloy large size bar material

The invention relates to a large-scale processing method of Ti-6Al-4V titanium alloy rod bars with the phi of 200-400mm and the length of over 3000mm. The technique is characterized by adopting Ti-6Al-4V titanium alloy casting ingots with the phi of 700-950 mm, a gas furnace for heating and heat preserving at 1150 DEG C, a hydraulic press for hammer cogging, and adopting multi-heating number smithing over the beta transition temperature with the whole smithing ratio not smaller than 3; heating and smithing below the beta transition temperature by 20-30 DEG C with a smithing ratio of 1.5-1.8; preserving the heat for 0.5-3 hours over the beta transition temperature by 20 DEG C, water cooling, performing homogenization treatment; finally heating below the beta transition temperature by 30-50DEG C, performing multi-heating number smithing in the alpha+beta phase section to the finished product format and the total forging ratio of the alpha+beta phase section being not less than 6. The weight of a single rod bar is greatly improved through integral smithing of casting ingots / large-scale smithing stocks, the length of the rod bar can reach more than 3 m and the rod bars have favorabletissue and performance.

Owner:BAOJI TITANIUM IND CO LTD

Angle swage block and forging technology using same

ActiveCN101695737BImprove uniformitySacrifice compactionForging/hammering/pressing machinesStructural engineeringIndustrial engineering

The invention relates to an angle swage block and a forging technology using the same, belonging to forging equipment and application technology field thereof. The left side and the right side of the angle swage block are inclined planes which have the same included angle with the vertical direction, wherein the included angel is set to be beta which is not less than 0 DEG but not more than 12 DEG. The bottom surface of the angle swage block is a curved surface which is eudipleural. The included angle formed by the left plane of the bottom surface and the horizontal plane is alpha which is not less than -10 DEG but not more than 10 DEG. When large shaft forgings, such as rotor forgings, are forged by using the angle swage block, a first upsetting technology can be omitted, and a drawing-out technology can be carried out by firstly using a concave angle swage block and then using a convex angle swage block. By using the forging technology of the combination of the angle swage blocks, the invention has the advantages that the process flow is shortened, the structure properties of forgings are improved, forging with small ratio of forging reduction is obtained, and the developments and the changes of internal defects in the forging process can be effectively controlled to eliminate the existing defects so as to prevent the generation of new defects.

Owner:TSINGHUA UNIV

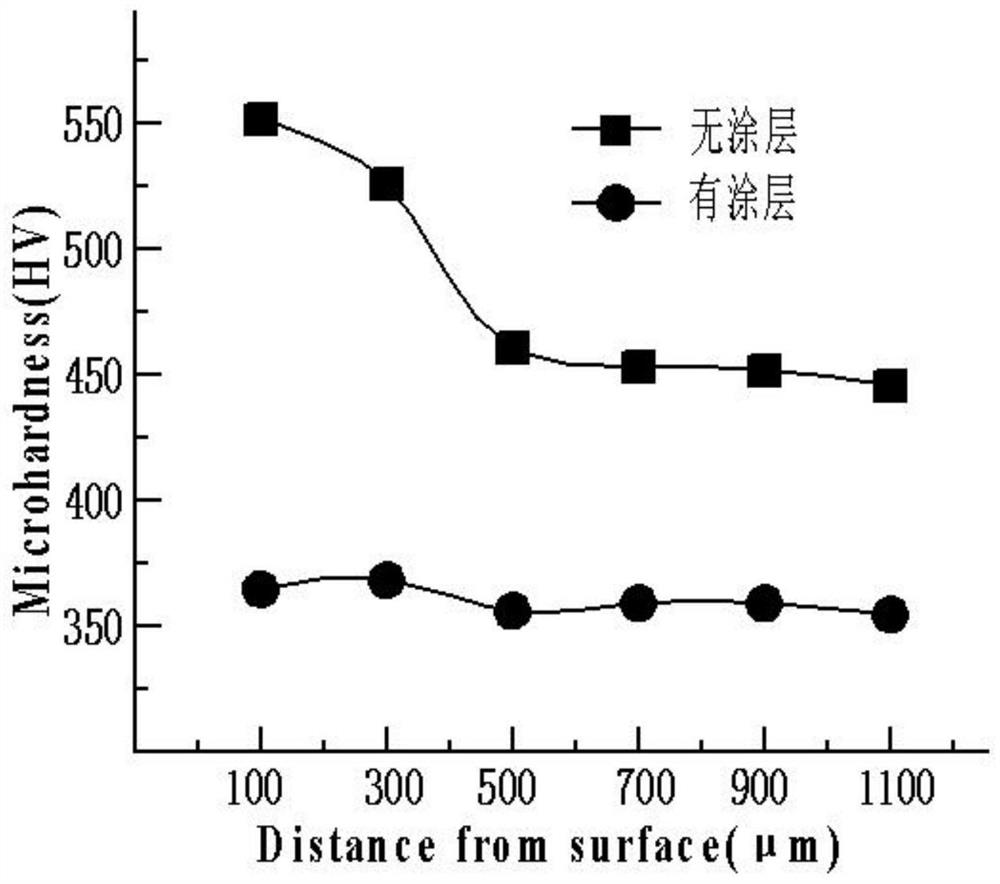

Lubricant for hot extrusion molding titanium alloy pipe as well as preparation method and application thereof

PendingCN112538393AIncrease high temperature viscosityImprove high temperature transient meltingAdditivesCoatingsTitanium alloyLubrication

The invention discloses a lubricant for a hot extrusion molding titanium alloy pipe as well as a preparation method and application thereof, which belongs to the field of lubricants and preparation thereof, and aims to solve the technical problems of poor fluidity and easy peeling and cracking of the existing glass lubricant in the extrusion lubrication process. The lubricant for the hot extrusionmolding titanium alloy pipe is prepared from the following components in parts by mass: 35 to 45 parts of SiO2, 2 to 4 parts of Al2O3, 18 to 28 parts of B2O3, 17 to 21 parts of Na2O, 5 to 8 parts ofCaO, 1 to 5 parts of MgO, 1 to 8 parts of BaO, 1 to 5 parts of ZnO and 1 to 2 parts of LiO. The preparation method comprises the following steps of 1, uniformly mixing materials according to a formula, and then heating and smelting to obtain molten glass, and 2, pouring into cold water, carrying out cold quenching, drying, carrying out ball milling, drying, and screening to obtain the lubricant. The lubricant can be used as a lubricant for hot extrusion molding of titanium alloy pipes. After the TC4 titanium alloy coated with the lubricant coating is extruded, the surface of a pipe is integrally smooth, other obvious defects such as longitudinal and transverse scratches are avoided, and the overall surface quality is superior to the surface quality of the pipe extruded by a lubricant in the traditional process.

Owner:AEROSPACE HIWING HARBIN TITANIUM IND

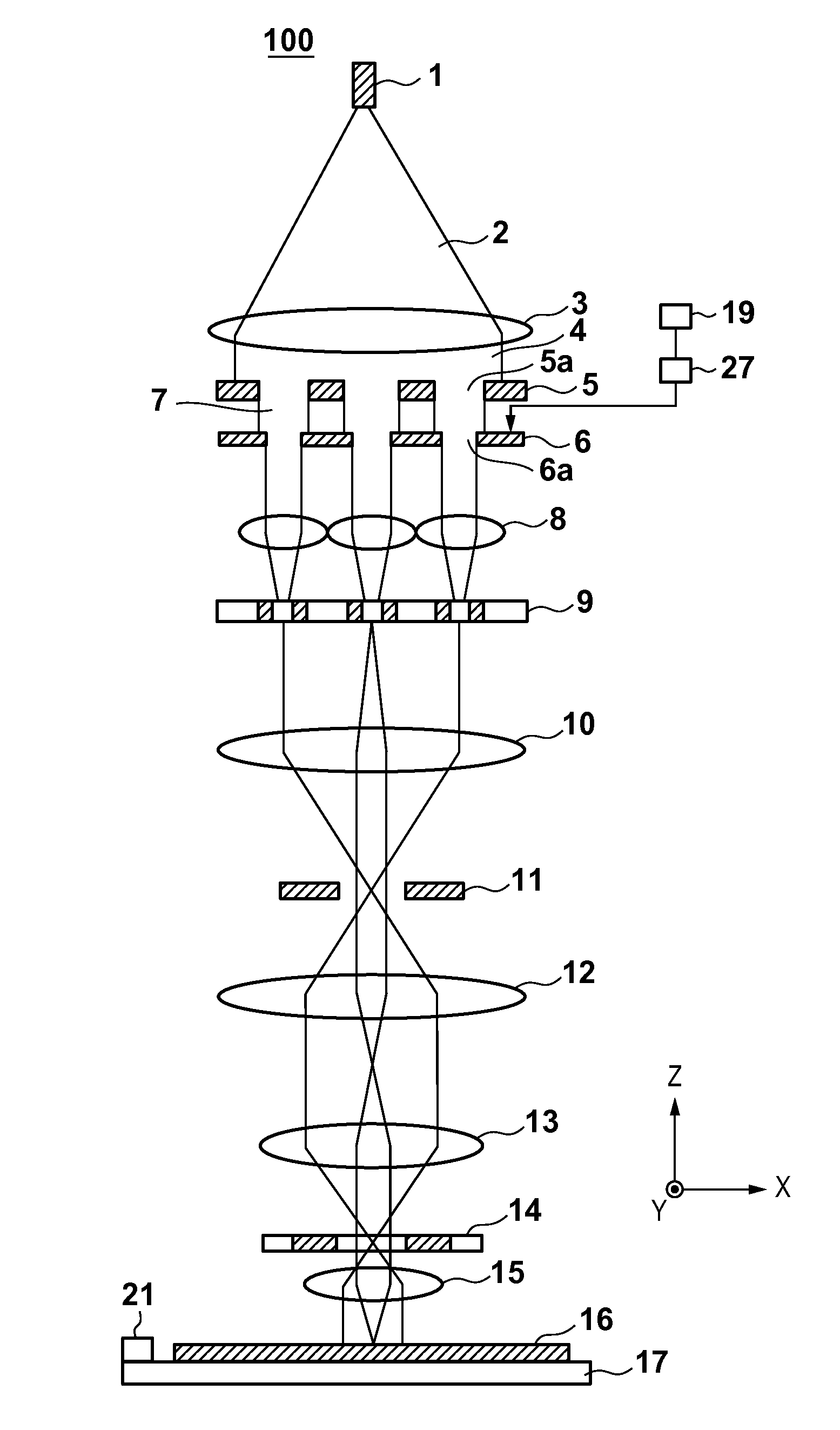

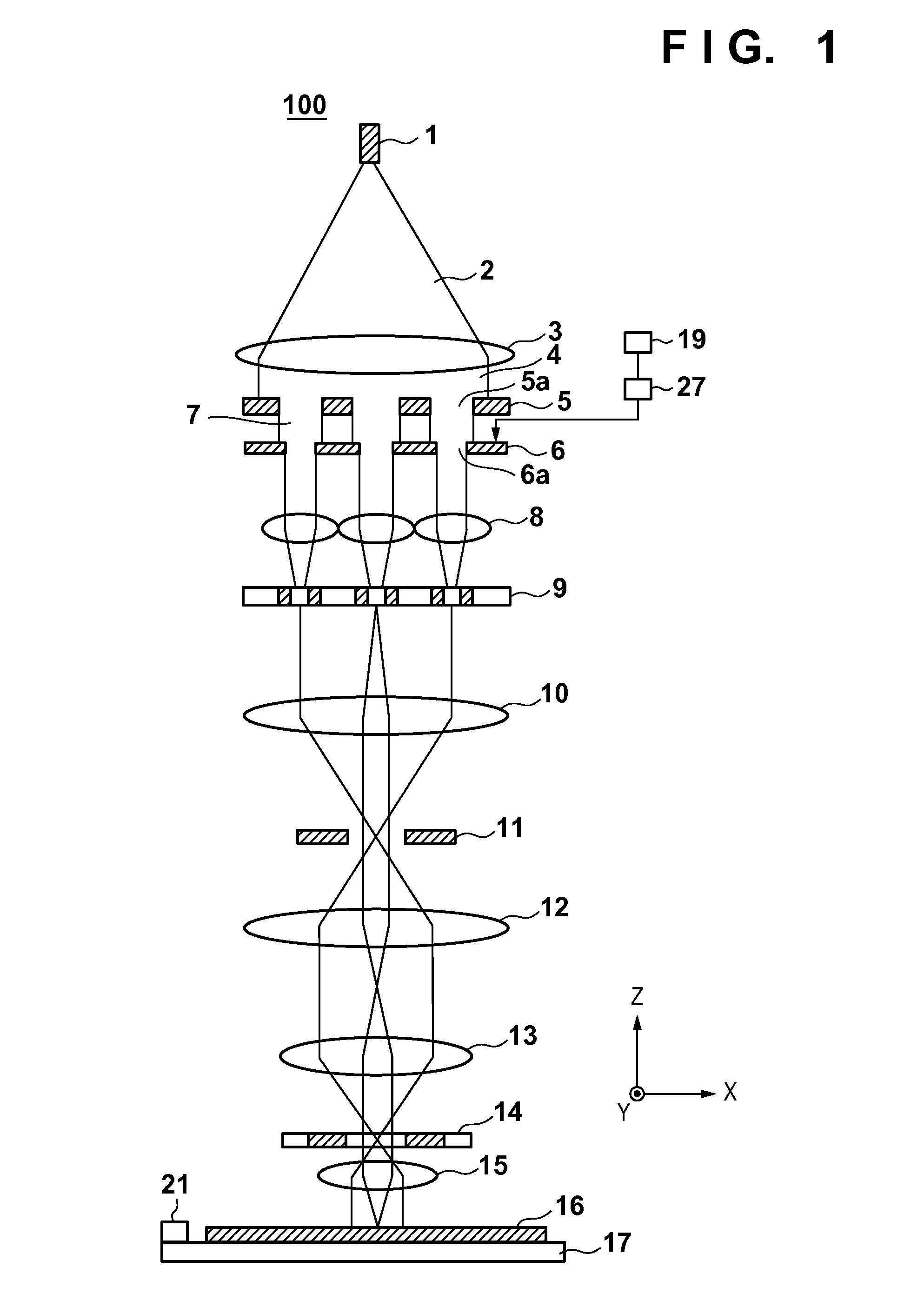

Drawing apparatus, and method of manufacturing article

InactiveUS20140349235A1Reduce uneven deformationElectric discharge tubesPhotomechanical exposure apparatusEngineeringMechanical engineering

The present invention provides a drawing apparatus for performing drawing on a substrate with a plurality of charged particle beams, the apparatus including an aperture array member in which a plurality of first apertures, for generating the plurality of charged particle beams, is formed, and a generating device configured to individually generate electric potentials in a plurality of regions of the aperture array member, wherein each of the plurality of regions corresponds to at least one of the plurality of first apertures.

Owner:CANON KK

Waste rock bag roadside support method for anchoring low coal seam with strong roof

The invention discloses a waste rock bag roadside support method for anchoring low coal with seam strong roof. The waste rock bag roadside support method comprises a top cut round log supporting column part and an 'obturator + top contracted squared timber' part, wherein the top cut round log supporting column is arranged on the goaf side of a roadside packing body; the roadside packing body consists of waste rock bag bodies, fine particle bag bodies and plastic double resisting nets, the squared timber is adopted for top contract after the obturator is built; the obturator after being compacted is reinforced by an 'anchor rod + reinforcing steel ladder' support; the reinforcing steel ladder and a roadway top plate reinforcing steel ladder are in a bridging connection. According to the waste rock bag roadside support method disclosed by the invention, the round log is adopted as a top cut supporting column, and the waste rock bag bodies, the clay bag bodies and the plastic double resisting nets are selected to build the roadside packing bodies; the squared timber is adopted for top contracting; the 'anchor rod + reinforcing steel ladder' support is utilized for reinforcing the obturator; the waste rock bag roadside support method disclosed by the invention is well adapted to the roof strata movement, and the stability of the obturator and a roadway is improved.

Owner:SHANDONG UNIV OF SCI & TECH

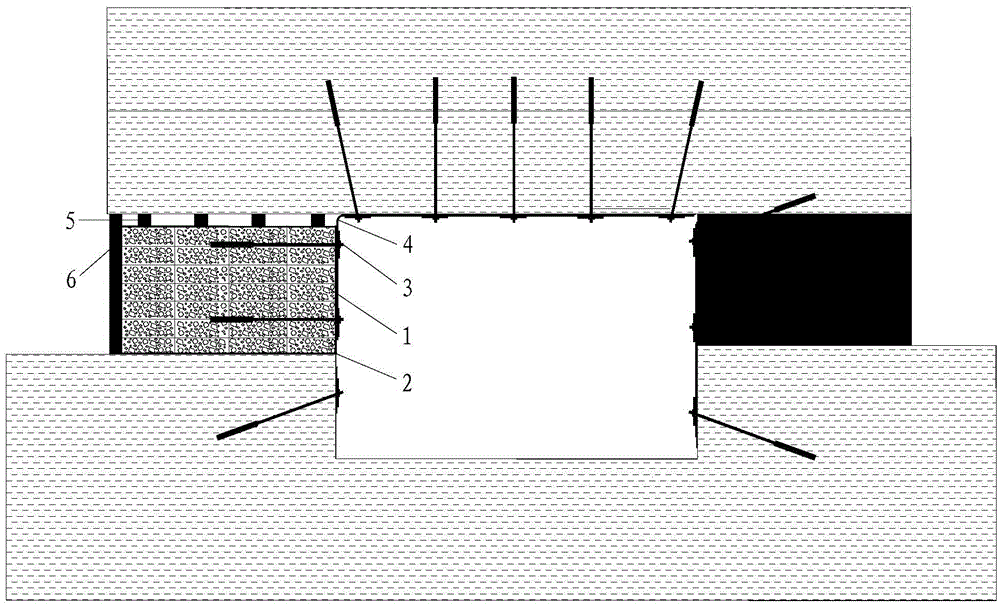

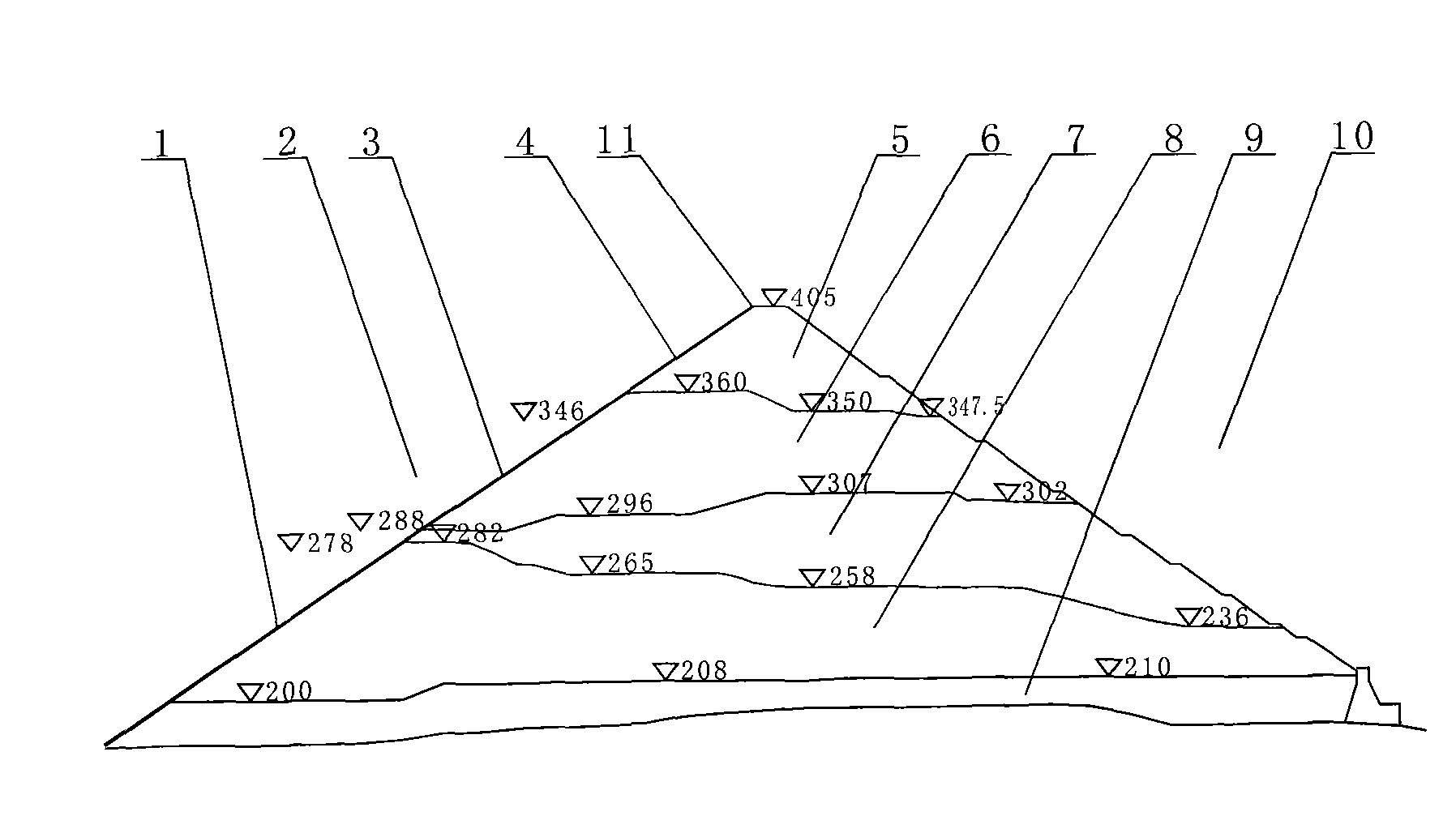

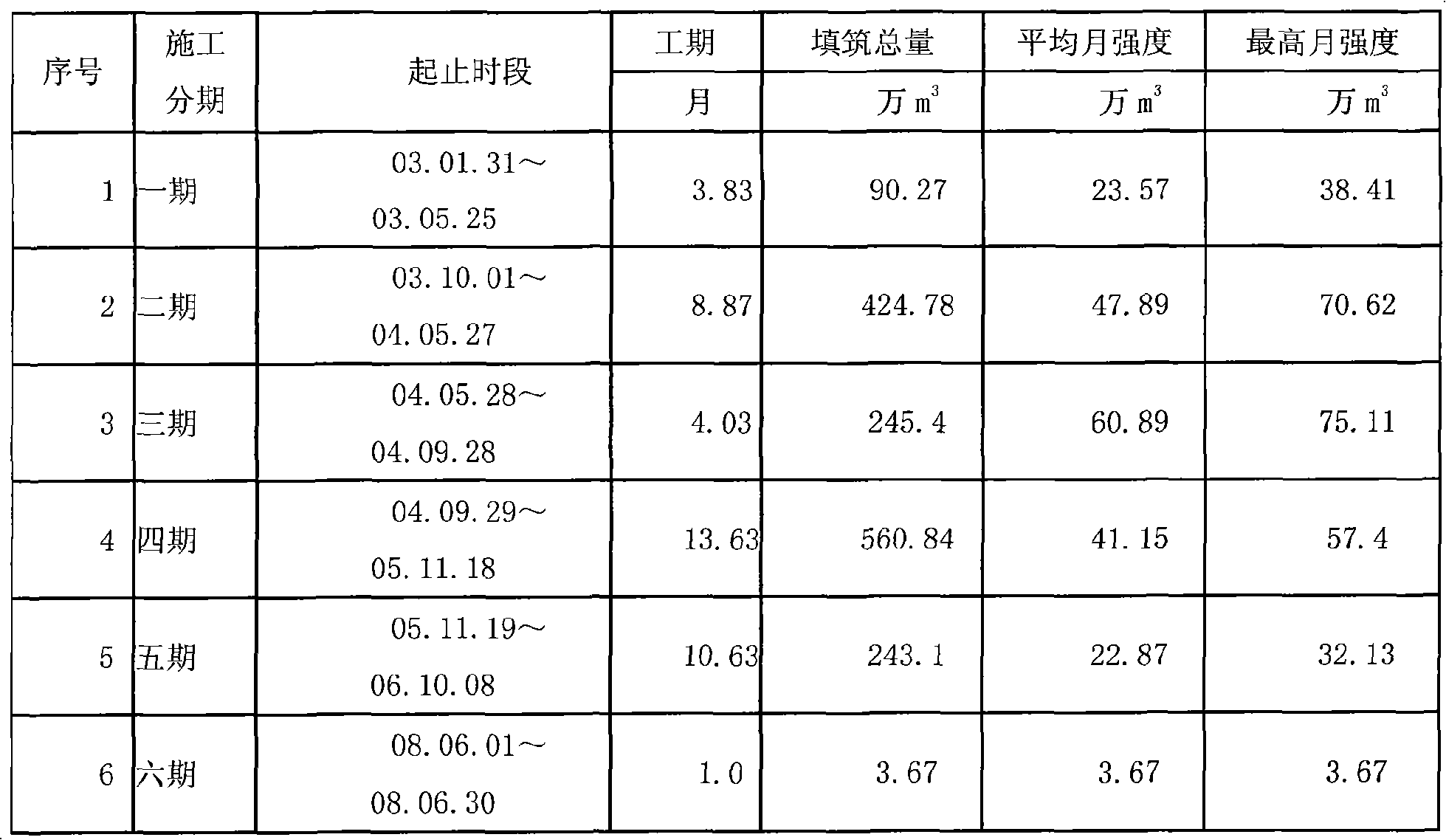

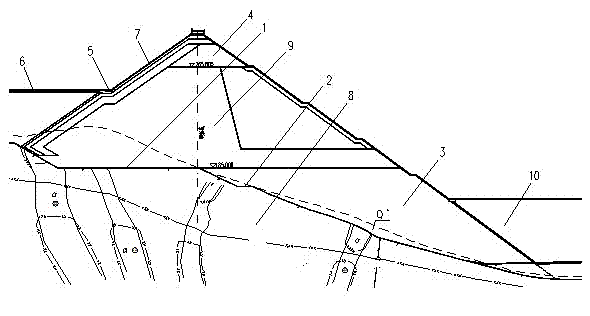

High concrete slab rock-fill dam dam-filling space-time pre-settlement control method

ActiveCN101581087ASafe and stable operationReduce uneven deformationEarth-fill damsRock-fill damsControl mannerHigh intensity

The invention discloses a high concrete slab rock-fill dam dam-filling space-time pre-settlement control method, an interval between a first stage of filling and a second stage of filling on the rock-fill dam is nearly five months, a certain subsidence stage is for a first stage rock-fill dam; after the dam-filling of a second stage rock-fill dam, a concrete first stage deck is constructed, meanwhile a third stage inverted mesa filling is constructed in the space control manner of a post area above a proparea; the filling of rockfill is constructed to the height of a wave wall in the manner of continuous high strength filling from the third stage to the fifth stage; the interval between a fifth stage rock-fill dam and a sixth stage rock-fill dam is nearly twenty month, the rock-fill dam is constructed to a designed height of crest to complete the construction of an ultrahigh rock-fill dam, a second stage of pouring concrete slab is constructed in the interval, and after the rock-fill dam is constructed to the designed height of crest, a third stage of concrete slab and wave wall are constructed.

Owner:中国葛洲坝集团第三工程有限公司 +1

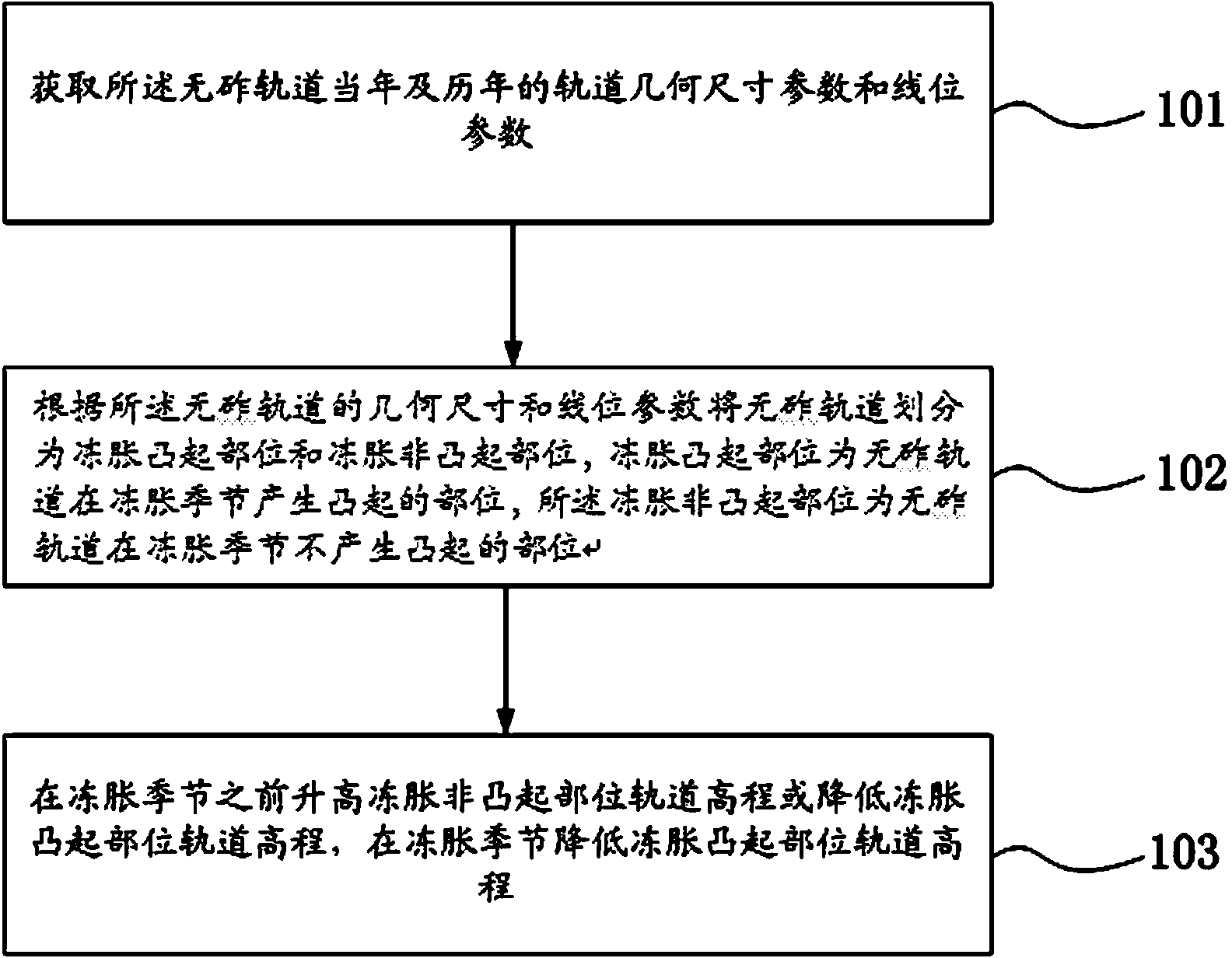

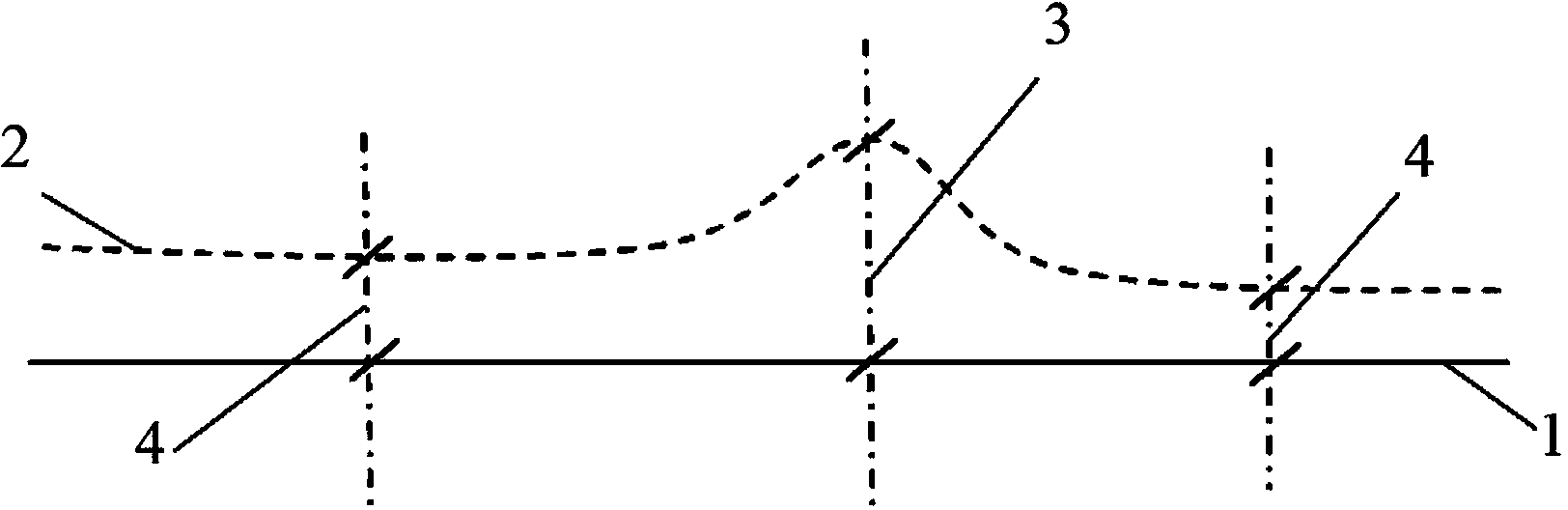

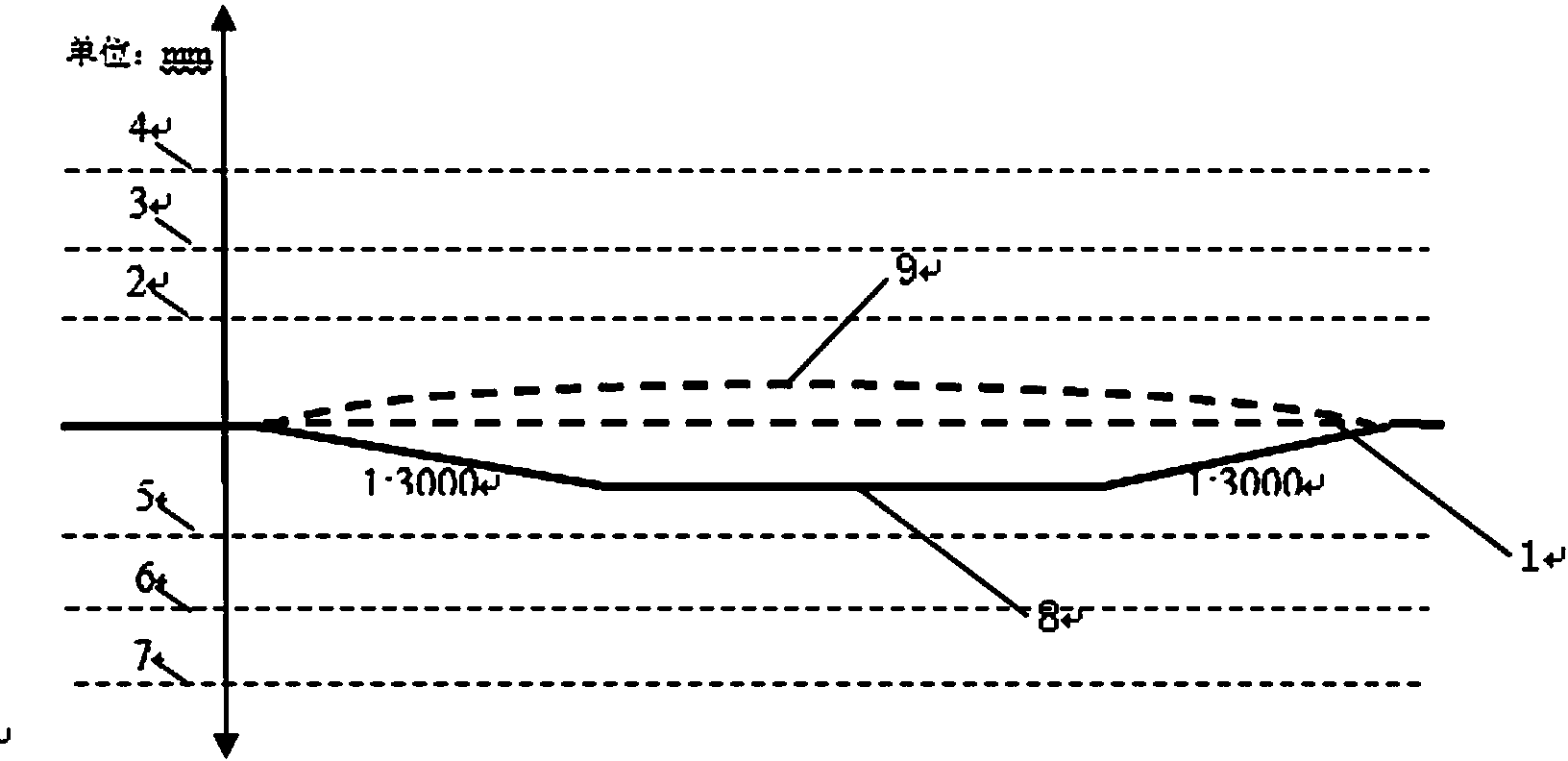

Method for maintaining and handling railway ballastless track with frost heaving

InactiveCN104032631AEasy to adjustReduce uneven deformationTrack maintainenceEngineeringFrost heaving

The invention provides a method for maintaining and handling a railway ballastless track with frost heaving. The method includes the steps that geometric dimensions and linear position parameters of the railway ballastless track are obtained; the railway ballastless track is divided into frost heaving convex parts and frost heaving non-convex parts according to the geometric dimensions and linear position parameters of the railway ballastless track, the frost heaving convex parts are parts where protrusions are generated by the railway ballastless track in a frost heaving season, and the frost heaving non-convex parts are parts where protrusions are not generated by the railway ballastless track in the frost heaving season. According to the method, track elevations of the frost heaving non-convex parts are lifted or track elevations of the frost heaving convex parts are lowered before a roadbed frost heaving season, part of the track elevations of the frost heaving convex parts is preferably selected to be lowered in the roadbed frost heaving season, the elevation of the railway ballastless track can be adjusted accurately, the situation that the railway ballastless track unevenly deforms and the geometric dimensions and the parameters exceed specified values caused by the fact that a roadbed and a bridge and culvert foundation suffer from frost heaving is avoided, ride comfort of the railway ballastless track is improved, and comfort, stability and security are guaranteed when a train runs.

Owner:陈志新 +2

Method for improving wall-thickness uniformity during large-sized thick-wall pipe vertical hot extrusion process

ActiveCN106216415AReduce temperature dropReduce uneven deformationExtrusion control devicesProduction rateEngineering

The invention relates to a method for improving the wall-thickness uniformity during a large-sized thick-wall pipe vertical hot extrusion process. The method for improving the wall-thickness uniformity during the large-sized thick-wall pipe vertical hot extrusion process belongs to the technical field of large-sized thick-wall pipe hot extrusion forming, and comprises the process steps and control technical parameters as below: one end of a pipe blank to be extruded is processed to a specific shape; mold preheating temperature is set: for a heat-resisting steel material, the mold preheating temperature is 400 to 450 DEG C, and for a heat-resisting alloy material, the mold preheating temperature is 350 to 400 DEG C; the pipe blank extrusion minimum limit temperature is controlled: for the heat-resisting steel material, the extrusion minimum limit temperature is 1,000 to 1,010 DEG C, and for the heat-resisting alloy material, the extrusion minimum limit temperature is 1,030 to 1,040 DEG C; and reasonable glass lubricant type and granularity are selected according to extrusion characteristics of different positions. The method for improving the wall-thickness uniformity during the large-sized thick-wall pipe vertical hot extrusion process has the advantages that the metal uniformity flow of the pipe blank during a stable extrusion process is greatly improved, the wall-thickness uniformity during the large-sized thick-wall pipe hot extrusion process is remarkably improved, meanwhile, the cost of raw materials is saved by 20 percent, the service life of a mold is prolonged by 20 percent, the labor productivity during the extrusion process is improved by 15 percent, and about 70 percent of workload of follow-up cutting processing is reduced.

Owner:CENT IRON & STEEL RES INST

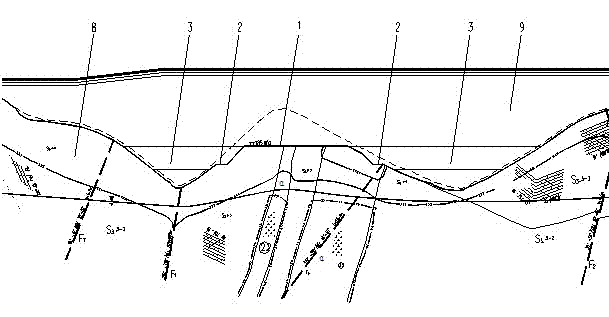

Method for constructing reservoir dam

InactiveCN103526727AEnsure stabilityReduce uneven deformationEarth-fill damsRock-fill damsStructural engineeringRidge

The invention discloses a method for constructing a reservoir dam. The cross section of a dam foundation is W-shaped, the middle of the W-shaped cross section of the dam foundation represents mountain ridges, and the bottom of the W-shaped cross section of the dam foundation represents two valleys; the longitudinal slope of the foundation is larger than 17 degrees. The method includes cutting protruded positions of the mountain ridges to form platforms, digging a plurality of horizontal steps along a longitudinal slope surface of the foundation, and setting a bottom modulus increasing area, a top modulus increasing area and the like on a dam body to reduce uneven deformation of the dam body; setting a back pressure platform at a dam toe of the dam body and performing double-standard control on the pouring time of a face plate of the dam body to reduce adverse impact of deformation of the dam body on the impervious face plate. The method has the advantage that uneven deformation of the dam body is greatly reduced by the aid of measures such as improving a topographical condition of the dam foundation, reasonably partitioning the dam body, filling residues at the dam toe to form the back pressure platform and reasonably preserving excessive sedimentation height and sedimentation cycle, so that the stability of the dam body can be guaranteed.

Owner:POWERCHINA ZHONGNAN ENG

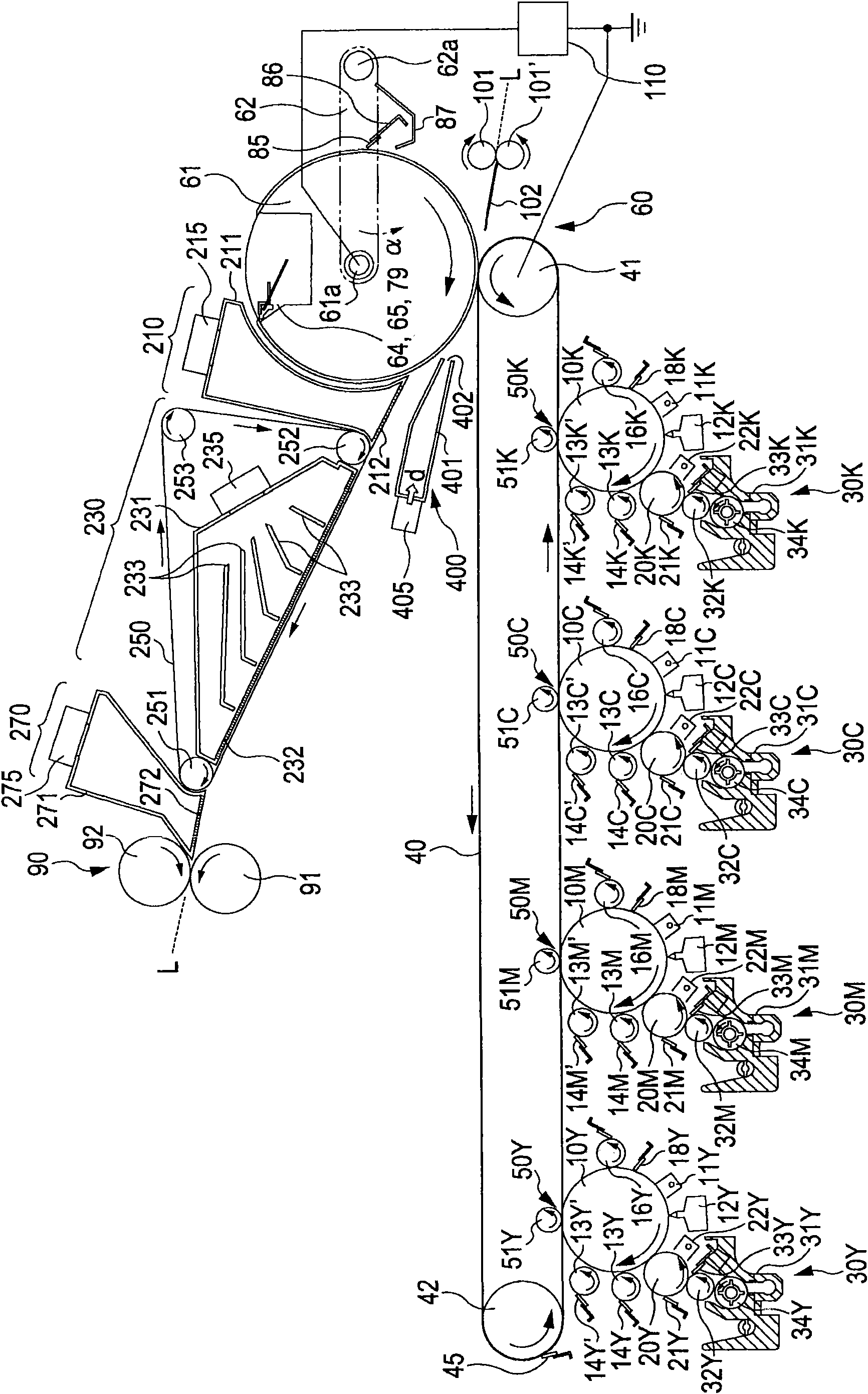

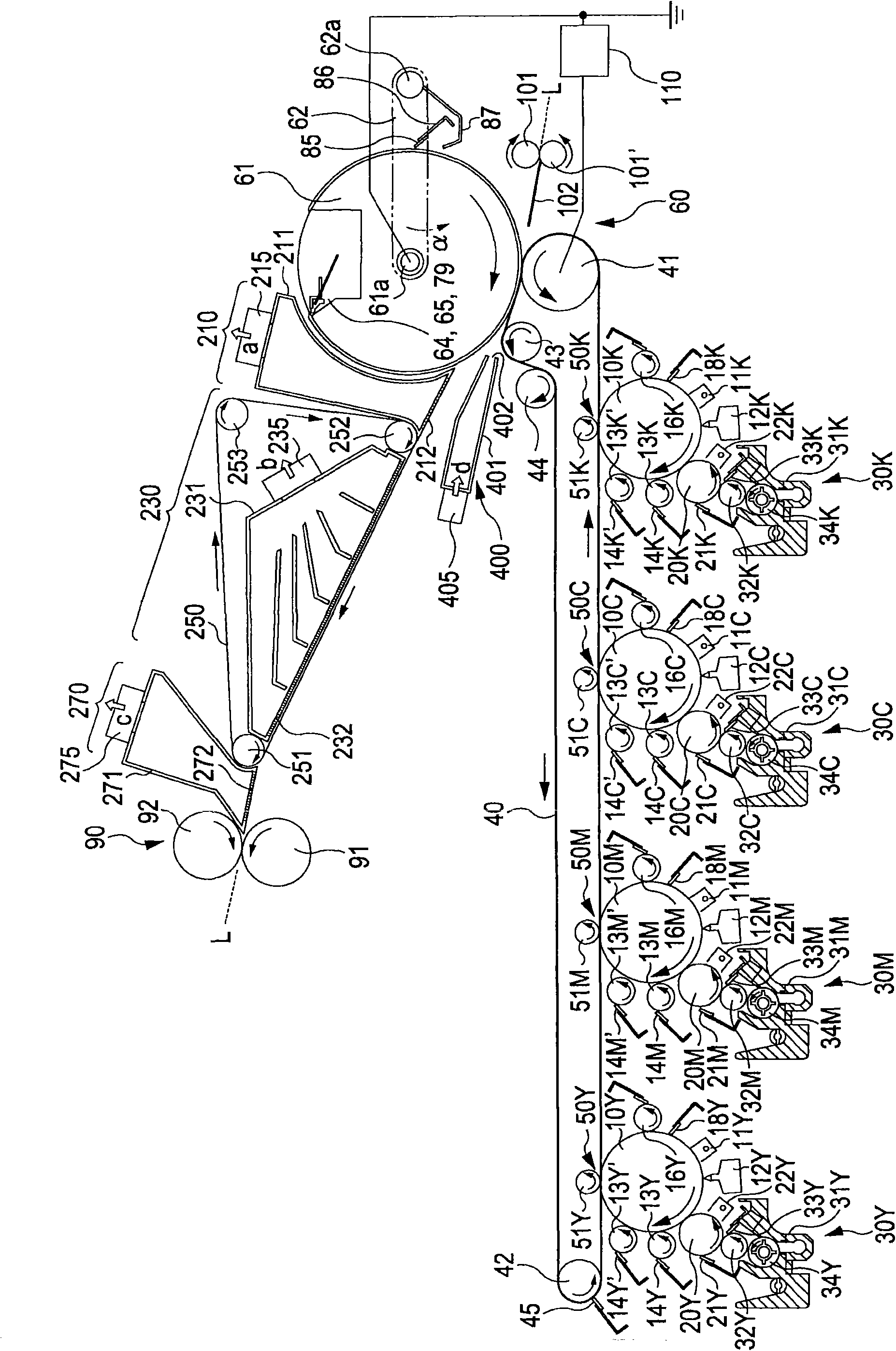

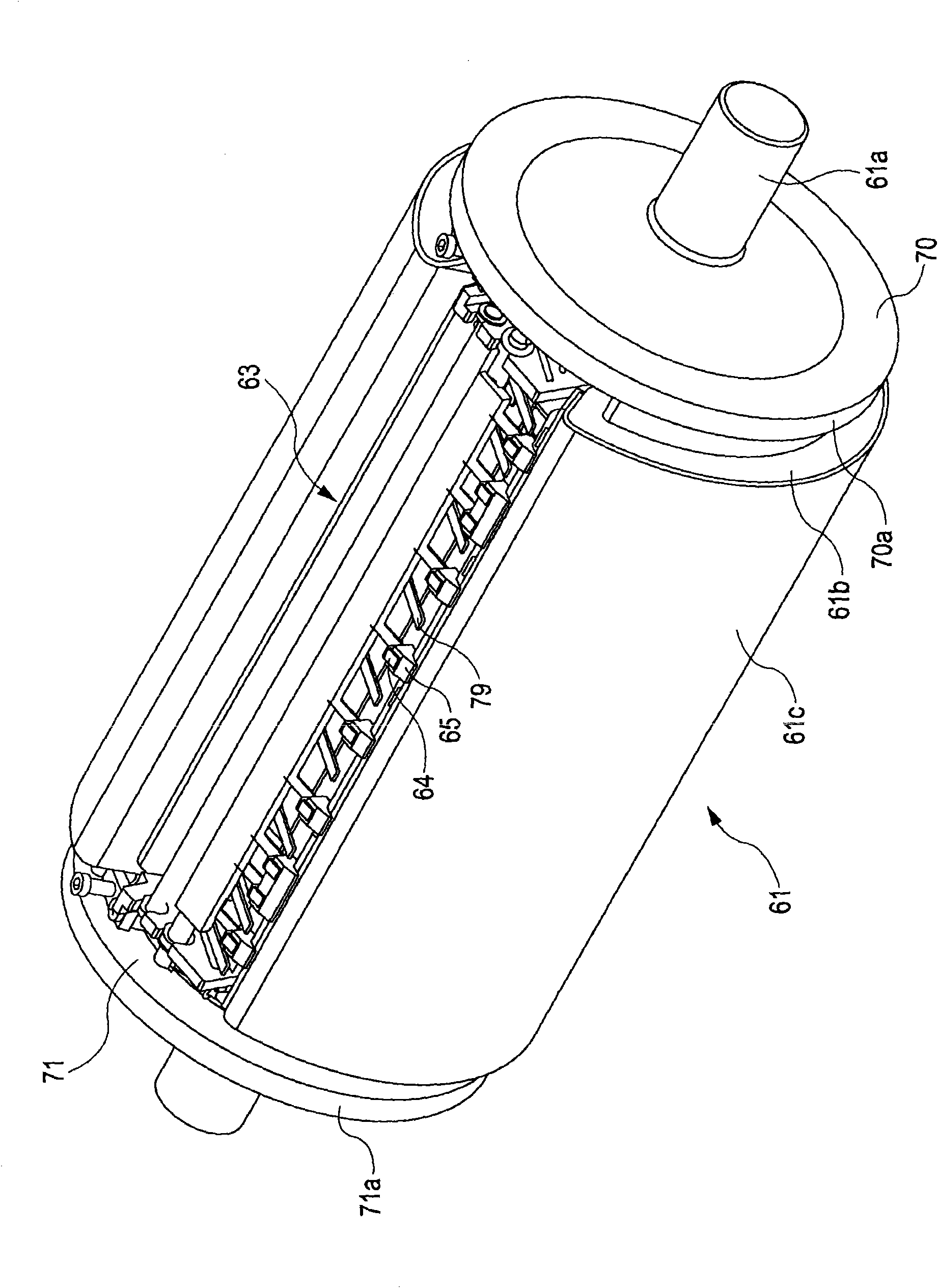

Transfer apparatus, image forming apparatus, and image forming method

InactiveCN101900976AReduce skewReduce poor transferElectrographic process apparatusImage formationEngineering

The invention provides a transfer apparatus excellently performing transfer by reducing distortion of an elastic layer of a transfer roller and transfer defect involved with the distortion and to provide an image forming apparatus excellently forming an image and an image forming method. The transfer apparatus includes: image carriers 10Y, 10M, 10C and 10K carrying the image; a transfer member 61 including a base material 61b having a recessed portion 63 having an opening width longer than the width of a nip portion formed with the image carriers in the moving direction of the image carriers 10Y, 10M, 10C and 10K and an elastic member 61c which is fixed by the recessed portion 63 and wound around the base material 61b and whose volume resistivity is 1*10<SP>6< / SP>-1*10<SP>11< / SP>[Omega]cm; and a bias generating portion 110 applying a bias to the nip portion.

Owner:SEIKO EPSON CORP

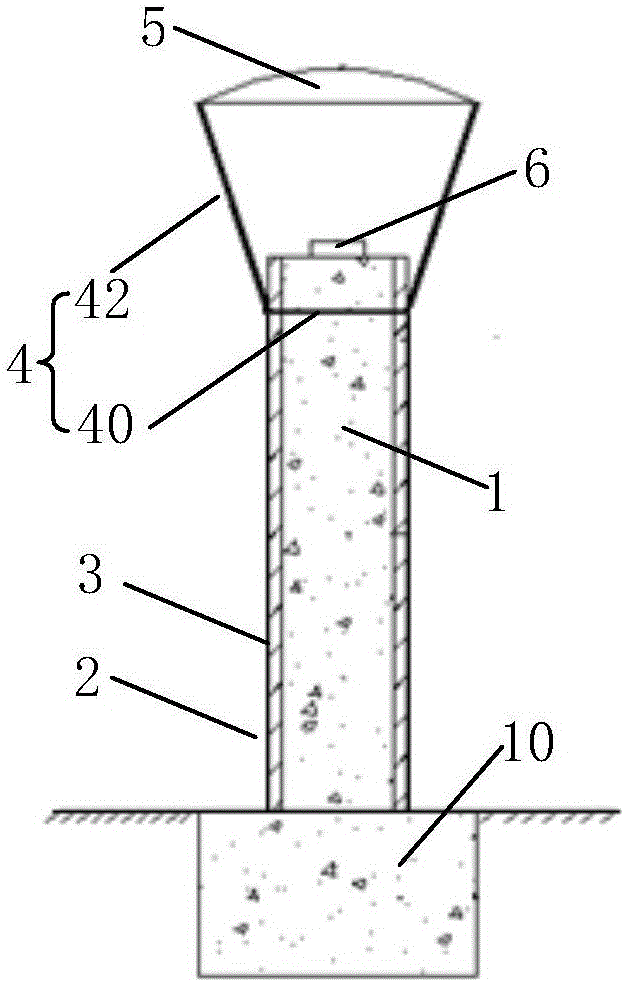

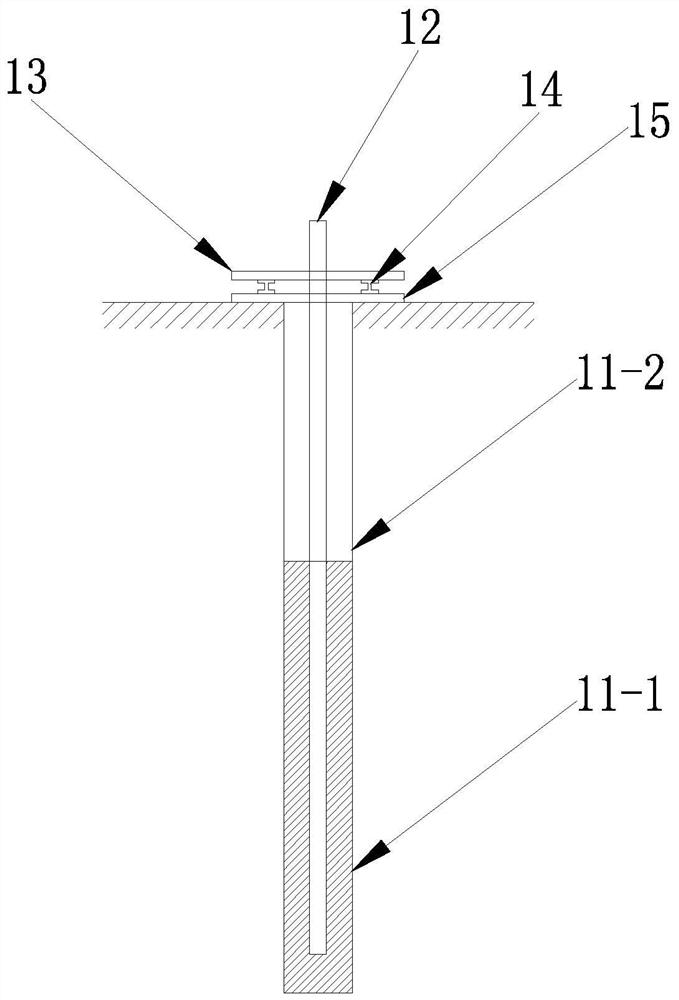

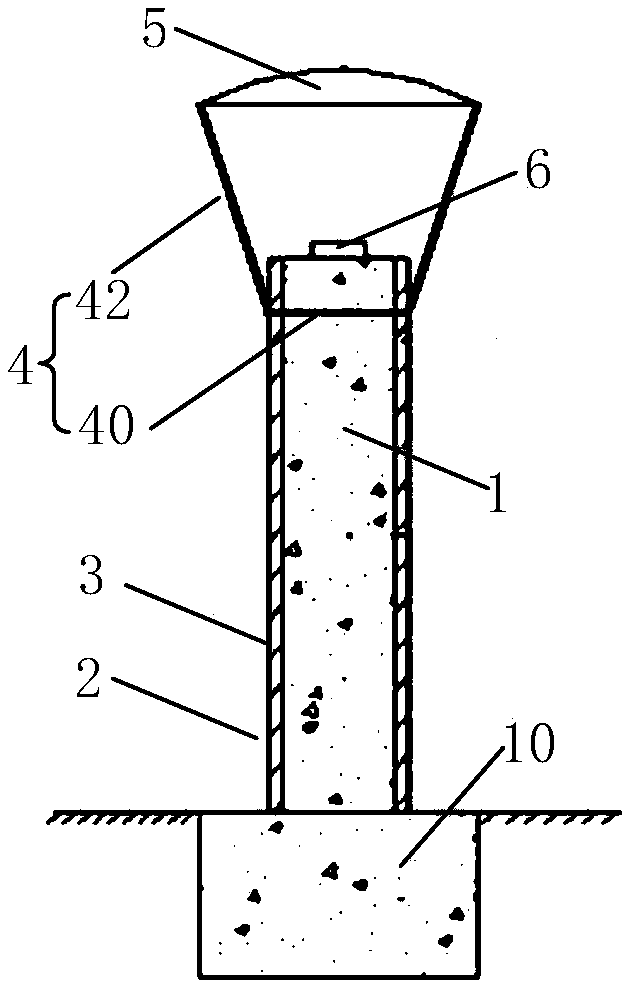

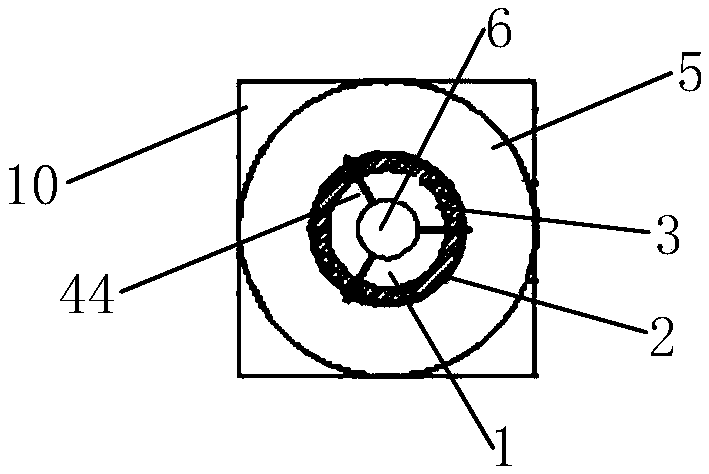

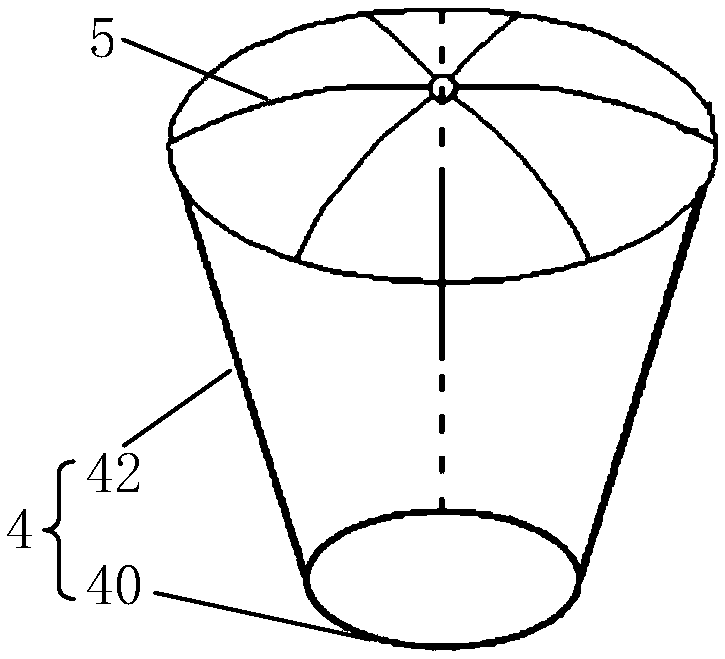

Settlement deformation monitoring pier and erection construction method thereof

ActiveCN106759218AReduce uneven deformationReduce the impactHeight/levelling measurementIn situ soil foundationDeformation monitoringAir temperature

The invention discloses a settlement deformation monitoring pier and an erection construction method thereof. The settlement deformation monitoring pier comprises a pier body of the monitoring pier, a protective insulating structure is arranged on the outer wall of the pier body of the monitoring pier, and three parts such as a light-shading rain-blocking structure are arranged at the top of the pier body. According to the settlement deformation monitoring pier and the erection construction method thereof, the influence of temperature change and lighting of the outside world on settlement monitoring is reduced, and thus the monitoring construction quality is ensured.

Owner:TONGJI UNIV

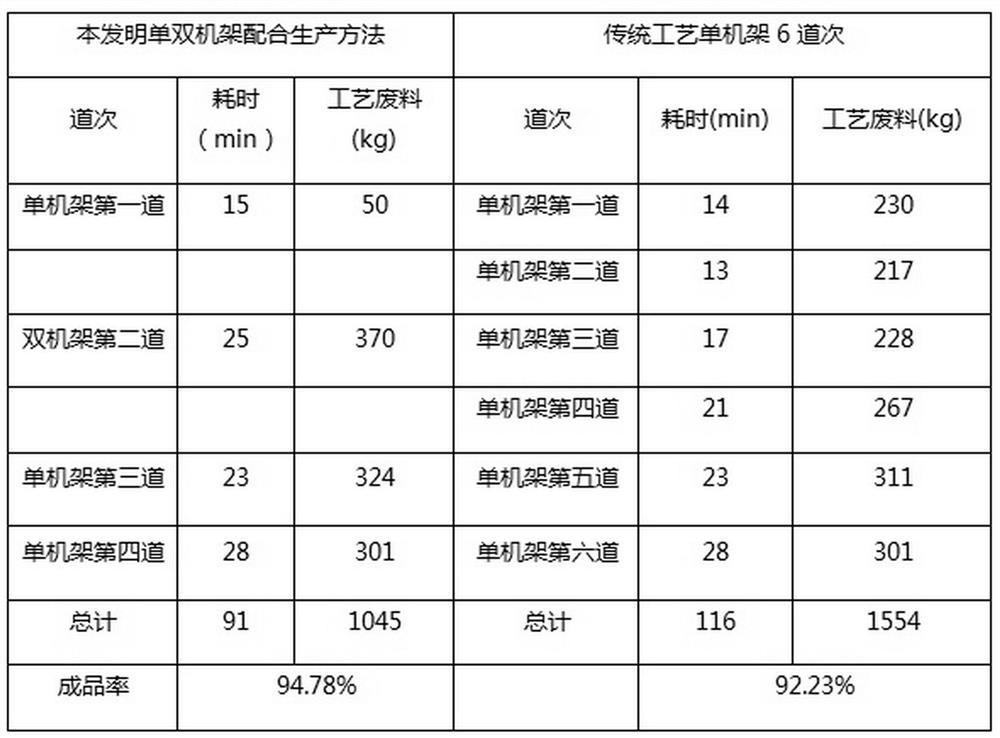

Short-process rolling method for cold-rolled 5182 alloy tank cover material

ActiveCN113714289AImprove pass rateReduce contact arcMetal rolling arrangementsAlloyIndustrial engineering

The invention provides a short-process rolling method for a cold-rolled 5182 alloy tank cover material, and solves the problems that cold rolling is divided into six passes, and each pass is drifted, so that in the rolling process, the consumed time is long, the working efficiency is low, the number of times on a machine is increased and the probability of generation of bumping defects is also increased. The method comprises the following steps of: 1, single-stand cogging, wherein the thickness of a plate subjected to single-stand cold rolling is converted from 2.8 mm to 1.38 mm; 2, double-stand edge trimming, wherein the thickness of the plate subjected to double-stand cold rolling is converted from 1.38 mm to 0.76 mm and then converted to 0.46 mm, then the plate subjected to cold rolling is cooled to the rolling temperature of 60 DEG C and then is transferred to a finishing edge trimmer, and the edges of the plate are cut by 20 mm separately; 3, single-stand cold rolling, wherein the thickness of the plate subjected to single-stand cold rolling is converted from 0.46 mm to 0.3 mm; and 4, single-rack cold rolling, wherein the plate treated in the step 3 is transferred to a single stand to be subjected to finished product cold rolling treatment, and cold rolling is conducted on the plate through the single stand. The method is simple in structure and has extremely high universality.

Owner:河南中孚高精铝材有限公司

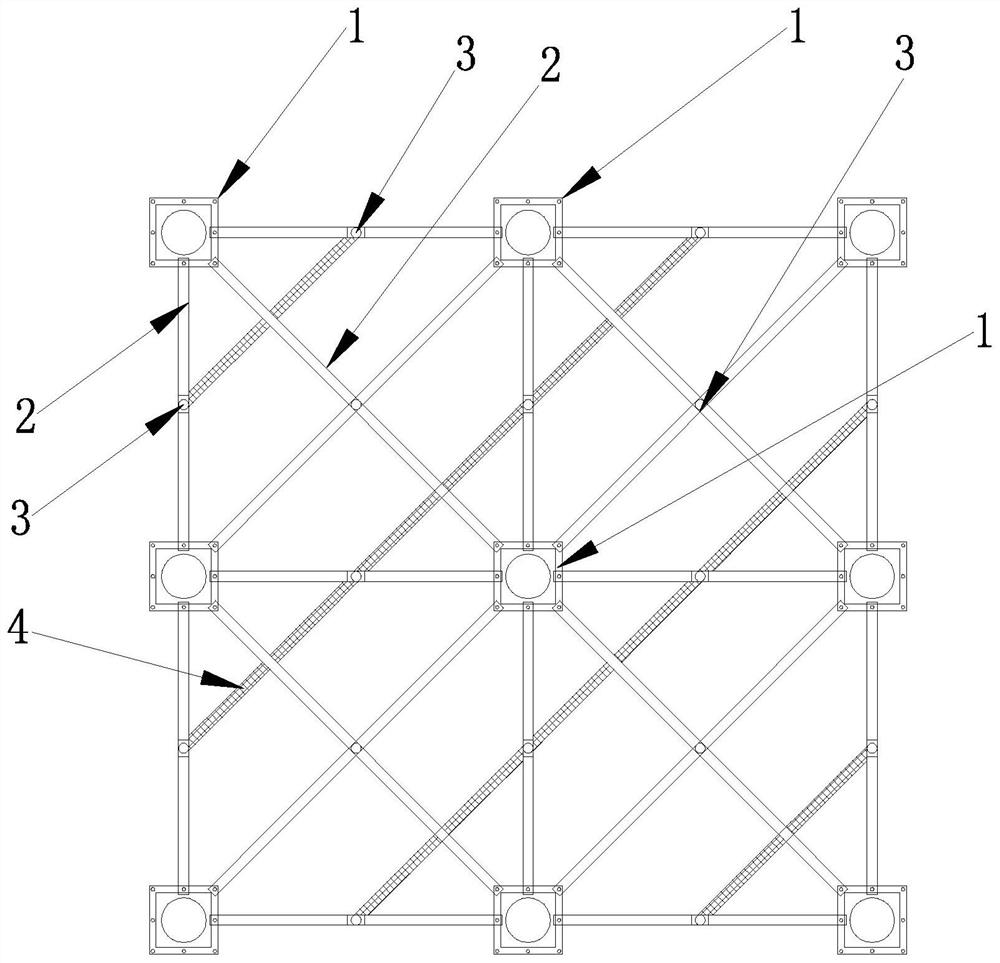

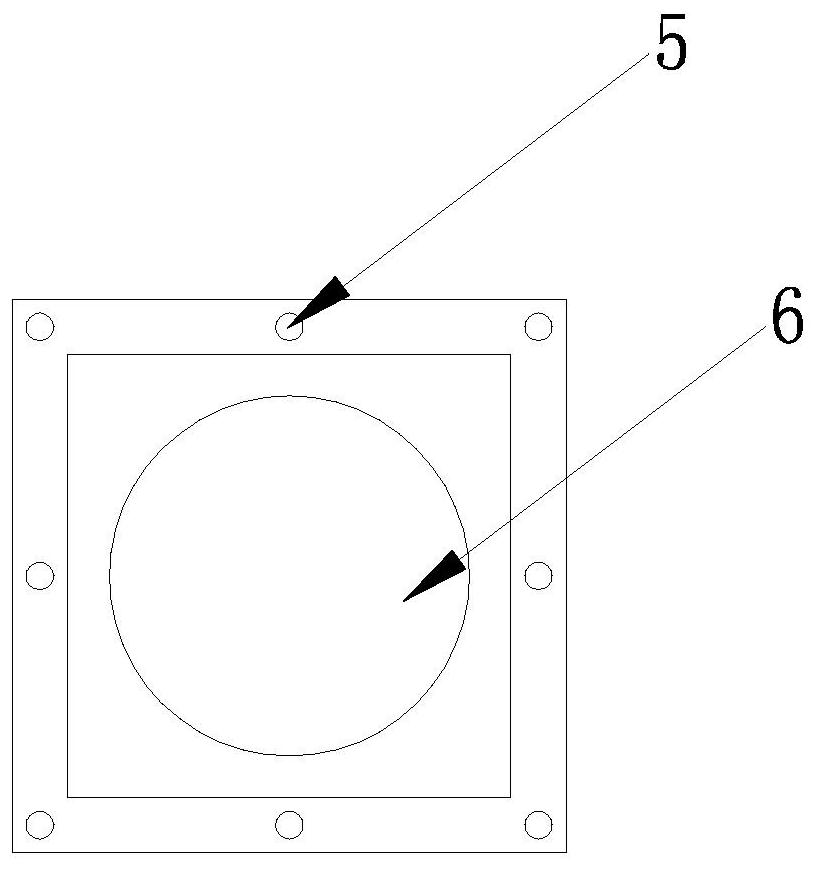

Anchor rod combined anti-floating system

InactiveCN112922044ASimple structureIngenious designProtective foundationBulkheads/pilesStructural reliabilityEngineering

The invention relates to an anchor rod combined anti-floating system. The anchor rod combined anti-floating system comprises a plurality of main anti-floating anchor rod assemblies, and the adjacent main anti-floating anchor rod assemblies are connected through channel steel purlines; and each main anti-floating anchor rod assembly comprises a drill hole, an anchor rod body, a polygonal base plate, a conventional base plate and a plurality of I-shaped cushion blocks, wherein an anchor rod hole is formed in the middle of the polygonal base plate and the middle of the conventional base plate, the anchor rod body is arranged in the anchor rod hole in a penetrating mode, and the I-shaped cushion blocks are assembled between the polygonal base plate and the conventional base plate. The anchor rod combined anti-floating system is simple in structure and ingenious in design, has the characteristics of being low in construction cost, good in structural reliability, high in adaptability and the like, and has good construction convenience.

Owner:ZHEJIANG UNIV OF TECH

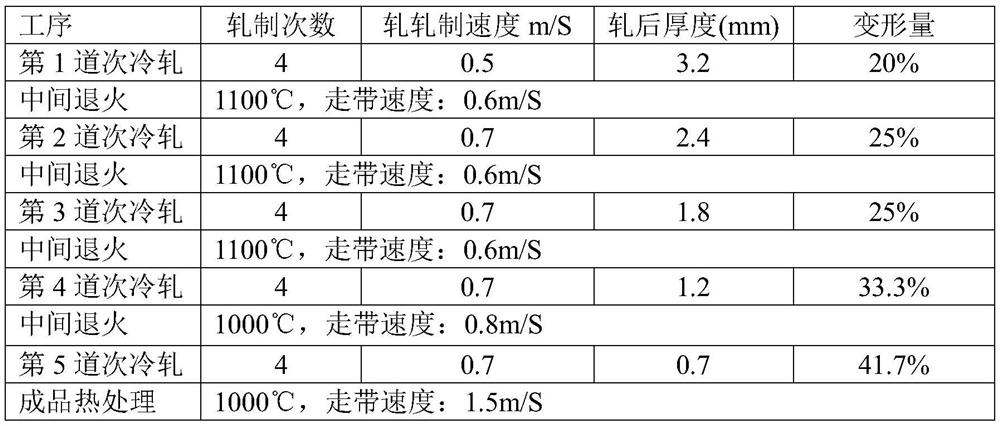

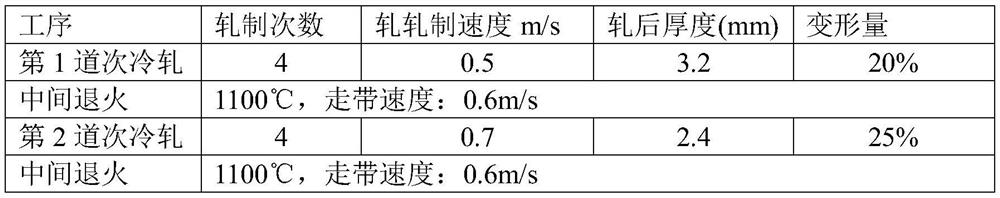

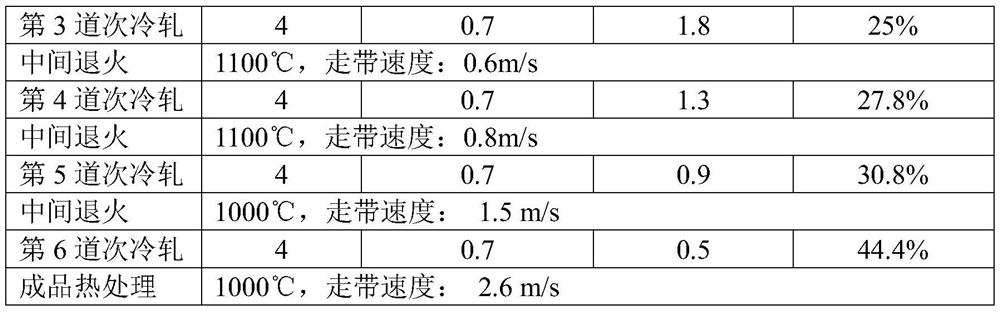

A kind of preparation method of gh3625 alloy strip

ActiveCN109468561BReduce uneven deformationHigh dimensional accuracySolution treatmentMetallic materials

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

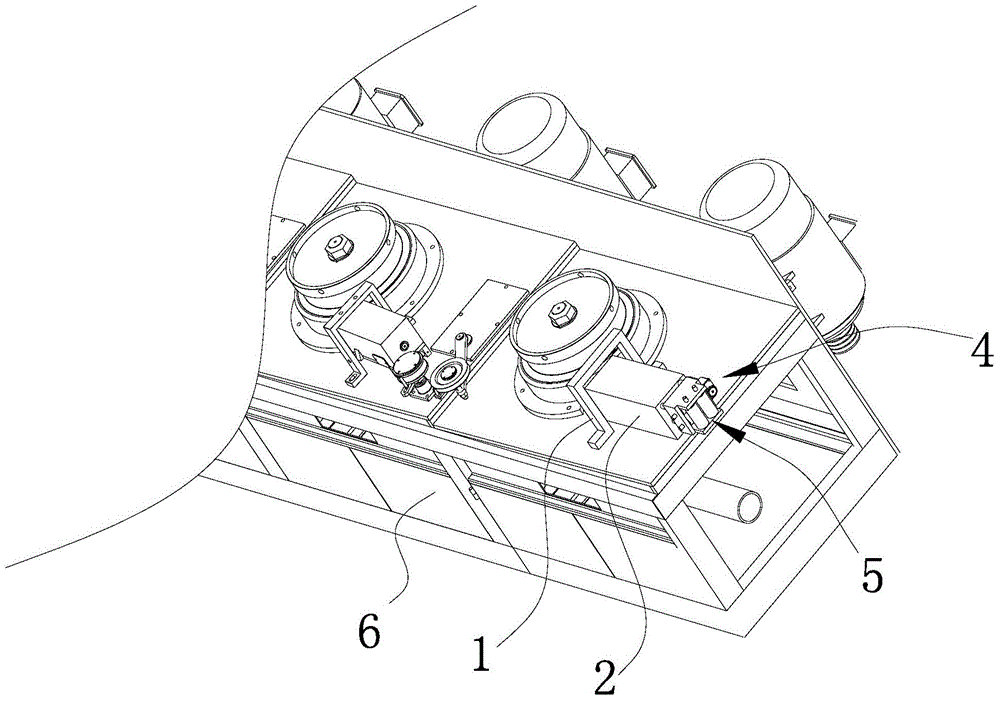

Opposite-stirring lubricating device for wire rod

The invention discloses an opposite-stirring lubricating device for a wire rod, which comprises a wire passing box body, an opposite-stirring mechanism and a driving device, wherein the opposite-stirring mechanism comprises a driving spiral stirring shaft and a driven spiral stirring shaft rotating opposite to the driving spiral stirring shaft; the driven spiral stirring shaft and the driving spiral stirring shaft are symmetrically arranged on the two sides of the position through which a steel wire penetrate and are parallel to the steel wire; a transmission gear connected with the driven spiral stirring shaft is arranged at one end of the driving spiral stirring shaft. By the arrangement of the opposite-stirring lubricating device, lubricating powder can be fully turned and stirred, and the lubricating powder can generate extruding force on the steel wire, so that the steel wire can be uniformly coated with the lubricating powder, and the lubricating effect is enhanced; therefore, non-uniform deformation during drawing and drawing heat are reduced, the quality and the performance of the steel wire are effectively improved, the service life of the wire passing box body is prolonged, and the production cost is reduced.

Owner:陈训宏

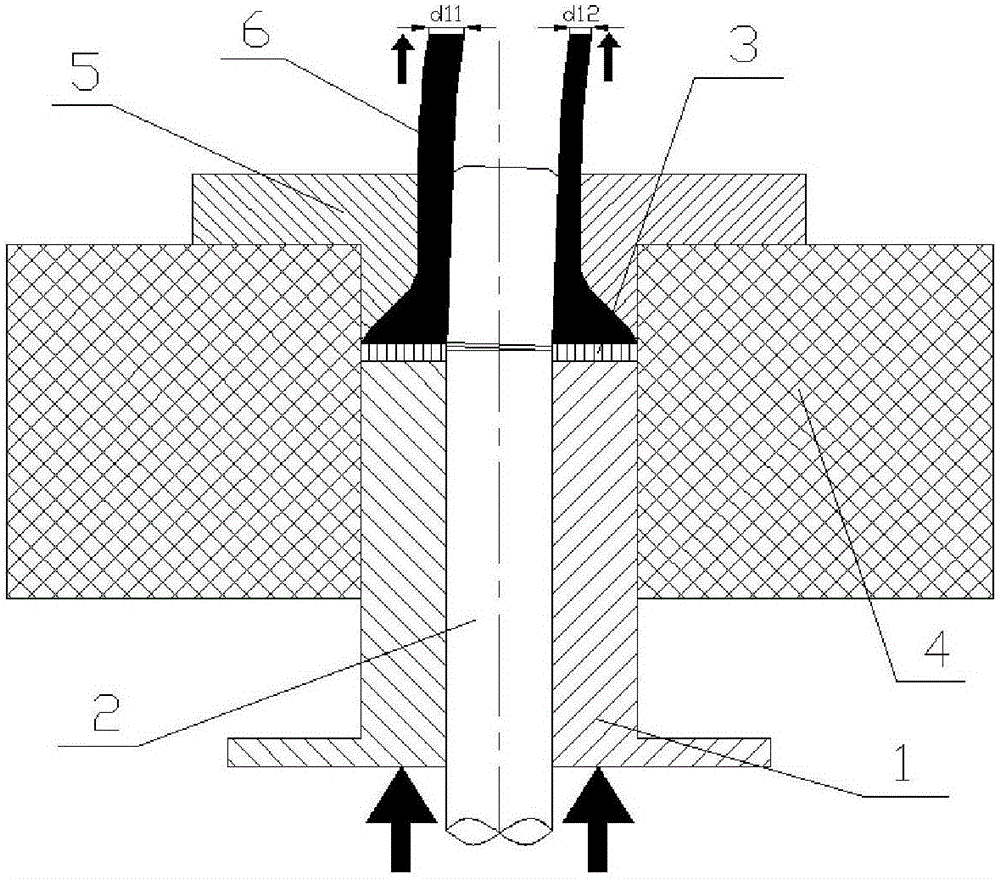

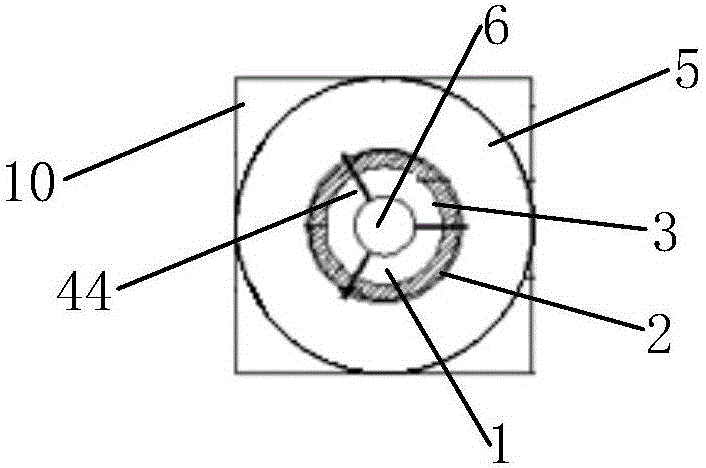

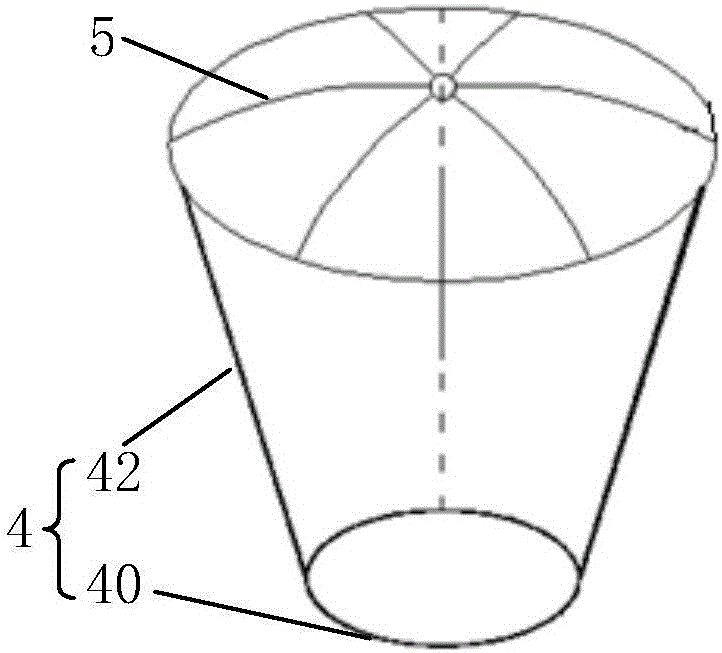

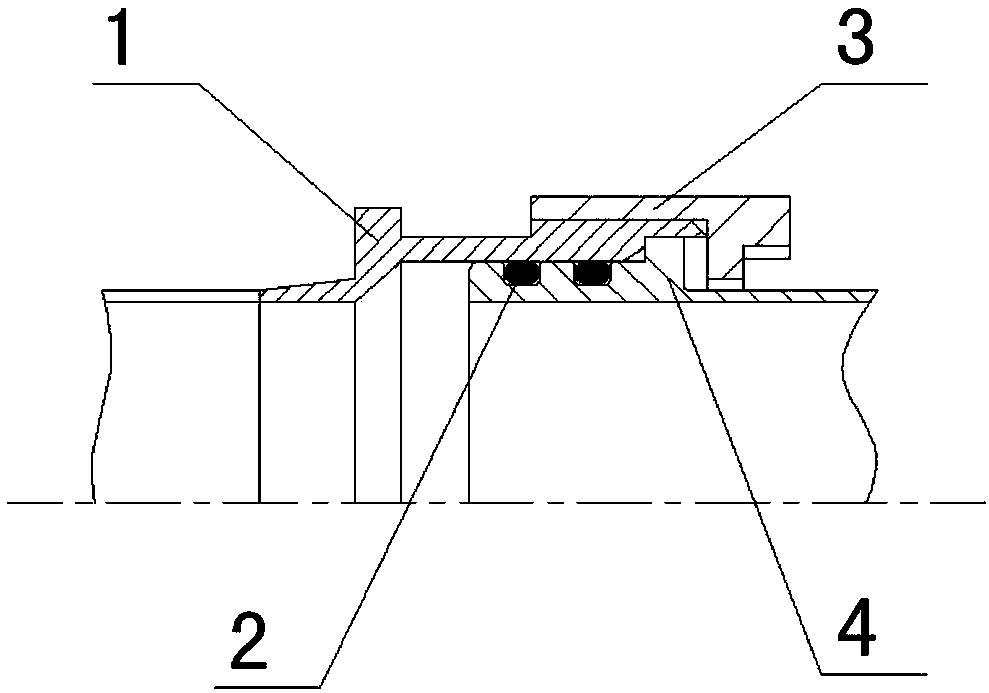

Structure of rubber sealing ring radial sealing connector with automatic centering section

InactiveCN108050257AReduce riskReduce unevenness of deformationEngine sealsEngineeringMechanical engineering

A structure of a rubber sealing ring radial sealing connector with an automatic centering section is characterized by comprising an unthreaded hole lining connector, a rubber sealing ring, a cap nut and a flat-end connecting mouth with a sealing ring groove. The structure of the rubber sealing ring radial sealing connector with the automatic centering section realizes sealing through extrusion deformation of the rubber sealing ring installed on the flat-end connecting mouth with the sealing ring groove after installation of the rubber sealing ring. The unthreaded hole lining connector and theflat-end connecting mouth with the sealing ring groove are axially connected through the cap nut. The structure of the rubber sealing ring radial sealing connector with the automatic centering sectionhas the advantages of effectively realizing the automatic centering function of connector matching, lowering non-uniform deformation of the sealing ring and touch abrasion of the sealing surface of the connector, lowering torsion and tearing faults caused by fretting wear accumulation generated by large partial deformation after long-time use of the rubber sealing ring, and improving the use reliability of the sealing structure.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

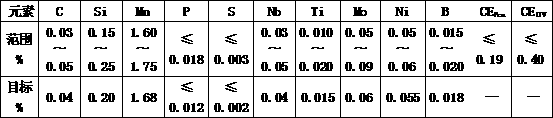

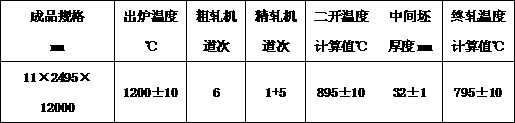

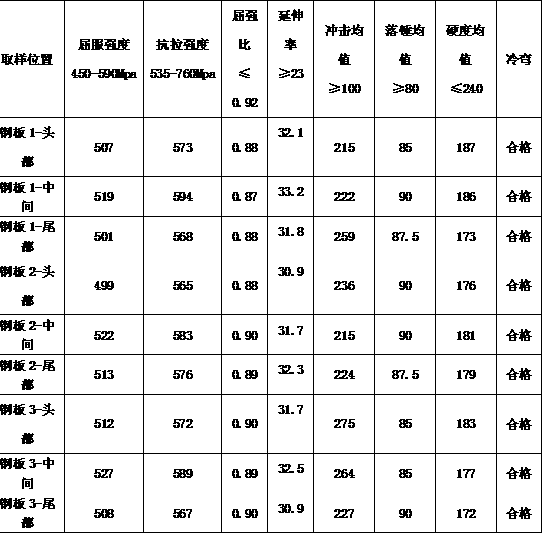

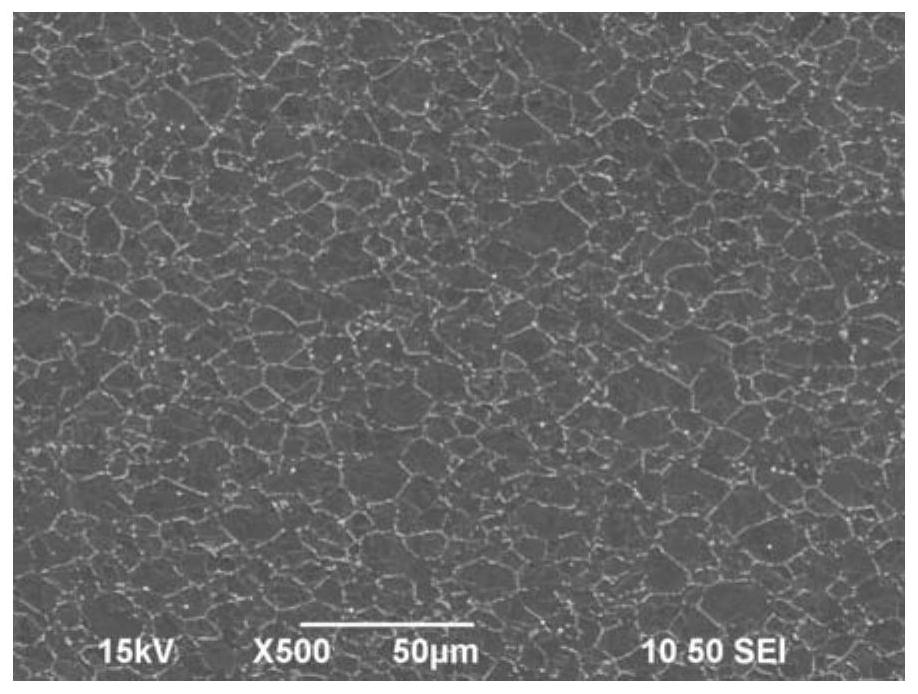

A thin-gauge pipeline steel rolling method

ActiveCN107363094BReduce carbon contentIncrease the content of alloying elementsRoll mill control devicesMetal rolling arrangementsOne passSheet steel

The invention relates to a thin gauge pipeline steel rolling method. In the steel, the content of C is within 0.05 percent; the content of Ni is 0.05 to 0.06 percent; the content of Ti is 0.01 to 0.02 percent; the content of B is 0.015 to 0.002 percent; the soaking temperature during rolling is 1,180 to 1,220 DEG C; the soaking time is 45 to 100 minutes; the torque of a roughing mill is 3,500 to 3,600 kN.m; the compression ratio is controlled to be 5 to 20; the width spread ratio is controlled to be 1.25 to 2.0; rough rolling is performed within 50 seconds after steel is discharged from a furnace; in rough rolling, the pressing down ratio of at least one pass is ensured not to be less than 21 percent when transverse rolling is performed, and the single pass pressing down ratio of at least two passes is ensured not to be less than 25 percent when longitudinal rolling is performed; and the temperature reducing speed is within 60 DEG C. According to the method, a controlled cooling link after the steel is rolled is cancelled by regulating chemical components of pipeline steel and heating; the type of a steel plate is improved; the production efficiency is greatly improved; and the production cost is reduced.

Owner:ANGANG STEEL CO LTD

Cold machining method for GH4099 high-temperature alloy wire

The invention discloses a cold machining method for a GH4099 high-temperature alloy wire, belongs to the technical field of high-temperature alloy wire preparation, and provides the cold machining method for the GH4099 high-temperature alloy wire, which can improve the surface quality of the wire. The cold machining method comprises the steps that A, solid solution heat treatment is carried out; B, intermediate billet rotary swaging reducing treatment is carried out, specifically, multi-pass annealing rotary swaging reducing treatment is carried out on a bar obtained in the step A through a rotary swaging process, and the rotary swaging deformation of each pass is controlled to be 30% - 45%; and after each pass of rotary swaging reducing treatment, a vacuum heat treatment furnace is adopted for annealing treatment, the vacuum degree is less than 10 <-3> Pa, the annealing temperature is 1050 DEG C - 1100 DEG C, and the heat preservation time is 10 min - 30 min; and C, a finished productis prepared. A wire product prepared through the cold machining method is uniform in structure distribution and free of coarse grain structure; and the surface of the wire is free of defects such ascracks and pits, and the wire has the characteristics of being high in dimensional precision, excellent in surface quality and the like.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

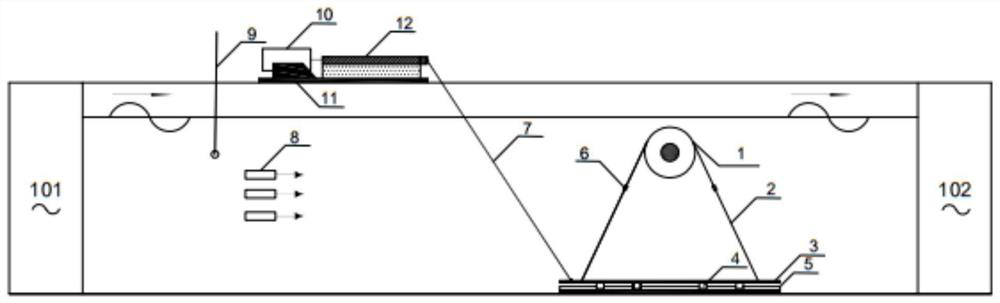

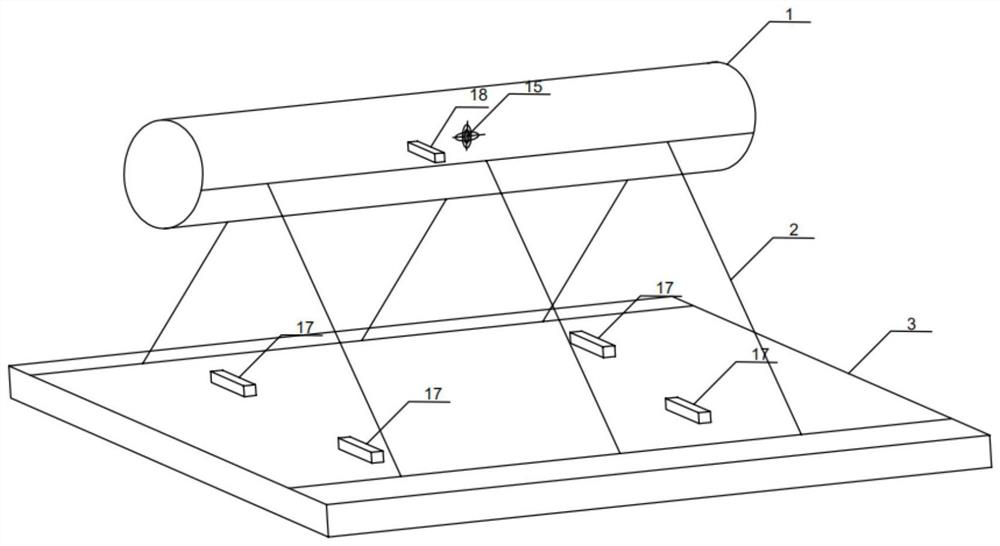

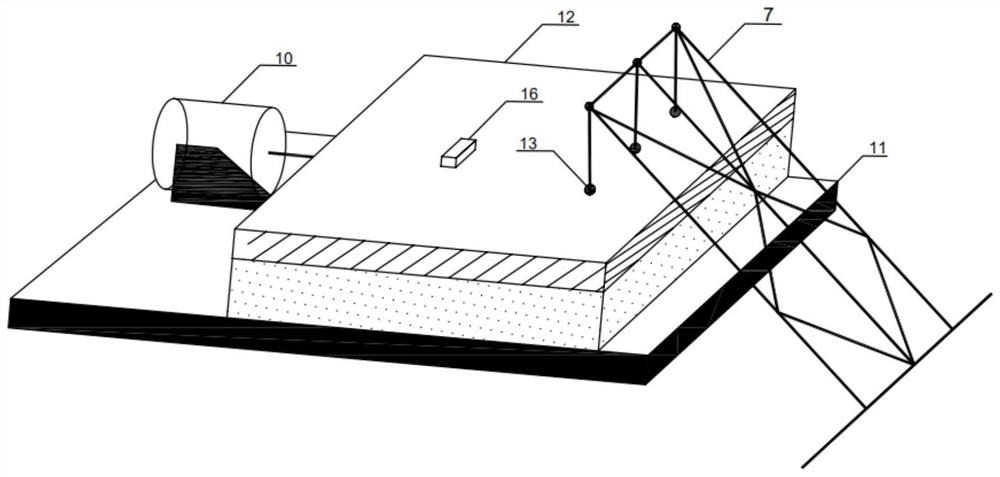

A test model and method of a floating tunnel under the joint action of earthquake and wave current

ActiveCN113295356BImprove reliabilityVerifiable reliabilityNavigation by speed/acceleration measurementsMaterial strength using tensile/compressive forcesGyroscopeMooring system

A test model and method for a floating tunnel under the joint action of earthquake and wave current. The test model includes a test tank, a test model pipe body, an anchoring system, a vibration generation and transmission system, and a sensing and measuring instrument. The vibration generation and transmission system includes a small Vibrating table, mechanical transmission device and sliding false bottom, the small vibrating table is installed directly above the test water tank through the load-bearing bracket, the table top of the small vibration table is connected with the sliding false bottom through the mechanical transmission device; the sliding false bottom is installed in the test water tank; The test model pipe body is installed on the sliding false bottom through the mooring system; a white background paper is pasted on one end of the test model pipe body; the sensing and measuring instruments include a gyroscope, an acceleration sensor, and a non-contact strain displacement measuring instrument. The invention realizes the dynamic response test of the suspension tunnel under the joint action of various seismic loads and wave current loads, greatly reduces the test cost, and provides a reliable basis for the design and construction of the suspension tunnel in the future.

Owner:GUANGXI UNIV

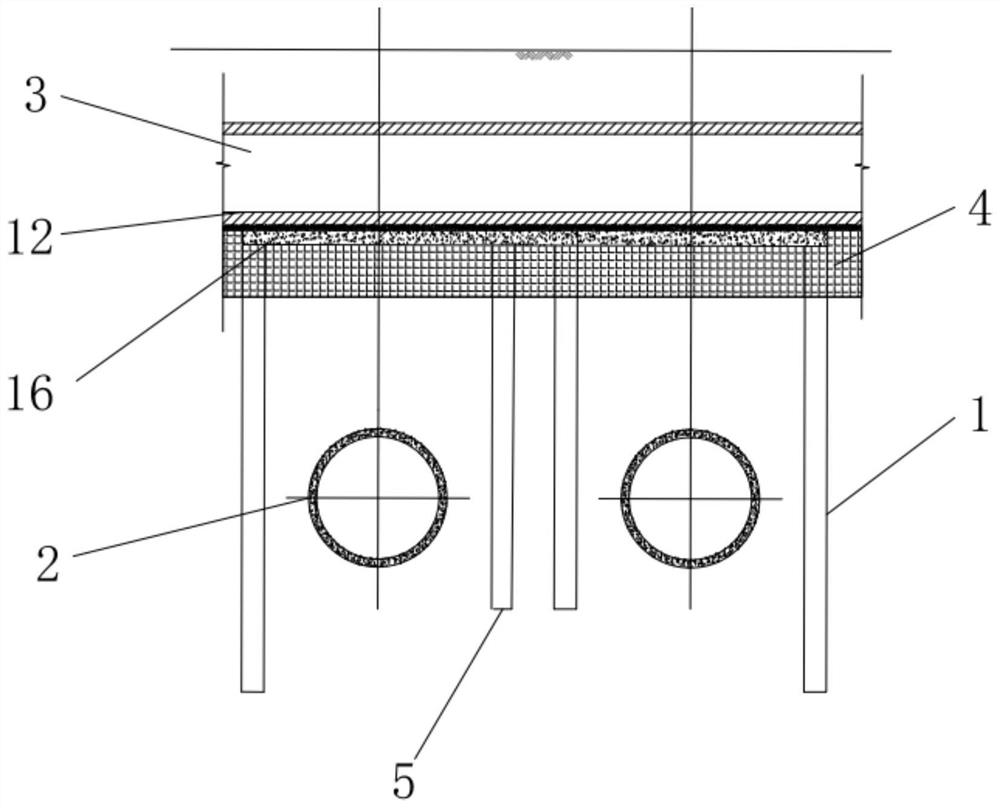

A construction method for the pre-protection structure of the underground comprehensive utility gallery of the proposed tunnel with upper span

The invention relates to a construction method for the pre-protection structure of the underground comprehensive pipe gallery of the proposed tunnel with the upper span, comprising the following steps: (1) tying the steel cage, (2) construction: first setting the concrete guide wall to locate the enclosing structure of the drilled occlusal pile , then bury the casing, prepare mud, drill holes, clear the holes, lower the reinforcement cage, pour concrete, and then carry out the reinforcement construction of the high-pressure rotary spray column, and then drill holes and plant bars on the enclosure structure of the drilled occlusal piles, and then drill The steel cages of the enclosing structure of the occlusal piles are tied together so that the side walls of the underground comprehensive pipe gallery and the enclosing structure of the bored occlusal piles form a composite wall, which can be jointly stressed, and then the bottom plate, side plate and roof of the underground comprehensive pipe gallery are poured (3) Backfill the soil and restore the road surface, and hand over the project for acceptance. The invention adopts the method of reinforcing the whole building with rotary grouting piles, which can improve the bearing capacity of the foundation and reduce uneven deformation.

Owner:ZHEJIANG COMM CONSTR GRP CO LTD

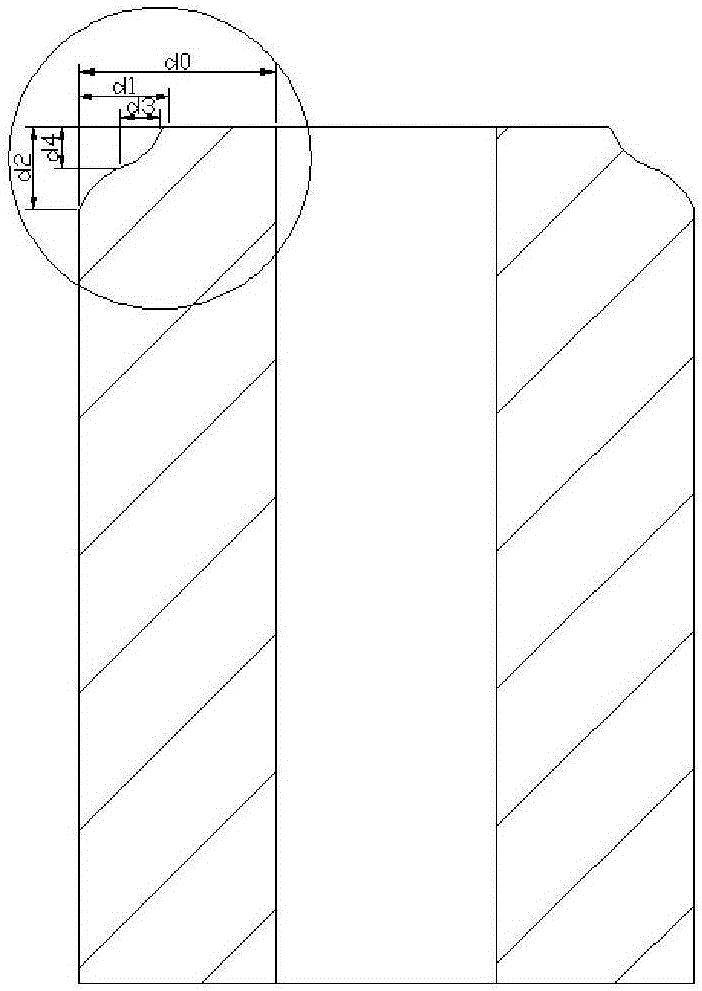

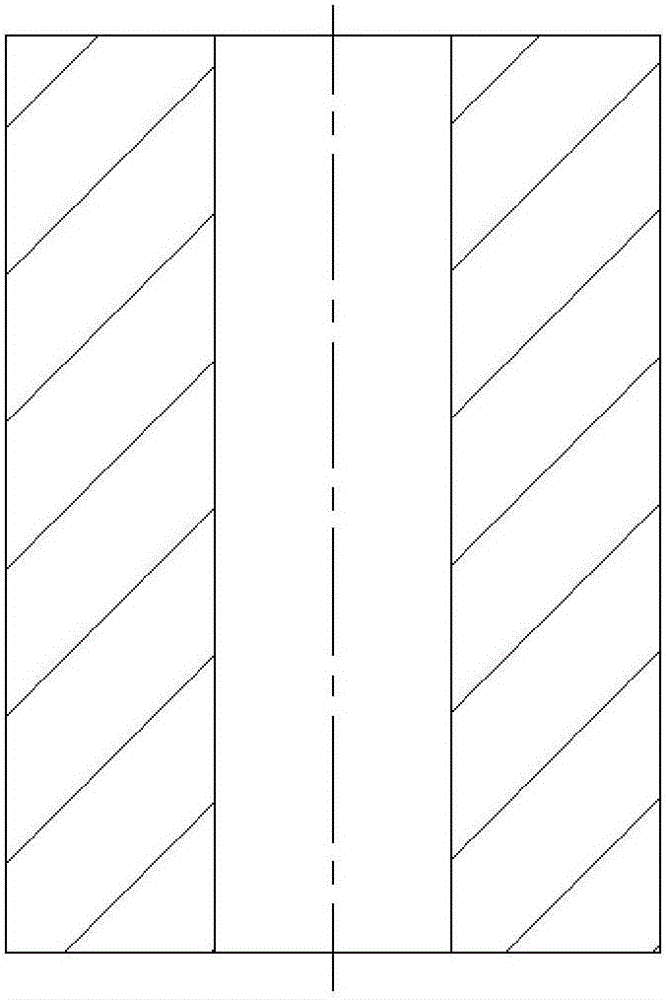

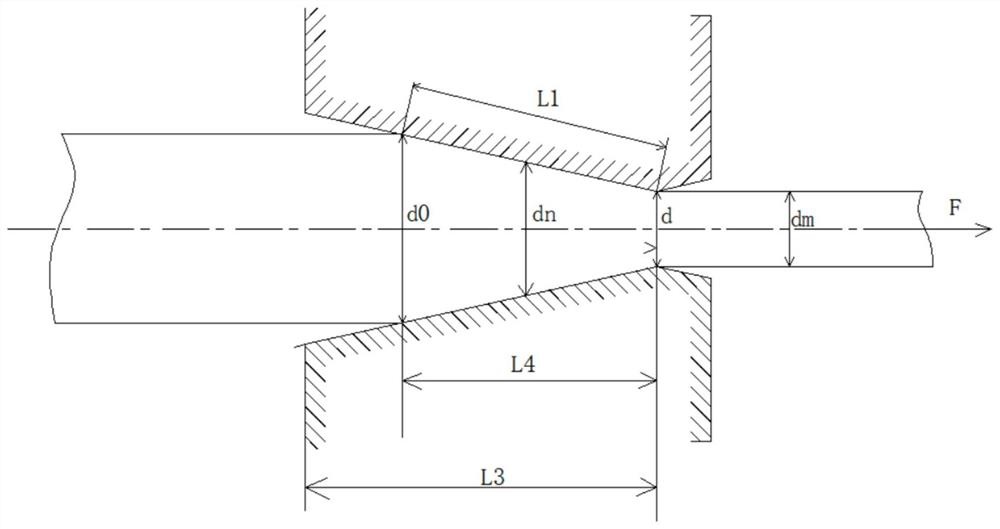

Process optimization method for continuous drawing die of copper wire

PendingCN113600625AReduce uneven deformationElastic storage energy stabilityDrawing diesWire rodProcess optimization

The invention provides a process optimization method for a continuous drawing die of a copper wire. The process optimization method comprises the steps that S1, the diameter of a die sizing belt is determined according to the wire inlet diameter d0 and the wire outlet diameter dm of a copper wire needing drawing production, and the diameter d of the die sizing belt is equal to the wire outlet diameter dm; and S2, the effective contact length L1 of the selected die and the copper wire is determined according to the diameter d of the die sizing belt determined in the step S1. According to the method, the influence of the structural composition of an existing die and parameters of all parts on the quality of the copper wire drawing process is researched, the range value of the parameters of the drawing die is controlled, uneven deformation in the copper wire drawing machining process can be reduced to the maximum extent, meanwhile, elastic storage energy is stable in the copper wire drawing machining process, and meanwhile, the residual stress is low, and the cone length is twice of the actual deformation area length of the die, so that the die cone can completely participate in lubrication, and the wire processing quality is improved by setting the die with corresponding proportions and parameters.

Owner:ANHUI CHUJIANG HIGH TECH ELECTRIC WIRE CO LTD

Settlement deformation monitoring pier and its support construction method

ActiveCN106759218BReduce uneven deformationSmall fluctuationMeasuring points markingHeight/levelling measurementDeformation monitoringEngineering

The invention discloses a settlement deformation monitoring pier and an erection construction method thereof. The settlement deformation monitoring pier comprises a pier body of the monitoring pier, a protective insulating structure is arranged on the outer wall of the pier body of the monitoring pier, and three parts such as a light-shading rain-blocking structure are arranged at the top of the pier body. According to the settlement deformation monitoring pier and the erection construction method thereof, the influence of temperature change and lighting of the outside world on settlement monitoring is reduced, and thus the monitoring construction quality is ensured.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com